Fractal Characteristics and Influencing Factors of Pore Structure in Tight Sandstone: A Case Study from Chang 6 Member of the Southwestern Yishan Slope

Abstract

1. Introduction

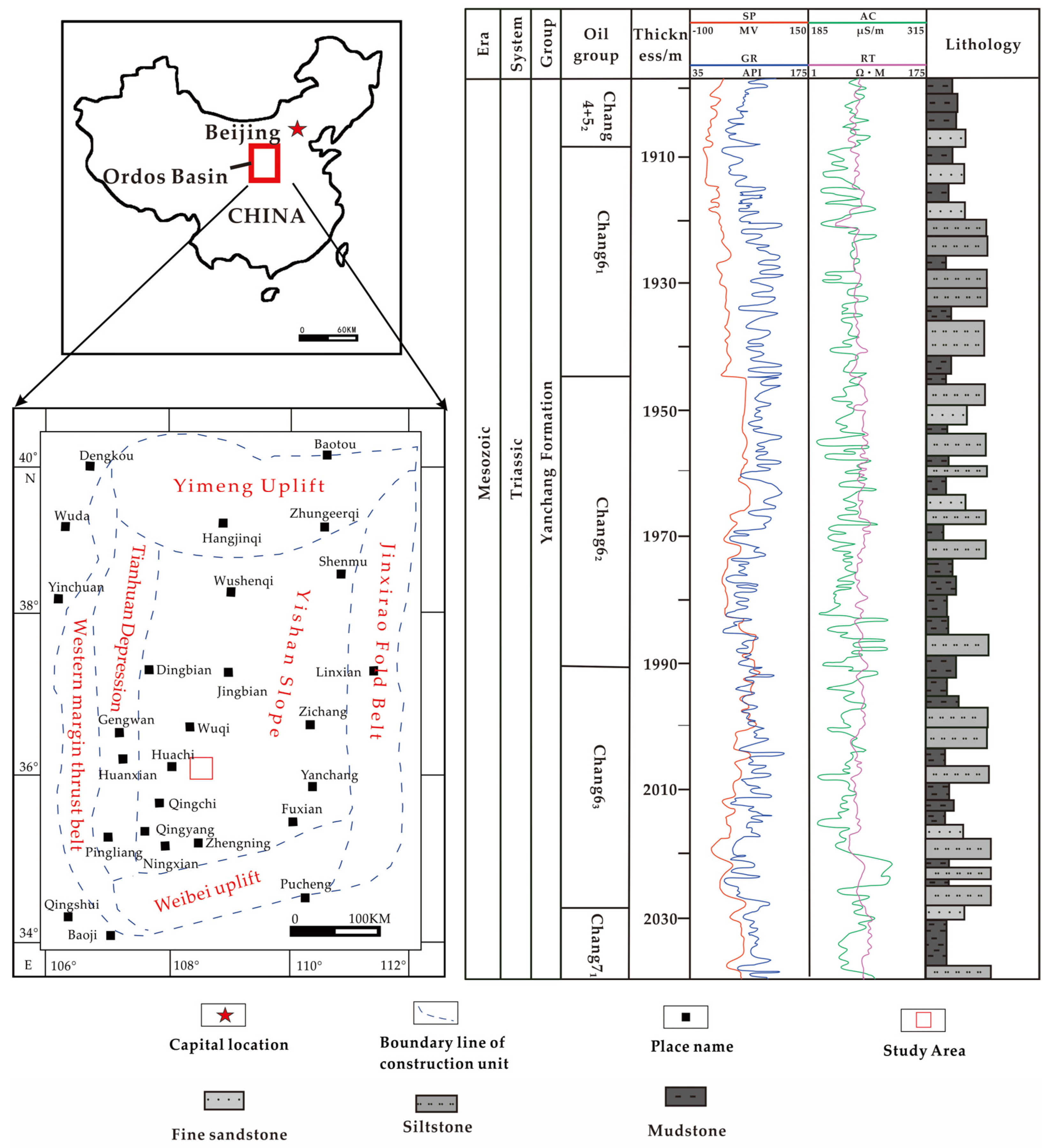

2. Geological Background

3. Methods

3.1. Experimental Method

3.2. Fractal Theory

4. Result

4.1. Physical Properties

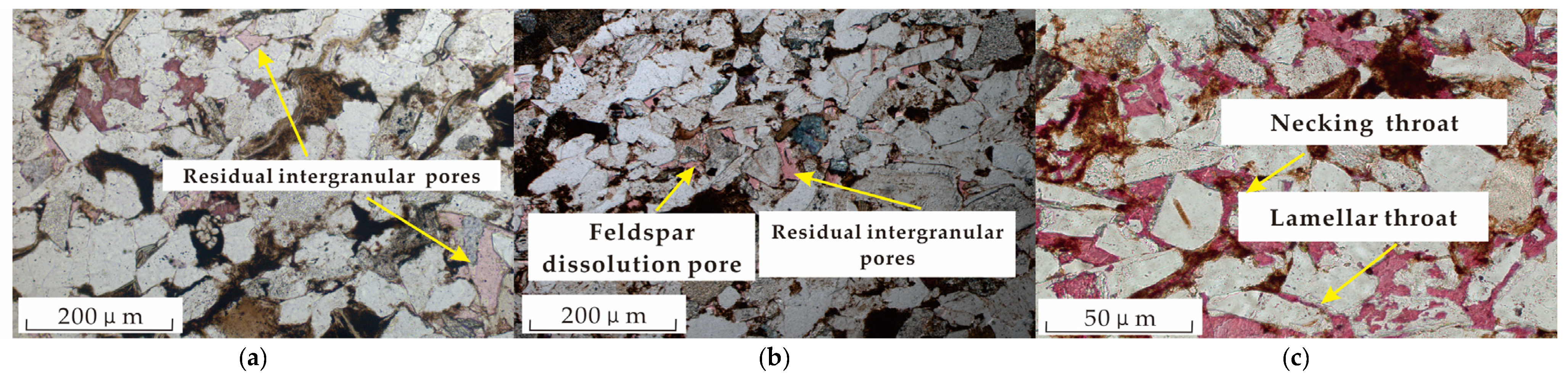

4.2. Mineral Composition and Pore-Throat Type

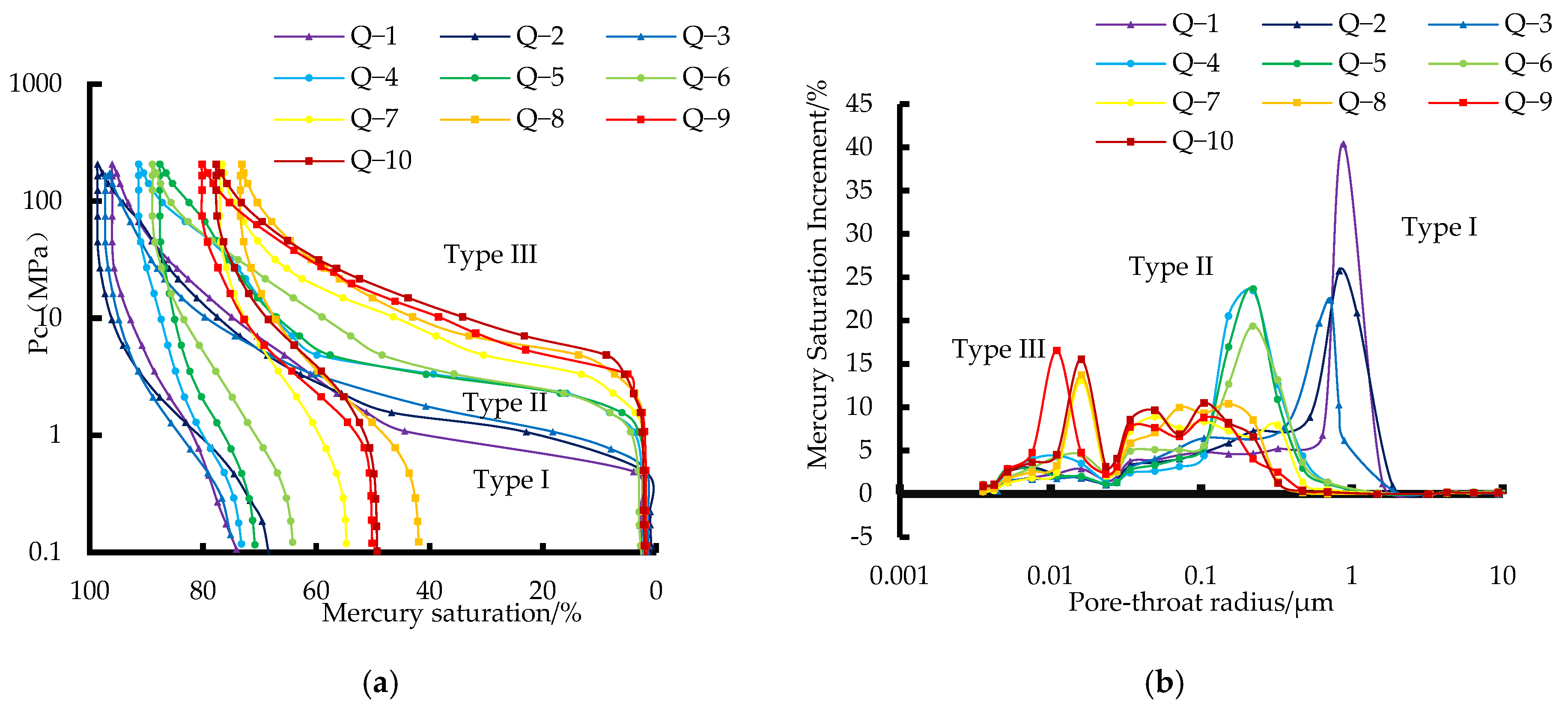

4.3. Mercury Pressure Curve

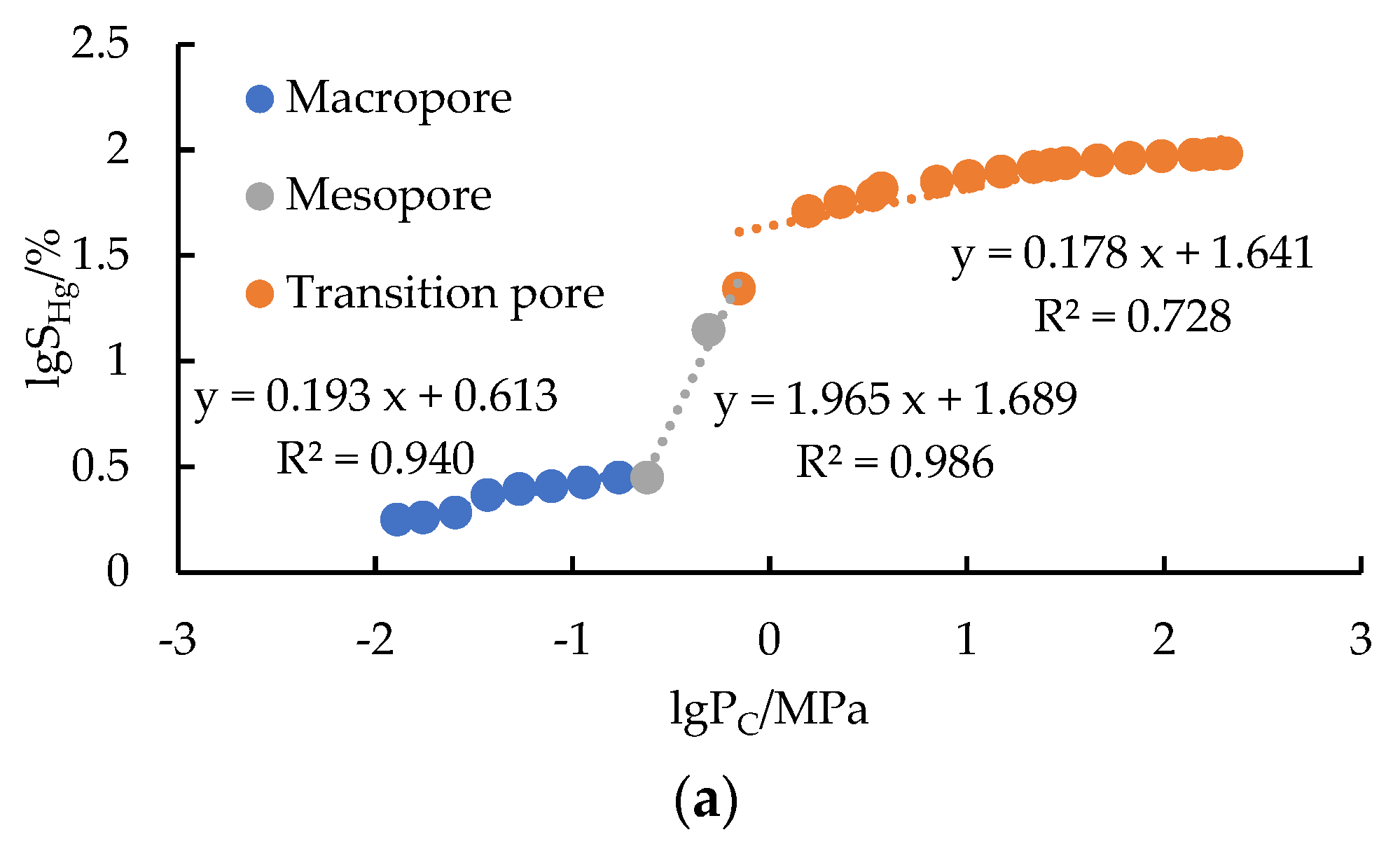

4.4. Fractal Results

5. Discussion

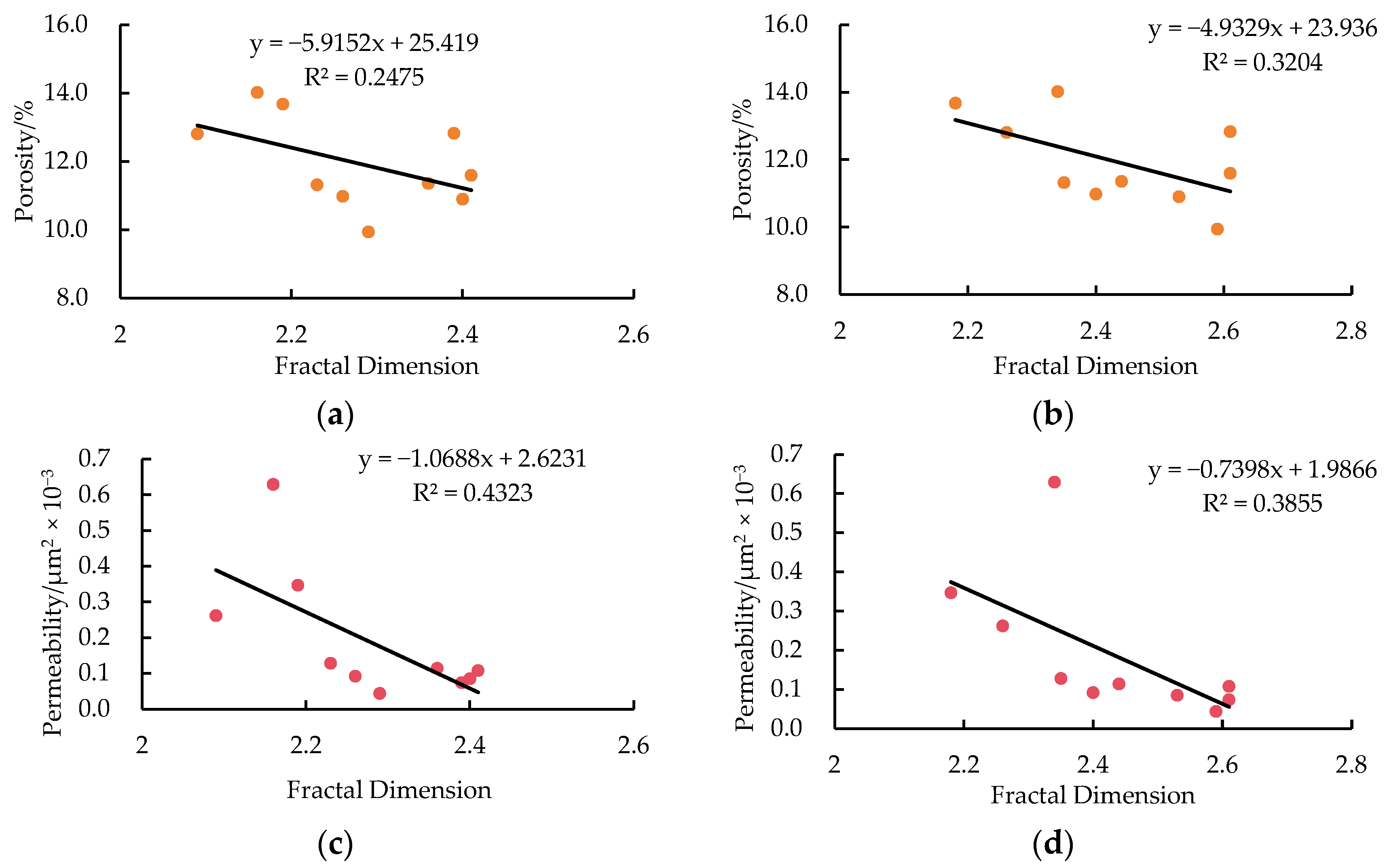

5.1. The Relationship Between Fractal Dimension and Porosity, Permeability

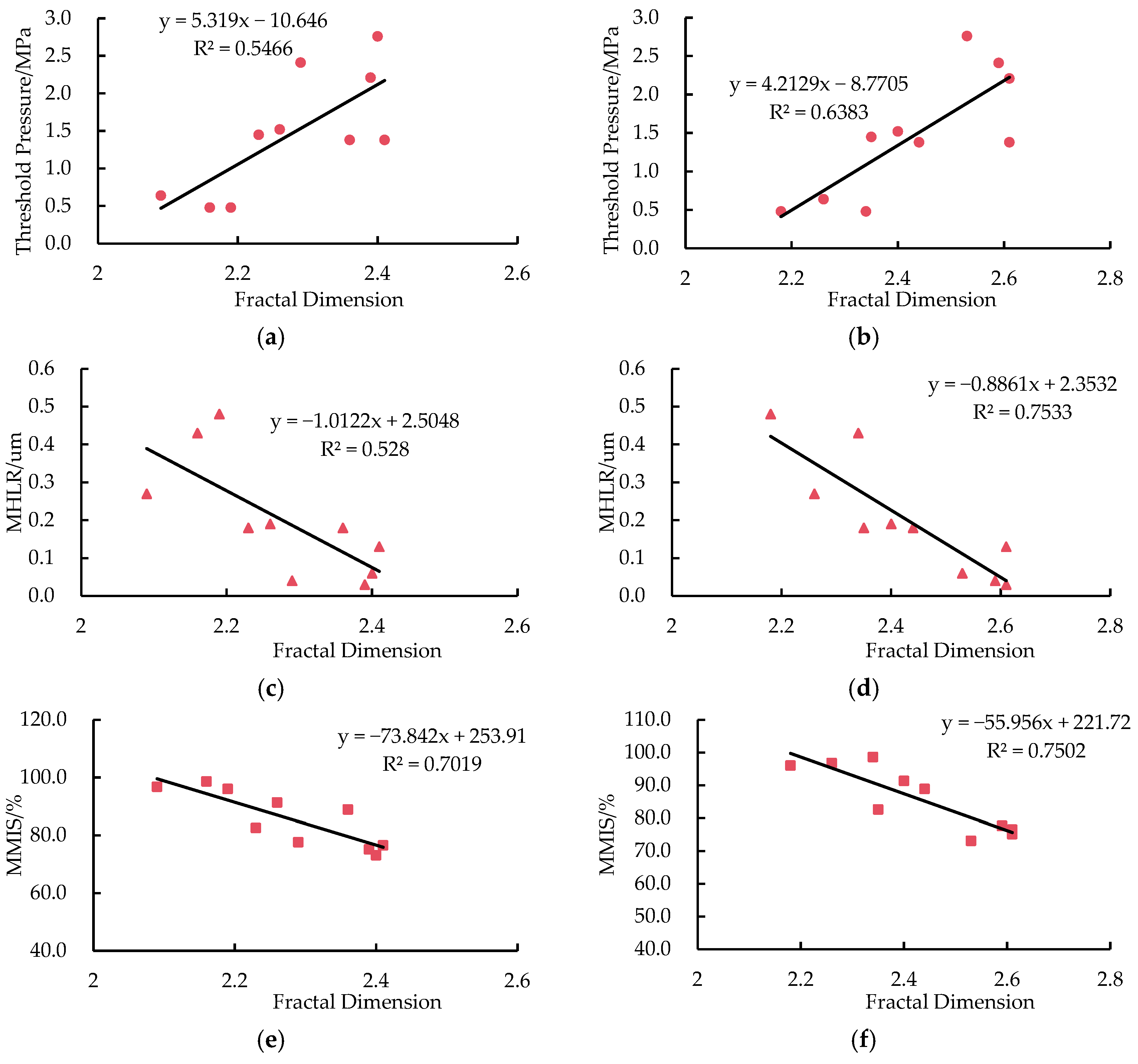

5.2. The Relationship Between Fractal Dimension and Structural Parameters of the Pore-Throat

5.3. The Relation Between the Fractal Dimension and the Mineral Composition

6. Conclusions

- The Chang 6 tight reservoir primarily features residual intergranular, dissolution, and intercrystalline pores. Fractal analysis delineates three segments with average dimensions of 2.28 for macropores (D1), 3.67 for mesopores (D2), and 2.43 for transitional pores (D3), indicating that pore heterogeneity increases from macropores to mesopores, with transitional pores in between.

- The study area reservoirs are classified into three types, each with unique mercury injection capillary pressure curves and pore-throat radius distributions. Type I reservoirs exhibit average fractal dimensions of 2.15 (D1), 3.67 (D2), and 2.26 (D3) (total = 2.69); Type II show 2.28, 3.50, and 2.40 (total = 2.72); and Type III display 2.37, 3.80, and 2.59 (total = 2.92). This indicates an increasing pore heterogeneity from Type I to III, while their storage capacity and permeability decrease accordingly.

- Reservoir heterogeneity is chiefly controlled by a combination of factors, the fractal dimensions for macropores (D1) and transitional pores (D3) exhibit negative correlations with reservoir physical properties, median pore-throat radius, maximum mercury injection saturation, and quartz/feldspar content, while showing a positive correlation with displacement pressure; no significant correlation exists with clay mineral content.

- Porosity correlates more strongly with D3 and permeability with D1, indicating that transitional pore heterogeneity primarily governs storage capacity, whereas macropore heterogeneity predominantly influences permeability.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MHLR | Median hole larynx radius |

| MMIS | Maximum mercury intake saturation |

References

- Yuan, H.Q.; Deng, X.Y.; Du, H.; Yu, Y.H.; Xu, F.M. Characterization Methods of Heterogeneity in Permian Shanxi Formation Outcrop Tight Sandstone Reservoirs. Pet. Geol. Exp. 2023, 44, 468–479. [Google Scholar]

- Fu, S.T.; Yao, J.L.; Li, S.X.; Zhou, X.P.; Li, M.R. Enrichment Characteristics and Resource Potential of Mesozoic Yanchang Formation Continental Shale Oil in Ordos Basin. Pet. Exp. Geol. 2020, 42, 698–710. [Google Scholar]

- Zheng, Q.H.; Liu, Q.; Liang, X.L.; Zhang, J.N.; Liu, T. Sedimentary Facies Distribution Characteristics of Chang 4 + 5 Oil Layers in Longdong Area, Ordos Basin. Lith. Oil Gas Res. 2019, 31, 26–35. [Google Scholar]

- Wang, H.; Shi, Y.M.; Xu, D.W.; Chen, X.; Li, L.M.C.D. Characterization Techniques and Progress of Pore Structure in Unconventional Reservoirs. Pet. Geol. Recov. 2019, 26, 21–30. [Google Scholar] [CrossRef]

- Zhang, Q.P.; Wu, W.R.; Liu, L.P.; Yang, H.M.; Wang, L.G.; Xie, Y.H.; Zhu, Y.S. Pore Structure and Fractal Characteristics of Ultra-Low Permeability Reservoirs in the Chang Formation of the Ordos Basin. Pet. Geol. Recov. 2020, 27, 20–31. [Google Scholar]

- Zhang, S.L.; Yang, Y.T.; Zhang, L.; Cao, Y.H. Formation Mechanism of Secondary Quartz in the Second Member of Xujiahe Formation in Western Sichuan Depression and Its Impact on Reservoir Physical Properties. Xinjiang Pet. Geol. 2023, 44, 25–32. [Google Scholar]

- Chen, F.; Zhou, Y.; Yang, D.; Wan, H. Study on Pore Structure of Tight Sandstone Reservoir Based on Fractal Theory: A Case Study of Chang 7 Member in Qingcheng Area, Ordos Basin. J. China Univ. Min. Technol. 2022, 51, 941–955. [Google Scholar]

- Liu, Y.; Pang, X.Q.; Ding, C.; Chen, D.; Li, M. Pore Structure and Fractal Characteristics of Tight Sandstone Reservoirs in the Yan 10 Member of Wuqi Area. Sci. Technol. Eng. 2023, 23, 12474–12483. [Google Scholar]

- Zhan, H.; Li, X.; Hu, Z.; Chen, L.; Shen, W.; Guo, W.; He, W.; Zhou, Y. Effect of Particle Size on Pore Structure and Fractal Characteristics of Deep Siliceous Shales in Southern Sichuan, China, Measured Using Small-Angle Neutron Scattering and Low-Pressure Nitrogen Adsorption. Fractal Fract. 2025, 9, 165. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, S.; Wu, J.; Li, Z.; Wang, X. Full-Scale Pore Structure Characterization and Its Impact on Methane Adsorption Capacity and Seepage Capability: Differences between Shallow and Deep Coal from the Tiefa Basin in Northeastern China. Fractal Fract. 2024, 8, 48. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Dong, W. Calculating method of the fractal dimensions of the relative permeability by the capillary pressure curve of the tight sandstone. Pet. Geol. Oilfield Dev. Daqing 2017, 36, 164–168. [Google Scholar]

- Zhu, H.Q.; Jia, A.L.; Wer, Y.S.; Jia, C.Y.; Yuan, H. Microscopic porestructure and fractal characteristics of Wufeng—Longmaxi shale, south Sichuan. Sci. Technol. Eng. 2018, 18, 12–19. [Google Scholar]

- Han, C.; Li, G.; Dan, S.; Yang, Y.; He, X.; Qi, M.; Liu, G. Study of Fractal and Multifractal Features of Pore Structure in Tight Sandstone Reservoirs of the Permian Lucaogou Formation, Jimsar Sag, Junggar Basin, Northwest China. ACS Omega 2022, 7, 31352–31366. [Google Scholar] [CrossRef] [PubMed]

- Zang, Q.; Liu, C.; Awan, R.S.; Yang, X.; Li, G.; Wu, Y.; Lu, Z.; Feng, D. Occurrence Characteristics of the Movable Fluid in Heterogeneous Sandstone Reservoir Based on Fractal Analysis of NMR Data: A Case Study of the Chang 7 Member of Ansai Block, Ordos Basin, China. J. Pet. Sci. Eng. 2022, 214, 110497. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Sun, Y.; Am, X.Y. Sedimentary-Diagenetic and Reservoir Pore Characteristics of the Upper Paleozoic Shan_2–He_8 Members in the Northern Slope of Ordos Basin. J. Geomech. 2014, 20, 230–242. [Google Scholar]

- Dou, W.; Liu, L.; Jia, L.; Xu, Z.; Wang, M.; Du, C. Pore Structure, Fractal Characteristics and Permeability Prediction of Tight Sandstones: A Case Study from Yanchang Formation, Ordos Basin, China. Mar. Pet. Geol. 2020, 123, 104682. [Google Scholar] [CrossRef]

- Wang, W.; Chen, C.; Xu, S.; Li, Y.; Zhu, Y.; Huang, X. Fractal Characteristics and Controlling Factors of Pore-Throat in Tight Sandstones of Yanchang Formation, Ordos Basin. Pet. Exp. Geol. 2022, 44, 33–40. [Google Scholar]

- Wang, C.; Zhang, H.; Yao, Z.; Huo, J.H. Fractal Characteristics of Tight Sandstone Reservoirs Based on Mercury Injection Experiment. J. Chongqing Univ. Sci. Technol. 2023, 25, 7–12. [Google Scholar]

- Xu, X. Sedimentary Characteristics and Favorable Reservoir Controlling Factors of Gravity Flow in High-Frequency Sequence Framework of Chang 6 Oil Layer Group in Huaqing Area. Ph.D. Thesis, Northwest University, Xi’an, China, 2021. [Google Scholar]

- Lu, C.; Zhang, S.; Mao, X.; Zhao, D.F. Quantitative Characterization of Micro-Pore Heterogeneity and Its Reservoir Significance in Tight Sandstones: A Case Study of Shanxi Formation in X Area, Ordos Basin. Pet. Exp. Geol. 2017, 39, 556–561. [Google Scholar]

- Zhang, Q.P.; Wang, H.; Liu, M.R.; Zhou, C.F.; Xu, J.G.; Hu, K.L.; Zhu, Y.S. Full-Pore Diameter Distribution and Its Fractal Characteristics in Ultra-Low Permeability Reservoirs. J. China Univ. Min. Technol. 2020, 49, 1137–1149. [Google Scholar]

- Lu, Z.; Liu, C.; Zang, Q.; Wu, Y.P.; Yang, X.Y.; Yang, H.; Zeng, X.X.; Li, W.D. Analysis of Tight Sandstone Pore Structure Using High-Pressure Mercury Injection Combined with Fractal Theory: A Case Study of Heshui Area, Ordos Basin. Geol. Sci. Technol. Bull. 2023, 42, 264–273. [Google Scholar]

- Lai, J.; Wang, G.; Wang, Z.; Chen, J.; Pang, X.; Wang, S.; Zhou, Z.; He, Z.; Qin, Z.; Fan, X. A Review on Pore Structure Characterization in Tight Sandstones. Earth Sci. Rev. 2018, 177, 436–457. [Google Scholar] [CrossRef]

- Liu, J.P.; Liu, D.X.; Hu, H.Y.; Jiao, P.F.; Wang, T.; Xie, Z.; Liu, L.H. Pore Structure Characteristics of Marine-Continental Transitional Shale in the Eastern Margin of Ordos Basin. China Sci. Pap. 2022, 17, 21–30. [Google Scholar]

- Chai, B.; Zhao, F.; Ji, Y.; Wang, W.; Chen, L.; Cheng, Q.; Yan, X. Pore Structure and Fractal Characteristics of Longmaxi Shale in the Southeastern Sichuan Basin. Sci. Technol. Eng. 2023, 23, 4973–4983. [Google Scholar]

- Yang, J.; Li, Z.; Lai, F. Retention of Nano-Slippery Water in Tight Sandstones and Its Impact on Micro-Pore Structure. Sci. Technol. Eng. 2022, 22, 6942–6950. [Google Scholar]

- Wang, Y.; Han, D.; Lin, W.; Jia, Y.; Zhang, J.; Wang, C.; Ma, B. Factors Controlling Differences in Morphology and Fractal Characteristics of Organic Pores of Longmaxi Shale in Southern Sichuan Basin, China. Fractal Fract. 2024, 8, 555. [Google Scholar] [CrossRef]

- Cai, J.; Berg, S. Emerging Advances in Modeling for Water Imbibition in Porous Media: A Multiscale Perspective. Water 2021, 13, 1234. [Google Scholar]

- Liu, S.; Wang, F.; Yu, R.; Gao, J.X.; Shi, H.; Zhu, Y.S. Micro-Pore Throat Structure and Fractal Characteristics of Tight Sandstone Reservoirs. J. China Univ. Min. Technol. 2024, 54, 96–107. [Google Scholar]

- Li, P.; Zheng, M.; Bi, H.; Wu, S.; Wang, X. Pore Throat Structure and Fractal Characteristics of Tight Oil Sandstone: A Case Study in the Ordos Basin, China. J. Pet. Sci. Eng. 2017, 149, 665–674. [Google Scholar] [CrossRef]

- Zhu, Y. Characterization and Typeification Evaluation of Pore Structure in Tight Sandstone Reservoirs of Shahejie Formation in Dongying Sag. Master’s Thesis, Chengdu University of Technology, Chengdu, China, 2021. [Google Scholar]

- Guan, Y.; Ye, Q.; Zhang, C.; Chen, J.; Tang, X.Y. Pore Structure Characteristics and Typeification Evaluation of High-Pressure Low-Permeability Clastic Rock Reservoirs: A Case Study of the Huangliu Formation in Yinggehai Basin. J. Northeast Pet. Univ. 2024, 48, 75–89+137. [Google Scholar]

| Sample Number | Porosity/% | Permeability/ 10−3 μm2 | Mineral Content/% | Clay Mineral Content/% | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Quartz | Feldspar | Rock Fragments | Clay Mineral | Illite | Emon Mixed Layer | Kaolinite | Chlorite | |||

| Q-1 | 14.02 | 0.847 | 39.0 | 35.0 | 11.0 | 15.0 | 28.53 | 8.38 | 9.44 | 53.65 |

| Q-2 | 11.86 | 0.629 | 38.0 | 30.0 | 12.0 | 20.0 | 41.37 | 4.83 | 0.00 | 53.80 |

| Q-3 | 12.81 | 0.262 | 34.0 | 27.0 | 30.0 | 9.0 | 45.40 | 3.90 | 0.00 | 50.70 |

| Q-4 | 8.98 | 0.092 | 38.0 | 31.0 | 13.0 | 18.0 | 74.00 | 0.00 | 0.00 | 26.00 |

| Q-5 | 11.32 | 0.128 | 38.3 | 34.1 | 11.7 | 16.0 | 47.33 | 4.28 | 2.36 | 46.04 |

| Q-6 | 10.36 | 0.114 | 31.3 | 29.0 | 21.7 | 18.0 | 64.14 | 1.19 | 0.00 | 34.67 |

| Q-7 | 11.60 | 0.108 | 31.0 | 25.0 | 28.0 | 16.0 | 20.95 | 4.36 | 13.80 | 60.89 |

| Q-8 | 10.90 | 0.085 | 29.0 | 21.5 | 38.5 | 11.0 | 37.49 | 14.31 | 0.00 | 48.20 |

| Q-9 | 12.83 | 0.074 | 29.0 | 27.0 | 31.3 | 12.7 | 57.80 | 1.89 | 0.00 | 40.31 |

| Q-10 | 9.94 | 0.044 | 26.0 | 32.0 | 31.0 | 11.0 | 26.95 | 8.94 | 0.00 | 64.11 |

| Average value | 11.46 | 0.238 | 33.36 | 29.16 | 22.82 | 14.67 | 44.40 | 5.21 | 2.56 | 47.84 |

| Sample Number | Threshold Pressure/MPa | Median Pressure/MPa | Maximum Aperture Larynx Radius/μm | Median Hole Larynx Radius/μm | Maximum Mercury Intake Saturation (%) | Efficiency of Mercury Withdrawal (%) | Separation Factor |

|---|---|---|---|---|---|---|---|

| Q-1 | 0.48 | 1.52 | 1.52 | 0.48 | 96.04 | 22.83 | 1.88 |

| Q-2 | 0.48 | 1.72 | 1.51 | 0.43 | 98.62 | 30.73 | 1.39 |

| Q-3 | 0.64 | 1.76 | 1.49 | 0.27 | 96.81 | 22.80 | 1.94 |

| Q-4 | 1.52 | 3.79 | 0.48 | 0.19 | 91.37 | 19.85 | 2.40 |

| Q-5 | 1.45 | 4.84 | 0.51 | 0.18 | 82.60 | 19.14 | 2.54 |

| Q-6 | 1.38 | 4.85 | 0.53 | 0.18 | 88.92 | 27.84 | 2.32 |

| Q-7 | 1.38 | 10.28 | 0.51 | 0.13 | 76.57 | 28.58 | 2.02 |

| Q-8 | 2.76 | 14.97 | 0.27 | 0.06 | 73.14 | 42.67 | 2.02 |

| Q-9 | 2.21 | 19.77 | 0.33 | 0.03 | 75.19 | 37.47 | 3.32 |

| Q-10 | 2.41 | 21.76 | 0.31 | 0.04 | 77.69 | 36.54 | 2.93 |

| Average value | 1.47 | 8.53 | 0.75 | 0.20 | 85.70 | 28.85 | 2.28 |

| Type | Sample Number | Macropore | Mesopore | Transition Pore | |||

|---|---|---|---|---|---|---|---|

| D1 | R2 | D2 | R2 | D3 | R2 | ||

| Type I | Q-1 | 2.19 | 0.94 | 3.82 | 0.99 | 2.18 | 0.728 |

| Type I | Q-2 | 2.16 | 0.95 | 3.73 | 0.93 | 2.34 | 0.97 |

| Type I | Q-3 | 2.09 | 0.96 | 3.45 | 0.92 | 2.26 | 0.96 |

| Type II | Q-4 | 2.26 | 0.90 | 3.58 | 0.95 | 2.40 | 0.99 |

| Type II | Q-5 | 2.23 | 0.92 | 3.53 | 0.89 | 2.35 | 0.94 |

| Type II | Q-6 | 2.36 | 0.94 | 3.38 | 0.94 | 2.44 | 0.96 |

| Type III | Q-7 | 2.41 | 0.90 | 3.82 | 0.95 | 2.61 | 0.83 |

| Type III | Q-8 | 2.40 | 0.76 | 3.85 | 0.96 | 2.53 | 0.91 |

| Type III | Q-9 | 2.39 | 0.85 | 4.05 | 0.95 | 2.61 | 0.84 |

| Type III | Q-10 | 2.29 | 0.94 | 3.47 | 0.97 | 2.59 | 0.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Liu, J.; He, X.; Feng, F.; Li, W.; Wang, M.; Zhu, W.; Zhu, Y. Fractal Characteristics and Influencing Factors of Pore Structure in Tight Sandstone: A Case Study from Chang 6 Member of the Southwestern Yishan Slope. Processes 2025, 13, 988. https://doi.org/10.3390/pr13040988

Zhang L, Liu J, He X, Feng F, Li W, Wang M, Zhu W, Zhu Y. Fractal Characteristics and Influencing Factors of Pore Structure in Tight Sandstone: A Case Study from Chang 6 Member of the Southwestern Yishan Slope. Processes. 2025; 13(4):988. https://doi.org/10.3390/pr13040988

Chicago/Turabian StyleZhang, Lun, Junfeng Liu, Xiaojin He, Feng Feng, Wei Li, Meng Wang, Wenjian Zhu, and Yushuang Zhu. 2025. "Fractal Characteristics and Influencing Factors of Pore Structure in Tight Sandstone: A Case Study from Chang 6 Member of the Southwestern Yishan Slope" Processes 13, no. 4: 988. https://doi.org/10.3390/pr13040988

APA StyleZhang, L., Liu, J., He, X., Feng, F., Li, W., Wang, M., Zhu, W., & Zhu, Y. (2025). Fractal Characteristics and Influencing Factors of Pore Structure in Tight Sandstone: A Case Study from Chang 6 Member of the Southwestern Yishan Slope. Processes, 13(4), 988. https://doi.org/10.3390/pr13040988