Wellhead Stability During Development Process of Hydrate Reservoir in the Northern South China Sea: Sensitivity Analysis

Abstract

1. Introduction

2. Methodology

2.1. Study Area and Basic Data

2.2. Model Geometry and Simulation Detials

2.3. Boundary Conditions, Initial Conditions, and Loads

3. Applicability and Superiority Verification of the Investigation Methodology

4. Results and Discussion

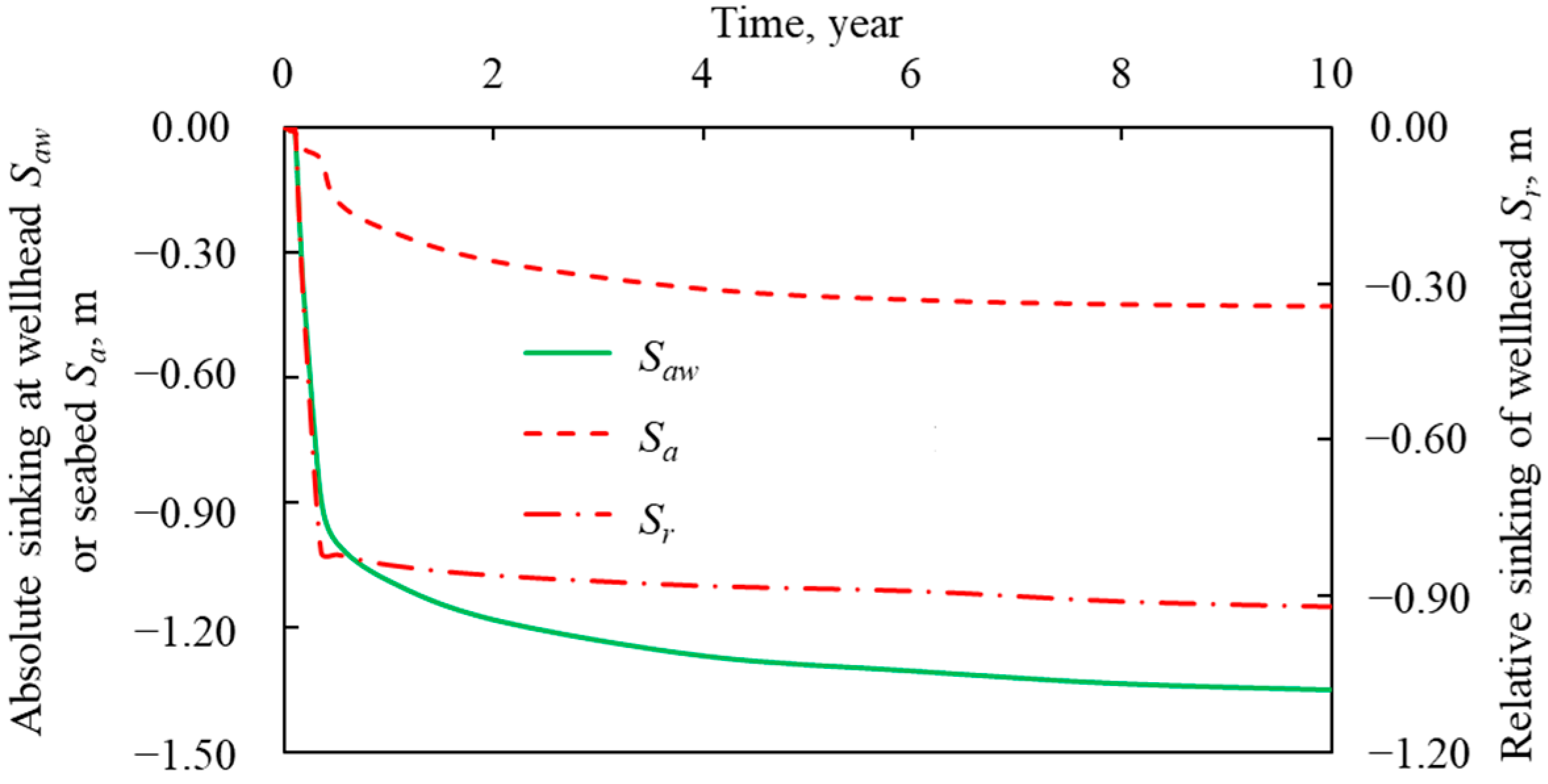

4.1. Evolution of Wellhead Instability During Hydrate Development

4.2. Impact of Depressurization Amplitude

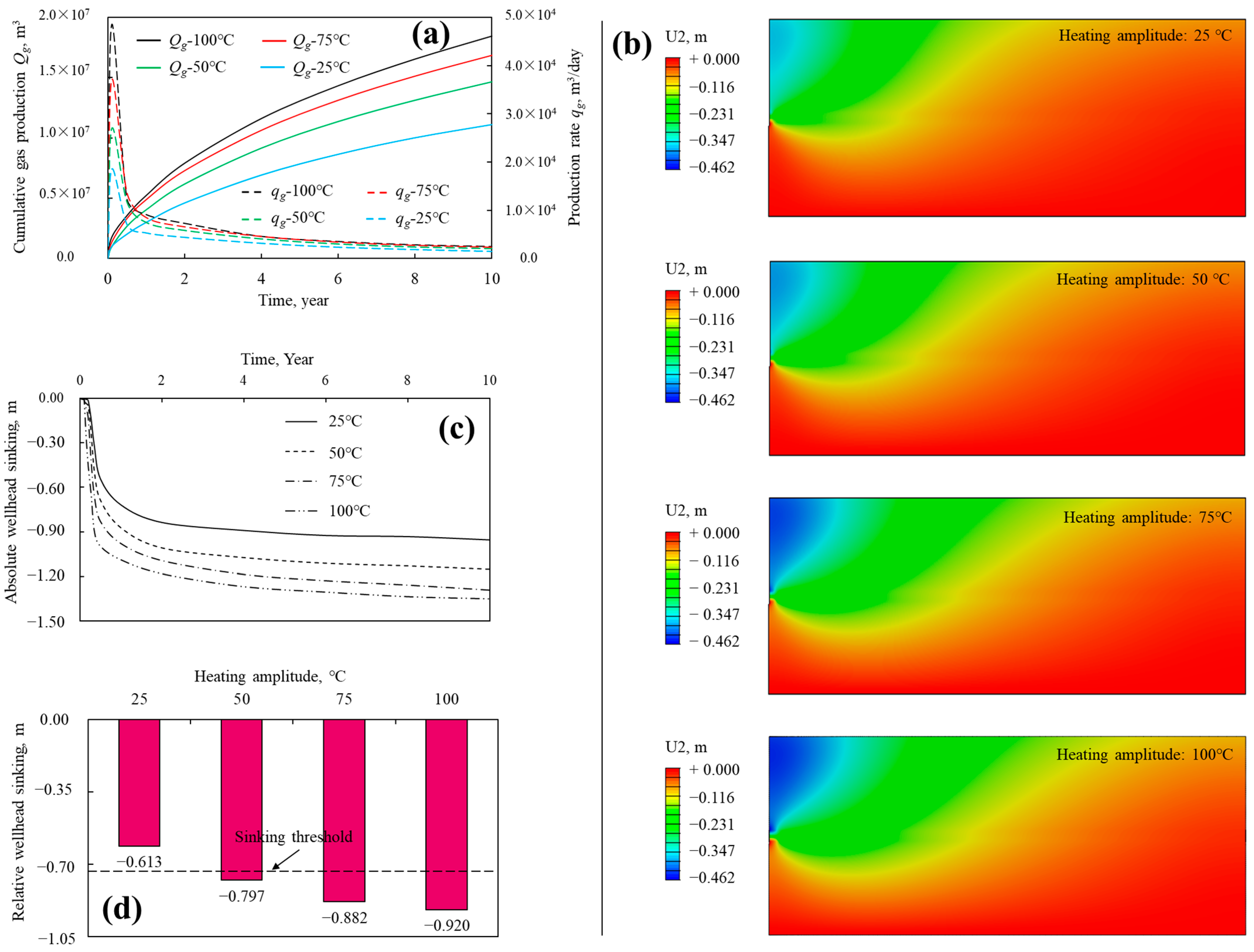

4.3. Impact of Heating Amplitude

4.4. Impact of Reservoir Permeability

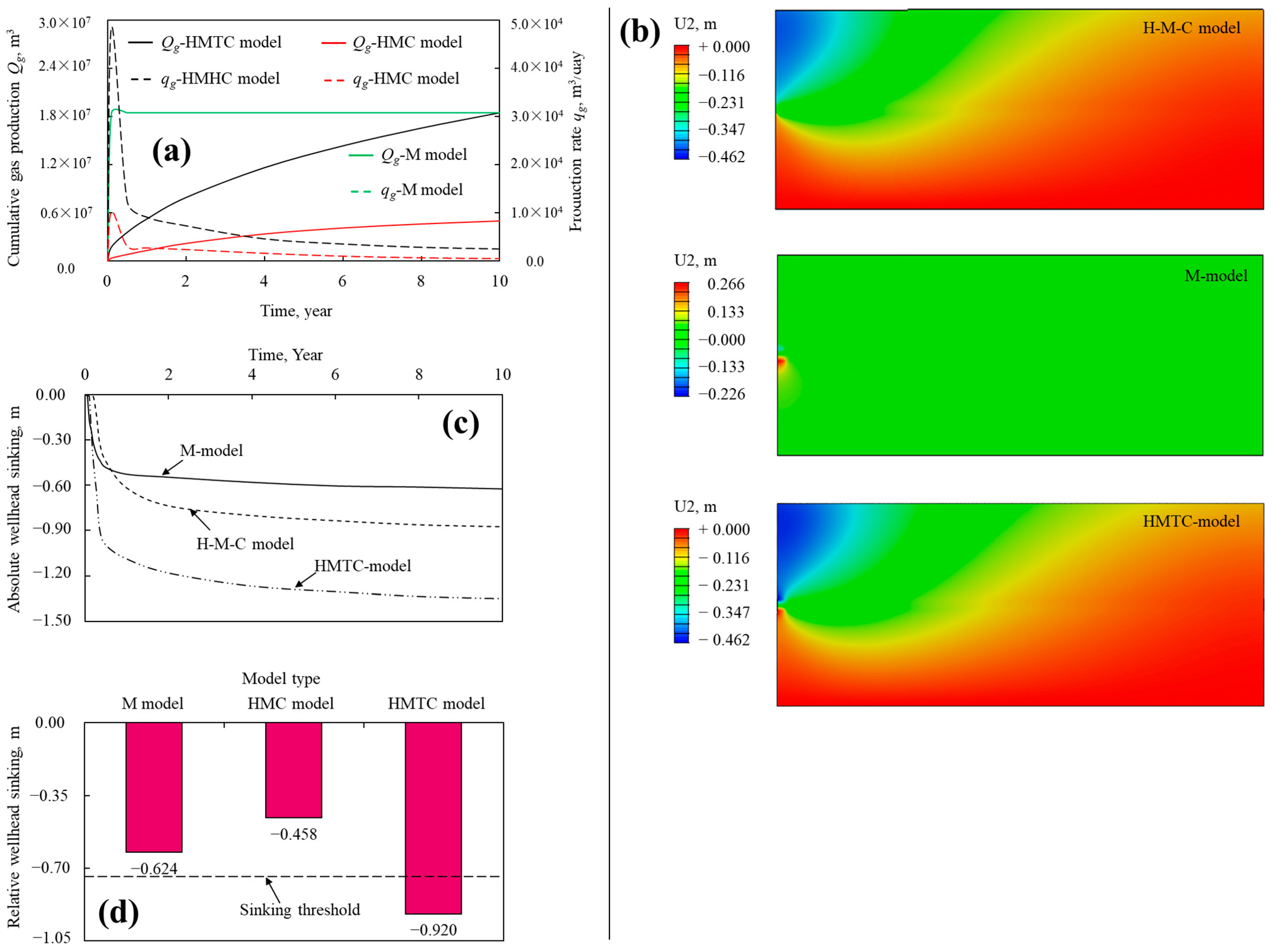

4.5. Impact of Model Type

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, X.; Geng, Q.; Zhang, Z.; Qiu, Z.; Fang, Q.; Wang, Z.; Yan, C.; Ma, Y.; Li, Y. Phase change material microcapsules for smart temperature regulation of drilling fluids for gas hydrate reservoirs. Energy 2023, 263, 125715. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Cao, H.; Wu, J.; Wang, F.; Wang, Y. The Crack Propagation Behaviour of CO2 Fracturing Fluid in Unconventional Low Permeability Reservoirs: Factor Analysis and Mechanism Revelation. Processes 2025, 13, 159. [Google Scholar] [CrossRef]

- Wang, Z.; Fan, Z.; Chen, X.; Fan, Z.; Wei, Q.; Wang, X.; Yue, W.; Liu, B.; Wu, Y. Global oil and gas development in 2022: Situation, trends and enlightenment. Pet. Explor. Dev. 2023, 50, 1167–1186. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, B.; Höök, M.; Feng, L. Forecast of oil reserves and production in Daqing oilfield of China. Energy 2010, 35, 3097–3102. [Google Scholar] [CrossRef]

- He, Y.; Qiao, Y.; Qin, J.; Tang, Y.; Wang, Y.; Chai, Z. A novel method to enhance oil recovery by inter-fracture injection and production through the same multi-fractured horizontal well. J. Energy Resour. Technol. 2022, 144, 043005. [Google Scholar] [CrossRef]

- Mansouri, M.; Ahmadi, Y. Applications of zeolite-zirconia-copper nanocomposites as a new asphaltene inhibitor for improving permeability reduction during CO2 flooding. Sci. Rep. 2022, 12, 6209. [Google Scholar] [CrossRef]

- Lei, Q.; Wang, D.; Guan, B.; Shi, J.; Cai, B.; He, C.; Sun, Q.; Huang, R. Shale oil and gas exploitation in China: Technical comparison with US and development suggestions. Pet. Explor. Dev. 2023, 50, 944–954. [Google Scholar] [CrossRef]

- Ahmadi, Y.; Mansouri, M.; Pourafshary, P. Enhanced oil recovery by using modified ZnO nanocomposites in sandstone oil reservoirs. Sci. Rep. 2024, 14, 2766. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wang, F.; Wu, J.; Usman, T.; Li, Q.; Yuan, L.; Liu, Z. Effect of thickener and reservoir parameters on the filtration property of CO2 fracturing fluid. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 1705–1715. [Google Scholar] [CrossRef]

- Ahmadi, Y.; Akbari, A.; Mansouri, M.; Alibak, A.H.; Vaferi, B. Innovative xanthan gum-based nanocomposites for asphaltene precipitation prevention in shale and carbonate rocks. Int. J. Biol. Macromol. 2024, 280, 136331. [Google Scholar] [CrossRef]

- Er, C.; Zhao, J.; Li, Y.; Si, S.; Bai, Y.; Wu, W.; Han, Q. Relationship between tight reservoir diagenesis and hydrocarbon accumulation: An example from the early Cretaceous Fuyu reservoir in the Daqing oil field, Songliao Basin, China. J. Pet. Sci. Eng. 2022, 208, 109422. [Google Scholar] [CrossRef]

- Mansouri, M.; Ahmadi, Y.; Sedghamiz, M.A.; Vaferi, B. Experimental investigation of the influence of ZnO–CuO nanocomposites on interfacial tension, contact angle, and oil recovery by spontaneous imbibition in carbonate rocks. Phys. Fluids 2024, 36, 106612. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhao, J.; Zhou, T.; Huang, Y. Study on in-depth profile control system of low-permeability reservoir in block H of Daqing oil field. J. Pet. Sci. Eng. 2017, 157, 1192–1196. [Google Scholar] [CrossRef]

- Jin, Z.; Liang, X.; Bai, Z. Exploration breakthrough and its significance of Gulong lacustrine shale oil in the Songliao Basin, Northeastern China. Energy Geosci. 2022, 3, 120–125. [Google Scholar] [CrossRef]

- Yuan, S.; Lei, Z.; Li, J.; Yao, Z.; Li, B.; Wang, R.; Liu, Y.; Wang, Q. Key theoretical and technical issues and countermeasures for effective development of Gulong shale oil, Daqing Oilfield, NE China. Pet. Explor. Dev. 2023, 50, 638–650. [Google Scholar] [CrossRef]

- Li, Q.; Wu, J.; Li, Q.; Wang, F.; Cheng, Y. Sediment Instability Caused by Gas Production from Hydrate-bearing Sediment in Northern South China Sea by Horizontal Wellbore: Sensitivity Analysis. Nat. Resour. Res. 2025, 34, 1667–1699. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, D.; Sun, J.; Gu, Y.; Zhang, C.; Zhang, C. Status-quo of proved oil/gas initially-in-place in China as of 2020 and its variation trend in the past decade. Energy Geosci. 2022, 3, 343–348. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, X.; Zhou, Y. Stability Characteristics of Natural Gas Hydrate Wellbores Based on Thermo-Hydro-Mech Modeling. Processes 2024, 12, 2196. [Google Scholar] [CrossRef]

- He, D.; Jia, C.; Zhao, W.; Xu, F.; Luo, X.; Liu, W.; Tang, Y.; Gao, S.; Zheng, X.; Li, D.; et al. Research progress and key issues of ultra-deep oil and gas exploration in China. Pet. Explor. Dev. 2023, 50, 1333–1344. [Google Scholar] [CrossRef]

- Zhao, S.; Zhao, Q.; Zhang, X.; Jiang, X.; Wu, H.; Yan, J. Key policy needs for the success of China’s shale gas revolution. Energy Rep. 2024, 11, 4015–4020. [Google Scholar] [CrossRef]

- Wang, Q.; Li, S.; Li, R. China’s dependency on foreign oil will exceed 80% by 2030: Developing a novel NMGM-ARIMA to forecast China’s foreign oil dependence from two dimensions. Energy 2019, 163, 151–167. [Google Scholar] [CrossRef]

- Guo, J.; Gao, J.; Gao, S.; Yan, K.; Zhang, B.; Guan, C. Increasing impacts of China’s oil and gas demands on global CH4 emissions. Sci. Total Environ. 2024, 912, 169624. [Google Scholar] [CrossRef]

- Chen, S.; Ding, Y.; Song, Y.; Zhang, M.; Nie, R. Study on China’s energy system resilience under the scenarios of long-term shortage of imported oil. Energy 2023, 270, 126831. [Google Scholar] [CrossRef]

- Yi, J.; Qi, Z.; Li, X.; Liu, H.; Zhou, W. Spatial correlation-based machine learning framework for evaluating shale gas production potential: A case study in southern Sichuan Basin, China. Appl. Energy 2024, 357, 122483. [Google Scholar] [CrossRef]

- Zeng, B.; Chen, G.; Meng, W.; Wang, J. Prediction, analysis and suggestions of shale gas production in China based on a new grey model with four parameters. Alex. Eng. J. 2024, 86, 258–276. [Google Scholar] [CrossRef]

- Li, Z.; Xie, R.; Wu, Y.; Yuan, J. Progress and prospect of CNOOC’s oil and gas well drilling and completion technologies. Nat. Gas Ind. B 2022, 9, 209–217. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, G.; Yin, Z.; Khan, F.; Meng, X. An integrated methodology for dynamic risk evaluation of deepwater blowouts. J. Loss Prev. Process Ind. 2022, 74, 104647. [Google Scholar] [CrossRef]

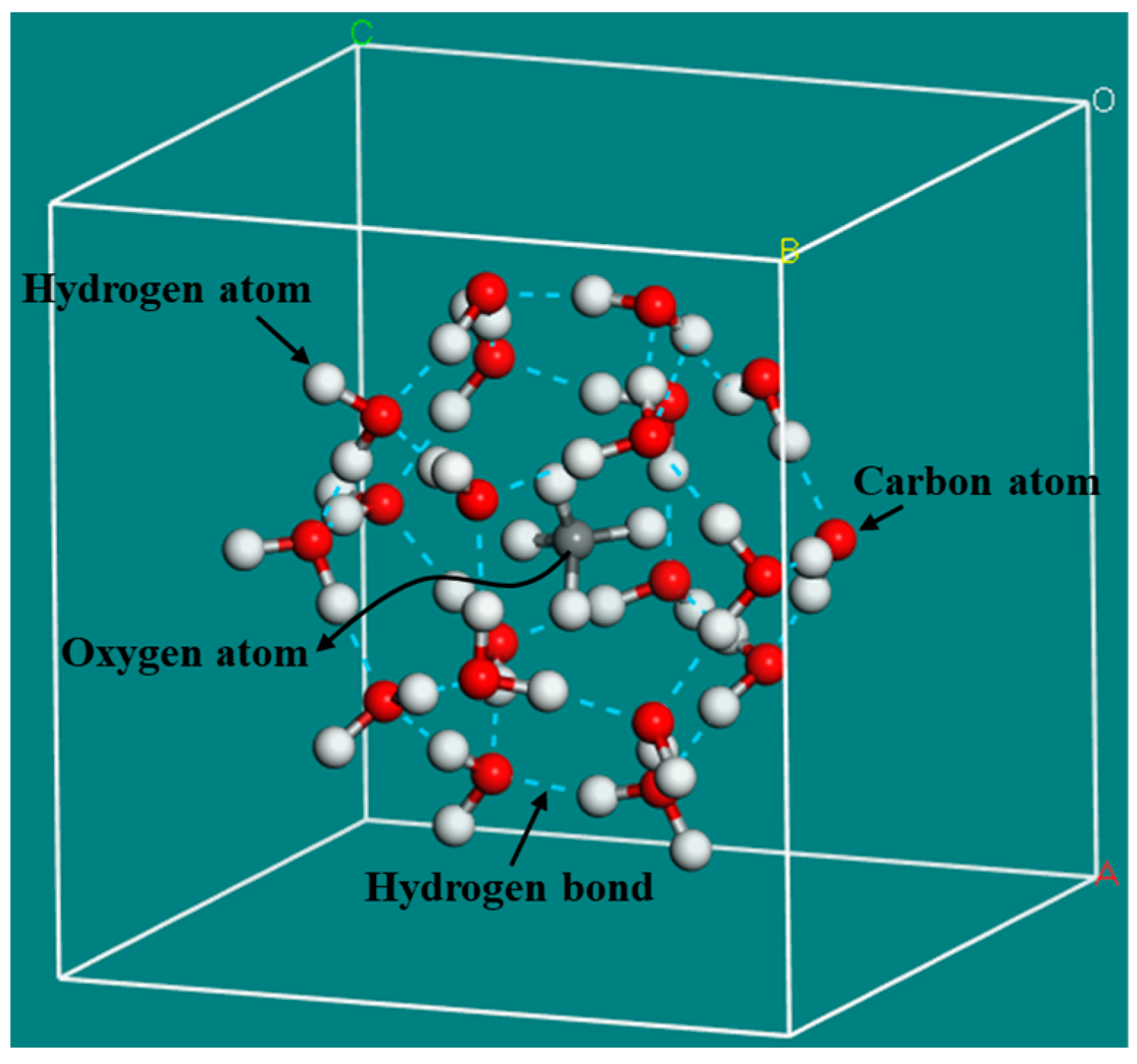

- Liu, J.; Hou, J.; Xu, J.; Liu, H.; Chen, G.; Zhang, J. Formation of clathrate cages of sI methane hydrate revealed by ab initio study. Energy 2017, 120, 698–704. [Google Scholar] [CrossRef]

- Yan, C.; Ren, X.; Cheng, Y.; Song, B.; Li, Y.; Tian, W. Geomechanical issues in the exploitation of natural gas hydrate. Gondwana Res. 2020, 81, 403–422. [Google Scholar] [CrossRef]

- Li, Q.; Cheng, Y.; Ansari, U.; Han, Y.; Liu, X.; Yan, C. Experimental Investigation on Hydrate Dissociation in Near-Wellbore Region Caused by Invasion of Drilling Fluid: Ultrasonic Measurement and Analysis. Environ. Sci. Pollut. Res. 2022, 29, 36920–36937. [Google Scholar] [CrossRef]

- Fu, C.; Yang, J.; Long, Y.; Yin, Q.; Hu, Z.; Zhang, M.; Lu, M.; Li, X.; Chen, Z.J.; Ma, H. Analysis of subsidence patterns of the formation around the wellbore during deepwater natural gas hydrate test production conditions. Appl. Ocean Res. 2024, 153, 104257. [Google Scholar] [CrossRef]

- Xiong, T.; Cheng, L.; Guo, D.; Guan, L.; Jiang, Q.; Hu, Z.; Yin, S.; Chen, G. Overpressure characteristics and geological origin of the paleogene in Baiyun Sag, Pearl River Mouth Basin. Front. Earth Sci. 2023, 11, 1118443. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Zhang, Q.; Fan, M.; Yin, B.; Wang, X.; Sun, X.; Wang, Z. Effect of liquid viscosity on the gas-liquid two phase countercurrent flow in the wellbore of bullheading killing. Geoenergy Sci. Eng. 2023, 221, 111274. [Google Scholar] [CrossRef]

- Liu, X.; Chen, G.; Chang, Y.; Zhang, L.; Zhang, W.; Xie, H. Multistring analysis of wellhead movement and uncemented casing strength in offshore oil and gas wells. Pet. Sci. 2014, 11, 131–138. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, D.; Fang, J. Finite element analysis of deepwater conductor bearing capacity to analyze the subsea wellhead stability with consideration of contact interface models between pile and soil. J. Pet. Sci. Eng. 2015, 126, 48–54. [Google Scholar] [CrossRef]

- Yan, W.; Chen, Z.J.; Deng, J.G.; Zhu, H.Y.; Deng, F.C.; Liu, Z.L. Numerical method for subsea wellhead stability analysis in deepwater drilling. Ocean Eng. 2015, 98, 50–56. [Google Scholar] [CrossRef]

- Qiu, N.; Liu, X.; Liu, Z.; Li, Y.; Chang, Y.; Chen, G.; Xu, L. Dynamic stability evaluation of subsea wellhead based on fully coupled model. Ocean Eng. 2022, 257, 111720. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wu, J.; Li, X.; Li, H.; Cheng, Y. Wellhead Stability during Development Process of Hydrate Reservoir in the Northern South China Sea: Evolution and Mechanism. Processes 2025, 13, 40. [Google Scholar] [CrossRef]

- Guo, K.; Fan, S.; Wang, Y.; Lang, X.; Zhang, W.; Li, Y. Physical and chemical characteristics analysis of hydrate samples from northern South China sea. J. Nat. Gas Sci. Eng. 2020, 81, 103476. [Google Scholar] [CrossRef]

- Wu, Y.; Tahmasebi, P.; Liu, K.; Lin, C.; Kamrava, S.; Liu, S.; Fagbemi, S.; Liu, C.; Chai, R.; An, S. Modeling the physical properties of hydrate-bearing sediments: Considering the effects of occurrence patterns. Energy 2023, 278, 127674. [Google Scholar] [CrossRef]

- Shan, Z.; Wang, X.; Li, Z.; Gong, Z.; Ma, N.; Zhang, J.; Wang, Z.; Sun, B. Research on Key Parameters of Wellbore Stability for Horizontal Drilling in Offshore Hydrate Reservoirs. Appl. Sci. 2024, 14, 10922. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, G.; Zhang, R.; Zhou, W.; Hu, Y.; Zhao, X.; Wang, P. Early monitoring of gas kick in deepwater drilling based on ensemble learning method: A case study at South China Sea. Process Saf. Environ. Prot. 2023, 169, 504–514. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J.; Tang, X.; Li, C.; Li, B.; Wang, Y.; Zhao, Z. Propagation characteristics and application effects of measurement-while-drilling pressure wave for early gas-kick detection. J. Loss Prev. Process Ind. 2022, 76, 104741. [Google Scholar] [CrossRef]

- Xu, Z.; Song, X.; Li, G.; Zhu, Z.; Zhu, B. Gas kick simulation in oil-based drilling fluids with the gas solubility effect during high-temperature and high-pressure well drilling. Appl. Therm. Eng. 2019, 149, 1080–1097. [Google Scholar] [CrossRef]

- Yin, B.; Liu, G.; Li, X. Multiphase transient flow model in wellbore annuli during gas kick in deepwater drilling based on oil-based mud. Appl. Math. Model. 2017, 51, 159–198. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, M.; Jiang, H. Influence of unconnected pores on effective stress in porous geomaterials: Theory and case study in unconventional oil and gas reservoirs. J. Nat. Gas Sci. Eng. 2021, 88, 103787. [Google Scholar] [CrossRef]

- Cha, Y.; Yun, T.S.; Kim, Y.J.; Lee, J.Y.; Kwon, T.H. Geomechanical, hydraulic and thermal characteristics of deep oceanic sandy sediments recovered during the second ulleung basin gas hydrate expedition. Energies 2016, 9, 775. [Google Scholar] [CrossRef]

- Klar, A.; Soga, K.; Ng, M.Y.A. Coupled deformation–flow analysis for methane hydrate extraction. Geotechnique 2010, 60, 765–776. [Google Scholar] [CrossRef]

- Masui, A.; Haneda, H.; Ogata, Y.; Aoki, K. Effects of methane hydrate formation on shear strength of synthetic methane hydrate sediments. In Proceedings of the ISOPE International Ocean and Polar Engineering Conference, Seoul, Republic of Korea, 19 June 2005. ISOPE-I-05-056. [Google Scholar]

- Li, C.H.; Zhao, Q.; Xu, H.J.; Feng, K.; Liu, X.W. Relation between relative permeability and hydrate saturation in Shenhu area, South China Sea. Appl. Geophys. 2014, 11, 207–214. [Google Scholar] [CrossRef]

- Li, C.; Feng, K.; Liu, X. Study on p-Wave Attenuation in Hydrate-Bearing Sediments Based on BISQ Model. J. Geol. Res. 2013, 1, 176579. [Google Scholar] [CrossRef]

- Chen, X.; He, M.; Xu, M.; Zhou, C. Fully transient coupled prediction model of wellbore temperature and pressure for multi-phase flow during underbalanced drilling. Geoenergy Sci. Eng. 2023, 223, 211540. [Google Scholar] [CrossRef]

- Yang, H.; Li, J.; Jiang, J.; Zhang, H.; Guo, B.; Zhang, G.; Chen, W. A dynamic managed pressure well-control method for rapid treatment of gas kick in deepwater managed pressure drilling. Pet. Sci. 2022, 19, 2297–2313. [Google Scholar] [CrossRef]

- Chen, X.; He, M.; Xu, M.; Wang, S.; Dai, B. Early gas kick detection-inversion-control integrated system: The significance of applications of managed pressure drilling: A review. Geoenergy Sci. Eng. 2023, 229, 212134. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wang, F.; Li, Q.; Kobina, F.; Bai, H.; Yuan, L. Effect of a modified silicone as a thickener on rheology of liquid CO2 and its fracturing capacity. Polymers 2019, 11, 540. [Google Scholar] [CrossRef]

- Zhang, X.; Ding, T.; Zhou, B.; Yin, B. Mechanism of displacement gas kick in horizontal well drilling into deep fractured gas reservoir. Front. Energy Res. 2024, 12, 1412038. [Google Scholar] [CrossRef]

- May, F.; Warsitzka, M.; Kukowski, N. Analogue modelling of leakage processes in unconsolidated sediments. Int. J. Greenh. Gas Control 2019, 90, 102805. [Google Scholar] [CrossRef]

- Zhao, X.; Qiu, Z.; Wang, M.; Xu, J.; Huang, W. Experimental investigation of the effect of drilling fluid on wellbore stability in shallow unconsolidated formations in deep water. J. Pet. Sci. Eng. 2019, 175, 595–603. [Google Scholar] [CrossRef]

- Hosseini, S.M. Hydraulic Fracture Mechanism in Unconsolidated Formations. Master’s Thesis, University of Texas at Austin, Austin, TX, USA, 2012. [Google Scholar]

- Yarushina, V.M.; Bercovici, D.; Oristaglio, M.L. Rock deformation models and fluid leak-off in hydraulic fracturing. Geophys. J. Int. 2013, 194, 1514–1526. [Google Scholar] [CrossRef]

- Magzoub, M.I.; Salehi, S.; Hussein, I.A.; Nasser, M.S. Loss circulation in drilling and well construction: The significance of applications of crosslinked polymers in wellbore strengthening: A review. J. Pet. Sci. Eng. 2020, 185, 106653. [Google Scholar] [CrossRef]

- Alsaba, M.; Nygaard, R.; Saasen, A.; Nes, O.M. Lost circulation materials capability of sealing wide fractures. In Proceedings of the SPE Deepwater Drilling and Completions Conference, Galveston, TX, USA, 10–11 September 2014. SPE-170285-MS. [Google Scholar]

- Feng, J.; Wang, Q.; Li, M.; Li, X.; Zhou, K.; Tian, X.; Niu, J.; Yang, Z.; Zhang, Q.; Sun, M. Pore Pressure Prediction for High-Pressure Tight Sandstone in the Huizhou Sag, Pearl River Mouth Basin, China: A Machine Learning-Based Approach. J. Mar. Sci. Eng. 2024, 12, 703. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, D.; Yin, J.; Zhou, X.; Li, Y.; Chi, P.; Han, Y.; Ansari, U.; Cheng, Y. Investigation on Sediment Instability Caused by Gas Production from Hydrate-Bearing Sediment in Northern South China Sea by Horizontal Wellbore: Evolution and Mechanism. Nat. Resour. Res. 2023, 32, 1595–1620. [Google Scholar] [CrossRef]

- Li, Q.; Liu, J.; Wang, S.; Guo, Y.; Han, X.; Li, Q.; Cheng, Y.; Dong, Z.; Li, X.; Zhang, X. Numerical insights into factors affecting collapse behavior of horizontal wellbore in clayey silt hydrate-bearing sediments and the accompanying control strategy. Ocean Eng. 2024, 297, 117029. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, Z.; Li, X.; Zheng, Y.; Li, C.; Li, Z.; Liu, X. Research on the mechanism of the influence of flooding on the killing of empty wells. J. Pet. Explor. Prod. Technol. 2021, 11, 3571–3598. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, Y.; Zhao, X.; Wang, Z.; Li, H.; Sun, B. Risk analysis on the blowout in deepwater drilling when encountering hydrate-bearing reservoir. Ocean Eng. 2018, 170, 1–5. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Han, Y. A Numerical Investigation on Kick Control with the Displacement Kill Method during a Well Test in a Deep-Water Gas Reservoir: A Case Study. Processes 2024, 12, 2090. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Wu, J.; Wang, Y. The carrying behavior of Water-based fracturing fluid in shale reservoir fractures and Molecular dynamics of sand carrying mechanism. Processes 2024, 12, 2051. [Google Scholar] [CrossRef]

- Cheng, Y.; Xue, M.; Shi, J.; Li, Y.; Yan, C.; Han, Z.; Yang, J. Numerical simulating the influences of hydrate decomposition on wellhead stability. Processes 2023, 11, 1586. [Google Scholar] [CrossRef]

- Xue, M.; Cheng, Y.; Li, Y.; Yan, C.; Han, Z.; Chen, Y.; Sun, B. Numerical Analysis on Gas Production and Geomechanical Responses of Natural Gas Hydrate Reservoirs. ACS Omega 2023, 8, 39604–39615. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, Y.; Xu, Z.; Zhang, Y.; Liu, X.; Zhong, X.; Tu, G.; Chen, C. Numerical simulation study of natural gas hydrate extraction by depressurization combined with CO2 replacement. Energy 2024, 303, 131998. [Google Scholar] [CrossRef]

- Song, B.; Cheng, Y.; Yan, C.; Lyu, Y.; Wei, J.; Ding, J.; Li, Y. Seafloor subsidence response and submarine slope stability evaluation in response to hydrate dissociation. J. Nat. Gas Sci. Eng. 2019, 65, 197–211. [Google Scholar] [CrossRef]

- Clarke, M.A.; Bishnoi, P.R. Measuring and modelling the rate of decomposition of gas hydrates formed from mixtures of methane and ethane. Chem. Eng. Sci. 2001, 56, 4715–4724. [Google Scholar] [CrossRef]

- Li, B.; Sun, Y.; Jiang, S.; Zhang, G.; Feng, J.; Shan, H.; Li, X. Production characteristics and sensitivity analysis on gas hydrate and shallow gas coexistence reservoirs: Focus on gas hydrate formation. Appl. Energy 2025, 386, 125572. [Google Scholar] [CrossRef]

- Hou, J.; Zhao, E.; Ji, Y. Numerical simulation of gas production from Class III hydrate reservoirs using low-frequency electric heating-assisted depressurization with horizontal wells. Fuel 2024, 357, 129906. [Google Scholar] [CrossRef]

- Ge, K.; Liu, J.; Wang, J.; Long, Z.; Zhang, X.; Wei, H.; Yu, W. Numerical simulation of gas production behavior of class Ⅰ, class Ⅱ and class Ⅲ hydrate reservoirs for different well locations. J. Clean. Prod. 2023, 433, 139844. [Google Scholar] [CrossRef]

- Li, S.; Liu, L.; Wu, D.; Zhang, N.; Guo, Y. Numerical simulation on gas production from hydrate-bearing sediments by depressurization considering time-varying reservoir compressibility. Gas Sci. Eng. 2024, 121, 205180. [Google Scholar] [CrossRef]

- Hui, C.; Zhang, Y.; Wu, X.; Zhang, P.; Li, G.; Lu, J.; Zhang, B. Numerical analysis of the production behaviors and geomechanical responses during natural gas hydrate production by vertical wells fracturing. Energy 2024, 292, 130526. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wang, X.; Yu, H.; Li, Q.; Wang, F.; Bai, H.; Kobina, F. An application of thickener to increase viscosity of liquid CO2 and the assessment of the reservoir geological damage and CO2 utilization. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 368–377. [Google Scholar]

- Zhang, Z.; Xu, T.; Li, S.; Guo, P.; Li, X.; Lu, C.; Sun, Y.; Wang, P.; Qin, X. Comparative analysis of three heating methods for natural gas hydrate production: Electric heating, steam injection, and hot water injection. Appl. Therm. Eng. 2025, 269, 126131. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Y.; Li, S.; He, J.; Li, X.; Xu, T.; Lu, C.; Qin, X. Optimization of the natural gas hydrate hot water injection production method: Insights from numerical and phase equilibrium analysis. Appl. Energy 2024, 361, 122963. [Google Scholar] [CrossRef]

- Xue, K.; Liu, Y.; Yu, T.; Yang, L.; Zhao, J.; Song, Y. Numerical simulation of gas hydrate production in shenhu area using depressurization: The effect of reservoir permeability heterogeneity. Energy 2023, 271, 126948. [Google Scholar] [CrossRef]

- Li, Q.; Cheng, Y.; Li, Q.; Zhang, C.; Ansari, U.; Song, B. Establishment and evaluation of strength criterion for clayey silt hydrate-bearing sediments. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 742–750. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, Z.; Zhao, Y.; Zuo, J.; Li, P.; Liang, W.; Wang, B.; Chen, X.; Lei, H.; Jin, G. Coupled thermal–hydrodynamic–mechanical numerical simulation of natural gas hydrate horizontal well depressurization production: Method and application in the South China Sea. Nat. Gas Ind. B 2022, 9, 548–560. [Google Scholar] [CrossRef]

- Li, X.; Wan, Y.; Lei, G.; Sun, J.; Cheng, W.; Dou, X.; Zhao, Y.; Ning, F. Numerical investigation of gas and sand production from hydrate-bearing sediments by incorporating sand migration based on IMPES method. Energy 2024, 288, 129556. [Google Scholar] [CrossRef]

- Jiang, Y.; Ma, X.; Luan, H.; Liang, W.; Yan, P.; Song, W.; Shan, Q. Numerical simulation on the evolution of physical and mechanical characteristics of natural gas hydrate reservoir during depressurization production. J. Nat. Gas Sci. Eng. 2022, 108, 104803. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Q.; Dong, W.; Li, Q.; Wang, F.; Bai, H.; Zhang, R.; Owusu, A.B. Effect of different factors on the yield of epoxy-terminated polydimethylsiloxane and evaluation of CO 2 thickening. RSC Adv. 2018, 8, 39787–39796. [Google Scholar] [CrossRef]

- Sohn, Y.; Park, T.; Kwon, T.H. Geomechanical responses of sand–clay interbedded gas hydrate-bearing deposits under depressurization-driven gas production at site UBGH2-6 in Ulleung Basin, offshore Korea. Gas Sci. Eng. 2024, 126, 205337. [Google Scholar] [CrossRef]

- Ma, X.; Luan, H.; Jiang, Y.; Yan, P.; Wu, X.; Wang, C.; Shan, Q. Numerical investigation on hydrate reservoir deformation induced by depressurization production and analysis of CO2 reinjection potential. Geoenergy Sci. Eng. 2025, 213723. [Google Scholar] [CrossRef]

- Ye, H.; Chen, J.; Yao, Y.; Chen, D.; Wu, X.; Li, D.; Zi, M. Gas recovery from low-permeability muddy silt gas hydrate reservoirs by depressurization coupled with hot water injection: Impact of hydro-lock effect. Energy 2025, 316, 134413. [Google Scholar] [CrossRef]

- Zhou, X.; Mao, L.; Guo, Z.; Gao, Y. Prediction of wellbore gas hydrate generation based on temperature-pressure coupling model in deepwater testing. Int. J. Hydrogen Energy 2024, 90, 395–408. [Google Scholar] [CrossRef]

- Ye, H.; Wu, X.; Li, D.; Jiang, Y. Numerical simulation of productivity improvement of natural gas hydrate with various well types: Influence of branch parameters. J. Nat. Gas Sci. Eng. 2022, 103, 104630. [Google Scholar] [CrossRef]

- Yoon, H.C.; Kim, J. The impacts of scaled capillary pressure combined with coupled flow and geomechanics on gas hydrate deposits. Geomech. Energy Environ. 2024, 37, 100529. [Google Scholar] [CrossRef]

- Li, Q.; Li, Y.; Cheng, Y.; Li, Q.; Wang, F.; Wei, J.; Liu, Y.; Zhang, C.; Song, B.; Yan, C.; et al. Numerical simulation of fracture reorientation during hydraulic fracturing in perforated horizontal well in shale reservoirs. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 1807–1813. [Google Scholar] [CrossRef]

- Yang, M.; Wang, Y.; Wu, H.; Zhang, P.; Ju, X. Thermo-hydro-chemical modeling and analysis of methane extraction from fractured gas hydrate-bearing sediments. Energy 2024, 292, 130490. [Google Scholar] [CrossRef]

- Yang, H.; Liu, X.; Yue, J.; Tang, X. Analysis of factors affecting microwave heating of natural gas hydrate combined with numerical simulation method. Petroleum 2022, 8, 391–402. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Z.; Li, P.; Song, Y.; Wang, D. Numerical modeling of coupled behavior of gas production and mechanical deformation of gas hydrate reservoir in Shenhu area, South China Sea: Enlightenments for field monitoring and model verification. Energy 2022, 254, 124406. [Google Scholar] [CrossRef]

- Li, Q.; Cheng, Y.; Li, Q.; Ansari, U.; Liu, Y.; Yan, C.; Lei, C. Development and verification of the comprehensive model for physical properties of hydrate sediment. Arab. J. Geosci. 2018, 11, 1–16. [Google Scholar] [CrossRef]

- Gu, Y.; Sun, J.; Qin, F.; Ning, F.; Li, Y.; Cao, X.; Liu, T.; Wang, R.; Jiang, G. Numerical analysis on gas production from silty hydrate reservoirs in the South China sea by depressurizing: The effect of permeability reduction caused by pore compression. J. Nat. Gas Sci. Eng. 2022, 104, 104680. [Google Scholar] [CrossRef]

- Sang, S.; Kong, L.; Zhao, Y.; Hua, L.; Liu, J.; Zhao, S.; Xiaoyu, B.; Sun, G. Application of Discrete Element Numerical Simulation Methods in Mechanical Characterization of Hydrate-bearing Sediments: Research Status and Challenges. Geomech. Energy Environ. 2025, 100650. [Google Scholar] [CrossRef]

- Moon, S.Y.; Shin, H.J.; Lim, J.S. Field-scale simulation of gas hydrate dissociation behavior in multilayered sediments under different depressurization conditions. J. Pet. Sci. Eng. 2023, 220, 111221. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, L.; Kanda, Y.; Suzuki, A.; Komiya, A.; Maruyama, S. Numerical analysis of gas production from large-scale methane hydrate sediments with fractures. Energy 2021, 236, 121485. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Water depth at site SH2 | 1230 | m |

| Sediment porosity | ϕ = ϕ0(1 − Sh) | |

| Sediment cohesion | C = 0.5 + 1.50Sh (MPa) | |

| Sediment friction angle | 34.6 | Degree |

| Sediment Elastic modulus | E = 125 + 1000Sh (MPa) | |

| Sediment Poisson’s ratio | 0.35 | - |

| Sediment permeability | K = K0(1 − Sh)7.97 (mD) | |

| Specific heat | 1900 | J/(kg·K) |

| Total simulation time | 10 | Years |

| Borehole radius | 0.22 | m |

| Reservoir dry density | 2500 | g/cm3 |

| Density of sea water | 1.03 | g/cm3 |

| Parameter | Value | Unit |

|---|---|---|

| Depressurization amplitude | 1.5, 3.0, 4.5, 6.0 | MPa |

| Heating amplitude | 25, 50, 75, 100 | °C |

| Initial permeability | 0.5, 1.0, 2.5, 5.0 | mD |

| Total production cycle | 10 | Years |

| Boundary Condition Type | Notes | |

|---|---|---|

| Wellbore | Temperature | Fixed |

| Pore pressure | Fixed | |

| Top boundary | Pore pressure | Fixed |

| Load | Fixed | |

| Bottom boundary | Normal displacement | 0 |

| Pore pressure | Fixed | |

| Side boundary | Normal displacement | 0 |

| Pore pressure | Fixed |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Li, Q.; Wu, J.; He, K.; Xia, Y.; Liu, J.; Wang, F.; Cheng, Y. Wellhead Stability During Development Process of Hydrate Reservoir in the Northern South China Sea: Sensitivity Analysis. Processes 2025, 13, 1630. https://doi.org/10.3390/pr13061630

Li Q, Li Q, Wu J, He K, Xia Y, Liu J, Wang F, Cheng Y. Wellhead Stability During Development Process of Hydrate Reservoir in the Northern South China Sea: Sensitivity Analysis. Processes. 2025; 13(6):1630. https://doi.org/10.3390/pr13061630

Chicago/Turabian StyleLi, Qingchao, Qiang Li, Jingjuan Wu, Kaige He, Yifan Xia, Junyi Liu, Fuling Wang, and Yuanfang Cheng. 2025. "Wellhead Stability During Development Process of Hydrate Reservoir in the Northern South China Sea: Sensitivity Analysis" Processes 13, no. 6: 1630. https://doi.org/10.3390/pr13061630

APA StyleLi, Q., Li, Q., Wu, J., He, K., Xia, Y., Liu, J., Wang, F., & Cheng, Y. (2025). Wellhead Stability During Development Process of Hydrate Reservoir in the Northern South China Sea: Sensitivity Analysis. Processes, 13(6), 1630. https://doi.org/10.3390/pr13061630