Steady Smoldering of Fuel Rods: Relationship Between Propagation Velocity and Fume Thickness on Schlieren Photographs

Abstract

1. Introduction

2. Materials and Methods

2.1. Experiment

2.1.1. Preparation of Biomass Rods and Char Rods

2.1.2. Placement Methods and Environmental Conditions for Smoldering of Rod-Shaped Fuels

2.1.3. Experimental Methods

Smoldering Propagation Velocity Measurement

Char Cone Shape Microscopic Photographs

Smoldering Fume Contour Schlieren Detection

2.2. Theoretical Analysis

2.2.1. Mathematical Description of Carbon Oxidation Spread Rate on Fuel Rod Surface

2.2.2. Determination of Fume Layer Thickness δRox on Rod’s Outer Surface

2.2.3. Oxygen Diffusion Coefficient in Fume Layer and Parameters Involved in Calculation

3. Results and Discussion

3.1. Analysis of Experimental Results

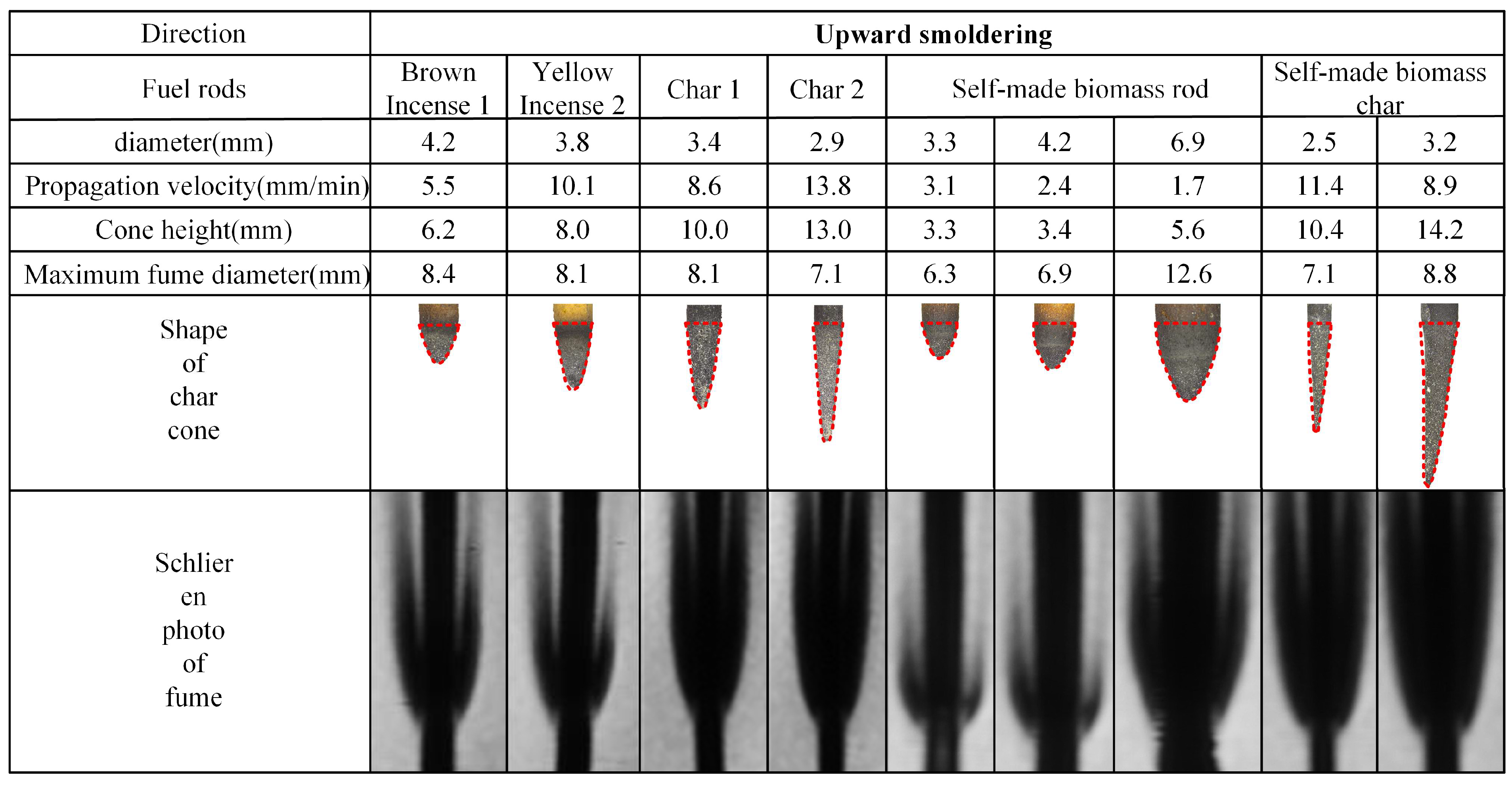

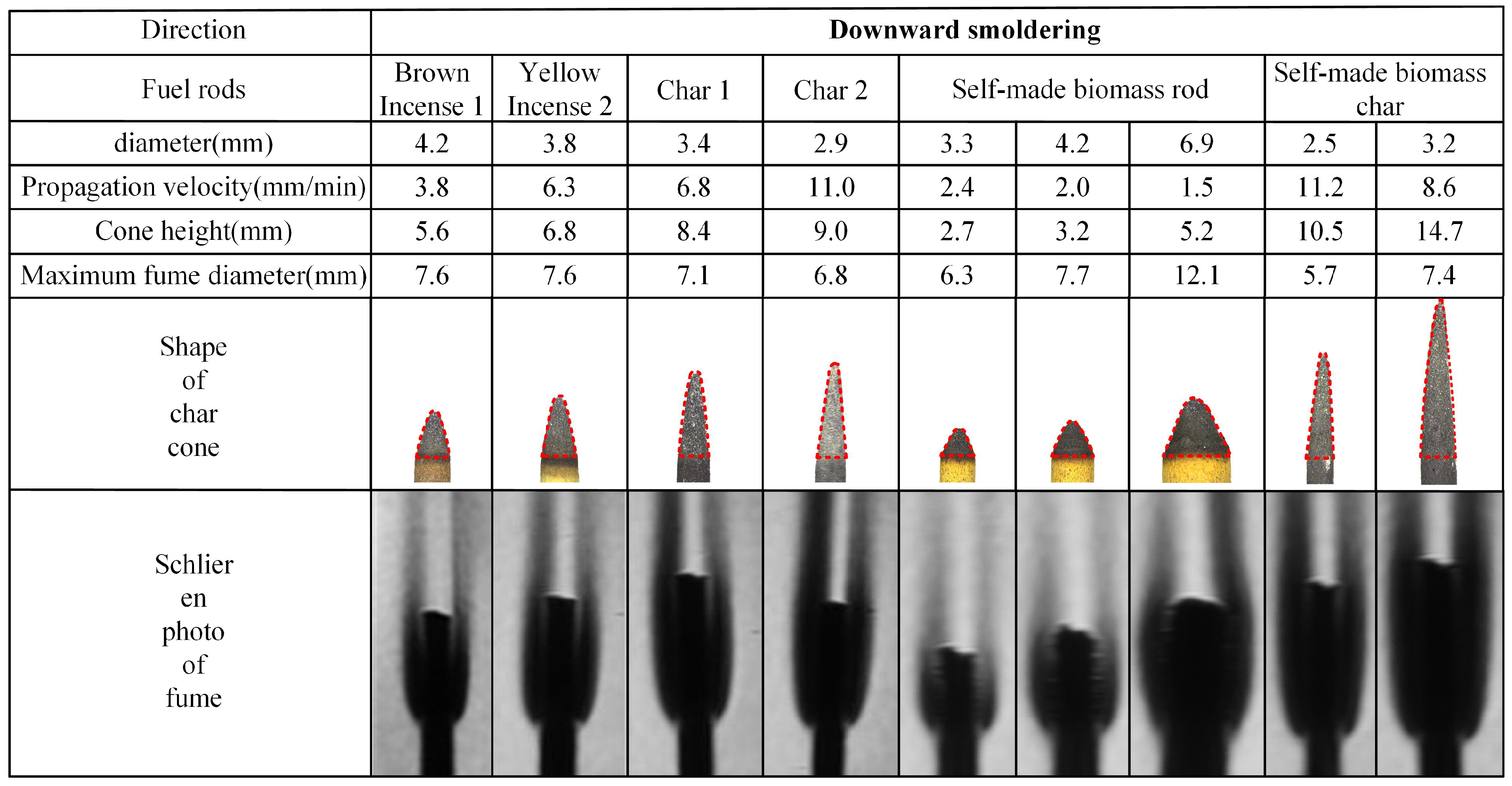

3.1.1. Comparison of Smoldering Propagation Speed of Fuel Rods

3.1.2. Comparison of Char Cone Heights of Fuel Rods

3.1.3. Comparison of Fume Contours of Fuel Rods

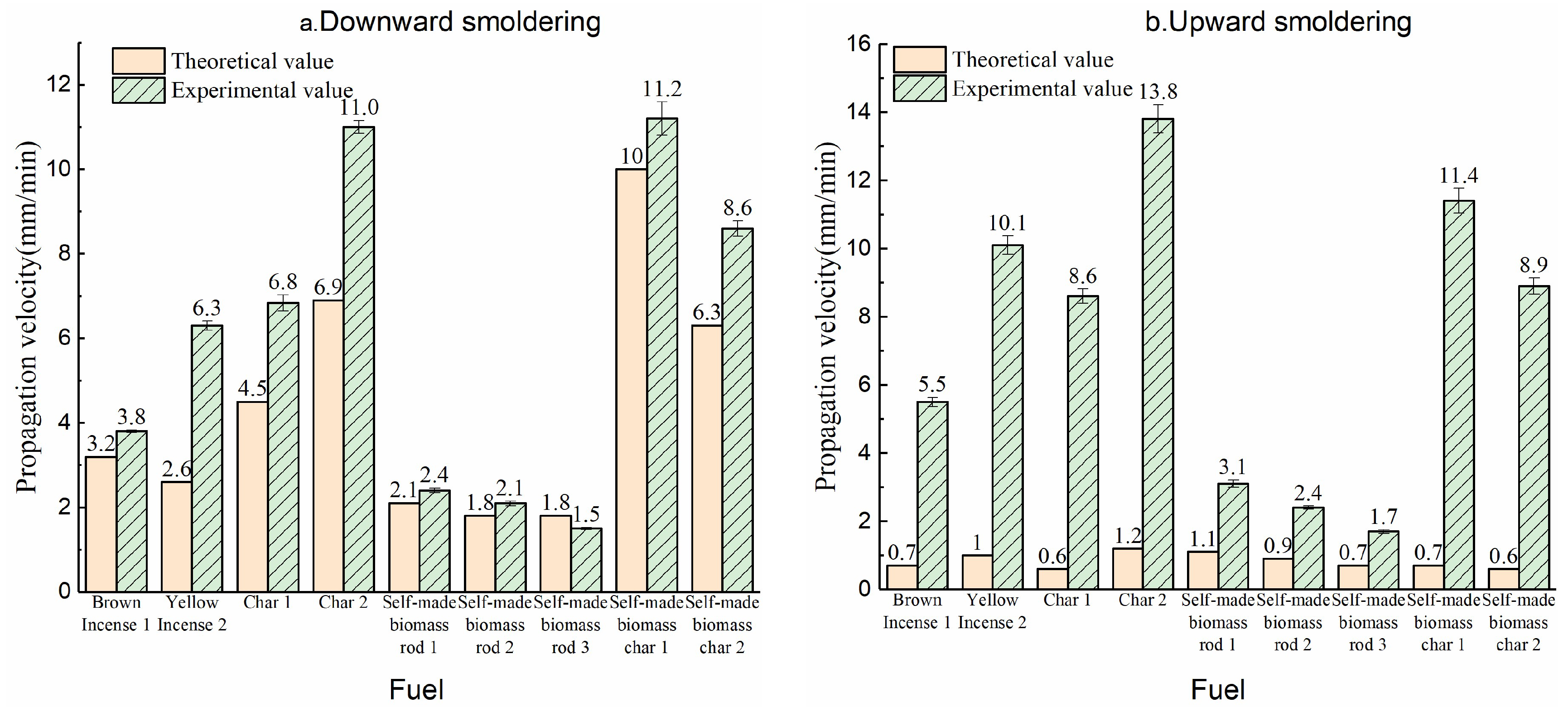

3.2. Comparison of Smoldering Propagation Speed Between Experiment and Calculated Values

3.2.1. Comparison of Downward Smoldering Propagation Speed Between Experiment and Calculated Values

3.2.2. Comparison of Upward Smoldering Propagation Speed Between Experiment and Calculated Values

3.2.3. Analysis of Control Mechanisms for Smoldering Propagation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mustafa, A.; Faisal, S.; Singh, J.; Rezki, B.; Kumar, K.; Moholkar, V.S.; Kutlu, O.; Aboulmagd, A.; Thabet, H.K.; El-Bahy, Z.M.; et al. Converting lignocellulosic biomass into valuable end products for decentralized energy solutions: A comprehensive overview. Sustain. Energy Technol. Assess. 2024, 72, 104065. [Google Scholar] [CrossRef]

- Yousuf, A.; Pirozzi, D.; Sannino, F. Fundamentals of lignocellulosic biomass. In Lignocellulosic Biomass to Liquid Biofuels; Academic Press: Cambridge, MA, USA, 2020; pp. 1–15. [Google Scholar] [CrossRef]

- Escalante, J.; Chen, W.H.; Tabatabaei, M.; Hoang, A.T.; Kwon, E.E.; Lin, K.Y.; Saravanakumar, A. Pyrolysis of lignocellulosic, algal, plastic, and other biomass wastes for biofuel production and circular bioeconomy: A review of thermogravimetric analysis (TGA) approach. Renew. Sustain. Energy Rev. 2022, 169, 112914. [Google Scholar] [CrossRef]

- Vivekanandhan, P.; Senthil-Nathan, S.; Shivakumar, M.S. Larvicidal, pupicidal and adult smoke toxic effects of Acanthospermum hispidum (DC) leaf crude extracts against mosquito vectors. Physiol. Mol. Plant Pathol. 2018, 101, 156–162. [Google Scholar] [CrossRef]

- Tayel, A.A. Innovative system using smoke from smoldered plant materials to control Aspergillus flavus on stored grain. Int. Biodeterior. Biodegrad. 2010, 64, 114–118. [Google Scholar] [CrossRef]

- Li, J.; Xu, H.; Song, D.; Wang, Z.; Zhang, B.; Feng, R.; Gu, Y.; Jiang, Z.; Ji, X.; Liu, S.; et al. Emission characteristics and assessment of potential health risks on PM2.5-bound organics from incense burning. Atmos. Pollut. Res. 2022, 13, 101326. [Google Scholar] [CrossRef]

- Liang, Z.; Chen, Y.; Lin, S.; Huang, X. Emission Characteristics of Smoldering Combustion of Peat. J. Combust. Sci. Technol. 2023, 29, 429–434. (In Chinese) [Google Scholar]

- Liu, M.; Zhou, H. Comparison of Chemical Constituents Between Essential Oil and Smog from Artemisia argyi. J. South China Univ. Technol. (Nat. Sci. Ed.) 2012, 40, 30–34. (In Chinese) [Google Scholar]

- Hasheminia, S.; Sho’ouri, N. The effect of musk incense rod aroma inhalation on different features of electroencephalogram signals and working memory for use in neurofeedback training. Biomed. Signal Process. Control 2023, 83, 104658. [Google Scholar] [CrossRef]

- Kinbara, T.; Endo, H.; Sega, S. Combustion propagation through solid materials I—Downward propagation of smouldering along a thin vertical sheet of paper. Combust. Flame 1966, 10, 29–36. [Google Scholar] [CrossRef]

- Kinbara, T.; Endo, H.; Sega, S. Downward propagation of smoldering combustion through solid materials. Symp. (Int.) Combust. 1967, 11, 525–531. [Google Scholar] [CrossRef]

- Mukunda, H.S.; Basani, J.; Shravan, H.M.; Philip, B. Smoldering Combustion of “Incense” Rods—Experiments and Modeling. Combust. Sci. Technol. 2007, 179, 1113–1129. [Google Scholar] [CrossRef]

- Lin, S.; Chow, T.H.; Huang, X. Smoldering propagation and blow-off on consolidated fuel under external airflow. Combust. Flame 2021, 234, 111685. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhou, P.; Bu, R.; Zhang, X.; Chu, T.; Wang, Z. Horizontal flame spread behavior of densified wood: Effect of structural characteristics. Fuel 2024, 362, 130687. [Google Scholar] [CrossRef]

- Yan, S.; He, F.; Cai, J.; Sun, P.; Zhang, Y.; Behrendt, F.; Dieguez-Alonso, A. Characteristics of Char Cone Covered by Ash in Steady Smoldering of a Char Rod. J. Combust. Sci. Technol. 2022, 196, 2697–2706. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, Y.; Yu, G.; Behrendt, F.; He, F. Comparison on the steady smoldering characteristics of char and biomass rods. Trans. Chin. Soc. Agric. Eng. 2023, 39, 215–221. (In Chinese) [Google Scholar]

- GB/T 28731-2012; Proximate Analysis of Solid Biofuels. The Standardization Administration of China: Beijing, China, 2012.

| Type | Proximate Analysis (%) | Density (kg/m3) | Diameter (mm) | |||||

|---|---|---|---|---|---|---|---|---|

| Moisture yw | Volatile yv | Fixed Carbon yC | Ash ya | Raw | Carbon | Ash | ||

| Brown Incense 1 | 6.2 | 58.1 | 12.2 | 23.5 | 719.4 | (287.8) a | 373.2 | 4.2 |

| Yellow Incense 2 | 5.9 | 60.7 | 14.6 | 18.8 | 590.9 | (247.0) a | 248.5 | 3.8 |

| Biomass rods 1, 2, 3 | 7.4 | 65.5 | 18.9 | 8.2 | 787.2 | (367.9) a | 128.4 | 2.9; 4.8; 7.6 |

| Char 1 | 3.3 | - | 42.1 | 54.6 | 683.6 | 287.8 | 373.2 | 3.4 |

| Char 2 | 3.7 | - | 48.2 | 48.5 | 512.4 | 247.0 | 248.5 | 2.9 |

| Char 1, 2, 3 | 5.7 | - | 69.9 | 24.4 | 526.3 | 367.9 | 128.4 | 2.3; 3.8; 6.3 |

| Symbol | Formula | Unit | Remark |

|---|---|---|---|

| T | (Tmax + T∞)/2 | m2 s−1 | Incense Tmax = 1038 K, Incense char Tmax = 1073 K, Self-made biomass rod Tmax = 983 K, Self-made biomass char Tmax = 1043 K, T∞ = 298 K, |

| DO2,∞ | 1.9 × 10−5 | m2 s−1 | Oxygen diffusion coefficient in the environment |

| ρO2,∞ | PO2MO2/(RgT) | kg/m3 | PO2 = 0.21P0, MO2 = 32 g/mol; T = 298 K |

| γ | β × MO2/MC | - | β = 0.75; MC = 12 g/mol; |

| ρC | - | kg/m3 | Density of carbon in fuel rods |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, G.; Chen, X.; Zhang, Y.; Zha, J.; He, F. Steady Smoldering of Fuel Rods: Relationship Between Propagation Velocity and Fume Thickness on Schlieren Photographs. Processes 2025, 13, 954. https://doi.org/10.3390/pr13040954

Yu G, Chen X, Zhang Y, Zha J, He F. Steady Smoldering of Fuel Rods: Relationship Between Propagation Velocity and Fume Thickness on Schlieren Photographs. Processes. 2025; 13(4):954. https://doi.org/10.3390/pr13040954

Chicago/Turabian StyleYu, Guangxin, Xin Chen, Yi Zhang, Jianwen Zha, and Fang He. 2025. "Steady Smoldering of Fuel Rods: Relationship Between Propagation Velocity and Fume Thickness on Schlieren Photographs" Processes 13, no. 4: 954. https://doi.org/10.3390/pr13040954

APA StyleYu, G., Chen, X., Zhang, Y., Zha, J., & He, F. (2025). Steady Smoldering of Fuel Rods: Relationship Between Propagation Velocity and Fume Thickness on Schlieren Photographs. Processes, 13(4), 954. https://doi.org/10.3390/pr13040954