A Microgrid Simulation Platform Based on Cyber-Physical Technology

Abstract

1. Introduction

- (1)

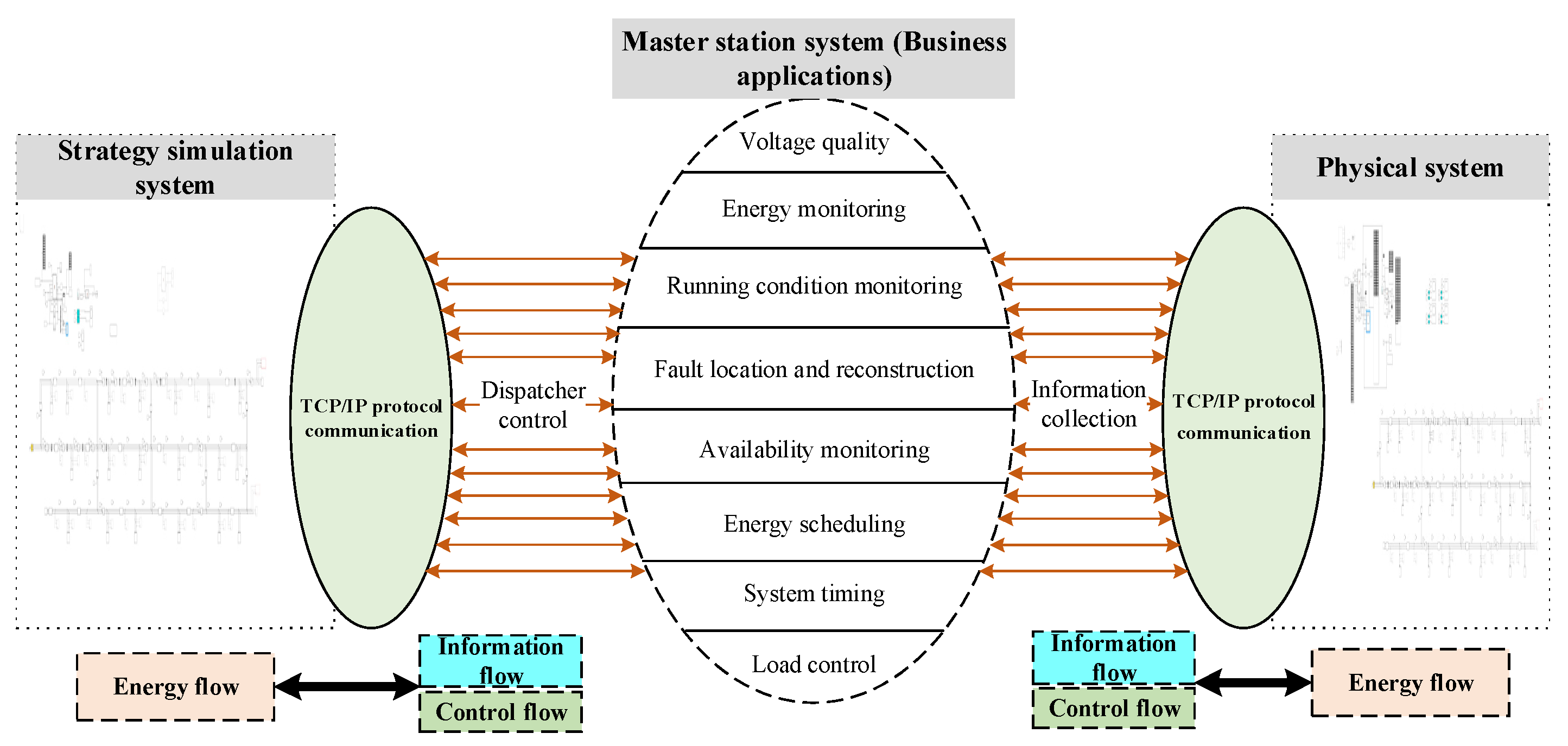

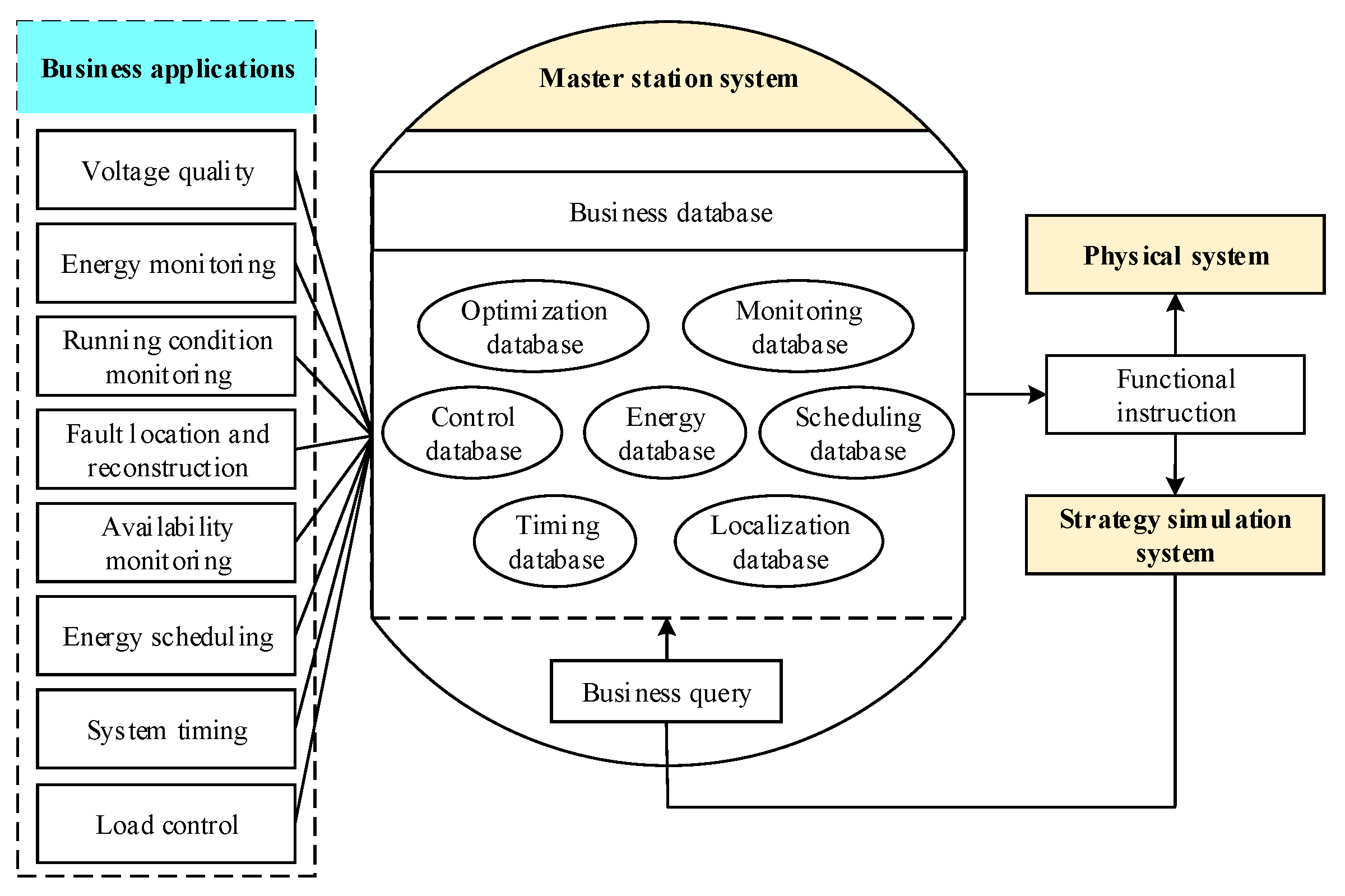

- An architecture integrating cyber-physical technology and business applications is proposed. This architecture incorporates the physical system, the central station system, and the strategy simulation system. By leveraging the business query method of the central station system, real-time simulation of various business applications is achieved.

- (2)

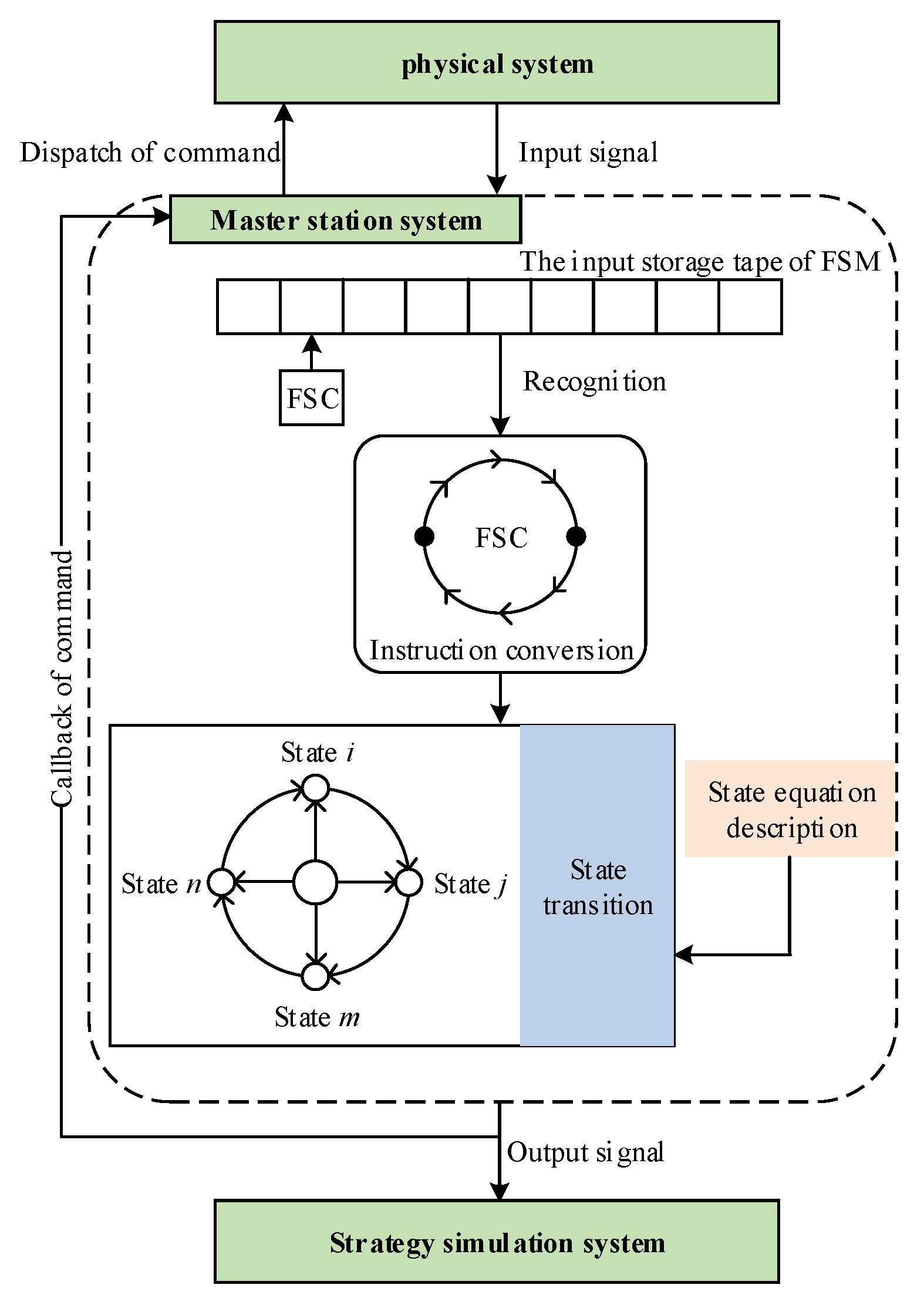

- An FSM model for the integrated simulation platform is developed. Through state division and transitions, the deep integration of the physical system, the central station system, and the strategy simulation system is realized, thereby enhancing simulation efficiency and business scenario reproduction capabilities.

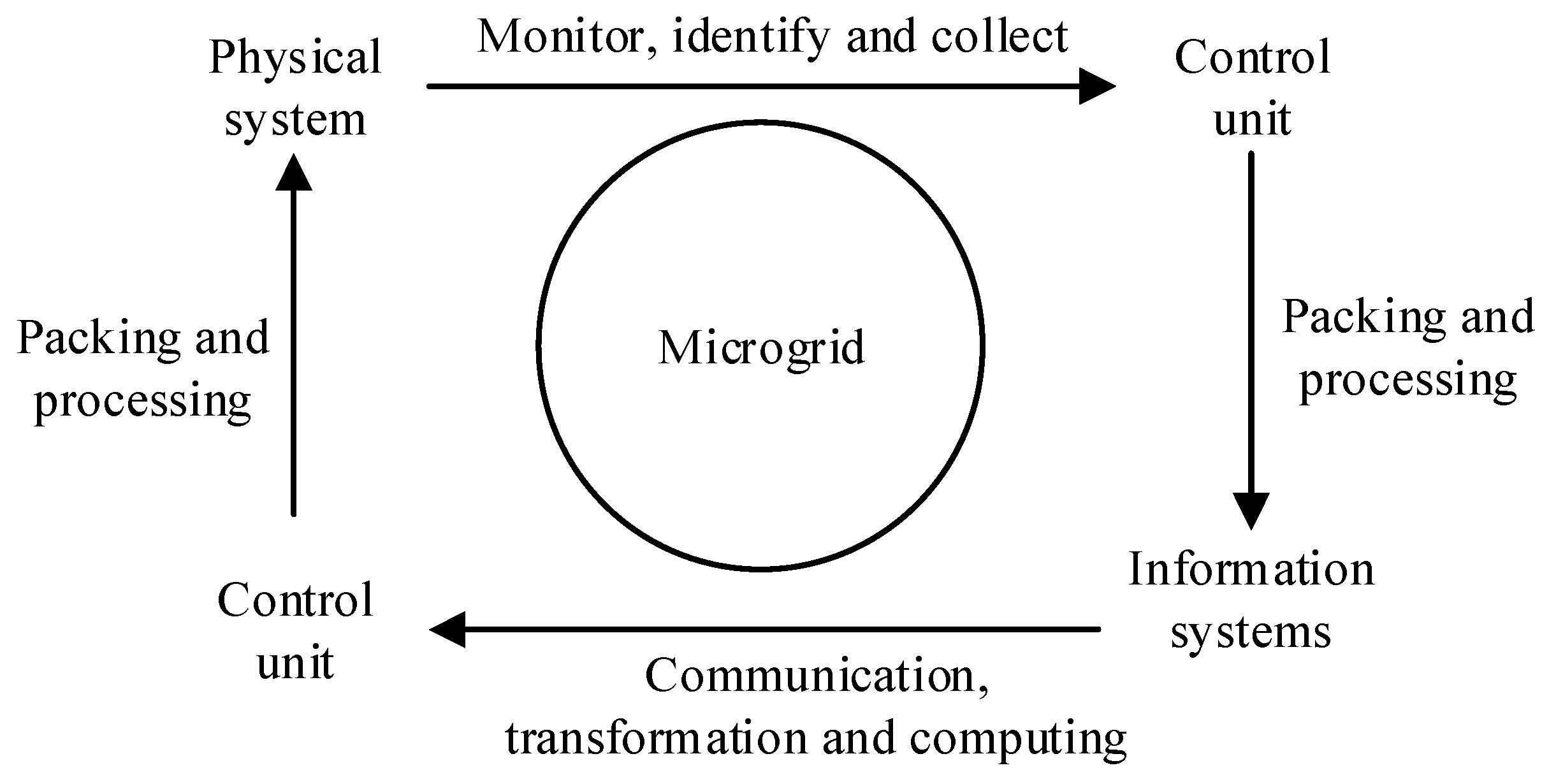

2. Microgrid CPS and Business Integration Methods

2.1. Cyber-Physical Technology

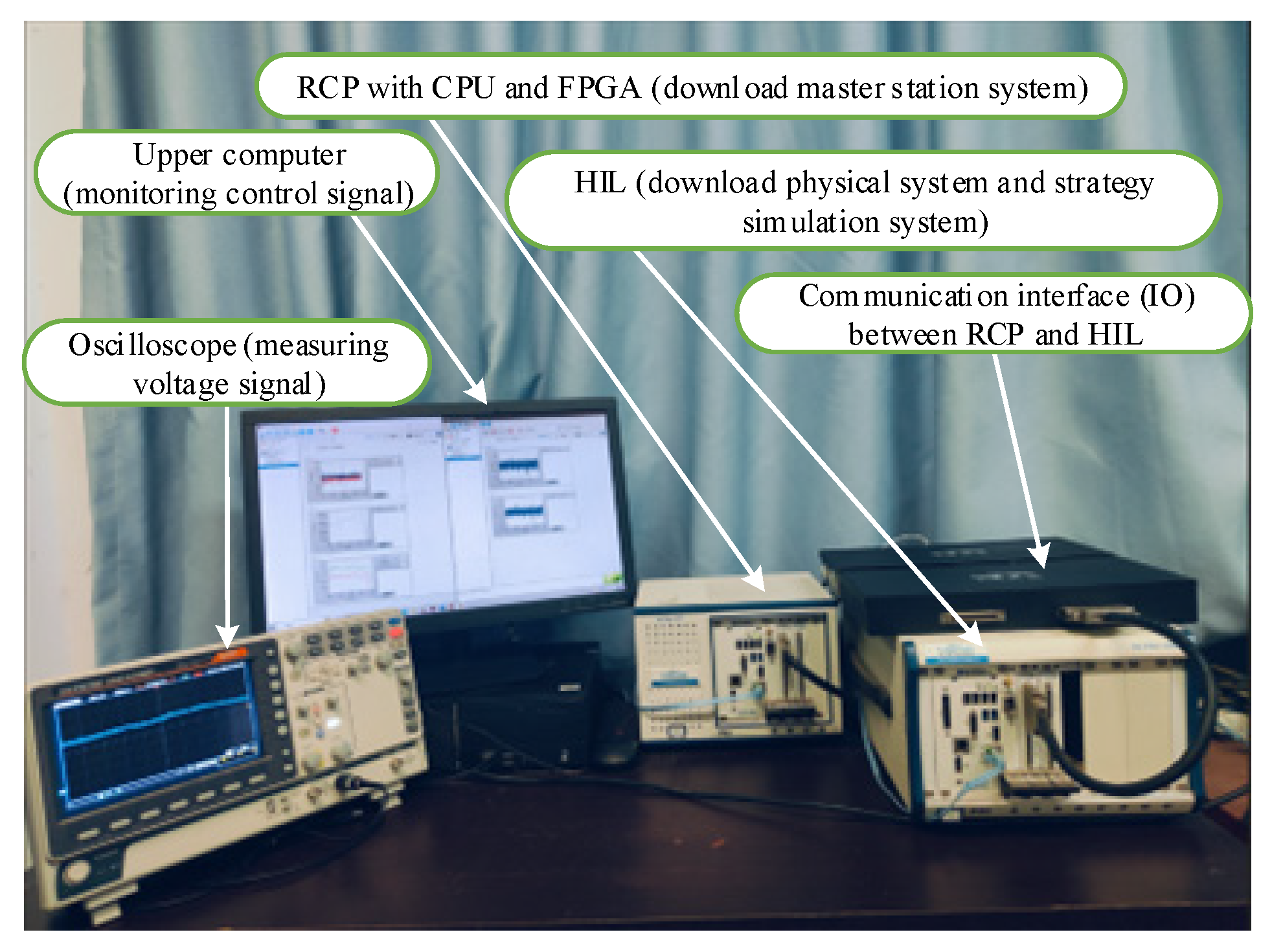

2.2. CPS-Based Microgrid Simulation Platform

3. Construction of Simulation Model Based on FSM

3.1. Principles of FSM

3.2. Mathematical Description of FSM Model

- (1)

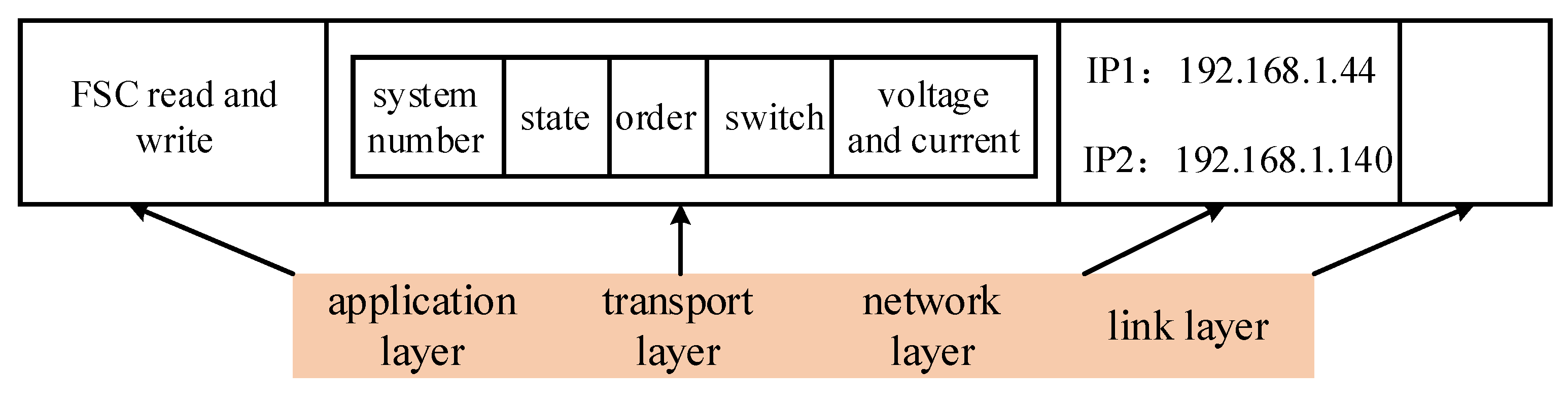

- The TCP/IP communication protocol defines the four-layer framework of network interconnection, as shown in Figure 6. This paper mainly applies the application layer, transport layer, and network layer of the TCP/IP communication protocol. The network layer is responsible for finding a suitable path for the data packets to be sent in the complex network environment. The specific address information is 192.168.1.44 and 192.168.1.140.

- (2)

- The transmission layer carries transmission information, including system number, status, command information, switch information, node voltage, and current information. The transmission layer sends them in the specified order.

- (3)

- The application layer can support user applications. When the application layer is combined with the finite state machine, the FSC is responsible for reading and writing the data of the transport layer. After reading and before writing, it needs to go through the instruction transition and state transition of the finite state machine model.

4. Fault Optimization Business State Transition Based on the Simulation Platform

4.1. Defining Fault Optimization State Strategy

- (1)

- The system number of the physical system is 0, and the communication resolution address is located in the first bit of the TCP/IP communication layer. The communication information resolution address of its state is located in the second bit of the TCP/IP communication layer. The specific status attributes are as follows:

- Initial state: The physical system is powered on and initialized.

- Data collection state: The energy information of each node in the topology is monitored at all times, including current information and voltage information.

- Recloser state: In case of a fault, the physical system will initiate the reclosing operation first and solve the fault problem separately in the physical system.

- Fault state: After a reclosing failure, the physical system is defined as a fault state.

- Finite state machine communication state: The state definition of a finite state machine in a physical system that interacts with the main station system, and can exchange communication layer information through the TCP/IP protocol.

- Waiting state: The physical system is waiting for instruction information optimized by the main station system fault.

- (2)

- The series number of the main station system is 1, and the communication resolution address is located in the first bit of the TCP/IP communication layer. The communication information resolution address for its status is located in the second bit of the TCP/IP communication layer. The specific status attributes are as follows:

- Finite state machine communication state: The state definition of the finite state machine in the main station system when it interacts with the physical system and policy simulation system, and can exchange communication layer information through the TCP/IP protocol.

- Finite state machine parsing state: When information exchange occurs between the physical system and the main station system, it parses the TCP/IP protocol communication layer. The parsing method is to copy the TCP/IP protocol communication layer information into the input storage tape of FSM. FSC will identify each storage tape based on its location and correspond the identified content to the optimization library in FSM. The optimization library will determine the state transition and output the content of the TCP/IP protocol communication layer.

- Judging-the-optimization-result state: The simulation results of the main station system’s multi-directional processing strategy simulation system, such as simulation time, solution consumption time, voltage deviation, voltage mean square error, and number of switch actions, are judged.

- Issue functional instruction state: Instruction information with good performance is issued to the physical system.

- (3)

- The system number of the strategy simulation system is 2, and the communication resolution address is located at the first bit of the TCP/IP communication layer. The communication information resolution address for its status is located at the second bit of the TCP/IP communication layer. The specific status attributes are as follows:

- Simulation execution status: Execute parsed instruction information and simulate different optimization paths.

- Simulation result feedback status: The strategy simulation system feeds back the simulation results to the main station system and transitions the state to the initial state.

4.2. Defining Fault Optimization State Transition and Communication

- (1)

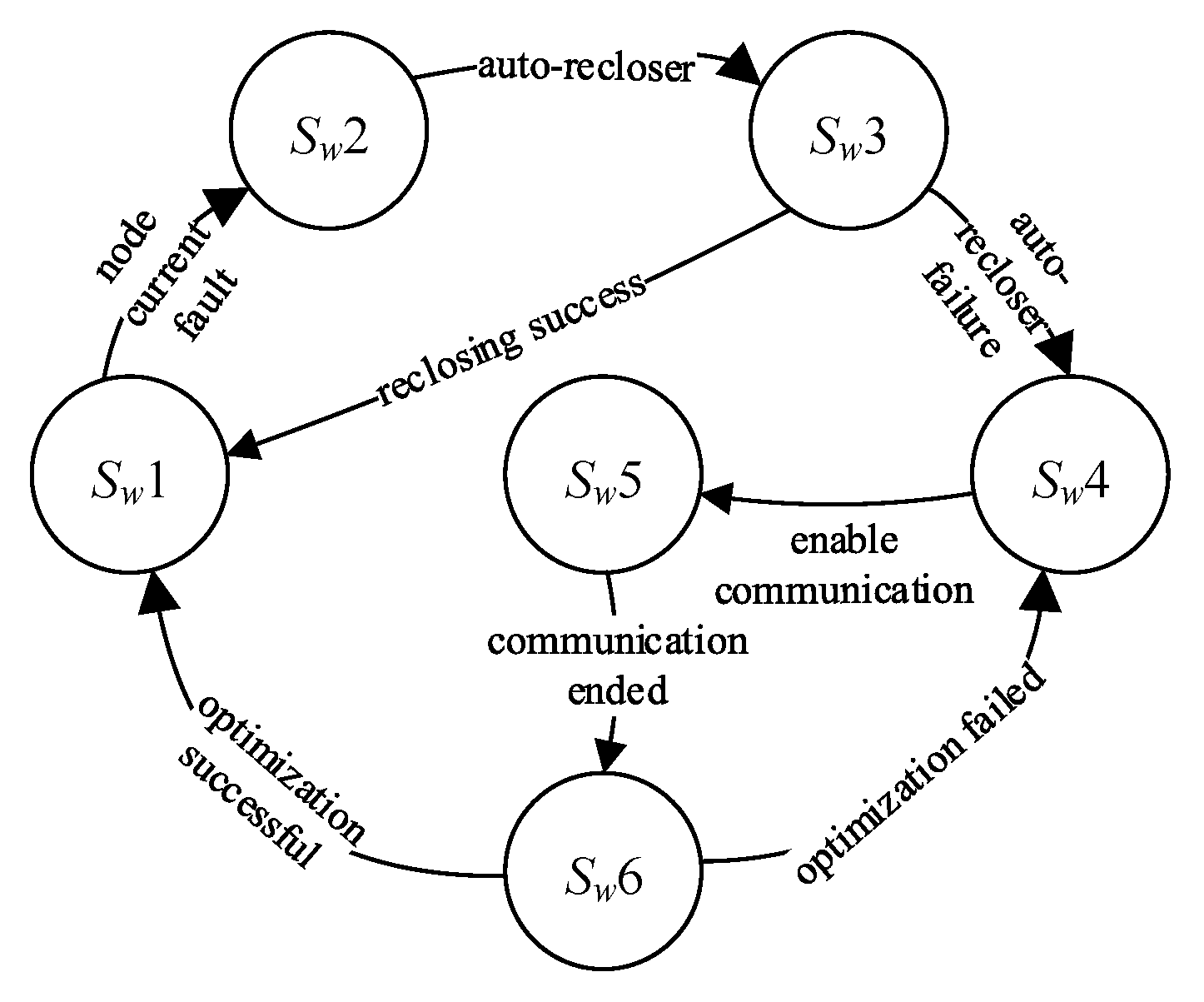

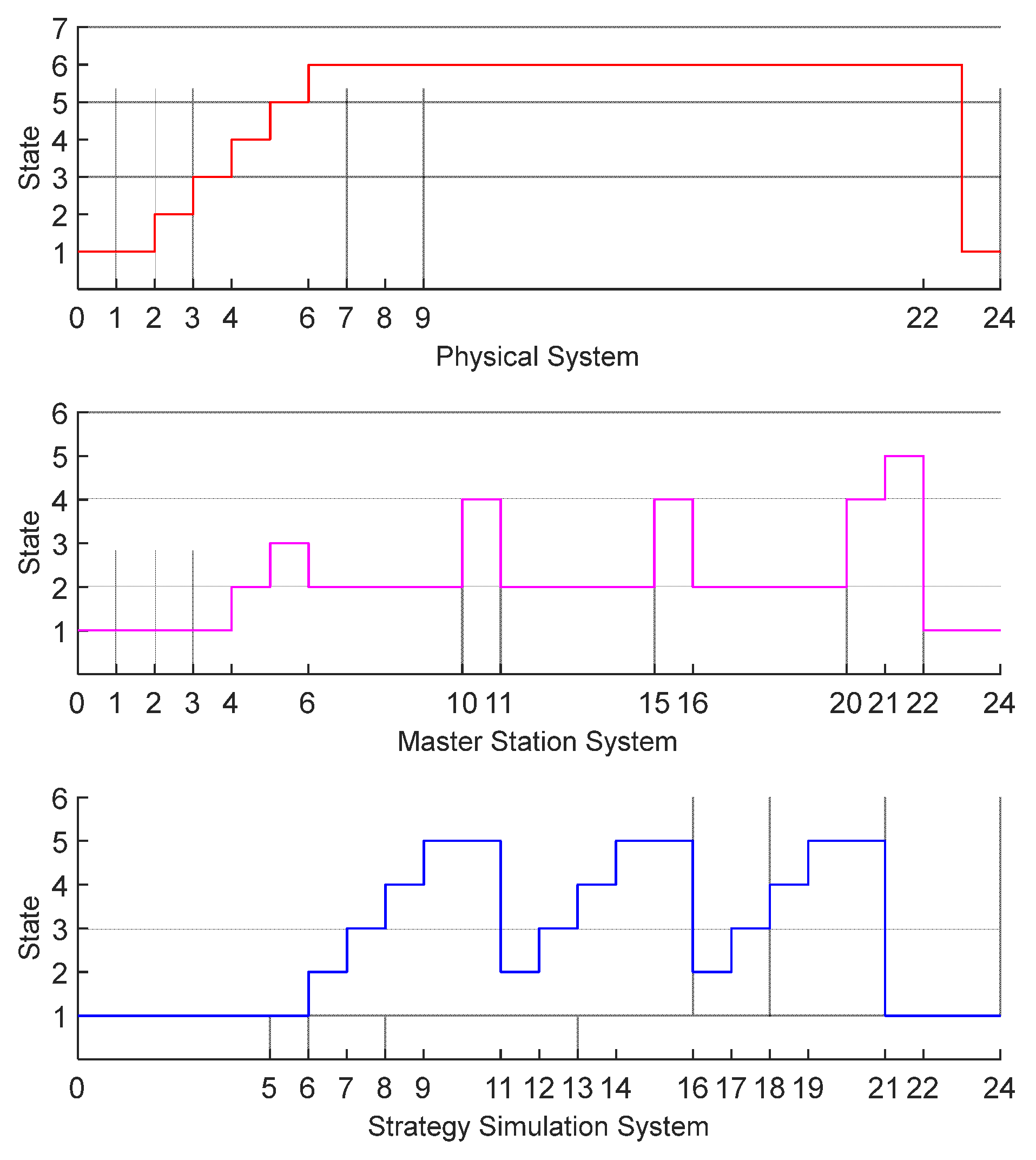

- The state transition of the physical system in the simulation platform is shown in Figure 7. The physical system initially resides in the initial state. When a significant change in the monitoring node’s current occurs, the state transitions to the data collection state, and real-time current information from each node is collected. Then, using a difference-based method, the fault node on the primary side is identified, and the switches on both ends of the fault node are disconnected.

- (2)

- After the fault node is determined, the state transitions to the reclosing state. The physical system then initiates the reclosing operation and re-evaluates the processed current difference. If the current state is normal, the fault is cleared; if the reclosing fails, the fault information is locked, and the state transitions to the fault state.

- (3)

- In the fault state, the physical system uploads the system ID, current state, fault node ID, instruction information, switch information, node voltage, and current information (collectively referred to as program variable parameters) through TCP/IP communication to the master system. After the information is transmitted, the system then transitions to the waiting state.

- (4)

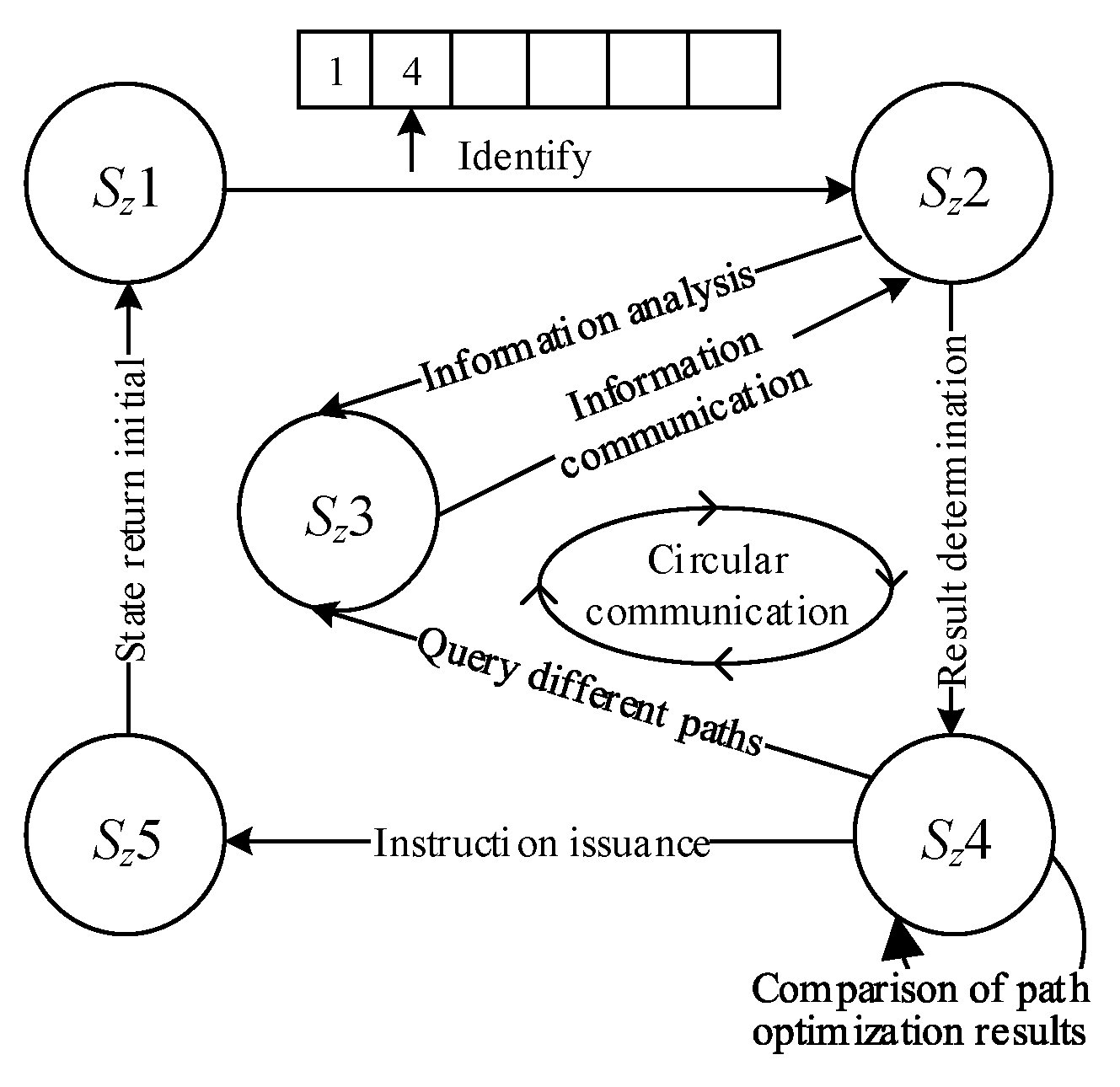

- The state transition of the master station system in the simulation platform is shown in Figure 8. Initially, the master station system is in the initial state. When the second position of the program variable parameters received from the physical system equals 4, the state transitions to the finite state machine communication state, where the received information is parsed. At this point, the state transitions to the finite state machine parsing state, where the fault node is used to query the corresponding instruction and switch information. The specific path information for fault optimization is shown in Table 3. Upon successful parsing, the state transitions back to the finite state machine communication state, where communication with the strategy simulation system occurs.

- (5)

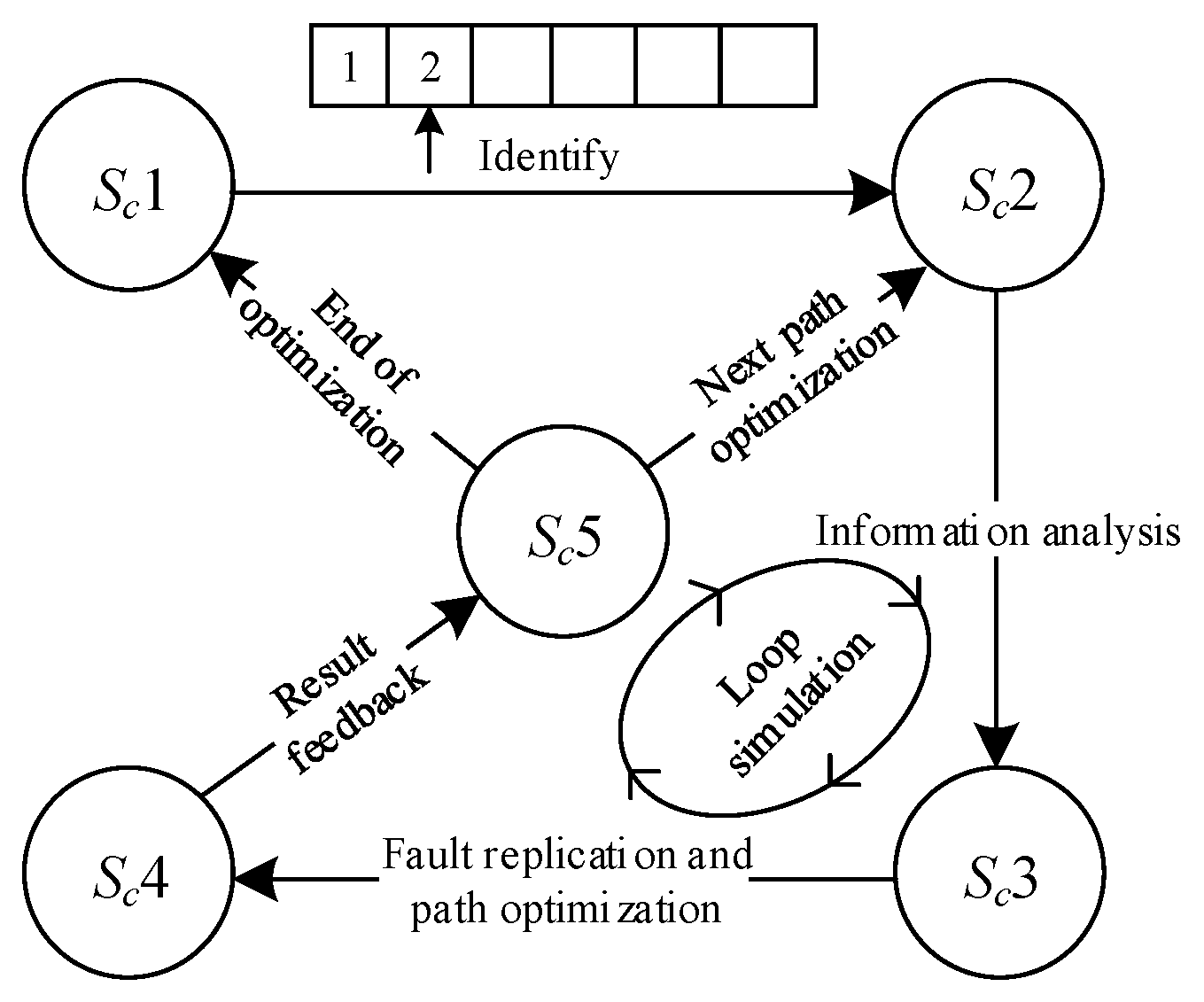

- In the simulation platform, the state transition of the strategy simulation system is shown in Figure 9. The strategy simulation system is initially in the initial state. When it receives the program variable parameter with the second position as 2 from the master station system, the state transitions to the finite state machine communication state and begins parsing the received information. At this point, the state transitions to the finite state machine parsing state, and the parsing process is as follows: a. Copy the fault information of the physical system based on the fault node number; b. Modify the topology based on switch and instruction information, and optimize different paths. During the execution of related instruction information, the state of the strategy simulation system is the simulation execution state. After the simulation concludes, the state transitions to the simulation result feedback state, where the optimized program variable parameters (mainly voltage and current information) are uploaded to the master station system.

- (6)

- When the master station system in the finite state machine communication state receives the result feedback information from the strategy simulation system, the state transitions to the judgment of optimization results state. The system then evaluates and records the feedback information for optimization results. At this point, the first fault optimization is completed. The master station system will continue to communicate in a loop with the strategy simulation system, based on different path optimization information from the optimization library, until all path optimizations are simulated and completed.

- (7)

- Similarly, the strategy simulation system in the simulation result feedback state will continue to identify the program variable parameter in the second position from the master station system and continue performing the loop simulations until all path simulation results are completed. All feedback information will then be uploaded, and the final state transitions to the initial state.

- (8)

- After the final path optimization result feedback, the master station system will perform a determination based on the mean square deviation and simulation time for all path optimization information. The optimal result will be selected, and the path optimization information with the best result will be sent to the physical system. The state will then transition to the initial state.

- (9)

- The physical system, in the waiting state, will execute the best path information sent by the master station system, control the switches for fault optimization, and, after a successful optimization, the state will transition back to the initial state.

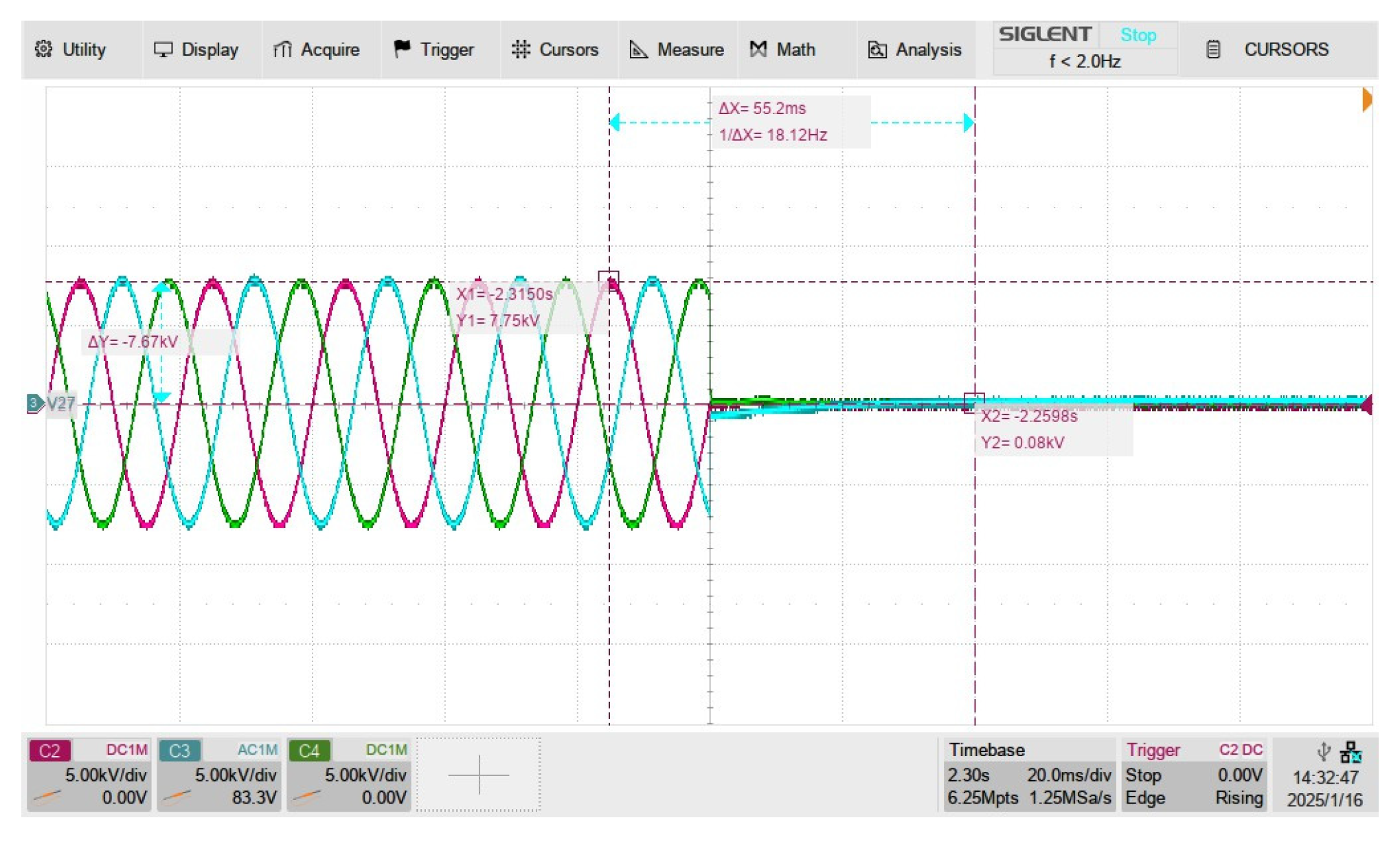

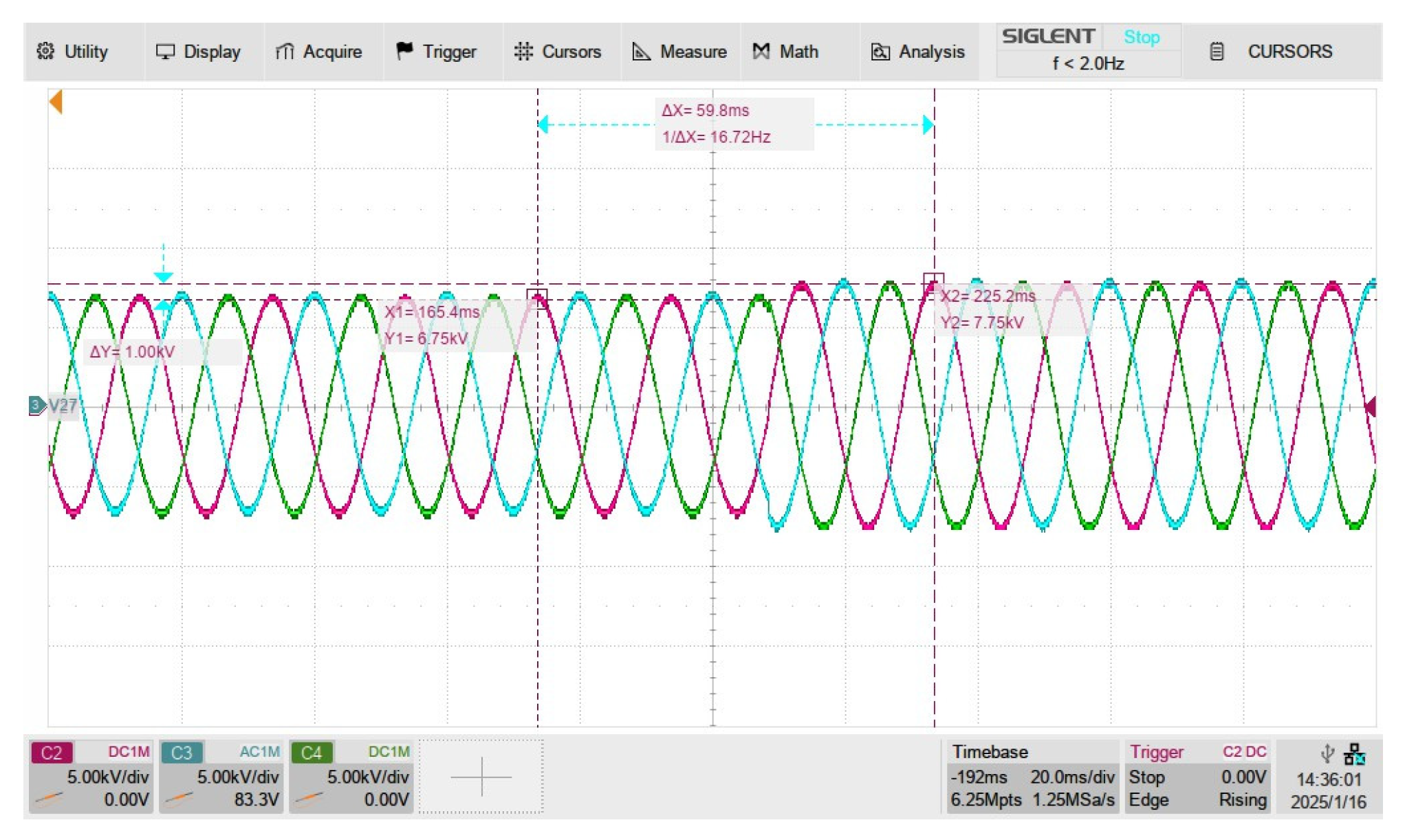

5. Simulation Experiment Verification and Analysis

5.1. Simulation Experiment Analysis

5.2. Conclusion Analysis

- (1)

- When the main objective is to minimize the voltage mean square deviation and the average voltage deviation, while auxiliary objective is to minimize the number of switching actions, the first recovery path is optimal;

- (2)

- When the only objective is to minimize the number of switching actions, the second recovery path is optimal;

- (3)

- When taking the minimum voltage mean square deviation, the minimum average voltage deviation, and the minimum number of switching actions as the same weight objectives, the third recovery path is optimal.

6. Conclusions

- (1)

- A CPS-based microgrid simulation platform is proposed, which integrates information physics technology and business architecture to achieve real-time simulation and reproduction of business scenarios. In theory, it can be connected to the main control system to achieve state decision-making and control.

- (2)

- The fault optimization time of the proposed platform in this paper is 0.512 s, which consumes the least time compared with the traditional optimization methods, and is reduced by about 16–86.6%.

- (3)

- The proposed platform can design different state transition strategies according to different business. Taking fault optimization business as an example, the best path can be selected through state transition, and the optimal fault recovery of the physical system can be achieved through communication and real-time control.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hirokazu, I.; Honoka, D.; Soshi, S.; Hidehiko, T.; Yoshikiyo, H.; Takato, N.; Nobuyoshi, N. Enhancing understanding of pressure drop in carbon porous electrodes for vanadium redox flow batteries. J. Energy Storage 2023, 73, 109066. [Google Scholar]

- Yang, Y.; Lu, Q.; Yu, Z.; Wang, W.; Hu, Q. Multi-Type Energy Storage Collaborative Planning in Power System Based on Stochastic Optimization Method. Processes 2024, 12, 2079. [Google Scholar] [CrossRef]

- Yang, Q.M.; Li, G.F.; Bie, Z.H.; Wu, J.Y.; Lin, C.F.; Liu, D.F. Coordinated Power Supply Restoration Method of Resilient Urban Transmission and Distribution Networks Considering Intermittent New Energy. High Volt. Eng. 2023, 49, 2764–2774. [Google Scholar]

- China National Knowledge Infrastructure. Available online: https://kns.cnki.net/kcms2/article/abstract?v=_pLk7jldQwhLeziox4zGOk3D4UsyyRQEE1hIx3i7AKGHnjuAiWUSpyijOuUPM7h40Dxt0bdJFTPk0eje3PR06M5YpzwlcQsVnHfa6GxLD2AYByXu_MYWaInYy8oJSceNUvE1aDw8DLWKejnJMw6dV7ghGGGXW3LY0Ukz74LYc5snz-Id5gUPCQISm5VMFMP3&uniplatform=NZKPT&language=CHS (accessed on 15 November 2024).

- Yang, H.; Yin, B.; Meng, K.; Yu, H.; Zhou, N.; Xu, Z. Distributed Robust Optimal Scheduling of the New Interconnected Power System with the Inter-province and Intra-province Considering Moment Uncertainty of Source Load Power. Electr. Power Constr. 2023, 44, 98–110. [Google Scholar]

- Yang, L.; Huang, Z.H.; Chen, J.H.; Zheng, D.L.; Hong, M.Z.; Liu, J.X. Optimal Stability Analysis of DC Microgrid Based on Crisscross Optimization Algorithm. High Volt. Eng. 2023, 49, 4632–4641. [Google Scholar]

- Zhang, J.M.; Ouyang, S.; Wu, H.; Xin, X.; Huang, Y. Optimal configuration of grid-side energy storage considering reliability and operation economy of distribution network. Electr. Power Autom. Equip. 2024, 44, 62–68+85. [Google Scholar]

- Li, L.J.; Xu, Y. Flexible DC distribution network fault location method based on beetle swarm optimization algorithm. J. Phys. Conf. Ser. 2023, 2625, 012001. [Google Scholar] [CrossRef]

- Dong, G.C.; He, C.; Liu, X.; Nan, L.; Liu, T.Q.; Zhang, Y.Q. Coordinated recovery method of post-disaster distribution network cyber-physical system considering network reconstruction and emergency resources. Electr. Power Autom. Equip. 2024, 44, 106–113. [Google Scholar]

- China National Knowledge Infrastructure. Available online: https://kns.cnki.net/kcms2/article/abstract?v=_pLk7jldQwiDoWzfs8RAyxeeZIEbbJjLQVSuuh_uNazaRRKP2Arr2tjSEATWlpfOWbM5EqYDlxZBo0ubasdjCpUZu3Q_fuC3Gql4Lhkt6Wfr6MARMB4abRS1u76D7pPaiPpo3kamPX7kqCBcusN0Ky-QfX6gRMpbXWWKWsoOTT23WVHvr5GYHvTvW9q3Lh4f&uniplatform=NZKPT&language=CHS (accessed on 9 October 2024).

- Li, H.Z.; Guo, X.C. Reliability Evaluation of Cyber-physical System of Distribution Network Based on Petri Net. Power Syst. Technol. 2023, 47, 347–359. [Google Scholar]

- Pang, Q.L.; Han, S.Y.; Zhou, T.; Zhang, F.; Jiao, X.G.; Wang, Y.Q. False Data Injection Attack Detection of Cyber-physical Power System Based on ASRUKF and IMC Algorithms. Grid Anal. Study 2024, 52, 111–118. [Google Scholar]

- Chen, L.J.; Wang, B. Disaster recovery strategies for cyber-physical systems considering the Interdependence. Electr. Power Syst. Res. 2024, 232, 110397. [Google Scholar] [CrossRef]

- Liu, Y.L.; Feng, H.N.; Hatziargyriou, N.D. Multi-stage collaborative resilient enhancement strategy for coupling faults in distribution cyber physical systems. Appl. Energy 2023, 348, 121560. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, P. The Hierarchical Modeling Approach for Centralized Control Microgrid Cyber Physical System. Proc. CSEE 2022, 42, 7088–7102. [Google Scholar]

- Zheng, H.K.; Lv, T.T.; Sun, Y.W.; Li, Y.J.; Yu, K.D. Reliability Analysis of Integrated Energy Cyber Physical System Considering Information Equipment Failure. High Volt. Eng. 2022, 48, 3078–3087. [Google Scholar]

- He, H.; Liang, Y.; Liu, K.Y.; Weng, Y.H. Active Distribution Network Voltage Control Method Considering Communication Interruption. Power Inf. Commun. Technol. 2022, 20, 1–10. [Google Scholar]

- Huang, Z.; Liu, D.; Chen, G.H.; Weng, J.M.; Yin, H.Y.; Wang, Z. The evolution mechanism of the cyber-physical cascading failure of power distribution system based on event-driven. Electr. Power Eng. Technol. 2022, 41, 2–13. [Google Scholar]

- Anant, M.T.; Dusmanta, K.M. RBFNN assisted transient instability-based risk assessment of cyber-physical power system. Int. J. Electr. Power Energy Syst. 2022, 137, 107787. [Google Scholar]

- Zhang, J.; Yang, T.; Ji, H.; Li, W. Optimal locating method of edge computing device in cyber physical distribution system. Energy Rep. 2022, 8, 684–694. [Google Scholar] [CrossRef]

- Fang, Y.; Tang, X.; Tang, L.; Chen, Y.; Wang, W. Local Evolution Model of the Communication Network for Reducing Outage Risk of Power Cyber-Physical System. Energies 2022, 15, 7876. [Google Scholar] [CrossRef]

- Yang, Z.; Jia, W.; Xu, B.W.; Min, X.; Zhao, F.L.; Xu, L. Error Proof Control Method for Real-time Power Dispatching Based on Finite State Machine. Electr. Eng. 2023, 12, 176–178+182. [Google Scholar]

- Zhou, H.B.; Yang, J.; Huang, L.S.; Song, D.R.; Chen, X.J.; Dong, M. Double-vector Model Predictive Control Strategy of Three-level Inverter Based on Finite State Machine. Autom. Electr. Power Syst. 2023, 47, 155–164. [Google Scholar]

- Zhong, M.H.; Tong, X.Q.; Liu, X.H. A new fast PWM modulation strategy for power electric converter based on finite set state machine theory. Energy Rep. 2023, 9, 90–96. [Google Scholar] [CrossRef]

- Liu, K.Y.; Li, Z.; Jia, D.L.; Ye, X.S. Multi-flow Fusion Simulation Engine for New Distribution Network Based on Finite State Machine. High Volt. Eng. 2023, 50, 4826–4836. [Google Scholar]

- Fu, W.; Xie, H.; Wang, H.; Chen, C.; Bie, Z. Post-Disaster Topological Reconfiguration Approachfor Distribution Networks Using Hybrid Quantum-Classical Algorithm. J. Xi’an Jiaotong Univ. 2025, 59, 1–16. [Google Scholar]

| Symbol | Explanation | |

|---|---|---|

| variables | S | Finite set of states |

| C | Collection of events | |

| S0 | Initial state | |

| Sn | Target state | |

| f | State transition function | |

| Si | Current state | |

| Ci | Current input event | |

| On | Output state | |

| g | Output function | |

| Cn | Set of output events | |

| technical terms | C-ADMM-A | Alternating direction method of multiplier algorithm in classical computing environment, A stands for adaptive update with penalty factor |

| C-ADMM-F | Alternating direction method of multiplier algorithm in classical computing environment, F stands for fixed penalty factor | |

| CADMM + SA | Simulated annealing algorithm for discrete problems in classical computing environment | |

| QA-ADMM-A-1 | Quantum annealing embedded ADMM algorithm under a solver | |

| QA-ADMM-A-2 | Quantum annealing embedded ADMM algorithm based on b solver |

| System | System Identifier | State | Communication Information | Strategy Definition |

|---|---|---|---|---|

| Physical system | 0 | sw_1 | 1 | initial state |

| sw_2 | 2 | data collection state | ||

| sw_3 | 3 | reclosing state | ||

| sw_4 | 4 | fault state | ||

| sw_5 | 5 | FSM communication state | ||

| sw_6 | 6 | waiting state | ||

| Master station system | 1 | sz_1 | 1 | initial state |

| sz_2 | 2 | FSM communication state | ||

| sz_3 | 3 | FSM parses state | ||

| sz_4 | 4 | determine the status of the optimization result | ||

| sz_5 | 5 | issue functional command status | ||

| Strategy simulation system | 2 | sc_1 | 1 | initial state |

| sc_2 | 2 | FSM communication state | ||

| sc_3 | 3 | FSM parses state | ||

| sc_4 | 4 | simulation execution status | ||

| sc_5 | 5 | simulation result feedback status |

| Node | 1–3 | 4–6 | 7–9 | 10 | 15–17 | 18–20 | 21 | 24–25 | 26–28 | 29–32 | 11–14, 23, 33 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Path | L1 | L1–L6 | L1–L3 | L1 | L1 | L1–L2 | L1 | L1 | L1–L3 | L1 | off-grid |

| Switch (k1–k6) | 100000 | 000100 | 001000 | 000001 | 000100 | 000010 | 000001 | 100000 | 010000 | 001000 | 000000 |

| 010000 | |||||||||||

| 001000 | 000010 | 001000 | |||||||||

| 011000 | 000001 | ||||||||||

| 010100 | 000001 | 011000 | |||||||||

| 001100 |

| Strategy | Time Consumption for Fault Optimization Solution (s) | |

|---|---|---|

| Traditional optimization strategies | C-ADMM-A | 0.609 |

| C-ADMM-F | 3.829 | |

| CADMM + SA | 2.830 | |

| QA-ADMM-A-1 | 2.044 | |

| QA-ADMM-A-2 | 0.725 | |

| The method proposed in this article | 0.512 | |

| Objectives | Voltage Mean Square Deviation (kV) | Average Voltage Deviation (%) | Switching Action Times | |

|---|---|---|---|---|

| Path | ||||

| First path | 0.02 | 0.26 | 3 | |

| Second path | 0.83 | 10.71 | 3 | |

| Third path | 0.03 | 0.39 | 4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, D.; Yang, X.; Sheng, W.; Liu, K.; Yang, K.; Li, X.; Dong, W. A Microgrid Simulation Platform Based on Cyber-Physical Technology. Processes 2025, 13, 1441. https://doi.org/10.3390/pr13051441

Jia D, Yang X, Sheng W, Liu K, Yang K, Li X, Dong W. A Microgrid Simulation Platform Based on Cyber-Physical Technology. Processes. 2025; 13(5):1441. https://doi.org/10.3390/pr13051441

Chicago/Turabian StyleJia, Dongli, Xiaoyu Yang, Wanxing Sheng, Keyan Liu, Kaitong Yang, Xiaoming Li, and Weijie Dong. 2025. "A Microgrid Simulation Platform Based on Cyber-Physical Technology" Processes 13, no. 5: 1441. https://doi.org/10.3390/pr13051441

APA StyleJia, D., Yang, X., Sheng, W., Liu, K., Yang, K., Li, X., & Dong, W. (2025). A Microgrid Simulation Platform Based on Cyber-Physical Technology. Processes, 13(5), 1441. https://doi.org/10.3390/pr13051441