1. Introduction

Reclaimed asphalt pavement (RAP), obtained from recycling the top layer of old pavements, is used in new asphalt concrete for reducing the need for new materials and minimizing waste in roadway construction. In recent years, the use of RAP in road construction has drawn significant attention as a viable replacement for natural aggregate and binder in flexible pavement. However, the use of a higher percentage of RAP results in several concerns related to the performance and subsequent service life of asphalt pavement. One of the main challenges of using RAP in bituminous mixtures stems from the increased stiffness of aged pavement, posing a major challenge to its use in road construction. Without a softening treatment, RAP can make the mix excessively stiff and difficult to compact, potentially leading to premature pavement failure [

1]. This increased stiffness results from progressive oxidation, which modifies asphalt components and degrades its viscoelastic properties [

2]. The rigidity of RAP can be mitigated through methods such as warm mix technology, increased asphalt content, and the use of softer asphalt [

3]. These approaches reduce stiffness by softening aged asphalt without altering its chemical composition. However, at higher RAP contents, these techniques become less effective or impractical. To sustainably meet the growing demand for road materials without compromising performance, RAP must be utilized efficiently. Rejuvenators have emerged as a reliable alternative for incorporating higher RAP content, as they replenish lost aromatic components in aged asphalt, restoring its chemical structure and reducing binder viscosity. Various commercial rejuvenators (CRs) are particularly recommended for RAP levels exceeding 30% [

4]. In addition to CR, the use of waste materials as recycling agents has been found to be a sustainable solution and to promote an environmentally friendly approach to RAP utilization in road construction. The use of waste materials is also considered to a more cost-effective solution for pavement construction which needs large quantities of raw materials [

5]. The use of waste materials as rejuvenators mitigates the issue of their disposal and reduces the need for commercial production of rejuvenators. The latter involves chemical processes which produce harmful impacts for the environment. Different kinds of waste material have been considered potential sources of recycling agents and can be found elsewhere [

6]. The scope of the study is limited to the waste cooking oil (WCO) and the waste engine oil (WEO).

WEO and WCO, two different types of waste oil, have both been investigated as potential additives for asphalt mixtures by numerous studies [

6,

7,

8,

9,

10,

11,

12,

13,

14]. These studies found that WCO and WEO could significantly change some asphalt mixture properties. Other earlier investigations concluded that using a significant amount of aromatic fractions or resin can have a stronger rejuvenating effect and proposed WEO and WCO based on different characteristics [

15]. The majority of the essential physical and chemical features of bitumen are shared by WEOs, since both of them originate as a product of petroleum refinement. Due to its similarity to the molecular structures of asphalt with sufficient aromatic concentration, WEO modifies the components and revitalizes aged asphalt. However, till 2009, very few studies attempted to explore the potential of WEO as a rejuvenator. According to research conducted over the last ten years, WEO improves several properties, including low-temperature cracking [

16], fatigue resistance [

17], workability [

18], and temperature sensitivity [

19]. In addition to WEO, various kinds of edible vegetable oil, animal oil, and palm oil are utilized in frying and cooking processes, which produce significant amounts of WCO [

20]. The organic acid component of WCO belongs to the family of cohesive agents [

13]. RAP’s cohesive element reduces viscosity, reducing the binder’s surface tension. It also produces cohesion and removes the air curtain that encloses the aggregate. As a result, the addition of cohesive agents and new bituminous materials accelerates the development of homogeneous mixtures. While the addition of waste oil has been shown to enhance pavement performance, it may also reduce ductility and weaken the adhesion between aggregate and asphalt [

21], potentially impacting Indirect Tensile Strength (ITS). Therefore, a thorough understanding of the effects of waste oil on the ITS of rejuvenated RAP asphalt mixtures is crucial, particularly when incorporating higher percentages of RAP.

The mechanical characteristics and resistance to distress of asphalt mixes incorporate two important parameters, the Indirect Tensile Strength (ITS) and ITS loss. Indirect tensile strength is a parameter which is used to measure the asphalt mix’s ability to withstand the shear failure which materializes in the form of rutting which is a commonly observed distress in flexible pavements [

22]. ITS loss refers to the reduction in ITS of a wet sample compared to a dry sample. This parameter shows the pavement’s ability to withstand damage due to water accumulation. Developing a prediction model for ITS and ITS loss in RAP-incorporated HMA is essential for assessing pavement durability and performance. It enables early detection of distress, evaluates material quality, and predicts pavement lifespan, aiding in proactive maintenance and rehabilitation. Given the influence of traffic, environmental conditions, and material properties on ITS loss, such models help optimize mix designs and ensure long-term pavement sustainability. Unfortunately, none of the studies attempted to develop prediction models for ITS and ITS loss for RAP incorporated HMA mixtures rejuvenated by two such potential rejuvenating agents, WCO and WEO. The current models for prediction asphalt mix properties are empirical and do not provide the adaptability to be used in unique cases with non-traditional components [

23]. Hence, the present study aimed to develop prediction models tailored for measuring ITS and ITS loss using statistical and machine learning techniques.

Researchers have studied methods for predicting and optimizing the ITS properties of RAP-containing rejuvenated asphalt mixtures through computational modeling. One approach simulates the behavior of asphalt mixtures under different loading and environmental conditions. Another method involves analyzing the properties of asphalt mixtures with varying RAP content and evaluating their field performance through experimental testing. Statistical methods have traditionally been used to predict the ITS characteristics of asphalt mixtures. Garrick and Biskur developed a regression model to examine the relationship between ITS and asphalt properties [

23]. The study involved mixtures made with two types of aggregate (gravel and traprock) and 15 different asphalt types. A regression analysis indicated that, as ITS increased, penetration decreased. Additionally, the slope of the relationship between penetration and tensile strength varied significantly depending on the aggregate type. Another study explored the effect of RAP combined with waste high-density polyethylene on the indirect tensile stiffness modulus (ITSM) of asphalt concrete surfaces at different RAP contents [

24]. The regression analysis revealed that ITSM increased with higher RAP content but decreased as the test temperature rose. Similarly, a regression model was used to optimize RAP content for each RAP size while ensuring the unconfined compressive strength (UCS) remained above the lower limit of 27.6 MPa [

25]. The results showed that incorporating RAP led to reductions in ITS, UCS, and the elastic modulus. These studies have relied on statistical models and empirical data analysis to establish relationships between input variables and output responses. However, with the advent of machine learning, more advanced computational techniques have emerged, enabling the efficient processing of large datasets and the identification of complex patterns. The use of machine learning techniques, for the prediction of ITS and its loss of rejuvenated asphalt mixtures incorporating RAP, has been rarely found in the literature in which such a combination is attempted [

26,

27,

28,

29,

30]. These studies compare the performance of statistical and machine learning methodologies for prediction of ITS and its loss. Previous studies have mainly employed analytical models, on standard asphalt mixes, for the prediction of ITS using stress parameters. This would be the first study in which machine learning techniques have been used to predict ITS and its loss for asphalt mixes with rejuvenation and high RAP content. The following objectives have been set for this study:

The previous literature shows a lack in the development and suggestion of workable models which can be used for optimizing mix design of asphalt mix with rejuvenated asphalt and high RAP content. Hence, this study aims to identify optimal modeling methods to predict ITS and ITS loss in rejuvenated asphalt mixtures with RAP concentration by contrasting and evaluating the efficacy of statistical and machine learning methodologies.

The remainder of this paper is divided into the following sections:

Section 2 presents an overview of the modeling techniques used for the study.

Section 3 describes the research approach adopted for experimental work. Results and discussions are provided in

Section 4.

Section 5 presents the comparison of developed models. The main conclusions of this study are finally outlined in

Section 6, along with suggestions for additional research.

2. Modeling Techniques

Three types of modeling technique have been used in this study, namely, multivariate regression model, support vector machines (SVM), and artificial neural networks (ANNs). Regression models are statistical models that take the form of Equation (1) [

31].

where

Y is the output,

a and

b are the model coefficients, and

x is the vector of input parameters. The coefficients are determined using ordinary least squares and accepted if they significantly impact the model, indicated by a t-value with a 5% probability threshold. SVMs are widely used for modeling discrete or pattern recognition data, and are increasingly applied to prediction problems [

32]. They identify data samples that map to hyperplanes while maximizing their separation (as shown in

Figure 1), known as support vectors [

33,

34,

35].

Due to dataset complexity, input parameters are mapped using a kernel function, similar to regression (see Equation (2)).

where

Y is the output parameter,

b and

are the constants for the mapping function, and bias and

W are the model coefficients for each support vector.

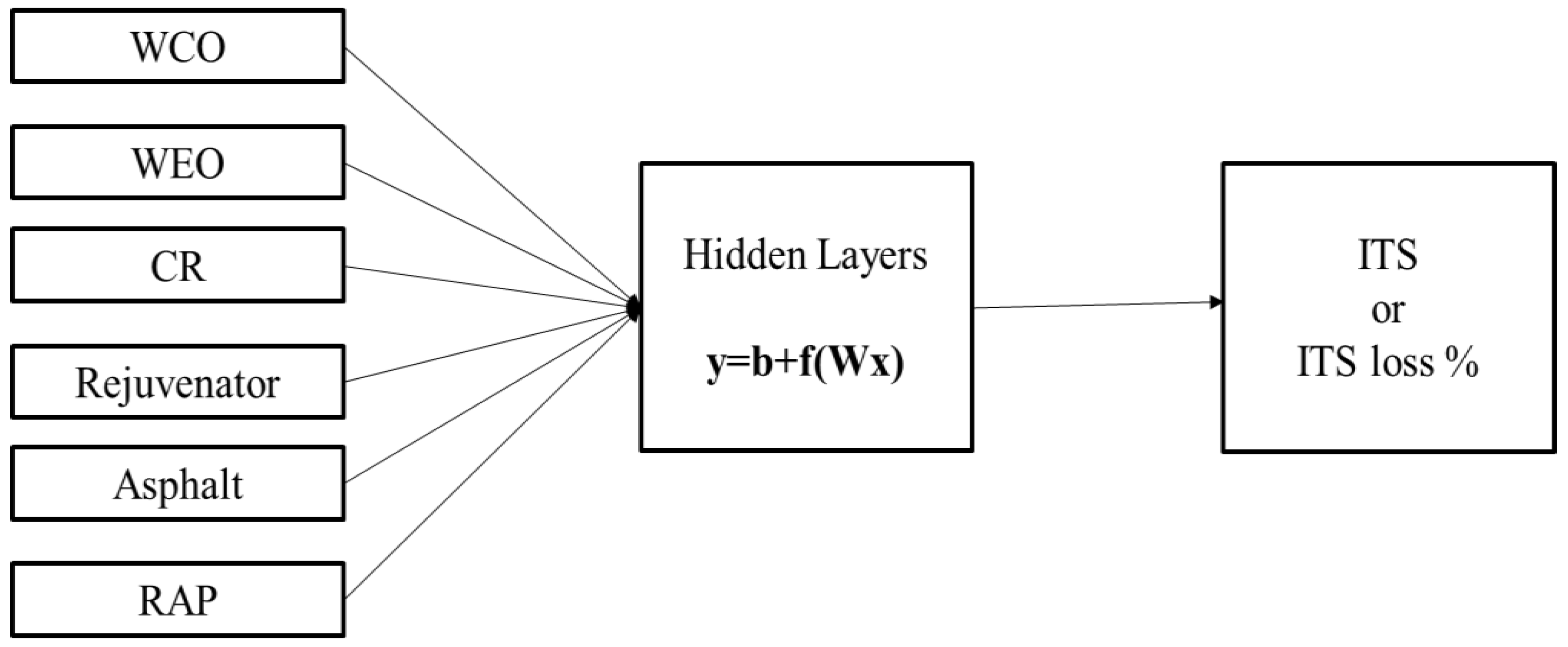

The ANN model is another popular branch of machine learning techniques, which is considered very efficient at predicting problems. This is mainly due to its generalization abilities for noisy data [

36]. There are different types of ANN, such as multilayer feedforward (MLFF), radial basis function (RBF), and general regression neural network (GRNN) [

34]. In this study, MLFF has been used due to their popularity among researchers and simpler architecture [

37]. MLFF architecture is depicted in

Figure 2, in which the variables used in this study have also been shown. It comprises three types of layer, namely, input, hidden, and output. The input layer feeds the network with the independent variables, which are moved forward to the hidden layer(s). The hidden layer comprises several neurons, each taking all the input values and processing them through an activation function after estimating weights and bias. The processed quantity is moved forward to the next hidden layer (if there is any) or the output layer, which takes these quantities and processes them to give the final output. The predicted output is compared with the actual values and the sum of the square of errors is used to update the weights and biases of the network [

38].

There can be several parameters of MLFF architecture which affect its accuracy, such as the number of hidden layers and hidden neurons in each layer, activation function, learning algorithm, etc. It is virtually impossible to determine the optimum combination of these parameters without fixing any of them [

39]. This is due to the large number of parameters involved in the training of MLFNN, resulting in infinite combinations which are practically impossible to compare completely. Hence, the activation functions for the hidden layer were set as hyperbolic while that for the output layer was set as a logistic, which is shown in Equations (3) and (4) [

40]. The activation functions transform the outputs from the previous layers, with the use of estimated weights, and provide outputs for the model or the proceeding layer. Conjugate gradient and backpropagation learning algorithms were used. The maximum number of hidden layers was set at 2, while the maximum number of hidden neurons in each layer was set at 11. The optimum values of hidden layers, neurons, and their associated weights were found by trying all possible combinations within the given ranges and then selecting the combination with the highest accuracy.

4. Results and Discussion

The regression model developed for predicting ITS is shown in Equation (7), while that for ITS loss % is shown in Equation (8). The model fitness parameters are shown in

Table 1, while the scatterplots are plotted in

Figure 5, which show the comparison of observed and predicted values for the training and test datasets.

Figure 6 shows the comparison of accuracy parameters calculated for the regression models for training and test datasets.

Each type of rejuvenator was taken as a dichotomous dummy variable in the model. Equation (7) shows that type of rejuvenators increases the tensile strength with the highest increase observed for WCO, shown by its coefficient which is the highest for the model. These results conform to those of previous studies, such as Ziari et al. [

42]. This impact is attributed to the rejuvenator’s molecular interaction with asphaltene molecules in RAP [

43]. RAP content did not have a significant effect on the model which could be due to its range, and a wider range may show a significant impact on the model. Rejuvenator content has a negative impact on ITS. The model presented by Equation (8) shows that all rejuvenator types decrease the loss in ITS with the highest effect (coefficient) due to WEO, in addition to asphalt content. This could be attributed to the molecular interaction of these rejuvenators, as stated above. Moreover, RAP and rejuvenator content increase the loss in ITS, hence, it could be said that using them in lower proportions increases the durability of asphalt mix. The previous studies have attributed such behavior to the loss in viscosity of these asphaltic items due to their ageing [

44].

Table 1 shows that both models had a statistically significant F-statistic (

p-value = 0), which confirms that the regression models can capture significant variation in the data.

Figure 5a,b show a wide spread of the scatterplot for training and test datasets.

Figure 6a shows that MAE increases by 20 kPa and MAPE increases by 5% for the test dataset as compared to training data, while predicting ITS using a regression model. On the other hand, there is no significant change in MAE for the ITS loss prediction model (

Figure 6b) between test and training samples, while an approximately 50% increase in MAPE is shown for test samples of this model, compared to the training dataset.

Table 2 shows the parameters for SVM models for ITS and ITS loss % prediction while the weights for this model are provided in

Appendix A. The kernel function used was the radial basis function, which gave the best accuracy. There are no restrictions for the significance of any parameter, hence, all six parameters were used as an input for the model.

Figure 7 shows the scatterplots for the predicted values while error values are shown in

Figure 8. A total number of 104 samples were identified from the training dataset as the support vectors for the ITS prediction model, while 114 of them were found as support vectors for the ITS loss % prediction model. The number of support vectors in this problem are considerable large which makes the model computationally problematic and inappropriate for optimization of parameters [

45].

Figure 7 shows a close spread of the predicted values with very few values (for training and test datasets) in the middle range having a high prediction for ITS (

Figure 7a).

Figure 8a presents an increase of approximately 15 KPa in MAE and 5% in MAPE for the test dataset compared to training samples.

Figure 8b shows a negligible change in MAE (%) and a 50% increase in MAPE for test samples of the ITS loss prediction model, compared to training samples. The R

2 value for the ITS prediction model was very low for the test dataset, and significantly different from the training dataset which is an indication of overfitting issue [

46].

Parameters for ANN models are presented in

Table 3, while the scatterplot and error values for these models are shown in

Figure 9 and

Figure 10, respectively.

Appendix B contains the values for the weights of neurons in the ANN model. Two hidden layers were required in both these models to have maximum accuracy. The number of hidden neurons in the first layer was eleven for ITS prediction, while those for ITS loss prediction were 6. The second hidden layer in both cases had 8 neurons. The number of hidden layers can enable accurate predictions for complex problems [

47], such as the one at hand in this case which has multiple variables with unknown impacts. However, increasing the number of layers to a high number can have a large impact on processing time. In this regard, hidden layers equal to or less than 3 are considered appropriate [

47]. The dual learning approach, which has been adopted in this study for training the neural networks, was found to be helpful in previous studies to refine the results [

48].

Figure 9a shows that only a couple of values from the middle range in the test dataset were predicted high by the model, while all other predicted values seem close to the observed data.

Figure 9b shows that most of the test samples have a wider spread as compared to the training samples for ITS loss predictions.

Figure 10a shows an increase of 25 KPa in MAE and 5% in MAPE for the test dataset in comparison to training samples.

Figure 10b shows an increase of approximately 3% in MAE and 55% for MAPE for ITS loss predictions on test samples as compared to training samples.

All models have shown a high change in MAPE for ITS loss prediction while having a small change in MAE. This could be because ITS loss has a limited range (>1 and <100), hence, a small increase in its value results in a large increase in the percentage error.

6. Conclusions

This study was aimed at developing models for predicting ITS and ITS loss for rejuvenated asphalt mix with a high RAP content. Three types of technique were used for this purpose, namely, a linear regression model, SVM, and ANN. The type of rejuvenator and the content of asphalt, rejuvenator, and RAP were used as inputs in the model. The regression model showed that the use of WCO would increase the initial ITS for the mix, while the use of WEO can give better durability than other types of rejuvenator. Secondly, it was found that using the lower content of asphalt and RAP gives better durability. ANN performed better than the other models used in this study. The scatterplots for these models showed less variation compared to the other models. Moreover, error parameters for ANN models, except MAE for ITS loss % prediction, were lower than regression models and SVMs. MAE for ITS loss % was found to be approximately the same for all models. The models developed in this study would be useful for researchers involved with the design and testing of modified asphalt mixes, especially with RAP content. However, future research should expand experimental data with diverse variables to refine prediction models. Additionally, studies should assess long-term aging, economic and environmental impacts, alternative rejuvenators, and real-world validation for sustainable pavement development.