Winery Wastewater Innovative Biotreatment Using an Immobilized Biomass Reactor Followed by a Sequence Batch Reactor: A Case Study in Australia

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Design and Concept

2.2. Bacterial Cultures and SBP Encapsulation Procedure

2.3. Water Analysis and Sampling

2.4. Microscopic Analysis for Monitoring Floc Particles and Microorganisms Within the Mixed Liquor

2.5. Enumeration of Culturable Heterotrophic Bacteria

2.6. Statistical Analysis

3. Results

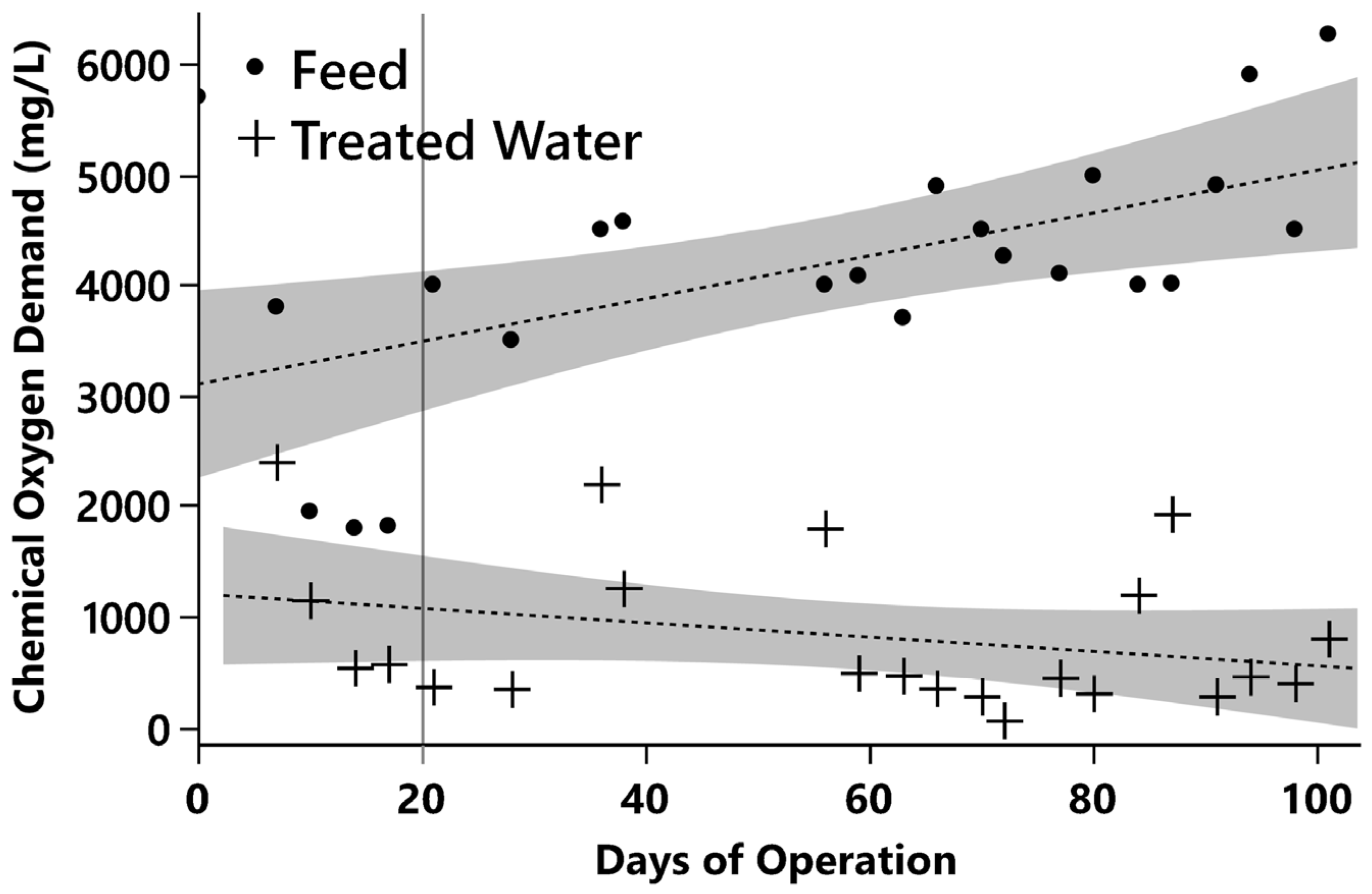

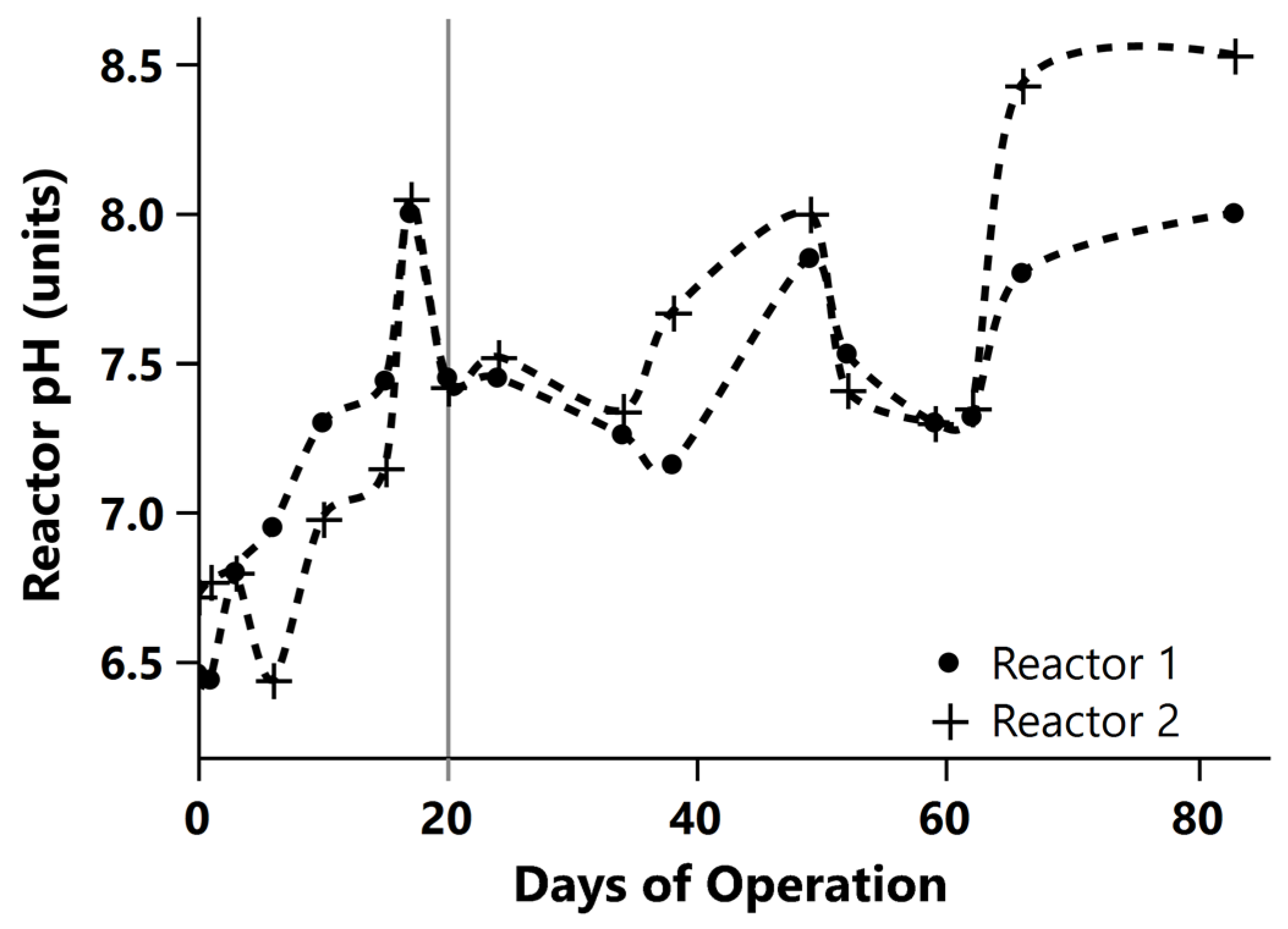

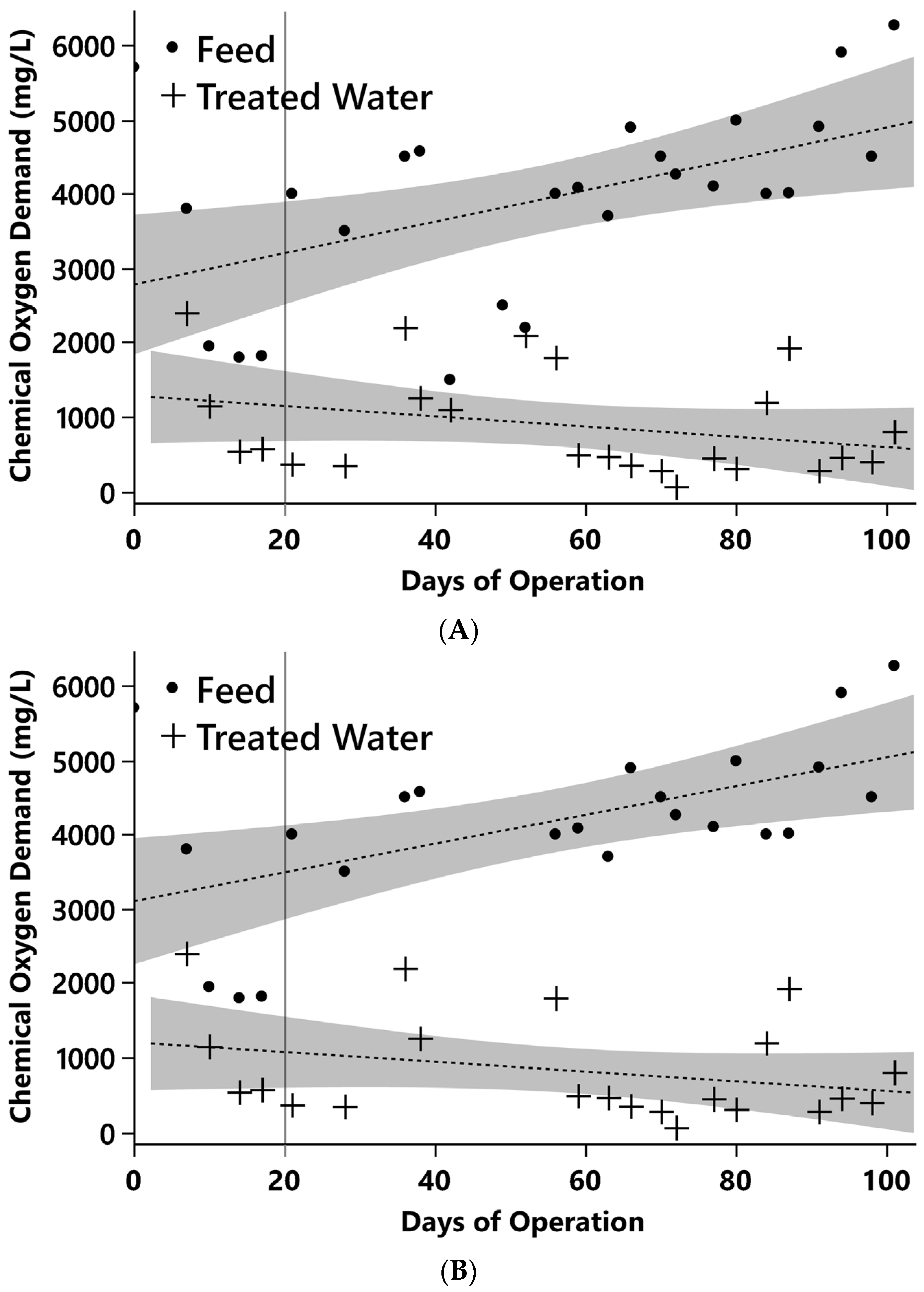

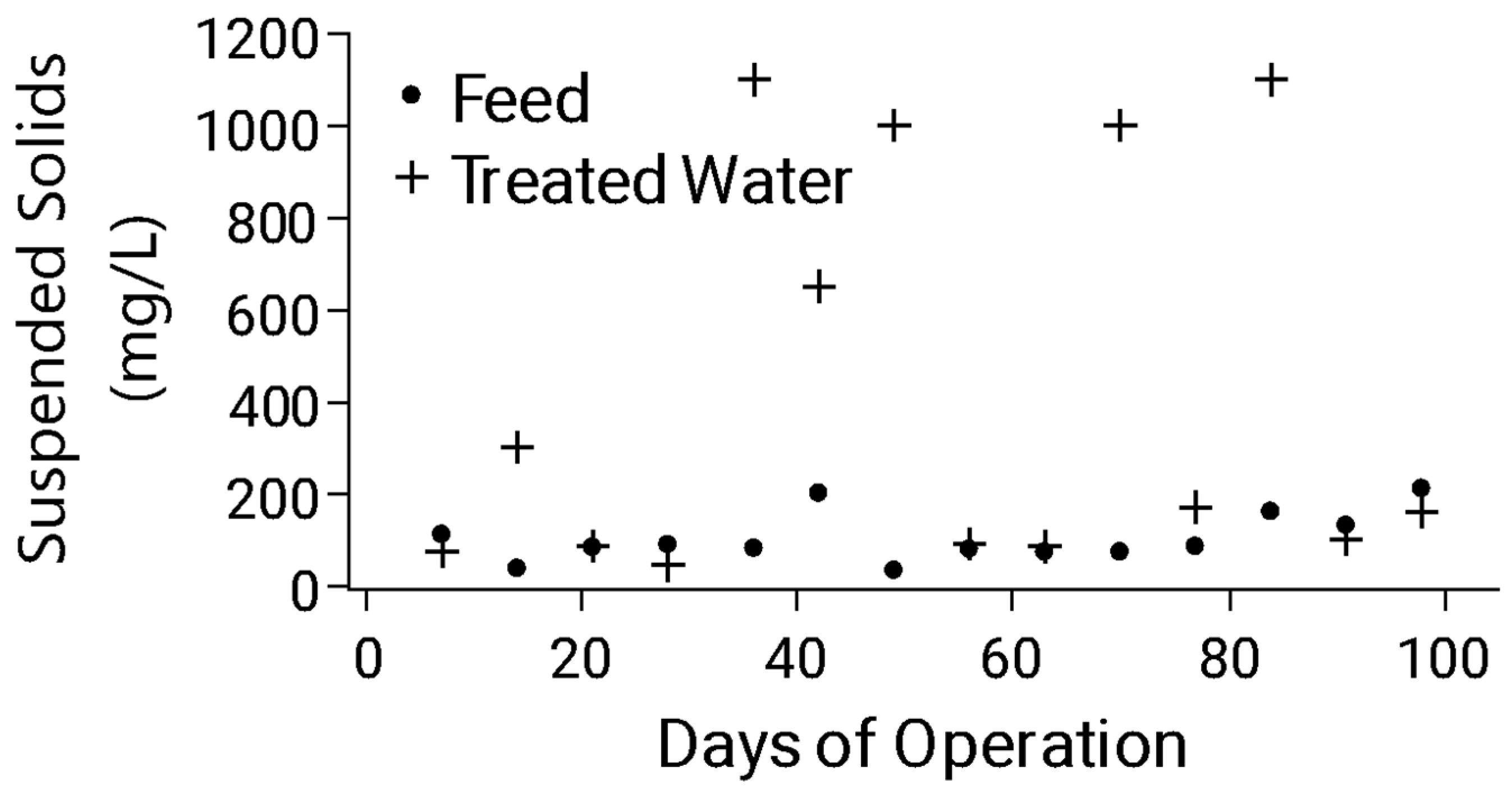

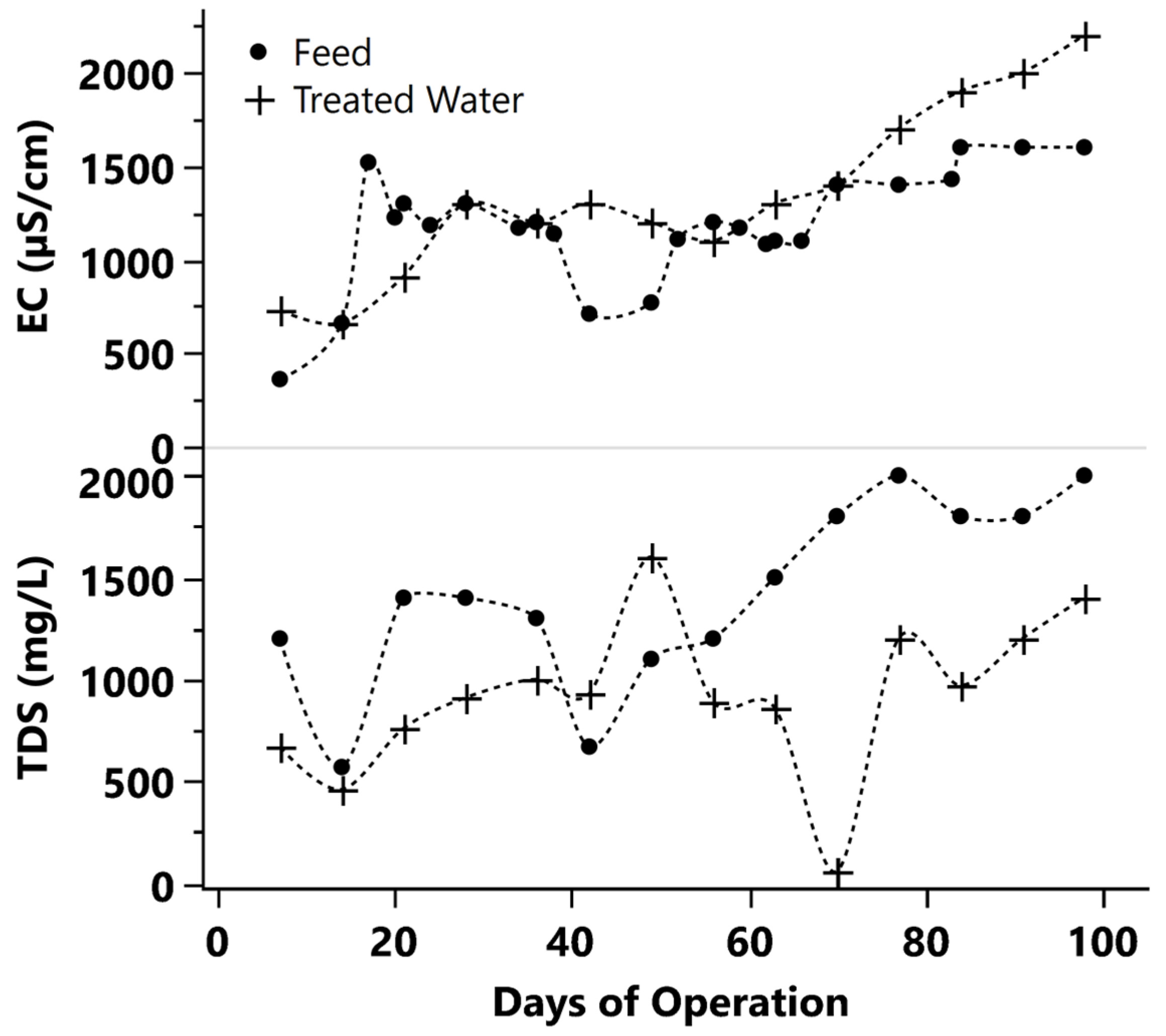

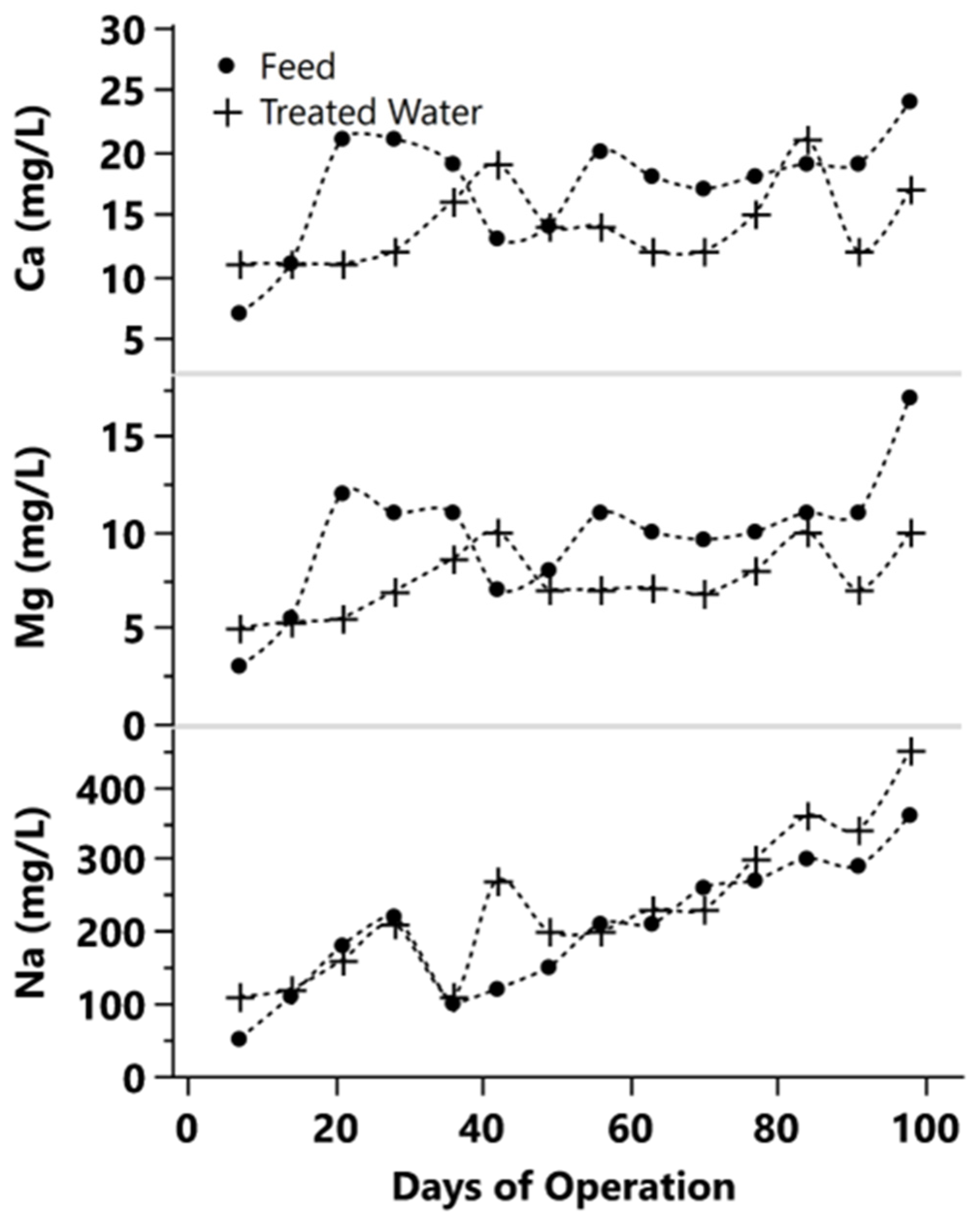

3.1. System Operation and Treatment Process Stability

3.2. System Efficacy Evaluation

3.3. Scaling Up Design

4. Discussion

5. Conclusions

- Winery wastewater presents a serious environmental and economical challenge due to the inability of ordinary biological processes to consistently degrade the acidic and recalcitrant organic matter in the wastewater. The potential environmental impacts of WWW include pollution of ground and surface water, soil degradation, damage to vegetation, and odors; therefore, it is critical to allocate a cost-effective solution for small to medium wineries.

- This study presents a potential cost-effective treatment solution tailored for small to medium wineries. The solution incorporates the following stages:

- A pre-sedimentation stage to initially remove larger particles and debris.

- pH regulation to optimize the treatment conditions for microbial activity.

- The use of robust microbes encapsulated within the novel confined environment of the SBP process to enhance biological treatment.

- The SBR stage as the final treatment process, effectively treating the organic matter in the wastewater.

- The performance of the pilot system was evaluated over a period of more than 80 days, consistently achieving high removal rates for both COD and BOD. Specifically, the system demonstrated removal efficiencies exceeding 90% for both parameters, indicating the effectiveness and stability of the treatment process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kojić, N.; Prodanović, R. By-wproducts of ine production in the service of the circular economy. J. Agron. Technol. Eng. Manag. 2024, 7, 1245–1251. [Google Scholar] [CrossRef]

- Andreottola, G.; Foladori, P.; Ziglio, G. Biological treatment of winery wastewater: An overview. Water Sci. Technol. 2009, 60, 1117–1125. [Google Scholar] [CrossRef]

- Bolzonella, D.; Papab, M.; Da Ros, C.; Muthukumar, L.; Rosso, D. Winery wastewater treatment: A critical overview of advanced biological processes. Crit. Rev. Biotechnol. 2019, 39, 489–507. [Google Scholar] [CrossRef]

- Kyzas, G.; Symeonidou, M.; Matis, K. Technologies of winery wastewater treatment: A critical approach. Desalin. Water Treat. 2014, 57, 3372–3386. [Google Scholar] [CrossRef]

- Mosse, K.; Patti, A.; Christen, E.; Cavagnaro, T. Review: Winery wastewater quality and treatment options. Aust. J. Grape Wine Res. 2011, 17, 111–122. [Google Scholar] [CrossRef]

- Latessa, S.H.; Hanley, L.; Tao, W. Characteristics and practical treatment technologies of winery wastewater: A review for wastewater management at small wineries. J. Environ. Manag. 2023, 342, 118343. [Google Scholar] [CrossRef] [PubMed]

- Litaor, M.; Meir-Dinar, N.; Castro, B.; Azaizeh, H.; Rytwo, G.; Levi, N.; Levi, M.; MarChaim, U. Treatment of winery wastewater with aerated cells mobile system. Environ. Nanotechnol. Monit. Manag. 2015, 4, 17–26. [Google Scholar] [CrossRef]

- Kurzbaum, E.; Raizner, Y.; Cohen, O.; Suckeveriene, R.; Kulikov, A.; Hakimi, B.; Kruh, L.I.; Armon, R.; Farber, Y.; Menashe, O. Encapsulated Pseudomonas putida for phenol biodegradation: Use of a structural membrane for construction of a well-organized confined particle. Water Res. 2017, 121, 37–45. [Google Scholar] [CrossRef]

- Ma, H.; Zhao, Y.; Yang, K.; Wang, Y.; Zhang, C.; Ji, M. Application oriented bioaugmentation processes: Mechanism, performance improvement and scale-up. Bioresour. Technol. 2022, 344B, 126192. [Google Scholar] [CrossRef]

- Menashe, O.; Rosen-Kligvasser, J.; Kurzbaum, E.; Suckeveriene, R. Structural properties of a biotechnological capsule confined by a 3D-cellulose acetate membrane. Polym. Adv. Technol. 2021, 32, 681–689. [Google Scholar] [CrossRef]

- Wojcieszyńska, D.; Marchlewicz, A.; Guzik, U. Suitability of immobilized systems for microbiological degradation of endocrine disrupting compounds. Molecules 2020, 25, 4473. [Google Scholar] [CrossRef]

- Fradkin, O.; Mamane, H.; Kaplan, A.; Menashe, O.; Kurzbaum, E.; Betzalel, Y.; Avisar, D. UV-LED combined with small bioreactor platform (SBP) for degradation of 17α-ethynylestradiol (EE2) at very short hydraulic retention time. Materials 2021, 14, 5960. [Google Scholar] [CrossRef] [PubMed]

- Menashe, O.; Kurzbaum, E. A novel bioaugmentation treatment approach using a confined microbial environment: A case study in a Membrane Bioreactor wastewater treatment plant. Environ. Technol. 2016, 37, 1582–1590. [Google Scholar] [CrossRef] [PubMed]

- Menashe, O.; Raizner, Y.; Kuc, M.; Cohen-Yaniv, V.; Kaplan, A.; Mamane, H.; Avisar, D.; Kurzbaum, E. Biodegradation of the endocrine-disrupting chemical 17α-ethynylestradiol (EE2) by Rhodococcus zopfii and Pseudomonas putida encapsulated in Small Bioreactor Platform (SBP) capsules. Appl. Sci. 2020, 10, 336. [Google Scholar] [CrossRef]

- Lew, B.; Monosov, M.M.; Betito, S.; Vizel, N.; Khan, A.A.; Kurzbaum, E.; Kruh, L.I.; Menashe, O. High-rate ex situ and in situ treatment system for groundwater denitrification via membrane-based bacterial macro-encapsulation. J. Water Process Eng. 2022, 50, 103230. [Google Scholar] [CrossRef]

- Benedek, T.; Szentgyörgyi, F.; Gergócs, V.; Menashe, O.; Abigai, P.; Gonzalez, F.; Probst, A.J.; Kriszt, B.; Táncsics, A. Potential of Variovorax paradoxus isolate BFB1_13 for bioremediation of BTEX contaminated sites. AMB Expr. 2022, 11, 126. [Google Scholar] [CrossRef]

- Dzionek, A.; Wojcieszyńska, D.; Menashe, O.; Szada, D.; Potocka, I.; Jesionowski, T.; Guzik, U. The influence of activated sludge augmentation on its ability to degrade paracetamol. Molecules 2024, 29, 4520. [Google Scholar] [CrossRef]

- Jorge, N.; Teixeira, A.R.; Gomes, A.; Peres, J.A.; Lucas, M.S. Winery wastewater: Challenges and perspectives. Eng. Proc. 2023, 56, 267. [Google Scholar] [CrossRef]

- Melchiors, E.; Freire, F.B. Winery wastewater treatment: A systematic review of traditional and emerging technologies and their efficiencies. Environ. Process. 2023, 10, 43. [Google Scholar] [CrossRef]

- Silva, S.; Pirra, A.; Jorge, N.; Peres, J.A.; Lucas, M.S. Enhancing sustainability in wine production: Evaluating winery wastewater treatment using sequencing batch reactors. Eng. Proc. 2023, 56, 163. [Google Scholar] [CrossRef]

- Welz, P.J.; Holtman, G.; Haldenwang, R.; le Roes-Hill, M. Characterisation of winery wastewater from continuous flow settling basins and waste stabilisation ponds over the course of 1 year: Implications for biological wastewater treatment and land application. Water Sci. Technol. 2016, 74, 2036–2050. [Google Scholar] [CrossRef] [PubMed]

- Papadimitriou, C.; Samaras, P.; Sakellaropoulos, G. Comparative study of phenol and cyanide containing wastewater in CSTR and SBR activated sludge reactors. Bioresour. Technol. 2009, 100, 31–37. [Google Scholar] [CrossRef] [PubMed]

- Akratos, C.; Tatoulis, T.; Tekerlekopoulou, A. Biotreatment of winery wastewater using a hybrid system combining biological trickling filters and constructed wetlands. Appl. Sci. 2020, 10, 619. [Google Scholar] [CrossRef]

- Moletta, R. Winery and distillery wastewater treatment. Water Sci. Technol. 2005, 51, 137–144. [Google Scholar] [CrossRef]

- Solís, R.; Rivas, F.; Ferreira, L.; Pirra, A.; Peres, J. Integrated aerobic biological–chemical treatment of winery wastewater diluted with urban wastewater. LED-based photocatalysis in the presence of monoperoxysulfate. J. Environ. Sci. Health A 2017, 53, 124–131. [Google Scholar] [CrossRef]

- De Heredia, J.; Torregrosa, J.; Dominguez, J.; Partido, E. Degradation of wine distillery wastewaters by the combination of aerobic biological treatment with chemical oxidation by Fenton’s reagent. Water Sci. Technol. 2005, 51, 167–174. [Google Scholar] [CrossRef]

- Li, J.; Chen, Z.; Xia, W.; Yang, X.; Dong, J.; Li, J. Study on the composition of resistant organics in winery wastewater and their degradation technique. IOP Conf. Ser. Earth Environ. Sci. 2018, 191, 012057. [Google Scholar] [CrossRef]

- Lucas, M.; Mouta, M.; Pirra, A.; Peres, J. Winery wastewater treatment by a combined process: Long term aerated storage and Fenton’s reagent. Water Sci. Technol. 2009, 60, 1089–1095. [Google Scholar] [CrossRef]

- Vlotman, D.; Key, D.; Bladergroen, B. Technological advances in winery wastewater treatment: A comprehensive review. S. Afr. J. Enol. Vitic. 2022, 43, 58–80. [Google Scholar] [CrossRef]

- Alisawi, H. Performance of wastewater treatment during variable temperature. Appl. Water Sci. 2020, 10, 89. [Google Scholar] [CrossRef]

- Eusebio, A.; Petruccioli, M.; Lageiro, M.; Federici, F.; Duarte, J.C. Microbial characterisation of activated sludge in jet-loop bioreactors treating winery wastewaters. J. Ind. Microbiol. Biotechnol. 2004, 31, 29–34. [Google Scholar] [CrossRef] [PubMed]

- Tillman, R.; Surapaneni, A. Some soil-related issues in the disposal of effluent on land. Aust. J. Exp. Agric. 2002, 42, 225–235. [Google Scholar] [CrossRef]

- Rengasamy, P.; Olsson, K. Sodicity and soil structure. Aust. J. Soil Res. 1991, 29, 935–952. [Google Scholar] [CrossRef]

- Stevens, R.M.; Walker, R.R. Response of grapevines to irrigation-induced saline–sodic soil conditions. Aust. J. Exp. Agric. 2002, 42, 323–331. [Google Scholar] [CrossRef]

- Essington, M. Soil and Water Chemistry: An Integrative Approach; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

| Parameters | ||||||

|---|---|---|---|---|---|---|

| Value | pH | COD mg/L | BOD mg/L | TP mg/L | TKN mg/L | TSS mg/L |

| Mean | 6.3 ± 0.7 | 3920 ± 1282 | 2220 ± 671.4 | 9.8 ± 4.6 | 11.5 ± 5.7 | 102 ± 54.4 |

| Min | 3.7 | 1500 | 780 | 1.2 | 5.1 | 32 |

| Max | 7.2 | 6265 | 2900 | 21 | 26 | 210 |

| Step | Operational Activity | Aim and Treatment Position (PFD) |

|---|---|---|

| First treatment stage: Pre-treatment (solids removal) | ||

| 1 | The inflow pump (P-4) fed the system with raw wastewater at a flow rate of 9.4 L/h (225.6 L/d). An auxiliary pump (P-5) circulated the raw wastewater constantly. During the 8 d start-up phase, the raw wastewater was, in advance, diluted (1:1 v/v) with tap water and raw wastewater. Wastewater dilution was conducted to reduce organic concentration, thus allowing the development of aerobic conditions within the bioreactors. | T-4–T-5 Water preparation prior to the pre-treatment stage |

| 2 | The wastewater was fed to an equilibrium tank (T5, HRT: 12.0 h) through a 210 µm filter to reduce the concentration of suspended solids. Within the tank, pH was adjusted (P-1) with NaOH, poly-aluminium chloride (PAC) was provided (P-3) for coagulation, nutrients (P, N, Fe) were provided (P-2) to ensure microbial growth in the bioreactors, and the wastewater was stirred for homogenization. | T-5–T-6 Solids separation: filtration, coagulation, and sedimentation processes |

| 3 | From the equilibrium tank, the wastewater was transferred to a sedimentation tank for 12 h. Solids were discarded from the bottom of the tank (V-2). | |

| Second treatment stage: encapsulated biomass reactor (bioaugmentation) | ||

| 4 | Wastewater was sent to the first bioreactor with an HRT of 2 d. The SBP capsules (NatiCap Hard Clean—500 units) were held within a perforated cage located approximately 15 cm below the water surface. The inflow rate capacity was 18.8 L/h (451 L/d). | T-7 Degradation of recalcitrant and toxic compounds |

| Third treatment stage: SBR | ||

| 5 | From the first bioreactor, overflow wastewater flowed to the second bioreactor (SBR) for an additional 2 d HRT. The SBR operational stages were as follows: Aeration stage (biodegradation)—47 h; Sedimentation stage—0.5 h (closing the blower); Effluent discharge—0.5 h (opening valve number 3); 500 L (half the bioreactor volume) is discharged into the effluent collector; Blower on, closing valve 1. End of cycle 1; Starting cycle number 2—repeat stages i to iv. | T-8 Organic load reduction |

| General terms, sampling and microscopic analysis | ||

| ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menashe, O.A.; Orlofsky, E.; Bankowski, P.; Kurzbaum, E. Winery Wastewater Innovative Biotreatment Using an Immobilized Biomass Reactor Followed by a Sequence Batch Reactor: A Case Study in Australia. Processes 2025, 13, 1375. https://doi.org/10.3390/pr13051375

Menashe OA, Orlofsky E, Bankowski P, Kurzbaum E. Winery Wastewater Innovative Biotreatment Using an Immobilized Biomass Reactor Followed by a Sequence Batch Reactor: A Case Study in Australia. Processes. 2025; 13(5):1375. https://doi.org/10.3390/pr13051375

Chicago/Turabian StyleMenashe, Ofir A., Ezra Orlofsky, Piotr Bankowski, and Eyal Kurzbaum. 2025. "Winery Wastewater Innovative Biotreatment Using an Immobilized Biomass Reactor Followed by a Sequence Batch Reactor: A Case Study in Australia" Processes 13, no. 5: 1375. https://doi.org/10.3390/pr13051375

APA StyleMenashe, O. A., Orlofsky, E., Bankowski, P., & Kurzbaum, E. (2025). Winery Wastewater Innovative Biotreatment Using an Immobilized Biomass Reactor Followed by a Sequence Batch Reactor: A Case Study in Australia. Processes, 13(5), 1375. https://doi.org/10.3390/pr13051375