Analysis of Waterflooding Oil Recovery Efficiency and Influencing Factors in the Tight Oil Reservoirs of Jilin Oilfield

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Samples

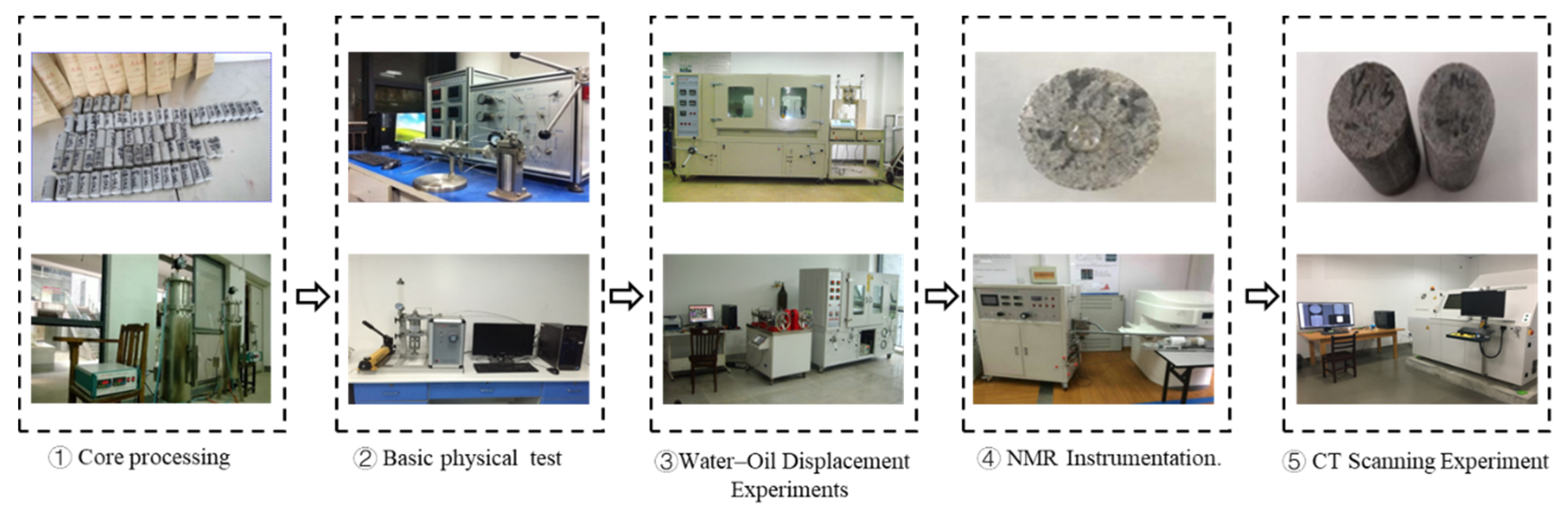

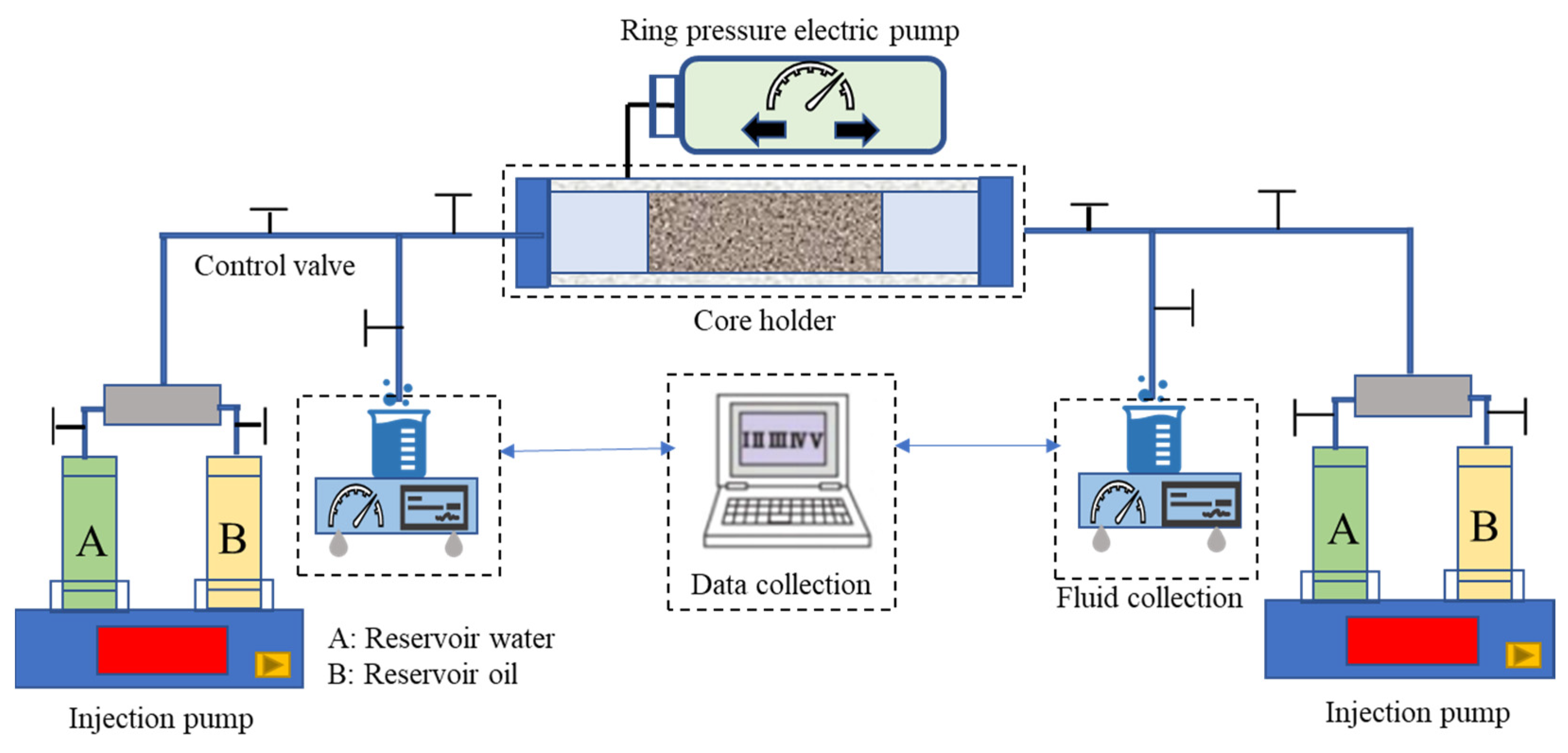

2.2. Experimental Procedure

2.2.1. Basic Preparation

2.2.2. Displacement Experiment Procedure Design

3. Results

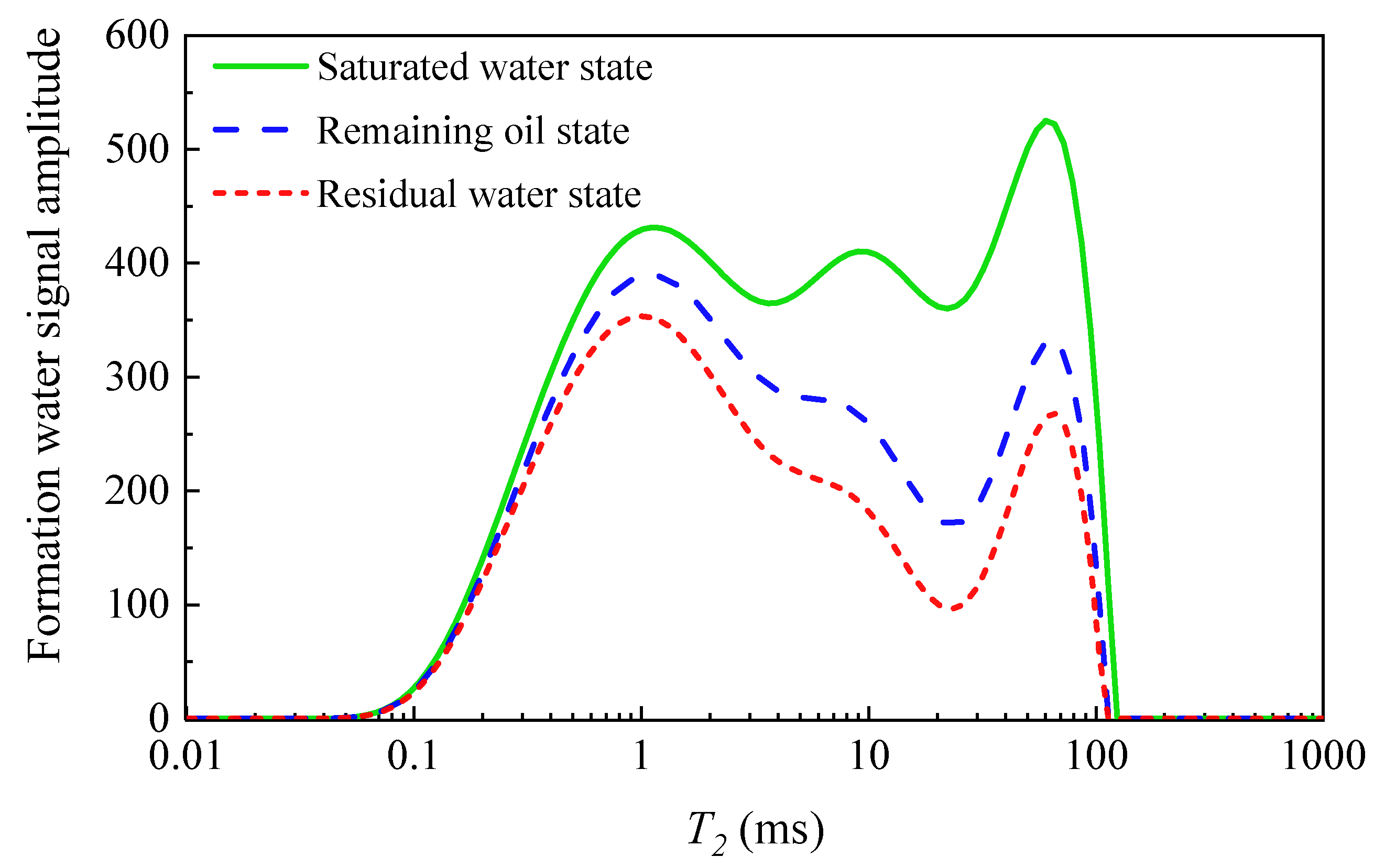

3.1. Analysis of Displacement Characteristics Results

3.1.1. Oil-Displacing-Water Experiment Results

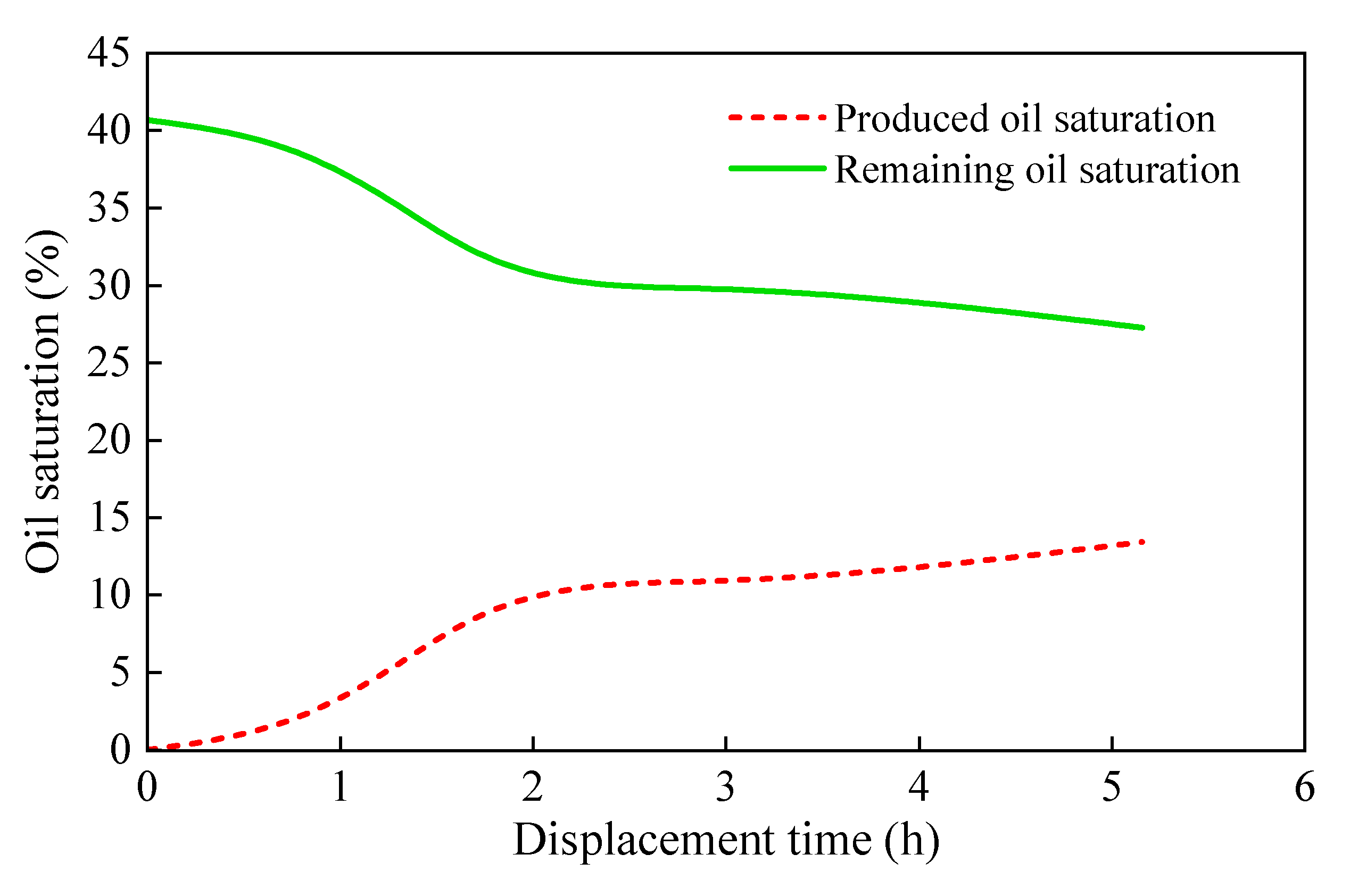

3.1.2. Water-Displacing-Oil Experiment Results

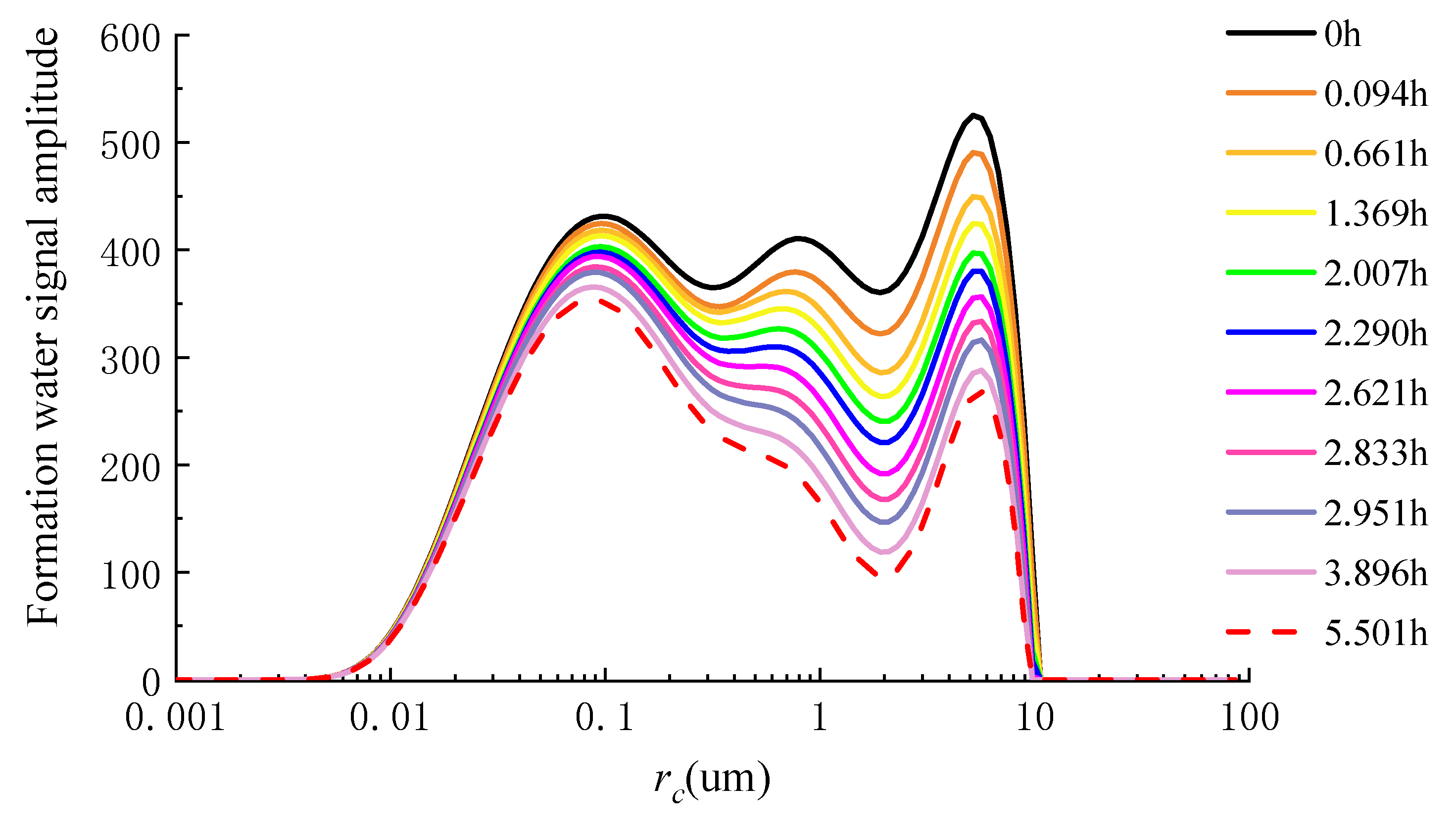

3.2. Analysis of Movable Fluid Saturation Distribution and Displacement Efficiency Characteristics

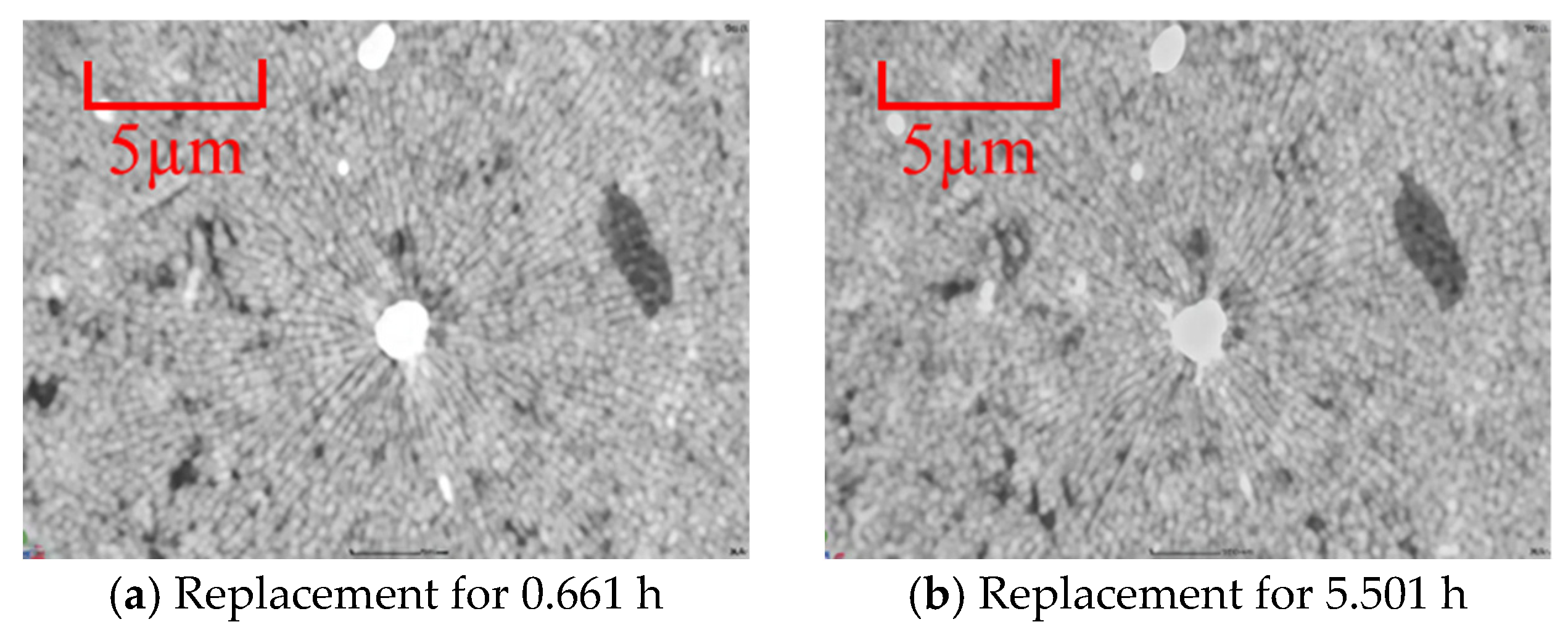

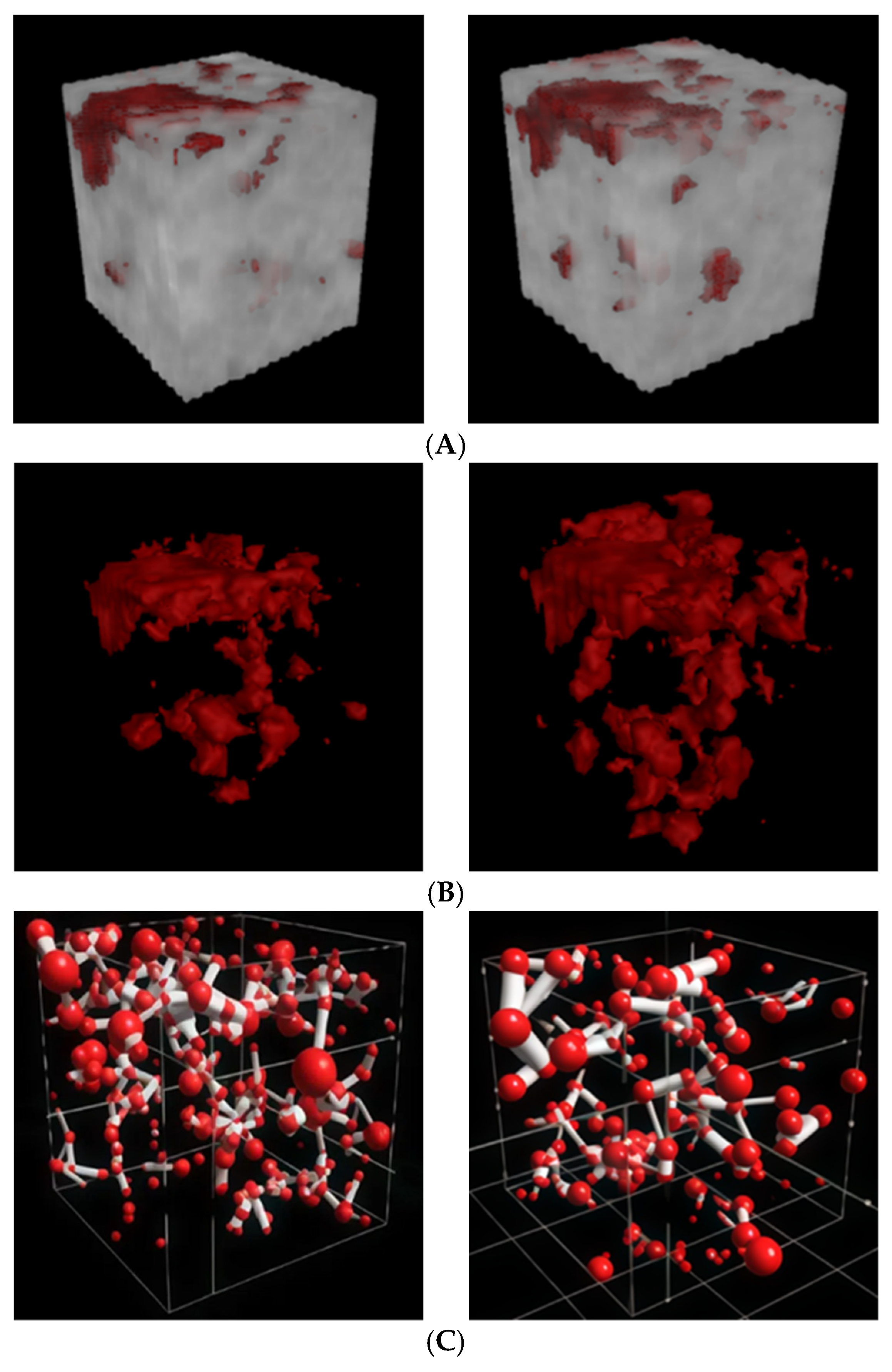

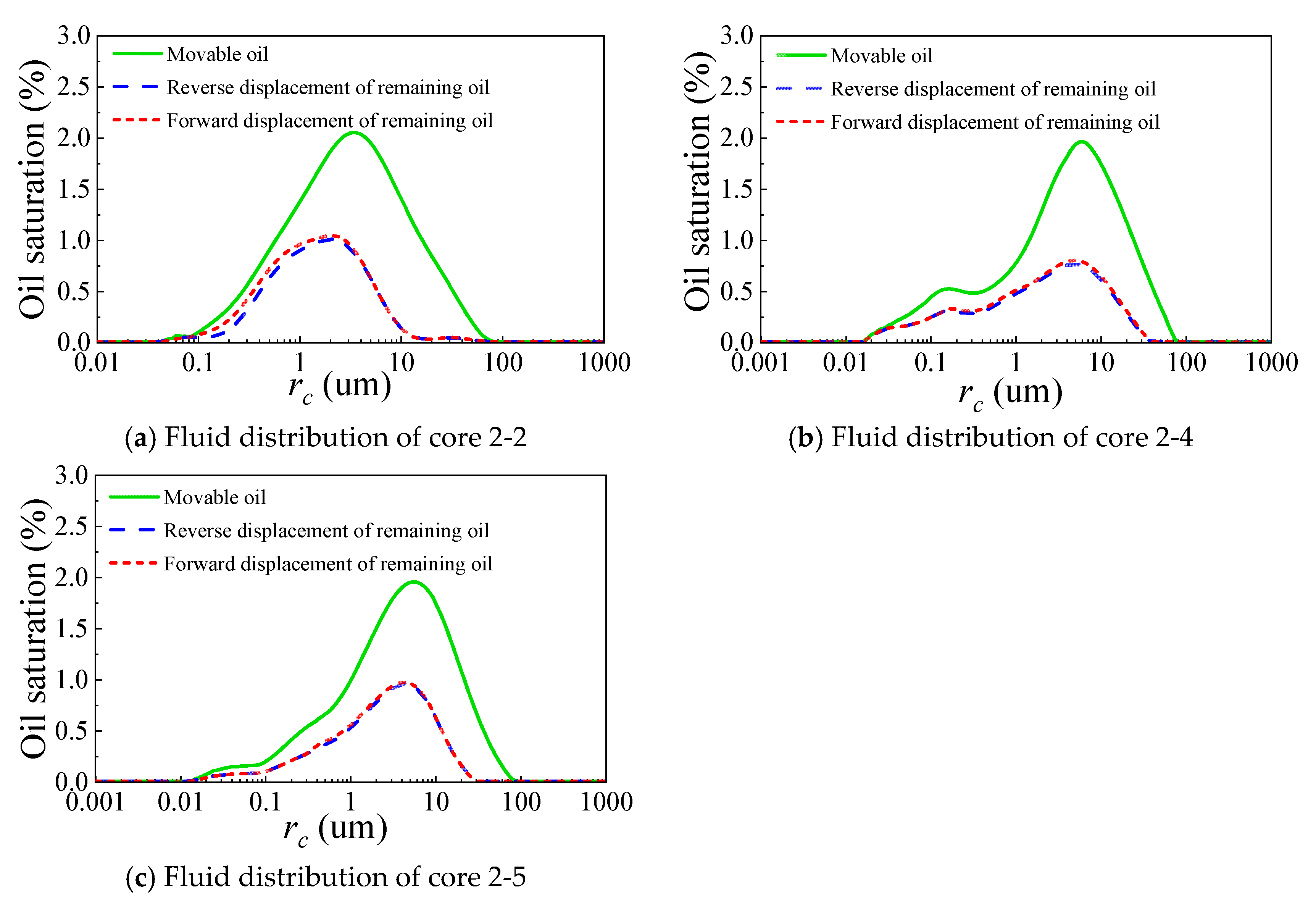

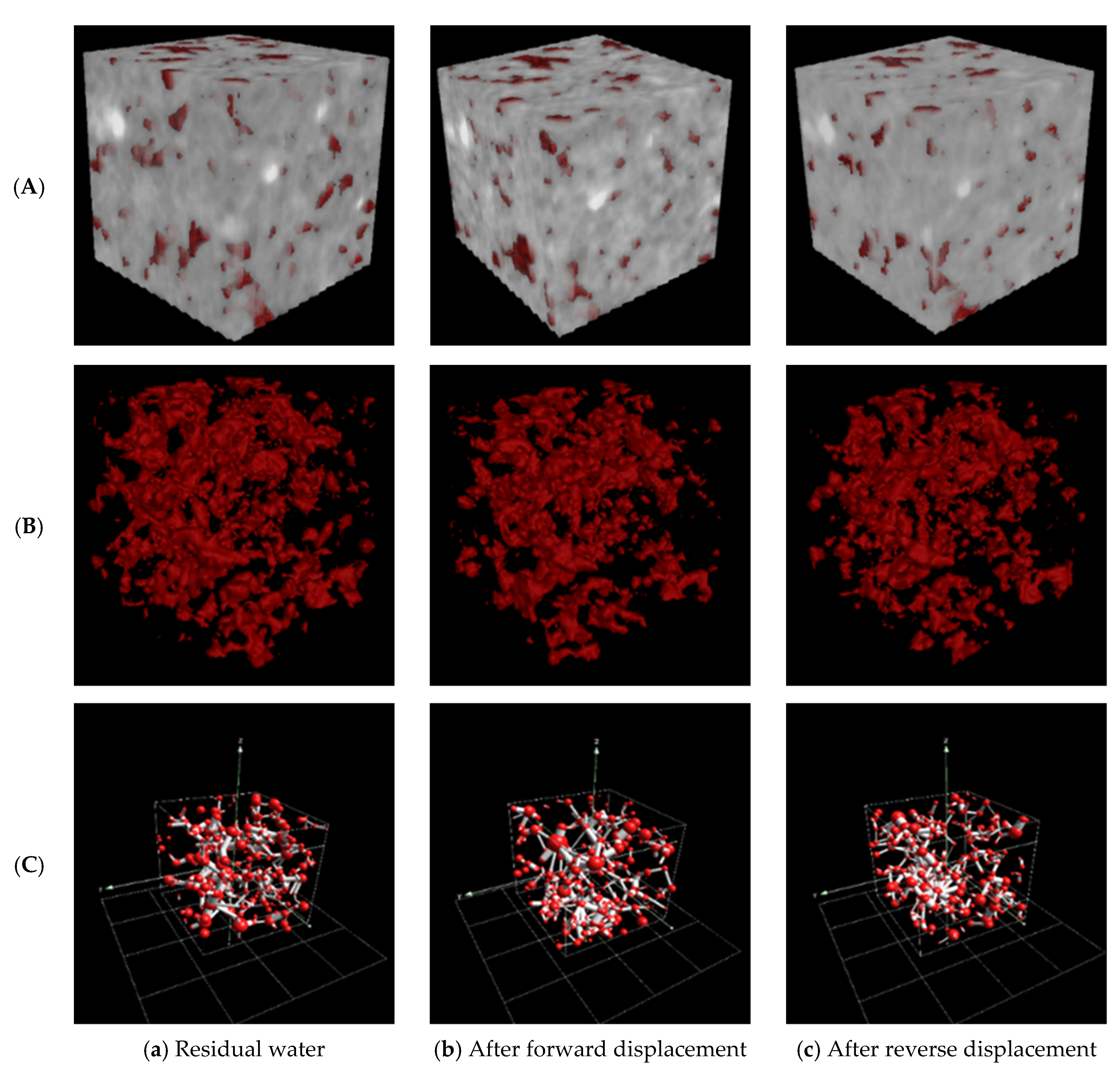

3.3. Analysis of Remaining Oil Distribution Characteristics

4. Analysis of Factors Affecting Oil Displacement Efficiency

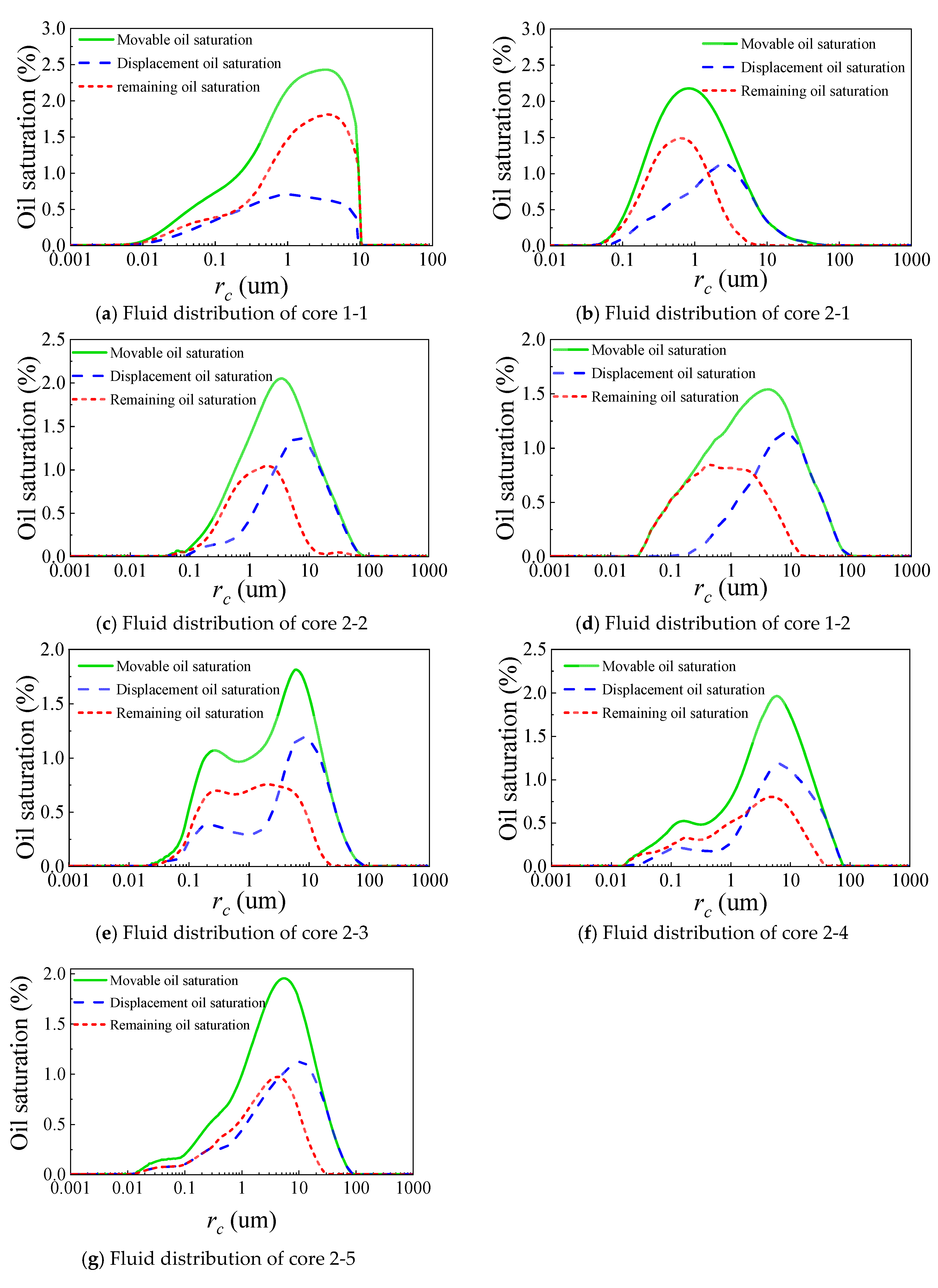

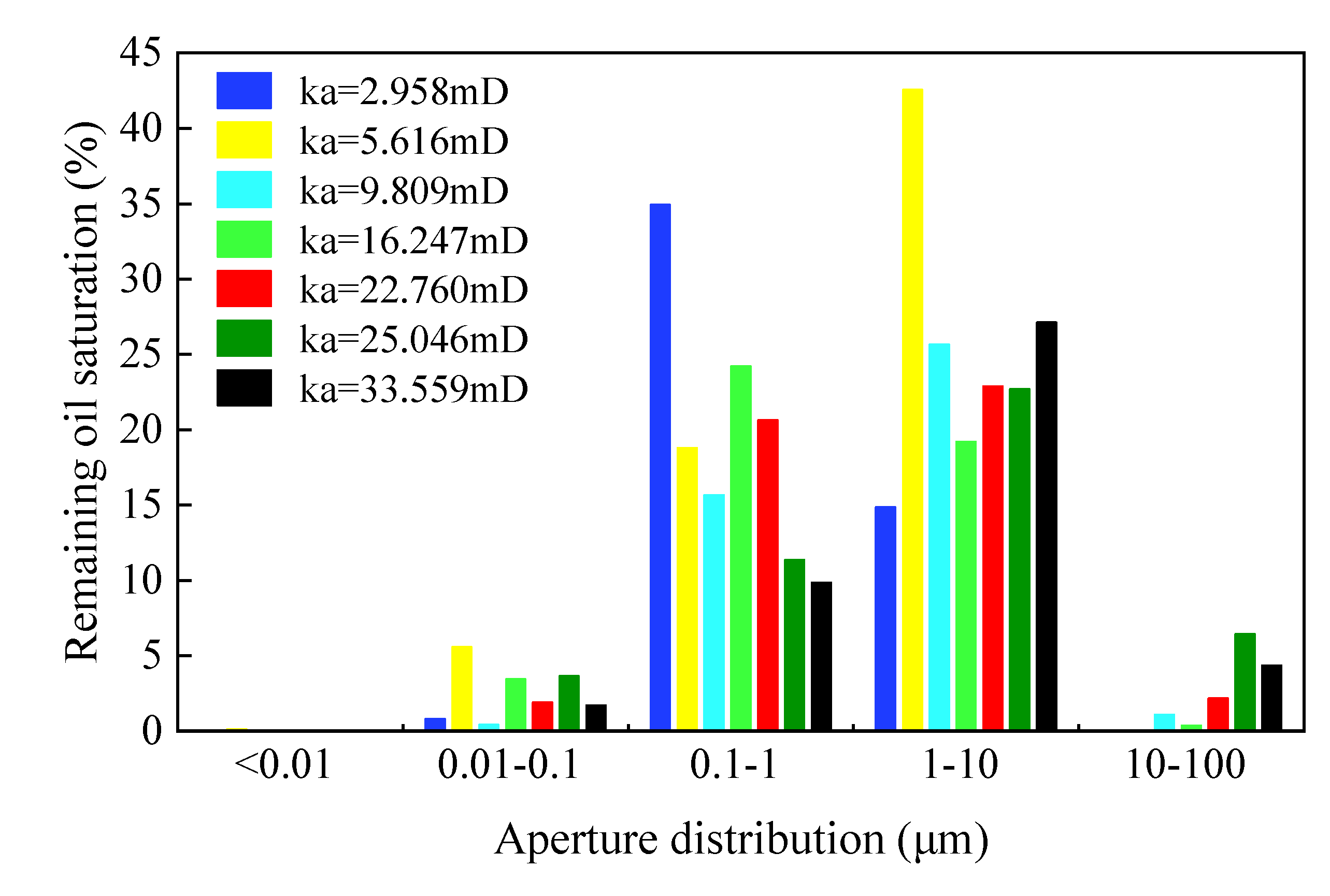

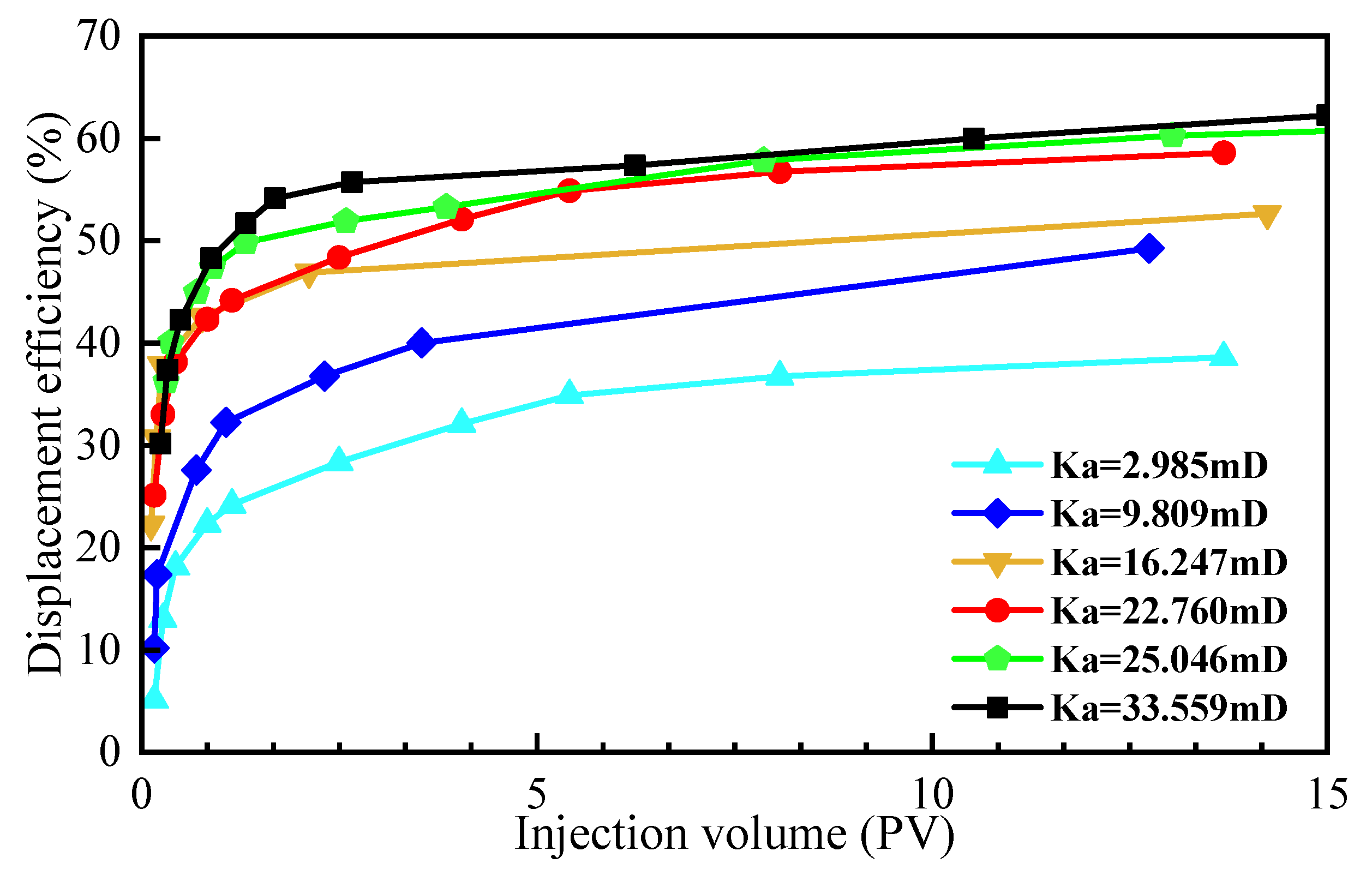

4.1. Variation Pattern of Movable Oil Distribution and Oil Recovery Efficiency in Reservoirs with Different Permeabilities

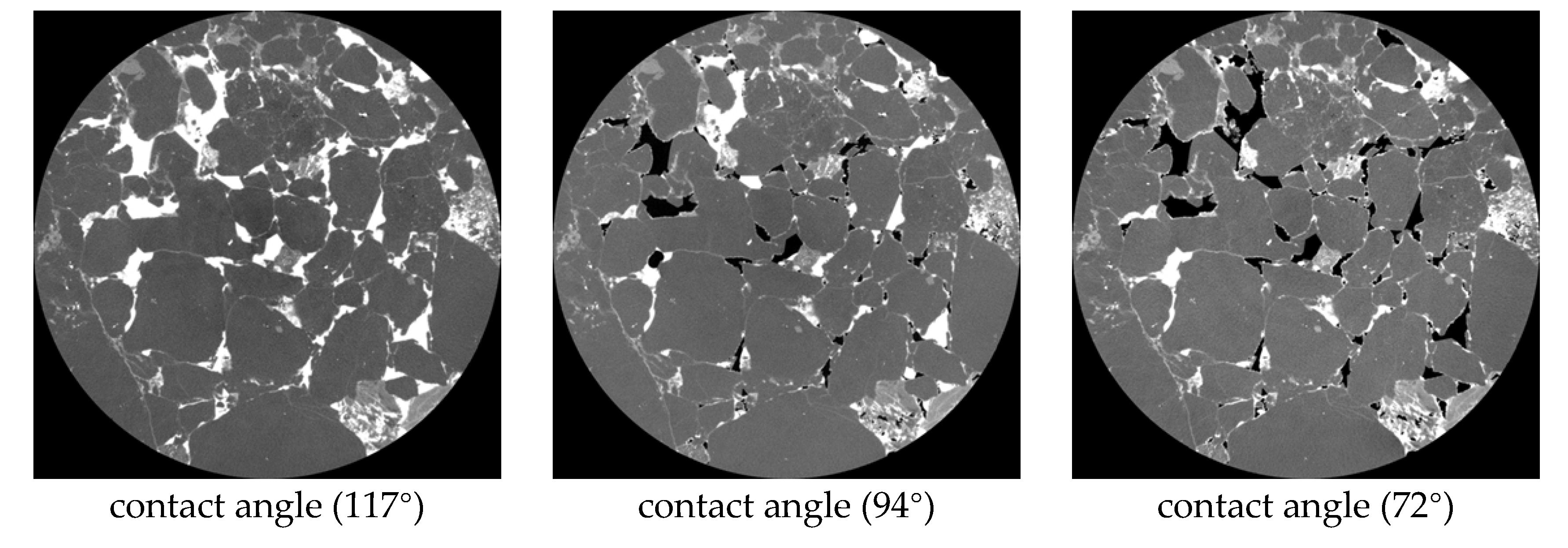

4.2. The Influence of Wettability

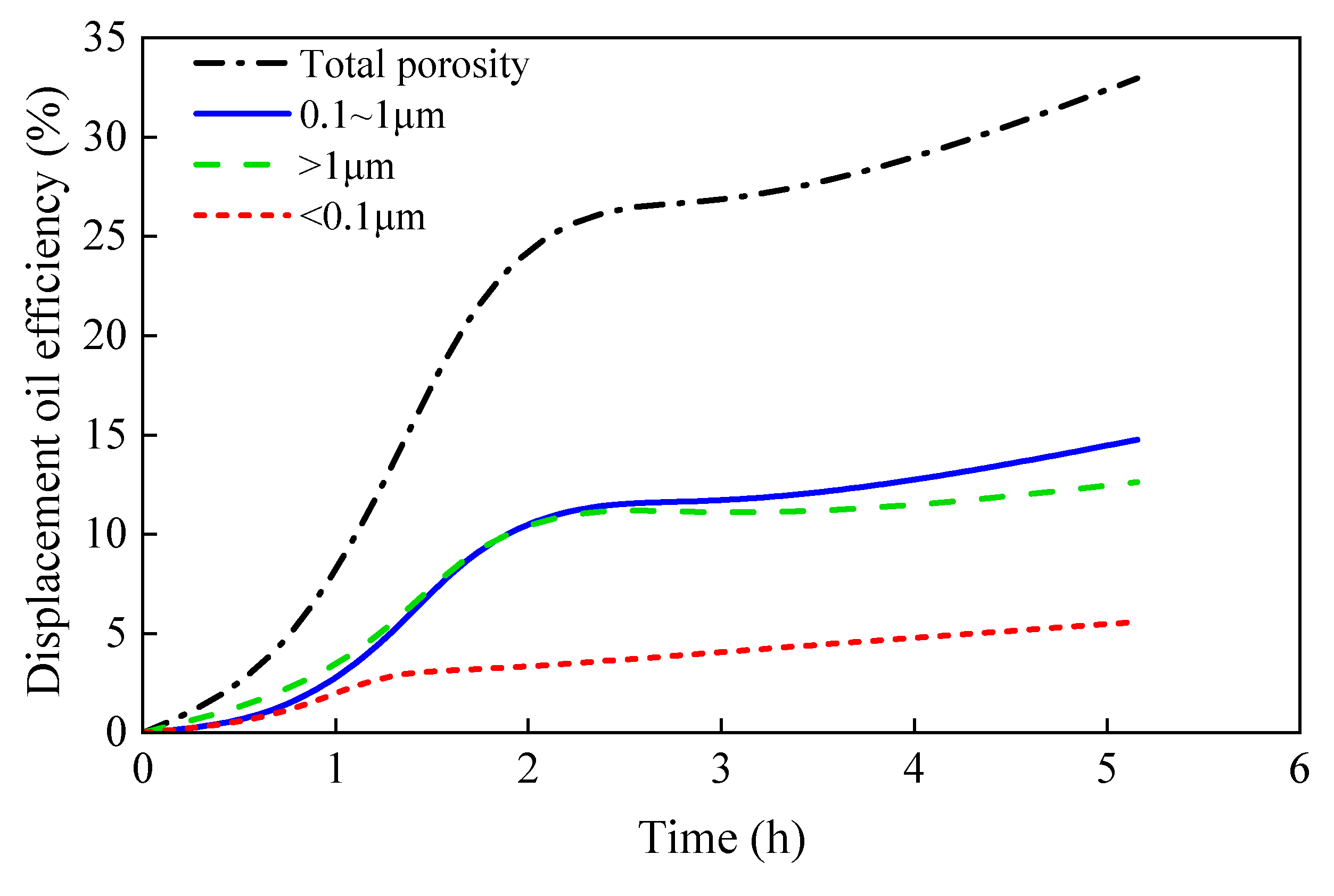

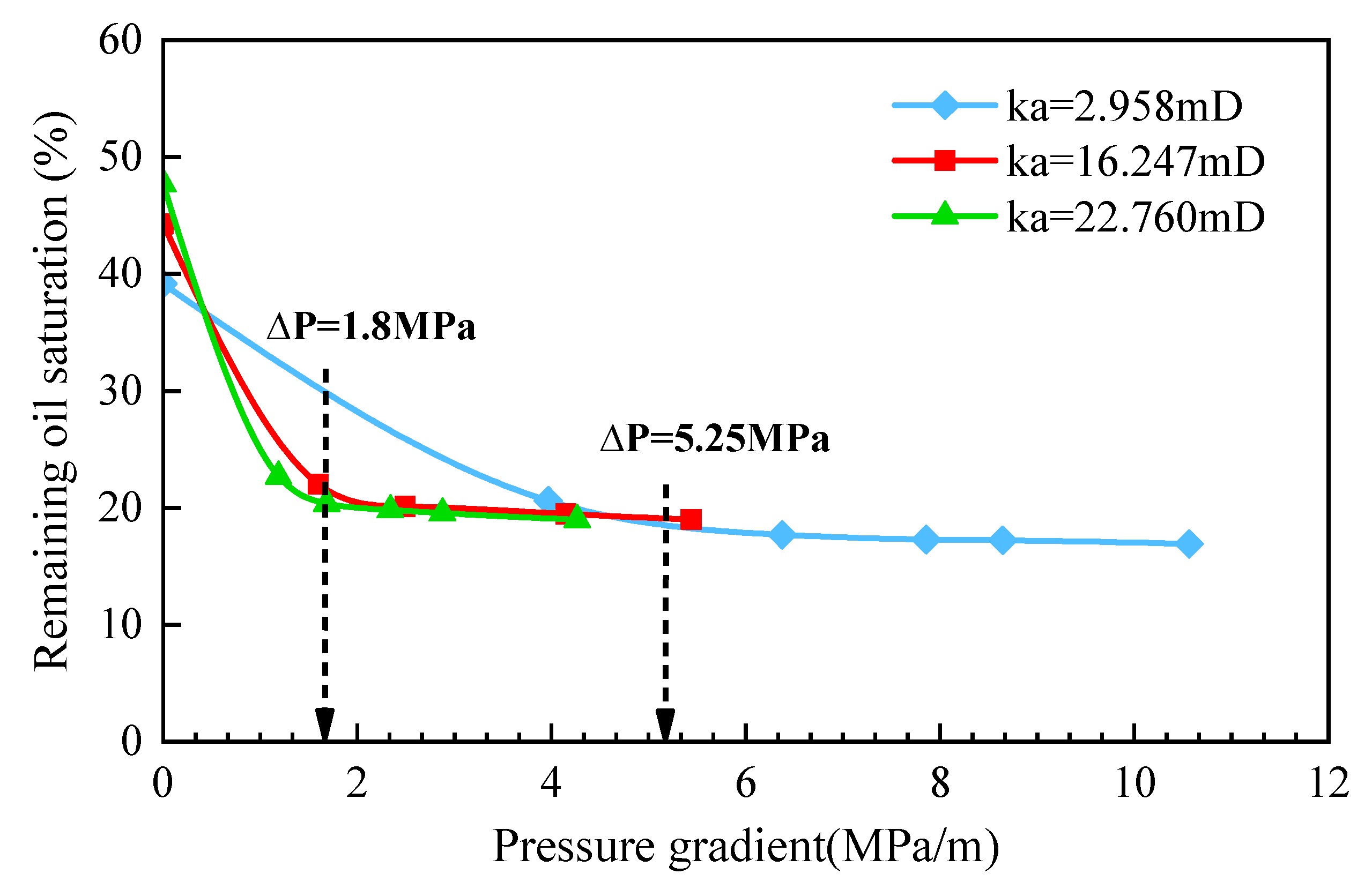

4.3. The Influence of Pressure Gradient

4.4. The Effect of Injection Water Multiples

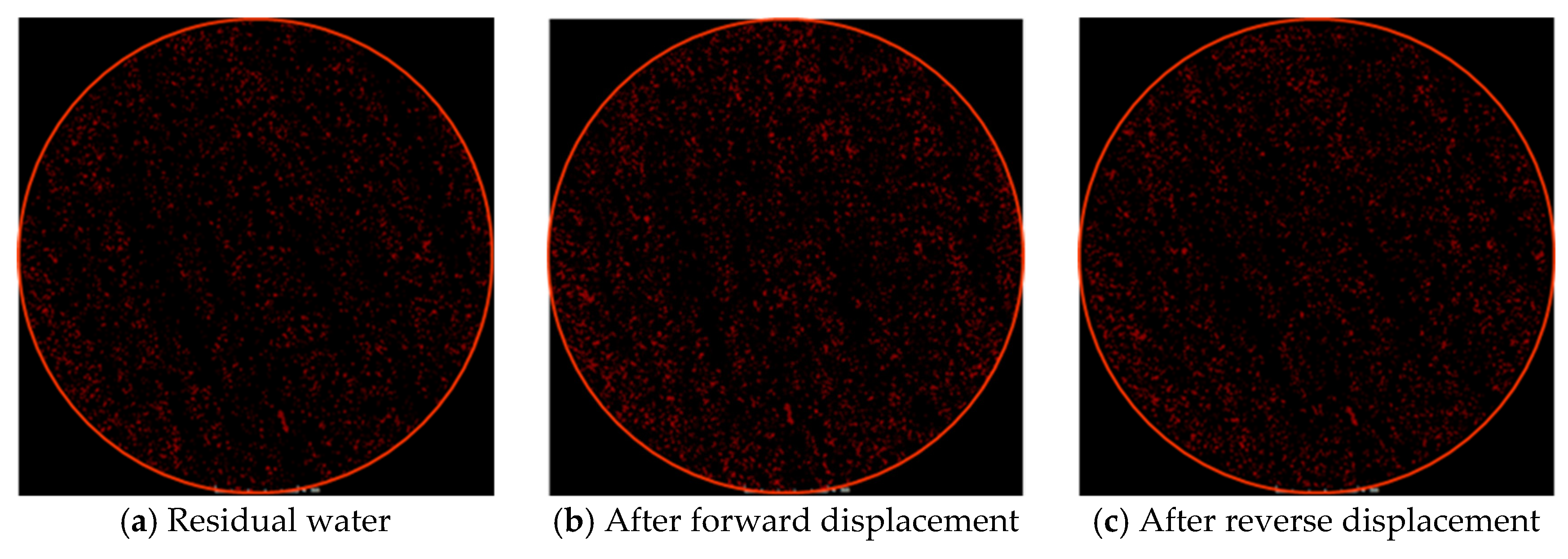

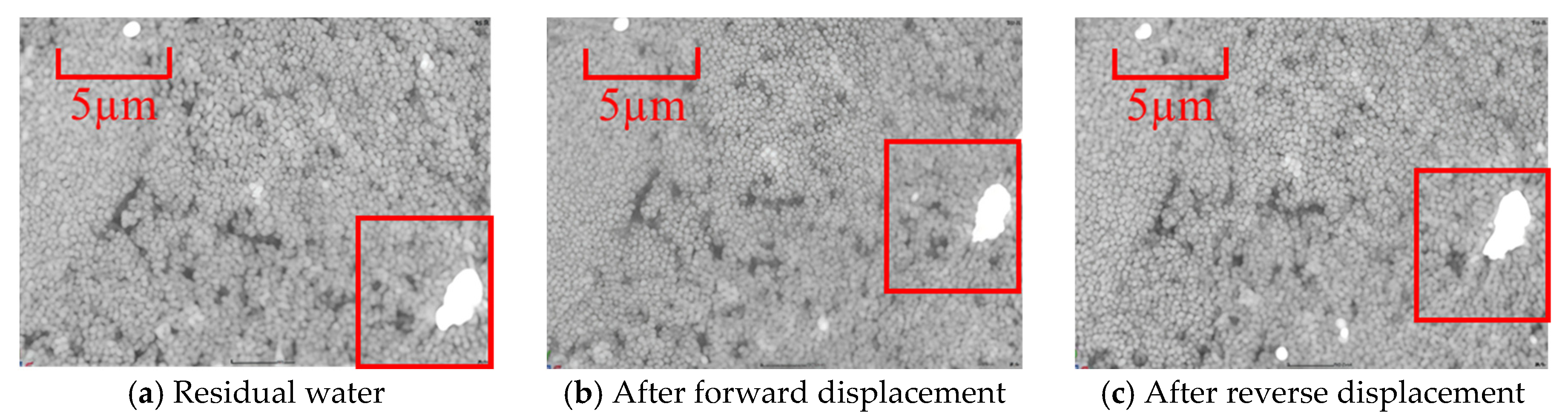

4.5. Effect of Reverse Displacement on Microscopic Fluid Distribution

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Burdine, N.T. Relative Permeability Calculations from Pore Size Distribution Data. Trans. Am. Inst. Min. Metall. Eng. 1953, 198, 71–78. [Google Scholar] [CrossRef]

- Kleinberg, R.L. Utility of NMR T-2 distributions, connection with capillary pressure, clay effect, and determination of the surface relaxivity parameter rho(2). Magn. Reson. Imaging 1996, 14, 761–767. [Google Scholar] [CrossRef] [PubMed]

- Purcell, W.R. Capillary Pressures—Their Measurement Using Mercury and the Calculation of Permeability Therefrom. Trans. Am. Inst. Min. Metall. Eng. 1949, 186, 39–48. [Google Scholar] [CrossRef]

- Brooks, R.H.; Corey, A.T. Properties of porous media affecting fluid flow. J. Irrig. Drain. Div. 1966, 92, 02. [Google Scholar] [CrossRef]

- Pirson, S.J.; Boatman, E.M.; Nettle, R.L. Prediction of Relative Permeability Characteristics of Intergranular Reservoir Rocks from Electrical Resistivity Measurements. Trans. Soc. Pet. Eng. AIME 1964, 231, 564–570. [Google Scholar] [CrossRef]

- Hidajat, I.; Singh, M.; Cooper, J.; Mohanty, K.K. Permeability of porous media from simulated NMR response. Transp. Porous Med. 2002, 48, 225–247. [Google Scholar] [CrossRef]

- Liu, Y.F.; Deng, R.; Luo, S.C.; Li, H.; Zhang, L.; Gan, L.X. The Saturation Calculation of NMR Logging Based on Constructing Water Spectrum Function. Processes 2024, 12, 2518. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Tahmasebi, P.; Lin, C.Y.; Zahid, M.A.; Dong, C.M.; Golab, A.N.; Ren, L.H. A comprehensive study on geometric, topological and fractal characterizations of pore systems in low-permeability reservoirs based on SEM, MICP, NMR, and X-ray CT experiments. Mar. Petrol. Geol. 2019, 103, 12–28. [Google Scholar] [CrossRef]

- Chalmers, G.R.; Bustin, R.M.; Power, I.M. Characterization of gas shale pore systems by porosimetry, pycnometry, surface area, and field emission scanning electron microscopy/transmission electron microscopy image analyses: Examples from the Barnett, Woodford, Haynesville, Marcellus, and Doig units. AAPG Bull. 2012, 96, 1099–1119. [Google Scholar]

- Li, L.; Hao, Y.M.; Lv, Y.T.; Wang, C.W.; Yao, C.J.; Zhao, Q.M.; Xiao, P.F. Experimental investigation on low-velocity seepage characteristics and influencing factors in a shale oil reservoir. J. Petrol. Sci. Eng. 2020, 195, 107732. [Google Scholar] [CrossRef]

- Hui, G.; Chen, Z.X.; Wang, Y.J.; Zhang, D.M.; Gu, F. An integrated machine learning-based approach to identifying controlling factors of unconventional shale productivity. Energy 2023, 266, 126512. [Google Scholar] [CrossRef]

- Al-Quraishi, A.; Khairy, M. Pore pressure versus confining pressure and their effect on oil-water relative permeability curves. J. Petrol. Sci. Eng. 2005, 48, 120–126. [Google Scholar] [CrossRef]

- Mohammadkhani, S.; Shahverdi, H.; Esfahany, M.N. Impact of salinity and connate water on low salinity water injection in secondary and tertiary stages for enhanced oil recovery in carbonate oil reservoirs. J. Geophys. Eng. 2018, 15, 1242–1254. [Google Scholar] [CrossRef]

- Li, J.J.; Jiang, H.Q.; Wang, C.; Zhao, Y.Y.; Gao, Y.J.; Pei, Y.L.; Wang, C.C.; Dong, H. Pore-scale investigation of microscopic remaining oil variation characteristics in water-wet sandstone using CT scanning. J. Nat. Gas Sci. Eng. 2017, 48, 36–45. [Google Scholar] [CrossRef]

- Zhou, Y.; Helland, J.O.; Hatzignatiou, D.G. Pore-Scale Modeling of Waterflooding in Mixed-Wet-Rock Images: Effects of Initial Saturation and Wettability. SPE J. 2014, 19, 88–100. [Google Scholar] [CrossRef]

- Wang, Z.N.; Liu, K.Y.; Zhang, C.Q.; Yan, H.J.; Yu, J.; Yu, B.; Liu, J.L.; Jiang, T.L.; Dan, W.D.; Hu, C.Z. Integral Effects of Porosity, Permeability, and Wettability on Oil-Water Displacement in Low-Permeability Sandstone Reservoirs-Insights from X-ray CT-Monitored Core Flooding Experiments. Processes 2023, 11, 2786. [Google Scholar] [CrossRef]

- Wei, J.G.; Zhou, X.F.; Zhou, J.M.; Li, J.T.; Wang, A.L. Recovery efficiency of tight oil reservoirs with different injection fluids: An experimental investigation of oil-water distribution feature. J. Petrol. Sci. Eng. 2020, 195, 107678. [Google Scholar] [CrossRef]

- Hassanizadeh, S.M.; Celia, M.A.; Dahle, H.K. Dynamic Effect in the Capillary Pressure-Saturation Relationship and its Impacts on Unsaturated Flow. Vadose Zone J. 2002, 1, 38–57. [Google Scholar] [CrossRef]

- Zhang, H.Y.; He, S.L.; Jiao, C.Y.; Luan, G.H.; Mo, S.Y.; Lei, G. Investigation of Dynamic Effect of Capillary Pressure in Ultra-Low Permeability Sandstones. Indian Geotech. J. 2015, 45, 79–88. [Google Scholar] [CrossRef]

- Al-Mahrooqi, S.H.; Grattoni, C.A.; Muggeridge, A.H.; Zimmerman, R.W.; Jing, X.D. Pore-scale modelling of NMR relaxation for the characterization of wettability. J. Petrol. Sci. Eng. 2006, 52, 172–186. [Google Scholar] [CrossRef]

- Guan, H.; Brougham, D.; Sorbie, K.S.; Packer, K.J. Wettability effects in a sandstone reservoir and outcrop cores from NMR relaxation time distributions. J. Petrol. Sci. Eng. 2002, 34, 33–52. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, Y.Z.; Zhang, M.L.; Mao, Z.; Wang, C.C.; Hu, R.R.; Yang, L.; Liu, Y. Research on Micro-Pore Structure and 3D Visual Characterization of Inter-Salt Shale Based on X-CT Imaging Digital Core Technology. Processes 2022, 10, 1321. [Google Scholar] [CrossRef]

- Daigle, H.; Johnson, A. Combining Mercury Intrusion and Nuclear Magnetic Resonance Measurements Using Percolation Theory. Transp. Porous Med. 2016, 111, 669–679. [Google Scholar] [CrossRef]

- Li, Z.; Sun, X.; Wang, F.; Liang, Y. Microscopic Flow Characteristics of Fluids in Porous Medium and Its Relationship with Remaining Oil Distribution: A Case Study in Saertu Oilfield of Daqing in China. Geofluids 2018, 2018, 7549831. [Google Scholar] [CrossRef]

- Ryazanov, A.V.; Sorbie, K.S.; van Dijke, M.I.J. Structure of remaining oil as a function of wettability using pore-network modelling. Adv. Water Resour. 2014, 63, 11–21. [Google Scholar] [CrossRef]

- Jin, G.W.; Xie, R.H.; Liu, M.; Guo, J.F. Petrophysical Parameter Calculation Based on NMR Echo Data in Tight Sandstone. IEEE Trans. Geosci. Remote Sens. 2019, 57, 5618–5625. [Google Scholar] [CrossRef]

- Hosseinzadeh, S.; Kadkhodaie, A.; Yarmohammadi, S. NMR derived capillary pressure and relative permeability curves as an aid in rock typing of carbonate reservoirs. J. Petrol. Sci. Eng. 2020, 184, 106593. [Google Scholar] [CrossRef]

- Guo, Y.H.; Pan, B.Z.; Zhang, L.H. A New Method to Identify Reservoirs in Tight Sandstones Based on the New Model of Transverse Relaxation Time and Relative Permeability. Geofluids 2017, 2017, 1–16. [Google Scholar] [CrossRef]

- Liu, M.; Xie, R.H.; Guo, J.F.; Jin, G.W. Characterization of Pore Structures of Tight Sandstone Reservoirs by Multifractal Analysis of the NMR Distribution. Energy Fuel 2018, 32, 12218–12230. [Google Scholar] [CrossRef]

- Fan, Z.F.; Li, K.C.; Li, J.X.; Song, H.; He, L.; Wu, X.L. A study on remaining oil distribution in a carbonate oil reservoir based on reservoir flow units. Petrol. Explor. Dev. 2014, 41, 634–641. [Google Scholar] [CrossRef]

- Zhang, T.J.; Yang, X.P.; Yan, X.C.; Luo, Z.M. Deriving the Oil-Water Seepage Pressure Distribution from Two-Phase Oil-Water Flow Stress Gradient. Chem. Tech. Fuels Oils 2019, 55, 199–205. [Google Scholar]

- Yu, H.M.; Wang, Y.Q.; Zhang, L.; Zhang, Q.X.; Guo, Z.H.; Wang, B.Z.; Sun, T. Remaining oil distribution characteristics in an oil reservoir with ultra-high water-cut. Energy Geosci. 2024, 5, 100116. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, M.L.; Wang, C.C.; Mao, Z.; Zhang, Y.Z. Application of the Backpropagation Neural Network Image Segmentation Method with Genetic Algorithm Optimization in Micropores of Intersalt Shale Reservoirs. ACS Omega 2021, 6, 25246–25257. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Yang, Z.B.; Huang, C.B.; Liu, J.M.; Wang, Y.T.; Wu, W. Evaluating the pore structure of low permeability glutenite reservoir by 3D digital core technology. SN Appl. Sci. 2022, 4, 294. [Google Scholar] [CrossRef]

- Wang, H.; Su, Y.L.; Wang, W.D.; Li, L.; Sheng, G.L.; Zhan, S.Y. Relative permeability model of oil-water flow in nanoporous media considering multi-mechanisms. J. Petrol. Sci. Eng. 2019, 183, 106361. [Google Scholar] [CrossRef]

- Zhang, F.Q.; Kor, T.; Yan, J.Z. Oil secondary migration simulation in tight reservoir and fingering factors analysis. J. Petrol. Sci. Eng. 2022, 209, 109969. [Google Scholar] [CrossRef]

| Block | Number | Depth (m) | Length (cm) | Permeability (mD) | Porosity (%) | Experimental Type |

|---|---|---|---|---|---|---|

| C4 | 1-1 | 1207.30 | 5.168 | 5.616 | 15.27 | |

| C7 | 3-1 | 1250.50 | 5.022 | 2.320 | 8.89 | |

| C7 | 2-1 | 1225.6 | 5.726 | 2.958 | 10.24 | A |

| C7 | 2-2 | 1201.76 | 4.814 | 9.809 | 18.77 | B |

| C4 | 1-2 | 1198.00 | 5.118 | 16.247 | 20.20 | A |

| C7 | 2-3 | 1225.75 | 5.040 | 22.760 | 13.67 | A |

| C7 | 2-4 | 1237.22 | 4.910 | 25.046 | 13.75 | B |

| C7 | 2-5 | 1237.97 | 5.130 | 33.559 | 15.00 | B |

| Core | Saturation Spectral Area | Immovable Peak Area | Movable Peak Area | Movable Fluid Saturation (%) | Remaining Oil Saturation (%) | Oil Displacement Efficiency (%) |

|---|---|---|---|---|---|---|

| 1-1 | 27,281.96 | 16,181.89 | 11,100.08 | 40.69 | 67.04 | 32.96 |

| 2-1 | 38,846.38 | 23,636.53 | 15,209.85 | 39.15 | 50.63 | 49.37 |

| 2-2 | 40,890.18 | 23,485.59 | 17,404.59 | 42.56 | 42.85 | 57.15 |

| 1-2 | 44,574.38 | 24,834.93 | 19,739.45 | 44.28 | 47.25 | 52.75 |

| 2-3 | 31,839.64 | 16,647.20 | 15,192.44 | 47.72 | 47.58 | 52.42 |

| 2-4 | 35,895.53 | 18,283.29 | 17,612.25 | 49.07 | 44.13 | 55.87 |

| 2-5 | 33,986.50 | 16,811.93 | 17,174.57 | 50.53 | 43.05 | 56.95 |

| Core | Permeability (mD) | Aperture Distribution (μm) | ||||

|---|---|---|---|---|---|---|

| <0.01 | 0.01~0.1 | 0.1~1 | 1~10 | >10 | ||

| 1-1 | 2.958 | 0 | 1.61 | 69.01 | 29.37 | 0.01 |

| 2-1 | 5.616 | 0.17 | 8.30 | 28.04 | 63.48 | 0 |

| 2-2 | 9.809 | 0 | 0.99 | 36.58 | 59.90 | 2.53 |

| 1-2 | 16.247 | 0 | 7.30 | 51.25 | 40.66 | 0.79 |

| 2-3 | 22.760 | 0 | 3.99 | 43.38 | 48.06 | 4.57 |

| 2-4 | 25.046 | 0 | 8.27 | 25.73 | 51.44 | 14.56 |

| 2-5 | 33.559 | 0 | 3.97 | 22.89 | 63.01 | 10.13 |

| Core | Permeability (mD) | Forward Oil Displacement Efficiency (%) | Reverse Oil Displacement Efficiency (%) | Increase in Oil Displacement Efficiency (%) |

|---|---|---|---|---|

| 2-2 | 9.809 | 57.15 | 60.73 | 3.57 |

| 2-4 | 25.046 | 55.87 | 58.15 | 2.28 |

| 2-5 | 33.559 | 56.95 | 58.05 | 1.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, J.; Liu, Z.; Zhang, Z.; Wang, Y.; Wang, L. Analysis of Waterflooding Oil Recovery Efficiency and Influencing Factors in the Tight Oil Reservoirs of Jilin Oilfield. Processes 2025, 13, 1490. https://doi.org/10.3390/pr13051490

Cao J, Liu Z, Zhang Z, Wang Y, Wang L. Analysis of Waterflooding Oil Recovery Efficiency and Influencing Factors in the Tight Oil Reservoirs of Jilin Oilfield. Processes. 2025; 13(5):1490. https://doi.org/10.3390/pr13051490

Chicago/Turabian StyleCao, Jie, Zhou Liu, Zhipeng Zhang, Yuezhi Wang, and Liangliang Wang. 2025. "Analysis of Waterflooding Oil Recovery Efficiency and Influencing Factors in the Tight Oil Reservoirs of Jilin Oilfield" Processes 13, no. 5: 1490. https://doi.org/10.3390/pr13051490

APA StyleCao, J., Liu, Z., Zhang, Z., Wang, Y., & Wang, L. (2025). Analysis of Waterflooding Oil Recovery Efficiency and Influencing Factors in the Tight Oil Reservoirs of Jilin Oilfield. Processes, 13(5), 1490. https://doi.org/10.3390/pr13051490