Optimizing Hydrogen Liquefaction Efficiency Through Waste Heat Recovery: A Comparative Study of Three Process Configurations

Abstract

1. Introduction

2. Literature Review

2.1. Characteristics of the Hydrogen Liquefaction Process

2.2. Efficiency Improvement of Hydrogen Liquefaction Processes

2.3. Navigating Current Research Aims and Objectives

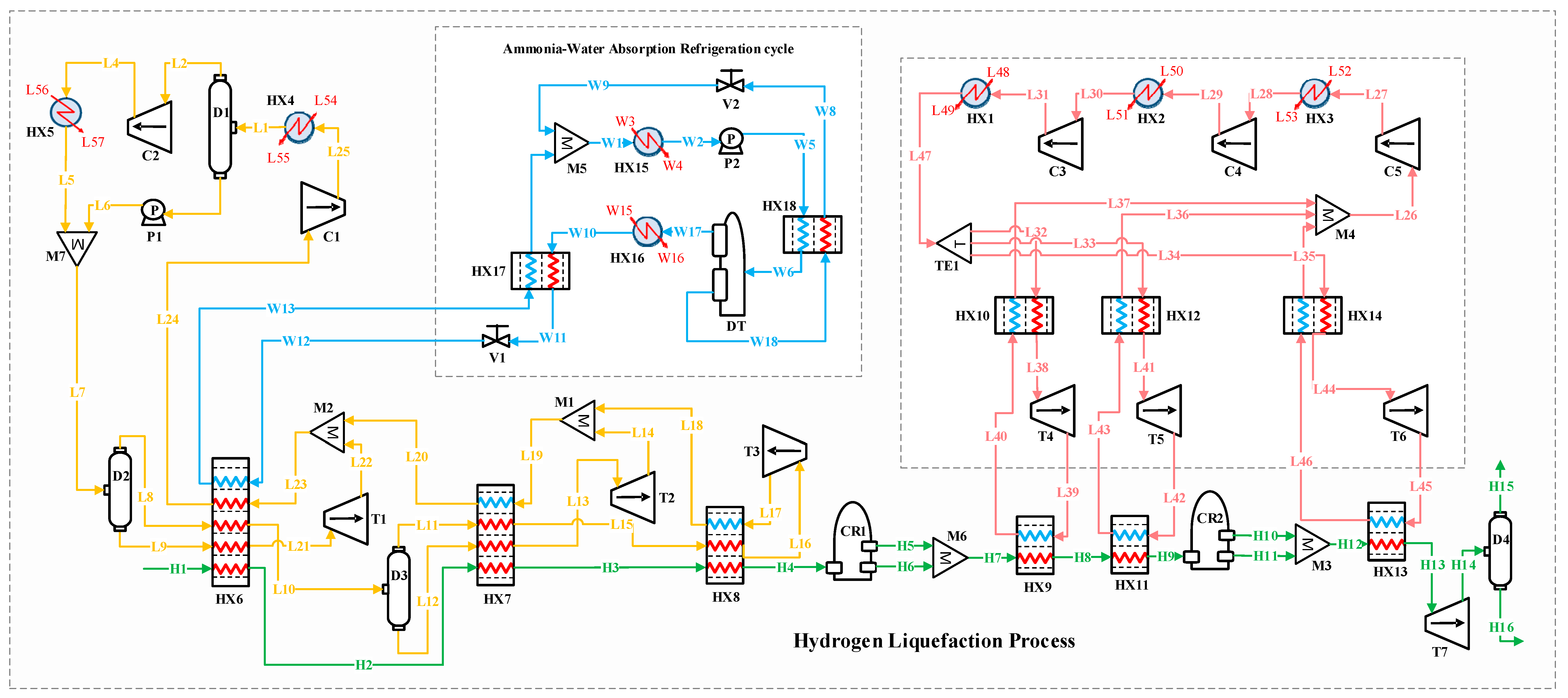

3. Proposed Solutions to Improve Performance of a Hydrogen Liquefaction Unit Using Waste Energy

- Ammonia-water absorption refrigeration cycle for precooling

- Diffusion absorption refrigeration cycle for precooling

- Combined Organic Rankine and Kalina cycles for power generation

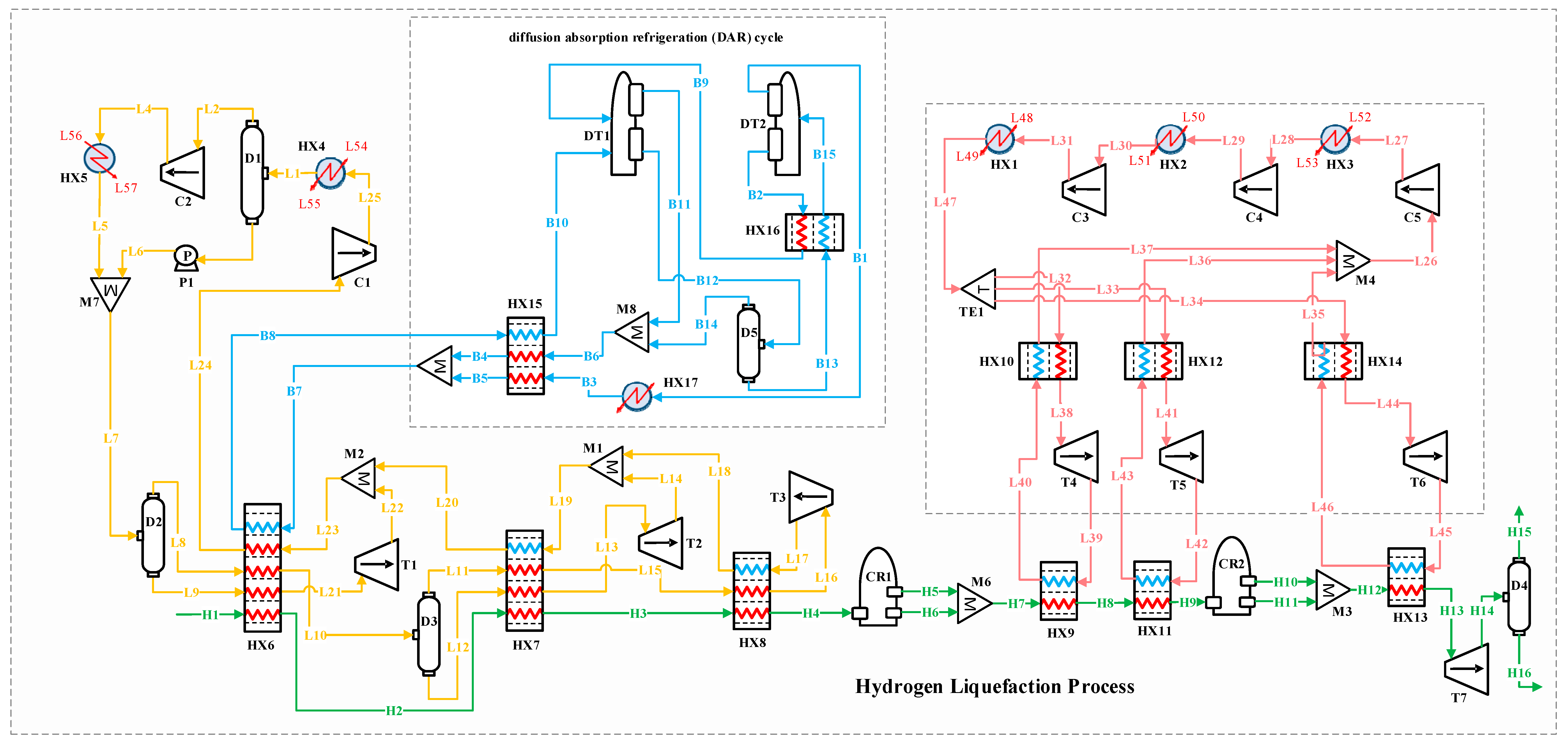

3.1. Process Description

3.1.1. Precooling Stage

3.1.2. Claude Cryogenic Refrigeration Cycle

3.2. Ammonia–Water Absorption Refrigeration Cycle (First Scenario)

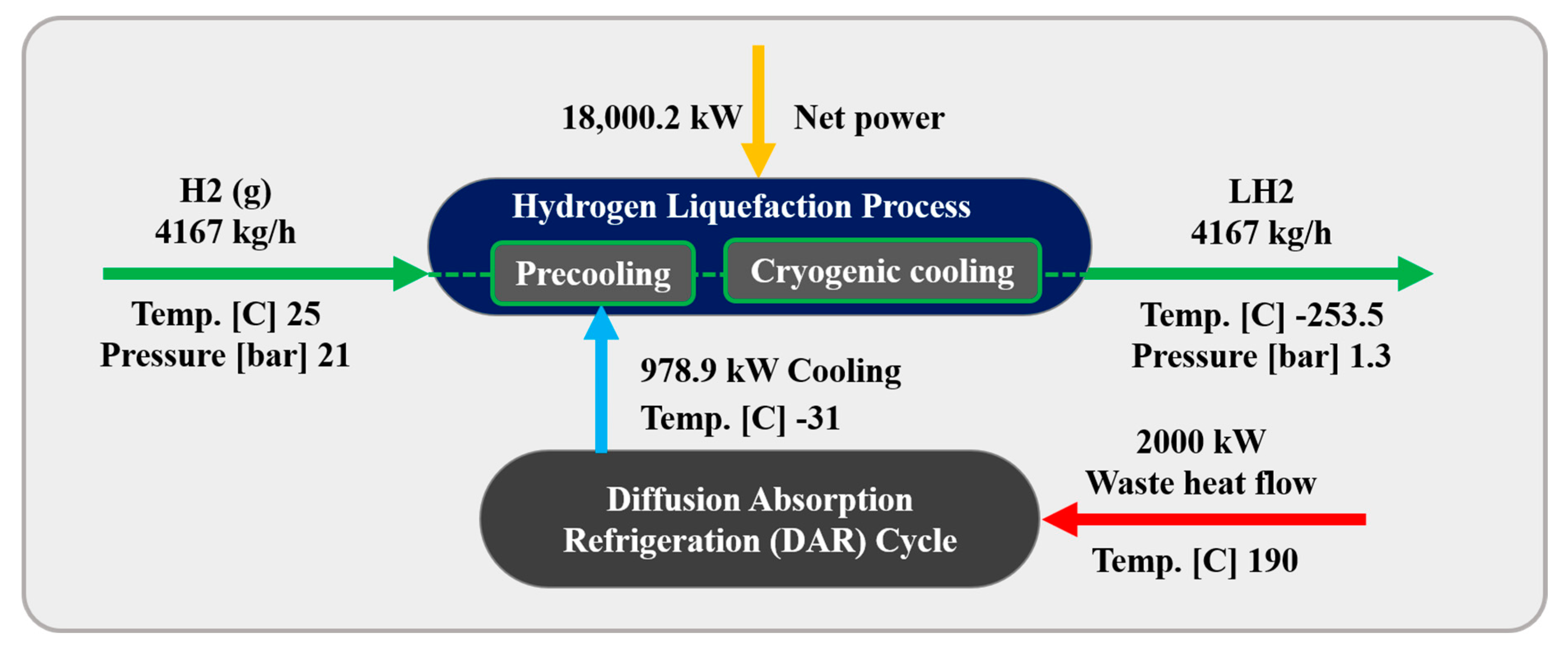

3.3. Diffusion Absorption Refrigeration Cycle (Second Scenario)

- Heat exchange and vaporization: The concentrated ammonia–water solution (i.e., stream B15) enters the DT2 column, where it is preheated by a weaker ammonia–water solution coming from the bubble pump output. This heat input vaporizes the ammonia, creating a vapor mixture of ammonia and water.

- Separation in the rectifier: In the DT2’s rectifier, the ammonia vapor is condensed, separating it into pure ammonia vapor (i.e., stream B1), while the water condensate returns to the generator by gravity. The ammonia vapor undergoes a phase change into liquid, releasing heat through an exothermic process.

- Precooling with helium: After being cooled to 2 °C in the HX17 and HX15 heat exchangers, the liquid ammonia (i.e., stream B5) is mixed with helium (i.e., stream B4). The resulting mixture (i.e., stream B7) enters the HX6 heat exchanger at −31.7 °C and 2500 kPa, providing 978.9 kW of cooling to precool the H2 during liquefaction. Stream B8 exits the HX6 heat exchanger at −5.85 °C and then passes through the HX15 heat exchanger before entering the DT1 tower at 24.05 °C.

- Absorption in DT1 column: In DT1, the absorber mixes stream B10 (a preheated ammonia-helium mixture from the HX15 heat exchanger) with stream B9 (a precooled weak ammonia–water solution from the HX16 heat exchanger). This forms a strong ammonia–water solution (i.e., stream B12), which exits the absorber while releasing heat to the environment.

- Helium recovery: Helium is extracted from the top of the DT1 tower and the D5 drum (i.e., streams B11 and B14), and these are collected in the M8 mixer for recirculation within the cycle.

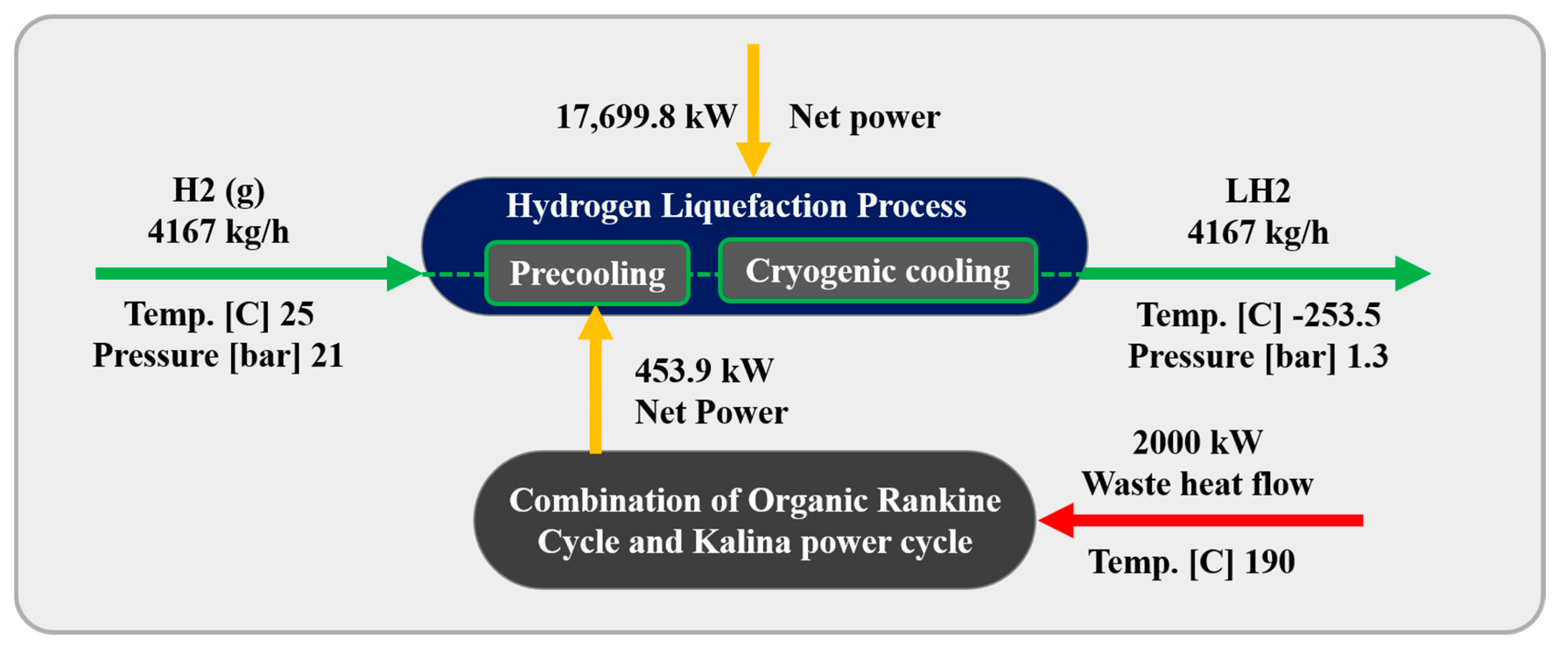

3.4. Combination of Organic Rankine and Kalina Power Cycles (Third Scenario)

3.4.1. Organic Rankine Cycle Process Description

- Heat absorption: In this process, stream R1, initially at 30.0 °C and 2500 kPa, enters the HX16 heat exchanger and absorbs 2000 kW of heat, exiting at 178.7 °C (i.e., stream R2).

- Power generation: Stream R2 splits into two streams, R3 and R5, which enter the T8 and T9 turbines, respectively, for power generation. The T8 turbine reduces the pressure to 1500 kPa, generating 220.1 kW of power. Also, the T9 turbine generates 21.77 kW by reducing the pressure of stream R5.

- Heat transfer to Kalina cycle: Stream R4 transfers 1786.2 kW of heat to the Kalina cycle via the HX15 heat exchanger, cooling from 125.1 to 7.23 °C (i.e., stream R7).

3.4.2. Kalina Power Cycle Process Description

- Ammonia–water solution heating: A rich ammonia–water solution (i.e., stream K12) enters the flash drum at 96.66 °C and 2290 kPa, where ammonia vapor is separated and directed to the T10 turbine for power generation.

- Power generation: the T10 turbine lowers the pressure from 2280 kPa (i.e., stream K13) to 450 kPa (i.e., stream K15), producing 245.2 kW of power.

- Absorption and pressure recovery: After the turbine, the ammonia vapor is absorbed into the weak ammonia–water solution (i.e., stream K17) in the M9 mixer, forming stream K18. This stream is pumped to 2300 kPa by the P3 pump, consuming 6.14 kW of electrical power to complete the cycle.

- Energy integration: The total net electrical power generated in this scenario contributes to the electricity required for the precooling stage in the H2 liquefaction process, enhancing system efficiency by utilizing waste heat to generate part of the necessary energy.

4. Simulation Methodology

- Kinetic and potential energy changes in the process streams are considered negligible. This simplification assumes that these energy contributions are insignificant compared to the thermal and mechanical energy flows involved in the process.

- All streams are assumed to be in a steady-state condition, meaning their properties (temperature, pressure, flow rates) remain constant over time.

- Pressure drops and heat losses in the heat exchangers are ignored. This assumes ideal behavior in heat exchangers, focusing on their thermal performance without accounting for inefficiencies due to pressure losses or external heat leakage.

- The pumps and turbines in the system are modeled using isentropic efficiency, representing the ratio of actual work to the ideal (isentropic) work. This ensures realistic performance modeling while simplifying mechanical work and heat interaction calculation.

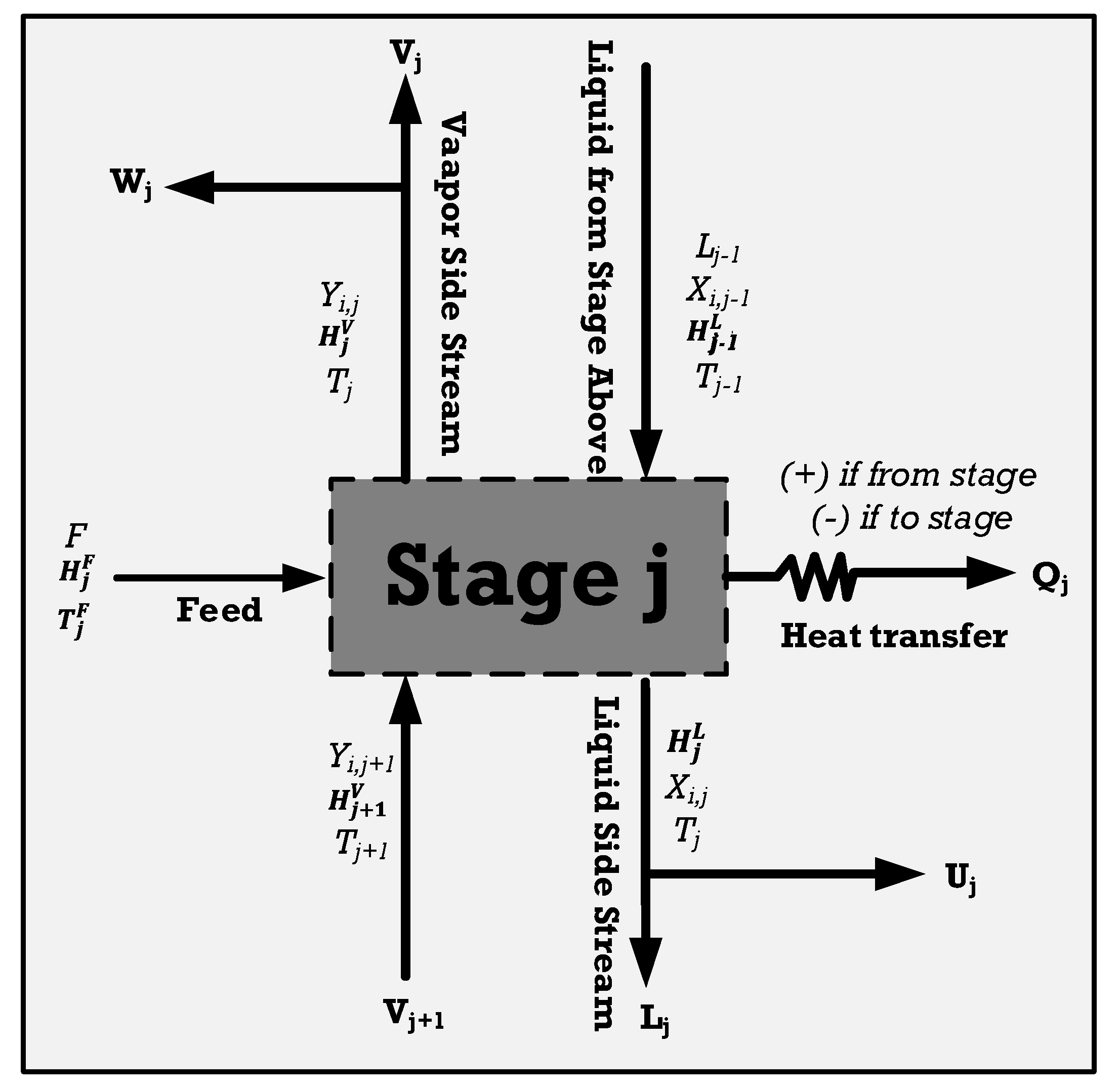

4.1. Energy Analysis

4.2. Exergy Analysis

5. Results and Discussion

5.1. Pinch Analysis

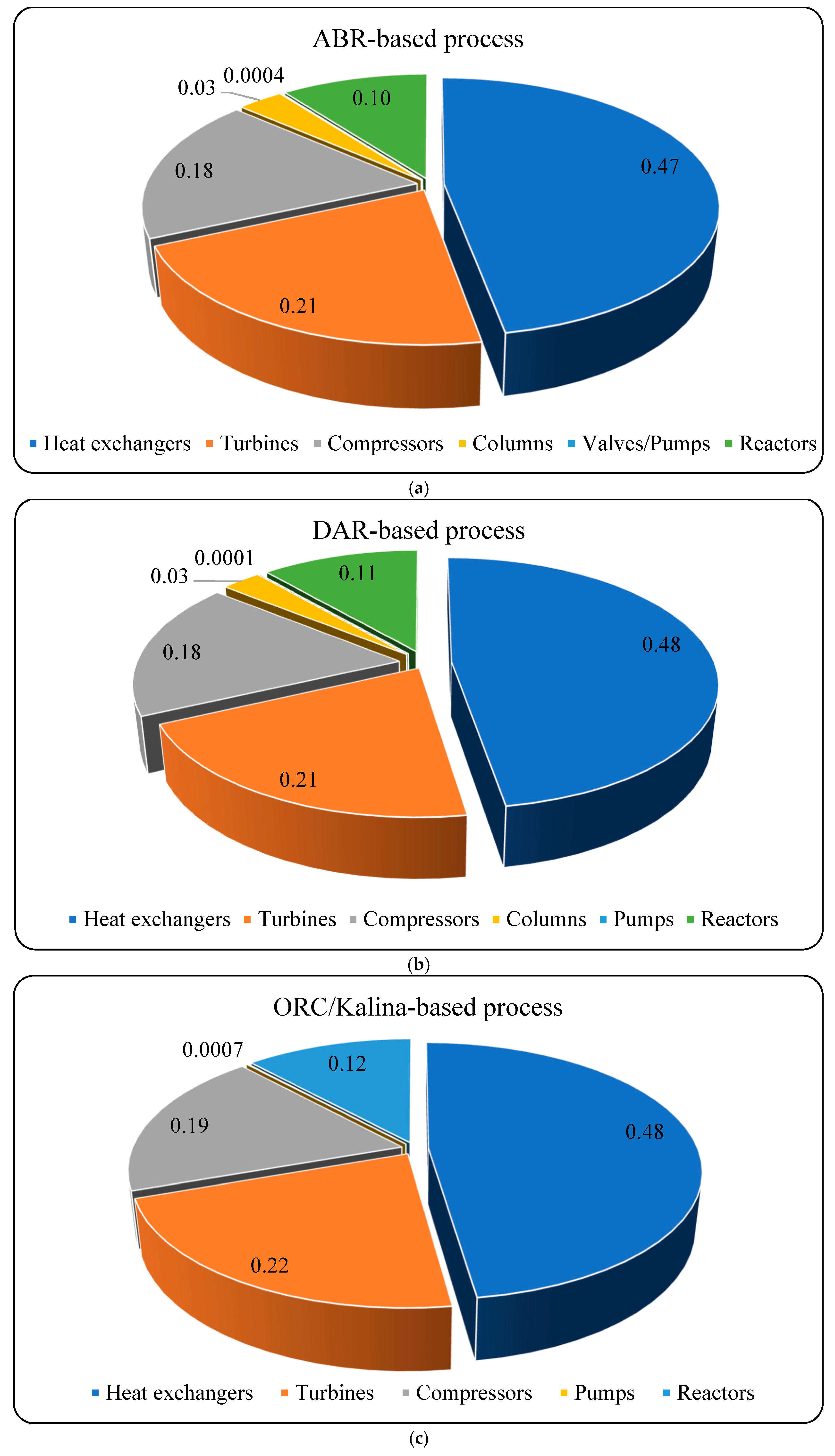

5.2. Exergy Analysis Results

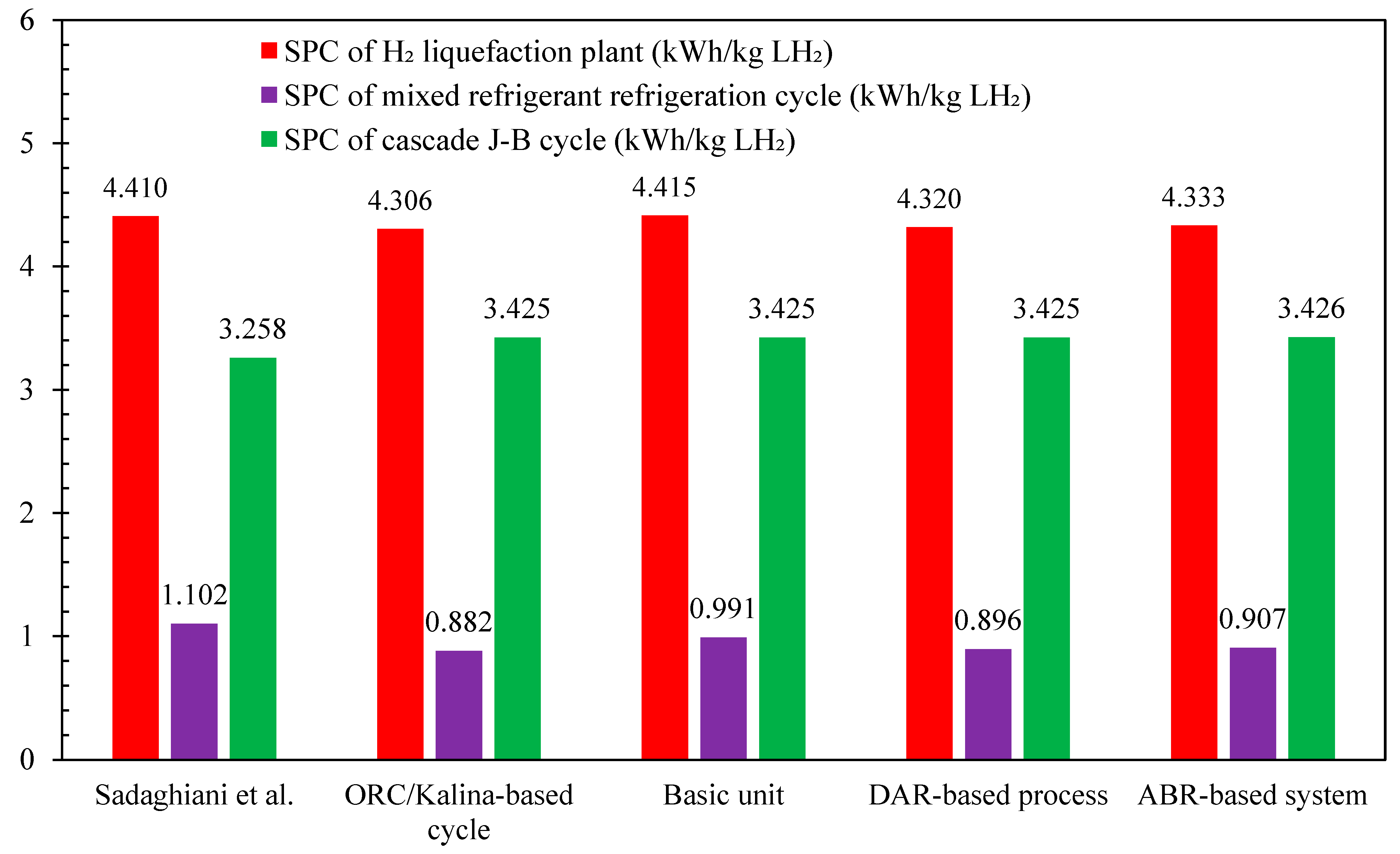

5.3. Comparison and Validation Analyses

6. Conclusions

- Ammonia–Water Absorption Refrigeration Cycle: uses waste heat to drive an absorption-based precooling system, reducing reliance on electrical refrigeration.

- Diffusion Absorption Refrigeration Cycle: employs a single-pressure absorption cooling system powered by waste heat to enhance H2 precooling.

- Organic Rankine and Kalina Power Cycles: converts waste heat into electricity, reducing external energy demands for liquefaction.

- Energy Efficiency Gains: The ORC/Kalina-based system demonstrated the lowest SPC at 4.306 kWh/kg LH2, outperforming the DAR-based (4.320 kWh/kg LH2) and ABR-based (4.333 kWh/kg LH2) methods. All scenarios improved the COP by approximately 2% over the baseline, showing a significant efficiency advantage over previous studies. Pinch analysis confirmed optimized energy integration across all cases.

- Exergy optimization: Exergy analysis identified heat exchangers as the dominant source of exergy destruction, contributing nearly 50% of the total irreversible processes. Among the proposed methods, the ORC/Kalina cycle achieved the highest exergy efficiency for hydrogen precooling (70.84%), while the ABR-based system exhibited the highest overall exergy efficiency (52.47%). These results provide critical insights into the thermodynamic limitations of hydrogen liquefaction and the role of waste heat recovery in mitigating losses.

- Impact on Hydrogen Liquefaction Technology: The ORC/Kalina scenario emerged as the most energy-efficient solution regarding SPC and exergy destruction, whereas the ABR-based cycle achieved the highest overall exergy efficiency. These findings validate the feasibility of integrating industrial waste heat into hydrogen liquefaction, establishing a scalable and practical framework for reducing operational costs and enhancing sustainability.

- Based on the detailed energy and exergy analyses, the three H2 liquefaction scenarios can be ranked as follows:

- ORC/Kalina-based scenario: best performance in terms of energy efficiency, with the lowest SPC (4.306 kWh/kg LH2) and highest exergy efficiency in the precooling unit (70.84%).

- DAR-based scenario: slightly higher SPC (4.320 kWh/kg LH2) and competitive exergy efficiency (precooling unit at 69.83%), with a balanced performance.

- ABR-based scenario—highest SPC (4.333 kWh/kg LH2) but the best overall exergy efficiency (52.47%), making it favorable from a thermodynamic optimization perspective.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| ABR-Based Process | ||||||

| Stream | Temperature (°C) | Pressure (kPa) | Molar Enthalpy (kJ/kmol) | Molar Entropy (kJ/kmol °C) | Mass Flow (kg/h) | Exergy (kW) |

| L1 | 25.0 | 700.0 | −124,459.3 | 163.8 | 100,833.3 | 994,814.1 |

| L2 | 25.0 | 700.0 | −121,010.2 | 171.1 | 86,958.8 | 810,201.2 |

| L3 | 25.0 | 700.0 | −161,438.5 | 85.0 | 13,874.6 | 184,612.9 |

| L4 | 69.6 | 1600.0 | −118,732.6 | 171.8 | 86,958.8 | 811,506.7 |

| L5 | 25.0 | 1600.0 | −123,476.7 | 156.8 | 86,958.8 | 811,340.6 |

| L6 | 25.4 | 1600.0 | −161,329.6 | 85.0 | 13,874.6 | 184,618.4 |

| L7 | 27.0 | 1600.0 | −126,706.1 | 150.7 | 100,833.3 | 995,946.4 |

| L8 | 27.0 | 1600.0 | −120,790.4 | 164.5 | 71,711.5 | 613,094.1 |

| L9 | 27.0 | 1600.0 | −150,858.4 | 94.4 | 29,121.8 | 382,852.2 |

| L10 | −43.0 | 1600.0 | −129,599.4 | 130.9 | 71,711.5 | 613,756.7 |

| L11 | −43.0 | 1600.0 | −128,504.1 | 152.8 | 42,051.9 | 250,363.8 |

| L12 | −43.0 | 1600.0 | −131,716.1 | 88.7 | 29,659.6 | 363,392.9 |

| L13 | −105.0 | 1600.0 | −137,147.2 | 61.3 | 29,659.6 | 363,906.3 |

| L14 | −107.7 | 200.0 | −137,239.7 | 61.4 | 29,659.6 | 363,885.4 |

| L15 | −105.0 | 1600.0 | −136,127.8 | 113.8 | 42,051.9 | 251,820.4 |

| L16 | −195.0 | 1600.0 | −143,755.2 | 52.1 | 42,051.9 | 255,726.0 |

| L17 | −196.4 | 200.0 | −143,824.7 | 52.2 | 42,051.9 | 255,689.9 |

| L18 | −110.5 | 200.0 | −132,654.2 | 146.3 | 42,051.9 | 249,559.1 |

| L19 | −106.1 | 200.0 | −134,217.7 | 117.5 | 71,711.5 | 613,411.0 |

| L20 | −47.5 | 200.0 | −125,625.4 | 161.8 | 71,711.5 | 610,877.4 |

| L21 | −45.0 | 1600.0 | −160,283.0 | 58.6 | 29,121.8 | 383,018.5 |

| L22 | −49.3 | 200.0 | −160,434.8 | 58.7 | 29,121.8 | 382,995.0 |

| L23 | −46.2 | 200.0 | −132,474.0 | 141.5 | 100,833.3 | 993,864.8 |

| L24 | 11.1 | 200.0 | −123,018.6 | 178.4 | 100,833.3 | 992,798.6 |

| L25 | 70.7 | 700.0 | −119,525.4 | 179.5 | 100,833.3 | 994,987.9 |

| L26 | 23.5 | 100.0 | −32.6 | 92.8 | 41,804.6 | 87,029.2 |

| L27 | 138.8 | 215.4 | 2420.3 | 93.4 | 41,804.6 | 91,801.5 |

| L28 | 25.0 | 215.4 | −1.0 | 86.5 | 41,804.6 | 91,024.2 |

| L29 | 140.8 | 464.2 | 2464.3 | 87.1 | 41,804.6 | 95,822.7 |

| L30 | 25.0 | 464.2 | −2.2 | 80.1 | 41,804.6 | 95,019.3 |

| L31 | 140.8 | 1000.0 | 2463.3 | 80.7 | 41,804.6 | 99,818.1 |

| L32 | 25.0 | 1000.0 | −4.6 | 73.7 | 8151.9 | 19,307.8 |

| L33 | 25.0 | 1000.0 | −4.6 | 73.7 | 20,693.3 | 49,012.2 |

| L34 | 25.0 | 1000.0 | −4.6 | 73.7 | 12,959.4 | 30,694.5 |

| L35 | 23.9 | 100.0 | −23.8 | 92.8 | 12,959.4 | 26,979.0 |

| L36 | 23.4 | 100.0 | −35.3 | 92.8 | 20,693.3 | 43,079.5 |

| L37 | 23.2 | 100.0 | −39.5 | 92.8 | 8151.9 | 16,970.7 |

| L38 | −194.0 | 1000.0 | −4676.4 | 45.4 | 8151.9 | 20,851.9 |

| L39 | −236.5 | 100.0 | −5562.7 | 48.3 | 8151.9 | 20,138.5 |

| L40 | −196.5 | 100.0 | −4711.3 | 64.0 | 8151.9 | 18,569.2 |

| L41 | −219.0 | 1000.0 | −5216.4 | 37.2 | 20,693.3 | 54,912.1 |

| L42 | −248.2 | 100.0 | −5813.1 | 40.0 | 20,693.3 | 53,412.2 |

| L43 | −221.7 | 100.0 | −5247.1 | 55.5 | 20,693.3 | 49,207.5 |

| L44 | −245.0 | 1000.0 | −5792.6 | 22.7 | 12,959.4 | 36,835.8 |

| L45 | −255.0 | 100.0 | −6128.0 | 24.8 | 12,959.4 | 36,208.0 |

| L46 | −248.2 | 100.0 | −5811.9 | 40.1 | 12,959.4 | 33,441.6 |

| L47 | 25.0 | 1000.0 | −4.6 | 73.7 | 41,804.6 | 99,014.6 |

| L48 | 24.0 | 101.1 | −285,672.3 | 55.2 | 60,153.9 | 10,861.3 |

| L49 | 99.0 | 101.1 | −280,190.8 | 71.6 | 60,153.9 | 11,397.9 |

| L50 | 24.0 | 101.1 | −285,672.3 | 55.2 | 61,276.5 | 11,064.0 |

| L51 | 99.0 | 101.1 | −280,190.8 | 71.6 | 61,276.5 | 11,610.6 |

| L52 | 24.0 | 101.1 | −285,672.3 | 55.2 | 61,309.3 | 11,069.9 |

| L53 | 99.0 | 101.1 | −280,190.8 | 71.6 | 61,309.3 | 11,616.8 |

| L54 | 24.0 | 101.1 | −285,672.3 | 55.2 | 143,763.8 | 25,957.8 |

| L55 | 45.0 | 101.1 | −284,143.8 | 60.2 | 143,763.8 | 26,061.0 |

| L56 | 24.0 | 101.1 | −285,672.3 | 55.2 | 102,123.8 | 18,439.3 |

| L57 | 50.0 | 101.1 | −283,779.9 | 61.3 | 102,123.8 | 18,552.8 |

| H1 | 25.0 | 2100.0 | 8475.5 | 116.9 | 4166.7 | 141,251.6 |

| H2 | −45.0 | 2100.0 | 6472.0 | 109.2 | 4166.7 | 141,411.6 |

| H3 | −105.0 | 2100.0 | 4822.9 | 100.9 | 4166.7 | 141,898.4 |

| H4 | −195.0 | 2100.0 | 2579.5 | 81.9 | 4166.7 | 143,853.9 |

| H5 | −195.0 | 2100.0 | 2291.9 | 81.8 | 4166.6 | 143,156.1 |

| H7 | −195.0 | 2100.0 | 2291.9 | 81.8 | 4166.6 | 143,156.2 |

| H8 | −219.0 | 2100.0 | 1684.8 | 72.5 | 4166.6 | 144,402.0 |

| H9 | −239.5 | 2100.0 | 660.2 | 47.3 | 4166.6 | 148,118.3 |

| H10 | −240.0 | 2100.0 | −120.6 | 28.4 | 4166.4 | 147,975.8 |

| H12 | −240.0 | 2100.0 | −120.6 | 28.4 | 4166.4 | 149,483.0 |

| H13 | −253.0 | 2100.0 | −479.0 | 15.2 | 4166.4 | 151,540.9 |

| H14 | −253.5 | 130.0 | −528.2 | 15.5 | 4166.4 | 151,464.5 |

| H16 | −253.5 | 130.0 | −528.2 | 15.5 | 4166.4 | 151,464.5 |

| W1 | 54.1 | 120.0 | −225,213.2 | 80.6 | 14,356.9 | 21,783.8 |

| W2 | 31.9 | 120.0 | −230,824.9 | 62.9 | 14,356.9 | 21,713.3 |

| W3 | 25.0 | 200.0 | −285,010.9 | 6.6 | 217,182.2 | 39,220.1 |

| W4 | 30.0 | 190.0 | −284,634.6 | 7.9 | 217,182.2 | 39,229.9 |

| W5 | 32.0 | 1300.0 | −230,796.6 | 62.9 | 14,356.9 | 21,719.5 |

| W6 | 126.7 | 1300.0 | −222,020.6 | 87.5 | 14,356.9 | 22,038.7 |

| W7 | 104.2 | 1300.0 | −55,230.4 | 159.0 | 3869.5 | 20,614.8 |

| W8 | 37.0 | 1300.0 | −271,521.7 | 59.2 | 11,485.5 | 5862.2 |

| W9 | 37.3 | 120.0 | −271,521.7 | 59.2 | 11,485.5 | 5857.8 |

| W10 | 34.0 | 1300.0 | −66,320.8 | 83.9 | 2871.4 | 16,224.7 |

| W11 | −24.5 | 1300.0 | −71,072.1 | 66.7 | 2871.4 | 16,241.2 |

| W12 | −29.6 | 120.0 | −71,072.1 | 66.9 | 2871.4 | 16,239.0 |

| W13 | −29.5 | 120.0 | −54,214.6 | 136.1 | 2871.4 | 16,062.3 |

| W14 | 154.9 | 1300.0 | −248,032.3 | 87.1 | 14,754.1 | 12,917.7 |

| W15 | 25.0 | 200.0 | −285,010.9 | 6.6 | 164,951.3 | 29,787.9 |

| W16 | 30.0 | 190.0 | −284,634.6 | 7.9 | 164,951.3 | 29,795.4 |

| W17 | 45.5 | 1300.0 | −45,883.0 | 150.3 | 2871.4 | 16,253.6 |

| W18 | 173.9 | 1300.0 | −260,433.7 | 88.7 | 11,485.5 | 6268.0 |

| W19 | −29.3 | 120.0 | −49,463.3 | 155.6 | 2871.4 | 16,012.6 |

| DAR-Based Process | ||||||

| Stream | Temperature (°C) | Pressure (kPa) | Molar Enthalpy (kJ/kmol) | Molar Entropy (kJ/kmol °C) | Mass Flow (kg/h) | Exergy (kW) |

| L1 | 25.0 | 700.0 | −124,459.3 | 163.8 | 100,833.3 | 994,814.1 |

| L2 | 25.0 | 700.0 | −121,010.2 | 171.1 | 86,958.8 | 810,201.2 |

| L3 | 25.0 | 700.0 | −161,438.5 | 85.0 | 13,874.6 | 184,612.9 |

| L4 | 69.6 | 1600.0 | −118,732.6 | 171.8 | 86,958.8 | 811,506.7 |

| L5 | 25.0 | 1600.0 | −123,476.7 | 156.8 | 86,958.8 | 811,340.6 |

| L6 | 25.4 | 1600.0 | −161,329.6 | 85.0 | 13,874.6 | 184,618.4 |

| L7 | 27.0 | 1600.0 | −126,706.1 | 150.7 | 100,833.3 | 995,946.4 |

| L8 | 27.0 | 1600.0 | −120,790.4 | 164.5 | 71,711.5 | 613,094.1 |

| L9 | 27.0 | 1600.0 | −150,858.4 | 94.4 | 29,121.8 | 382,852.2 |

| L10 | −43.0 | 1600.0 | −129,599.4 | 130.9 | 71,711.5 | 613,756.7 |

| L11 | −43.0 | 1600.0 | −128,504.1 | 152.8 | 42,051.9 | 250,363.8 |

| L12 | −43.0 | 1600.0 | −131,716.1 | 88.7 | 29,659.6 | 363,392.9 |

| L13 | −105.0 | 1600.0 | −137,147.2 | 61.3 | 29,659.6 | 363,906.3 |

| L14 | −107.7 | 200.0 | −137,239.7 | 61.4 | 29,659.6 | 363,885.4 |

| L15 | −105.0 | 1600.0 | −136,127.8 | 113.8 | 42,051.9 | 251,820.4 |

| L16 | −195.0 | 1600.0 | −143,755.2 | 52.1 | 42,051.9 | 255,726.0 |

| L17 | −196.4 | 200.0 | −143,824.7 | 52.2 | 42,051.9 | 255,689.9 |

| L18 | −110.5 | 200.0 | −132,654.2 | 146.3 | 42,051.9 | 249,559.1 |

| L19 | −106.1 | 200.0 | −134,217.7 | 117.5 | 71,711.5 | 613,411.0 |

| L20 | −47.5 | 200.0 | −125,625.4 | 161.8 | 71,711.5 | 610,877.4 |

| L21 | −45.0 | 1600.0 | −160,283.0 | 58.6 | 29,121.8 | 383,018.5 |

| L22 | −49.3 | 200.0 | −160,434.8 | 58.7 | 29,121.8 | 382,995.0 |

| L23 | −46.2 | 200.0 | −132,474.0 | 141.5 | 100,833.3 | 993,864.8 |

| L24 | 6.4 | 200.0 | −123,294.4 | 177.5 | 100,833.3 | 992,809.5 |

| L25 | 65.8 | 700.0 | −119,860.8 | 178.5 | 100,833.3 | 994,958.8 |

| L26 | 23.1 | 100.0 | −40.1 | 92.8 | 41,804.6 | 87,029.3 |

| L27 | 138.3 | 215.4 | 2410.0 | 93.4 | 41,804.6 | 91,795.5 |

| L28 | 25.0 | 215.4 | −1.0 | 86.5 | 41,804.6 | 91,024.2 |

| L29 | 140.8 | 464.2 | 2464.3 | 87.1 | 41,804.6 | 95,822.7 |

| L30 | 25.0 | 464.2 | −2.2 | 80.1 | 41,804.6 | 95,019.3 |

| L31 | 140.8 | 1000.0 | 2463.3 | 80.7 | 41,804.6 | 99,818.1 |

| L32 | 25.0 | 1000.0 | −4.6 | 73.7 | 8151.9 | 19,307.8 |

| L33 | 25.0 | 1000.0 | −4.6 | 73.7 | 20,693.3 | 49,012.2 |

| L34 | 25.0 | 1000.0 | −4.6 | 73.7 | 12,959.4 | 30,694.5 |

| L35 | 23.9 | 100.0 | −23.8 | 92.8 | 12,959.4 | 26,979.0 |

| L36 | 22.6 | 100.0 | −50.5 | 92.7 | 20,693.3 | 43,079.6 |

| L37 | 23.2 | 100.0 | −39.5 | 92.8 | 8151.9 | 16,970.7 |

| L38 | −194.0 | 1000.0 | −4676.4 | 45.4 | 8151.9 | 20,851.9 |

| L39 | −236.5 | 100.0 | −5562.7 | 48.3 | 8151.9 | 20,138.5 |

| L40 | −196.5 | 100.0 | −4711.3 | 64.0 | 8151.9 | 18,569.2 |

| L41 | −219.0 | 1000.0 | −5216.4 | 37.2 | 20,693.3 | 54,912.1 |

| L42 | −248.2 | 100.0 | −5813.1 | 40.0 | 20,693.3 | 53,412.2 |

| L43 | −222.4 | 100.0 | −5262.3 | 55.2 | 20,693.3 | 49,283.9 |

| L44 | −245.0 | 1000.0 | −5792.6 | 22.7 | 12,959.4 | 36,835.8 |

| L45 | −255.0 | 100.0 | −6128.0 | 24.8 | 12,959.4 | 36,208.0 |

| L46 | −248.2 | 100.0 | −5811.9 | 40.1 | 12,959.4 | 33,441.6 |

| L47 | 25.0 | 1000.0 | −4.6 | 73.7 | 41,804.6 | 99,014.6 |

| L48 | 24.0 | 101.1 | −285,672.3 | 55.2 | 59,897.8 | 10,815.0 |

| L49 | 99.0 | 101.1 | −280,190.8 | 71.6 | 59,897.8 | 11,349.3 |

| L50 | 24.0 | 101.1 | −285,672.3 | 55.2 | 61,276.5 | 11,064.0 |

| L51 | 99.0 | 101.1 | −280,190.8 | 71.6 | 61,276.5 | 11,610.6 |

| L52 | 24.0 | 101.1 | −285,672.3 | 55.2 | 61,309.3 | 11,069.9 |

| L53 | 99.0 | 101.1 | −280,190.8 | 71.6 | 61,309.3 | 11,616.8 |

| L54 | 24.0 | 101.1 | −285,672.3 | 55.2 | 133,990.4 | 24,193.1 |

| L55 | 45.0 | 101.1 | −284,143.8 | 60.2 | 133,990.4 | 24,289.3 |

| L56 | 24.0 | 101.1 | −285,672.3 | 55.2 | 102,123.8 | 18,439.3 |

| L57 | 50.0 | 101.1 | −283,779.9 | 61.3 | 102,123.8 | 18,552.8 |

| H1 | 25.0 | 2100.0 | 8475.5 | 116.9 | 4166.7 | 141,251.6 |

| H2 | −45.0 | 2100.0 | 6472.0 | 109.2 | 4166.7 | 141,411.6 |

| H3 | −105.0 | 2100.0 | 4822.9 | 100.9 | 4166.7 | 141,898.4 |

| H4 | −195.0 | 2100.0 | 2579.5 | 81.9 | 4166.7 | 143,853.9 |

| H5 | −195.0 | 2100.0 | 2291.9 | 81.8 | 4166.6 | 143,156.1 |

| H7 | −195.0 | 2100.0 | 2291.9 | 81.8 | 4166.6 | 143,156.2 |

| H8 | −219.0 | 2100.0 | 1684.8 | 72.5 | 4166.6 | 144,402.0 |

| H9 | −239.0 | 2100.0 | 687.7 | 48.1 | 4166.6 | 147,995.2 |

| H10 | −240.0 | 2100.0 | −82.8 | 30.3 | 4166.4 | 147,737.2 |

| H12 | −240.0 | 2100.0 | −82.8 | 30.4 | 4166.4 | 149,242.0 |

| H13 | −253.0 | 2100.0 | −441.2 | 17.1 | 4166.4 | 151,299.8 |

| H14 | −253.5 | 130.0 | −490.4 | 17.4 | 4166.4 | 151,223.5 |

| H16 | −253.5 | 130.0 | −490.4 | 17.4 | 4166.4 | 151,223.5 |

| B1 | 65.3 | 2500.0 | −45,671.5 | 145.8 | 2999.3 | 17,038.4 |

| B2 | 188.5 | 2500.0 | −243,856.7 | 93.8 | 8927.4 | 8217.1 |

| B3 | 35.0 | 2500.0 | −66,040.8 | 84.1 | 2999.3 | 16,941.9 |

| B4 | −3.1 | 2500.0 | −1574.4 | 57.3 | 10,285.3 | 29,030.7 |

| B5 | 2.0 | 2500.0 | −68,794.1 | 74.7 | 2999.3 | 16,945.0 |

| B6 | 22.3 | 2500.0 | −992.8 | 59.3 | 10,285.3 | 29,009.3 |

| B7 | −31.7 | 2500.0 | −6108.0 | 58.8 | 13,284.7 | 45,900.9 |

| B8 | −5.8 | 2500.0 | −4761.2 | 64.2 | 13,284.7 | 45,717.0 |

| B9 | 43.0 | 2500.0 | −255,907.2 | 62.6 | 8927.4 | 7837.3 |

| B10 | 24.1 | 2500.0 | −4033.1 | 66.8 | 13,284.7 | 45,686.8 |

| B11 | 22.3 | 2500.0 | −992.8 | 59.3 | 10,285.2 | 29,008.8 |

| B12 | 25.3 | 2500.0 | −209,227.5 | 63.6 | 11,927.4 | 24,492.9 |

| B13 | 21.8 | 2500.0 | −209,511.7 | 62.7 | 11,927.3 | 24,492.7 |

| B14 | 21.8 | 2500.0 | −3383.5 | 65.3 | 0.2 | 0.5 |

| B15 | 128.0 | 2500.0 | −200,608.3 | 88.3 | 11,927.3 | 24,728.0 |

| ORC/Kalina-Based Process | ||||||

| Stream | Temperature (°C) | Pressure (kPa) | Molar Enthalpy (kJ/kmol) | Molar Entropy (kJ/kmol °C) | Mass Flow (kg/h) | Exergy (kW) |

| L1 | 25.0 | 700.0 | −124,459.3 | 163.8 | 106,775.5 | 1,053,439.5 |

| L2 | 25.0 | 700.0 | −121,010.2 | 171.1 | 92,083.3 | 857,947.2 |

| L3 | 25.0 | 700.0 | −161,438.5 | 85.0 | 14,692.2 | 195,492.3 |

| L4 | 69.6 | 1600.0 | −118,732.6 | 171.8 | 92,083.3 | 859,329.6 |

| L5 | 25.0 | 1600.0 | −123,476.7 | 156.8 | 92,083.3 | 859,153.7 |

| L6 | 25.4 | 1600.0 | −161,329.6 | 85.0 | 14,692.2 | 195,498.2 |

| L7 | 27.0 | 1600.0 | −126,706.1 | 150.7 | 106,775.5 | 1,054,638.5 |

| L8 | 27.0 | 1600.0 | −120,790.4 | 164.5 | 75,937.5 | 649,224.4 |

| L9 | 27.0 | 1600.0 | −150,858.4 | 94.4 | 30,838.0 | 405,414.1 |

| L10 | −45.0 | 1600.0 | −129,863.2 | 129.8 | 75,937.5 | 649,972.4 |

| L11 | −45.0 | 1600.0 | −128,689.4 | 152.3 | 43,520.3 | 254,850.5 |

| L12 | −45.0 | 1600.0 | −132,006.7 | 88.7 | 32,417.2 | 395,122.0 |

| L13 | −105.0 | 1600.0 | −137,225.8 | 62.3 | 32,417.2 | 395,672.0 |

| L14 | −108.0 | 200.0 | −137,319.3 | 62.3 | 32,417.2 | 395,648.8 |

| L15 | −105.0 | 1600.0 | −136,037.8 | 114.5 | 43,520.3 | 256,329.9 |

| L16 | −195.0 | 1600.0 | −143,727.0 | 52.4 | 43,520.3 | 260,408.2 |

| L17 | −196.4 | 200.0 | −143,796.7 | 52.5 | 43,520.3 | 260,370.6 |

| L18 | −111.4 | 200.0 | −132,695.0 | 146.4 | 43,520.3 | 253,998.0 |

| L19 | −106.8 | 200.0 | −134,331.3 | 116.9 | 75,937.5 | 649,612.2 |

| L20 | −51.6 | 200.0 | −126,115.6 | 159.6 | 75,937.5 | 646,972.6 |

| L21 | −45.0 | 1600.0 | −160,283.0 | 58.6 | 30,838.0 | 405,590.1 |

| L22 | −49.3 | 200.0 | −160,434.8 | 58.7 | 30,838.0 | 405,565.2 |

| L23 | −48.8 | 200.0 | −132,867.7 | 139.8 | 106,775.5 | 1,052,526.3 |

| L24 | 25.7 | 200.0 | −122,144.0 | 181.4 | 106,775.5 | 1,051,290.8 |

| L25 | 86.1 | 700.0 | −118,468.1 | 182.5 | 106,775.5 | 1,053,740.4 |

| L26 | 23.1 | 100.0 | −40.1 | 92.8 | 41,804.6 | 87,029.3 |

| L27 | 138.3 | 215.4 | 2410.0 | 93.4 | 41,804.6 | 91,795.5 |

| L28 | 25.0 | 215.4 | −1.0 | 86.5 | 41,804.6 | 91,024.2 |

| L29 | 140.8 | 464.2 | 2464.3 | 87.1 | 41,804.6 | 95,822.7 |

| L30 | 25.0 | 464.2 | −2.2 | 80.1 | 41,804.6 | 95,019.3 |

| L31 | 140.8 | 1000.0 | 2463.3 | 80.7 | 41,804.6 | 99,818.1 |

| L32 | 25.0 | 1000.0 | −4.6 | 73.7 | 8151.9 | 19,307.8 |

| L33 | 25.0 | 1000.0 | −4.6 | 73.7 | 20,693.3 | 49,012.2 |

| L34 | 25.0 | 1000.0 | −4.6 | 73.7 | 12,959.4 | 30,694.5 |

| L35 | 23.9 | 100.0 | −23.8 | 92.8 | 12,959.4 | 26,979.0 |

| L36 | 22.6 | 100.0 | −50.5 | 92.7 | 20,693.3 | 43,079.6 |

| L37 | 23.2 | 100.0 | −39.5 | 92.8 | 8151.9 | 16,970.7 |

| L38 | −194.0 | 1000.0 | −4676.4 | 45.4 | 8151.9 | 20,851.9 |

| L39 | −236.5 | 100.0 | −5562.7 | 48.3 | 8151.9 | 20,138.5 |

| L40 | −196.5 | 100.0 | −4711.3 | 64.0 | 8151.9 | 18,569.2 |

| L41 | −219.0 | 1000.0 | −5216.4 | 37.2 | 20,693.3 | 54,912.1 |

| L42 | −248.2 | 100.0 | −5813.1 | 40.0 | 20,693.3 | 53,412.2 |

| L43 | −222.4 | 100.0 | −5262.3 | 55.2 | 20,693.3 | 49,283.9 |

| L44 | −245.0 | 1000.0 | −5792.6 | 22.7 | 12,959.4 | 36,835.8 |

| L45 | −255.0 | 100.0 | −6128.0 | 24.8 | 12,959.4 | 36,208.0 |

| L46 | −248.2 | 100.0 | −5811.9 | 40.1 | 12,959.4 | 33,441.6 |

| L47 | 25.0 | 1000.0 | −4.6 | 73.7 | 41,804.6 | 99,014.6 |

| L48 | 24.0 | 101.1 | −285,672.3 | 55.2 | 59,897.8 | 10,815.0 |

| L49 | 99.0 | 101.1 | −280,190.8 | 71.6 | 59,897.8 | 11,349.3 |

| L50 | 24.0 | 101.1 | −285,672.3 | 55.2 | 61,276.5 | 11,064.0 |

| L51 | 99.0 | 101.1 | −280,190.8 | 71.6 | 61,276.5 | 11,610.6 |

| L52 | 24.0 | 101.1 | −285,672.3 | 55.2 | 61,309.3 | 11,069.9 |

| L53 | 99.0 | 101.1 | −280,190.8 | 71.6 | 61,309.3 | 11,616.8 |

| L54 | 24.0 | 101.1 | −285,672.3 | 55.2 | 149,309.7 | 26,959.1 |

| L55 | 50.0 | 101.1 | −283,779.9 | 61.3 | 149,309.7 | 27,125.1 |

| L56 | 24.0 | 101.1 | −285,672.3 | 55.2 | 108,142.1 | 19,526.0 |

| L57 | 50.0 | 101.1 | −283,779.9 | 61.3 | 108,142.1 | 19,646.2 |

| H1 | 25.0 | 2100.0 | 8475.5 | 116.9 | 4166.7 | 141,251.6 |

| H2 | −45.0 | 2100.0 | 6472.0 | 109.2 | 4166.7 | 141,411.6 |

| H3 | −105.0 | 2100.0 | 4822.9 | 100.9 | 4166.7 | 141,898.4 |

| H4 | −195.0 | 2100.0 | 2579.5 | 81.9 | 4166.7 | 143,853.9 |

| H5 | −195.0 | 2100.0 | 2291.9 | 81.8 | 4166.6 | 143,156.1 |

| H7 | −195.0 | 2100.0 | 2291.9 | 81.8 | 4166.6 | 143,156.2 |

| H8 | −219.0 | 2100.0 | 1684.8 | 72.5 | 4166.6 | 144,402.0 |

| H9 | −239.0 | 2100.0 | 687.7 | 48.1 | 4166.6 | 147,995.2 |

| H10 | −240.0 | 2100.0 | −82.8 | 30.3 | 4166.4 | 147,737.2 |

| H12 | −240.0 | 2100.0 | −82.8 | 30.4 | 4166.4 | 149,242.0 |

| H13 | −253.0 | 2100.0 | −441.2 | 17.1 | 4166.4 | 151,299.8 |

| H14 | −253.5 | 130.0 | −490.4 | 17.4 | 4166.4 | 151,223.5 |

| H16 | −253.5 | 130.0 | −490.4 | 17.4 | 4166.4 | 151,223.5 |

| R1 | 30.0 | 5000.0 | −120,789.5 | 208.4 | 12,258.7 | 167,476.4 |

| R2 | 178.7 | 5000.0 | −94,877.3 | 277.9 | 12,258.7 | 167,879.0 |

| R3 | 178.7 | 5000.0 | −94,877.3 | 277.9 | 11,155.4 | 152,769.9 |

| R4 | 125.1 | 1500.0 | −98,009.3 | 278.7 | 11,155.4 | 152,531.4 |

| R5 | 178.7 | 5000.0 | −94,877.3 | 277.9 | 1103.3 | 15,109.1 |

| R6 | 125.1 | 1500.0 | −98,009.3 | 278.7 | 1103.3 | 15,085.5 |

| R7 | 7.2 | 1500.0 | −123,427.3 | 200.4 | 11,155.4 | 152,386.9 |

| R8 | 26.6 | 1500.0 | −121,139.7 | 208.3 | 12,258.7 | 167,453.3 |

| K1 | 100.0 | 2300.0 | −89,095.0 | 130.3 | 5609.0 | 25,966.3 |

| K2 | 96.7 | 2290.0 | −89,701.4 | 128.7 | 6469.2 | 30,051.1 |

| K3 | 96.5 | 2280.0 | −47,712.7 | 151.4 | 4207.0 | 23,495.6 |

| K4 | 96.5 | 2280.0 | −169,886.9 | 85.3 | 2262.2 | 6554.8 |

| K5 | 19.5 | 450.0 | −51,289.0 | 152.8 | 4207.0 | 23,222.4 |

| K6 | 21.3 | 2270.0 | −175,754.5 | 67.5 | 2262.2 | 6533.9 |

| K7 | 21.7 | 450.0 | −175,754.5 | 67.7 | 2262.2 | 6532.3 |

| K8 | 28.2 | 450.0 | −94,065.1 | 123.6 | 6469.2 | 29,753.4 |

| K9 | 6.8 | 440.0 | −108,878.4 | 72.0 | 6469.2 | 29,812.6 |

| K10 | 5.5 | 101.3 | −287,022.6 | 50.5 | 70,504.8 | 12,783.3 |

| K11 | 25.0 | 101.3 | −285,599.5 | 55.4 | 70,504.8 | 12,730.3 |

| K12 | 7.2 | 2300.0 | −108,819.6 | 72.0 | 6469.2 | 29,817.9 |

| K13 | 7.2 | 2300.0 | −108,819.6 | 72.0 | 860.3 | 3965.1 |

| K14 | 80.0 | 2290.0 | −93,655.0 | 117.7 | 860.3 | 3983.4 |

| K15 | 7.2 | 2300.0 | −108,819.6 | 72.0 | 5609.0 | 25,852.7 |

| ABR-Based Process | ||||

| Equipment | Input Exergy (kW) | Output Exergy (kW) | Exergy Destruction (kW) | Exergy Efficiency |

| HX1 | 102,662.7 | 102,422.0 | 240.7 | 0.953 |

| HX2 | 106,886.7 | 106,629.9 | 256.8 | 0.950 |

| HX3 | 110,888.0 | 110,631.4 | 256.6 | 0.950 |

| HX4 | 1,020,945.7 | 1020,875.1 | 70.6 | 0.979 |

| HX5 | 829,946.0 | 829,893.4 | 52.6 | 0.982 |

| HX6 | 2,147,301.8 | 2,147,047.6 | 254.2 | 0.796 |

| HX7 | 1,368,579.2 | 1,368,502.6 | 76.7 | 0.970 |

| HX8 | 649,408.7 | 649,139.0 | 269.8 | 0.956 |

| HX9 | 163,294.7 | 162,971.1 | 323.6 | 0.794 |

| HX10 | 37,877.0 | 37,822.6 | 54.4 | 0.966 |

| HX11 | 197,814.2 | 197,325.8 | 488.4 | 0.884 |

| HX12 | 98,219.7 | 97,991.6 | 228.1 | 0.963 |

| HX13 | 185,691.1 | 184,982.5 | 708.6 | 0.744 |

| HX14 | 64,136.2 | 63,814.8 | 321.4 | 0.950 |

| HX15 | 61,004.0 | 60,943.2 | 60.7 | 0.952 |

| HX16 | 46,041.5 | 46,020.0 | 21.5 | 0.978 |

| HX17 | 32,286.9 | 32,253.8 | 33.2 | 0.851 |

| T1 | 383,018.5 | 383,015.5 | 3.0 | 0.872 |

| T2 | 363,906.3 | 363,902.8 | 3.5 | 0.834 |

| T3 | 255,726.0 | 255,715.2 | 10.8 | 0.700 |

| T4 | 20,851.9 | 20,501.4 | 350.6 | 0.509 |

| T5 | 54,912.1 | 54,032.4 | 879.7 | 0.413 |

| T6 | 36,835.8 | 36,426.3 | 409.4 | 0.348 |

| T7 | 151,540.9 | 151,492.7 | 48.1 | 0.370 |

| C1 | 995,197.5 | 994,987.9 | 209.6 | 0.913 |

| C2 | 811,631.8 | 811,506.7 | 125.1 | 0.913 |

| C3 | 92,179.6 | 91,801.5 | 378.1 | 0.927 |

| C4 | 96,200.8 | 95,822.7 | 378.1 | 0.927 |

| C5 | 100,196.2 | 99,818.1 | 378.2 | 0.927 |

| P1 | 184,619.3 | 184,618.4 | 0.8 | 0.869 |

| CR1 | 143,853.9 | 143,158.8 | 695.0 | 0.995 |

| CR2 | 148,118.3 | 147,983.2 | 135.1 | 0.999 |

| D1 | 994,814.1 | 994,814.1 | 0.0 | 1.000 |

| D2 | 995,946.4 | 995,946.4 | 0.0 | 1.000 |

| D3 | 613,756.7 | 613,756.7 | 0.0 | 1.000 |

| D4 | 151,464.5 | 151,464.5 | 0.0 | 1.000 |

| DT | 22,778.9 | 22,521.6 | 257.3 | 0.989 |

| V1 | 16,241.2 | 16,239.0 | 2.1 | 0.679 |

| HX18 | 27,987.5 | 27,900.9 | 86.6 | 0.956 |

| P2 | 21,719.7 | 21,719.5 | 0.2 | 0.969 |

| DAR-Based Process | ||||

| Equipment | Input Exergy (kW) | Output Exergy (kW) | Exergy Destruction (kW) | Exergy Efficiency |

| HX1 | 102,610.5 | 102,373.5 | 237.0 | 0.953 |

| HX2 | 106,886.7 | 106,629.9 | 256.8 | 0.950 |

| HX3 | 110,888.0 | 110,631.4 | 256.6 | 0.950 |

| HX4 | 1,019,151.9 | 1,019,103.4 | 48.5 | 0.985 |

| HX5 | 829,946.0 | 829,893.4 | 52.6 | 0.982 |

| HX6 | 2,176,963.7 | 2,176,713.3 | 250.4 | 0.798 |

| HX7 | 1,368,579.2 | 1,368,502.6 | 76.7 | 0.970 |

| HX8 | 649,408.7 | 649,139.0 | 269.8 | 0.956 |

| HX9 | 163,294.7 | 162,971.1 | 323.6 | 0.794 |

| HX10 | 37,877.0 | 37,822.6 | 54.4 | 0.966 |

| HX11 | 197,814.2 | 197,279.1 | 535.1 | 0.870 |

| HX12 | 98,296.1 | 97,991.7 | 304.5 | 0.951 |

| HX13 | 185,450.1 | 184,741.5 | 708.6 | 0.744 |

| HX14 | 64,136.2 | 63,814.8 | 321.4 | 0.950 |

| HX15 | 91,668.2 | 91,662.5 | 5.7 | 0.811 |

| HX16 | 32,709.8 | 32,565.2 | 144.6 | 0.619 |

| HX17 | 17,038.4 | 16,941.9 | 96.5 | 0.994 |

| T1 | 383,018.5 | 383,015.5 | 3.0 | 0.872 |

| T2 | 363,906.3 | 363,902.8 | 3.5 | 0.834 |

| T3 | 255,726.0 | 255,715.2 | 10.8 | 0.700 |

| T4 | 20,851.9 | 20,501.4 | 350.6 | 0.509 |

| T5 | 54,912.1 | 54,032.4 | 879.7 | 0.413 |

| T6 | 36,835.8 | 36,426.3 | 409.4 | 0.348 |

| T7 | 151,299.8 | 151,251.7 | 48.1 | 0.370 |

| C1 | 995,167.8 | 994,958.8 | 209.0 | 0.911 |

| C2 | 811,631.8 | 811,506.7 | 125.1 | 0.913 |

| C3 | 92,173.6 | 91,795.5 | 378.1 | 0.926 |

| C4 | 96,200.8 | 95,822.7 | 378.1 | 0.927 |

| C5 | 100,196.2 | 99,818.1 | 378.1 | 0.927 |

| P1 | 184,619.3 | 184,618.4 | 0.8 | 0.869 |

| CR1 | 143,853.9 | 143,158.8 | 695.0 | 0.995 |

| CR2 | 147,995.2 | 147,744.5 | 250.7 | 0.998 |

| D1 | 994,814.1 | 994,814.1 | 0.0 | 1.000 |

| D2 | 995,946.4 | 995,946.4 | 0.0 | 1.000 |

| D3 | 613,756.7 | 613,756.7 | 0.0 | 1.000 |

| D4 | 151,223.5 | 151,223.5 | 0.0 | 1.000 |

| DT1 | 53,524.1 | 53,501.7 | 22.4 | 1.000 |

| DT2 | 25,468.1 | 25,255.5 | 212.6 | 0.992 |

| ORC/Kalina-Based Process | ||||

| Equipment | Input Exergy (kW) | Output Exergy (kW) | Exergy Destruction (kW) | Exergy Efficiency |

| HX1 | 102,610.5 | 102,373.5 | 237.0 | 0.953 |

| HX2 | 106,886.7 | 106,629.9 | 256.8 | 0.950 |

| HX3 | 110,888.0 | 110,631.4 | 256.6 | 0.950 |

| HX4 | 1,080,699.5 | 1,080,564.5 | 135.0 | 0.969 |

| HX5 | 878,855.6 | 878,799.9 | 55.7 | 0.982 |

| HX6 | 2,248,416.3 | 2,248,264.9 | 151.4 | 0.877 |

| HX7 | 1,440,996.2 | 1,440,872.9 | 123.3 | 0.953 |

| HX8 | 658,599.0 | 658,260.1 | 338.9 | 0.947 |

| HX9 | 163,294.7 | 162,971.1 | 323.6 | 0.794 |

| HX10 | 37,877.0 | 37,822.6 | 54.4 | 0.966 |

| HX11 | 197,814.2 | 197,279.1 | 535.1 | 0.870 |

| HX12 | 98,296.1 | 97,991.7 | 304.5 | 0.951 |

| HX13 | 185,450.1 | 184,741.5 | 708.6 | 0.744 |

| HX14 | 64,136.2 | 63,814.8 | 321.4 | 0.950 |

| HX15 | 178,384.1 | 178,353.2 | 30.9 | 0.983 |

| HX16 | 168,216.8 | 167,879.0 | 1.0 | 0.998 |

| HX17 | 10,520.0 | 10,517.2 | 2.7 | 0.987 |

| T1 | 405,590.1 | 405,586.9 | 3.2 | 0.872 |

| T2 | 395,672.0 | 395,668.1 | 3.8 | 0.834 |

| T3 | 260,408.2 | 260,396.9 | 11.3 | 0.700 |

| T4 | 20,851.9 | 20,501.4 | 350.6 | 0.509 |

| T5 | 54,912.1 | 54,032.4 | 879.7 | 0.413 |

| T6 | 36,835.8 | 36,426.3 | 409.4 | 0.348 |

| T7 | 151,299.8 | 151,251.7 | 48.1 | 0.370 |

| C1 | 1,053,963.9 | 1,053,740.4 | 223.5 | 0.916 |

| C2 | 859,462.1 | 859,329.6 | 132.5 | 0.913 |

| C3 | 92,173.6 | 91,795.5 | 378.1 | 0.926 |

| C4 | 96,200.8 | 95,822.7 | 378.1 | 0.927 |

| C5 | 100,196.2 | 99,818.1 | 378.1 | 0.927 |

| P1 | 195,499.0 | 195,498.2 | 0.9 | 0.869 |

| CR1 | 143,853.9 | 143,158.8 | 695.0 | 0.995 |

| CR2 | 147,995.2 | 147,744.5 | 250.7 | 0.998 |

| D1 | 1,053,439.5 | 1,053,439.5 | 0.0 | 1.000 |

| D2 | 1,054,638.5 | 1,054,638.5 | 0.0 | 1.000 |

| D3 | 649,972.4 | 649,972.4 | 0.0 | 1.000 |

| D4 | 151,223.5 | 151,223.5 | 0.0 | 1.000 |

| T8 | 152,769.9 | 152,751.5 | 18.4 | 0.923 |

| T9 | 15,109.1 | 15,107.3 | 1.8 | 0.923 |

| T10 | 23,495.6 | 23,467.6 | 28.0 | 0.898 |

| P2 | 167,503.4 | 167,453.3 | 3.8 | 0.860 |

| P3 | 29,818.7 | 29,817.9 | 0.9 | 0.856 |

| References | Liquefaction Cycle | SPC (kW/kgLH2 & LNG) | Exergy Efficiency | COP |

|---|---|---|---|---|

| Krasae-In et al. [59] (2014) | MR and J-B | 5.91 | 0.489 | 0.149 |

| Ghorbani et al. [44] (2021) | MR and J-B | 5.46 | 0.494 | 0.138 |

| Bian et al. [60] (2021) | LNG regasification and J-B | 6.60 | 0.47 | - |

| Ghorbani et al. [61] (2022) | LNG regasification and J-B | 4.772 | 0.38 | 0.171 |

| Noh et al. [62] (2022) | LNG regasification MR and J-B | 5.798 | 0.686 | - |

| Faramarzi et al. [63] (2022) | LNG cold energy, MR and J-B | 6.59 | 0.46 | - |

| Kim et al. [64] (2022) | MR | 9.477 | 0.34 | 0.23 |

| Yang et al. [25] (2023) | LNG regasification and J-B | 6.59 | 0.47 | - |

| Taghavi et al. [36] (2024) | DAR, MR and J-B | 4.32 | 0.533 | 0.286 |

| Taghavi et al. [36] (2024) | ORC, MR and J-B | 4.359 | 0.508 | 0.280 |

| In this study (basic cycle) | MR and J-B | 4.415 | 0.5018 | 0.280 |

References

- Ghorbani, B.; Zendehboudi, S.; Saady, N.M.C.; Dusseault, M.B. Hydrogen storage in North America: Status, prospects, and challenges. J. Environ. Chem. Eng. 2023, 11, 109957. [Google Scholar] [CrossRef]

- Aasadnia, M.; Mehrpooya, M. Large-scale liquid hydrogen production methods and approaches: A review. Appl. Energy 2018, 212, 57–83. [Google Scholar] [CrossRef]

- Naquash, A.; Qyyum, M.A.; Islam, M.; Sial, N.R.; Min, S.; Lee, S.; Lee, M. Performance enhancement of hydrogen liquefaction process via absorption refrigeration and organic Rankine cycle-assisted liquid air energy system. Energy Convers. Manag. 2022, 254, 115200. [Google Scholar] [CrossRef]

- Al Ghafri, S.Z.; Munro, S.; Cardella, U.; Funke, T.; Notardonato, W.; Trusler, J.M.; Leachman, J.; Span, R.; Kamiya, S.; Pearce, G. Hydrogen liquefaction: A review of the fundamental physics, engineering practice and future opportunities. Energy Environ. Sci. 2022, 15, 2690–2731. [Google Scholar] [CrossRef]

- Ni, M. An overview of hydrogen storage technologies. Energy Explor. Exploit. 2006, 24, 197–209. [Google Scholar]

- Ghorbani, B.; Zendehboudi, S.; Saady, N.M.C.; Azarpour, A.; Albayati, T.M. Thermoeconomic Analysis of an Innovative Integrated System for Cogeneration of Liquid Hydrogen and Biomethane by a Cryogenic-Based Biogas Upgrading Cycle and Polymer Electrolyte Membrane Electrolysis. Ind. Eng. Chem. Res. 2024, 63, 7227–7257. [Google Scholar]

- Rusman, N.; Dahari, M. A review on the current progress of metal hydrides material for solid-state hydrogen storage applications. Int. J. Hydrogen Energy 2016, 41, 12108–12126. [Google Scholar] [CrossRef]

- Taghavi, M.; Salarian, H.; Ghorbani, B. Economic evaluation of a hybrid hydrogen liquefaction system utilizing liquid air cold recovery and renewable energies. Renew. Energy Res. Appl. 2023, 4, 125–143. [Google Scholar]

- Zhang, J.; Fisher, T.S.; Ramachandran, P.V.; Gore, J.P.; Mudawar, I. A review of heat transfer issues in hydrogen storage technologies. ASME J. Heat Mass Transf. 2005, 127, 1391–1399. [Google Scholar]

- Ghorbani, B.; Zendehboudi, S.; Saady, N.M.C.; Duan, X.; Albayati, T.M. Strategies to improve the performance of hydrogen storage systems by liquefaction methods: A comprehensive review. ACS Omega 2023, 8, 18358–18399. [Google Scholar] [CrossRef]

- Kharel, S.; Shabani, B. Hydrogen as a long-term large-scale energy storage solution to support renewables. Energies 2018, 11, 2825. [Google Scholar] [CrossRef]

- Ghorbani, B.; Ebrahimi, A.; Rooholamini, S.; Ziabasharhagh, M. Integrated Fischer-Tropsch synthesis process with hydrogen liquefaction cycle. J. Clean. Prod. 2021, 283, 124592. [Google Scholar] [CrossRef]

- Quack, H. Conceptual Design of a High Efficiency Large Capacity Hydrogen Liquefier; AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2002; pp. 255–263. [Google Scholar]

- Lee, D.; Gbadago, D.Q.; Jo, Y.; Hwang, G.; Jo, Y.; Smith, R.; Hwang, S. Integrating hydrogen liquefaction with steam methane reforming and CO2 liquefaction processes using techno-economic perspectives. Energy Convers. Manag. 2021, 245, 114620. [Google Scholar] [CrossRef]

- Krasae-In, S.; Stang, J.H.; Neksa, P. Simulation on a proposed large-scale liquid hydrogen plant using a multi-component refrigerant refrigeration system. Int. J. Hydrogen Energy 2010, 35, 12531–12544. [Google Scholar] [CrossRef]

- Nouri, M.; Miansari, M.; Ghorbani, B. Exergy and economic analyses of a novel hybrid structure for simultaneous production of liquid hydrogen and carbon dioxide using photovoltaic and electrolyzer systems. J. Clean. Prod. 2020, 259, 120862. [Google Scholar] [CrossRef]

- Riaz, A.; Qyyum, M.A.; Min, S.; Lee, S.; Lee, M. Performance improvement potential of harnessing LNG regasification for hydrogen liquefaction process: Energy and exergy perspectives. Appl. Energy 2021, 301, 117471. [Google Scholar] [CrossRef]

- Qi, M.; Park, J.; Kim, J.; Lee, I.; Moon, I. Advanced integration of LNG regasification power plant with liquid air energy storage: Enhancements in flexibility, safety, and power generation. Appl. Energy 2020, 269, 115049. [Google Scholar] [CrossRef]

- Ghorbani, B.; Zendehboudi, S.; Alizadeh Afrouzi, Z.; Lohi, A.; Khan, F. Efficient Design of the Hydrogen Liquefaction System: Thermodynamic, Economic, Environmental, and Uncertainty Perspectives. Ind. Eng. Chem. Res. 2024, 63, 14668–14699. [Google Scholar] [CrossRef]

- Zendehboudi, S.; Ghorbani, B. Chapter 3—Physical-based hydrogen storage. In Hydrogen Production, Transportation, Storage, and Utilization; Zendehboudi, S., Ghorbani, B., Eds.; Elsevier: Amsterdam, The Netherlands, 2025; pp. 163–253. [Google Scholar] [CrossRef]

- Srikhirin, P.; Aphornratana, S.; Chungpaibulpatana, S. A review of absorption refrigeration technologies. Renew. Sustain. Energy Rev. 2001, 5, 343–372. [Google Scholar] [CrossRef]

- Kanoglu, M.; Dincer, I.; Rosen, M.A. Geothermal energy use in hydrogen liquefaction. Int. J. Hydrogen Energy 2007, 32, 4250–4257. [Google Scholar] [CrossRef]

- Ratlamwala, T.A.H.; Dincer, I.; Gadalla, M.; Kanoglu, M. Thermodynamic analysis of a new renewable energy based hybrid system for hydrogen liquefaction. Int. J. Hydrogen Energy 2012, 37, 18108–18117. [Google Scholar] [CrossRef]

- Kousksou, T.; Bruel, P.; Jamil, A.; El Rhafiki, T.; Zeraouli, Y. Energy storage: Applications and challenges. Sol. Energy Mater. Sol. Cells 2014, 120, 59–80. [Google Scholar] [CrossRef]

- Yang, J.; Li, Y.; Tan, H.; Bian, J.; Cao, X. Optimization and analysis of a hydrogen liquefaction process integrated with the liquefied natural gas gasification and organic Rankine cycle. J. Energy Storage 2023, 59, 106490. [Google Scholar] [CrossRef]

- Ratlamwala, T.A.H.; Dincer, I.; Gadalla, M. Thermodynamic analysis of a novel integrated geothermal based power generation-quadruple effect absorption cooling-hydrogen liquefaction system. Int. J. Hydrogen Energy 2012, 37, 5840–5849. [Google Scholar] [CrossRef]

- Kanoglu, M.; Yilmaz, C.; Abusoglu, A. Geothermal energy use in absorption precooling for Claude hydrogen liquefaction cycle. Int. J. Hydrogen Energy 2016, 41, 11185–11200. [Google Scholar] [CrossRef]

- Yilmaz, C.; Kaska, O. Performance analysis and optimization of a hydrogen liquefaction system assisted by geothermal absorption precooling refrigeration cycle. Int. J. Hydrogen Energy 2018, 43, 20203–20213. [Google Scholar] [CrossRef]

- Yilmaz, C. A case study: Exergoeconomic analysis and genetic algorithm optimization of performance of a hydrogen liquefaction cycle assisted by geothermal absorption precooling cycle. Renew. Energy 2018, 128, 68–80. [Google Scholar] [CrossRef]

- Aasadnia, M.; Mehrpooya, M. Conceptual design and analysis of a novel process for hydrogen liquefaction assisted by absorption precooling system. J. Clean. Prod. 2018, 205, 565–588. [Google Scholar] [CrossRef]

- Aasadnia, M.; Mehrpooya, M.; Ansarinasab, H. A 3E evaluation on the interaction between environmental impacts and costs in a hydrogen liquefier combined with absorption refrigeration systems. Appl. Therm. Eng. 2019, 159, 113798. [Google Scholar] [CrossRef]

- Ghorbani, B.; Mehrpooya, M.; Aasadnia, M.; Niasar, M.S. Hydrogen liquefaction process using solar energy and organic Rankine cycle power system. J. Clean. Prod. 2019, 235, 1465–1482. [Google Scholar] [CrossRef]

- Rezaie Azizabadi, H.; Ziabasharhagh, M.; Mafi, M. Introducing a proper hydrogen liquefaction concept for using wasted heat of thermal power plants-case study: Parand gas power plant. Chin. J. Chem. Eng. 2021, 40, 187–196. [Google Scholar] [CrossRef]

- Zhang, S.; Li, K.; Liu, G. An efficient hydrogen liquefaction process integrated with a solar power tower and absorption precooling system. Clean Technol. Environ. Policy 2023, 25, 1015–1041. [Google Scholar] [CrossRef]

- Mousavi, S.A.; Mehrpooya, M.; Delpisheh, M. Development and life cycle assessment of a novel solar-based cogeneration configuration comprised of diffusion-absorption refrigeration and organic Rankine cycle in remote areas. Process Saf. Environ. Prot. 2022, 159, 1019–1038. [Google Scholar] [CrossRef]

- Taghavi, M.; Lee, C.-J. Development of novel hydrogen liquefaction structures based on waste heat recovery in diffusion-absorption refrigeration and power generation units. Energy Convers. Manag. 2024, 302, 118056. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Mousavi, S.A.; Asadnia, M.; Zaitsev, A.; Sanavbarov, R. Conceptual design and evaluation of an innovative hydrogen purification process applying diffusion-absorption refrigeration cycle (Exergoeconomic and exergy analyses). J. Clean. Prod. 2021, 316, 128271. [Google Scholar] [CrossRef]

- Yildiz, A.; Ersöz, M.A.; Gözmen, B. Effect of insulation on the energy and exergy performances in Diffusion Absorption Refrigeration (DAR) systems. Int. J. Refrig. 2014, 44, 161–167. [Google Scholar] [CrossRef]

- Yildiz, A. Thermoeconomic analysis of diffusion absorption refrigeration systems. Appl. Therm. Eng. 2016, 99, 23–31. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Amirhaeri, Y.; Hadavi, H. Proposal and investigation of a novel small-scale natural gas liquefaction process using diffusion absorption refrigeration technology. Chem. Pap. 2022, 76, 5901–5927. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Ghorbani, B.; Ziabasharhagh, M. Exergy and economic analyses of an innovative integrated system for cogeneration of treated biogas and liquid carbon dioxide using absorption–compression refrigeration system and ORC/Kalina power cycles through geothermal energy. Process Saf. Environ. Prot. 2022, 158, 257–281. [Google Scholar] [CrossRef]

- Jouybari, A.K.; Ilinca, A.; Ghorbani, B.; Rooholamini, S. Thermodynamic and exergy evaluation of an innovative hydrogen liquefaction structure based on ejector-compression refrigeration unit, cascade multi-component refrigerant system, and Kalina power plant. Int. J. Hydrogen Energy 2022, 47, 26369–26393. [Google Scholar] [CrossRef]

- Nemati, A.; Nami, H.; Ranjbar, F.; Yari, M. A comparative thermodynamic analysis of ORC and Kalina cycles for waste heat recovery: A case study for CGAM cogeneration system. Case Stud. Therm. Eng. 2017, 9, 1–13. [Google Scholar] [CrossRef]

- Ghorbani, B.; Zendehboudi, S.; Moradi, M. Development of an integrated structure of hydrogen and oxygen liquefaction cycle using wind turbines, Kalina power generation cycle, and electrolyzer. Energy 2021, 221, 119653. [Google Scholar] [CrossRef]

- Liu, X.; Hu, G.; Zeng, Z. Performance characterization and multi-objective optimization of integrating a biomass-fueled brayton cycle, a kalina cycle, and an organic rankine cycle with a claude hydrogen liquefaction cycle. Energy 2023, 263, 125535. [Google Scholar] [CrossRef]

- Sadaghiani, M.S.; Mehrpooya, M. Introducing and energy analysis of a novel cryogenic hydrogen liquefaction process configuration. Int. J. Hydrogen Energy 2017, 42, 6033–6050. [Google Scholar] [CrossRef]

- Jensen, J.; Stewart, R.G.; Tuttle, W.; Brechna, H. Brookhaven National Laboratory Selected Cryogenic Data Notebook: Sections I–IX; Brookhaven National Laboratory: Upton, NY, USA, 1980; Volume 1.

- Ghorbani, B.; Zendehboudi, S.; Afrouzi, Z.A.; Mohammadzadeh, O. Efficient Hydrogen Production via Electro-Thermochemical Process and Solid Oxide Fuel Cell: Thermodynamics, Economics, Optimization, and Uncertainty Analyses. Energy Convers. Manag. 2024, 307, 118175. [Google Scholar] [CrossRef]

- Saleh, B.; Koglbauer, G.; Wendland, M.; Fischer, J. Working fluids for low-temperature organic Rankine cycles. Energy 2007, 32, 1210–1221. [Google Scholar] [CrossRef]

- Hutter, K.; Wang, Y.; Hutter, K.; Wang, Y. Thermodynamics—Fundamentals. In Fluid and Thermodynamics: Volume 2: Advanced Fluid Mechanics and Thermodynamic Fundamentals; Springer: Cham, Switzerland, 2016; pp. 317–420. [Google Scholar]

- Ebrahimi, A.; Ziabasharhagh, M. Optimal design and integration of a cryogenic Air Separation Unit (ASU) with Liquefied Natural Gas (LNG) as heat sink, thermodynamic and economic analyses. Energy 2017, 126, 868–885. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ahmadi, M.-A.; Maleki, A.; Pourfayaz, F.; Bidi, M.; Açıkkalp, E. Exergetic sustainability evaluation and multi-objective optimization of performance of an irreversible nanoscale Stirling refrigeration cycle operating with Maxwell–Boltzmann gas. Renew. Sustain. Energy Rev. 2017, 78, 80–92. [Google Scholar] [CrossRef]

- Kotas, T.J. The Exergy Method of Thermal Plant Analysis; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Pourfayaz, F.; Imani, M.; Mehrpooya, M.; Shirmohammadi, R. Process development and exergy analysis of a novel hybrid fuel cell-absorption refrigeration system utilizing nanofluid as the absorbent liquid. Int. J. Refrig. 2019, 97, 31–41. [Google Scholar] [CrossRef]

- Cao, Y.; Mihardjo, L.W.; Farhang, B.; Ghaebi, H.; Parikhani, T. Development, assessment and comparison of three high-temperature geothermal-driven configurations for power and hydrogen generation: Energy, exergy thermoeconomic and optimization. Int. J. Hydrogen Energy 2020, 45, 34163–34184. [Google Scholar] [CrossRef]

- Seyam, S.; Dincer, I.; Agelin-Chaab, M. Development of a clean power plant integrated with a solar farm for a sustainable community. Energy Convers. Manag. 2020, 225, 113434. [Google Scholar] [CrossRef]

- Seyam, S.; Dincer, I.; Agelin-Chaab, M. Analysis of a clean hydrogen liquefaction plant integrated with a geothermal system. J. Clean. Prod. 2020, 243, 118562. [Google Scholar] [CrossRef]

- Linnhoff, B. Pinch analysis-a state-of-the-art overview. Chem. Eng. Res. Des. 1993, 71, 503–522. [Google Scholar]

- Krasae-in, S. Optimal operation of a large-scale liquid hydrogen plant utilizing mixed fluid refrigeration system. Int. J. Hydrogen Energy 2014, 39, 7015–7029. [Google Scholar] [CrossRef]

- Bian, J.; Yang, J.; Li, Y.; Chen, Z.; Liang, F.; Cao, X. Thermodynamic and economic analysis of a novel hydrogen liquefaction process with LNG precooling and dual-pressure Brayton cycle. Energy Convers. Manag. 2021, 250, 114904. [Google Scholar] [CrossRef]

- Ghorbani, B.; Zendehboudi, S.; Jouybari, A.K. Thermo-economic optimization of a hydrogen storage structure using liquid natural gas regasification and molten carbonate fuel cell. J. Energy Storage 2022, 52, 104722. [Google Scholar] [CrossRef]

- Noh, W.; Park, S.; Kim, J.; Lee, I. Comparative design, thermodynamic and techno-economic analysis of utilizing liquefied natural gas cold energy for hydrogen liquefaction processes. Int. J. Energy Res. 2022. [Google Scholar] [CrossRef]

- Faramarzi, S.; Nainiyan, S.M.M.; Mafi, M.; Ghasemiasl, R. Energy, exergy, and economic analyses of an innovative hydrogen liquefaction process utilising liquefied natural gas regasification system. Int. J. Exergy 2022, 38, 442–456. [Google Scholar] [CrossRef]

- Kim, H.; Haider, J.; Qyyum, M.A.; Lim, H. Mixed refrigerant–based simplified hydrogen liquefaction process: Energy, exergy, economic, and environmental analysis. J. Clean. Prod. 2022, 367, 132947. [Google Scholar] [CrossRef]

| Components | Exergy Efficiency | Exergy Destruction |

|---|---|---|

| Heat exchangers | ||

| Compressors | ||

| Expanders | ||

| Towers and flash drums | ||

| Pumps | ||

| Reactors | ||

| Cycle/process |

| Components | ABR-Based Process (Share) | DAR-Based Process (Share) | ORC/Kalina-Based Process (Share) |

|---|---|---|---|

| Heat exchangers | 0.47 | 0.48 | 0.48 |

| Turbines | 0.21 | 0.21 | 0.22 |

| Columns | 0.18 | 0.18 | - |

| Compressors | 0.10 | 0.11 | 0.19 |

| Reactors | 0.03 | 0.03 | 0.0007 |

| Valves/Pumps | 0.0004 | - | - |

| Pumps | - | 0.0001 | 0.12 |

| Specifications | ORC/Kalina-Based | Basic Cycle | DAR-Based Cycle | ABR-Based Cycle |

|---|---|---|---|---|

| Liquid hydrogen flow rate (kg/h) | 4166.4 | 4166.4 | 4166.4 | 4166.4 |

| SPC of H2 liquefaction system (kWh/kgLH2) | 4.306 | 4.415 | 4.320 | 4.333 |

| Exergy efficiency of the hybrid process | 0.5145 | 0.5018 | 0.5128 | 0.5247 |

| Required power consumption (kW) | 17,941.8 | 18,395.7 | 18,000.4 | 18,053.5 |

| Exergy destruction of integrated system (kW) | 8032.7 | 7946.2 | 8297.7 | 8069.1 |

| SPC of H2 precooling process (kWh/kgLH2) | 0.8816 | 0.9906 | 0.8957 | 0.9070 |

| SPC of H2 cryogenic system (kWh/kgLH2) | 3.424 | 3.424 | 3.424 | 3.426 |

| Exergy efficiency of H2 precooling process | 0.7084 | 0.6304 | 0.6972 | 0.6885 |

| Exergy efficiency of H2 cryogenic unit | 0.5165 | 0.5165 | 0.5165 | 0.5331 |

| COP of diffusion absorption refrigeration | - | - | 0.4893 | - |

| COP of absorption refrigeration | - | - | 0.3934 | |

| Exergy of diffusion absorption refrigeration | - | - | 0.2485 | - |

| Exergy of absorption refrigeration | - | - | - | 0.2369 |

| Process/System | COP of H2 Liquefaction Plant | Exergy Efficiency of H2 Liquefaction Plant (%) | Exergy Efficiency of Mixed Refrigerant Refrigeration Unit (%) | Exergy Efficiency of Cascade Joule-Brayton Unit (%) |

|---|---|---|---|---|

| Sadaghiani et al. | 0.180 | 0.555 | 0.675 | 0.522 |

| ORC/Kalina-based | 0.287 | 0.515 | 0.882 | 0.517 |

| Basic Unit | 0.280 | 0.502 | 0.991 | 0.517 |

| DAR-based Process | 0.286 | 0.513 | 0.896 | 0.517 |

| ABR-based System | 0.286 | 0.525 | 0.907 | 0.533 |

| Cycle/Process | Exergy Efficiency of the Hybrid Process | SPC of H2 Precooling Process (kWh/kgLH2) | Exergy Efficiency of H2 Liquefaction Process | COP of H2 Cryogenic Unit |

|---|---|---|---|---|

| ORC/Kalina-based | 0.515 | 0.882 | 0.708 | 0.287 |

| Basic cycle | 0.502 | 0.991 | 0.630 | 0.280 |

| DAR-based cycle | 0.513 | 0.896 | 0.697 | 0.286 |

| ABR-based cycle | 0.525 | 0.907 | 0.689 | 0.286 |

| Process | COP of Diffusion Absorption Refrigeration | Exergy Efficiency of Diffusion Absorption Refrigeration |

|---|---|---|

| Taghavi et al. | 0.489 | 0.248 |

| In this process | 0.4893 | 0.2485 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banijamali, S.M.; Ilinca, A.; Afrouzi, A.A.; Rousse, D.R. Optimizing Hydrogen Liquefaction Efficiency Through Waste Heat Recovery: A Comparative Study of Three Process Configurations. Processes 2025, 13, 1349. https://doi.org/10.3390/pr13051349

Banijamali SM, Ilinca A, Afrouzi AA, Rousse DR. Optimizing Hydrogen Liquefaction Efficiency Through Waste Heat Recovery: A Comparative Study of Three Process Configurations. Processes. 2025; 13(5):1349. https://doi.org/10.3390/pr13051349

Chicago/Turabian StyleBanijamali, Seyed Masoud, Adrian Ilinca, Ali Alizadeh Afrouzi, and Daniel R. Rousse. 2025. "Optimizing Hydrogen Liquefaction Efficiency Through Waste Heat Recovery: A Comparative Study of Three Process Configurations" Processes 13, no. 5: 1349. https://doi.org/10.3390/pr13051349

APA StyleBanijamali, S. M., Ilinca, A., Afrouzi, A. A., & Rousse, D. R. (2025). Optimizing Hydrogen Liquefaction Efficiency Through Waste Heat Recovery: A Comparative Study of Three Process Configurations. Processes, 13(5), 1349. https://doi.org/10.3390/pr13051349