1. Introduction

Today, there are trends in environmental issues, and many attempts have been made to fix ecological problems due to environmental concerns. Acquiring environmentally friendly materials addresses these issues and can be utilized to fabricate biodegradable materials. Rice husk (RH) and straw (RS), one of the residue materials from the rice milling process, are among the most abundant biomass materials in rice-culturing countries, especially in Asia, due to 90% of the total global rice produced from these regions [

1]. The Food and Agriculture Organization (FAO) reported a global rice production of 1000 million tons, and approximately 200 million tons of rice husk (20% of rice production) were generated [

2]. The annual output of rice produces enormous quantities of straw and husk, approximately 8 × 10

11 kg and 1.5 × 10

11 kg, respectively [

3]. In Thailand, rice production of around 22.2 million tons results in 3–5 million tons of these wastes [

4]. The burning of RH, RS, and other crop residuals is released to free up land space and clear the field for subsequent cultivation. Agricultural residual burning is now associated with environmental problems, particularly PM 2.5 emissions [

5]. In 2024, Thailand’s Pollution Control Department (PCD) reported that 24% of hotspots were in agricultural zones. In the agricultural sector, rice farms were the primary source of burning, which was also detected in rice paddy fields [

6]. The massive amount of burning for the subsequent cultivation introduces the air problem, including PM 2.5 in rural areas, and to control it, the law of burning has been reported as illegal. Stealth of burning has still occurred, especially in northern Thailand. Then, agricultural residual materials must address these PM 2.5 emission issues and be interested in fabricating biodegradable materials.

Using RH and RS, a biomass residue material containing cellulose, hemicellulose, lignin, silica, and other minor components has been utilized to manage waste. RH comprises 25–35% cellulose, 18–21% hemicellulose, 26–31% lignin, and 15–25% silica [

7]. The difference in the amount of RS contains cellulose (32–38%), hemicellulose (20–36%), lignin (14–22%), and silica (10–17%). The work reported cellulose contents in RS and RH to be 32.0–38.6% and 28.6–43.3%, respectively [

3]. These residual materials could be value-added, such as adsorbents, biofertilizers, bio-insulators, and superhydrophobic coatings [

1]. However, the compositions of RH and RS differ in the rice varieties. The cellulose content in the Thai rice of “

Phitsanulok 2” ranges from 2.0% to 32.0% [

8]; these cellulose values could be used for transformation in various applications. Consequently, researchers have been interested in converting cellulose into high-value materials and using them to make paperboard [

4,

9].

Cellulose, a significant component, is converted to Carboxymethyl cellulose (CMC) through carboxymethylation, where the hydroxy group (-OH) is substituted with monochloroacetic acid under strong alkaline conditions [

3,

10]. The CMC’s synthesis was first found in 1918 and first depicted in Germany in the early 1920s as a commercial product [

11]. Its applications are varied due to its white color, lack of taste and odor, high soluble content in water or alkaline solutions, and pH stability [

12]. The CMC’s synthesis could be from various materials or agricultural wastes composed of cellulose, such as corn husks [

13,

14], banana rachis [

15], pineapple leaf and core [

16,

17], durian husk [

18], orange peel [

19], rice husks and sugar cane bagasse [

20]. The significant difference in the solubilities of cellulose and CMC is that CMC contains anionic groups (carboxyl groups, -COO-), which originate from carboxymethyl (-CH

2-COO-) groups in its structure, replacing the hydroxy groups of cellulose. Due to its negative charge, the carboxyl group can interact with cationic compounds in solution, depending on the pH value. This interaction helps stabilize the emulsion, disperse particles, and acts as a thickening agent of CMC. Therefore, CMC is utilized in various applications, such as in biomedical fields. CMC is widely used in tissue engineering [

21], wound dressing [

22], and food as a thickening agent [

23].

CMC has been a preferred choice for fabricating biodegradable films in recent decades, replacing polymer films [

10]. Blending CMC with another polymer has been presented for accomplishing the desired properties, e.g., with starch for electrical conductivity property [

24], with zein for water uptake capacity (WUC) property [

25], with chitosan or with gelatin for bioactive properties [26, 27]. Biodegradable films are polymeric materials that exhibit biodegradability, biocompatibility, recyclability, and good mechanical properties [

12]. Biodegradable CMC-based composites are preferred due to their abundance, non-toxic nature, and environmental benefits, which can be applied in food packaging [

24,

25,

26,

27,

28]. Not only in food packaging applications, CMC-based hydrogel has also been reviewed as ref. [

12] in the agriculture field for releasing NPK fertilizers, in wastewater treatment for dye removal, in fabric for antibacterial properties, or as a scaffold material in tissue engineering [

12].

The cellulose contents from RS (32.0–38.6%) and RH (28.6–43.3%) [

3] were interesting to our knowledge of extracting through chemical processing in preparing CMC biodegradable film. Due to the vast amount of waste in our country contributing to environmental problems, this excessive waste was left in the field and burned for the next cultivation; therefore, this study focused on reducing and utilizing it, converting it into CMC and starch-CMC-based films. Starch is commonly used to form degradable films due to its low cost and ability to form a continuous matrix [

20]. Citric acid served as a crosslinking agent to enhance the obtained film’s water barrier and mechanical properties [

29]. In this work, we synthesized CMC from RH and RS through alkaline treatments with KOH and NaOH, respectively, acid hydrolysis, bleaching, maceration, and etherification, and characterized the chemical and mechanical properties. We also blended biodegradable films of RH-CMC and RS-CMC with corn starch, demonstrating their properties for fabricating biodegradable starch/CMC films using citric acid and glycerol fillers. We utilized these starch-based CMC biodegradable films to demonstrate their practical application in tomato preservation, highlighting their potential for food applications. Importantly, we investigated customer satisfaction with the biodegradable film-based RH, providing insights into the public’s perception of sustainable environmental material for adopting sustainable material applications and uses. This evaluation is crucial for understanding the broader implications of our research.

3. Results

3.1. Cellulose Extraction from RH and RS

After drying, cellulose was treated with an alkaline process, resulting in approximately 4.0% RH and 7.0% RS moisture content. The alkaline process removes silica, lignin, and hemicellulose from RH and RS materials. KOH was employed for RH treatment because it required a slightly basic environment to remove silica from the rigid structure of RS [

20], due to the higher silica content than RS. The results showed a physical change in the appearance of materials after alkaline treatment. The RH turned from dark brown to light brown, whereas RS showed significant differences even when using NaOH. As ref. [

31], Johar [

31] reported that alkali treatment could effectively remove hemicellulose, reducing it from 33.0% to 12.0%, which led to a color change. Decolorization involved removing non-cellulosic materials and other impurities, such as lignin, hemicellulose, pectin, and wax [

30,

31,

32]. The material’s size became smaller and softer after alkaline treatment. RS obtained more significant differences in lighter colors, finer textures, and smoother surfaces than RH. The high lignin content of RH makes it more rigid and stiffer than RS [

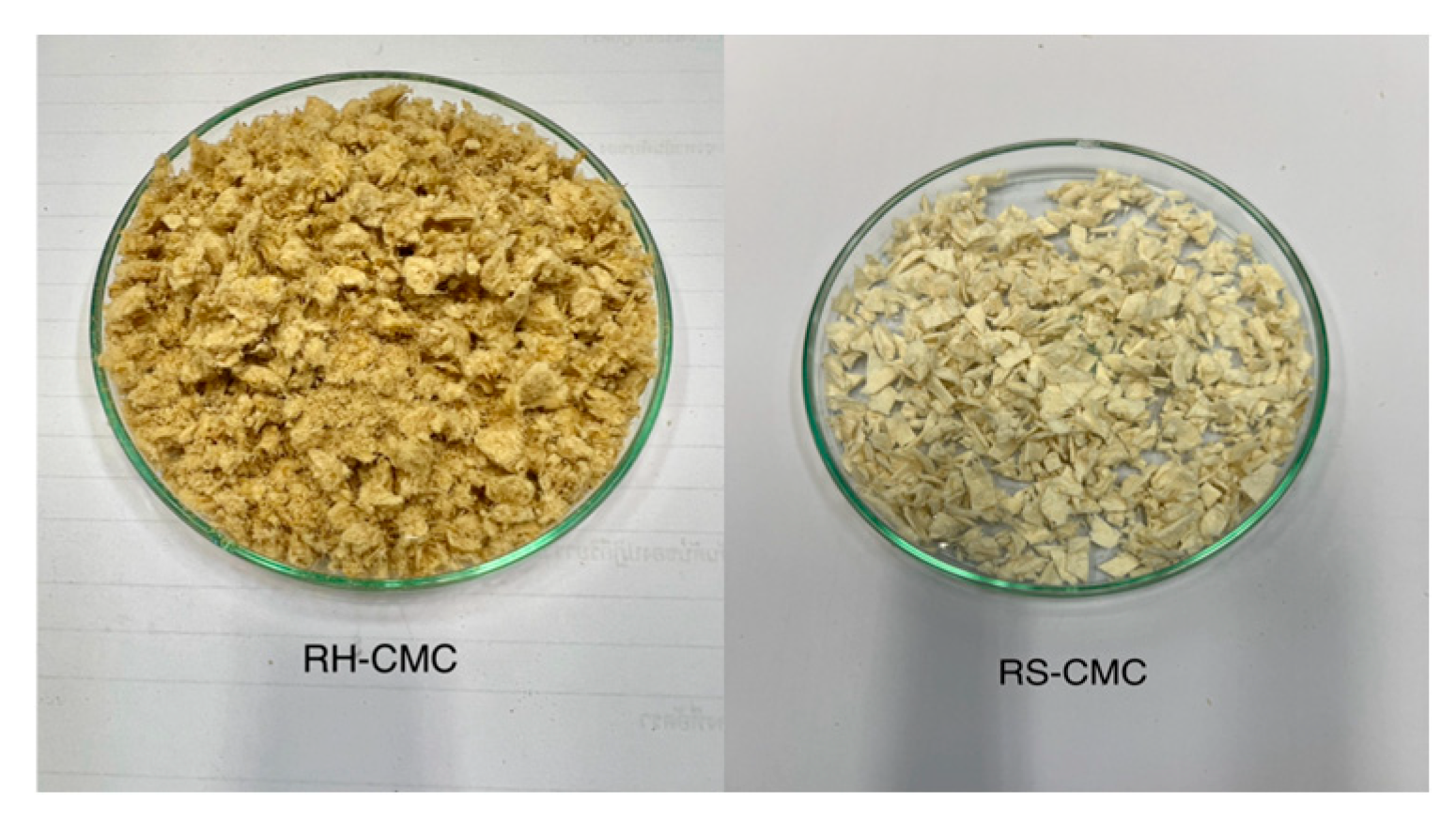

9]. The hydrolysis of cellulose-RH and RS removed imperfect fibers and enhanced purity, resulting in a refined material structure. The fiber bleaching was intended to improve the whiteness of the fibers by removing hemicellulose and lignin during the bleaching process. They became lighter in color; RH turned yellowish-brown, while RS showed white, as in

Figure 1. Additionally, they became softer and more fragile. The cellulose yields in RH and RS were 80.95% and 76.56%, respectively. Compared to previous work, the obtained celluloses were higher than those reported in ref. [

33]; however, the cellulose content depends on the chemical composition of the starting materials and the extraction conditions, including NaOH concentration, temperature, and reaction time. As a result, cellulose-RH and RS possessed the general properties required for CMC production.

3.2. Conversion of Cellulose from RH and RS to CMCs

Macerations of cellulose-RH and RS were to enhance their strength and lustrous appearance. Gel formations were floated in the alcohol layer, improving the stability and shiny appearance of the cellulose fibers. Cellulose reacts with NaOH, removing the hydroxy group (-OH) in its structure and forming sodium cellulose (cellulose-ONa). The product reacts with ClCH

2COONa to form CMC via etherification, converting it into an ether group. The resulting product was more gel-like and more elastic. The RH-CMC and RS-CMC exhibited physical changes compared to celluloses, which were softer, more fragile, and more easily dissolved in water. The color appearance of RH-CMC was yellowish, and RS-CMC was lighter, as shown in

Figure 2. The CMC yield of RH-CMC (84.8%), which was close to 20, was higher than that of RS-CMC (76.4%). It may be caused by the material’s chemical composition and the size of the starting material, due to the different physicochemical characteristics of sized materials [

33]. In general, smaller starting materials provide a larger surface area for chemical reactions, which could explain the higher percentage of RH-CMC.

3.3. Characterization of RH-CMC and RS-CMC

3.3.1. Degree of Substitution

The degree of substitution (DS) determines the average number of -OH groups on the cellulose structure replaced by ether (-CH

2COO-) groups. The value depends on the source and synthesis conditions of cellulose. DS determination is based on acid-base titration of NaOH and HCl. Results showed that the DS values of CMCs (RH-CMC and RS-CMC) were 0.386, similar to those reported in refs. [

20,

34]. This value was lower than reported in ref. [

35], likely due to the methyl groups obstructing the replacement of –OH groups in the cellulose structure. The lowest DS could be assigned to its more significant interactions with the non-cellulosic components, causing lesser exposure of the –OH groups to substitution. The fundamental compositional differences and the NaOH concentration used in the initial stage of the carboxymethylation process significantly affected the final etherifying stage, regulating the product properties [

36].

3.3.2. CMC Contents

The CMC contents were tested after the impurities in the methanol solution were removed. Weight differences were calculated from the CMC contents. RH-CMC provided 80.9%, higher than RS (57.7%), reflecting the high amount of cellulose and the good efficiency of cellulose-RH after alkaline treatment. However, compared to 36, the results were lower because of weaker alkaline conditions and different rice varieties.

3.3.3. NaCl Contents

The NaCl content is from the side reaction (Equation (7)). The NaCl content is related to the efficiency of CMC synthesis, which is characterized by a high synthesis efficiency, and CMC’s purity presents a low amount of NaCl content.

The NaCl determination used a precipitation titration based on the Mohr method. The NaCl contents were 0.77% in RH-CMC and 3.67% in RS-CMC. The result showed that RH’s product purity (99.23%) was higher than RS’s (96.33%). The smaller particle size of RH-CMC exhibited lower NaCl content (0.77%) and higher purity (99.23%) than RS-CMC, due to the larger surface area of RH providing the contraction in a chemical reaction. Our measurements (% CMC yields, % CMC content, degree of substitution (DS), and % NaCl) were compared to those of commercial-grade Na-CMC, which were obtained using the same processes described in

Table 1.

3.3.4. Chemical Characterizations

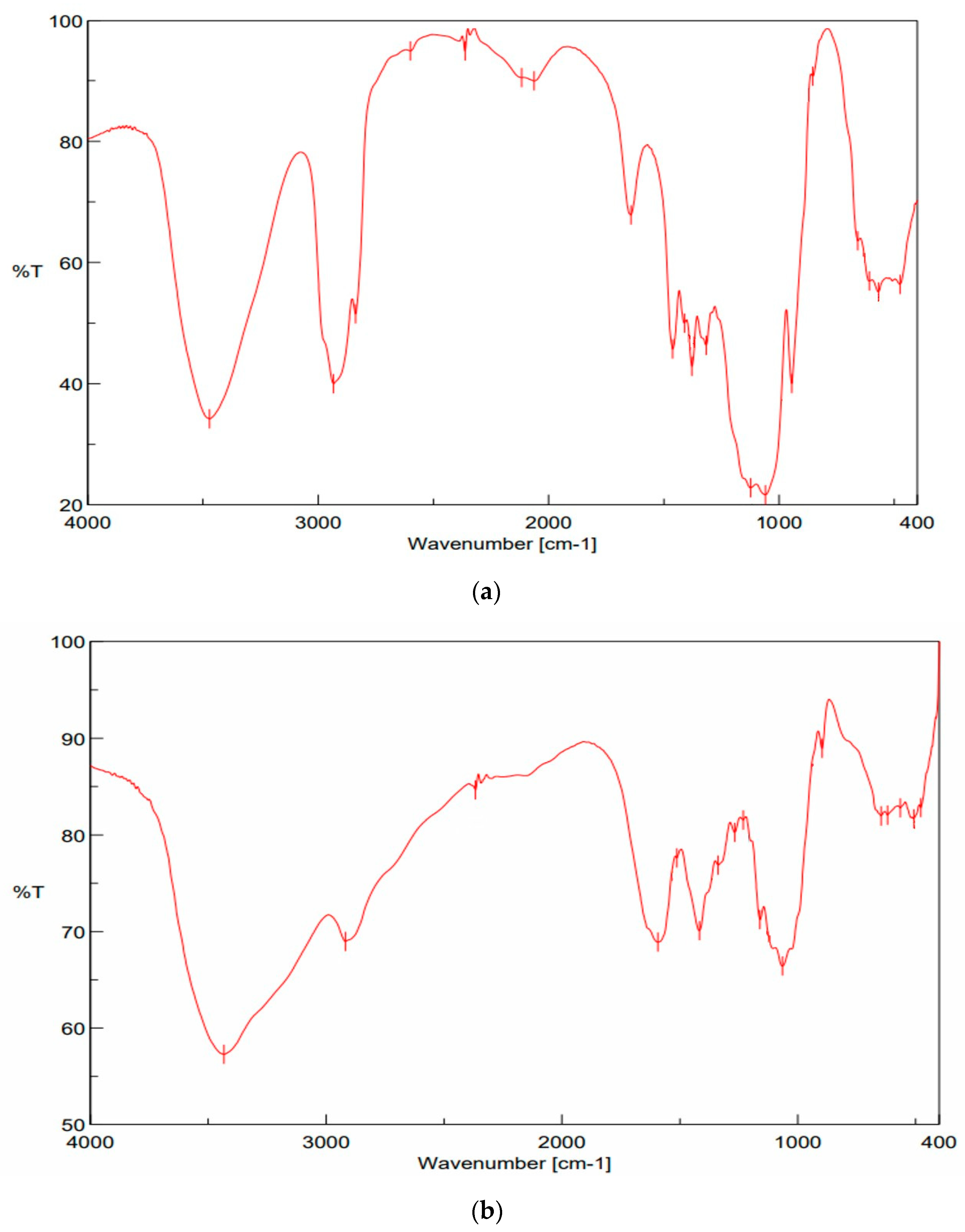

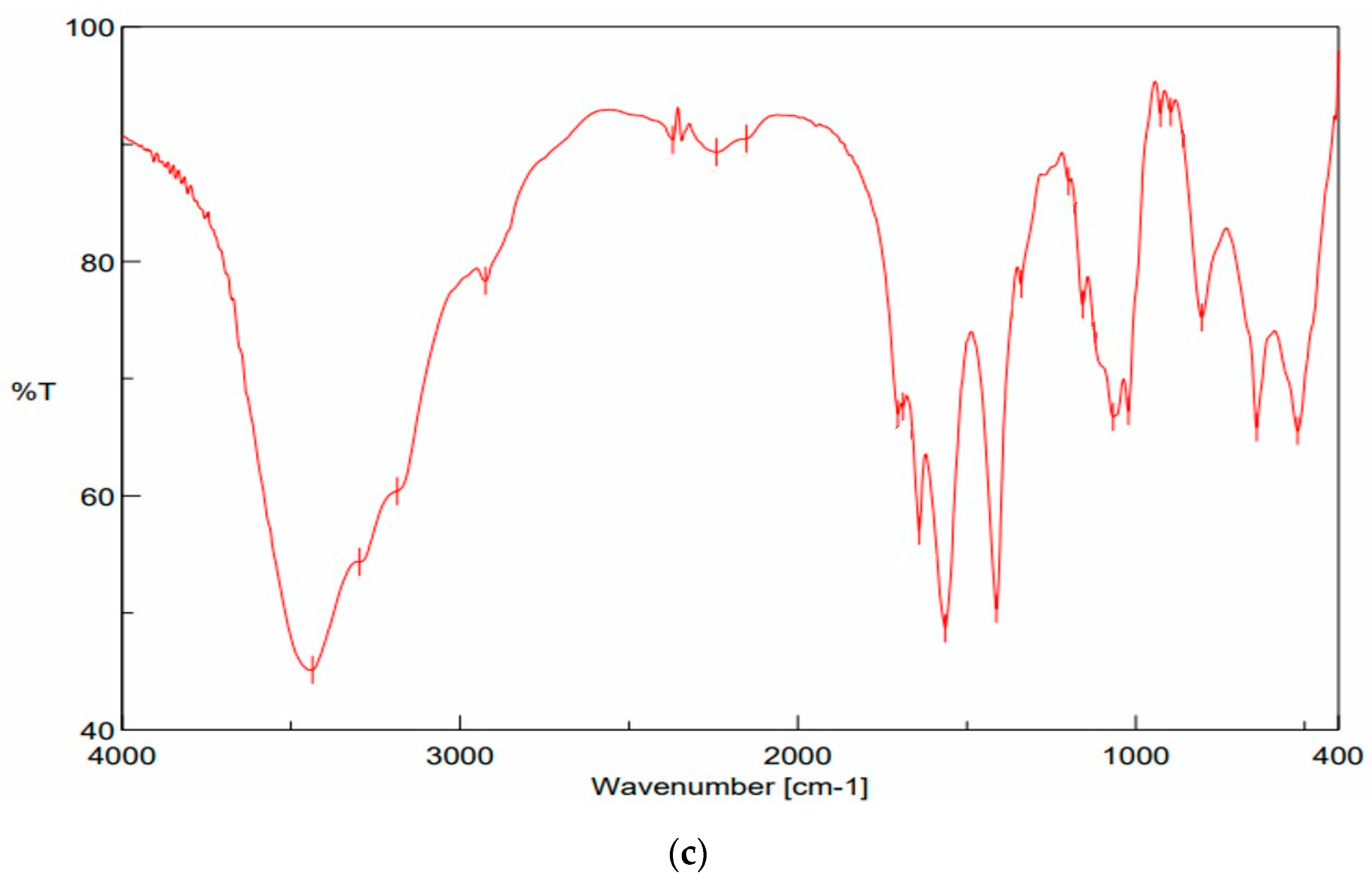

FT-IR analysis determines the functional groups of CMCs: Na-CMC, RH-CMC, and RS-CMC, as shown in

Figure 3. The FT-IR spectrums of CMC provided the key findings [

10,

31], concluding the carbonyl (C=O) peak of carboxylic at 1400–1600 cm

−1, CH

2 peak at 1000–1100 cm

−1, ether (-O- ether stretching) peak at 1070–1300 cm

−1, the C-O peak of ether at 1400–1700 cm

−1 CH stretching at 2800–2900 cm

−1 and hydroxy (-OH) peak at 3200–3600 cm

−1. RH-CMC broadened the OH stretching band at 3433 cm

−1 and a C-H stretching band at 2917 cm

−1. A carbonyl (C=O) vibration was at 1592 cm

−1, indicating the presence of carboxylate functional groups from etherification. The peak at 1064 cm

−1 corresponded to the stretching of the -C-O-C- group in the ether. The peaks of Na-CMC (at 1642 cm

−1) and RH-CMC (at 1592 cm

−1) suggested that hydrogen bond stretching and the hydroxy group bond bending were associated with the cellulose structure around 1640 cm

−1, indicating that the cellulose component was not removed during treatment [

10]. RS-CMC found the peak of OH stretching at 3463 cm

−1. C-H stretching was attributed to the OH peak. The appearance of a sharp peak around 1500 cm

−1 suggested a C-H vibration, which was significantly different from that of RH-CMC and Na-CMC. Considering the spectrum of CMCs, the spectrum of RH-CMC was similar to Na-CMC compared to RS-CMC; the pattern confirmed the purity of RH-CMC.

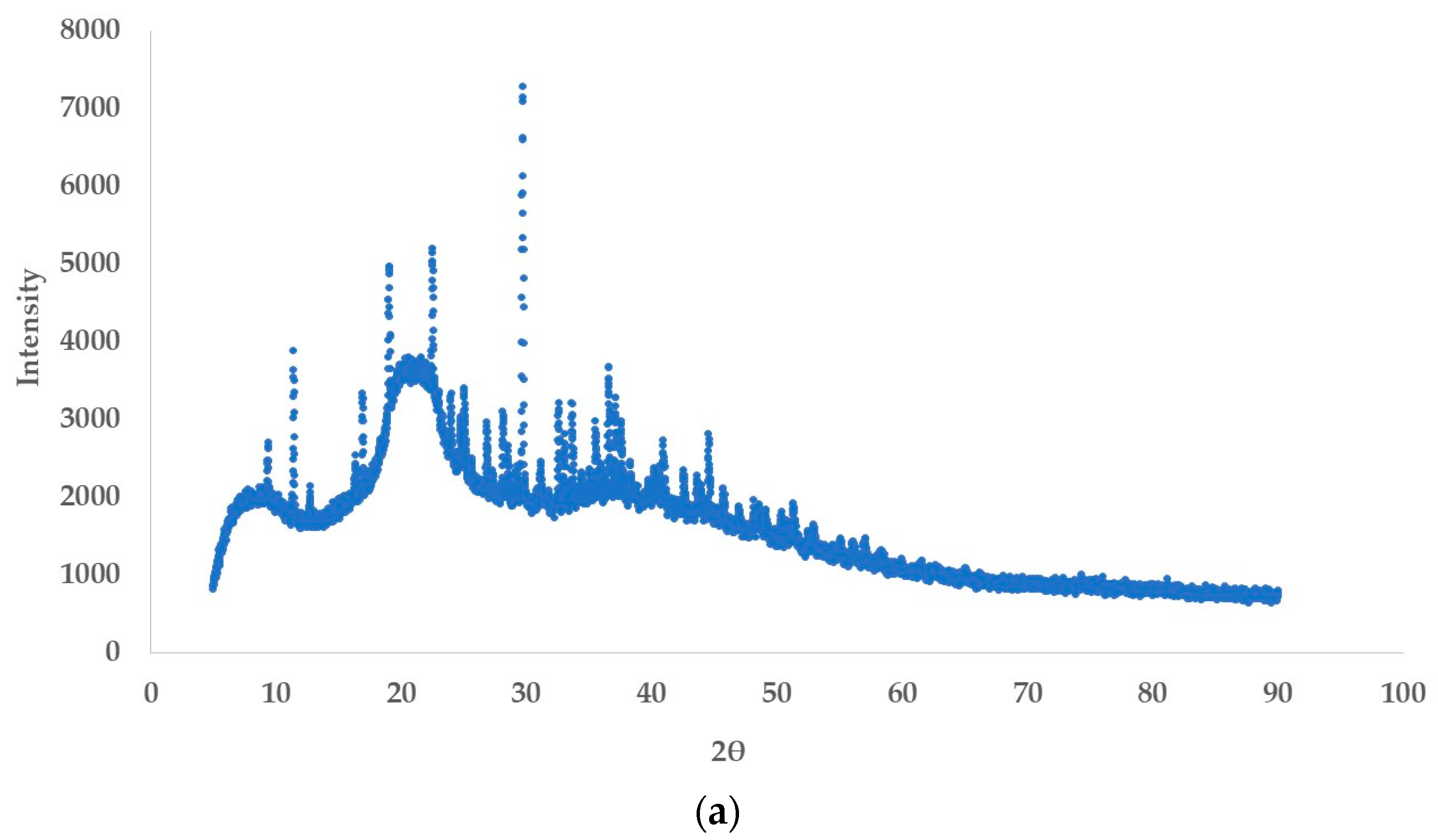

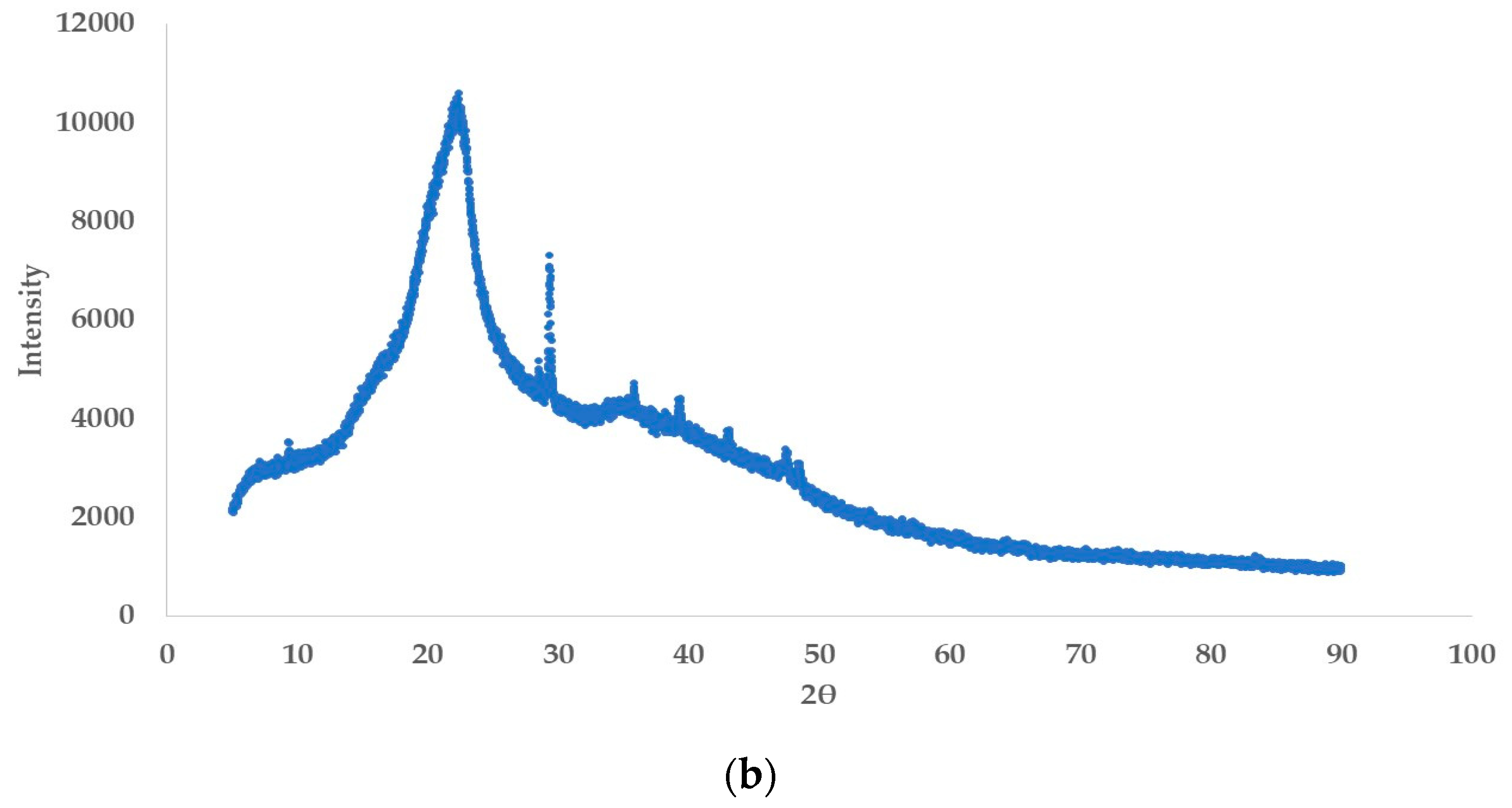

XRD analysis examines the crystalline structure of materials, revealing a unique pattern that identifies structural information and confirms structural transformations. CMC has a semi-crystalline structure, unlike crystalline cellulose; therefore, CMC is more amorphous than crystalline cellulose. The XRD pattern of RH-CMC exhibits a small peak at 20–220, and the pattern is dependent on the chemical modification and degree of substitution (DS) [

32,

34,

36]. From the results, RH-CMC and RS-CMC exhibited the same pattern, albeit with varying intensities, particularly when high intensities were observed, suggesting a cellulose crystalline structure as shown in

Figure 4. RS-CMC gave higher intensity, indicating more crystallinity. The achieved crystallinity is attributed to removing hemicellulose and lignin from the amorphous region, which results in fatigue within the cellulose structure [

30,

32]. RH-CMC provided a low intensity with a broad peak of around 20–22°, close to CMC. Inter- and intra-molecular hydrogen bonds primarily govern the crystallinity of cellulose within its structure; therefore, during CMC synthesis, the alkaline process disrupts these hydrogen bonds and reduces crystallinity. Considering the FT-IR spectrum and XRD pattern, the disappearance of a crystalline band around 1300–1400 cm

−1 in the RH-CMC spectrum could be attributed to the presence of crystalline material upon carboxymethylation [

37]. RH-CMC was a suitable choice for fabricating biodegradable films and was applied to practical applications.

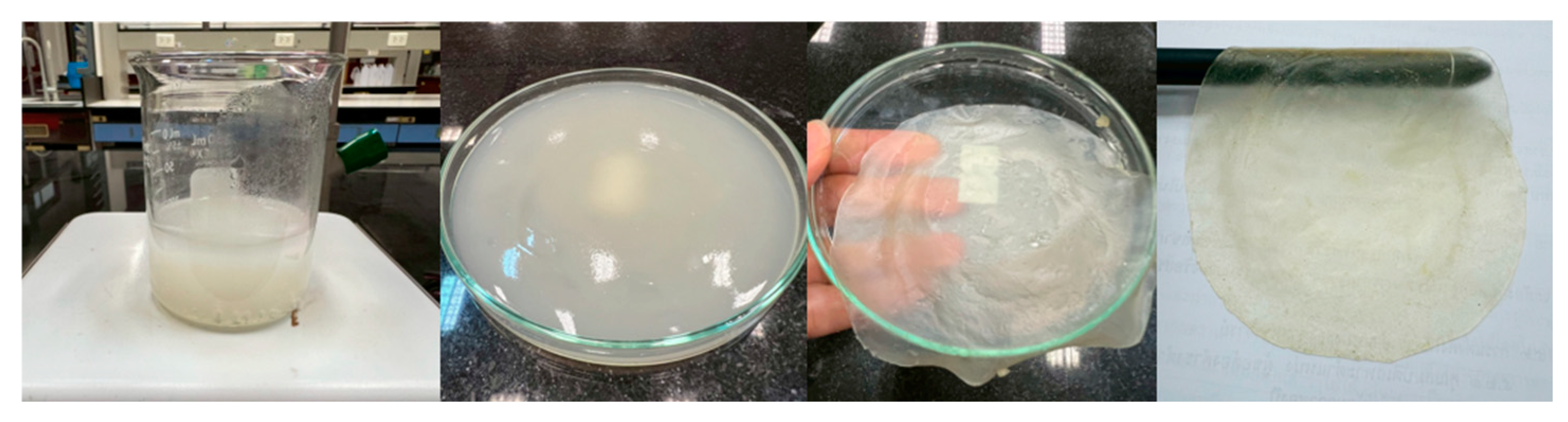

3.4. Fabrication of Starch-Based CMC Biodegradable Film

From our results, RH outperforms RS. The film was prepared using the casting method, gelatinizing above corn starch’s gelatinization temperature (T

gel) at 77.6 °C. The starch blended with CMC was designed to be cost-effective, and it heats up to convert the white, turbid mixture into a clear gel. Citric acid served as a crosslinking agent, utilizing multi-carboxyl cross-linking to enhance the obtained film’s water barrier and mechanical properties [

20,

29]. Due to the limitations of starch film, glycerol, a polyol compound, serves as a plasticizer that breaks hydrogen bonds, scatters polymer chains, and increases the film’s flexibility [

38]. Our results yielded a starch-based RH-CMC biodegradable film with a milky white appearance, consistent with the color of the starting material (

Figure 5).

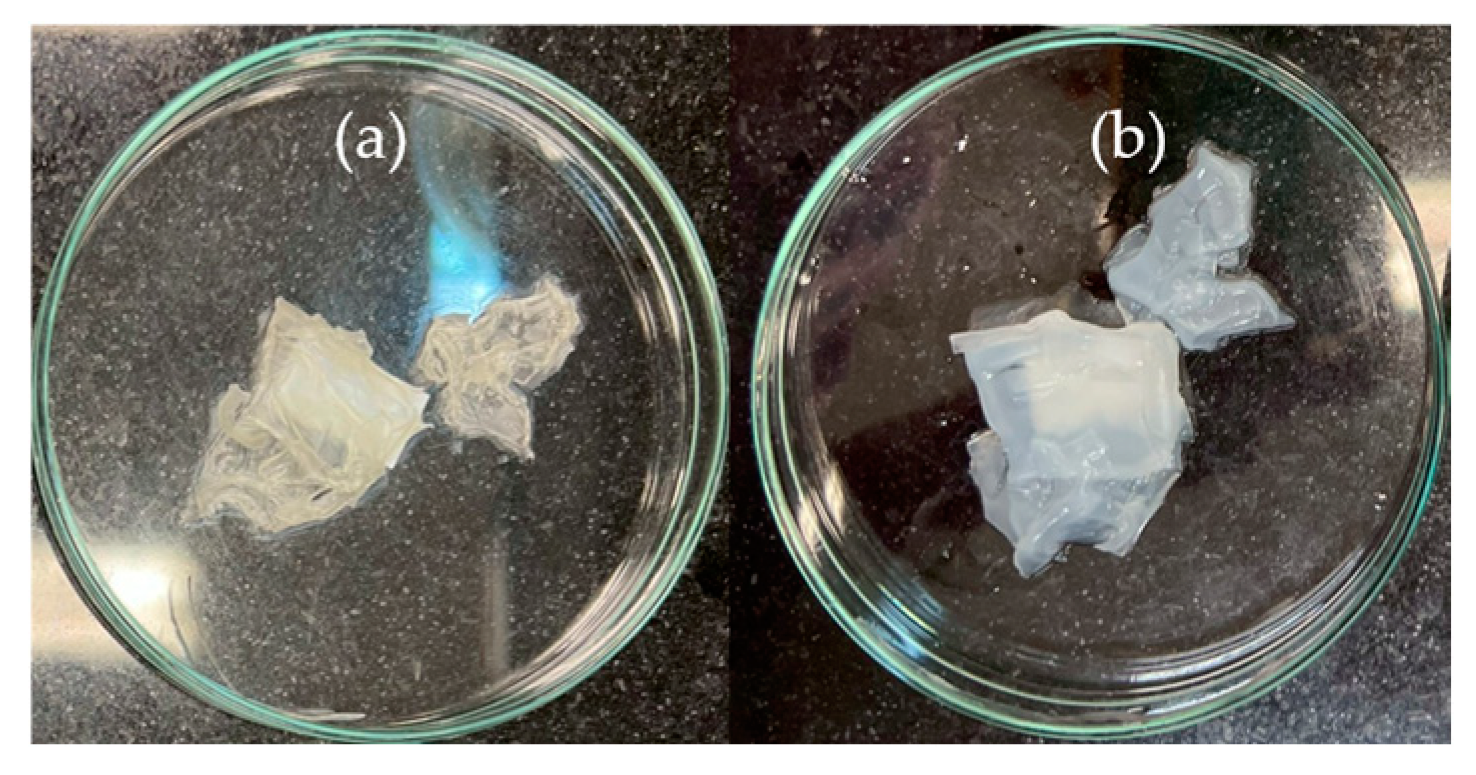

3.5. Characterization of Starch-Based CMC Biodegradable Film

3.5.1. Water Solubility

Water solubility indicates the film’s resistance to water. Biodegradable films with low water solubility exhibit water barrier properties, thereby maintaining the film’s water resistance. In contrast, biodegradable films with high water solubility are suitable for applications where the film is intended to dissolve quickly before use. After solubility testing, the starch-based CMC films exhibited a clear, white color and were flexible and soft in texture, as shown in

Figure 6. The water solubility of the RS-CMC film (55.0%) was higher than that of the RH-CMC film. In a practical application for food preservation, RH provides low water solubility and more water barriers; therefore, it is suitable for foods to prevent moisture and water and maintain the water resistance of the film [

39]. Moreover, in terms of durability, RH was more durable than RS.

The biodegradability of the starch-based RH-CMC film was also investigated through a soil burial test. It refers to the assessment of the degradation of the film in the environment. The measurement involves biological processes in which microorganisms break down the film into natural components such as CO

2, H

2O, and biomass [

40]. The physical change and weight loss were recorded during the desired period. Under study conditions, the film (1-inch size) was placed in soil at a depth of 10 cm for 10 days. No film fragments remained in the soil, indicating complete degradation; neither physical changes nor weight loss could be observed, which means 100% weight loss, and the film was degraded to CO

2, H

2O, and biomass under study conditions. It may cause starch to have acetal bonds that are easily degradable [

41].

3.5.2. Swelling

Swelling refers to the ability of the biodegradable film to absorb water into its structure, indicating how well it maintains its storage capacity. RS-film exhibited a swelling value of 40.9%, whereas RH-film had a swelling value of 12.2%. The difference in values may be due to the physical characteristics of the starting fiber; RS is longer and more fibrous than RH, allowing more efficient water absorption. Size may affect swelling, and compared to other composites containing RH, it showed lower swelling due to the high hydrophobicity of RH [

42]. The high swelling value of the RS film makes it more susceptible to damage and loss of durability. RH provided lower swelling, demonstrated a smaller water absorption capacity, and was more stable and durable in the presence of moisture. Therefore, RH-film was better suited to control water permeability in our application, focusing on starch-based RH-CMC film to study its capability for food preservation.

3.5.3. Mechanical Testing

Since RH and RS films are anisotropic materials, the results according to the standard ASTM D882 may deviate from the specific criteria required for smooth and thin films. Using commercial CMC, Qin et al. reported that the corn starch/CMC composite film provided high tensile strength (TS, over 40 MPa) and elongation at break [

24]. Compared to the films in the mechanical results as in

Table 2, the RH film was thicker than the RS film; therefore, RH provided a maximum load lower than RS and was more suitable for general applications. Elongation at the break of both is slightly different. The elastic modulus of the RH film was higher than that of the RS film, indicating that the RH film was stiffer and more resistant to deformation. The mechanical properties of the RH films were better than those of RS. Compared to Gupta et al., the obtained starch CMC film provided similar elongation at break with lower tensile strength [

20].

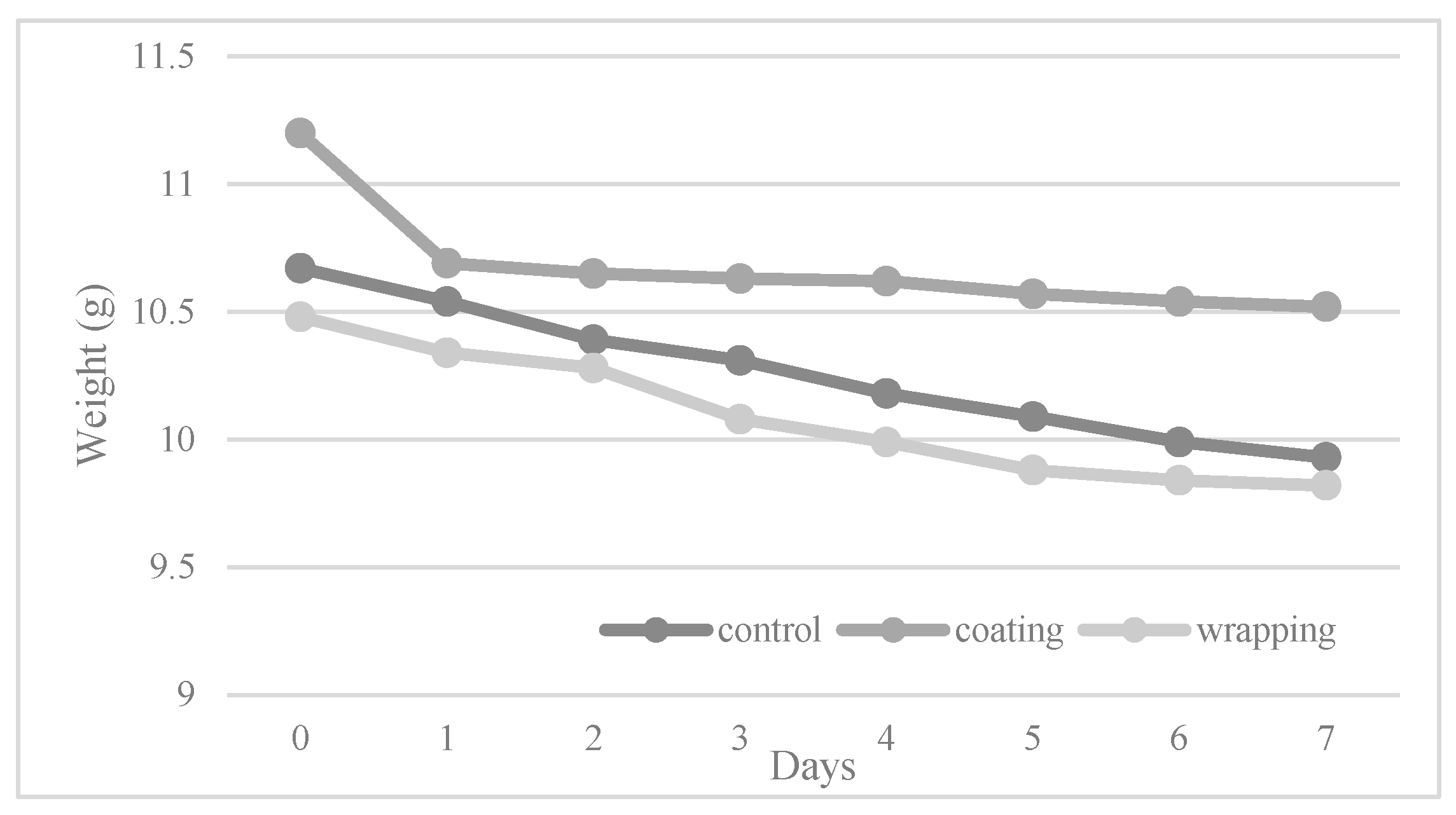

3.6. Practical Application of Starch-Based RH-CMC Biodegradable Film

A starch-based RH-CMC film was tested for food preservation by measuring the weight difference over 7 days of storage. The study involved storing tomato samples in three conditions: (1) the control group, tomatoes without CMC for preservation; (2) the coating using a dip coating with RH-CMC; and (3) the wrapping with RH-CMC film. The results showed that the average weight loss percentage was 6.9, 6.1, and 6.3 for the control, coating, and wrapping groups. The plot of weight loss percentage versus day is shown in

Figure 7. The RH film could preserve the tomato, helping it maintain its weight and freshness. The coating method appears suitable for preservation; however, coating with a dip caused the tomato to bruise and rot more frequently than wrapping as shown in

Figure 8. The other coatings may be altered to utilize the starch-CMC solution.

3.7. Customer Perception and Satisfaction Survey of Starch-Based CMC Biodegradable Film

The survey was conducted on the randomly selected respondents, based on their accessibility to smartphones and the Internet, to complete the questionnaire. Data from 200 participants were analyzed using statistical methods in SPSS software (IBM SPSS Statistics Version 23) and the Likert scale. The respondents’ demographic data revealed that most were female, accounting for 72% of the respondents within the 20–30 age range. Most respondents had a bachelor’s degree, indicating a relatively high educational level; however, 81.3% had an income of less than 15,000 THB, suggesting they were in their careers’ early stages. These aged people were focused because they had the capability and opportunity to access social information, and they are an essential part in pushing the perception of environmental issues.

The perception toward biodegradable film from RH or agricultural waste was evaluated, and 48.7% of respondents did not perceive it. This amount indicated the low level of awareness regarding biodegradable film. Almost half of the respondents (22.0%) received information about biodegradable films through social media, and 21.3% received it through research. These findings suggest that online platforms and educational communication are key sources of perception. However, they had a slight understanding of the properties of biodegradable film, and they only accepted it as an environmental benefit for reducing waste and environmental problems. 42.7% of respondents were delighted with the biodegradability properties.

The satisfaction with the CMC-biodegradable film application was evaluated: most (66.0%) were highly satisfied with the durability criteria, 43.3% were satisfied with the safety aspect, and 40.0% were confident in the preservation of freshness, indicating that safety and product quality preservation were key points. Additionally, the design, facilitation, and special function of use were expected. For example, 45.3% expected the film to prevent bacteria and germs, as they (68.0%) were willing to purchase it even if it had an extra price (up to 5.0%). These results indicated that most consumers were open to purchasing biodegradable films. The purchasing decision was based on price, function, durability, safety, and environmental friendliness. From these states, we observed chances to develop the environmental products in the market, making more perceptions and acceptances; however, the price (pain point) should be reasonable. Price is a factor in the 4Ps, which should be further investigated. Moreover, 43.0% of respondents stated that biodegradable films could help entrepreneurs establish a positive image for their product brand. Then, using biodegradable film instead of plastic promotes environmental responsibility, not only by introducing the perception and realization to the next generation, but also as an essential aspect of further establishing the CSR strategy of entrepreneurs.

4. Conclusions

Based on the resulting data on the fabrication and characterization of RH and RS, they have a high potential as an alternative material to replace conventional materials. The work successfully demonstrated the conversion of this waste into CMC. RH-CMC exhibited better properties compared to RS-CMC. The cellulose synthesis yielded a higher net CMC content for RH-CMC (84.8%) than for RS-CMC (57.7%), and RH-CMC exhibited lower NaCl content (0.77%) and higher purity. Structural analysis using FT-IR confirmed the presence of similar functional groups to those found in commercial CMC. In contrast, XRD analysis revealed an amorphous structure and a higher degree of substitution (DS). A starch-based biodegradable film, crosslinked with citric acid, is an eco-friendly material for packaging applications. The film exhibited promising physical and mechanical properties; the biodegradable film demonstrated 40.9% swelling, 55% water solubility, and a 20.0% moisture content, with mechanical properties of 0.65 mm thickness, a maximum load of 6.54 N, a tensile strength of 670.52 kN/m2, an elongation at break of 13.3%, and an elastic modulus of 2679 kN/m2, indicating durability and flexibility. However, specific properties like transparency, color, and elasticity require further improvement. The film is applied for tomato preservation, effectively reducing weight loss. In addition to the material development, a consumer survey revealed limited awareness but significant interest in adopting sustainable alternatives. This indicates potential market opportunities for biodegradable food packaging. To apply for commercial use, the 4Ps should be further investigated, and the marketing study should be addressed to develop the product’s properties following customer demand.