Numerical Investigation of Energy Efficiency and Remediation Performance of Steam Injection via Horizontal Wells for Soil Xylene Pollution

Abstract

1. Introduction

1.1. Background

1.2. Research Status

1.3. Research Objectives

2. Horizontal Well Steam Injection–Production Design

2.1. Horizontal Well System

2.2. Injection–Production Method

3. Numerical Model

3.1. Simulation Tool

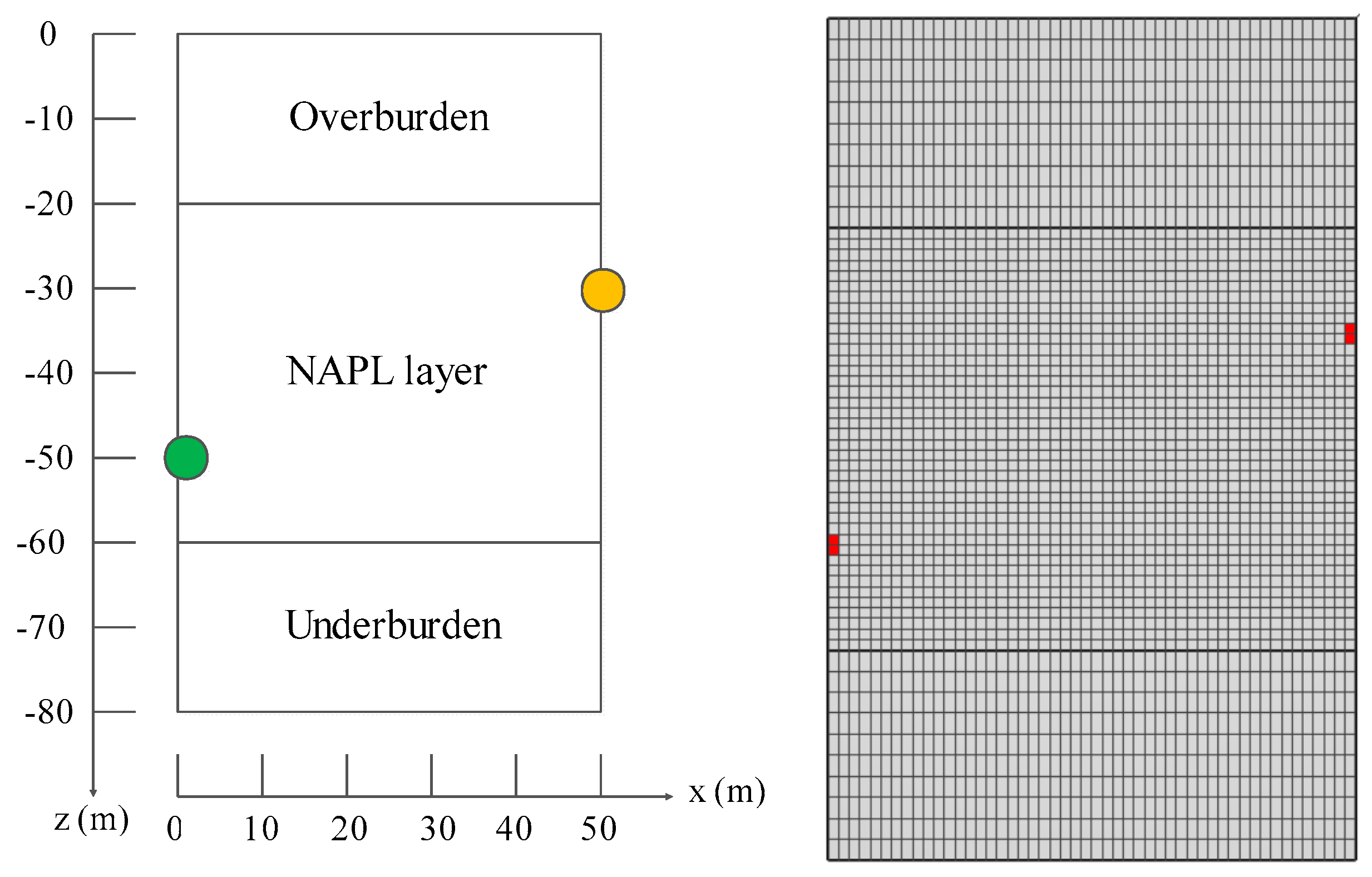

3.2. Conceptual Model

3.3. Initial and Boundary Conditions

4. Simulation Results and Analysis

4.1. The Reference Case

4.2. Production Fluid Saturation

4.3. Production Mass Flow Rate and Production Temperature

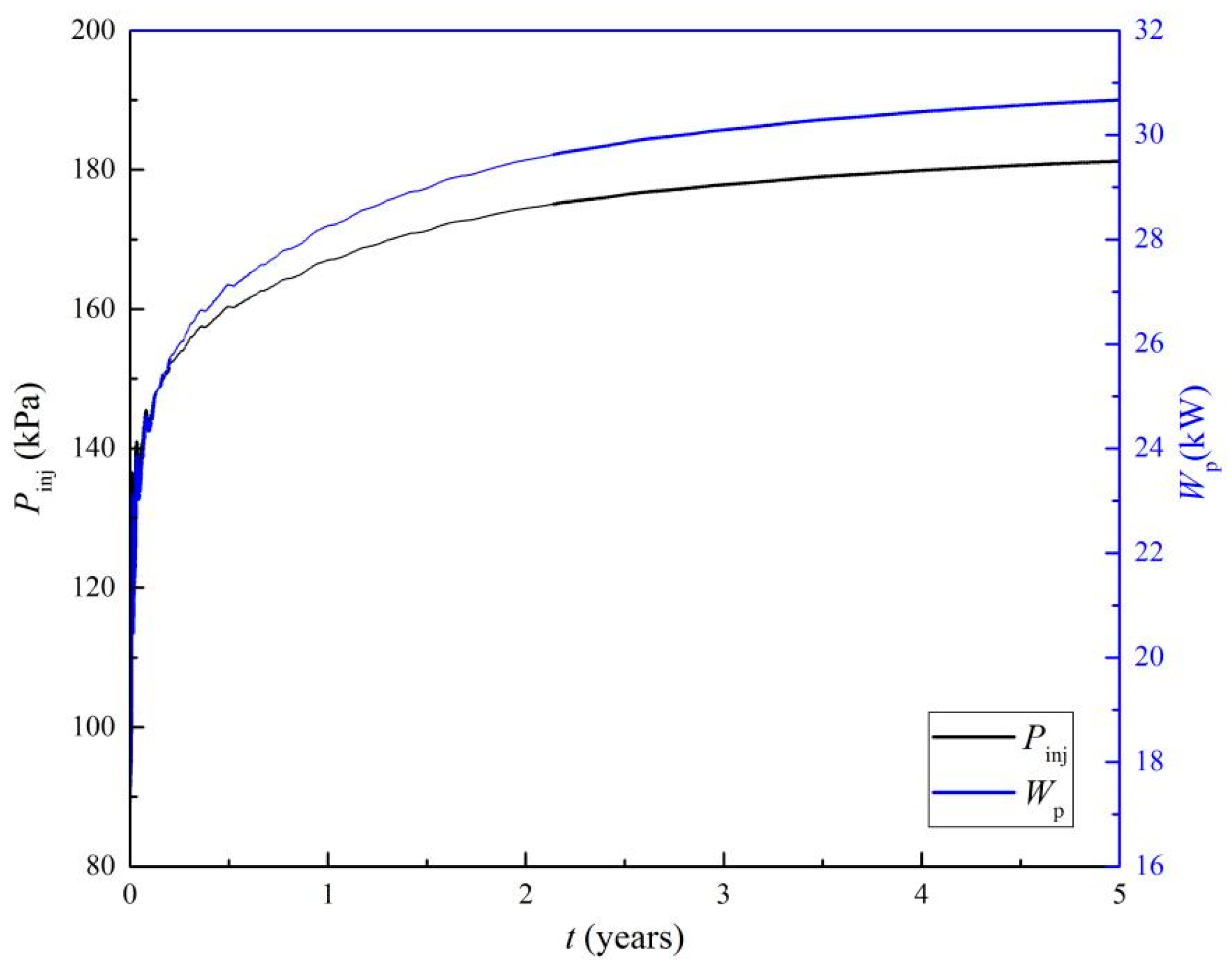

4.4. Injection Pressure and Pump Power Consumption

4.5. Production VOC Mass Flow Rate and Energy Efficiency

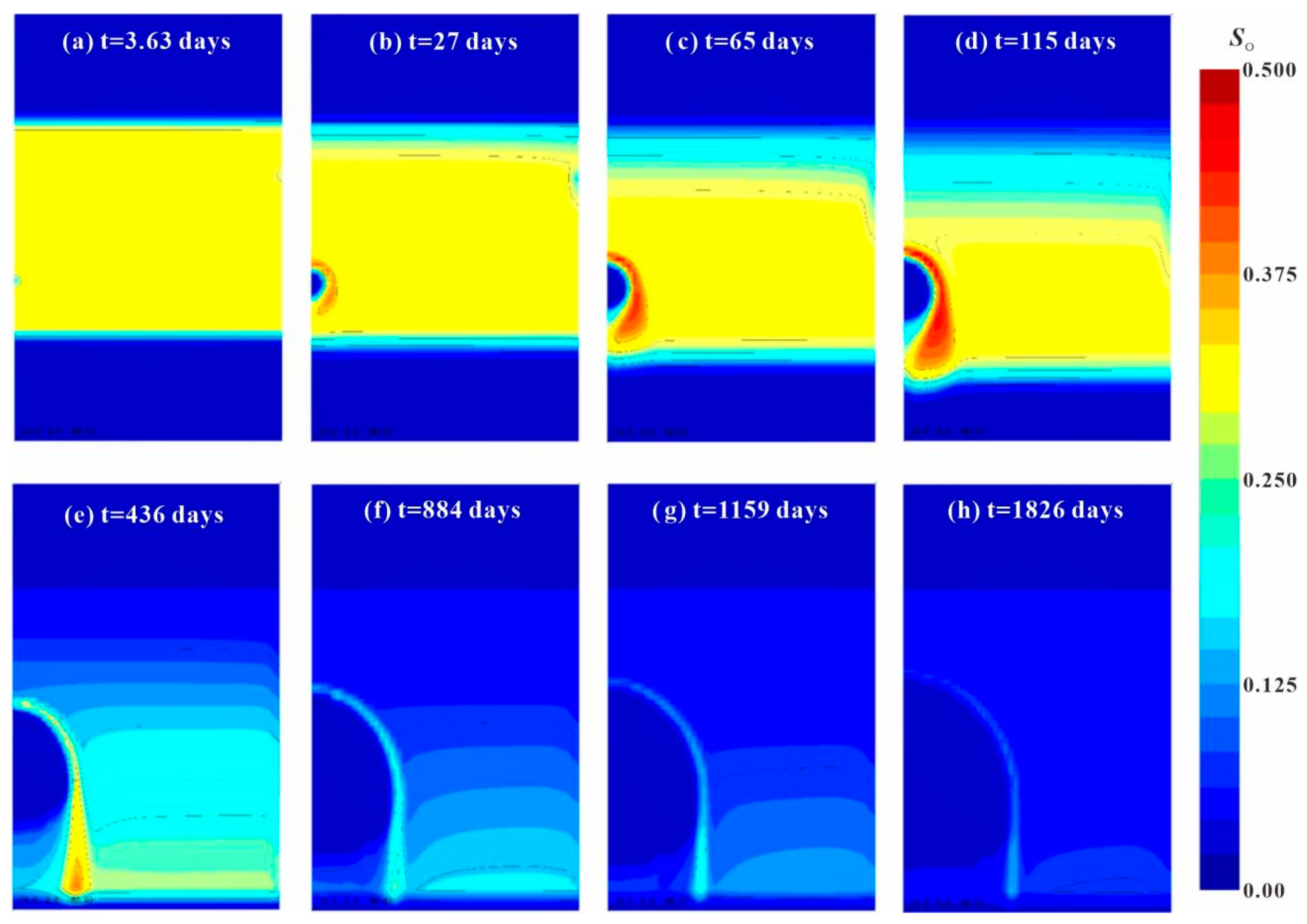

4.6. Spatial Distribution of Xylene Saturation

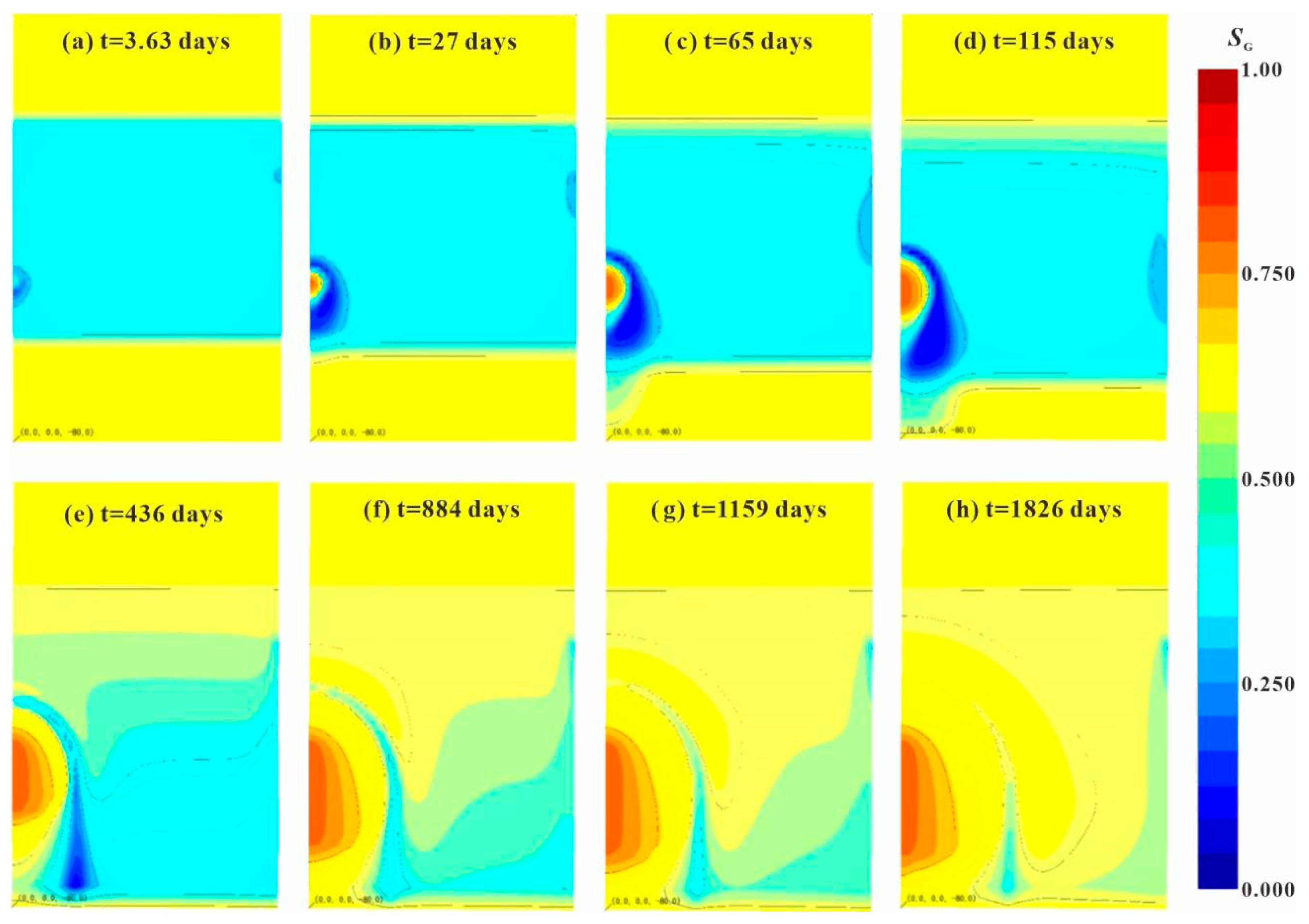

4.7. Spatial Distribution of Gas Saturation

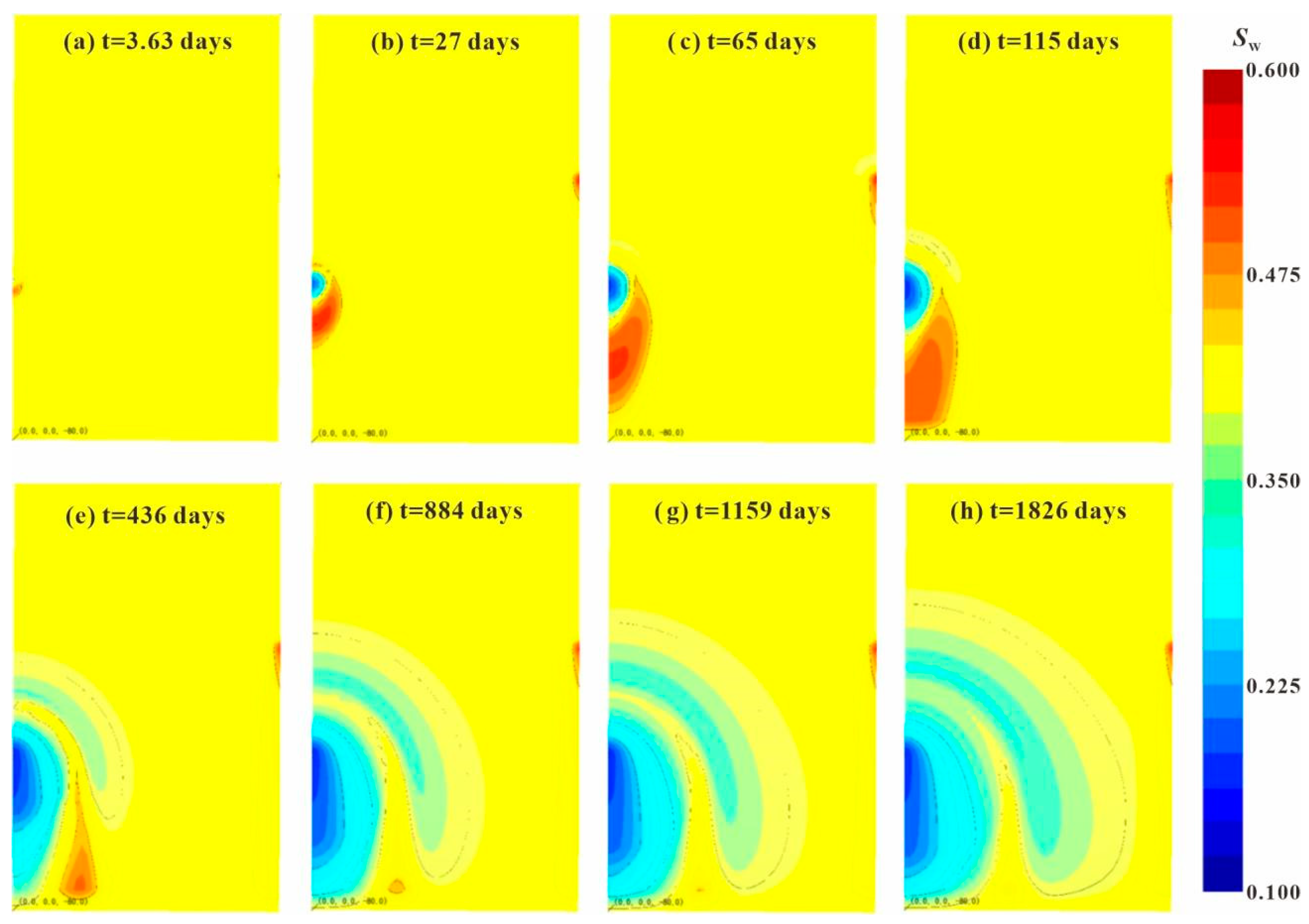

4.8. Spatial Distribution of Water Saturation

4.9. Spatial Distribution of Temperature

4.10. Spatial Distribution of Pressure

5. Discussion

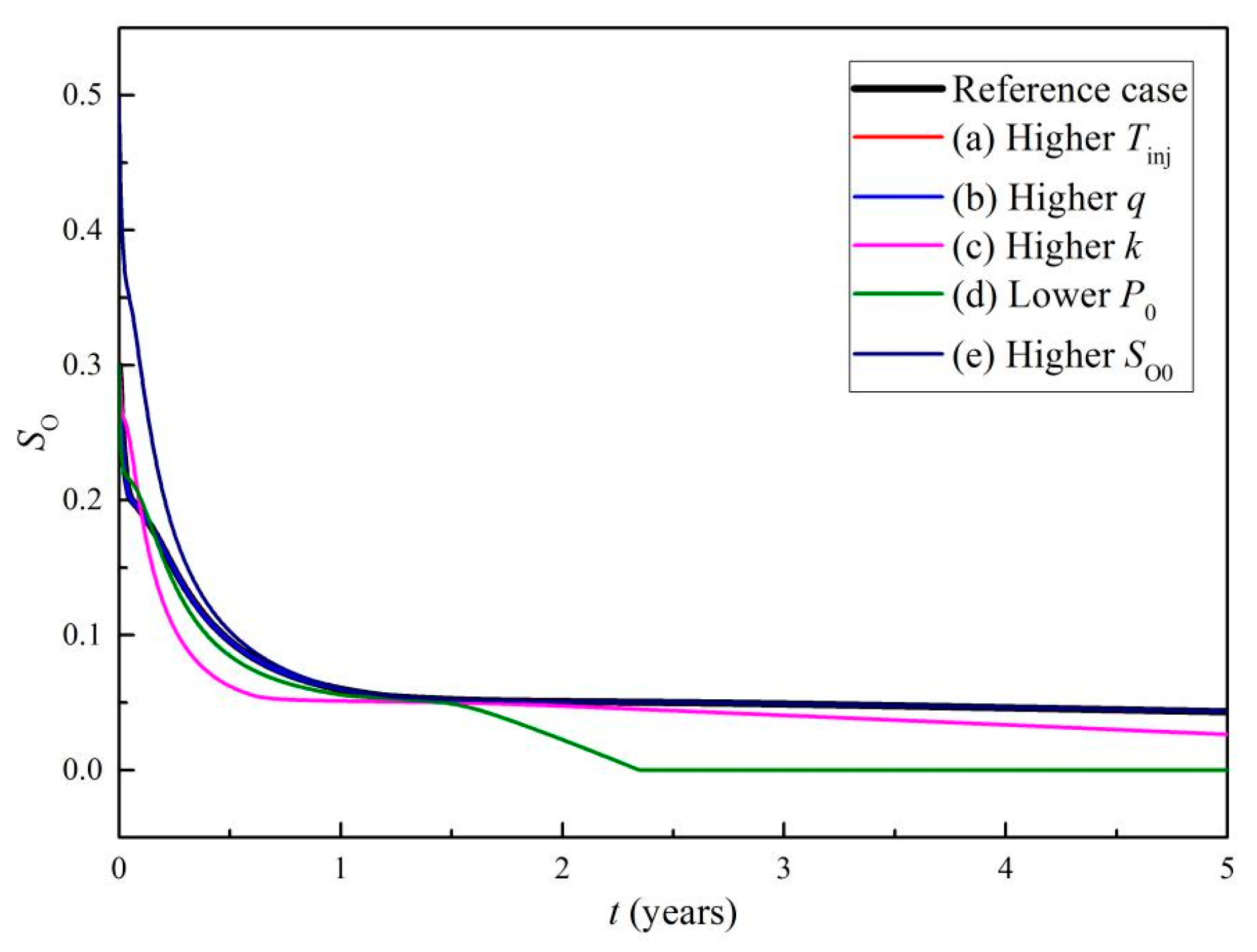

5.1. Sensitivity of Production VOC Saturation to Various Parameters

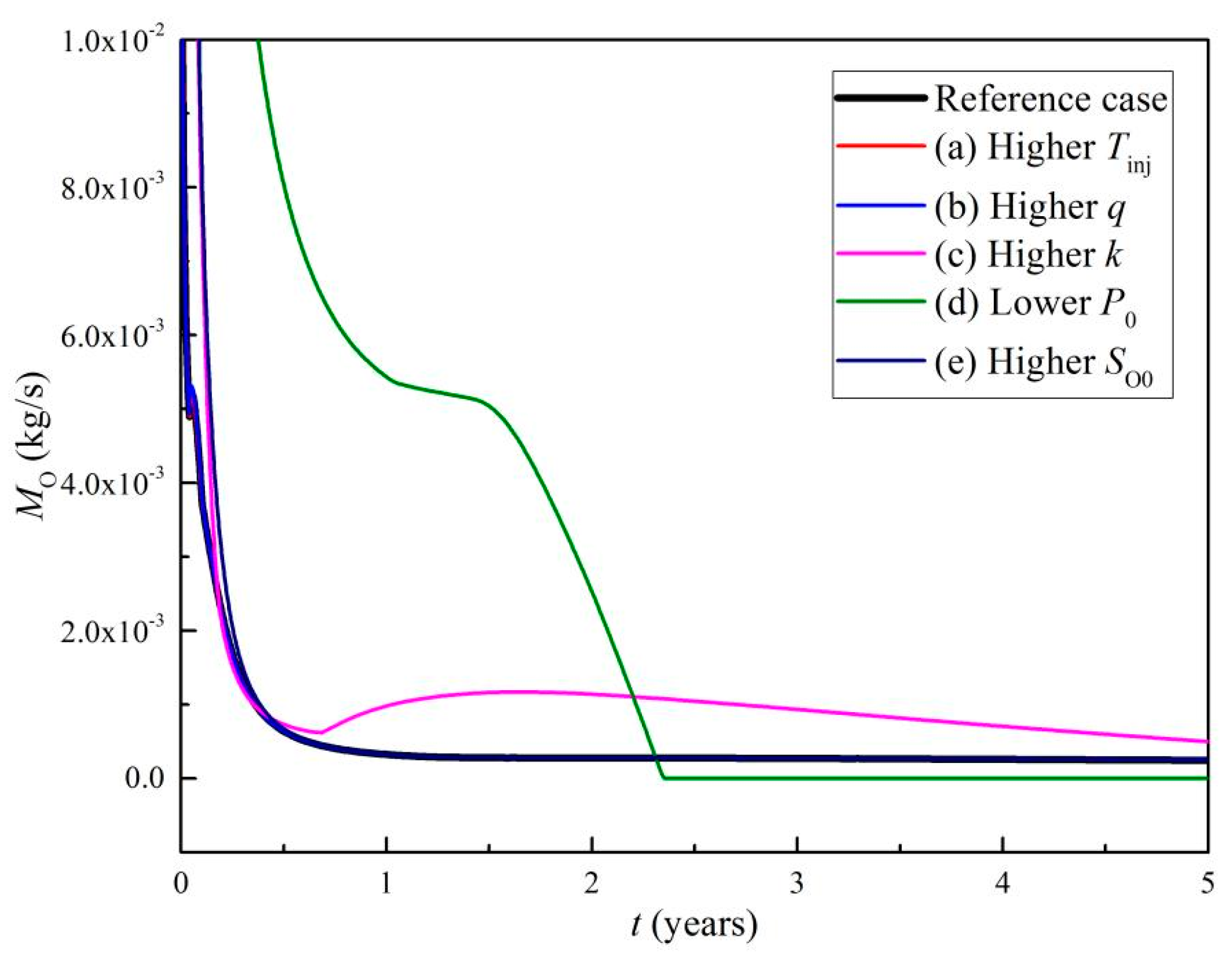

5.2. Sensitivity of Production VOC Mass Flow Rate to Various Parameters

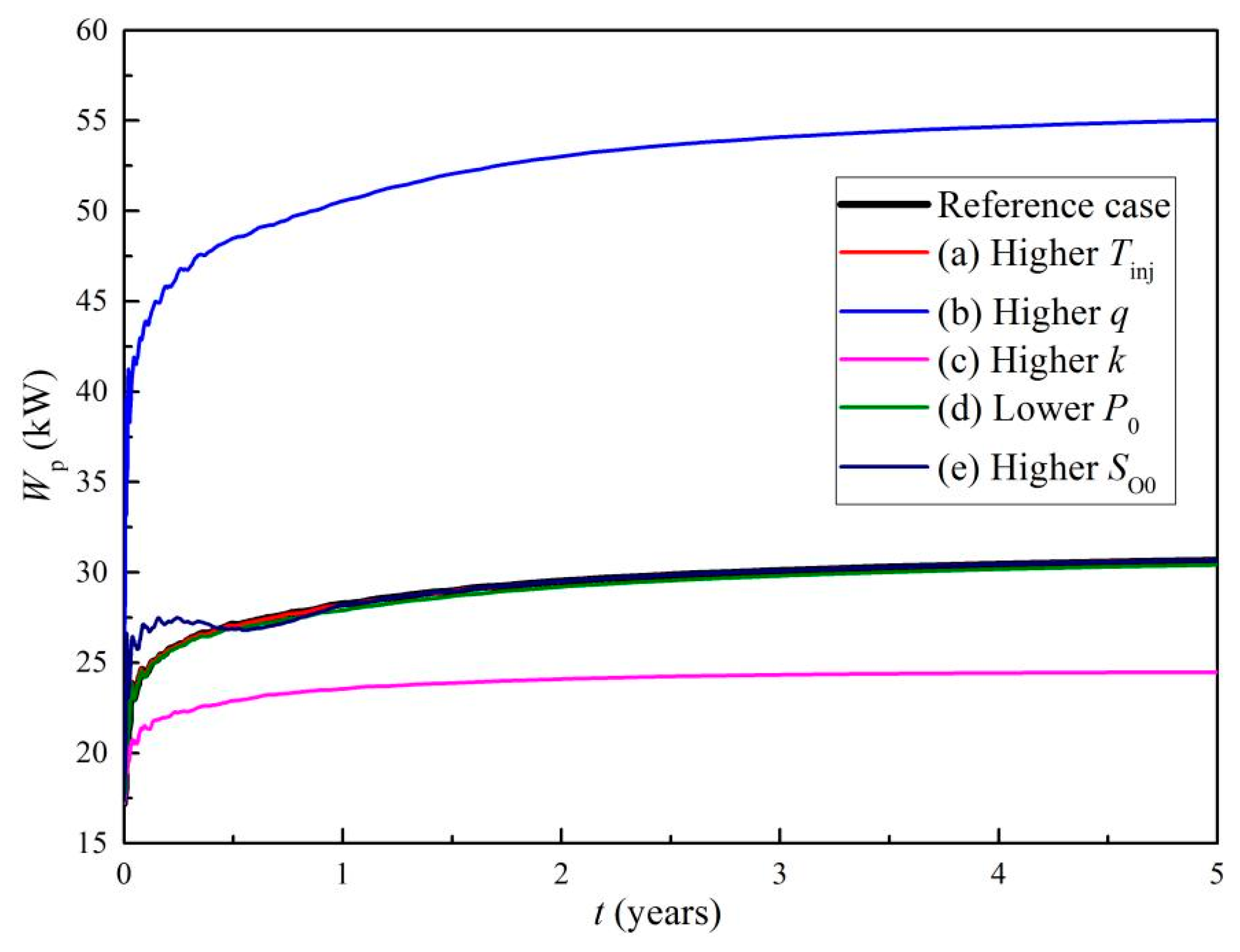

5.3. Sensitivity of Pump Power Consumption to Various Parameters

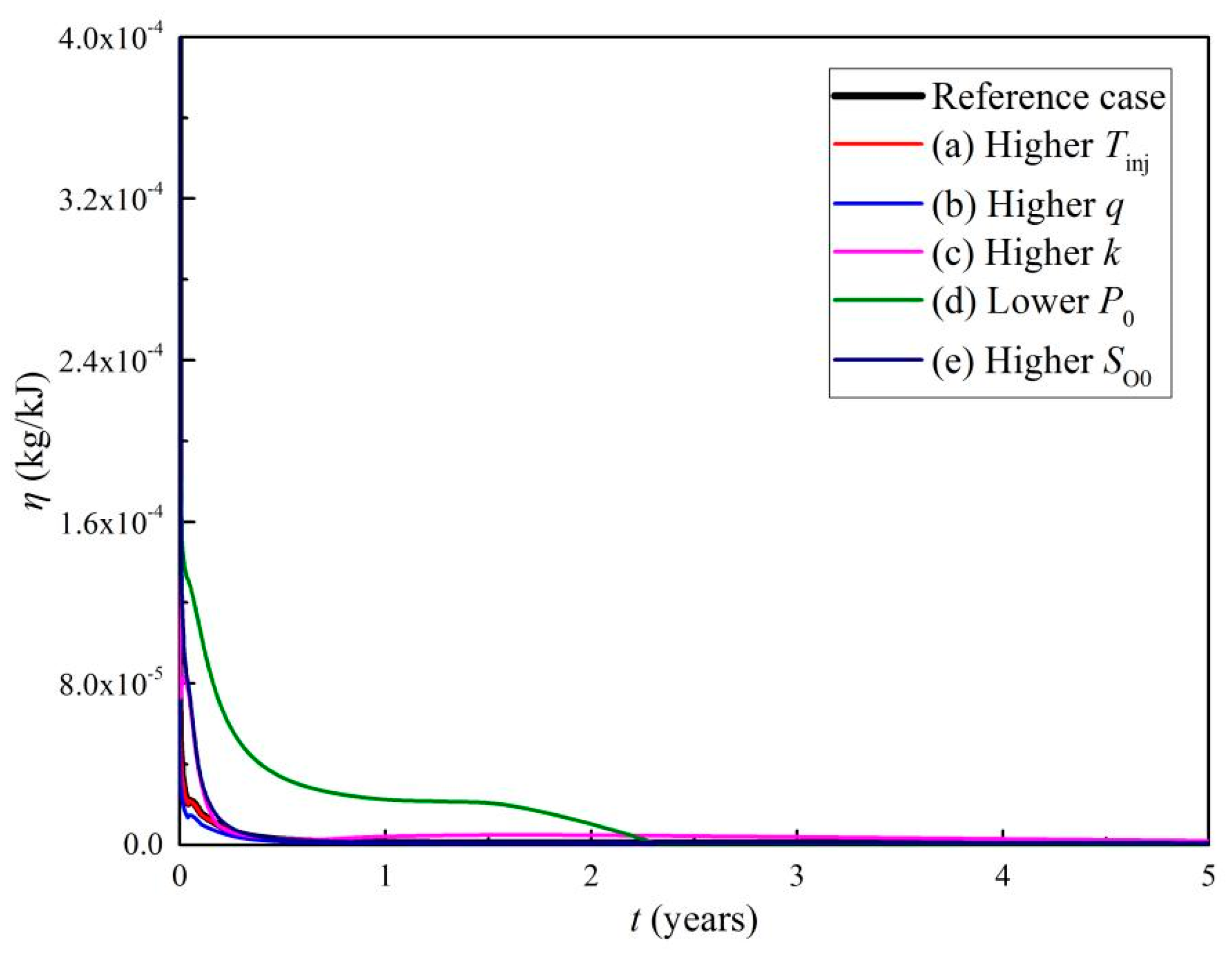

5.4. Sensitivity of Energy Efficiency to Various Parameters

6. Conclusions

- (1)

- In the reference case, the 5-year operation period can be divided into two stages: the remediation stage and maintenance stage. The production VOC saturation decreases gradually during the remediation stage and remains at a low value during the maintenance stage. During the first 1.5 years of remediation, the production mass flow rate gradually decreases from 0.45 kg/s to 3.7 × 10−3 kg/s and then remains unchanged. The production temperature is maintained at the initial soil temperature for 3 years and slightly increases afterwards.

- (2)

- Injection pressure and pump power increase gradually. With the continuous injection of steam into the formation, the formation temperature increases, and the gas content and viscosity increases, which increases the injection pressure and pump power.

- (3)

- The production VOC mass flow rate and energy efficiency decreases gradually. In the initial stage of steam injection, the VOC production rate is at its highest because the initial xylene content is at its highest and can be driven out of the formation quickly. After that, the xylene production rate decreases with steam injection. The total input energy of the system gradually increases, while the VOC mass flow rate decreases, so the energy efficiency of the system decreases.

- (4)

- After steam injection, a zero-xylene saturation zone is formed around the injection well, which expands toward the production well as steam is injected. Between the zero saturation zone and the original saturation zone, a high saturation column is formed with a maximum saturation value of 0.45. With the injection of steam, the zero saturation area expands, and xylene saturation decreases, indicating that xylene is driven out gradually. This shows that steam injection is an effective method to remediate xylene pollution.

- (5)

- The steam injection flow rate, formation permeability, production pressure and initial xylene saturation have significant effects on production VOC saturation. Within certain ranges, increasing the steam injection flow rate and formation permeability increases xylene saturation during the remediation stage, decreasing the production pressure decreases xylene saturation during the maintenance stage, and increasing the initial xylene saturation significantly increases xylene saturation during the remediation stage.

- (6)

- Formation permeability, production pressure and the initial xylene saturation have significant effects on the production VOC mass flow rate. Increasing formation permeability, reducing production pressure and increasing the initial xylene saturation can improve the production VOC mass flow rate.

- (7)

- The pump power of the system is mainly affected by the steam injection flow rate and formation permeability. Increasing the steam injection flow rate significantly increases the pump power, while increasing formation permeability significantly reduces the pump power.

- (8)

- The energy efficiency of the system is significantly affected by the steam injection flow rate, formation permeability, production pressure, and initial xylene saturation. Increasing formation permeability, reducing production pressure, and increasing the initial xylene saturation significantly improves energy efficiency, while increasing the injection flow rate significantly reduces energy efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ramón, F.; Lull, C. Legal measures to prevent and manage soil contamination and to increase food safety for consumer health: The case of Spain. Environ. Pollut. 2019, 250, 883–891. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Yin, Y.; Zhang, Y.; Shi, S. Legal System of Soil Pollution Remediation in China and Its Regulation and Guidance to Soil Pollution Remediation. Sustainability 2023, 15, 11504. [Google Scholar] [CrossRef]

- Soga, K.; Page, J.W.E.; Illangasekare, T.H. A review of NAPL source zone remediation efficiency and the mass flux approach. J. Hazard. Mater. 2004, 110, 13–27. [Google Scholar] [CrossRef]

- Li, P.; Liu, W.; Sun, T.; Gong, Z.; Fu, S. Remediation of contaminated soil: Its present research situation and prospect. Chin. J. Ecol. 2006, 25, 1544–1548. (In Chinese) [Google Scholar]

- Wu, Y. Soil and Groundwater Pollution and Its Remediation; Science Press: Beijing, China, 2018. [Google Scholar]

- He, R.; Yang, Y.; Liang, W.; Zhang, L.; Wu, Q. Study on thermal intensified vapor extraction technology of soil contaminated by benzene series. Environ. Prot. Sci. 2021, 47, 167–171. [Google Scholar]

- Zhang, Q.; Wang, C. Natural and human factors affect the distribution of soil heavy metal pollution: A review. Water Air Soil Pollut. 2020, 231, 350. [Google Scholar] [CrossRef]

- Wiles, C.C. A view of solidification/stabilization technology. J. Hazard. Mater. 1987, 14, 5–21. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, X.; Zhao, W.; Wang, X.; Yang, Z.; Li, L. Roles of n-hexadecane in the degradation of dibenzofuran by a biosurfactant-producing bacterium Rhodococcus sp. J. Clean. Prod. 2024, 434, 140500. [Google Scholar] [CrossRef]

- Wang, Y. Study on Simulation and Prediction of BTEX Contaminated Site Remediation Effect by Soil Vapor Extraction. Master’s Thesis, Hebei Agricultural University, Baoding, China, 2020. [Google Scholar]

- Vinegar, H.J.; Coles, J.M.; Menotti, J.I. In situ thermal desorption of coal tar. In Proceedings of the IGT/GRT International Symposium on Environmental Biotechnologies and Site Remediation Technologies, Orlando, FL, USA, 7–9 December 1998. [Google Scholar]

- Heron, G.; Parker, K.; Galligan, J.; Holmes, T.C. Therma treatment of eight CVOC source zones to near nondetect concentration. Ground Water Monit. Remediat. 2009, 29, 56–65. [Google Scholar] [CrossRef]

- Izgiris, E.E.; Edelsterin, W.A.; Philipp, H.R.; Iben, I.T. Complex thermal desorption of PCBs from soil. Chemosphere 1995, 30, 377–387. [Google Scholar] [CrossRef]

- Iben, E.T.; Edelstein, W.A.; Sheldon, R.B.; Shapiro, A.P.; Uzgiris, E.E.; Scatena, C.R.; Blaha, S.R.; Silverstein, W.B.; Brown, G.R.; Stegemeier, G.L.; et al. Thermal blanket for in-situ remediation of surficial contamination: A pilot test. Environ. Sci. Technol. 1996, 30, 3144–3154. [Google Scholar] [CrossRef]

- Zhu, J.; Luo, Q.; Li, X.Q. Thermodesorption of BTEX-contaminated soil using heat conduction. Environ. Chem. 2013, 32, 1546–1553. [Google Scholar]

- Li, B.Z.; Zhu, J.; Ji, M.; Tu, B.; Lin, X. Research upon steam enhanced vapor extraction for the remediation of benzene homologues contaminated clayed soil. J. Shanghai Jiaotong Univ. (Agric. Sci.) 2016, 34, 58–75. [Google Scholar]

- Huang, W.; Wang, J.; Deng, C.; Cheng, D.; Wang, Q. Research Progress of In-situ Remediation of Non-aqueous Liquid Contaminated Soil by Steam Injection Technology. Environ. Sci. Manag. 2022, 47, 92–97. (In Chinese) [Google Scholar]

- Azizan, N.A.; Kamaruddin, S.A.; Chelliapan, S. Steam-enhanced extraction experiments, simulations and field studies for dense non-aqueous phase liquid removal: A review. MATEC Web Conf. 2016, 47, 05012. [Google Scholar] [CrossRef]

- Engineering Forum Issue Paper. In In Situ Treatment Technologies for Contaminated Soil; Environmental Protection Agency: Washington, DC, USA, 2006.

- Li, X.S.; Li, B.; Li, G.; Yang, B. Numerical simulation of gas production potential from permafrost hydrate deposits by huff and puff method in a single horizontal well in Qilian Mountain, Qinghai province. Energy 2012, 40, 59–75. [Google Scholar] [CrossRef]

- Li, G.; Moridis, G.J.; Zhang, K.; Li, X.S. The use of huff and puff method in a single horizontal well in gas production from marine gas hydrate deposits in the Shenhu Area of South China Sea. J. Pet. Sci. Eng. 2011, 77, 49–68. [Google Scholar] [CrossRef]

- Zeng, Y.C.; Su, Z.; Wu, N.Y. Numerical simulation of heat production potential from hot dry rock by water circulating through two horizontal wells at Desert Peak geothermal field. Energy 2013, 56, 92–107. [Google Scholar] [CrossRef]

- Zeng, Y.C.; Wu, N.Y.; Su, Z.; Hu, J. Numerical simulation of electricity generation potential from fractured granite reservoir through a single horizontal well at Yangbajing geothermal field. Energy 2014, 65, 472–487. [Google Scholar] [CrossRef]

- Zeng, Y.C.; Zhan, J.M.; Wu, N.Y.; Luo, Y.; Cai, W. Numerical investigation of electricity generation potential from fractured granite reservoir by water circulating through three horizontal wells at Yangbajing geothermal field. Appl. Therm. Eng. 2016, 104, 1–15. [Google Scholar] [CrossRef]

- Song, X.; Shi, Y.; Li, G.; Yang, R.; Wang, G.; Zheng, R.; Li, J.; Lyu, Z. Numerical simulation of heat extraction performance in enhanced geothermal system with multilateral wells. Appl. Energy 2018, 218, 325–337. [Google Scholar] [CrossRef]

- Mao, P.; Wan, Y.; Sun, J.; Li, Y.; Hu, G.; Ning, F.; Wu, N. Numerical study of gas production from ffne-grained hydrate reservoirs using a multilateral horizontal well system. Appl. Energy 2021, 301, 117450. [Google Scholar] [CrossRef]

- Zhai, H.; Jin, G.; Liu, L.; Su, Z.; Zeng, Y.; Liu, J.; Li, G.; Feng, C.; Wu, N. Parametric study of the geothermal exploitation performance from a HDR reservoir through multilateral horizontal wells: The Qiabuqia geothermal area, Gonghe Basin. Energy 2023, 275, 127370. [Google Scholar] [CrossRef]

- Pruess, K.; Oldenburg, C.; Moridis, G. TOUGH2 User’s Guide, Version 2.0; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 1999. [Google Scholar]

- Falta, R.W.; Pruess, K.; Finsterle, S.; Battistelli, A. T2VOC User’s Guide; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 1995. [Google Scholar]

- Sima, J. Experimental Study on the Influencing Factors of Steam Migration in Steam Injection and Its Remediation of Phenanthrene Contaminated Soil. Guangdong Chem. Ind. 2022, 49, 94–97. (In Chinese) [Google Scholar]

| Parameters | Values |

|---|---|

| Thickness of overburden layer | 20 m |

| Thickness of NAPL layer | 40 m |

| Thickness of underburden layer | 20 m |

| Soil density | 2650 kg/m3 |

| Soil porosity | 40% |

| Soil permeability | 2.5 × 10−13 m2 |

| Soil thermal conductivity | 3.1 W/(m·K) |

| Soil heat capacity | 1000 J/(kg·K) |

| Swr in Stone model | 0.1 |

| Snr in Stone model | 0.05 |

| Sgr in Stone model | 0.01 |

| n in Stone model | 3 |

| Sm in Parker model | 0 |

| n in Parker model | 1.84 |

| αgn in Parker model | 5.0 × 104 |

| αnw in Parker model | 5.24 |

| Injection steam mass flow rate, qinj | 8.0 × 10−4 kg/s |

| Injection steam enthalpy, hinj | 2.676 × 106 J/kg |

| Injection temperature, Tinj | 100 °C |

| Production pressure, P0 | 8.0 × 104 Pa |

| Production index, PI | 2.0 × 10−12 m3 |

| Initial pressure | 101,325 Pa |

| Initial temperature | 22 °C |

| Initial xylene saturation of NAPL layer | 0.3 |

| Initial water saturation of NAPL layer | 0.4 |

| Initial air saturation of NAPL layer | 0.3 |

| Initial water saturation of overburden and underburden layer | 0.4 |

| Initial air saturation of overburden and underburden layer | 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Y.; Ding, L.; Zhai, H.; He, B. Numerical Investigation of Energy Efficiency and Remediation Performance of Steam Injection via Horizontal Wells for Soil Xylene Pollution. Processes 2025, 13, 1491. https://doi.org/10.3390/pr13051491

Zeng Y, Ding L, Zhai H, He B. Numerical Investigation of Energy Efficiency and Remediation Performance of Steam Injection via Horizontal Wells for Soil Xylene Pollution. Processes. 2025; 13(5):1491. https://doi.org/10.3390/pr13051491

Chicago/Turabian StyleZeng, Yuchao, Lixing Ding, Haizhen Zhai, and Bin He. 2025. "Numerical Investigation of Energy Efficiency and Remediation Performance of Steam Injection via Horizontal Wells for Soil Xylene Pollution" Processes 13, no. 5: 1491. https://doi.org/10.3390/pr13051491

APA StyleZeng, Y., Ding, L., Zhai, H., & He, B. (2025). Numerical Investigation of Energy Efficiency and Remediation Performance of Steam Injection via Horizontal Wells for Soil Xylene Pollution. Processes, 13(5), 1491. https://doi.org/10.3390/pr13051491