Study of the Extraction Process Using Natural Microtalc in the Malaxation Stage and Characterisation of Virgin Olive Oils from Moroccan Varieties

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Origin and Location of Olive Samples

2.3. Characterisation of the Olive Fruit

2.4. Extraction Process of Olive Oils

2.5. Physicochemical Characterisation of Olive Oils

- (i)

- Quality Parameters

- (ii)

- Determination of bioactive compounds’ contents

- (iii)

- Oxidative stability

2.6. Statistical Analysis

3. Results and Discussion

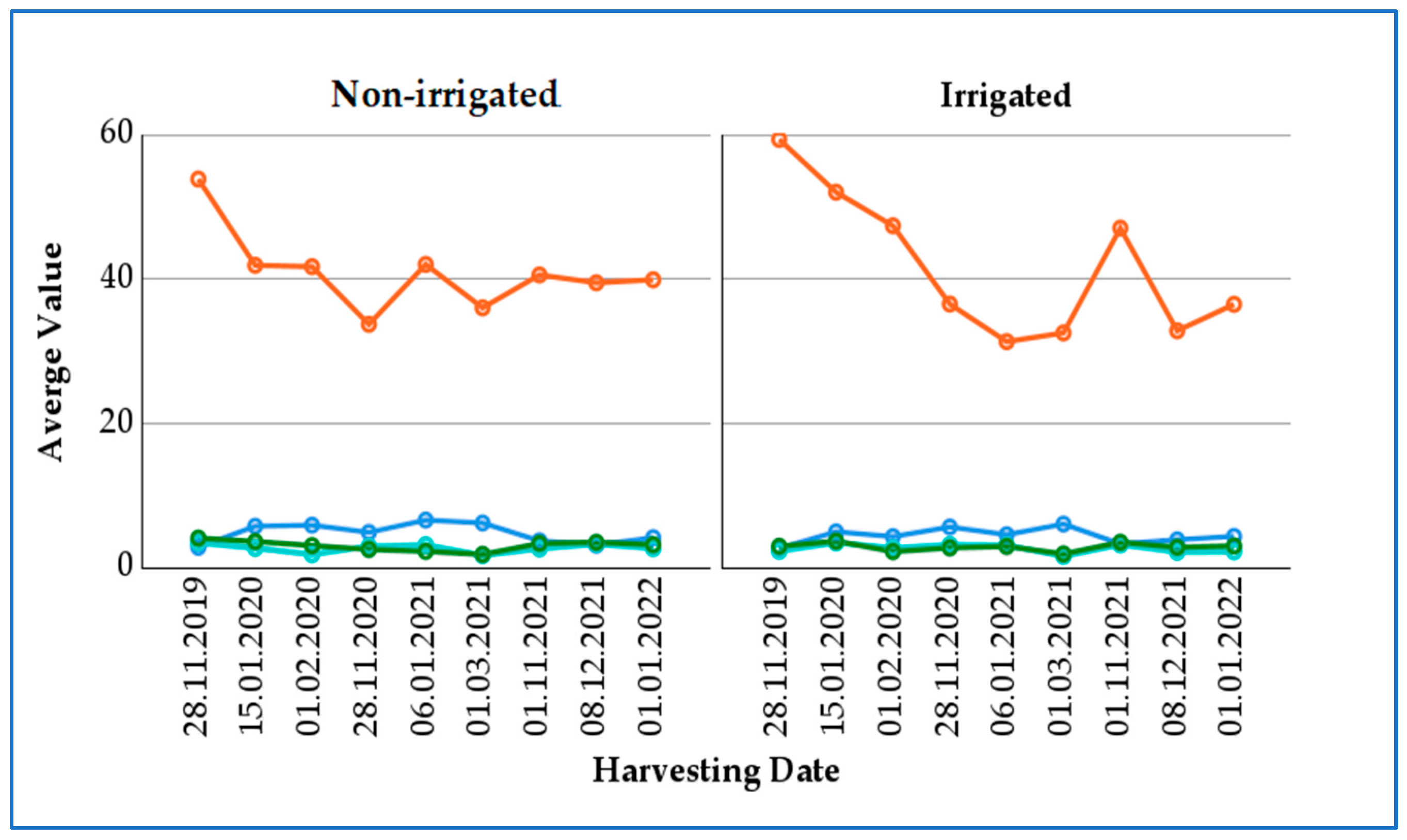

3.1. Characterisation of the Olive Fruit

3.2. Extraction Process of Virgin Olive Oils

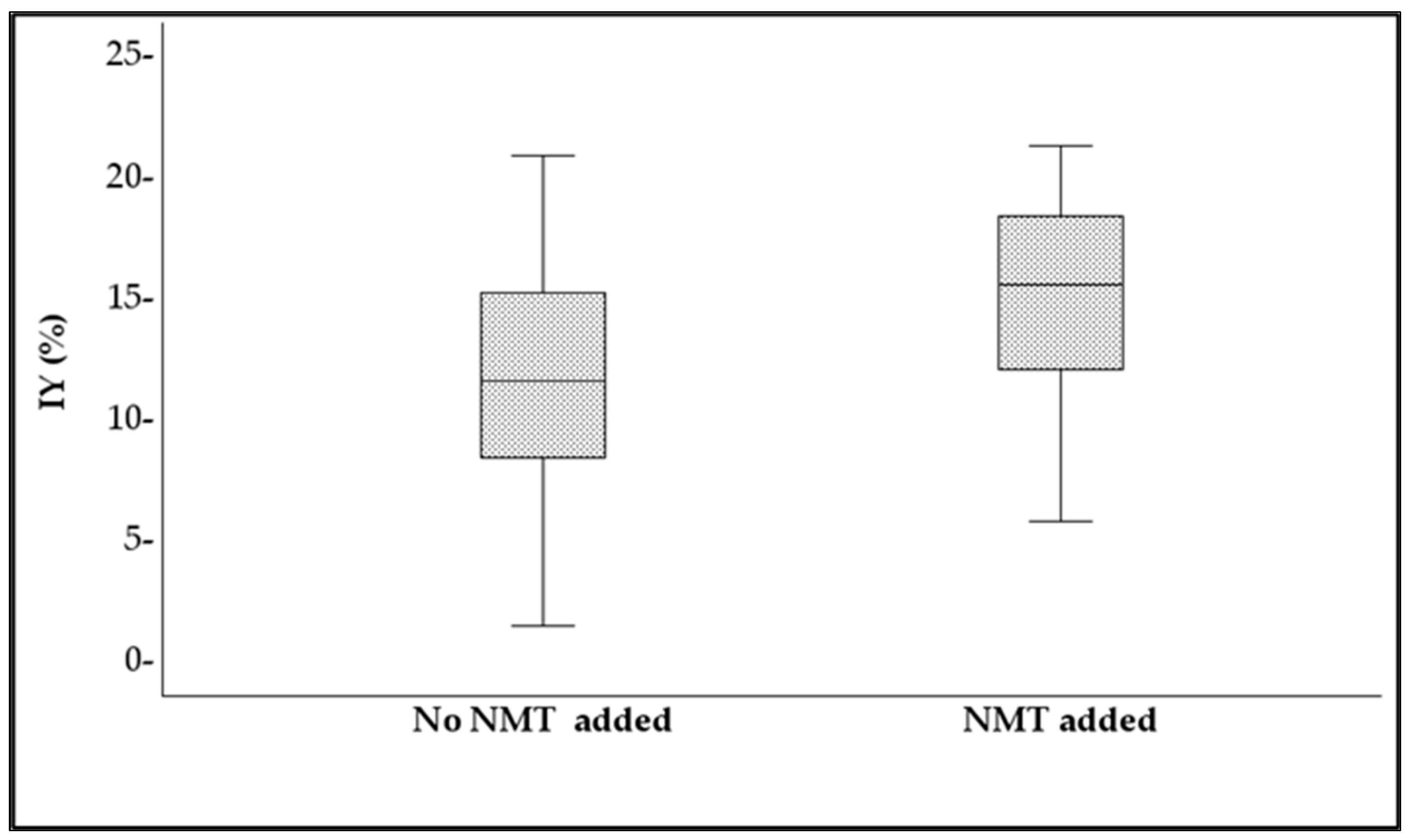

3.2.1. Industrial Oil Yield

3.2.2. Extractability Index

3.3. Quality Parameters

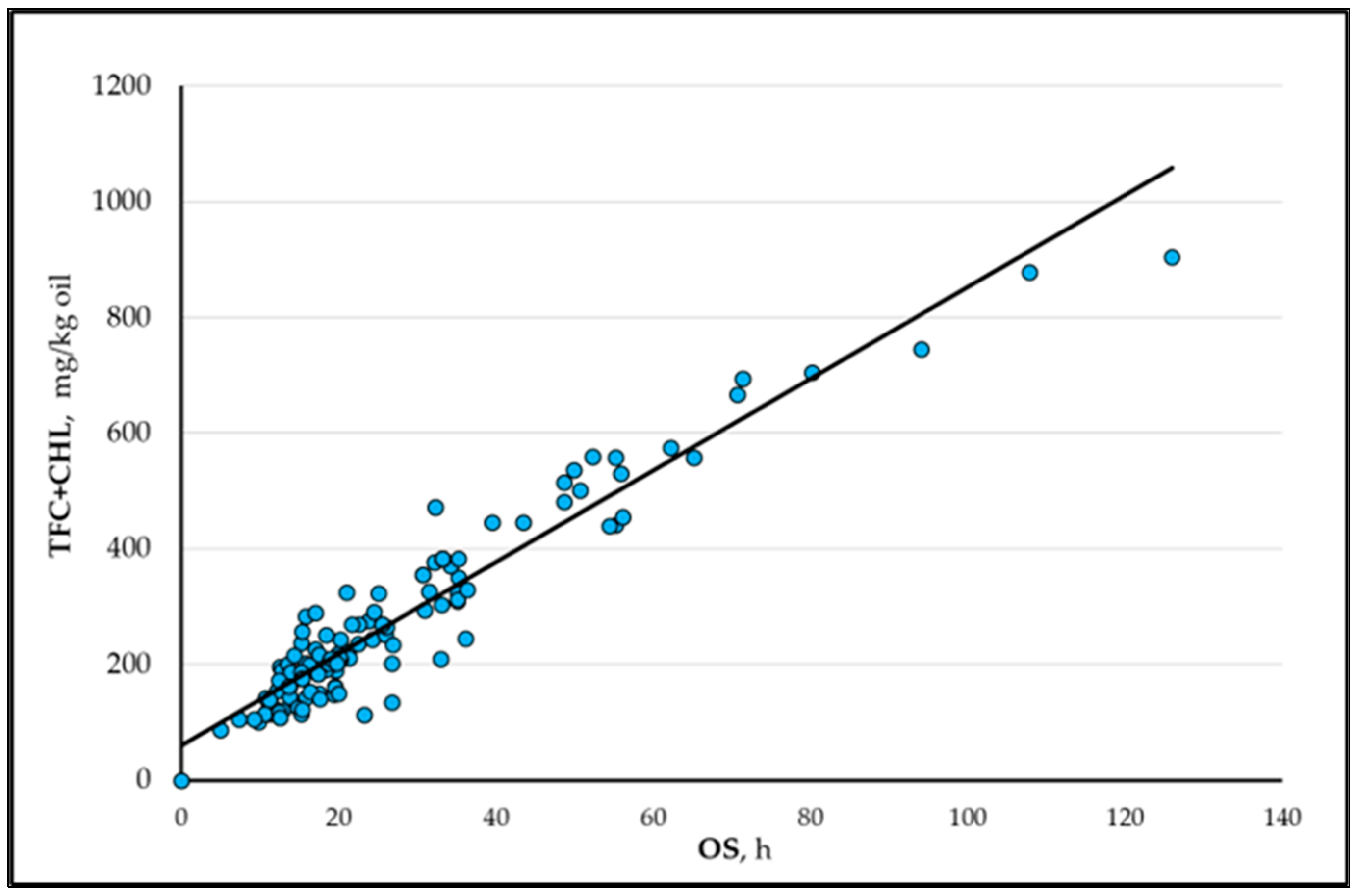

3.4. Total Concentrations of the Pigments

3.5. Profile in Fatty Acids

3.6. Contents in Total Sterols and Uvaol + Erythrodiol

3.7. Total Phenolic Compounds Concentration and Oxidative Stability in Virgin Olive Oils

4. Conclusions

- In oil olive production, the industrial yields and extractability indexes increased when the natural microtalc was used.

- Taking into account the criteria of the quality parameters, in general, the olive oils produced with microtalc showed lower values if they are compared with those obtained without any addition of natural microtalc.

- An improvement in pigment concentration (total carotenoids and chlorophyll contents) was observed in the olive oils produced by adding natural microtalc compared to those obtained without the addition of adjuvant.

- The highest percentage of oleic acid (76.44%), and with it, the fraction of monounsaturated fatty acids (77.25%), were determined in the samples from the Larache province and therefore associated with the variety ‘Haouzia’.

- In the provinces of majority cultivation of ‘Picholine marocaine’ and dry land (Chefchaouen and Ouazzane), the high values of the concentration of phenolic compounds and oxidative stability, characteristics of this variety, are clearly revealed. These olive oils, produced with natural microtalc, greatly and significantly increase the concentrations of phenolic compounds as well as oxidative stability.

5. Future Research

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Province | Harvesting Date | MI | AW (g/olive) | P/S (g/g) | HVM (%) | TFMC * (%) | TFMC ** (%) |

|---|---|---|---|---|---|---|---|

| 1 | 28 November 2019 | 2.97 | 3.52 | 3.50 | 57.19 | 52.28 ± 1.91 | 23.42 ± 2.28 |

| 15 January 2020 | 5.75 | 1.79 | 3.79 | 40.18 | 35.98 ± 0.40 | 21.73 ± 0.53 | |

| 1 February 2020 | 6.06 | 2.36 | 3.21 | 36.44 | 46.80 ± 0.00 | 29.75 ± 0.00 | |

| 2 | 28 November 2019 | 2.84 | 3.55 | 4.88 | 54.99 | 55.46 ± 3.70 | 25.32 ± 1.16 |

| 15 January 2020 | 5.91 | 3.81 | 3.62 | 58.08 | 47.90 ± 0.00 | 20.08 ± 0.00 | |

| 1 February 2020 | 5.90 | 1.48 | 3.08 | 35.57 | 36.69 ± 0.00 | 23.64 ± 0.00 | |

| 3 | 29 November 2019 | 2.18 | 2.89 | 4.61 | 54.06 | --- | --- |

| 16 January 2020 | 5.33 | 4.16 | 3.95 | 48.20 | 56.77 ± 0.00 | 26.08 ± 0.00 | |

| 2 February 2020 | 3.58 | 2.57 | 2.98 | 25.83 | 47.97 ± 0.00 | 24.85 ± 0.00 | |

| 4 | 29 November 2019 | 2.76 | 2.39 | 3.05 | 60.02 | 59.36 ± 1.12 | 24.45 ± 1.46 |

| 16 January 2020 | 4.79 | 2.95 | 3.58 | 47.31 | 47.34 ± 1.44 | 24.04 ± 0.53 | |

| 2 February 2020 | 5.21 | 3.07 | 1.66 | 45.57 | 46.84 ± 0.00 | 25.49 ± 0.00 | |

| 1 | 28 November 2020 | 5.87 | 3.65 | 3.13 | 57.42 ± 1.19 | 28.32 ± 2.34 | 12.05 ± 0.66 |

| 6 January 2021 | 6.36 | 3.44 ± 0.03 | 2.37 | 52.55 ± 0.04 | 41.37 ± 0.22 | 19.63 ± 0.12 | |

| 1 March 2021 | 6.15 | 1.79 ± 0.06 | 1.92 | 53.82 ± 0.74 | 35.01 ± 1.68 | 16.16 ± 0.52 | |

| 2 | 28 November 2020 | 4.09 | 2.44 | 2.11 | 52.25 ± 0.73 | 39.22 ± 0.00 | 17.80 ± 0.00 |

| 6 January 2021 | 7.00 | 3.06 ± 0.04 | 2.34 | 52.58 ± 0.64 | 42.75 ± 0.57 | 23.37 ± 0.21 | |

| 1 March 2021 | 6.41 | 1.82 ± 0.33 | 1.95 | 54.61 ± 0.00 | 37.10 ± 2.04 | 17.46 ± 0.49 | |

| 3 | 29 November 2020 | 5.23 | 2.99 | 2.75 | 50.36 ± 0.00 | 29.08 ± 0.00 | 14.44 ± 0.00 |

| 7 January 2021 | 4.67 | 3.40 | 3.08 | 52.64 ± 0.16 | 33.27 ± 2.64 | 15.76 ± 1.30 | |

| 2 March 2021 | 6.07 | 1.74 ± 0.09 | 2.23 | 50.66 ± 2.03 | 31.32 ± 3.69 | 15.42 ± 1.19 | |

| 4 | 29 November 2020 | 6.22 | 3.55 | 2.91 | 50.81 ± 0.00 | 44.08 ± 0.00 | 21.68 ± 0.00 |

| 7 January 2021 | 4.65 | 2.98 | 3.00 | 55.47 ± 0.00 | 29.48 ± 0.97 | 13.12 ± 0.27 | |

| 2 March 2021 | 6.19 | 1.65 ± 0.06 | 1.77 | 51.86 ± 1.06 | 33.84 ± 1.16 | 16.28 ± 0.20 | |

| 1 | 1 November 2021 | 4.12 ± 0.02 | 2.23 ± 0.05 | 3.05 ± 0.14 | 45.38 ± 0.99 | 37.68 ± 2.22 | 20.56 ± 0.84 |

| 8 December 2021 | 2.99 ± 0.21 | 3.52 ± 0.04 | 3.60 ± 0.03 | 46.82 ± 0.53 | 38.49 ± 1.51 | 20.46 ± 0.60 | |

| 1 January 2022 | 4.25 ± 0.09 | 2.88 ± 0.24 | 3.18 ± 0.14 | 43.85 ± 0.28 | 42.03 ± 0.14 | 23.60 ± 0.04 | |

| 2 | 1 November 2021 | 3.50 ± 0.20 | 3.22 ± 0.06 | 3.83 ± 0.04 | 54.95 ± 0.30 | 43.53 ± 0.96 | 19.61 ± 0.30 |

| 8 December 2021 | 3.45 ± 0.05 | 3.19 ± 0.11 | 3.62 ± 0.14 | 52.91 ± 0.71 | 40.55 ± 1.81 | 19.08 ± 0.57 | |

| 1 January 2022 | 4.24 ± 0.08 | 2.65 ± 0.01 | 3.36 ± 0.02 | 47.57 ± 0.90 | 37.84 ± 0.40 | 19.83 ± 0.13 | |

| 3 | 2 November 2021 | 4.06 ± 0.24 | 3.29 ± 0.08 | 3.70 ± 0.01 | 41.00 ± 0.21 | 49.76 ± 0.30 | 29.36 ± 0.07 |

| 9 December 2021 | 4.26 ± 0.01 | 2.22 ± 0.03 | 2.91 ± 0.01 | 46.19 ± 0.67 | 28.11 ± 1.33 | 15.12 ± 0.53 | |

| 2 January 2022 | 4.89 ± 0.02 | 1.96 ± 0.04 | 2.94 ± 0.13 | 48.24 ± 1.42 | 29.88 ± 2.42 | 15.43 ± 0.83 | |

| 4 | 2 November 2021 | 2.71 ± 0.16 | 3.27 ± 0.07 | 3.52 ± 0.07 | 56.01 ± 0.26 | 44.41 ± 0.55 | 19.53 ± 0.13 |

| 9 December 2021 | 3.65 | 2.31 ± 0.05 | 2.92 ± 0.23 | 45.32 ± 0.28 | 37.65 ± 0.49 | 20.59 ± 0.16 | |

| 2 January 2022 | 3.97 ± 0.09 | 2.70 ± 0.03 | 3.26 ± 0.04 | 51.54 ± 0.14 | 43.20 ± 0.96 | 20.93 ± 0.40 |

| Province | Harvesting Date | NMT Addition | Acidity (%) | Peroxide Value (mEq O2/kg oil) | K232 | K270 | ΔK |

|---|---|---|---|---|---|---|---|

| 1 | 28 November 2019 | NT | 0.45 ± 0.00 | 7.28 ± 0.00 | 1.75 ± 0.02 | 0.16 ± 0.05 | 0.02 ± 0.00 |

| T | 0.43 ± 0.00 | 9.37 ± 0.22 | 1.69 ± 0.01 | 0.20 ± 0.02 | 0.01 ± 0.00 | ||

| 15 January 2020 | NT | 1.64 ± 0.00 | 8.46 ± 0.44 | 0.98 ± 0.05 | 0.15 ± 0.05 | 0.00 ± 0.00 | |

| T | 2.09 ± 0.21 | 10.76 ± 0.14 | 1.74 ± 0.01 | 0.24 ± 0.02 | 0.02 ± 0.00 | ||

| 1 February 2020 | NT | 1.71 ± 0.06 | 7.98 ± 0.30 | 1.48 ± 0.01 | 0.14 ± 0.03 | 0.07 ± 0.00 | |

| T | 2.06 ± 0.17 | 8.57 ± 0.26 | 1.33 ± 0.04 | 0.10 ± 0.01 | 0.00 ± 0.00 | ||

| 2 | 28 November 2019 | NT | 0.88 ± 0.02 | 7.55 ± 0.30 | 1.56 ± 0.02 | 0.18 ± 0.05 | 0.01 ± 0.00 |

| T | 0.78 ± 0.00 | 10.84 ± 0.04 | 1.51 ± 0.07 | 0.16 ± 0.05 | 0.01 ± 0.00 | ||

| 15 January 2020 | NT | 1.68 ± 0.09 | 8.28 ± 0.85 | 1.57 ± 0.02 | 0.19 ± 0.05 | 0.00 ± 0.00 | |

| T | 1.73 ± 0.03 | 9.16 ± 0.32 | 1.60 ± 0.02 | 0.19 ± 0.07 | 0.00 ± 0.00 | ||

| 1 February 2020 | NT | 1.88 ± 0.03 | 8.09 ± 0.55 | 2.04 ± 0.02 | 0.23 ± 0.04 | 0.00 ± 0.00 | |

| T | 1.84 ± 0.03 | 9.46 ± 0.42 | 1.59 ± 0.01 | 0.11 ± 0.02 | 0.00 ± 0.00 | ||

| 3 | 29 November 2019 | NT | 0.36 ± 0.00 | 10.10 ± 0.04 | 1.64 ± 0.01 | 0.20 ± 0.02 | 0.00 ± 0.00 |

| T | 0.38 ± 0.02 | 7.75 ± 0.22 | 1.61 ± 0.03 | 0.20 ± 0.02 | 0.00 ± 0.00 | ||

| 16 January 2020 | NT | 0.50 ± 0.00 | 12.43 ± 0.23 | 1.24 ± 0.08 | 0.10 ± 0.02 | 0.00 ± 0.00 | |

| T | 1.00 ± 0.08 | 11.47 ± 0.30 | 1.68 ± 0.07 | 0.14 ± 0.02 | 0.00 ± 0.00 | ||

| 2 February 2020 | NT | -- | -- | -- | -- | -- | |

| T | 0.97 ± 0.07 | 9.76 ± 0.32 | 1.85 ± 0.05 | 0.19 ± 0.06 | 0.00 ± 0.00 | ||

| 4 | 29 November 2019 | NT | 0.31 ± 0.04 | 6.25 ± 0.42 | 1.31 ± 0.03 | 0.17 ± 0.05 | 0.01 ± 0.00 |

| T | 0.32 ± 0.02 | 6.38 ± 0.24 | 1.30 ± 0.09 | 0.18 ± 0.03 | 0.01 ± 0.00 | ||

| 16 January 2020 | NT | 0.95 ± 0.01 | 9.87 ± 0.20 | 1.45 ± 0.02 | 0.10 ± 0.01 | 0.00 ± 0.00 | |

| T | 1.00 ± 0.02 | 9.34 ± 0.45 | 1.30 ± 0.08 | 0.10 ± 0.03 | 0.00 ± 0.00 | ||

| 2 February 2020 | NT | 0.30 ± 0.05 | 13.23 ± 0.16 | 1.34 ± 0.02 | 0.11 ± 0.03 | 0.00 ± 0.00 | |

| T | 0.38 ± 0.06 | 13.20 ± 0.34 | 1.53 ± 0.02 | 0.12 ± 0.01 | 0.00 ± 0.00 | ||

| 1 | 28 November 2020 | NT | 5.18 ± 0.01 | 13.97 ± 1.15 | 1.90 ± 0.26 | 0.27 ± 0.06 | 0.00 ± 0.00 |

| T | 5.27 ± 0.10 | 10.36 ± 0.51 | 1.65 ± 0.23 | 0.32 ± 0.08 | 0.00 ± 0.00 | ||

| 6 January 2021 | NT | 3.65 ± 0.06 | 11.23 ± 0.06 | 1.77 ± 0.03 | 0.24 ± 0.00 | 0.00 ± 0.00 | |

| T | 3.53 ± 0.06 | 11.76 ± 1.55 | 1.49 ± 0.18 | 0.19 ± 0.02 | 0.00 ± 0.00 | ||

| 1 March 2021 | NT | 9.43 ± 0.11 | 11.09 ± 0.84 | 2.40 ± 0.02 | 0.40 ± 0.01 | 0.01 ± 0.00 | |

| T | 9.38 ± 0.08 | 10.89 ± 0.59 | 2.45 ± 0.07 | 0.43 ± 0.00 | 0.02 ± 0.00 | ||

| 2 | 28 November 2020 | NT | 15.02 ± 0.30 | 10.09 ± 0.79 | 1.81 ± 0.17 | 0.53 ± 0.04 | 0.02 ± 0.00 |

| T | 14.24 ± 0.04 | 10.12 ± 1.62 | 1.77 ± 0.01 | 0.52 ± 0.03 | 0.02 ± 0.00 | ||

| 6 January 2021 | NT | 3.86 ± 0.09 | 12.51 ± 1.23 | 1.90 ± 0.20 | 0.31 ± 0.09 | 0.00 ± 0.01 | |

| T | 3.67 ± 0.03 | 13.85 ± 0.48 | 1.72 ± 0.10 | 0.20 ± 0.01 | 0.00 ± 0.01 | ||

| 1 March 2021 | NT | 8.58 ± 0.04 | 9.95 ± 0.07 | 2.33 ± 0.07 | 0.49 ± 0.04 | 0.01 ± 0.00 | |

| T | 8.25 ± 0.02 | 9.67 ± 1.48 | 2.58 ± 0.03 | 0.59 ± 0.01 | 0.01 ± 0.00 | ||

| 3 | 29 November 2020 | NT | 3.27 ± 0.08 | 15.78 ± 0.78 | 2.27 ± 0.00 | 0.20 ± 0.00 | 0.00 ± 0.00 |

| T | 3.27 ± 0.00 | 13.23 ± 0.17 | 2.28 ± 0.09 | 0.28 ± 0.05 | 0.00 ± 0.00 | ||

| 7 January 2021 | NT | 2.05 ± 0.07 | 8.09 ± 0.39 | 1.88 ± 0.05 | 0.26 ± 0.07 | 0.00 ± 0.00 | |

| T | 2.18 ± 0.02 | 8.83 ± 0.62 | 1.61 ± 0.12 | 0.18 ± 0.04 | 0.00 ± 0.00 | ||

| 2 March 2021 | NT | 8.89 ± 0.04 | 11.02 ± 0.44 | 2.50 ± 0.36 | 0.57 ± 0.01 | 0.01 ± 0.00 | |

| T | 8.50 ± 0.10 | 11.36 ± 1.22 | 2.87 ± 1.06 | 0.66 ± 0.06 | 0.01 ± 0.00 | ||

| 4 | 29 November 2020 | NT | 6.43 ± 0.06 | 9.22 ± 0.09 | 1.67 ± 0.01 | 0.25 ± 0.05 | 0.00 ± 0.00 |

| T | 6.41 ± 0.09 | 9.80 ± 1.09 | 1.75 ± 0.15 | 0.21 ± 0.02 | 0.00 ± 0.00 | ||

| 7 January 2021 | NT | 3.02 ± 0.01 | 11.44 ± 0.57 | 1.64 ± 0.03 | 0.15 ± 0.01 | 0.00 ± 0.00 | |

| T | 2.91 ± 0.09 | 9.53 ± 0.46 | 1.70 ± 0.01 | 0.14 ± 0.00 | 0.00 ± 0.00 | ||

| 2 March 2021 | NT | 8.99 ± 0.16 | 8.56 ± 0.21 | 2.38 ± 0.11 | 0.45 ± 0.01 | 0.01 ± 0.00 | |

| T | 8.94 ± 0.05 | 8.13 ± 0.57 | 2.36 ± 0.00 | 0.41 ± 0.00 | 0.01 ± 0.00 | ||

| 1 | 1 November 2021 | NT | 0.83 ± 0.00 | 13.44 ± 0.71 | 1.81 ± 0.07 | 0.16 ± 0.01 | 0.01 ± 0.00 |

| T | 0.76 ± 0.10 | 11.56 ± 0.45 | 2.57 ± 0.10 | 0.21 ± 0.00 | 0.01 ± 0.00 | ||

| 8 December 2021 | NT | 1.20 ± 0.01 | 7.31 ± 0.75 | 2.02 ± 0.19 | 0.12 ± 0.14 | 0.00 ± 0.00 | |

| T | 1.11 ± 0.00 | 6.49 ± 1.49 | 1.94 ± 0.11 | 0.20 ± 0.00 | 0.00 ± 0.00 | ||

| 1 January 2022 | NT | 1.14 ± 0.18 | 13.15 ± 0.89 | 2.08 ± 0.07 | 1.26 ± 0.30 | 0.02 ± 0.01 | |

| T | 0.71 ± 0.24 | 13.29 ± 0.95 | 2.14 ± 1.11 | 0.77 ± 0.06 | 0.01 ± 0.00 | ||

| 2 | 1 November 2021 | NT | 9.44 ± 0.88 | 8.80 ± 0.75 | 1.23 ± 0.07 | 0.17 ± 0.02 | 0.00 ± 0.01 |

| T | 7.90 ± 0.87 | 8.21 ± 0.93 | 1.80 ± 0.03 | 0.27 ± 0.01 | 0.01 ± 0.01 | ||

| 8 December 2021 | NT | 3.04 ± 0.01 | 6.28 ± 0.61 | 1.74 ± 0.56 | 0.17 ± 0.00 | 0.00 ± 0.00 | |

| T | 2.75 ± 0.11 | 5.84 ± 1.24 | 1.80 ± 0.01 | 0.16 ± 0.00 | 0.00 ± 0.00 | ||

| 1 January 2022 | NT | 1.02 ± 0.00 | 23.79 ± 2.27 | 2.57 ± 0.36 | 0.70 ± 0.03 | 0.01 ± 0.00 | |

| T | 1.03 ± 0.01 | 21.98 ± 0.18 | 2.32 ± 0.55 | 0.13 ± 0.02 | 0.00 ± 0.00 | ||

| 3 | 2 November 2021 | NT | 0.74 ± 0.00 | 13.08 ± 1.15 | 2.34 ± 0.68 | 0.15 ± 0.01 | 0.01 ± 0.00 |

| T | 0.56 ± 0.26 | 11.17 ± 0.02 | 2.27 ± 0.12 | 0.14 ± 0.01 | 0.00 ± 0.00 | ||

| 9 December 2021 | NT | 0.14 ± 0.06 | 8.96 ± 0.46 | 1.34 ± 0.03 | 0.15 ± 0.01 | 0.01 ± 0.01 | |

| T | 0.12 ± 0.03 | 6.14 ± 0.40 | 1.69 ± 0.01 | 0.16 ± 0.00 | 0.00 ± 0.00 | ||

| 2 January 2022 | NT | 1.07 ± 0.06 | 17.68 ± 1.28 | 1.94 ± 0.02 | 0.04 ± 0.01 | 0.00 ± 0.00 | |

| T | 1.16 ± 0.06 | 17.65 ± 0.37 | 1.26 ± 0.04 | 0.70 ± 0.13 | 0.01 ± 0.00 | ||

| 4 | 2 November 2021 | NT | 4.25 ± 0.25 | 11.97 ± 0.53 | 1.77 ± 0.38 | 0.18 ± 0.03 | 0.00 ± 0.00 |

| T | 4.10 ± 0.53 | 9.91 ± 0.76 | 1.63 ± 0.08 | 0.36 ± 0.01 | 0.01 ± 0.01 | ||

| 9 December 2021 | NT | 0.79 ± 0.07 | 11.90 ± 0.85 | 1.96 ± 0.05 | 0.19 ± 0.01 | 0.00 ± 0.00 | |

| T | 0.28 ± 0.13 | 10.24 ± 0.04 | 1.57 ± 0.18 | 0.15 ± 0.00 | 0.00 ± 0.00 | ||

| 2 January 2022 | NT | 1.13 ± 0.16 | 12.39 ± 0.06 | 2.47 ± 0.29 | 0.15 ± 0.08 | 0.04 ± 0.00 | |

| T | 1.14 ± 0.02 | 12.09 ± 0.59 | 2.37 ± 0.38 | 0.29 ± 0.05 | 0.04 ± 0.00 | ||

| [35] | ≤0.80 | ≤20.0 | ≤2.50 | ≤0.22 | ≤0.01 |

| Province | Harvesting Date | CAR * (%) | CAR ** (%) | CHL * (%) | CHL ** (%) |

|---|---|---|---|---|---|

| 1 | 28 November 2019 | 6.23 ± 0.87 | 6.40 ± 0.50 | 9.31 ± 1.07 | 10.79 ± 0.97 |

| 15 January 2020 | 4.57 ± 0.46 | 4.76 ± 0.13 | 9.69 ± 1.18 | 10.58 ± 0.49 | |

| 1 February 2020 | 2.94 ± 0.51 | 2.54 ± 0.46 | 5.44 ± 1.98 | 4.40 ± 1.50 | |

| 2 | 28 November 2019 | 3.99 ± 0.39 | 4.52 ± 0.28 | 8.02 ± 1.86 | 9.40 ± 0.58 |

| 15 January 2020 | 5.49 ± 0.36 | 4.52 ± 0.30 | 12.40 ± 1.59 | 9.52 ± 0.08 | |

| 1 February 2020 | 3.92 ± 0.13 | 3.68 ± 1.33 | 8.79 ± 0.83 | 7.96 ± 1.90 | |

| 3 | 29 November 2019 | 6.53 ± 0.51 | 10.63 ± 1.51 | 12.86 ± 2.24 | 20.62 ± 4.28 |

| 16 January 2020 | 4.36 ± 0.05 | 4.60 ± 0.05 | 8.82 ± 0.21 | 9.71 ± 0.49 | |

| 2 February 2020 | -- | 4.28 ± 0.51 | -- | 5.41 ± 1.72 | |

| 4 | 29 November 2019 | 5.53 ± 0.15 | 7.31 ± 0.07 | 8.22 ± 0.69 | 11.96 ± 0.48 |

| 16 January 2020 | 2.36 ± 0.15 | 3.27 ± 0.24 | 4.83 ± 0.05 | 6.81 ± 0.57 | |

| 2 February 2020 | 2.01 ± 0.36 | 2.12 ± 0.04 | 3.78 ± 0.77 | 4.06 ± 0.59 | |

| 1 | 28 November 2020 | 10.59 ± 0.10 | 11.17 ± 0.14 | 23.42 ± 0.34 | 25.06 ± 0.61 |

| 6 January 2021 | 7.04 ± 0.26 | 7.44 ± 0.15 | 12.53 ± 0.18 | 13.23 ± 0.32 | |

| 1 March 2021 | -- | 4.38 ± 0.04 | -- | 5.90 ± 0.02 | |

| 2 | 28 November 2020 | 9.64 ± 0.11 | 9.91 ± 0.01 | 26.39 ± 0.02 | 27.49 ± 0.07 |

| 6 January 2021 | 6.49 ± 0.23 | 7.93 ± 0.04 | 12.25 ± 1.42 | 15.06 ± 0.21 | |

| 1 March 2021 | 5.22 ± 0.14 | 5.65 ± 0.12 | 7.89 ± 0.18 | 8.36 ± 0.44 | |

| 3 | 29 November 2020 | 5.39 ± 0.03 | 3.64 ± 0.01 | 10.59 ± 0.15 | 7.45 ± 0.29 |

| 7 January 2021 | 6.61 ± 0.27 | 6.85 ± 0.007 | 11.06 ± 0.26 | 12.53 ± 0.23 | |

| 2 March 2021 | 8.24 ± 0.00 | 5.36 ± 0.03 | 13.89 ± 0.00 | 8.09 ± 0.10 | |

| 4 | 29 November 2020 | 3.90 ± 0.04 | 3.79 ± 0.04 | 6.99 ± 0.02 | 6.98 ± 0.05 |

| 7 January 2021 | 6.02 ± 0.15 | 6.44 ± 0.10 | 10.50 ± 0.52 | 11.58 ± 0.31 | |

| 2 March 2021 | 4.73 ± 0.00 | 4.87 ± 0.26 | 7.27 ± 0.00 | 7.04 ± 0.43 | |

| 1 | 1 November 2021 | 7.068 | 8.68 ± 0.20 | 10.40 ± 1.74 | 11.42 |

| 8 December 2021 | 4.73 ± 0.69 | 9.66 ± 1.47 | 20.20 ± 3.03 | 22.69 ± 2.79 | |

| 1 January 2022 | 5.89 ± 0.89 | 4.99 ± 0.58 | 9.03 ± 2.25 | 6.99 ± 1.54 | |

| 2 | 1 November 2021 | 5.67 ± 0.92 | 6.68 ± 0.82 | 11.57 ± 2.82 | 13.70 ± 1.41 |

| 8 December 2021 | 3.78 ± 0.63 | 4.97 ± 0.28 | 9.57 ± 1.11 | 7.58 ± 1.52 | |

| 1 January 2022 | 5.26 ± 0.28 | 5.21 ± 0.59 | 8.58 ± 0.86 | 9.13 ± 1.57 | |

| 3 | 2 November 2021 | 5.73 ± 0.12 | 7.08 ± 0.42 | 8.17 ± 0.54 | 9.79 ± 0.95 |

| 9 December 2021 | 3.90 ± 0.18 | 3.08 ± 0.09 | 6.55 ± 0.65 | 5.51 ± 0.01 | |

| 2 January 2022 | 3.37 ± 0.31 | 5.17 ± 0.41 | 5.30 ± 1.25 | 7.96 ± 1.04 | |

| 4 | 2 November 2021 | 5.65 ± 0.10 | 7.22 ± 0.99 | 7.28 ± 0.06 | 10.47 ± 1.31 |

| 9 December 2021 | 3.60 ± 0.97 | 5.28 ± 0.49 | 7.26 ± 1.23 | 9.94 ± 1.17 | |

| 2 January 2022 | 2.53 ± 0.05 | 3.03 ± 0.24 | 4.78 ± 0.58 | 5.40 ± 0.55 |

References

- International Olive Council. 2019. Available online: https://www.internationaloliveoil.org/wp-content/uploads/2019/11/OLIVAE-125-ENG.pdf (accessed on 15 November 2024).

- Ministry of Agriculture, Maritime Fisheries, Rural Development and Water and Forests (MAPMDREF), Morocco. Filière oléicole|Ministère de l’agriculture. Available online: http://www.agriculture.gov.ma (accessed on 17 October 2024).

- Regional Directorate for Agriculture Tangier-Tetouan-Al Hoceima. 2022. Available online: https://www.agriculture.gov.ma/fr/region/tanger-tetouan-al-hoceima/Filièreoléicole (accessed on 4 November 2024).

- Office Régional de Mise en Valeur Agricole du Loukkos (ORMVAL), Larache, Morocco. 2022.

- National Institute for Agricultural Research of Morocco. 2002. Available online: https://www.inra.org.ma/sites/default/files/actesolivier.pdf (accessed on 22 October 2024).

- Pinatel, C.; Petit, C.; Ollivier, D.; Artaud, J. Outils pour l’amélioration organoleptique des huiles d’olive vierges. OCL-Oilseeds Fats Crops Lipids 2004, 11, 217–222. [Google Scholar] [CrossRef]

- Sánchez, S.; Olivares, I.; Puentes, J.G.; Órpez, R.; La Rubia, M.D.; Pacheco, R.; García-Martín, J.F. Use of natural microtalcs during the virgin olive oil production process to increase its content in antioxidant compounds. Processes 2022, 10, 950. [Google Scholar] [CrossRef]

- Uceda, M.; Frías, L. Épocas de recolección. Evolución del contenido graso, de la composición y la calidad del aceite. In Proceedings of the ‘II Seminario Oleícola International’, Córdoba, Spain, 6–17 October 1975; pp. 25–46. [Google Scholar]

- Beltrán, G.; Uceda, M.; Jiménez, A.; Aguilera, M.P. Olive oil extractability index as a parameter for olive cultivar characterisation. J. Sci. Food Agric. 2003, 83, 503–506. [Google Scholar] [CrossRef]

- Sánchez, S.; Landeta, J.M.; Sabalete, J.M.; Olivares, I.; Puentes, J.G.; Órpez, R.; La Rubia, M.D.; Pacheco, R. Aplicación de microtalco natural de tamaño de partícula pequeño en la elaboración de aceites de oliva vírgenes. In Proceedings of the XVIII Symposium Scientific Technical-Expoliva, Jaen, Spain, 12–13 May 2017. [Google Scholar]

- European Union Commission. Commission Regulation (EEC) No 2568/91 on the characteristics of olive oil and olive-residue oil and on the relevant methods of analysis. Off. J. Eur. Communities 1991, 248, 1991. Available online: https://leap.unep.org/countries/eu/national-legislation/commission-regulation-eec-no-256891-characteristics-olive-oil-and (accessed on 3 December 2024).

- Commission Implementing Regulation (EU) No 1348/2013 amending Regulation (EEC) No 2568/91. Off. J. Eur. Union 2013, L338, 31–67. Available online: https://www.fao.org/faolex/results/details/en/c/LEX-FAOC129253/ (accessed on 30 October 2024).

- García Martín, J.F. Potential of near-infrared spectroscopy for the determination of olive oil quality. Sensors 2022, 22, 2831. [Google Scholar] [CrossRef]

- Vázquez-Roncero, A.; Janer del Valle, C.; Janer del Valle, M.L. Determinación de los polifenoles totales del aceite de oliva. Grasas Aceites 1973, 24, 350–357. [Google Scholar]

- Mínguez, M.I.; Rejano, L.; Gandul, B.; Sánchez, A.; Garrido, J. Color-pigment correlation in virgin olive oil. J. Am. Oil Chem. Soc. 1991, 68, 332–336. [Google Scholar] [CrossRef]

- Papaseit, J. El color del aceite de oliva extra virgen, característica de calidad. Grasas Aceites 1986, 37, 204–206. [Google Scholar]

- Gutierrez Rosales, F. Determination of oxidative stability in virgin olive oils: Comparison between active oxygen method and Rancimat method. Grasas Aceites 1989, 40, 1–5. [Google Scholar]

- Farssi, O.; Touloun, O.; Ait Mansour, A.; Dayane, M.; Bouzida, B.; Erriqioui, N.; Farissi, M. Evaluation of the pomological characteristics of olive fruits (Olea europaea L.) of five varieties grown in the Beni-Mellal Region (Morocco). Int. J. Res. Agric. For. 2019, 6, 23–28. Available online: https://ijraf.org/papers/v6-i1/3.pdf (accessed on 26 September 2024).

- Gagoura, J.; Khaoula, E.G.; Ibourkia, M.; Sakar, E.H.; Gharbya, S. Physicochemical traits of olive fruit and oil from eight Moroccan wild olive (Olea europaea L. Subsp. Oleaster) populations. Biocatal. Agric. Biotechnol. 2024, 56, 103021. [Google Scholar] [CrossRef]

- Cert, A.; Alba, J.; León-Camacho, M.; Moreda, W.; Pérez-Camino, M.C. Effects of talc addition and operating mode on the quality and oxidative stability of virgin olive oils obtained by centrifugation. J. Agric. Food Chem. 1996, 44, 3930–3934. [Google Scholar] [CrossRef]

- Martínez Moreno, J.M. Fundamentos Físico-Químicos de la Técnica Oleícola; C.S.I.C.—Patronato Juan de la Cierva: Madrid, Spain, 1972. [Google Scholar]

- Sánchez, S.; Pacheco, R.; La Rubia, M.D.; Sánchez, A.; Pereira, G. Aplicación de distintos talcos naturales, como coadyuvantes tecnológicos, en los procesos de extracción de aceites de oliva. In Proceedings of the XII Symposium Scientific Technical-Expoliva, Jaen, Spain, 12–13 May 2005; p. TEC-65. [Google Scholar]

- Clodoveo, M.L.; Durante, V.; La Notte, D.; Punzi, R.; Gambacorta, G. Ultrasound-assisted extraction of virgin olive oil to improve the process efficiency. Eur. J. Lipid Sci. Technol. 2013, 115, 1062–1069. [Google Scholar] [CrossRef]

- Nushtaeva, A.V. Emulsion stabilization with talc microparticles. Colloid J. 2019, 81, 425–430. [Google Scholar] [CrossRef]

- Caponio, F.; Monteleone, J.I.; Marellini, G.; Summo, C.; Paradiso, V.M.; Pasqualone, A. Effect of talc addition on the extraction yield and quality of extra virgin olive oils from Coratina cultivar after production and during storage. J. Oleo Sci. 2014, 63, 1125–1132. [Google Scholar] [CrossRef]

- Pérez-Gálvez, A.; Viera, I.; Roca, M. Carotenoids and chlorophylls as antioxidants. Antioxidants 2020, 9, 505. [Google Scholar] [CrossRef]

- Bouymajane, A.; El Majdoub, Y.O.; Cacciola, F.; Russo, M.; Salafia, F.; Trozzi, A.; Filali, R.F.; Dugo, P.; Mondello, L. Characterization of phenolic compounds, vitamin E and fatty acids from monovarietal virgin olive oils of ‘Picholine marocaine’ cultivar. Molecules 2020, 25, 5428. [Google Scholar] [CrossRef]

- Alvarruiz, A.; Álvarez-Ortí, M.; Mateos, B.; Sena, E.; Pardo, J.E. Quality and composition of virgin olive oil from varieties grown in Castilla –La Mancha (Spain). J. Oleo Sci. 2015, 64, 1075–1082. [Google Scholar] [CrossRef]

- Servili, M.; Sordini, B.; Esposto, S.; Urbani, S.; Veneziani, G.; Di Maio, I.; Selvaggini, R.; Taticchi, A. Biological activities of phenolic compounds of extra virgin olive oil. Antioxidants 2014, 3, 1–23. [Google Scholar] [CrossRef]

- Fuentes, E.; Paucar, F.; Tapia, F.; Ortiz, J.; Jimenez, P.; Romero, N. Effect of the composition of extra virgin olive oils on the differentiation and antioxidant capacities of twelve monovariatals. Food. Chem. 2018, 243, 285–294. [Google Scholar] [CrossRef] [PubMed]

- Salas, J.; Pastor, M.; Castro, J.; Vega, V. Influencia del riego sobre la composición y características organolépticas del aceite de oliva. Grasas Aceites 1997, 48, 74–82. [Google Scholar] [CrossRef]

- Caponio, F.; Squeo, G.; Difonzo, G.; Pasqualone, A.; Summo, C.; Paradiso, V.M. Has the use of talc an effect on yield and extra virgin olive oil quality? J. Sci. Food Agric. 2016, 96, 3292–3299. [Google Scholar] [CrossRef] [PubMed]

- Issaoui, N.; Olivares, I.; Habsaoui, A.; Touhami, M.E.; Khtira, A.; Sakar, E.H.; Sánchez, S. New insights into the combined effects of geographical origin, cultivar and crop season on the physicochemical characteristics of Moroccan olive oils produced in northern Morocco. A comparative study. Oil Crop Sci. 2024, 9, 255–264. [Google Scholar] [CrossRef]

- Velasco, J.; Dobarganes, C. Oxidative stability of virgin olive oil. Eur. J. Lipid Sci. Technol. 2002, 104, 661–676. [Google Scholar] [CrossRef]

- IOC/T.15/NC No 3/Rev.17/2021; Trade Standard Applying to Olive Oils and Olive Pomace Oils. International Olive Council: Madrid, Spain, 2021; pp. 1–17. Available online: https://www.internationaloliveoil.org/what-we-do/chemistry-standardisation-unit/standards-and-methods/ (accessed on 16 December 2024).

(MI), Average Weight

(MI), Average Weight  (AW, g/olive), Pulp/Stone Ratio

(AW, g/olive), Pulp/Stone Ratio  (P/S, g/g) and Total Fatty Matter Content in dry basis

(P/S, g/g) and Total Fatty Matter Content in dry basis  (TFMC*, %).

(TFMC*, %).

(MI), Average Weight

(MI), Average Weight  (AW, g/olive), Pulp/Stone Ratio

(AW, g/olive), Pulp/Stone Ratio  (P/S, g/g) and Total Fatty Matter Content in dry basis

(P/S, g/g) and Total Fatty Matter Content in dry basis  (TFMC*, %).

(TFMC*, %).

) and with addition (

) and with addition ( ) of natural microtalc in the production process.

) of natural microtalc in the production process.

) and with addition (

) and with addition ( ) of natural microtalc in the production process.

) of natural microtalc in the production process.

| Province | Olive Variety | Olive Grove Typology | Olive Grove | Average Altitude (m) | Production Area (ha) |

|---|---|---|---|---|---|

| 1 | ‘Picholine marocaine’ | Traditional | Dry | 603 | 52,418.0 |

| 2 | ‘Picholine marocaine’ | Traditional | Dry | 339 | 59,050.0 |

| 3 | ‘Haouzia’ | Intensive | Irrigated | 46 | 17,095.5 |

| 4 | ‘Picholine marocaine’, ‘Haouzia’ and ‘Menara’ | Traditional Intensive | Irrigated | 177 | 22,528.0 |

| Province | Harvesting Date | IY * (%) | IY ** (%) | EI * (%) | EI ** (%) |

|---|---|---|---|---|---|

| 1 | 28 November 2019 | 17.70 | 20.97 | 75.58 | 89.54 |

| 15 January 2020 | 15.16 | 19.07 | 69.77 | 87.76 | |

| 1 February 2020 | 20.96 | 21.36 | 70.45 | 71.80 | |

| 2 | 28 November 2019 | 15.54 | 16.55 | 61.37 | 65.36 |

| 15 January 2020 | 9.75 | 13.11 | 48.56 | 65.29 | |

| 1 February 2020 | 15.70 | 17.53 | 66.41 | 74.15 | |

| 3 | 29 November 2019 | 13.45 | 19.14 | 30.11 | 42.85 |

| 16 January 2020 | 10.77 | 12.20 | 41.30 | 46.78 | |

| 2 February 2020 | -- | 16.59 | -- | 66.76 | |

| 4 | 29 November 2019 | 8.05 | 8.50 | 32.92 | 34.76 |

| 16 January 2020 | 17.92 | 18.76 | 74.54 | 78.04 | |

| 2 February 2020 | 20.08 | 20.02 | 78.78 | 78.54 | |

| 1 | 28 November 2020 | 9.47 | 10.65 | 78.59 | 88.38 |

| 6 January 2021 | 18.20 | 14.46 | 92.72 | 73.66 | |

| 1 March 2021 | 4.26 | 5.82 | 26.36 | 36.01 | |

| 2 | 28 November 2020 | 7.55 | 9.04 | 42.42 | 50.79 |

| 6 January 2021 | 13.77 | 14.37 | 58.92 | 61.49 | |

| 1 March 2021 | 9.49 | 12.00 | 54.35 | 68.73 | |

| 3 | 29 November 2020 | 7.22 | 11.20 | 50.00 | 77.56 |

| 7 January 2021 | 13.33 | 15.26 | 84.58 | 96.83 | |

| 2 March 2021 | 5.08 | 6.07 | 32.94 | 39.36 | |

| 4 | 29 November 2020 | 12.62 | 15.66 | 58.21 | 72.23 |

| 7 January 2021 | 17.31 | 18.68 | 131.94 | 142.38 | |

| 2 March 2021 | 3.32 | 6.60 | 20.39 | 40.54 | |

| 1 | 1 November 2021 | 1.56 | 12.67 | 7.60 | 61.62 |

| 8 December 2021 | 15.62 | 17.01 | 76.34 | 83.12 | |

| 1 January 2022 | 15.42 | 19.85 | 65.34 | 84.10 | |

| 2 | 1 November 2021 | 11.43 | 15.64 | 58.30 | 79.79 |

| 8 December 2021 | 10.10 | 15.39 | 52.92 | 80.66 | |

| 1 January 2022 | 10.64 | 17.17 | 53.62 | 86.58 | |

| 3 | 2 November 2021 | 9.28 | 21.19 | 31.60 | 72.20 |

| 9 December 2021 | 5.38 | 10.68 | 35.57 | 70.62 | |

| 2 January 2022 | 8.17 | 12.92 | 52.97 | 83.72 | |

| 4 | 2 November 2021 | 8.75 | 14.6 | 44.81 | 74.76 |

| 9 December 2021 | 12.97 | 17.63 | 63.00 | 85.63 | |

| 2 January 2022 | 11.94 | 16.97 | 57.05 | 81.06 |

| Component/Province | Chefchaouen (1) | Ouazzane (2) | Larache (3) | Tetouan (4) |

|---|---|---|---|---|

| Fatty Acids (%) | ||||

| 16:0 | 8.66 ± 0.42 | 7.45 ± 0.68 | 9.05 ± 0.08 | 8.67 ± 0.03 |

| 16:1 | 0.67 ± 0.01 | 0.51 ± 0.13 | 0.81 ± 0.01 | 1.00 ± 0.00 |

| 17:0 | 0.12 ± 0.00 | 0.11 ± 0.01 | 0.13 ± 0.01 | 0.09 ± 0.01 |

| 18:0 | 4.06 ± 0.06 | 4.21 ± 0.16 | 3.73 ± 0.01 | 3.7 ±0.19 |

| 18:1 | 75.74 ± 0.30 | 74.13 ± 0.12 | 76.44 ± 0.67 | 73.65 ± 0.10 |

| 18:2 | 11.02 ± 0.01 | 12.41 ± 0.14 | 10.68 ± 0.03 | 13.50 ± 0.10 |

| 18:3 | 0.80 ± 0.01 | 0.77 ± 0.04 | 0.79 ± 0.01 | 0.76 ± 0.01 |

| SAT | 12.84 ± 0.36 | 11.77 ± 0.52 | 12.90 ± 0.06 | 12.51 ± 0.21 |

| MUFA | 76.41 ± 0.30 | 74.64 ± 0.01 | 77.25 ± 0.69 | 74.65 ± 0.10 |

| PUFA | 11.81 ± 0.00 | 13.18 ± 0.11 | 11.47 ± 0.02 | 14.26 ± 0.08 |

| 18:1/18:2 | 6.88 ± 0.03 | 5.97 ± 0.08 | 7.16 ± 0.08 | 5.46 ± 0.05 |

| Total Sterols (mg/kg oil) | ||||

| 1970.00 ± 43.84 | 2118.50 ± 20.51 | 1951.50 ± 33.23 | 2170.00 ± 36.77 | |

| Uvaol + Erythrodiol (%) | ||||

| 3.17 ± 0.19 | 3.95 ± 0.01 | 2.86 ± 0.03 | 3.32 ± 0.21 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Issaoui, N.; Olivares-Merino, I.; Touhami, M.E.; Habsaoui, A.; Sánchez, S. Study of the Extraction Process Using Natural Microtalc in the Malaxation Stage and Characterisation of Virgin Olive Oils from Moroccan Varieties. Processes 2025, 13, 1399. https://doi.org/10.3390/pr13051399

Issaoui N, Olivares-Merino I, Touhami ME, Habsaoui A, Sánchez S. Study of the Extraction Process Using Natural Microtalc in the Malaxation Stage and Characterisation of Virgin Olive Oils from Moroccan Varieties. Processes. 2025; 13(5):1399. https://doi.org/10.3390/pr13051399

Chicago/Turabian StyleIssaoui, Noura, Inmaculada Olivares-Merino, Mohamed Ebn Touhami, Amar Habsaoui, and Sebastián Sánchez. 2025. "Study of the Extraction Process Using Natural Microtalc in the Malaxation Stage and Characterisation of Virgin Olive Oils from Moroccan Varieties" Processes 13, no. 5: 1399. https://doi.org/10.3390/pr13051399

APA StyleIssaoui, N., Olivares-Merino, I., Touhami, M. E., Habsaoui, A., & Sánchez, S. (2025). Study of the Extraction Process Using Natural Microtalc in the Malaxation Stage and Characterisation of Virgin Olive Oils from Moroccan Varieties. Processes, 13(5), 1399. https://doi.org/10.3390/pr13051399