Optimal Scheduling of Active Distribution Networks with Hybrid Energy Storage Systems Under Real Road Network Topology

Abstract

1. Introduction

- A hybrid ESS optimization scheduling method containing MESS and SESS is proposed, which fully considers the complementary characteristics of MESS and SESS and achieves optimized allocation of MESS and SESS resources. This method not only reduces the operating costs of ESS and ensures system voltage stability but also improves the utilization efficiency of power resources;

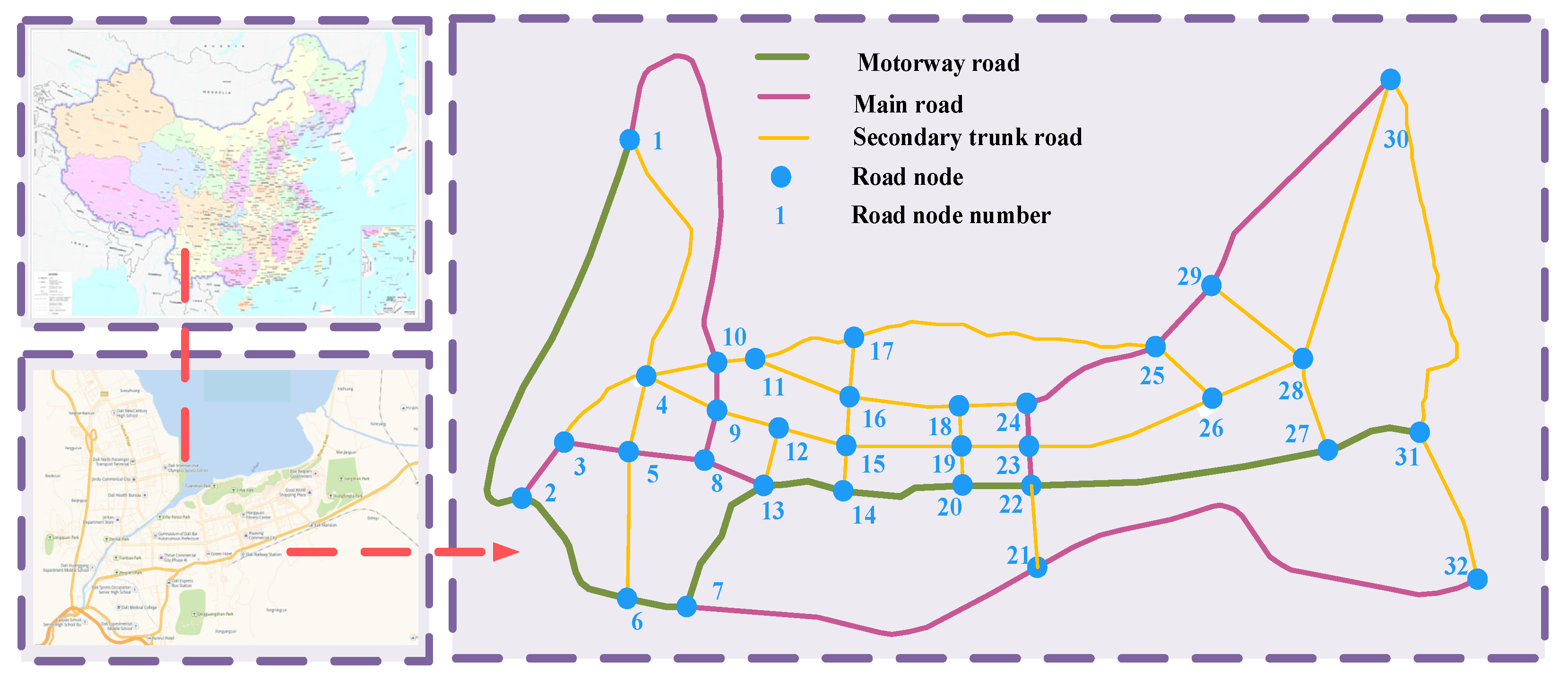

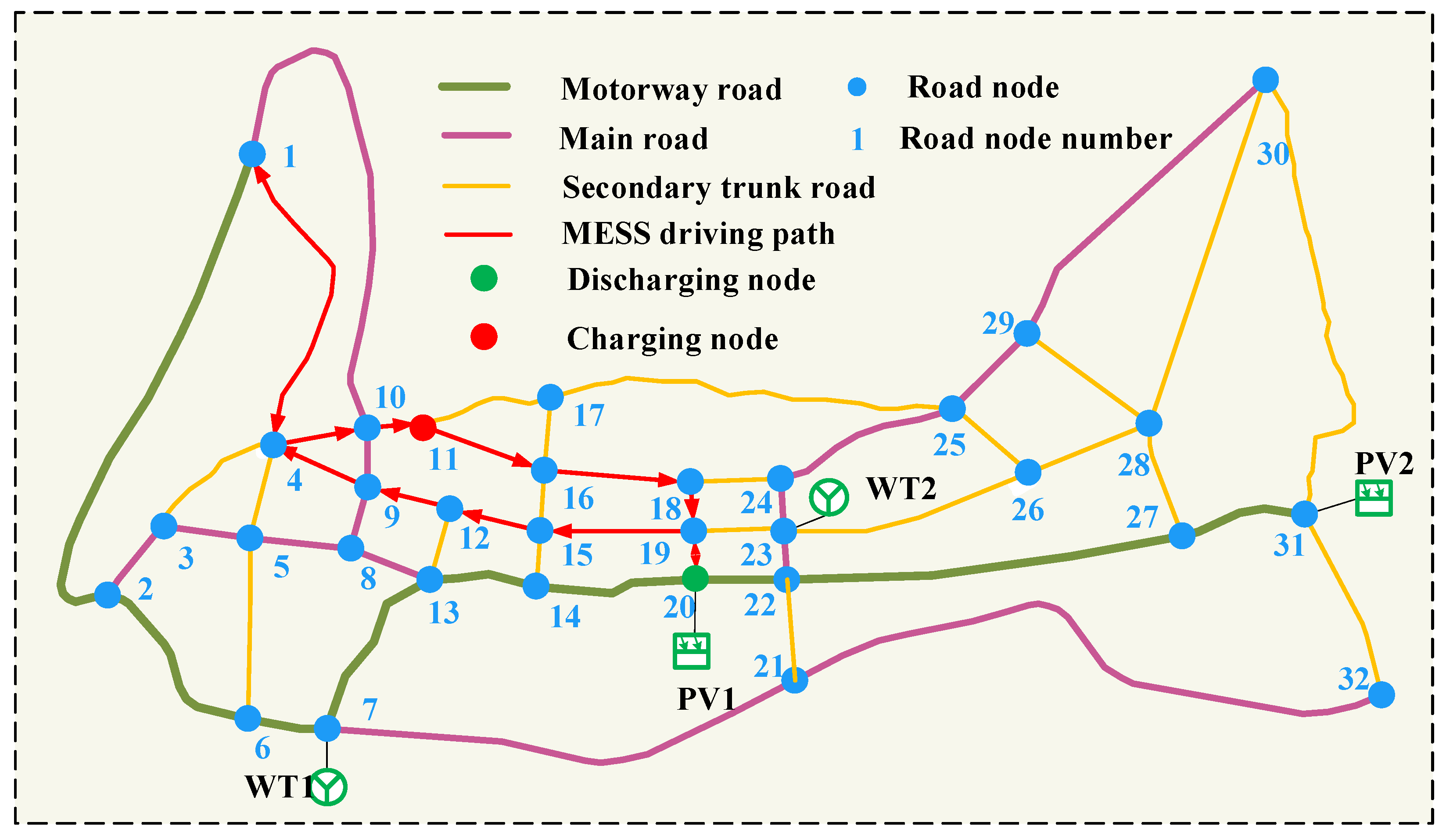

- The actual transportation network of Dali city is quantified based on the time-flow theory to obtain a dynamic road network model. Moreover, the path with the minimum weight in the dynamic road network model is obtained according to the Dijkstra algorithm, which is the optimal path for MESS scheduling.

2. Road Topology Modeling

2.1. Mathematical Model of Road Topology

2.2. Dynamic Mathematical Model of Road Topology

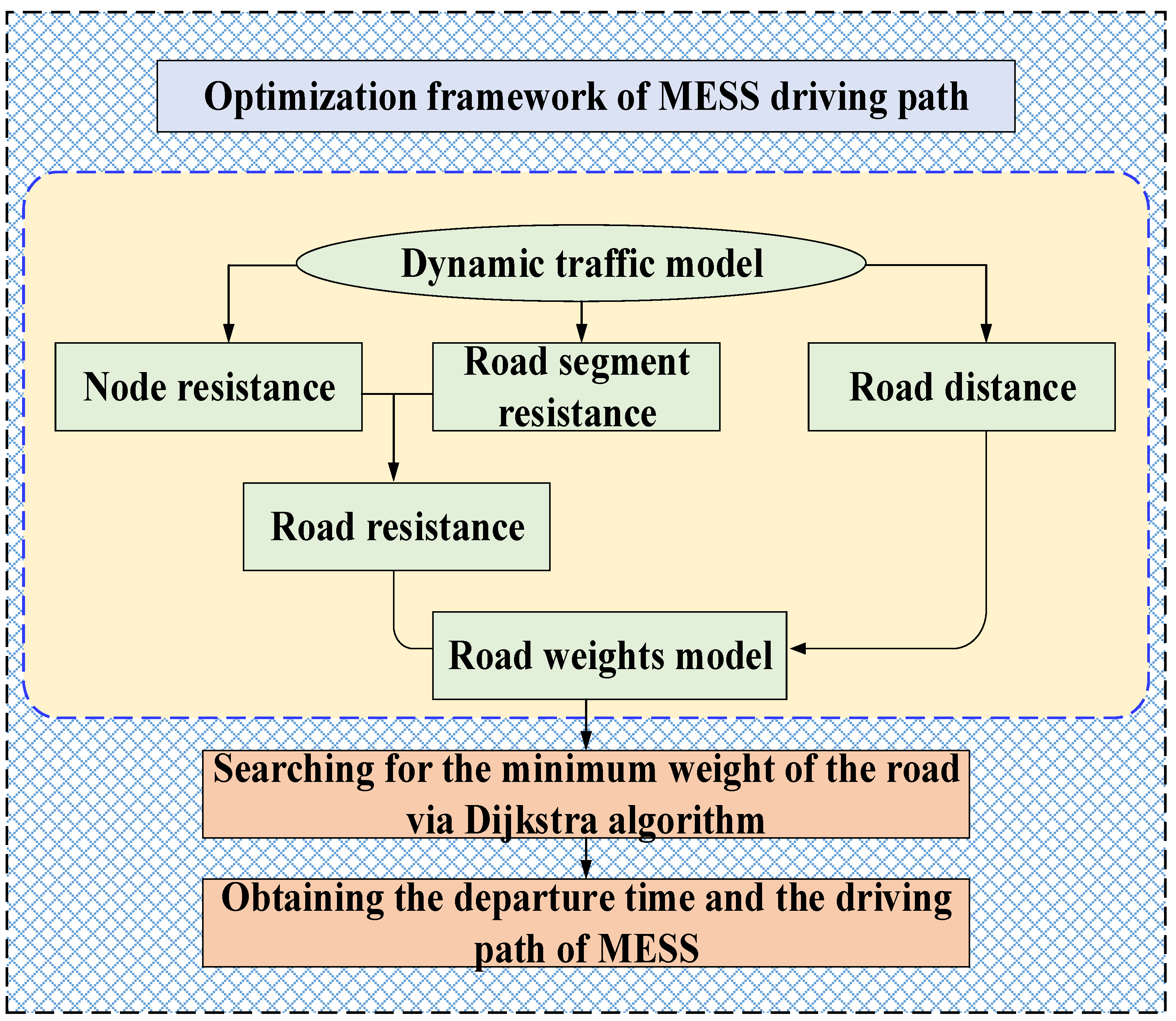

2.3. Optimization Framework of MESS Driving Path

2.4. Energy Storage System Operating Constraints

2.5. Temporal Constraints

2.6. Power Balcance Constraint

2.7. Node Voltage Constraints

3. Optimal Scheduling Framework for Hybrid ESS

3.1. Net Benefit of Scheduling

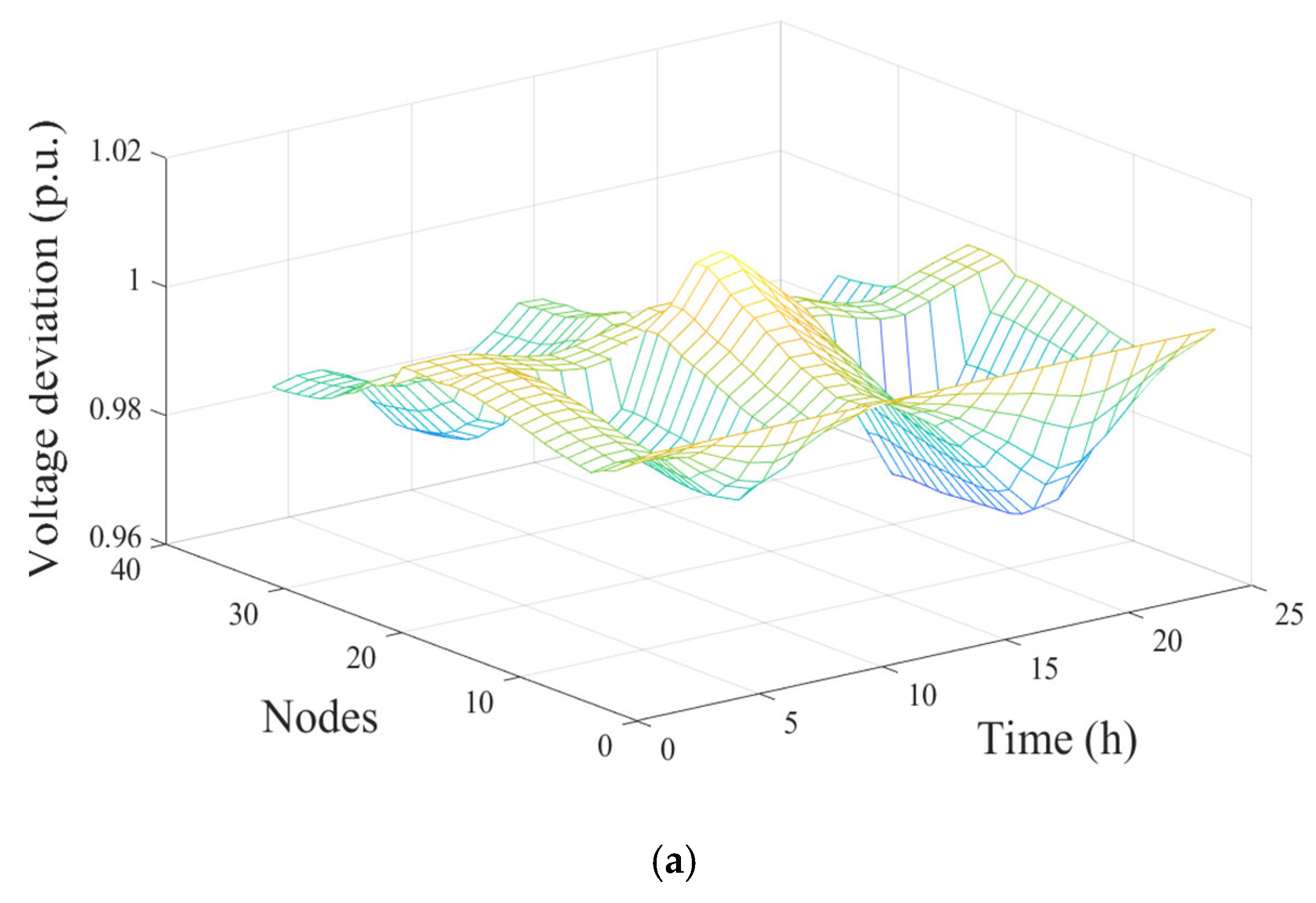

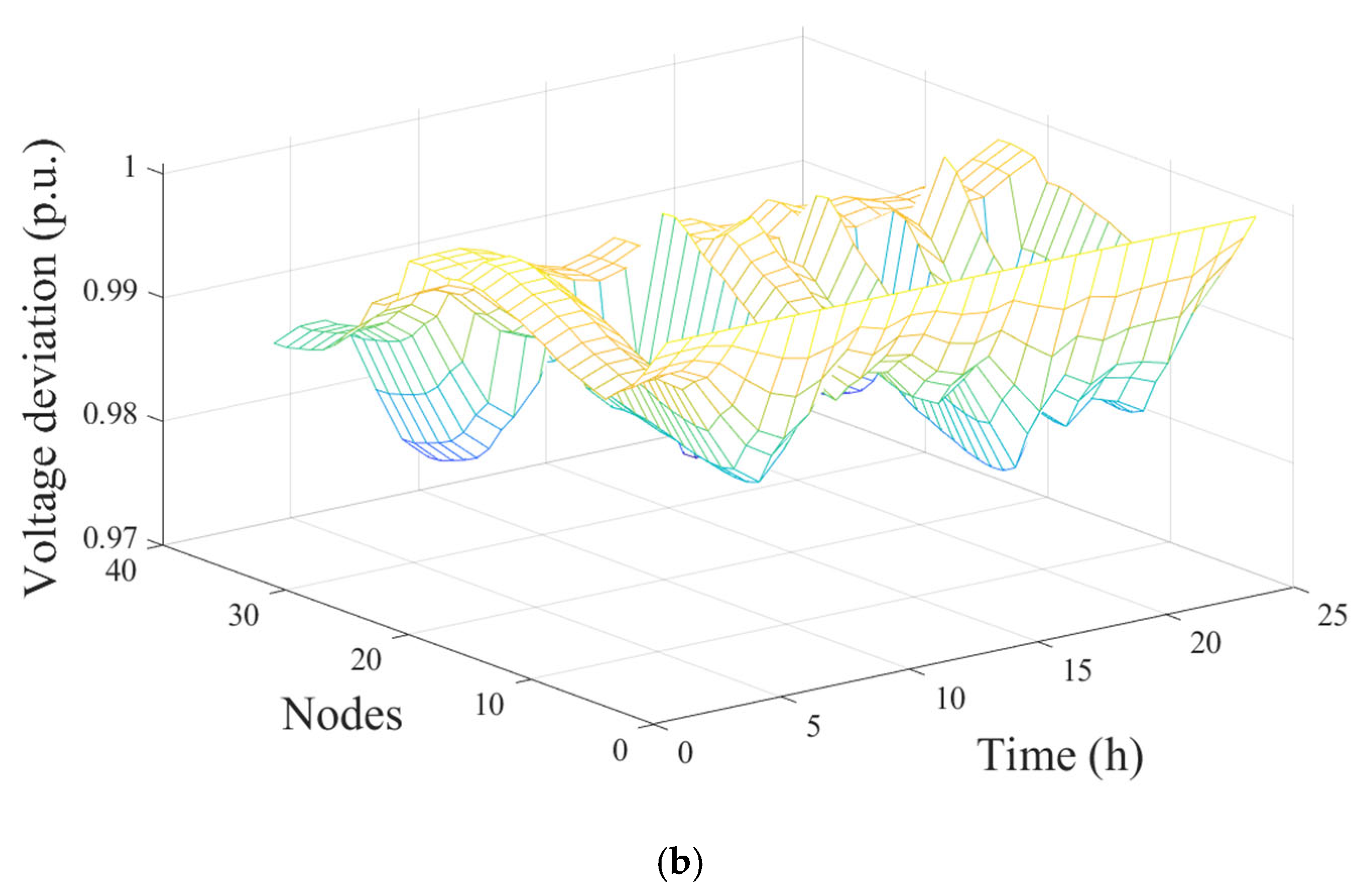

3.2. Total Voltage Deviation

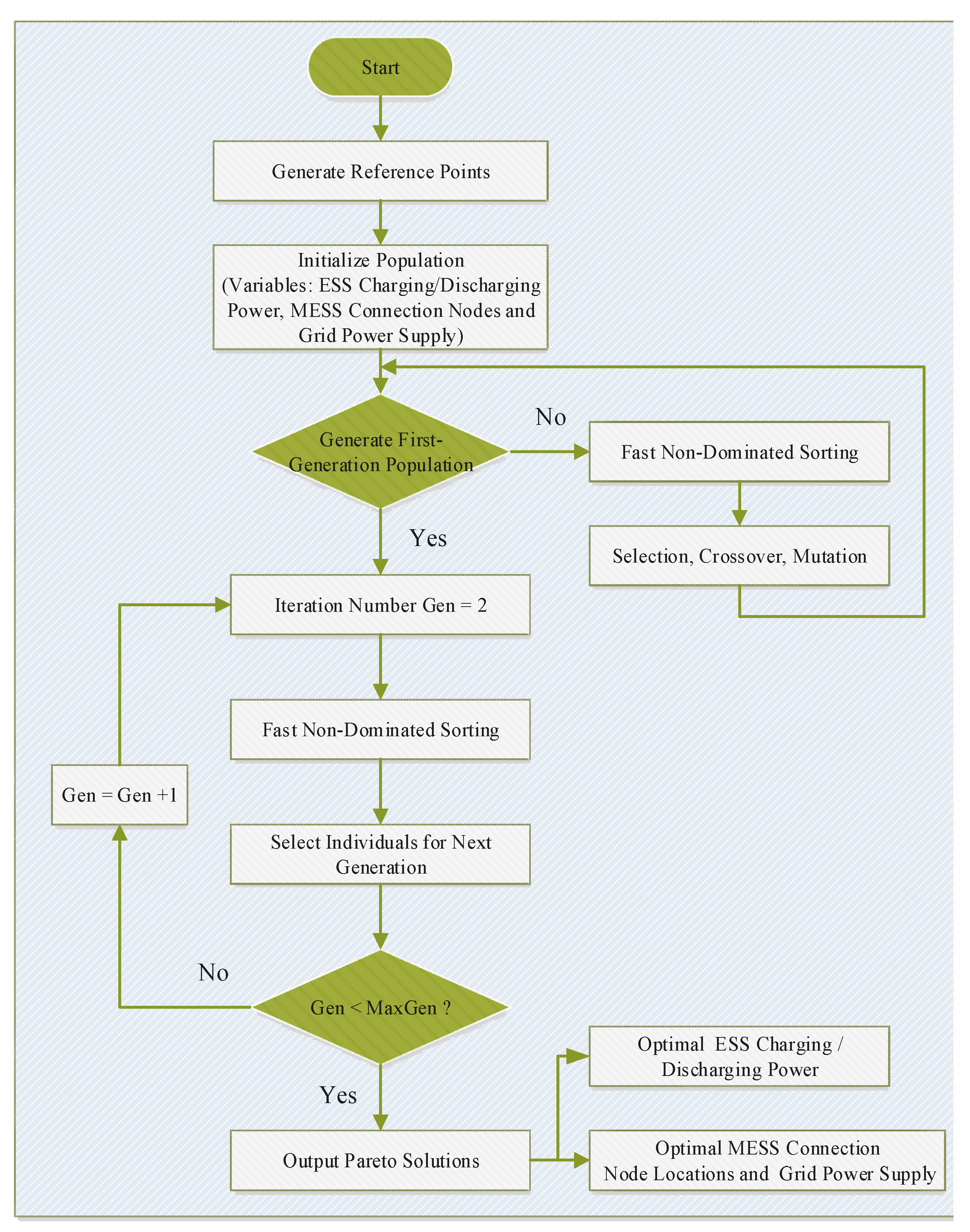

4. Solution Method

- (1)

- Multi-level hierarchical sorting: The population is divided into multiple hierarchical levels, each containing solutions of different densities. This hierarchical sorting enables NSGA-III to better maintain uniformly distributed solutions on the Pareto front;

- (2)

- Adaptive normalization of population individuals: NSGA-III algorithm normalizes the objective function values of each individual through adaptive normalization in order to compare the values between different objectives and determine the relative superiority of individuals in multi-objective optimization;

- (3)

- Association operation: The association operation can be regarded as a process similar to clustering, which divides the individuals in the population into multiple categories, each of which is defined by the closest reference point. Through this correlation operation, NSGA-III can determine the relative position of each individual in the multi-objective space, which will be used in the subsequent selection process to select the solution to construct the next generation of population. This process helps maintain diversity and better approximate the Pareto front.

- (4)

- Small habitat preservation operation: Small habitat preservation operation is one of the key mechanisms for maintaining diversity in NSGA-III. The association operation associates each individual with the nearest reference point. Each reference point and its associated individuals form a cluster category, which can be considered as a niche. In selection operations, individuals are usually selected from different small habitats to ensure that the selected solutions have a wide diversity and better approach the Pareto frontier.

5. Case Studies

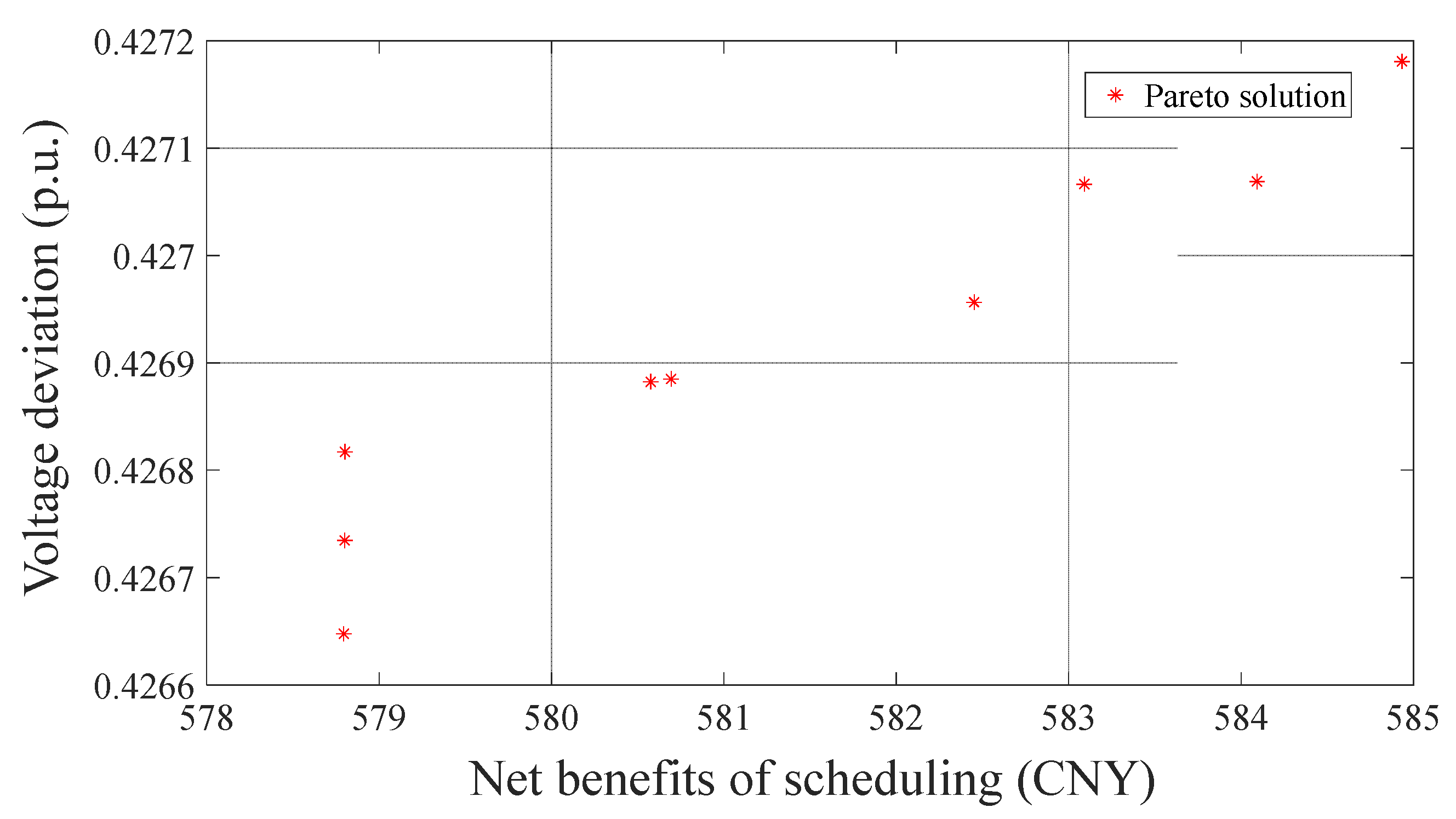

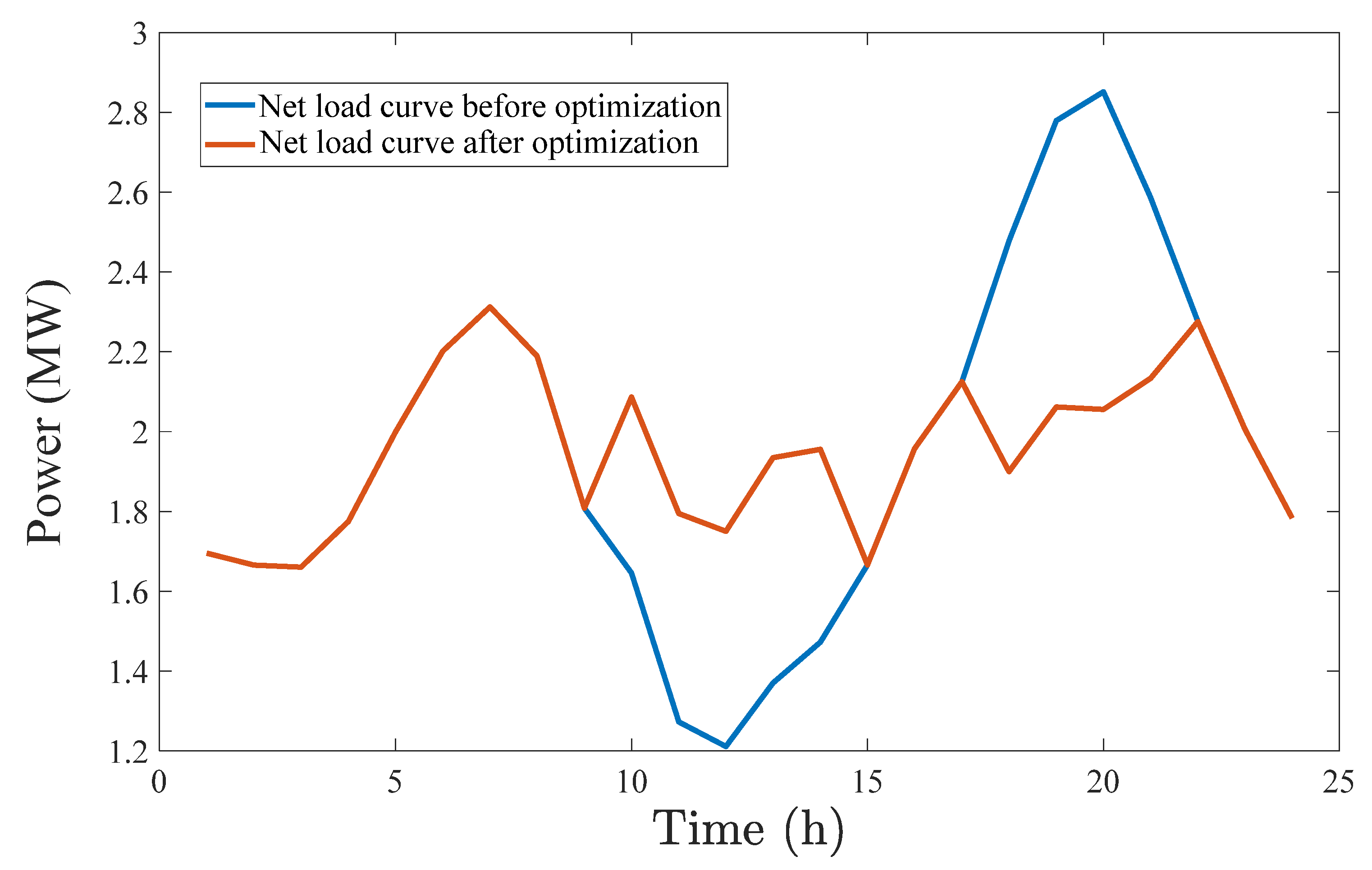

5.1. Economic Analysis of Optimizing Scheduling Results

5.2. Reliability Analysis of Optimizing Scheduling Results

6. Conclusions

- (1)

- Through coordinated scheduling of MESS and SESS, the net load curve of the DN can be effectively smoothed, the voltage distribution of the system can be improved, and the reliability of the DN is enhanced;

- (2)

- The profitability of MESS depends on the advantages of the scheduling strategy in spatial scale and time scale. Therefore, efficient ESS charging and discharging optimization strategy and MESS path optimization strategy are the key to improving the income of the hybrid ESS.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Variables | The number of road node | ||

| Road resistance at time t | Resistance influence factor | ||

| Road resistance of node at time | The ratio of green light | ||

| The road weights of road at time | Road weight | ||

| The th BESS SOC at time | The efficiency of charge and discharge | ||

| Start time of charge and discharge of MESS | Rated SOC | ||

| End time of charge and discharge of MESS | Active power | ||

| Travel time of MESS | Reactive power | ||

| Charge and discharge preparation time of MESS | Conductance and susceptance | ||

| Charge power of the ath BESS at time | Number of grid nodes | ||

| Discharge power of the th BESS at time | Phase angle difference | ||

| The supply power of the grid | The lower and upper limits of nodes voltage | ||

| TOU electricity price | The set of distances | ||

| Power loss after and before optimization | The cost coefficient of MESS per unit distance | ||

| Symbols | The arbitrage revenue | ||

| Road segments set | The benefits of reducing network losses | ||

| Road distan | The battery recession cost | ||

| Node voltage set | MESS driving cost | ||

| Traffic flows set | Number of MESS | ||

| Time periods set | linearity battery degradation cost factor | ||

| Driving speed set | The battery cell price | ||

| Road congestion set | The reference voltage value | ||

| The dynamic traffic set | The number of grid node | ||

| Road node | Upper and lower limits of SOC | ||

| The maximum number of cycles | |||

Abbreviations

| BESS | Battery energy storage system |

| DN | Distribution network |

| ESS | Energy storage system |

| EV | Electric vehicle |

| MESS | Mobile energy storage system |

| NSGA-III | Non-dominated sorting genetic algorithm III |

| NSGA-II | Non-dominated sorting genetic algorithm II |

| PV | Photovoltaic |

| SESS | Stationary energy storage system |

| SOC | State of charge |

| TOU | Time of use |

| WT | Wind turbine |

References

- Yang, B.; Yu, L.; Chen, Y.; Ye, H.; Shao, R.; Shu, H.; Yu, T.; Zhang, X.; Sun, L. Modelling, applications, and evaluations of optimal sizing and placement of distributed generations: A critical state-of-the-art survey. Int. J. Energy Res. 2021, 45, 3615–3642. [Google Scholar] [CrossRef]

- He, X.; Tang, Y.; Ma, S.; Ai, Q.; Tao, F.; Qiu, R. Redefinition of Digital Twin and Its Situation Awareness Framework Designing Toward Fourth Paradigm for Energy Internet of Things. IEEE Trans. Syst. Man Cybern. Syst. 2024, 54, 6873–6888. [Google Scholar] [CrossRef]

- Yang, B.; Li, J.; Shu, H.; Cai, Z.; Tang, B.; Huang, X.; Zhu, M. Recent advances of optimal sizing and location of charging stations: A critical overview. Int. J. Energy Res. 2022, 46, 17899–17925. [Google Scholar] [CrossRef]

- Li, J.; Yang, B.; Huang, J.; Guo, Z.; Wang, J.; Zhang, R.; Hu, Y.; Shu, H.; Chen, Y.; Yan, Y. Optimal planning of electricity hydrogen hybrid energy storage system considering demand response in active distribution network. Energy 2023, 273, 127142. [Google Scholar] [CrossRef]

- Hu, Y.; Yang, B.; Wu, P.; Wang, X.; Li, J.; Huang, Y.; Su, R.; He, G.; Yang, J.; Su, S.; et al. Optimal planning of electric-heating integrated energy system in low-carbon park with energy storage system. J. Energy Storage 2024, 99, 113327. [Google Scholar] [CrossRef]

- Yang, B.; Wang, J.; Chen, Y.; Li, D.; Zeng, C.; Chen, Y.; Guo, Z.; Shu, H.; Zhang, X.; Yu, T.; et al. Optimal sizing and placement of Energy storage system in power grids: A state-of-the-art one-stop handbook. J. Energy Storage 2020, 32, 101814. [Google Scholar] [CrossRef]

- He, X.; Ai, Q.; Wang, J.; Tao, F.; Pan, B.; Qiu, R.; Yang, B. Situation awareness of energy internet of things in smart city based on digital twin: From digitization to informatization. IEEE Internet Things J. 2023, 10, 7439–7458. [Google Scholar] [CrossRef]

- Elalfy, D.A.; Gouda, E.; Kotb, M.F.; Bureš, V.; Sedhom, B.E. Comprehensive review of energy storage systems technologies, objectives, challenges, and future trends. Energy Strategy Rev. 2024, 54, 101482. [Google Scholar] [CrossRef]

- Wu, T.; Zhuang, H.; Huang, Q.; Xia, S.; Zhou, Y.; Gan, W.; Terzić, J.S. Routing and scheduling of mobile energy storage systems in active distribution network based on probabilistic voltage sensitivity analysis and Hall’s theorem. Appl. Energy 2025, 386, 125535. [Google Scholar] [CrossRef]

- Benedetto, G.; Bompard, E.; Mazza, A.; Pons, E.; Jaboeuf, R.; Tosco, P.; Zampolli, M. Impact of bidirectional EV charging stations on a distribution network: A Power Hardware-In-the-Loop implementation. Sustain. Energy Grids Netw. 2023, 35, 101106. [Google Scholar] [CrossRef]

- Qiao, J.; Mi, Y.; Shen, J.; Xia, D.; Li, D.; Wang, P. Active and reactive power coordination optimization for active distribution network considering mobile energy storage system and dynamic network reconfiguration. Electr. Power Syst. Res. 2025, 238, 111080. [Google Scholar] [CrossRef]

- Yan, X.; Gao, C.; Francois, B. Multi-objective optimization of a virtual power plant with mobile energy storage for a multi-Stakeholders energy community. Appl. Energy 2025, 386, 125553. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, D.; Strbac, G. Multi-agent deep reinforcement learning for resilience-driven routing and scheduling of mobile energy storage systems. Appl. Energy 2022, 310, 118575. [Google Scholar] [CrossRef]

- Lu, Z.; Xu, X.; Yan, Z.; Shahidehpour, M. Routing and scheduling of mobile energy storage in coupled transportation and power distribution networks. IEEE Trans. Transp. Electrif. 2022, 8, 2583–2594. [Google Scholar] [CrossRef]

- Nazemi, M.; Dehghanian, P.; Lu, X.; Chen, C. Uncertainty-aware deployment of mobile energy storage systems for distribution grid resilience. IEEE Trans. Smart Grid 2021, 12, 3200–3214. [Google Scholar] [CrossRef]

- He, G.; Michalek, J.; Kar, S.; Chen, Q.; Zhang, D.; Whitacre, J.F. Utility-scale portable energy storage systems. Joule 2020, 5, 379–392. [Google Scholar] [CrossRef]

- Hu, S.; Liao, K.; Yang, J.; Li, B.; Yang, W. Power supply restoration strategy of urban power grid based on V2G technology. Electr. Power Autom. Equip. 2023, 43, 53–61. [Google Scholar]

- Yan, N.; Ma, G.; Li, X.; Ma, S. Low-carbon economic dispatch method of park integrated energy system considering cross-seasonal energy storage. High Volt. Eng. 2023, 49, 4182–4191. [Google Scholar]

- Xiao, Q.; Yang, K.; Song, Z. Scheduling strategy of industrial parks integrated energy system considering carbon trading and electric vehicle charging load. High Volt. Eng. 2023, 49, 1392–1401. [Google Scholar]

- Shen, Y.; Qian, T.; Li, W.; Zhao, W.; Tang, W.; Chen, X.; Yu, Z. Mobile energy storage systems with spatial–temporal flexibility for post-disaster recovery of power distribution systems: A bilevel optimization approach. Energy 2023, 282, 128300. [Google Scholar] [CrossRef]

- Meng, H.; Jia, H.; Xu, T.; Wei, W.; Wu, Y.; Liang, L.; Cai, S.; Liu, Z.; Wang, R.; Li, M. Optimal configuration of cooperative stationary and mobile energy storage considering ambient temperature: A case for Winter Olympic Game. Appl. Energy 2022, 325, 119889. [Google Scholar] [CrossRef]

- Ganivada, P.K.; El-Fouly, T.H.; Zeineldin, H.H.; Al-Durra, A. Optimal siting and sizing of mobile-static storage mix in distribution systems with high renewable energy resources penetration. Electr. Power Syst. Res. 2024, 226, 109860. [Google Scholar] [CrossRef]

- Li, Z.; Cai, Y.; Tang, X.; Cao, Y.; Zhou, Z.; Zhou, T. Collaborative optimization strategy of mobile energy storage devices and distribution network reconfiguration for power loss reduction scenarios. Electr. Power Constr. 2023, 44, 137–148. [Google Scholar]

- Wang, D.; Guo, J.; Zhang, Y.; Zhong, Q.; Xu, H. Optimizing expressway battery electric vehicle charging and mobile storage energy truck scheduling: A two-stage approach to improve photovoltaic generation utilization. Energy 2025, 320, 135145. [Google Scholar] [CrossRef]

- Shamani, M.; Foroud, A.; Rastgoo, R. Optimal routing and scheduling of mobile charging station considering operational limitations of energy sources in distribution system. J. Energy Storage 2025, 117, 116135. [Google Scholar] [CrossRef]

- He, B.; Yang, B.; Han, Y.; Zhou, Y.; Hu, Y.; Shu, H.; Su, S.; Yang, J.; Huang, Y.; Li, J.; et al. Optimal EVCS planning via spatial-temporal distribution of charging demand forecasting and traffic-grid coupling. Energy 2024, 313, 133885. [Google Scholar] [CrossRef]

- Yu, T.; Ma, J. A review of the link traffic time estimation of urban traffic. In Proceedings of the IEEE International Conference on Intelligent Transportation Engineering (ICITE), Singapore, 20–22 August 2016; pp. 123–127. [Google Scholar]

- Zhou, Y.; Yang, B.; Hu, Y.; He, P.; Zhou, G.; Li, J. Electricity-Heat-Gas Collaborative Low-Carbon Optimal Dispatch of Multi-Energy Complementary Integrated Energy System Considering Green Certificate and Carbon Emission Trading. Power Syst. Technol. Available online: https://doi.org/10.13335/j.1000-3673.pst.2024.0551 (accessed on 10 March 2025).

- Chen, M.; Lu, Z.; Liu, Y.; Ding, Z.; Rao, H.; Bao, G.; Lu, C. Research on optimal peak load shifting strategy of battery energy storage system operated in constant power mode. Power Syst. Technol. 2012, 36, 232–237. [Google Scholar]

- Tang, B.; Shi, Q.; Chen, Y.; Zhao, X.; Yang, P.; Lai, X.; Muyeen, S. Co-planning of network-load-storage to enhance the power-balancing capability of active distribution networks. Electr. Power Syst. Res. 2025, 246, 111723. [Google Scholar] [CrossRef]

- Miguel, P.C. Power sharing and voltage regulation control for grid forming of future distribution circuits with multiple voltage references. Electr. Power Syst. Res. 2025, 246, 111668. [Google Scholar]

- Shi, Y.; Xu, B.; Wang, D.; Zhang, B. Using battery storage for peak shaving and frequency regulation: Joint optimization for superlinear gains. IEEE Trans. Power Syst. 2017, 33, 2882–2894. [Google Scholar] [CrossRef]

- Xu, Z.; Tang, Z.; Chen, Y.; Liu, Y.; Gao, H.; Xu, X. Optimal robust allocation of distributed modular energy storage system in distribution networks for voltage regulation. Appl. Energy 2025, 388, 125625. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, S.; Liu, J.; Tong, J.; Dang, J.; Yang, F.; Ouyang, M. Multi-objective optimization of the Atkinson cycle gasoline engine using NSGA III coupled with support vector machine and back-propagation algorithm. Energy 2023, 262, 125262. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Maximum number of iterations | 600 |

| Population size | 500 |

| Reference points | 15 |

| Crossover percentage | 0.5 |

| Mutation percentage | 0.5 |

| Mutation rate | 0.2 |

| Parameters | Symbol | Value | |||

|---|---|---|---|---|---|

| MESS#1 | SESS#1 | SESS#2 | |||

| Rated power (kW) | 260 | 300 | 300 | ||

| Rated capacity (kW*h) | 1000 | 1500 | 1500 | ||

| Initial SOC | / | 0.1 | 0.1 | 0.1 | |

| Maximum/Minimum SOC | 0.9/0.1 | 0.9/0.1 | 0.9/0.1 | ||

| Maximum number of charge and discharge | 5000 | 5000 | 5000 | ||

| Unit iron core price (CNY/(W*h)) | 0.6 | 0.6 | 0.6 | ||

| The cost coefficient of MESS per unit distance (CNY/km) | 1.6 | / | / | ||

| TOU price (CNY/kW*h) | Peak price | / | 0.71 (18:00–22:00) | ||

| Standard price | / | 0.51 (5:00–9:00, 14:00–18:00, 22:00–24:00) | |||

| Valley price | / | 0.31 (1:00–5:00, 9:00–14:00) | |||

| Net Benefits of Scheduling (CNY) | Arbitrage Revenue (CNY) | Benefits of Reducing Network Losses (CNY) | Driving Cost (CNY) | Battery Recession Cost (CNY) |

|---|---|---|---|---|

| 578.80 | 1035.21 | 84.01 | 21.74 | 518.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, L.; Di, L.; Zhao, J.; Liu, H.; Hu, Y.; Wei, X. Optimal Scheduling of Active Distribution Networks with Hybrid Energy Storage Systems Under Real Road Network Topology. Processes 2025, 13, 1492. https://doi.org/10.3390/pr13051492

Miao L, Di L, Zhao J, Liu H, Hu Y, Wei X. Optimal Scheduling of Active Distribution Networks with Hybrid Energy Storage Systems Under Real Road Network Topology. Processes. 2025; 13(5):1492. https://doi.org/10.3390/pr13051492

Chicago/Turabian StyleMiao, Ling, Li Di, Jian Zhao, Hao Liu, Yurong Hu, and Xiaozhao Wei. 2025. "Optimal Scheduling of Active Distribution Networks with Hybrid Energy Storage Systems Under Real Road Network Topology" Processes 13, no. 5: 1492. https://doi.org/10.3390/pr13051492

APA StyleMiao, L., Di, L., Zhao, J., Liu, H., Hu, Y., & Wei, X. (2025). Optimal Scheduling of Active Distribution Networks with Hybrid Energy Storage Systems Under Real Road Network Topology. Processes, 13(5), 1492. https://doi.org/10.3390/pr13051492