Abstract

Optically triggering the core coalescence of double-emulsion droplets remains challenging. Herein, we utilize a photovoltaic field generated by laser illumination on LiNbO3 crystals to trigger the core coalescence in a high-throughput manner. The synergy between the interfacial pressure of the shell droplet and the internal flow induced by the photovoltaic field facilitates the core coalescence. With an increase in the core number, the illumination intensity required for the core coalescence is found to increase initially, whereas it tends to saturate at 5 × 107 W/m2, an intensity that does not cause a large temperature increase (<4 °C). The effective mixing of the substances contained in two core droplets after their coalescence is also verified. The proposed technique provides a precise, non-thermal and electrodeless strategy for high-throughput biochemical microreactions.

1. Introduction

Droplet microfluidic technology, with its advantages of miniaturization, compartmentalization, and parallelization [], has been widely applied in fields such as microreactors, biomedicine, and new material synthesis []. The unique core–shell structure of double-emulsion droplets isolates the core droplet from the external environment, effectively protecting its contents from external interference, and minimizing contamination in biochemical reactions []. Furthermore, the small volume and large surface area of the droplets significantly reduce the reagent consumption and improve the reaction efficiency []. Thus, double-emulsion droplets are an ideal platform for biochemical microreactors, including particle synthesis, cell experiments, and new drug testing. Triggering the coalescence of core droplets with different compositions is a key technology for realizing double-emulsion-droplet microreactors. However, strategies for the high-throughput core coalescence of double-emulsion droplets remain limited. Passively, core coalescence can be activated by controlling the flow rate []; however, this struggles to control the trigger timing. Active methods may use capillary forces generated by non-spherical shells [], utilize osmotic pressure differences [], or apply thermal stimulation to induce core coalescence []; however, they are subject to requirements for solution concentration and conductivity. Therefore, new flexible strategies to achieve core coalescence are required.

In recent years, the development of photonic devices based on LiNbO3 (LN) [,,,] and related advances in micro-manipulation technologies [,,,,,,,,,,,,,,,,] have opened new possibilities for core coalescence. When illuminated by a laser, LN exhibits a bulk photovoltaic effect, which generates a photovoltaic field on its surface. This field influences microdroplets, enabling their optical manipulation. As this field can be generated at low light intensities without introducing a strong photothermal effect, it is particularly suitable for temperature-sensitive microfluidic operations and biochemical microreactors [,]. Moreover, the distribution of the photovoltaic charges depends on the light intensity profile; therefore, the photovoltaic field can be better confined by the intensity profile, which is highly beneficial for efficient and precise microfluidic manipulation [,,,,,,,,,,,,,]. However, to date, no attempt has been made to trigger the core coalescence of double-emulsion droplets using a photovoltaic field on LN.

In this study, we optically triggered core coalescence in high-throughput double-emulsion droplets on LN. A microfluidic chip with two flow-focusing structures was employed to generate double-emulsion droplets, which were then directed into the main channel using iron-doped LiNbO3 (LN:Fe) crystals as substrates. A photovoltaic field was generated on LN:Fe through laser illumination to trigger the core coalescence. The subsequent mixing of the two-colored core was also demonstrated, confirming the feasibility of this technique in microreactors. This method can be applied to pL-scale chemical microreactors, enabling the continuous processing of large-scale samples.

2. Materials and Methods

2.1. Experimental Platform and Photovoltaic Field Generation

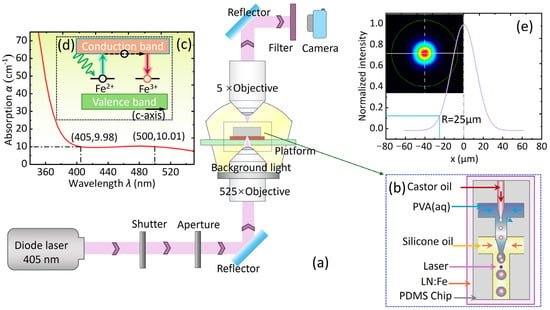

To achieve core coalescence triggered by the photovoltaic field and to observe and record the experimental process in real time, we built the experimental platform shown in Figure 1a. A 405 nm laser beam passes sequentially through a shutter, aperture, and laser mirror before entering a 25× objective lens, which focuses the beam onto the upper surface (−c face) of the LN:Fe substrate. The crystal used was a c-cut LN:Fe doped with 0.03 wt% Fe2O3 and had a thickness of 1 mm. At wavelengths of both 405 and 500 nm, the absorption coefficient (α) of the LN:Fe substrate was measured to be about 10 cm−1 (Figure 1c). Figure 1b shows a top-down scheme of the chip, which is tightly bonded to the LN:Fe substrate. In the photovoltaic field, the two cores of a double-emulsion droplet coalesce, ultimately forming a single-core droplet. This process was recorded using a side-facing camera.

Figure 1.

(a) Scheme of the platform for performing the experiment; (b) details of the chip; (c) absorption curve of LN:Fe; (d) scheme of the electron transition in LN:Fe; (e) laser spot measurement diagram and its corresponding Gaussian curve.

As shown in Figure 1d, under 405 nm laser illumination, electrons are excited from the Fe2+/Fe3+ traps in the LN:Fe crystal, creating a photovoltaic current directed towards the −c face of the LN:Fe crystal. This current accumulates positive and negative photovoltaic charges on the −c and +c surfaces, forming a spatially modulated non-uniform photovoltaic electrostatic field based on the light intensity profile [,]. It is important to note that the outer shell of the double-emulsion droplet is aqueous. We fabricated a 10 μm thick PDMS dielectric layer between the LN:Fe substrate and channel, which is crucial for the success of the experiment. This thin layer design effectively prevents ionic leakage from the shell phase and the subsequent compensation of the photovoltaic charges on the surface of LN:Fe. Meanwhile, this layer is sufficiently thin to avoid significant attenuation of the photovoltaic field [,]. Figure 1e shows the laser spot measured using a beam profiler after focusing through a 25× objective lens, along with the corresponding Gaussian fitting curve. According to the fitting result, the beam waist radius of the laser spot used in the experiment is about 25 µm.

2.2. Preparation of Double-Emulsion Droplets

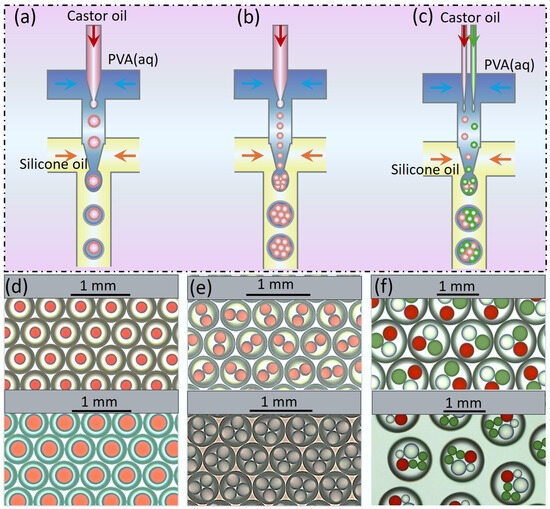

Microfluidic technology enables the on-demand generation of various types of double-emulsion droplets [,]. We utilized the flow-focusing method to efficiently generate double-emulsion droplets [,]. This technique works by squeezing the dispersed-phase fluid from both sides of the cross-focusing point, forming a “neck” structure at the liquid front, which causes the front to contract and become unstable, eventually resulting in droplet formation. The size of the droplets was adjusted by the flow-rate ratio between the dispersed and continuous phases. Double-emulsion droplets were generated by setting up two focusing structures (the first focusing structure generates the emulsion dispersed phase, and the second one encapsulates it into the outer droplet) []. Silicone oil was used as the outer phase. To prevent the double-emulsion droplets from adhering to the channel walls, 0.01 wt% Span80 surfactant was added to the silicone oil. The aqueous shell contained 2 wt% PVA, and the generated droplets remained stable in silicone oil for over 24 h. The core was composed of castor oil. By adjusting the flow-rate ratio, various types of double-emulsion droplets can be generated, including single-core double-emulsion droplets (Figure 2a,d) and multi-core double-emulsion droplets (Figure 2b,e). In addition, by increasing the number of silicone oil fluid channels, more complex double-emulsion droplets with different colors and sizes can be generated (Figure 2c,f). In the experiments, the types of double-emulsion droplets were primarily controlled by adjusting the flow-rate ratios of castor oil, PVA aqueous solution, and silicone oil. These three fluid phases are denoted by the letters a, b, and c, and the flow rates are set using peristaltic pumps connected to syringes. Specifically, for the single-core double-emulsion droplets in Figure 2d, the flow-rate settings were as follows: a = 3 mL/h, b = 4 mL/h, c = 6 mL/h; a = 4 mL/h, b = 3.5 mL/h, c = 6 mL/h. For the double-core and triple-core double-emulsion droplets in Figure 2e, the flow-rate settings were as follows: a = 5 mL/h, b = 4 mL/h, c = 6 mL/h; a = 7.5 mL/h, b = 4 mL/h, c = 7 mL/h. For the three-colored triple-core and six-core double-emulsion droplets in Figure 2f, the flow-rate settings were as follows: a1 = a2 = a3 = 4 mL/h, b = 6 mL/h, c = 10 mL/h; a1 = a2 = 4 mL/h, a3 = 5.5 mL/h, a₄ = 6.5 mL/h, b = 6 mL/h, c = 10 mL/h.

Figure 2.

Scheme of double-emulsion-droplet generation using the flow-focusing method. (a) Generation of single-core double-emulsion droplets; (b) generation of multi-core double-emulsion droplets with different numbers of cores; (c) generation of double-emulsion droplets with different types and numbers of core; (d–f) examples of single-core and multi-core double-emulsion droplets with varying core sizes, numbers, and colors.

2.3. Temperature Measurement and Control Experiments

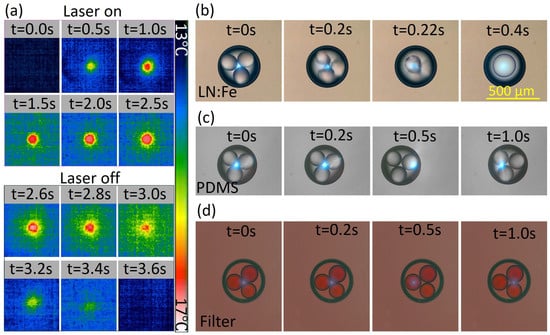

To evaluate the thermal effect induced by the laser illumination on the LN:Fe substrate, we measured the temperature increase of the LN:Fe substrate upon laser illumination by using a thermal camera. The illumination intensity typically used in this experiment was 5 × 107 W/m2, and the thermal images are shown in Figure 3. They reveal that after 1.5 s of laser illumination the temperature reaches the maximum, increasing by approximately 4 °C. After the laser was turned off, the temperature returned to room temperature within 1 s. In brief, our method does not cause a large temperature increase. In contrast, microdroplet manipulation using thermal strategies typically requires a substrate temperature increase of over 10 °C to effectively drive droplet motion []. To further exclude the possibility that the observed coalescence is caused by optical trapping forces or laser-induced heating rather than the photovoltaic effect of LN:Fe, we conducted additional analysis and control experiments. First, concerning the laser spot size, we measured the focused beam profile using a laser beam profiler with a 25× objective lens. As shown in Figure 1e, the measured spot exhibits a Gaussian profile, and the fitted beam radius is approximately 25 μm. Based on this value and the given laser intensity (5 × 107 W/m2), we evaluated the potential role of optical tweezer forces. According to reference [], for a small spherical particle, the optical trapping force F can be approximated by

where r is the radius of the particle (~100 μm), n is the refractive index of the surrounding medium (oil; ~1.4), c is the speed of light, and I is the laser intensity. Substituting in the values, the calculated optical force is approximately 1.5 × 10−12 N. According to reference [], this magnitude of force is only sufficient to manipulate nanoscale particles and is far too weak to move or deform micron-sized droplets. Therefore, optical trapping can be reasonably ruled out as a contributing factor in our experiment.

Figure 3.

(a) Thermal images of the LN:Fe under laser illumination, with a laser illumination intensity of 5 × 107 W/m2. The laser illumination was turned on at 0.0 s and turned off at 2.6 s; (b) on an LN:Fe substrate, the inner-core droplets of the double emulsion coalesce; (c) on a PDMS substrate, the inner-core droplets of the double emulsion do not coalesce; (d) on a high-absorption optical filter substrate with red-colored core droplets, no coalescence is observed. The laser illumination intensity in all three experiments (b–d) was set to 5 × 107 W/m2.

Second, to further investigate whether the coalescence of the inner-core droplets is caused by laser-induced optical forces or photothermal effects, we conducted a set of control experiments under consistent conditions (laser illumination intensity: 5 × 107 W/m2), as shown in Figure 3b–d. The only differences among the three groups were the substrate material and the color of the core droplets. In Figure 3b, using an LN:Fe substrate, the inner-core droplets coalesced rapidly upon laser illumination. This coalescence is attributed to the swift establishment of a photovoltaic field induced by the laser. In Figure 3c, using a PDMS substrate, no morphological changes were observed in the core droplets after laser exposure. Even when the laser spot was directed at different positions on the double-emulsion droplet at 0.5 s and 1 s, no coalescence or deformation occurred. In Figure 3d, a highly absorbing optical filter was used as the substrate, and red-colored core droplets were selected to further enhance photothermal effects. However, the experimental results were consistent with those in Figure 3c: no coalescence or morphological change of the core droplets was observed. It is important to note that in Figure 3d, both the absorption coefficient of the red substrate and the absorption of the red core droplets were higher than those in the LN:Fe case, implying that the heat generation due to laser illumination was maximized. Nonetheless, no coalescence occurred. These results collectively rule out the contributions of optical trapping and laser-induced heating as the primary mechanisms driving core droplet coalescence.

In conclusion, both theoretical estimation and control experiments support that neither optical trapping nor laser-induced heating is responsible for the observed coalescence. Thus, we believe that the photovoltaic effect in LN:Fe, which drives internal flow within the shell droplets, is the primary mechanism behind the core coalescence.

3. Results and Discussion

3.1. Coalescence Process of Double-Core Droplets

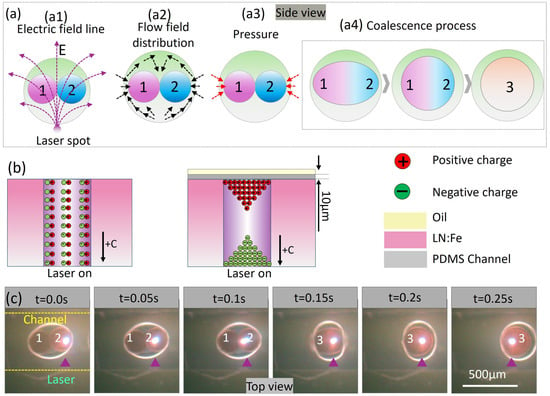

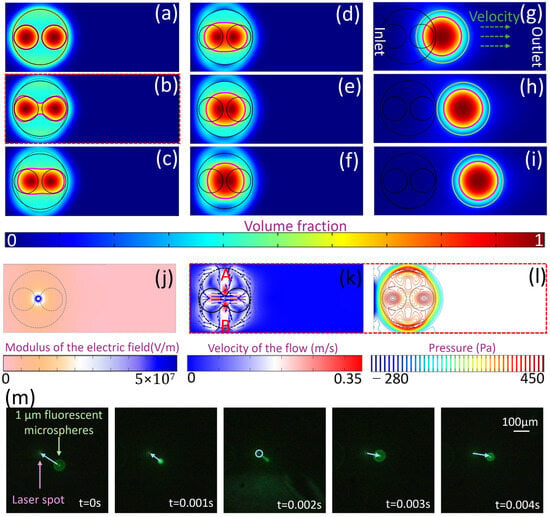

In the main channel, the double-emulsion droplets flow at a constant speed of 2000 µm/s. Upon laser activation, the photovoltaic charge field was instantly established, as shown in Figure 4b. Under this photovoltaic field, the double-emulsion droplets experience a dielectrophoretic force [], causing their motion to significantly slow down. Simultaneously, the photovoltaic field triggers the two cores to coalesce, ultimately forming a single-core double-emulsion droplet (see Figure 4a,c, Supporting Video S1, and Supporting information). When the double-emulsion droplet passes through the laser spot its speed noticeably decreases and within 0.2 s it undergoes coalescence. After coalescence, the double-emulsion droplet quickly returns to a spherical shape owing to surface tension. Figure 4(a1–a3) schematically depict the distributions of the electric field, flow field, and pressure, respectively.

Figure 4.

(a) Scheme of core coalescence of double-emulsion droplets. (a1–a3) Schematic depictions of the distributions of the electric field, flow field, and pressure, respectively (The purple arrows indicate the direction of the electric field, the black arrows represent the direction of the flow field, and the numbers 1 and 2 denote the two core droplets, respectively); (a4) The coalescence process of the two core droplets. (b) scheme of photovoltaic field establishment; (c) experimental process of core coalescence of a double-emulsion droplet in the main channel (Numbers 1 and 2 represent the two core droplets inside the double emulsion, and number 3 indicates the droplet formed after the coalescence of the two core droplets).

Notably, the proposed photovoltaic field strategy is primarily applicable to oil-in-water-in-oil (O/W/O) double-emulsion systems. In this configuration, the electric field acts on the intermediate aqueous shell, inducing polarization and generating non-uniform dielectrophoretic forces, which in turn drive electrohydrodynamic circulation within the shell. This flow enables indirect manipulation and coalescence of the inner oil droplets. The effectiveness of this strategy relies on the aqueous shell possessing a relatively high dielectric constant (to enhance polarization response), appropriate viscosity (to sustain effective flow), and the use of non-ionic surfactants (to minimize electrical interference), thereby ensuring the stability and controllability of the fluidic response. In contrast, water-in-oil-in-water (W/O/W) systems feature a highly conductive aqueous continuous phase that tends to screen the photovoltaic field generated at the LN:Fe surface, rendering the field ineffective for driving dielectric flows. Therefore, this strategy is not applicable to such configurations.

To verify the stability and reliability of this strategy, we have added a high-throughput video (Supporting Video S2) showing the light-induced coalescence of 470 dual-core double-emulsion droplets. Among these, only one droplet (the 25th in the sequence) failed to undergo successful coalescence, resulting in a success rate of 99.8%. We also performed multiple repeated batches of high-throughput experiments under the same conditions, all consistently achieving success rates above 95%, confirming the reliability and reproducibility of the coalescence process. Furthermore, according to Equation (2), under the leaky dielectric model, the photovoltaic charge density depends solely on the laser illumination intensity I0 and is independent of the illumination duration. Therefore, prolonged laser exposure does not degrade the photovoltaic performance of the LN:Fe crystal.

3.2. Mechanism of Core Droplet Coalescence

Under the photovoltaic field, significant polarization effects occur at the oil–water interfaces between the droplet with an aqueous shell and oil core [,]. These result in pronounced charge accumulation at the interfaces and the corresponding interfacial pressure. Specifically, this pressure elongates the outer shell vertically while shrinking it horizontally, thus reducing the distance between the oil cores and triggering their coalescence. In addition, the photovoltaic field induces a local flow loop inside the water shell. This flow loop reduces the pressure between the oil cores and accelerates their coalescence. The synergy of the interfacial pressure and flow loop breaks the stability between the cores, ultimately causing the cores to coalesce.

3.3. Coalescence of Multiple Core Droplets

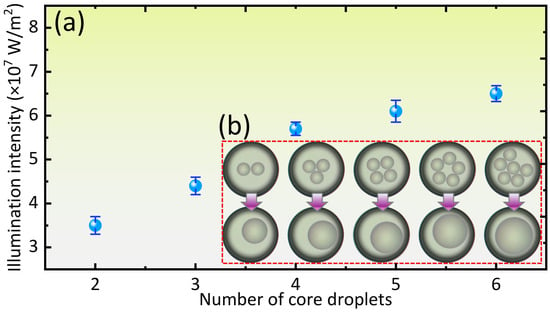

Considering that the coalescence of multiple cores may be involved in various applications, we further explored the minimum laser illumination intensity (critical intensity) required for the coalescence of different numbers of cores. The experimental results, shown in Figure 5, reveal that as the number of core droplets increases, the critical intensity required for the coalescence gradually increases. However, when the number of cores exceeds four, the rise in the critical intensity becomes less pronounced. The variation in the critical intensity with respect to the number of cores can be attributed to two factors. First, as the number of cores increases, the number of oil–water interfaces that must be overcome for the core coalescence increases. Consequently, a higher laser illumination intensity is required to generate a strong photovoltaic field to drive the coalescence of the oil cores. However, when the number of cores exceeds four, the volume fraction of the shell decreases significantly and the distance between the oil cores decreases. This facilitates the core coalescence under the influence of interfacial deformation and internal driving flow. Although the number of cores still adds critical intensity in this case, this enhancing effect obviously weakens and eventually tends to saturate. A demonstration of the coalescence process for multi-core double emulsions can be found in Supporting Video S3.

Figure 5.

(a) The blue data points indicate the minimum laser illumination intensity (critical intensity) required for the coalescence of different numbers of core droplets. (b) shows the appearance of droplets with varying numbers of cores before and after coalescence.

4. Simulation Analysis

The finite element method was used to simulate the core coalescence of double-emulsion droplets (see Figure 6a–i). The concentration of [Fe2+] in LN:Fe was denoted as ND. Considering the effect of the dark conductivity of the LN:Fe crystal and the conductivity of the oil phase, the steady-state surface charge density (σ∞) can be expressed by Equation (2) [,,]:

where K is the photovoltage ratio coefficient, I0 is the illumination intensity, e is the electron charge, μ is the carrier mobility, n is the carrier concentration, CLN is the conductivity of LN:Fe, Coil is the conductivity of oil, εLN is the relative permittivity of LN:Fe, εoil is the relative permittivity of oil, and ε0 is the vacuum permittivity.

Figure 6.

(a–f) Simulation of the core coalescence of a two-core double-emulsion droplet; (g–i) simulation of the movement of the coalescent droplet under the oil viscous force; (j) simulation of the photovoltaic field; (k) flow field inside the double-emulsion droplet, with the color indicating the flow velocity and the black arrows showing the flow direction; (l) pressure inside the double-emulsion droplet; (m) experimental validation of the simulated internal flow using 1 µm fluorescent PS microspheres.

The dielectrophoretic force FDEP acts on both the shell and core droplets. This force FDEP can be expressed as []

where E is the space charge field, and εl and εm are the relative permittivities of the current and surrounding phases, respectively. For the explicit charge density σ, the potential V and electric field E can be calculated from the electrostatic equations: E = −∇V and ∇(εE) = σ.

The coalescence of inner droplets is governed by the dielectrophoretic (DEP) force, which depends on the gradient of the electric field ∇E2, rather than directly on the laser spot size. As shown in Equation (2), the surface charge density σ∞ on the LN:Fe crystal is determined by the illumination intensity I0, the charge transport parameters, and the dielectric properties of the surrounding media. Importantly, σ∞ is independent of the laser spot size, assuming the spot covers the target region and provides sufficient I0.

Furthermore, as described in Equation (2), the DEP force acting on both the shell and the core droplets is proportional to the spatial gradient of the squared electric field, ∇E2. Since the electric field distribution is shaped by surface charge density and material permittivities, and not by the geometrical size of the laser spot per se, the spot size does not directly influence the coalescence dynamics as long as the illumination intensity I0 remains constant within the active area. Therefore, while the electric field gradient ∇E2 is critical to successful coalescence, the size of the laser spot has no significant effect, provided it fully covers the region of the LN:Fe surface as intended to generate the photovoltaic field.

To simplify the simulation, the interface shape of the double-emulsion droplets was simulated in two dimensions. Under laser illumination, the photovoltaic charge density is directly applied to the surface of LN:Fe, and FDEP is applied to the fluid in the form of a volumetric force. A triangular mesh was created for the entire computational domain, with a finer mesh applied at the interfaces, edges, and corners. As a boundary condition, the potential V was set to zero at infinity. To describe the mass and momentum transfer of the fluid, the Navier–Stokes equation was included:

where ρ is the density of the corresponding fluid, μ is the dynamic viscosity of the fluid, and P is the hydrostatic pressure.

Figure 6j shows the photovoltaic field generated on the substrate, with the maximum value reaching the 107 V/m range, which is consistent with the typical range of the photovoltaic field on the surface of LN:Fe. Figure 6k shows that the pressure on the shell interface is inhomogeneous, suggesting that the polarization effect induces interfacial pressure, causing the shell to shrink, thus driving the core coalescence. Figure 6k shows the flow field inside the double-emulsion droplet. The black dashed line and black circle represent the positions of the water shell and the oil core, respectively. This result shows that the fluid flows from the center of the shell toward points A and B, forming a loop along the shell interface. This loop facilitates the approach of the two cores. The synergy between the interfacial pressure and internal driving flow leads to the core coalescence.

To verify the reliability of the simulation results, we conducted an experimental demonstration of the flow field using fluorescent polystyrene (PS) microspheres with a diameter of 1 µm. The experimental process was recorded using a high-speed camera, and frame-by-frame analysis was performed (Figure 6m). This analysis provided two key pieces of information: First, the internal flow within the droplet exhibited a circulatory pattern. This was confirmed by observing the reversal of particle movement between the time intervals 0–0.002 s and 0.002–0.004 s. The experiment also showed that this motion was reciprocating in nature. Second, the velocity of the fluorescent microspheres was measured to be on the order of 1 × 105 µm/s, which is consistent with the simulated internal flow velocity of 0.35 m/s (i.e., 350,000 µm/s). While it is true that the simulation cannot capture all experimental nuances—such as the presence of impurities within the droplet—these results demonstrate that the simulation captures the correct flow pattern and velocity scale. Therefore, we believe the simulation results are reasonable and reliable.

5. Application

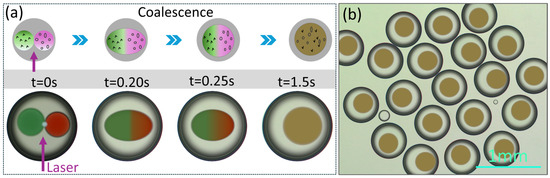

Micro/nanomaterials and micro/nanoreactions have been widely explored for diverse applications, including bacterial surface modification and gas sensing, due to their high spatial precision and reaction efficiency [,]. To verify the proposed strategy for microreactions, oil-soluble fuels of different colors (green and red) were incorporated into the two cores of the double-emulsion droplets. Upon laser illumination, the green and red cores rapidly coalesced, and their contents initially remained separated, resulting in a half-green, half-red appearance. Under the effect of surface tension, the shape of the core droplets gradually recovered from elliptical to spherical, with the encapsulated materials inside the two cores mixing and ultimately appearing yellow (Figure 7a). In other words, the photovoltaic field not only triggers the coalescence of the cores but also effectively mixes them. Furthermore, based on the high-throughput platform, a large number of double-emulsion droplets with yellow cores could be generated in a very short time, as shown in Figure 7b.

Figure 7.

(a) Schematic and experimental process of the coalescence of two cores labeled with green and red colors; (b) microscopic image of a large number of double-emulsion droplets with single yellow cores obtained through a high-throughput platform.

In summary, we optically triggered the core coalescence of double-emulsion droplets on a LiNbO3 platform, aiming to provide a flexible strategy for high-throughput biochemical microreactions. The experimental and simulation results showed that this core coalescence is governed by the photovoltaic field. Both the interfacial pressure of the shell droplet and internal flow induced by the photovoltaic field contribute to the core coalescence. With an increase in the core number, the illumination intensity required by the core coalescence was found to increase initially, whereas it tended to saturate when the core number exceeded four. Core coalescence and efficient mixing of double-emulsion droplets were validated in a high-throughput manner.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/pr13061640/s1, Supporting Video S1: Light-Triggered Core Coalescence of Double-Emulsion Droplets in a High-throughput Manner; Supporting Video S2: Sequential Coalescence Events of 470 Dual-Core Droplets Under Laser Illumination; Supporting Video S3: Light-Triggered Core Coalescence of Double-Emulsion Droplets with Varying Core Numbers; Supporting information: Video Descriptions.

Author Contributions

M.W.: conceptualization, data curation, formal analysis, investigation, methodology, validation, visualization, writing—original draft, and writing—review and editing; W.Y.: resources, writing—review, project administration and supervision; L.S.: investigation and methodology. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (NSFC) (Nos. 12474307, 12174083, 11874014); Natural Science Foundation of Hebei Province (No. F2024202001); Central Guidance on Local Science and Technology Development Fund of Hebei Province (No. 226Z2001G); “Chunhui” Collaborative Research Project of Ministry of Education of China (HZKY20220246); Science Research Project of Hebei Education Department (JCZX2025012).

Data Availability Statement

The data may be obtained from the corresponding author upon reasonable request.

Acknowledgments

We thank Yongfa Kong for his help with sample preparation.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Samimi, A.; Hengoju, S.; Rosenbaum, M.A. Combinatorial sample preparation platform for droplet-based applications in microbiology. Sens. Actuators B Chem. 2024, 417, 136162. [Google Scholar] [CrossRef]

- Tan, Z.; Zheng, Y.; Shi, H.; Xu, W.; Jia, X.; Dan, Z.; Liao, J.; Dai, Z.; Xu, C. Research progress and application exploration of typical microreactor technologies for health monitoring and disease Diagnosis/Treatment. Chem. Eng. J. 2024, 499, 155938. [Google Scholar] [CrossRef]

- Lee, S.S.; Abbaspourrad, A.; Kim, S.-H. Nonspherical Double Emulsions with Multiple Distinct Cores Enveloped by Ultrathin Shells. ACS Appl. Mater. Interfaces 2014, 6, 1294–1300. [Google Scholar] [CrossRef]

- Sprogies, T.; Kohler, J.; Gros, G. Evaluation of static micromixers for flow-through extraction by emulsification. Chem. Eng. J. 2008, 135, S199–S202. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, Y.; Li, J.; Guo, M.; Wan, J.; Weitz, D.A.; Stone, H.A. Reactions in double emulsions by flow-controlled coalescence of encapsulated drops. Lab A Chip 2011, 11, 2312–2315. [Google Scholar] [CrossRef]

- Lee, T.Y.; Praveenkumar, R.; Oh, Y.-K.; Lee, K.; Kim, S.-H. Alginate microgels created by selective coalescence between core drops paired with an ultrathin shell. J. Mater. Chem. B 2016, 4, 3232–3238. [Google Scholar] [CrossRef] [PubMed]

- Guan, X.; Hou, L.; Ren, Y.; Deng, X.; Lang, Q.; Jia, Y.; Hu, Q.; Tao, Y.; Liu, J.; Jiang, H. A dual-core double emulsion platform for osmolarity-controlled microreactor triggered by coalescence of encapsulated droplets. Biomicrofluidics 2016, 10, 034111. [Google Scholar] [CrossRef]

- Chen, X.; Hou, L.; Yin, Z.; Wang, K.; Zhang, Z.; Bao, F. NIR light-triggered core-coalescence of double-emulsion drops for micro-reactions. Chem. Eng. J. 2023, 454, 140050. [Google Scholar] [CrossRef]

- Hao, Z.; Zhang, L.; Mao, W.; Gao, A.; Gao, X.; Gao, F.; Bo, F.; Zhang, G.; Xu, J. Second-harmonic generation using d33 in periodically poled lithium niobate microdisk resonators. Photonics Res. 2020, 8, 311–317. [Google Scholar] [CrossRef]

- Bo, F.; Wang, J.; Cui, J.; Ozdemir, S.K.; Kong, Y.; Zhang, G.; Xu, J.; Yang, L. Lithium-Niobate-Silica Hybrid Whispering-Gallery-Mode Resonators. Adv. Mater. 2015, 27, 8075–8081. [Google Scholar] [CrossRef]

- Chen, K.; Razinskas, G.; Feichtner, T.; Grossmann, S.; Christiansen, S.; Hecht, B. Electromechanically Tunable Suspended Optical Nanoantenna. Nano Lett. 2016, 16, 2680–2685. [Google Scholar] [CrossRef]

- Yang, T.; Paiè, P.; Nava, G.; Bragheri, F.; Vazquez, R.M.; Minzioni, P.; Veglione, M.; Di Tano, M.; Mondello, C.; Osellame, R.; et al. An integrated optofluidic device for single-cell sorting driven by mechanical properties. Lab A Chip 2015, 15, 1262–1266. [Google Scholar] [CrossRef]

- Gao, Z.; Yan, J.; Shi, L.; Liu, X.; Wang, M.; Li, C.; Huai, Z.; Wang, C.; Wang, X.; Zhang, L.; et al. Efficient Surfactant-Mediated Photovoltaic Manipulation of fL-Scale Aqueous Microdroplets for Diverse Optofluidic Applications on LiNbO3 Platform. Adv. Mater. 2023, 35, 2304081. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Gao, Z.; Shi, L.; Wang, M.; Liu, X.; Li, C.; Huai, Z.; Wang, C.; Zhang, L.; Wang, X.; et al. Photovoltaic Rotation and Transportation of a Fragile Fluorescent Microrod Toward Assembling a Tunable Light-Source System. ACS Nano 2024, 18, 18743–18757. [Google Scholar] [CrossRef] [PubMed]

- Mi, Y.; Huai, Z.; Li, Y.; Shi, L.; Wang, M.; Gao, Z.; Liu, X.; Zhang, X.; Gao, B.; Cao, X.; et al. 3D Multimodal, omnidirectional router of aqueous microdroplets based on the synergy of photovoltaic and triboelectric effects. Nano Energy 2024, 124, 109509. [Google Scholar] [CrossRef]

- Mi, Y.; Liu, X.; Gao, Z.; Wang, M.; Shi, L.; Zhang, X.; Gao, K.; Mugisha, E.R.; Yan, W. 3D Photovoltaic Router of Water Microdroplets Aiming at Free-Space Microfluidic Transportation. ACS Appl. Mater. Interfaces 2021, 13, 45018–45032. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Mugisha, E.R.; Mi, Y.; Liu, X.; Wang, M.; Gao, Z.; Gao, K.; Shi, L.; Chen, H.; Yan, W. Photovoltaic Cycling to-and-fro Actuation of a Water-Microdroplet for Automatic Repeatable Solute Acquisition on Oil-Infused Hydrophobic LN:Fe Surface. ACS Photonics 2021, 8, 639–647. [Google Scholar] [CrossRef]

- Wang, M.; Gao, Z.; Liu, X.; Shi, L.; Mi, Y.; Gao, K.; Zhang, X.; Yan, W. Towards biochemical microreactor: Nonlocal photovoltaic actuation of aqueous microdroplets in oil-infused PDMS channels based on LiNbO3: Fe crystal. Sens. Actuators B Chem. 2021, 349, 130819. [Google Scholar] [CrossRef]

- Wang, M.; Liu, X.; Shi, L.; Gao, Z.; Li, C.; Huai, Z.; Wang, C.; Yan, J.; Zhang, L.; Wang, X.; et al. Photovoltaic high-throughput microfluidic platform for the mass-production of hybrid viscous microdroplets towards diverse applications. Chem. Eng. J. 2024, 487, 150610. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Tang, B.; Tan, X.; Xu, J.J.O.E. Optical trapping and manipulation of metallic micro/nanoparticles via photorefractive crystals. Opt. Express 2009, 17, 9981–9988. [Google Scholar] [CrossRef]

- Blázquez-Castro, A.; García-Cabañes, A.; Carrascosa, M. Biological applications of ferroelectric materials. Appl. Phys. Rev. 2018, 5, 041101. [Google Scholar] [CrossRef]

- Carrascosa, M.; García-Cabañes, A.; Jubera, M.; Ramiro, J.B.; Agulló-López, F. LiNbO3: A photovoltaic substrate for massive parallel manipulation and patterning of nano-objects. Appl. Phys. Rev. 2015, 2, 40605. [Google Scholar] [CrossRef]

- Tang, X.; Wang, L. Loss-Free Photo-Manipulation of Droplets by Pyroelectro-Trapping on Superhydrophobic Surfaces. ACS Nano 2018, 12, 8994–9004. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Li, W.; Wang, L. Furcated droplet motility on crystalline surfaces. Nat. Nanotechnol. 2021, 16, 1106–1112. [Google Scholar] [CrossRef]

- Puerto, A.; Méndez, A.; Arizmendi, L.; García-Cabañes, A.; Carrascosa, M. Optoelectronic Manipulation, Trapping, Splitting, and Merging of Water Droplets and Aqueous Biodroplets Based on the Bulk Photovoltaic Effect. Phys. Rev. Appl. 2020, 14, 024046. [Google Scholar] [CrossRef]

- Rincón, E.; Camarero, P.; Quintanilla, M.; Méndez, A.; García-Cabañes, A.; Haro-González, P.; Carrascosa, M. Manipulation of Cancer Cell Spheroids by Photovoltaic Tweezers: Determination of Their Charge State. Adv. Photonics Res. 2025, 6, 2400124. [Google Scholar] [CrossRef]

- Ferraro, P.; Coppola, S.; Grilli, S.; Paturzo, M.; Vespini, V. Dispensing nano–pico droplets and liquid patterning by pyroelectrodynamic shooting. Nat. Nanotechnol. 2010, 5, 429–435. [Google Scholar] [CrossRef]

- Grilli, S.; Miccio, L.; Gennari, O.; Coppola, S.; Vespini, V.; Battista, L.; Orlando, P.; Ferraro, P. Active accumulation of very diluted biomolecules by nano-dispensing for easy detection below the femtomolar range. Nat. Commun. 2014, 5, 5314. [Google Scholar] [CrossRef]

- Horiuchi, N. Microdroplet manipulation. Nat. Photonics 2024, 18, 111. [Google Scholar] [CrossRef]

- Zaltron, A.; Ferraro, D.; Meggiolaro, A.; Cremaschini, S.; Carneri, M.; Chiarello, E.; Sartori, P.; Pierno, M.; Sada, C.; Mistura, G. Optofluidic Platform for the Manipulation of Water Droplets on Engineered LiNbO3 Surfaces. Adv. Mater. Interfaces 2022, 9, 2200345. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, K.; Gao, Z.; Zan, Z.; Shi, L.; Liu, X.; Wang, M.; Chen, H.; Yan, W. Photovoltaic splitting of water microdroplets on a y-cut LiNbO3:Fe crystal coated with oil-infused hydrophobic insulating layers. Opt. Lett. 2020, 45, 1180–1183. [Google Scholar] [CrossRef]

- Cremaschini, S.; Cattelan, A.; Ferraro, D.; Filippi, D.; Marinello, F.; Meggiolaro, A.; Pierno, M.; Sada, C.; Zaltron, A.; Umari, P.; et al. Trifurcated Splitting of Water Droplets on Engineered Lithium Niobate Surfaces. ACS Appl. Mater. Interfaces 2024, 16, 4271–4282. [Google Scholar] [CrossRef] [PubMed]

- Gao, B.; Cao, X.; Wang, C.; Gao, Z.; Liu, X.; Wang, M.; Yan, J.; Huai, Z.; Shi, L.; Yan, W. Dielectrophoresis-electrophoresis transition during the photovoltaic manipulation of water microdroplets on LiNbO3:Fe platform. Opt. Express 2023, 31, 16495–16507. [Google Scholar] [CrossRef] [PubMed]

- Zamboni, R.; Sebastián-Vicente, C.; Denz, C.; Imbrock, J. Light-Induced Virtual Electrodes for Microfluidic Droplet Electro-Coalescence. Adv. Funct. Mater. 2023, 34, 2305286. [Google Scholar] [CrossRef]

- Esseling, M.; Zaltron, A.; Horn, W.; Denz, C. Optofluidic droplet router. Laser Photonics Rev. 2014, 9, 98–104. [Google Scholar] [CrossRef]

- Sturman, B.; Carrascosa, M.; Agullo-Lopez, F. Light-induced charge transport inLiNbO3 crystals. Phys. Rev. B 2008, 78, 245114. [Google Scholar] [CrossRef]

- García-Cabañes, A.; Blázquez-Castro, A.; Arizmendi, L.; Agulló-López, F.; Carrascosa, M. Recent Achievements on Photovoltaic Optoelectronic Tweezers Based on Lithium Niobate. Crystals 2018, 8, 65. [Google Scholar] [CrossRef]

- Wu, Q.; Yang, C.; Liu, G.; Xu, W.; Zhu, Z.; Si, T.; Xu, R.X. Multiplex coaxial flow focusing for producing multicompartment Janus microcapsules with tunable material compositions and structural characteristics. Lab A Chip 2017, 17, 3168–3175. [Google Scholar] [CrossRef]

- Chen, Z.; Lv, Z.; Zhang, Z.; Weitz, D.A.; Zhang, H.; Zhang, Y.; Cui, W. Advanced microfluidic devices for fabricating multi-structural hydrogel microsphere. Exploration 2021, 1, 20210036. [Google Scholar] [CrossRef]

- Zizzari, A.; Arima, V. Glass Microdroplet Generator for Lipid-Based Double Emulsion Production. Micromachines 2024, 15, 500. [Google Scholar] [CrossRef]

- Herranz-Blanco, B.; Arriaga, L.R.; Mäkilä, E.; Correia, A.; Shrestha, N.; Mirza, S.; Weitz, D.A.; Salonen, J.; Hirvonen, J.; Santos, H.A. Microfluidic assembly of multistage porous silicon–lipid vesicles for controlled drug release. Lab A Chip 2014, 14, 1083–1086. [Google Scholar] [CrossRef] [PubMed]

- Costantini, M.; Guzowski, J.; Żuk, P.J.; Mozetic, P.; De Panfilis, S.; Jaroszewicz, J.; Heljak, M.; Massimi, M.; Pierron, M.; Trombetta, M.; et al. Electric Field Assisted Microfluidic Platform for Generation of Tailorable Porous Microbeads as Cell Carriers for Tissue Engineering. Adv. Funct. Mater. 2018, 28, 1800874. [Google Scholar] [CrossRef]

- Nagelberg, S.; Totz, J.F.; Mittasch, M.; Sresht, V.; Zeininger, L.; Swager, T.M.; Kreysing, M.; Kolle, M. Actuation of Janus Emulsion Droplets via Optothermally Induced Marangoni Forces. Phys. Rev. Lett. 2021, 127, 144503. [Google Scholar] [CrossRef]

- Gao, D.; Ding, W.; Nieto-Vesperinas, M.; Ding, X.; Rahman, M.; Zhang, T.; Lim, C.; Qiu, C.W. Optical manipulation from the microscale to the nanoscale: Fundamentals, advances and prospects. Light Sci. Appl. 2017, 6, e17039. [Google Scholar] [CrossRef]

- Zhang, Y.; Min, C.; Dou, X.; Wang, X.; Urbach, H.P.; Somekh, M.G.; Yuan, X. Plasmonic tweezers: For nanoscale optical trapping and beyond. Light Sci. Appl. 2021, 10, 59. [Google Scholar] [CrossRef]

- Sun, Z.; Li, N.; Li, W.; Weng, S.; Liu, T.; Wang, Z. Effect of droplet angle on droplet coalescence under high-frequency pulsed electric fields: Experiments and molecular dynamics simulations. Chem. Eng. Sci. 2024, 295, 120195. [Google Scholar] [CrossRef]

- Krakhalev, M.N.; Prishchepa, O.O.; Sutormin, V.S.; Zyryanov, V.Y. Polymer dispersed nematic liquid crystal films with conical boundary conditions for electrically controllable polarizers. Opt. Mater. 2019, 89, 1–4. [Google Scholar] [CrossRef]

- Jermann, F.; Otten, J. Light-induced charge transport in LiNbO3:Fe at high light intensities. J. Opt. Soc. Am. B Opt. Phys. 1993, 10, 2085–2092. [Google Scholar] [CrossRef]

- Jia, H.R.; Zhu, Y.X.; Liu, Y.; Guo, Y.; Sayed, S.M.; Zhu, X.Y.; Cheng, X.; Wu, F.G. Direct chemical editing of Gram-positive bacterial cell walls via an enzyme-catalyzed oxidative coupling reaction. Exploration 2022, 2, 20220010. [Google Scholar] [CrossRef]

- Guo, J.; Gan, J.; Ruan, H.; Yuan, X.; Kong, C.; Liu, Y.; Su, M.; Liu, Y.; Liu, W.; Zhang, B.; et al. Active-ion-gated room temperature acetone gas sensing of ZnO nanowires array. Exploration 2022, 2, 20220065. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).