Abstract

Maintenance plays a key role in oil and gas enterprises, especially in the process of increasing pressure to improve equipment efficiency, reduce costs, and comply with environmental protection requirements towards sustainable production. This study proposes an optimal maintenance strategy based on the overall equipment effectiveness (OEE) index, using a multi-criteria decision-making method (MCDM) integrating an Analytical Hierarchy Process (AHP) and a Technique for Order of Preference by Similarity to an Ideal Solution (TOPSIS). The study evaluates five maintenance strategies—preventive maintenance (PM), risk-based maintenance (RBM), condition-based maintenance (CBM), reliability-centered maintenance (RCM), and predictive maintenance (PdM)—based on four key criteria: maintenance cost, safety, efficiency, and flexibility. The comparison of each pair of criteria and the maintenance strategy choices was carried out systematically to ensure consistency in the decision-making process. The Evaluation Distance to the Mean Solution (EDAS) method was used as a cross-validation tool to strengthen the reliability of the results. The results showed that RCM is the optimal maintenance strategy, providing superior equipment performance and reliability. The study expands the theoretical basis in industrial maintenance, providing a structured and data-driven decision support tool. The method can be flexibly applied in many industries to optimize maintenance strategies and promote sustainable production.

1. Introduction

The petrochemical industry is essential to each country’s economic, energy, transportation, and defense development. In particular, the maintenance of production equipment is vital to ensure continuous operation, stable product quality, and minimize leakage and negative environmental impacts. Production lines and equipment in oil refineries are the most significant assets of the enterprise, acting as the “heart” in maintaining continuous and efficient production operations. According to many previous studies, effective maintenance strategies help to reduce machine downtime, improve system reliability, optimize costs, and improve overall productivity [1,2,3]. Maintenance costs can account for up to 15–70% of total production costs [4], the second largest category after energy costs [5]. Therefore, choosing the correct maintenance strategy is an essential problem in industrial production management.

Modern maintenance models such as reliability-based maintenance (RCM), total productive maintenance (TPM), predictive maintenance (PdM), condition-based maintenance (CBM), and risk-based maintenance (RBM) have been widely applied [6,7,8,9]. However, these methods share the fact that they require the evaluation of many different factors, such as cost, safety, efficiency, flexibility, and practicality. Therefore, the optimal strategy selection must be based on a systematic, quantitative approach that can handle conflicting criteria. A popular indicator for evaluating maintenance effectiveness is the OEE, which analyzes losses related to availability, performance, and product quality [10]. In practice, OEE has been applied to identify the causes of major losses in critical equipment systems, typically the injection pump system at an oil field of the Pertamina group in Indonesia [11]. Despite many studies addressing different maintenance policies and methods, there is still a gap in building a systematic decision-making framework that integrates qualitative and quantitative factors to support selecting appropriate maintenance strategies. Particularly in the petrochemical industry complex and high-risk production environments, a structured decision support model with multi-criteria evaluation capabilities is extremely necessary.

The MCDM, which integrates two methods, namely the Analytical Hierarchy Process (AHP) and Technique for Order of Preference by Similarity to an Ideal Solution (TOPSIS), was proposed to address this gap. This combination allows for a systematic evaluation of maintenance options, based on both expert opinion (AHP determines the weighting of criteria) and real-world data to rank options (TOPSIS) [12,13,14,15,16,17].

However, through a survey of existing documents, there have not been many studies that systematically integrate AHP and TOPSIS to select the optimal maintenance strategy based on the OEE index in the real context of oil refineries. This is the research gap that this paper aims to overcome. Specifically, the study proposes an integrated AHP-TOPSIS model to select the optimal maintenance strategy for equipment in the oil and gas industry. The OEE index is used as the basis for measuring the overall efficiency of the equipment, combined with multidimensional evaluation criteria such as cost, safety, efficiency, flexibility, and deployment capability. The methodology is systematically built through defining objectives, creating a criteria system, evaluating weights through AHP, and ranking options using TOPSIS, ensuring objectivity and scientificity in decisions.

2. Literature Review

2.1. Equipment Maintenance Strategies in the Oil and Gas Industry

The maintenance of equipment in the oil and gas industry has garnered significant attention due to its critical role in enhancing operational efficiency, minimizing costs, and adhering to environmental regulations. Traditional maintenance strategies, such as preventive maintenance (PM) and corrective maintenance (CM), have been widely adopted; however, the evolving complexities of industrial operations necessitate the exploration of more dynamic and effective maintenance methodologies.

Over time, many new maintenance strategies have been developed, each with advantages and limitations. Abdel Bayoumi et al. [18] proposed a predictive maintenance (PdM) model based on sensor data collection and data analysis to support maintenance decision-making. Similarly, Hameed and Khan [19] developed a risk-based maintenance (RBM) model to effectively plan inspection and maintenance, significantly improving safety and cost and reducing downtime. Condition-based maintenance (CBM), as presented in [20], is based on condition monitoring data used to perform maintenance when there are signs of failure. They integrate real-time data to assess asset condition and predict potential failures, thereby taking timely maintenance actions, minimizing unnecessary interventions, and improving reliability. TPM and RCM are third-generation maintenance methods that help increase operational efficiency and maintain equipment stability [21]. Studies have also shown that the effectiveness of maintenance strategies can be evaluated through performance indicators such as OEE. For example, a study at the PEP field Bunyu injection system showed that measuring and analyzing OEE combined with the “six major losses” model significantly improved operating performance and reduced the risk of environmental pollution [11].

2.2. Application of the MCDM in Selecting Maintenance Strategies

Since each maintenance strategy has advantages and disadvantages, selecting the appropriate strategy requires the consideration of many factors simultaneously. The MCDM is an effective tool for selecting the optimal solution. Many studies have applied MCDM in the industrial field, including the AHP-Delphi-PROMETHEE method, which is applied to select the optimal maintenance solution for each marine engine part based on fuzzy reliability and many criteria [13]. The combined FAHP and TOPSIS model has been used in the paper industry to select the optimal pump maintenance strategy [14,15]. The studies of Hemmati et al. and Jamali et al. have demonstrated the effectiveness of combining AHP and TOPSIS in a fuzzy environment to make optimal maintenance decisions [16,17].

2.3. Criteria for Evaluating Maintenance Strategies

To ensure the effectiveness of maintenance strategy selection, the criteria commonly considered include cost, safety, efficiency, and flexibility. Studies have shown the following:

Cost: The implementation of PdM and RCM reduces unplanned downtime and maintenance costs by 15% to 25% [22,23].

Safety: The application of CBM reduces accidents due to equipment failures by up to 20% [24,25].

Effectiveness: Combining RCM and CBM increases OEE by up to 15%, while PdM can improve equipment performance by 18% [26,27].

Flexibility: PdM and RCM improve flexible planning by 20% to 25%, adapting to changing operating conditions [28,29,30].

In addition to the four main criteria, recent studies have expanded to 18 sub-criteria: spare parts, personnel training, outsourcing costs, machine downtime, CMMS system, reliability, product productivity, employee acceptance, and flexible scheduling. These criteria provide a more comprehensive and realistic evaluation framework in the decision-making process for selecting the optimal maintenance strategy. [27,28,30,31,32,33].

The selection and weighting of these sub-criteria, derived from expert consultation and literature synthesis, form the foundation for applying the AHP-TOPSIS model in this study. This comprehensive approach ensures the selection of a maintenance strategy that is not only cost-effective but also safe, efficient, and adaptable to operational demands.

2.4. Research Gap

Although many studies have applied MCDM models when selecting maintenance strategies in various industrial sectors, such as manufacturing, marine, and paper industries, the number of in-depth studies using these models in the oil and gas industry, especially for equipment in oil refining plants, is still limited. Building a systematic decision-making framework that integrates qualitative and quantitative factors to support selecting appropriate maintenance strategies is extremely necessary.

The MCDM that integrates two methods, AHP and TOPSIS, was proposed to address this gap. This combination allows for a systematic evaluation of maintenance options, based on the use of expert opinion (AHP determines the weighting of criteria) and real-world data to rank options (TOPSIS). In addition, the OEE index has been proven to be a useful tool for measuring equipment performance; the integration of OEE as an evaluation criterion in MCDM models for selecting maintenance strategies has not been studied. This novel combination is essential when businesses increasingly focus on optimizing equipment performance to improve productivity and reduce maintenance costs.

Therefore, this study aims to fill this gap by developing an AHP-TOPSIS-integrated model incorporating OEE as a performance measure to ensure that strategy selection reflects actual operational outcomes in the oil and gas industry. It supports the decision-making process of selecting the optimal maintenance strategy for equipment in complex and constrained operating environments.

3. Methods and Materials

3.1. Methodology

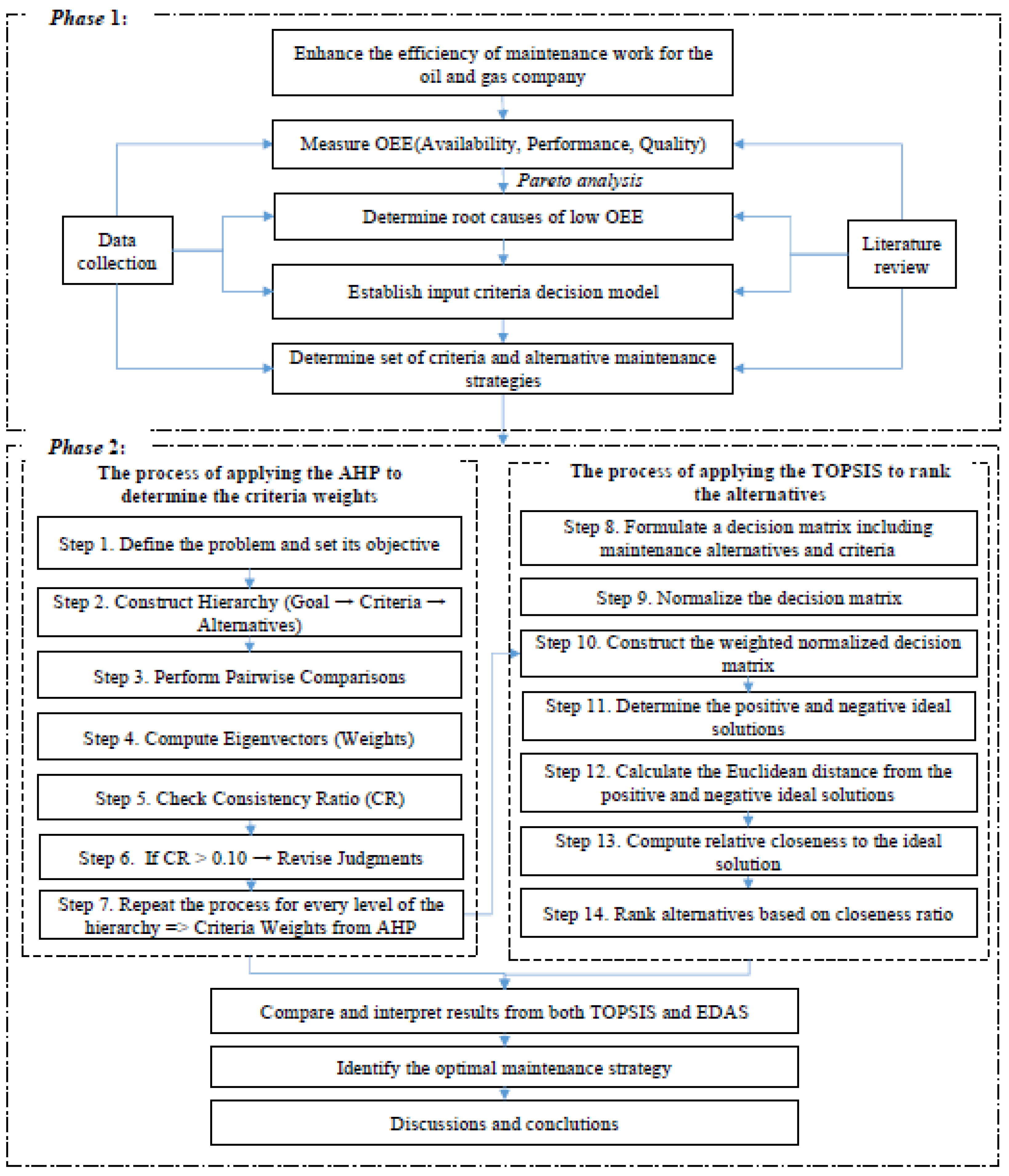

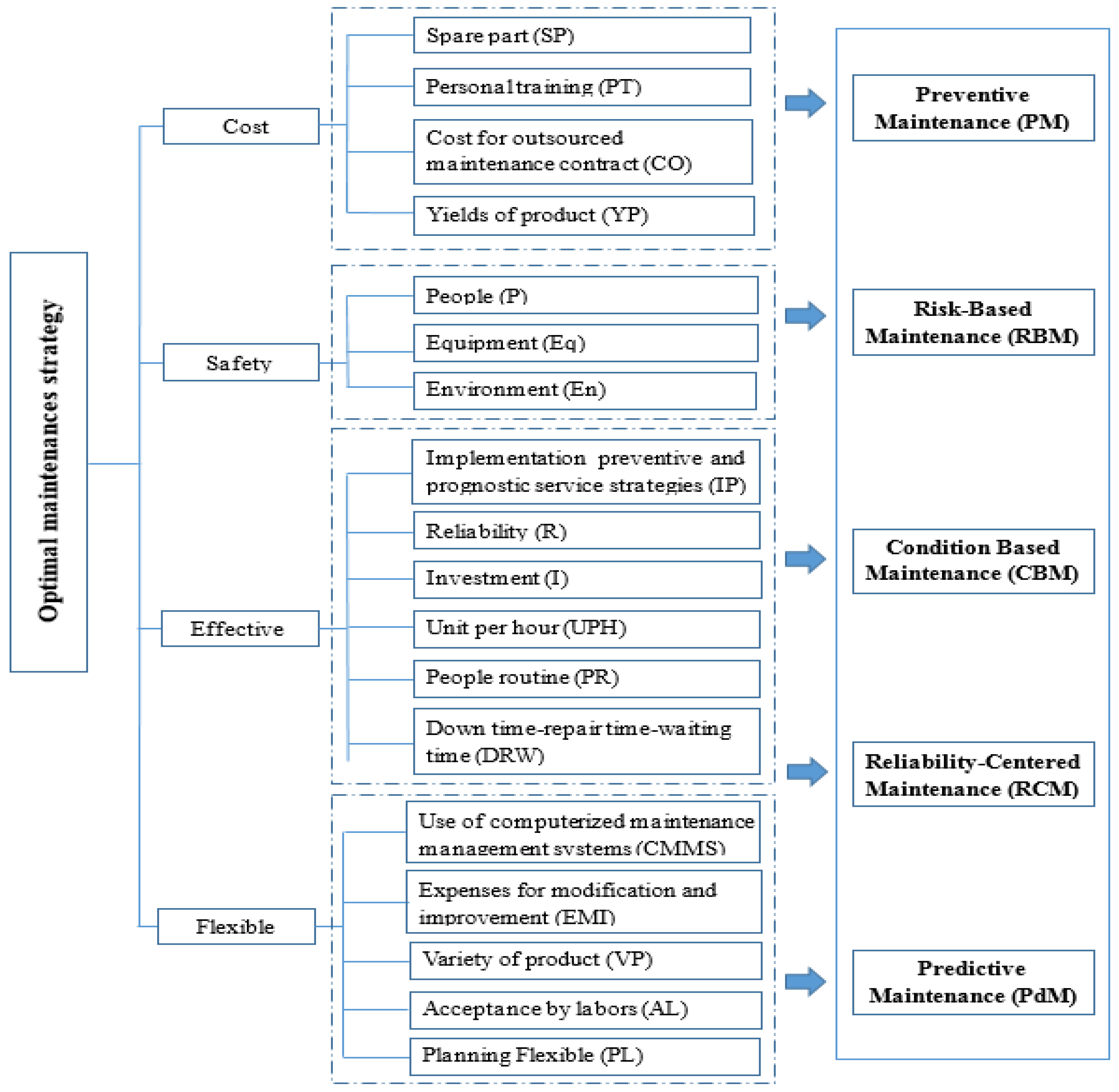

The research methodology is designed with an integrated approach to evaluate equipment performance and propose optimal maintenance strategies in the petrochemical refining sector. The research process includes two main stages, as described in Figure 1 below.

Figure 1.

Research methodology diagram.

3.1.1. Phase 1: Analyze Equipment Status Based on OEE Index and Identify Root Causes

The first phase focuses on measuring manufacturing equipment performance through the OEE index, which includes three components: availability, performance, and quality.

Overall equipment efficiency (OEE) is developed based on the TPM concept introduced by Nakajima in 1988. OEE has been widely applied in industrial production to measure equipment performance [34]. OEE has been applied in the semiconductor industry to evaluate and remove loss in manufacturing [35,36]. In another paper, Hwang et al. developed a new manufacturing performance model to measure real-time performance metrics based on the IoT and OEE [37]. Previous studies have found that the OEE index is a popular tool used to calculate the overall performance of equipment. OEE performs loss identification and the measurement of significant aspects of production in terms of three key factors: availability, operational efficiency, and quality ratio. The following equations calculate the OEE value:

OEE = Availability (A) × Performance efficiency (PE) × Rate of quality (Qr)

World-class OEE is a standard used to compare a company’s OEE. Studies worldwide show that the average OEE rate in manufacturing plants is 60%. Therefore, there is potential to improve OEE in many plant areas. World-class OEE is considered 85% or better [38].

After calculating the OEE for all equipment, Pareto analysis (80/20) is applied to identify the group of necessary equipment that accounts for most production losses. These types of equipment are subjected to in-depth analysis to propose appropriate maintenance strategies.

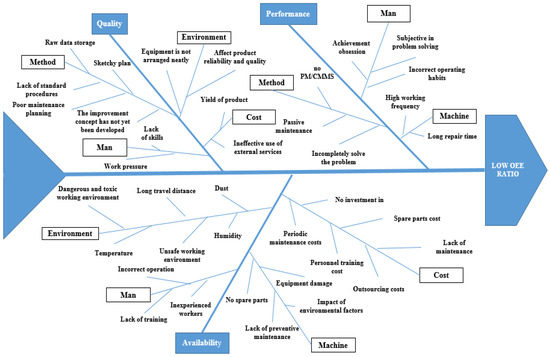

Next, to identify the root causes affecting the OEE index, a fishbone (Ishikawa) diagram is created based on combining real-world data and expert consultation.

OEE is an essential tool to evaluate the performance of equipment, including three main components:

- Availability: The time in which the equipment is ready to operate compared to the planned time.

- Performance: The actual speed of the equipment compared to the standard speed.

- Quality: The rate of products meeting quality requirements compared to the total number of products produced.

After analysis, the study identifies that the factors affecting OEE can be transformed into maintenance strategy evaluation criteria, creating a logical and practical input foundation for the AHP model, which helps to link qualitative data with the systematization of quantitative criteria. The requirements that are consistent with the enterprise’s actual goals were identified, ensuring that each AHP criterion accurately reflects the root cause affecting OEE. This bridges the current status analysis of OEE and maintenance strategy decisions, helping the decision-making model to be highly applicable.

3.1.2. Phase 2—Multi-Criteria Decision-Making Using the AHP–TOPSIS Integrated Method and Verifying the Optimal Results

The hybrid optimization method has become helpful in addressing complex decision-making problems, especially in MCDM tasks, where single methods may not be effective enough. This method combines the strengths of various techniques to achieve better optimization results, overcoming the limitations of single methods. AHP determines the weights of essential criteria in evaluating alternatives [39,40], while TOPSIS helps analyze these alternatives based on their distances to the ideal and negative ideal solutions.

Although other methods like PROMETHEE and VIKOR can be applied in MCDM situations, the combination of AHP and TOPSIS offers several advantages. PROMETHEE compares criteria-based alternatives and identifies the best solutions through a scoring system. However, PROMETHEE lacks a precise mechanism to systematically determine the criteria weights and ensure consistency in these weights, which AHP does very well.

On the other hand, VIKOR is primarily used to identify the “best” solution based on benefit or cost criteria. Still, it depends on establishing a system of weights and priorities for the requirements. VIKOR lacks a straightforward method for determining these weights, whereas AHP offers a rigorous process for calculating and ensuring the consistency of these weights. Moreover, VIKOR may face challenges in handling conflicting or unclear criteria, while AHP addresses these issues through pairwise comparisons and consistency checks. Therefore, the combination of AHP and TOPSIS helps overcome the drawbacks of PROMETHEE and VIKOR, while providing a more transparent, systematic, and efficient decision-making process. This method accurately determines the criteria weights, and then uses them to evaluate and rank alternatives objectively, leading to better decision outcomes.

a. The process of applying the AHP analytical hierarchy method is presented as follows:

Step 1: Define the problem and set its objective.

Step 2: Create a hierarchy from the top (objectives) down to the lower levels (criteria and alternatives).

Step 3: Create pairwise comparison matrices (size ) for each lower-level element compared to every other level component immediately above, using the relative scale measurement outlined in [39,40]. The comparisons should indicate which element dominates the other in terms of importance. A total of udgments are needed to construct the set of matrices in step 3. Reciprocals are automatically assigned in each pair-wise comparison.

Step 4: Hierarchical synthesis weights eigenvectors by criteria weight, summing over all corresponding entries at the next lower level of the hierarchy.

Step 5: After completing all pair-wise comparisons, consistency is assessed using the eigenvalue, λ max, to compute the consistency index as follows: . The size of the matrix, denoted by determines the consistency. The consistency ratio of the consistency index should be compared to the values in [39,40].

Step 6: An acceptable does not surpass 0.10. If it exceeds this threshold, the judgment matrix is inconsistent. It is necessary to review and enhance the judgments to ensure consistency.

Step 7: Steps 3 to 6 are carried out for every level within the hierarchy.

b. After determining the criteria weights using AHP, TOPSIS ranks the alternatives based on their distance from the ideal and negative ideal solutions.

The main steps in the TOPSIS approach are as follows [41,42]:

Step 8: Based on alternatives and criteria, a matrix with elements is made, where each element denotes the rating of the decision maker (DM) with respect to the criteria. The matrix is known as the decision matrix, denoted by :

Step 9: Normalization of the evaluation matrix:

This is denoted by H as follows:

where m is the number of feasible alternatives and n is the number of criteria.

Step 10: Construction of the weight-normalized decision matrix, which is denoted by Q:

The weights () were calculated using the AHP method.

Step 11: Determining the positive ideal solution and negative ideal solution by finding the maximum and minimum values of weighted normalized elements in each column for benefit criteria and reverse for cost criteria.

Step 12: Calculate the Euclidean distance for each alternative.

The Euclidean distance from the positive ideal solution is represented by :

where ; .

represents the Euclidean distance from the negative ideal solution.

Step 13: Calculate the relative closeness to the ideal solutions . If it is closest to 1, then it depicts the best solution:

represents the distance from the positive ideal solution, and represents the distance from a negative ideal solution.

Step 14: Rank the alternatives based on their closeness ratio in order of preference. The alternative with the shortest distance to the ideal solution is considered the best. The shortest distance to the ideal solution indicates the longest distance from the negative ideal solution.

Next, the reasonableness and reliability of the selected maintenance strategy must be ensured. The EDAS method (Evaluation based on Distance from Average Solution) was chosen as a comparison tool. EDAS evaluates the plans based on the distance to the average value, providing a different perspective to compare with the TOPSIS method. If the rankings are similar, this confirms the stability and reliability of the selected optimal choice.

3.2. Materials

A case study was conducted at an oil and gas company in Vietnam [43] to collect data. The company has come into operation after many years of having maintenance problems with the following issues: reduced production efficiency, increased maintenance costs, and challenges with pressure to improve machinery and equipment maintenance for sustainable production with the environment. Observations are performed on the machine operations, and the performance data available are recorded. The meeting discussions were conducted to contextualize staff responses and experts’ opinions regarding the observations made during the data collection process in the company’s maintenance department. The textual data of three years were collected from available historical records, such as downtime, failure time, output, and other data, to determine the OEE of the petrochemical refinery production company.

3.2.1. OEE Measurement and Identify Root Causes

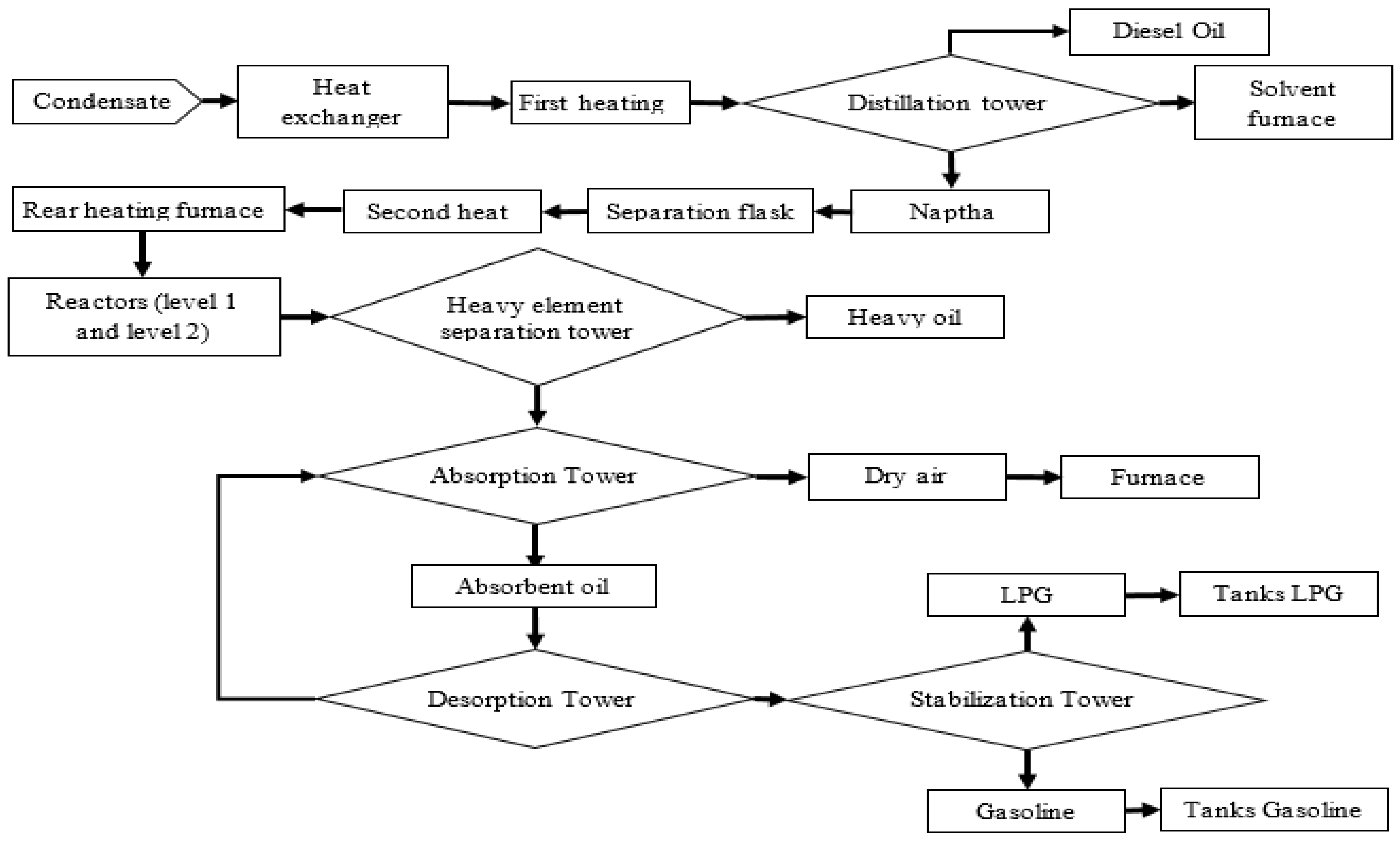

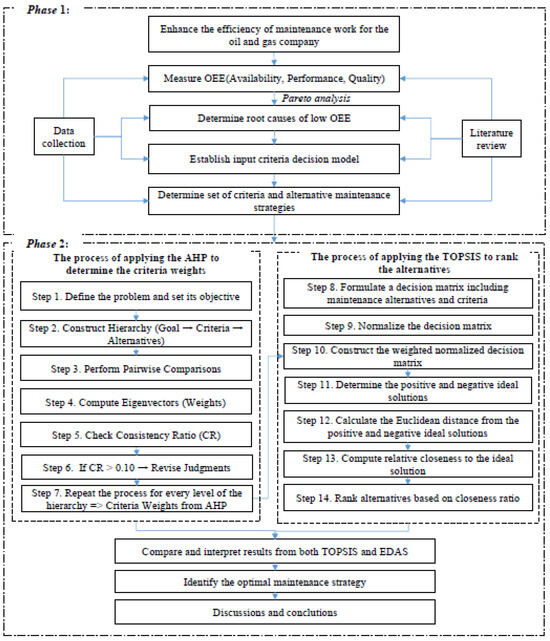

The production line operates daily for 24 h, being evenly divided into three 8 h shifts. The number of working days a week is seven days (including Sundays), and the number of working hours per year is 8760. The research team collected data for the last three years, including defects during each shift, corrective actions to correct errors, downtime, and the exact failure time. Common types of damage in each workstation are damage to the valve system, electrical, mechanical, pneumatic pressure, etc.… There may be the same failure mode in different workstations. In each case, the record also includes the failure type, machine, and failed workstation. To serve the process of preparing petroleum, the leading equipment in the plant includes seven devices: towers, heating furnaces, pumping equipment, containers, reaction towers, and valve systems. The process of mixing petroleum will be shown in detail through the technology diagram shown in Figure 2 below.

Figure 2.

Diagram of the process of mixing petroleum at company.

Research data are collected directly from maintenance department personnel and maintenance department statistics. The factory is divided into 30 leading equipment systems. During data collection, systems that have never been damaged are ignored. Therefore, only 24 systems will be selected for discussion in this study. According to the design, the maximum wattage of the plant is 130,000 tons/year. The real operating time of the equipment in each year is calculated as the sum of operating time in a year of 8760 h minus the number of downtime hours (the number of failures multiplied by the time each failure occurs). The real operation of the machinery is the availability of machinery and equipment. The time when the machinery and equipment are down and the availability time are shown in Table 1.

Table 1.

Data of downtime and availability time.

The production department has an annual registration of 80–85% of the capacity as a landmark for operation. On the other hand, for the quality ratio, due to the specificity of the oil and gas industry, the input materials through the separation process and the production system will be controlled on the computer by the DCS system, including adjusting the temperature, pressure, and flow rate of semi-finished products during production. When preparing to enter the final stage of exporting finished products, the chemical laboratory staff will be responsible for taking samples for testing. If the test does not pass, the finished product will be transferred to the reflux system for reprocessing. At this time, the parameters of the pressure and temperature conditions will be changed according to the results of the chemistry laboratory. The data on the pressure and temperature of the first flow will be based on experience and standard parameters to adjust until it runs through the finished tank system. Because the process does not have a forecast system for defective products, this causes a waste of raw materials and time and increases production costs. Additionally, the factory inevitably damaged machinery and equipment during production, affecting product quality. The summary table includes the availability index, equipment efficiency, and the ratio of product quality collected directly at the company in the past three years, as shown in Table 2.

Table 2.

Results of overall equipment effectiveness at Orient Oil, Vietnam.

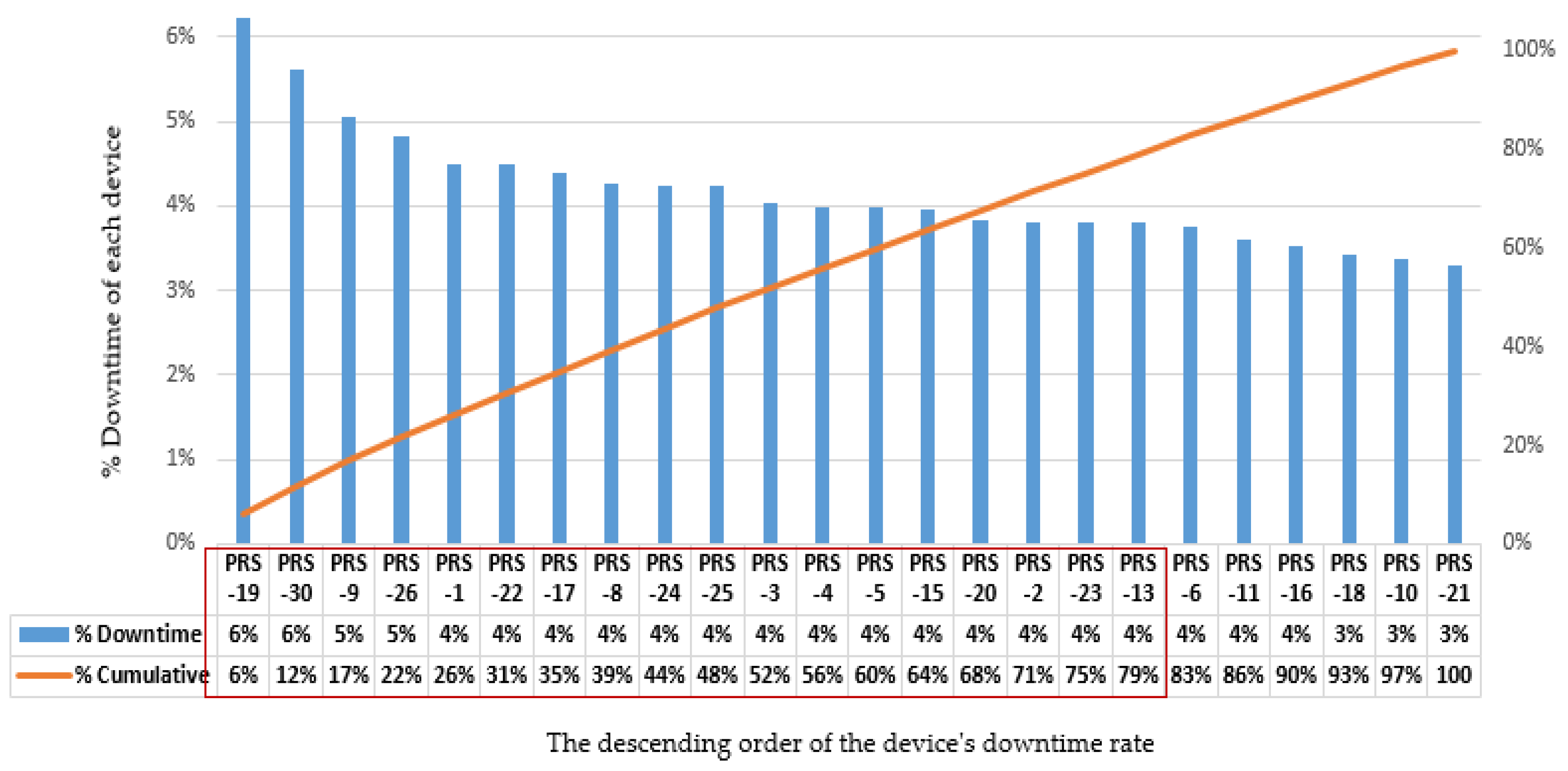

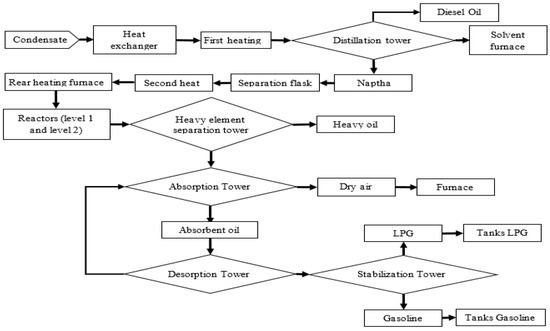

Formula 1 is applied to calculate the OEE index shown in Table 3. According to world standards, the standard value of the OEE index must reach 85% or more. The performance of OEE values from 2021 to 2023 is shown in Table 3, indicating that OEE values for the past three years are below the set requirements. More importantly, the company’s OEE index tends to decrease over 2021, 2022, and 2023. This signals that the problem of maintenance activities has not been researched, paid attention to, or implemented correctly from the start. Based on the analysis of the current state of maintenance at the company, many causes still need to be resolved to improve the maintenance work effectively. According to the Pareto principle, this maintenance strategy will be applied at the company for 19 pieces of equipment that affect 80% of the manufacturing downtime. The list is shown in the red frame in Figure 3.

Table 3.

Description of leading causes and their impact on OEE components.

Figure 3.

The list of 19 pieces of equipment affects 80% of the manufacturing’s downtime.

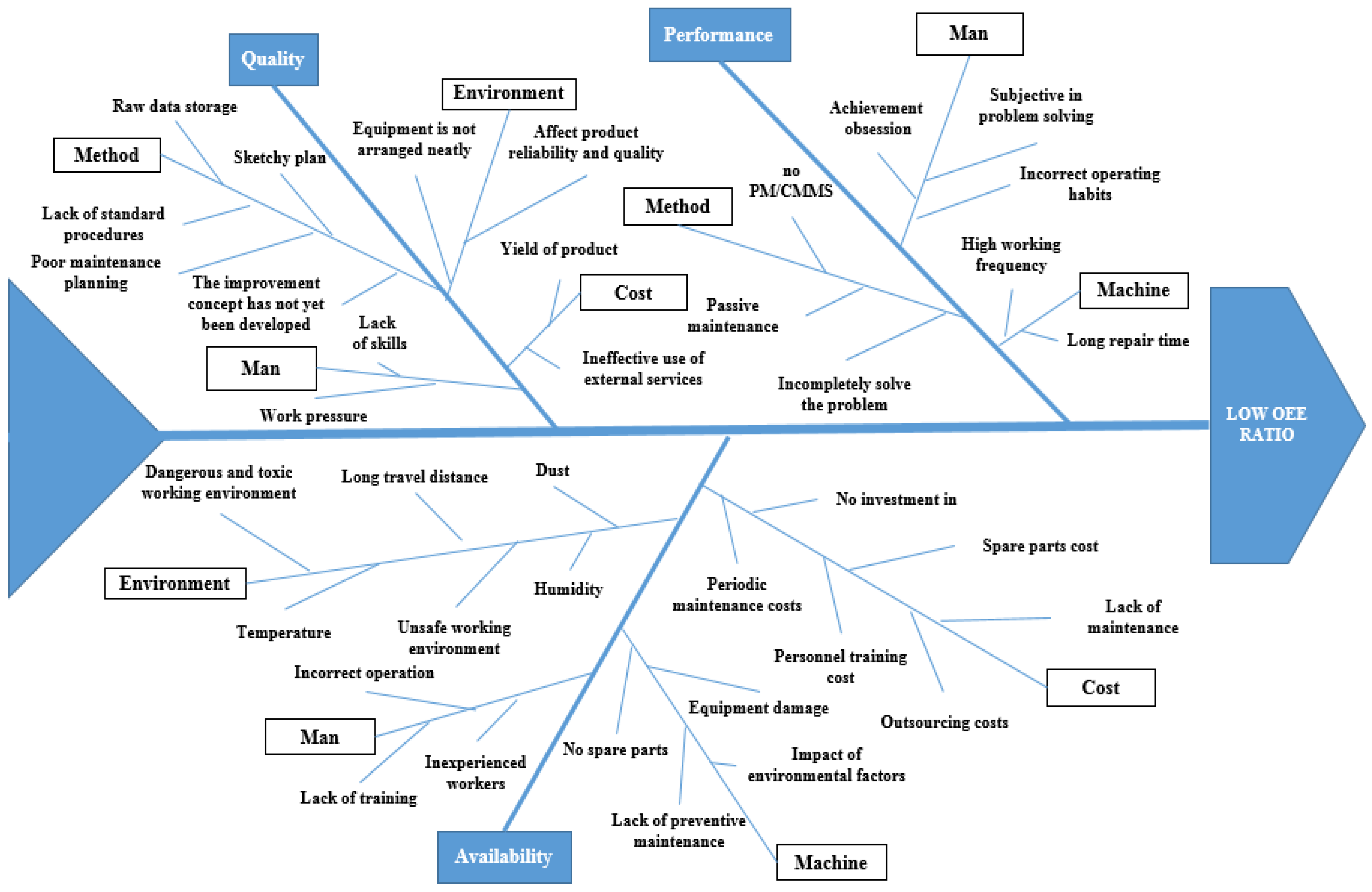

The study grouped the causes into five main groups, commonly found in industrial manufacturing environments: man, machine, method, cost/material, and environment. To identify the root causes of low OEE, each group of causes was directly linked to the three components that make up the OEE index, namely availability, performance, and quality, to clarify the mechanism that affects the overall operational efficiency of the equipment. This relationship is presented in Table 3.

Next, the Ishikawa method was used to analyze the root cause of low OEE (Fishbone diagram). This diagram is often used for “digging up” the cause after rearranging the causal relationships [44]. The resulting diagram, shown in Figure 4, highlights the five aforementioned categories as the company’s principal sources of OEE degradation.

Figure 4.

Fishbone chart analysis of the causes affecting OEE.

Through this root cause analysis, the study effectively established a causal pathway linking OEE decline to the company’s current maintenance inefficiencies. The next objective is to define criteria to select optimal maintenance strategies. These criteria must comprehensively reflect the underlying causes of poor OEE performance, ensuring that strategic decisions are evidence-based and practically applicable.

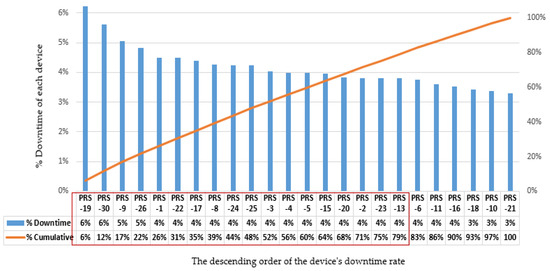

Accordingly, a hierarchical structure of decision criteria was developed using the AHP. The model consists of four primary criteria groups, namely cost, safety, efficiency, and flexibility, and eighteen sub-criteria, all directly derived from the root cause categories identified in the Fishbone diagram. This structured framework ensures alignment between observed performance issues and strategy selection. The mapping between the AHP criteria and their associated OEE impacts is presented in Table 4.

Table 4.

Relationship between AHP criteria and OEE root causes.

The factors affecting the OEE index have been transformed into input criteria for the decision-making model to select a maintenance strategy. Each AHP criterion reflects the root cause while ensuring that it is consistent with the goals and actual conditions of the enterprise. This transition bridges the current status analysis of OEE and maintenance strategy planning, helping the decision-making model achieve feasibility and high applicability in the industrial environment.

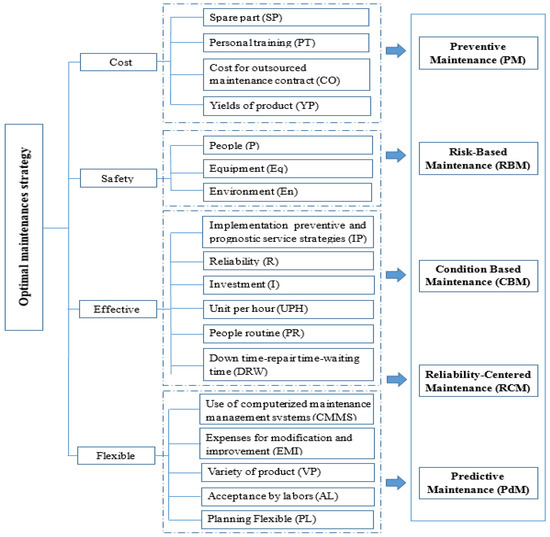

3.2.2. Choosing a Maintenance Strategy

a. Maintenance strategy

After the analysis process, the results are combined with the data collection from the maintenance department managers’ needs and related studies. The set input consists of 4 main criteria, and 18 sub-criteria were determined to select the maintenance strategies, including PM, CBM, RBM, RCM, and PdM, as shown in Figure 5.

Figure 5.

A hierarch of the criteria and maintenance strategy.

4. Results

The maintenance strategy for the refinery is determined using a model that combines the AHP and TOPSIS methods. The AHP method will be used first to assess the weights of the main criteria. From there, the weights for the sub-criteria are calculated based on the weights of the main criteria. After performing pairwise comparisons of the main criteria, the resulting weights are as follows: cost (0.055), safety (0.586), efficiency (0.256), and flexibility (0.102). The evaluation results show that the weight of safety and efficiency criteria is higher than that of cost and flexibility. This result is entirely consistent with the characteristics of the oil and gas industry because safety and efficiency factors will be given more special attention during the production process. The consistency ratio (CR) value was also tested to be 0.04, which is within the acceptable threshold of 0.1.

After determining the relationship between the overall goal and the main criteria, the sub-criteria related to the main criteria will be shown in the pairwise comparison process. The pairwise comparison matrix of the sub-criteria is built by synthesizing the experts’ assessments. After standardization, the initial pairwise comparison matrix of the sub-criteria will provide the local weights. Next, the local weights were multiplied by the main criteria weight in Table 5 to find the global weight. The CR for each sub-criteria group is also determined and presented in Table 5.

Table 5.

Comparison of each pair of sub-criteria.

Following this, the TOPSIS method was utilized to evaluate and compare the maintenance alternatives based on the weighted criteria obtained from the AHP method. A decision matrix is created based on five alternatives and eighteen criteria, with each element representing the rating of the people surveyed. In the TOPSIS method, the weight of each option related to each criterion is shown in Table 6.

Table 6.

The weights of the alternatives and criteria are aggregated using the arithmetic mean.

The elements of the decision matrix in Table 6 will be normalized to create the evaluation matrix. This step is performed according to Formulas (3) and (4) of the Methodology Section. After normalizing the elements in Table 7, the weight-normalized decision matrix will be constructed following Formula (5), where the weight is calculated using the AHP method. Apply Formulas (6) and (7) to calculate the Euclidean distance for each alternative. The positive ideal solution () and negative ideal solution () are identified by finding the maximum and minimum values of the weighted normalized elements in each column. The results in Table 7 are as follows:

Table 7.

Weighted normaliabilized decision matrix.

The Euclidean distance from the positive ideal solution () and negative ideal solution () is calculated for each alternative. The relative closeness to the ideal solutions, denoted as , is calculated for each alternative to determine the best solution. Finally, the alternatives are ranked based on their closeness ratio . This methodology calculates the close distance ratio () as in Formula (8), with the alternative closest to 1 being considered the best option.

The research results in Table 8 show that RCM is the most optimal maintenance strategy among the five strategies considered, with the ranking order of maintenance strategies being RCM > PdM > CBM > RBM > PM. The results have been verified and compared with the EDAS method; both methods provide the same results, with RCM being the most optimal maintenance strategy. The TOPSIS method will find the difference between the positive ideal value ( and the negative ideal value ), from which the ranking results are provided. From the ranking table, it is found that RCM has the highest score and shows the suitability of this strategy with the optimization criteria set by the company. The results from EDAS also provide similar ranking results, proving the consistency and high accuracy of RCM in optimizing maintenance strategies.

Table 8.

The results of optimal maintenance strategy by TOPSIS method.

The EDAS is a method for comparing and evaluating alternatives based on their distance from the average solution. This method was chosen to verify the results from TOPSIS because EDAS provides an independent approach with a more intuitive assessment of the suitability of maintenance strategies in real environments. Compared with TOPSIS, EDAS can be more flexible in handling heterogeneous and complex factors in production systems. The application of EDAS has demonstrated that the ranking results of RCM are stable and accurate in evaluating maintenance strategies, increasing the reliability of the research results. Both methods provide consistent results, indicating the rationality and high applicability of the RCM strategy. In addition to the verification by the EDAS method, the study also provides insight into the combination of AHP and TOPSIS methods in evaluating and comparing maintenance strategies. This method helps to determine the optimal strategy and clarifies the relationship between the criteria and the priority level of each factor. The result is a clear, reasonable, and convenient ranking that supports managers in making accurate and optimal decisions for the company. Another critical factor is the cost and feasibility of implementation. Hybrid methods such as GA or SA require significant computational resources and may require a long time to find the optimal solution. Meanwhile, TOPSIS can be implemented more easily in manufacturing companies, helping to save costs and reduce implementation time while ensuring maintenance efficiency. More importantly, TOPSIS considers each criterion separately and analyzes the relationship between the factors and the overall system, helping to optimize production performance and reduce maintenance costs comprehensively.

Moreover, RCM is theoretical and very practical when applied to industrial environments. Implementing the RCM strategy helps minimize failures, improve system reliability, and reduce overall maintenance costs, thanks to focusing on the most critical factors in the maintenance process and ensuring that maintenance resources are allocated reasonably. RCM is suitable for the company in the study and has broad applicability in the petrochemical refining industry. The petrochemical refining systems are highly complex and require excellent operational reliability and stability. The application of RCM helps optimize maintenance for these systems, minimize unexpected incidents, improve performance, and reduce maintenance costs. Therefore, RCM is an ideal choice for industries with complex maintenance requirements and high stability requirements, such as petrochemical refining.

Thus, this study provides a powerful tool to help the company choose the most optimal maintenance strategy and demonstrates the high practical applicability of the TOPSIS method in the petrochemical refining and production industry. Implementing an RCM strategy in the company will contribute to stable operation, improve maintenance efficiency, minimize incidents, optimize maintenance resources, and reduce overall costs for the business.

5. Discussion

The results of this study have emphasized the importance and necessity of maintenance activities in improving operational efficiency, minimizing downtime, and improving OEE in the oil blending sector of the oil and gas industry. The OEE measurement results of the enterprise show that the operational efficiency has been on a continuous downward trend over the past three years, with a value lower than the global standard of 85%. This situation further highlights the urgency of developing and applying a more effective maintenance strategy based on practical data.

To address this pressing issue, the study proposed applying the AHP-TOPSIS combined methodology framework in the MCDM system to evaluate and select the optimal maintenance strategy. It should be noted that the AHP-TOPSIS-integrated approach was first applied in the oil and gas sector to choose a maintenance strategy based on the criteria: safety, cost, efficiency, and flexibility. The application of AHP-TOPSIS allows for the systematic evaluation of multiple criteria at the same time, thereby enhancing consistency in the decision-making process in the oil and gas industry.

The outstanding contribution of the study is the construction of a comprehensive evaluation framework, including a detailed decision matrix and quantitative analysis of the criteria, ensuring that the evaluation process is based on real data and can be reproduced in subsequent studies.

Moreover, to bridge the gap between theoretical analysis and practical application, the study conducted compares the potential suitability of maintenance strategies by analyzing the advantages and disadvantages of each option in the actual context of the oil and gas industry, as shown in Table 9.

Table 9.

Comparison of maintenance strategies for the oil and gas industry.

Although all five maintenance strategies have advantages, the company’s long-term goal is to enhance the OEE index and reduce production losses due to equipment failures. Meanwhile, the RCM strategy balances operational efficiency, safety, and cost-effectiveness. Notably, compared with the existing literature [25,45], the study also shows consistent results: RCM is often favored in environments that require operational excellence but have not yet achieved a complete digital transformation. This indicates that the recommendation of RCM in this study is based on data and the context of the Vietnamese oil and gas industry.

The study is based on the AHP-TOPSIS results and was reconfirmed by the EDAS method, showing high consistency and reliability throughout the strategy selection process. This cross-validation confirms that RCM consistently outperforms other strategies, providing scientific rigor and additional credibility to the results.

In terms of practical implementation, although PdM and CBM strategies also demonstrate modernity and are ranked higher after RCM, the significant technological investment costs and operational complexity barriers make mass adoption difficult, especially for companies with limited infrastructure.

Meanwhile, RCM allows for a more systematic implementation roadmap, starting with training personnel in the analysis process and applying computerized maintenance management systems (CMMSs) and failure analysis tools such as FMEA. Furthermore, staying ahead of emerging technologies like IoT and machine learning can enhance the predictive capabilities of RCM, moving the strategy closer to real-time, intelligent maintenance ecosystems.

However, the study still has some limitations:

- Reliance on manual data: Data collection from personnel and manual recording can lead to bias or inconsistencies.

- Limited data scope: The data were collected from a single enterprise, while operational and maintenance factors can vary significantly across manufacturing facilities or industries.

- Limitations in applying modern technology: Although advanced strategies such as PdM or CBM have potential, they have not been widely deployed due to high investment and infrastructure requirements.

In conclusion, the study provides a quantitative, transparent, and scalable approach to maintenance strategy selection. It promotes operational efficiency, reduces costs, and increases sustainability in oil and gas production. Adopting RCM as a central strategy can be a practical solution for many businesses in the industry to achieve sustainable development and long-term competitiveness.

6. Conclusions

6.1. Findings

The findings of this study show the integrated model of the MCDM techniques (AHP, TOPSIS) along with the OEE index and verification using EDAS, which is useful specifically within the unique operational context and challenges of the oil and gas industry. This integrated framework provides a systematic, quantitative approach to maintenance strategy selection, which was previously limited in detailed studies within this sector. The structured process, from analyzing OEE and identifying root causes via the Fishbone diagram, defining the criteria and sub-criteria linked to these causes, determining criteria weights using AHP, evaluating and ranking strategies with TOPSIS based on these weighted criteria, to finally verifying the results with EDAS, represents the novel comprehensive methodology applied to the oil and gas industry-specific problem. This model uses a data-based decision, ensuring alignment with the company’s goals and conditions.

The study shows that RCM is theoretical and practical when applied to industrial environments. RCM is the optimal choice based on a systematic, data-driven, multi-criteria evaluation tailored to the specific context of the oil and gas industry. Additionally, implementing RCM helps minimize failures, improve system reliability, and reduce maintenance costs by focusing on critical factors and allocating resources reasonably. RCM is highlighted as suitable for the company in this study and has broad applicability in the petrochemical refining industry due to its complexity and requirement for high reliability and stability.

6.2. Contributions

The study proposed several significant contributions to both academic research and industrial practice.

The scholarly contributions include proposing a novel hybrid approach combining AHP and TOPSIS for maintenance strategy selection in the oil and gas industry and expanding the theoretical foundation in industrial maintenance. It marks the first application of the AHP-TOPSIS method to maintenance strategy selection within this sector, using safety, cost, efficiency, and flexibility as evaluation criteria. The study also validates the EDAS method as a cross-validation tool. It provides a structured, data-driven decision support tool applicable across various industries. Moreover, the research emphasizes the significance of the OEE index as a metric for evaluating performance and identifying maintenance needs. It employs a Fishbone diagram to analyze the primary factors impacting OEE in oil and gas companies. It offers a detailed analysis and comparison of five maintenance strategies (PM, RBM, CBM, RCM, and PdM) within the oil and gas industry context. It explores four main criteria and their eighteen sub-criteria for selection. The study also proposes future research directions and demonstrates the application of the AHP-TOPSIS model in an honest company. It quantitatively presents criteria weights and TOPSIS/EDAS results, explicitly highlighting its novelty in applying these techniques tailored to the oil and gas industry’s unique challenges.

In addition, industrial contributions include providing oil and gas enterprises with a systematic, data-driven methodology for selecting the optimal maintenance strategy and facilitating consistent and efficient decision-making. It emphasizes the crucial role of the correct maintenance strategy in enhancing OEE, reducing downtime, and lowering costs. The case study results indicate that RCM is the most optimal strategy for the studied company, offering superior performance and reliability. It provides a feasibility analysis for RCM in real industrial settings, highlighting its potential benefits and comparing different strategies regarding cost-effectiveness and implementation. The study underscores RCM’s alignment with the oil and gas industry’s high emphasis on safety and efficiency and suggests concrete steps for RCM’s implementation. It highlights RCM’s broad applicability in complex petrochemical refining systems and quantitatively indicates the company’s declining OEE, emphasizing the urgency for improved strategies.

6.3. Future Research Directions

Future research could develop a predictive maintenance model that integrates advanced technologies, building a predictive maintenance framework incorporating advanced technologies such as the Industrial Internet of Things (IIoT), artificial intelligence (AI), and machine learning. This model could provide real-time data analysis, the early detection of failure signals, and automatically recommend an optimal maintenance plan for each piece of equipment in the oil blending system.

In addition, the study may extend to test the sensitivity of changing the weight of each criterion to consider how the results depend on the criterion weights, especially safety and cost, which might influence the rankings of different maintenance strategies.

Moreover, the research may also compare maintenance strategies across the automotive, electronics, and chemical manufacturing industries. Evaluating similarities and differences in the selection and implementation of maintenance strategies would help identify each industry’s best way to implement and provide a basis for the flexible adaptation and application of RCM or a hybrid approach.

Author Contributions

The authors confirm their contribution to the paper as follows: study conception and design: C.-N.W. and M.-H.H.; data collection: Q.-T.D. and T.D.-M.L.; analysis and interpretation of results: D.-O.T.T. and C.-N.W.; draft manuscript preparation: T.D.-M.L. and D.-O.T.T. All authors have read and agreed to the published version of the manuscript.

Funding

This article is partially supported by the NSTC 113-2622-E-992-012 project.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within the article.

Conflicts of Interest

Author Q.-T.D. was employed by the company Orient Oil and Gas Joint Stock Company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The Orient Oil and Gas Joint Stock Company, in affiliation and funding, had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Velmurugan, R.S.; Dhingra, T. Maintenance strategy selection and its impact in maintenance function: A conceptual framework. Int. J. Oper. Prod. Manag. 2015, 35, 1622–1661. [Google Scholar] [CrossRef]

- Zhong, D.; Xia, Z.; Zhu, Y.; Duan, J. Overview of predictive maintenance based on digital twin technology. Heliyon 2023, 9, e14534. [Google Scholar] [CrossRef] [PubMed]

- Vyasa, V.; Xu, Z. Maintenance in automotive and aerospace applications—An overview. Int. J. Adv. Sci. Trans. 2024, 3, 349–361. [Google Scholar]

- Alsyouf, I. The role of maintenance in improving companies’ productivity and profitability. Int. J. Prod. Econ. 2007, 105, 70–78. [Google Scholar] [CrossRef]

- Dowlatshahi, S. The role of industrial maintenance in the maquiladora industry: An empirical analysis. Int. J. Prod. Econ. 2008, 114, 298–307. [Google Scholar] [CrossRef]

- Oluwatoyin, O.A.; Afolalu, S.A.; Monye, S.I. Maintenance Impact on Production Profitability in Industry—An Overview. In Proceedings of the 2024 International Conference on Science, Engineering and Business for Driving Sustainable Development Goals (SEB4SDG), Omu-Aran, Nigeria, 2–4 April 2024; IEEE: Piscataway, NJ, USA, 2024. [Google Scholar]

- Mostafa, S.; Lee, S.-H.; Dumrak, J.; Chileshe, N.; Soltan, H. Lean thinking for a maintenance process. Prod. Manuf. Res. 2015, 3, 236–272. [Google Scholar] [CrossRef]

- Kothamasu, R.; Huang, S.H. Adaptive Mamdani fuzzy model for condition-based maintenance. Fuzzy Sets Syst. 2007, 158, 2715–2733. [Google Scholar] [CrossRef]

- Pinjala, S.K.; Pintelon, L.; Vereecke, A. An empirical investigation on the relationship between business and maintenance strategies. Int. J. Prod. Econ. 2006, 104, 214–229. [Google Scholar] [CrossRef]

- Yang, L.; Zhao, Y.; Peng, R.; Ma, X. Opportunistic maintenance of production systems subject to random wait time and multiple control limits. J. Manuf. Syst. 2018, 47, 12–34. [Google Scholar] [CrossRef]

- Jaqin, C.; Alimudin, D.; Purba, H.H.; Aisyah, S. Performance Improvement of Injection Pump Machines Based on Overall Equipment Effectiveness: Case Study in Oil Company. In Proceedings of the 2019 1st International Conference on Engineering and Management in Industrial System (ICOEMIS 2019), Malang, Indonesia, 8–9 August 2019; Atlantis Press: Dordrecht, The Netherlands, 2019. [Google Scholar]

- Emovon, I.; Norman, R.A.; Murphy, A.J. Hybrid MCDM based methodology for selecting the optimum maintenance strategy for ship machinery systems. J. Intell. Manuf. 2018, 29, 519–531. [Google Scholar] [CrossRef]

- Seiti, H.; Hafezalkotob, A. Developing the R-TOPSIS methodology for risk-based preventive maintenance planning: A case study in rolling mill company. Comput. Ind. Eng. 2019, 128, 622–636. [Google Scholar] [CrossRef]

- Kirubakaran, B.; Ilangkumaran, M. Selection of optimum maintenance strategy based on FAHP integrated with GRA–TOPSIS. Ann. Oper. Res. 2016, 245, 285–313. [Google Scholar] [CrossRef]

- Wang, C.-N.; Pan, C.-F.; Nguyen, H.-P.; Fang, P.-C. Integrating fuzzy AHP and TOPSIS methods to evaluate operation efficiency of daycare centers. Mathematics 2023, 11, 1793. [Google Scholar] [CrossRef]

- Hemmati, N.; Rahiminezhad Galankashi, M.; Imani, D.; Mokhatab Rafiei, F. An integrated fuzzy-AHP and TOPSIS approach for maintenance policy selection. Int. J. Qual. Reliab. Manag. 2020, 37, 1275–1299. [Google Scholar] [CrossRef]

- Jamali, N.; Feylizadeh, M.R.; Liu, P. Prioritization of aircraft maintenance unit strategies using fuzzy Analytic Network Process: A case study. J. Air Transp. Manag. 2021, 93, 102057. [Google Scholar] [CrossRef]

- Bayoumi, A.; McCaslin, R. Internet of things–a predictive maintenance tool for general machinery, petrochemicals and water treatment. In Advanced Technologies for Sustainable Systems: Selected Contributions from the International Conference on Sustainable Vital Technologies in Engineering and Informatics, Proceedings of the BUE ACE1 2016, Cairo, Egypt, 7–9 November 2016; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Hameed, A.; Khan, F. A framework to estimate the risk-based shutdown interval for a processing plant. J. Loss Prev. Process Ind. 2014, 32, 18–29. [Google Scholar] [CrossRef]

- Cai, Y.; Teunter, R.H.; de Jonge, B. A data-driven approach for condition-based maintenance optimization. Eur. J. Oper. Res. 2023, 311, 730–738. [Google Scholar] [CrossRef]

- Braglia, M.; Castellano, D.; Frosolini, M. An integer linear programming approach to maintenance strategies selection. Int. J. Qual. Reliab. Manag. 2013, 30, 991–1016. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, D.; Wang, H. Data-driven methods for predictive maintenance of industrial equipment: A survey. IEEE Syst. J. 2019, 13, 2213–2227. [Google Scholar] [CrossRef]

- Alfahdi, K.; Gultekin, H.; Summad, E. A Novel Prognostics and Health Management Framework to Extract System Health Requirments in the Oil and Gas Industry. Int. J. Progn. Health Manag. 2024, 15, 2213–2227. [Google Scholar] [CrossRef]

- Prajapati, A.; Bechtel, J.; Ganesan, S. Condition based maintenance: A survey. J. Qual. Maint. Eng. 2012, 18, 384–400. [Google Scholar] [CrossRef]

- Zeinalnezhad, M.; Chofreh, A.G.; Goni, F.A.; Klemeš, J.J. Critical success factors of the reliability-centred maintenance implementation in the oil and gas industry. Symmetry 2020, 12, 1585. [Google Scholar] [CrossRef]

- Ylipää, T.; Skoogh, A.; Bokrantz, J.; Gopalakrishnan, M. Identification of maintenance improvement potential using OEE assessment. Int. J. Product. Perform. Manag. 2017, 66, 126–143. [Google Scholar] [CrossRef]

- Theissler, A.; Pérez-Velázquez, J.; Kettelgerdes, M.; Elger, G. Predictive maintenance enabled by machine learning: Use cases and challenges in the automotive industry. Reliab. Eng. Syst. Saf. 2021, 215, 107864. [Google Scholar] [CrossRef]

- Einabadi, B.; Mahmoodjanloo, M.; Baboli, A.; Rother, E. Dynamic predictive and preventive maintenance planning with failure risk and opportunistic grouping considerations: A case study in the automotive industry. J. Manuf. Syst. 2023, 69, 292–310. [Google Scholar] [CrossRef]

- Arinze, C.A.; Izionworu, V.O.; Isong, D.; Daudu, C.D.; Adefemi, A. Predictive maintenance in oil and gas facilities, leveraging ai for asset integrity management. Int. J. Front. Eng. Technol. Res. 2024, 6, 16–26. [Google Scholar] [CrossRef]

- Mallioris, P.; Aivazidou, E.; Bechtsis, D. Predictive maintenance in Industry 4.0: A systematic multi-sector mapping. CIRP J. Manuf. Sci. Technol. 2024, 50, 80–103. [Google Scholar] [CrossRef]

- Faghihinia, E.; Mollaverdi, N. Building a maintenance policy through a multi-criterion decision-making model. J. Ind. Eng. Int. 2012, 8, 14. [Google Scholar] [CrossRef]

- Pei, Y.; Liu, Z.; Xu, J.; Qi, B.; Cheng, Q. Grouping preventive maintenance strategy of flexible manufacturing systems and its optimization based on reliability and cost. Machines 2023, 11, 74. [Google Scholar] [CrossRef]

- Liu, X.-W.; Li, C.-Y.; Dang, S.; Wang, W.; Qu, J.; Chen, T.; Wang, Q.-L. Research on training effectiveness of professional maintenance personnel based on virtual reality and augmented reality technology. Sustainability 2022, 14, 14351. [Google Scholar] [CrossRef]

- Ng Corrales, L.d.C.; Lambán, M.P.; Hernandez Korner, M.E.; Royo, J. Overall equipment effectiveness: Systematic literature review and overview of different approaches. Appl. Sci. 2020, 10, 6469. [Google Scholar] [CrossRef]

- Prasetyo, Y.T.; Veroya, F.C. An application of overall equipment effectiveness (OEE) for minimizing the bottleneck process in semiconductor industry. In Proceedings of the 2020 IEEE 7th International Conference on Industrial Engineering and Applications (ICIEA), Bangkok, Thailand, 16–18 April 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar]

- Dovere, E.; Cavalieri, S.; Ierace, S. RFId systems for moveable asset management: An assessment model. Int. J. Prod. Res. 2017, 55, 1336–1349. [Google Scholar] [CrossRef]

- Hwang, G.; Lee, J.; Park, J.; Chang, T.-W. Developing performance measurement system for Internet of Things and smart factory environment. Int. J. Prod. Res. 2017, 55, 2590–2602. [Google Scholar] [CrossRef]

- Gupta, A.K.; Garg, R. OEE improvement by TPM implementation: A case study. Int. J. IT Eng. Appl. Sci. Res. 2012, 1, 115–124. [Google Scholar]

- Pant, S.; Kumar, A.; Ram, M.; Klochkov, Y.; Sharma, H.K. Consistency indices in analytic hierarchy process: A review. Mathematics 2022, 10, 1206. [Google Scholar] [CrossRef]

- Rios, R.; Duarte, S. Selection of ideal sites for the development of large-scale solar photovoltaic projects through Analytical Hierarchical Process–Geographic information systems (AHP-GIS) in Peru. Renew. Sustain. Energy Rev. 2021, 149, 111310. [Google Scholar] [CrossRef]

- Chakraborty, S. TOPSIS and Modified TOPSIS: A comparative analysis. Decis. Anal. J. 2022, 2, 100021. [Google Scholar] [CrossRef]

- Madanchian, M.; Taherdoost, H. A comprehensive guide to the TOPSIS method for multi-criteria decision making. Sustain. Soc. Dev. 2023, 1, 2220. [Google Scholar] [CrossRef]

- Orient Oil and Gas Joint Stock Company. Available online: https://www.topcv.vn/cong-ty/cong-ty-co-phan-dau-khi-dong-phuong/103004.html (accessed on 20 April 2025).

- Luo, T.; Wu, C.; Duan, L. Fishbone diagram and risk matrix analysis method and its application in safety assessment of natural gas spherical tank. J. Clean. Prod. 2018, 174, 296–304. [Google Scholar] [CrossRef]

- Van Nguyen, T. Research on solutions for connecting to marginal fields at Cuu Long basin to process and transport the products basing on existing petroleum technology and equipment. J. Min. Earth Sci. Vol. 2021, 62, 65–75. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).