Abstract

In recent years, the use of R744 natural refrigerant has become increasingly popular in a wide range of applications from air conditioning to low-temperature refrigeration. This study focuses on optimizing the thermodynamic parameters of the R744/R134a cascade cycle operating under evaporative temperature varying from −23 °C to −29 °C, operating in tropical climates region. The parameters include the evaporating temperature, the condensing temperature, the subcooling temperature, and the superheating temperature in the low temperature cycle, and the evaporating temperature, the subcooling temperature, and the superheating temperature in the high temperature cycle. The study has given a rating of the influence of thermodynamic parameters on the coefficient of performance (COP) of the system. In addition, the study shows that the optimal dataset for all the above thermodynamic parameters is A3B3C2D1E1F3 with a COP of 2.560 in theory and 2.461 in experiment. Moreover, the ANOVA analysis method for the variances also shows the consistency of the above results with the highest error of 3.54% compared to the experiment.

1. Introduction

The problems of climate change and the negative impacts of industrial production activities over the past several years have made the research on emissions reduction more urgent than ever. In particular, the refrigeration industry plays a key role in producing emissions that destroy the ozone layer. Traditional refrigerants can cause global warming and destroy the ozone layer and are gradually being studied in comparison to more environmentally friendly ones. Carbon Dioxide (CO2) or R744 refrigerant is a natural refrigerant that can be easily produced. It is considered a potential substitute for traditional refrigerants and is completely environmentally friendly because it has Ozone Depletion Potential (ODP = 0) and the ability to cause the effect of Global Warming Potential (GWP) is also negligible (GWP = 1). The application of R744 in air conditioning systems in recent years has led to many positive results, but the experimental studies of R744 in low-temperature cycles, especially in cascade refrigeration systems, are quite limited.

Regarding cascade refrigeration systems using R744, there is quite a lot of design research, applicability evaluation, and cycle performance evaluation by comparison with different configurations of refrigeration systems and different refrigerants. San-Kock et al. [1] experimentally evaluated a cascade refrigeration system of R134a/R744 refrigerant designed for commercial refrigeration systems with low evaporation temperatures from −40 °C to −30 °C. However, the optimization results were not mentioned in this study. Getu and Bansal [2] analyzed the thermodynamic parameters of the cascade refrigeration system using R744/R717 to optimize the design and operation parameters of the system. The design parameters considered include superheating, subcooling, evaporation temperature, and condensation temperature. A multilinear regression was used to propose the expressions for maximum COP. Dubey et al. [3,4] analyzed the thermodynamic parameters of the R744/C3H6 transcritical cascade system using EES software (version v10.561). This study proposed the optimal performance parameters such as Topt, COPmax, and a prediction of mass flow rate of C3H6 and R744. Lee et al. [5] analyzed the thermodynamic parameters of a cascade refrigeration system using the R744/R717 to determine the optimum condensing temperature of a cascade head exchanger with different design parameters. The studies related to a couple of refrigerants R717/R744 [6,7,8,9,10] focused on the effect of some operating parameters including condensation temperature, evaporation temperature, and temperature difference in the condenser in the cascade heat exchanger. Related to the systems using R744/R404A [11,12,13,14], the studies focused on optimizing the COP with the internal heat exchanger. In addition, Song et al. [15] compared the performance of combination systems using R134a/R744 and cascade systems for heating applications under specific operating conditions. Wang et al. [16] performed an experimental process to analyze the cooling performance of a cascade refrigeration system using the R717/R744 affected by operating parameters such as evaporation temperature and condensation temperature in the low temperature cycle, superheat, and temperature difference in the cascade heat exchanger. Queiroz et al. [17] studied and evaluated the performance of a cascade refrigeration system using R744/R134a as an alternative to conventional small systems that typically use R404A or R22 refrigerant. Dopazo and Fernández-Seara [18] conducted the research, design, and fabrication of a cascade refrigeration system using R717/R744 with a cooling capacity of 9 kW and an evaporation temperature of −50 °C. Bhattacharyya et al. [19] investigated the R744/C3H8 cascade system for simultaneous cooling and heating. Some studies [20,21] researched a cascade refrigeration system using a pair of R744/R717 where the devices are both an evaporator and a firming condensing device used as a cascade heat exchanger. Bhattacharyya et al. [22] investigated a N2O/R744 cascade system used for simultaneous refrigeration and heating applications. Yari and Mahmoudi [23] studied the cascading R744/R744 cycles with a transcritical R744 cycle per the subcritical R744 cycle and compared them to a two-stage cycle. Cabello et al. [24] compared the energy performance of a cascade refrigeration system working with R134a/R744 compared to R290/R744, R1270/R744, R600a/R744, and R1234ze/R744 to find proper refrigerant pairs which are effective and environmentally friendly. Zhao et al. [25] investigated the theoretical simulation and thermodynamic analyses of the Linde–Hampson refrigeration system to compare the optimal COP. Ojeda et al. [26] analyzed an experimental of the energy and environmental performance of low-GWP refrigerants R513A, R1234yf, and R436A as alternatives for R134a in a cascade refrigeration system. Ye et al. [27] presented multi-objective optimizations of an ultra-low temperature cascade refrigeration system using response surface methodology and desirability approach. Jara et al. [28] proposed two modifications of the cascade system C2H4/C4H10 by including an ejector device to improve the COP. Furthermore, some studies related to substitute refrigerants in high temperature cycle [29,30,31] analyzed and compared the operating parameters to optimize the COP of the system including R134a, R717, R1234yf, R600, R1234ze, and R290. Most research [10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31] focused on analyzing and optimizing the performance of these systems using different refrigerant pairs. Researchers typically concentrate on analyzing thermodynamic parameters such as the coefficient of performance, compressor discharge temperature, and the temperature difference in heat exchangers. To achieve maximum efficiency, several software were employed to calculate and predict system performance and compare it with other traditional systems. The main objective is to optimize the design and operation of cascade refrigeration systems by adjusting parameters such as evaporating temperature, condensation temperature, and temperature difference in heat exchangers. Additionally, studies also investigate the environmental impact and energy-saving potential of cascade refrigeration systems, continuously seeking methods to optimize performance through research in theory and experimentation.

Regarding the use of optimization algorithms in recent years for refrigeration cycles, the use of R744 is quite limited. Canbolat et al. [32] established thermodynamic modeling of the absorption refrigeration system cycle and the variability of COP and eCOP calculated for different working conditions with different parameter ranges. Some studies [33,34,35] evaluated the vapor compression cascade cooling cycle with R744, R404A, R407C, R717, R410A, R513A, R32, and R290 by considering statistical analysis methods and Taguchi and ANOVA methods to optimize performance to achieve optimal operating conditions to achieve maximum COP and exergy efficiency. COP and exergy efficiency within the operating parameters range in the assessment of 3.274% and 37.63%, respectively. Recent research [29,30,31,32] in optimizing the performance and exergy efficiency of refrigeration cycles has heavily relied on statistical analysis techniques such as Taguchi and ANOVA in theory, but they have not been verified and compared experimentally.

From the literature above, the studies have focused on the design and operation of cascade refrigeration systems by adjusting key parameters such as evaporating temperature, condensation temperature, and temperature differences in heat exchangers. Moreover, research on optimizing cascade refrigeration systems is essential because it helps determine the optimal operating conditions for refrigeration systems, thereby improving efficiency and energy savings. The optimization efforts (identifying the impact of parameters such as evaporating temperature, condensing temperature, subcooling, and superheating in the low temperature cycle, and evaporating temperature, subcooling, and superheating in the high temperature cycle both in theory and experiment) represent a new research direction, particularly in regions with tropical climates. This research has the potential to significantly contribute to reducing environmental impacts and enhancing the economic efficiency of refrigeration systems in the future, especially in countries located in tropical climate regions.

2. Experimental Methods

This research will be conducted in two steps: theoretical calculations and experimental setup. The theoretical calculation is applied based on statistical theory (robust design) and combines the calculation of cascade refrigeration systems and data analysis. The experimental system will then be set up and the experiments will be based on calculations as well as initial theoretical parameters accompanied by data acquisition. The results will be compared and evaluated.

2.1. System Parameters and Design

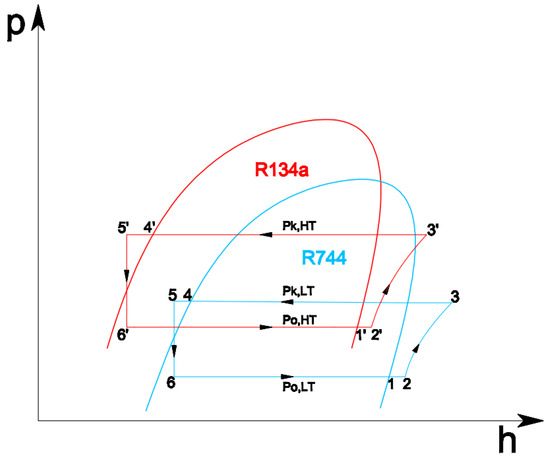

The cascade refrigeration system in this study operates based on coupling two refrigeration cycles using R134a (GWP = 1430) for the high temperature cycle (HTC) and R744 (GWP = 1) for the low temperature cycle (LTC). The evaporator of the high temperature cycle is used to cool the low-stage condenser at a welded plate heat exchanger which is called a cascade heat exchanger. The cascade heat exchanger serves as an evaporator of the high temperature cycle and a condenser of the low temperature cycle. The p-h diagram for this prototype is shown in Figure 1.

Figure 1.

The p-h diagram of the cascade vapor compression refrigeration cycle.

For calculating and designing the cascade refrigeration system, we will calculate each cycle separately and calculate the same as the single-stage refrigeration cycle. The condition for stable operation of the system is that the cooling capacity of HTC is equal to the condensing capacity of LTC while the heat loss is ignored.

In this study, the key components of a testing cycle were designed based on the computational theory [36] of the following equations:

The cooling capacity was calculated as follows:

The COP of the cascade system based on adiabatic compression work:

Energy balance equations for LTC compressor:

Energy balance equations for the cascade heat exchanger:

Energy balance equations for HTC compressor:

where QEVA is cooling capacity at LTC (kW); h is enthalpy of fluid at state points (kJ/kg); COP is coefficient of performance; W is adiabatic compression energy (kW); and m is mass flow rate of fluid (kg/s).

Based on the theory of calculating and designing a cascade refrigeration system as well as experimental conditions in this study, it can be shown that the factors that directly affect the system’s COP are superheat temperature, subcooling temperature, condensing temperature, and evaporating temperature at the low temperature cycle, and evaporating temperature and subcooling temperature at the high temperature cycle, respectively. For the overall system, the initial design parameters and their values are shown in Table 1.

Table 1.

The initial design data and their values.

2.2. Design of Experiments for Taguchi and ANOVA Analysis

Based on the thermodynamic parameters designed in Table 1 and the theoretical framework referenced in [34], this study considers typical operating conditions of tropical climates. Accordingly, it identifies the key factors and their respective levels that influence the optimization of the coefficient of performance (COP). The corresponding data are presented in Table 2. The outside temperature is a noise factor, and it depends on the time that data receive in a day. It ranges from 30 °C to 32 °C, so the condensing temperature of HTC created three results of the COP (COP cases for trial1, trial2, and trial3 are calculated in the morning, evening, and afternoon in a day, respectively). The factors and the level are mentioned in Table 2.

Table 2.

System parameters and values levels.

Robust designs in general and Taguchi in particular are approaches to product design to produce products of excellent quality and reliability. In this study, the Taguchi method is used for the purpose of calculating the input parameters of the system to provide data for the system COP.

The Taguchi method classifies the product characteristics into three categories, based on the signal to noise ratio relationship. The three categories that comprise the models for evaluation include Larger is better, Smaller is better, Normal is better. For a refrigeration system, the assessment of the completeness of the cycle is expressed through the COP, the higher COP is better. Therefore, in this study, the signal to noise ratio value will be taken to be as Large as possible with the following equations:

The Larger is better (maximize) value is calculated by

The total DOF can be described by the following:

ANOVA analysis is based on the parameters with the following equations, Adjusted Mean Square (MS) Regression and Adjusted Mean Square Error (MSE), which are described by the following:

The Larger is better (maximize) value is calculated by the following:

The F-value is determined by the following equation:

To set the orthogonal matrix level for the system based on the selected parameters and their levels, several orthogonal matrix tables have been considered to ensure accuracy and reliability during theoretical and experimental analysis. However, the L27 table is suitable in this case to balance the factors of cost and time for entire operating parameters of the system with high reliability. Table 3 shows the detailed data in the L27 orthogonal table.

Table 3.

L27 orthogonal table for the Taguchi method and its interpretation.

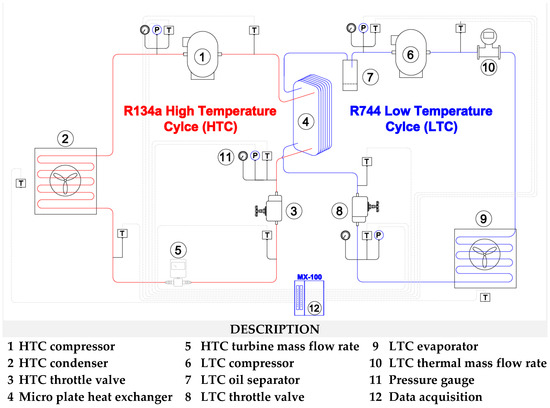

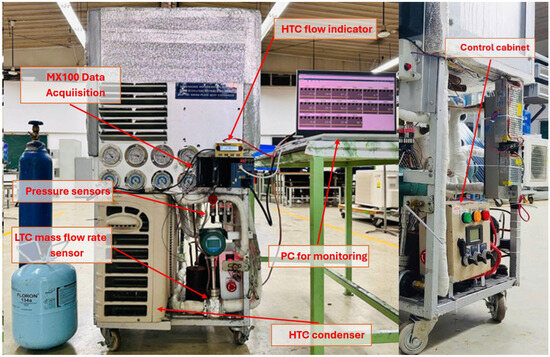

2.3. Experimental Setup

The experimental system is a cascade refrigeration system including the following: The high temperature cycle uses R134a, and the low temperature cycle uses R744. The two cycles are connected via a micro plate heat exchanger. The system is operated to obtain thermodynamic points of the cycle through the temperature sensors and the pressure sensors of the system. In addition, both cycles are equipped with mass flow rate meters with high accuracy; data are recorded in real time every 10 min via the MX100 data acquisition. Therefore, it is easy to determine the cooling capacity, adiabatic compression work, and the COP of the cycle. Details of the arrangement of experimental equipment and their accuracy are shown in Figure 2 and Table 4. A real photo of the testing system is shown in Figure 3. Details about the basic specifications, manufacturers, and models of the main components in the experimental system are presented in Table 5.

Figure 2.

The schematic view of the cascade vapor compression refrigeration cycle.

Table 4.

Measuring devices and their accuracies.

Figure 3.

Real experimental system.

Table 5.

Details of the main components and manufacturers.

3. Results and Discussion

This study will initially compare the use of the Taguchi method and the ANOVA variance analysis method using theoretical calculations on EES version v10.561 software, thereby suggesting which factors affect the COP of the system. The authors used the Stat function in Minitab software v22.2.2 to select optimization using the Taguchi method to determine the rank of elements and analyzed the variance using the General Linear Model function to give an F-value and p-value based on a given level of meaning. Next, the experimental data are used to verify the evaluations made on the theory. The cold room is guaranteed to be well insulated; the cooling load reaches the room temperature of −18 °C to meet the evaporating temperature requirements of −23 °C, −26 °C, −29 °C at steady-state. For the optimal dataset, a team will continue to run the test many times in various weather conditions to make a conclusion.

3.1. Taguchi and ANOVA Theory Calculation Results

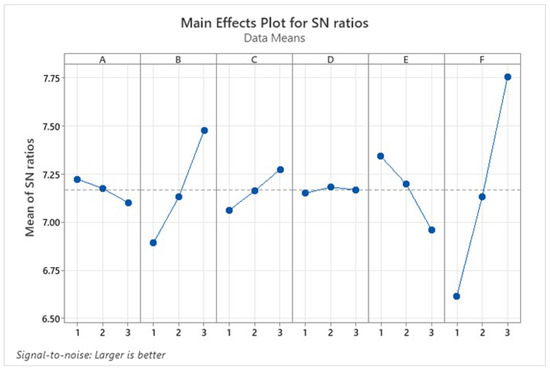

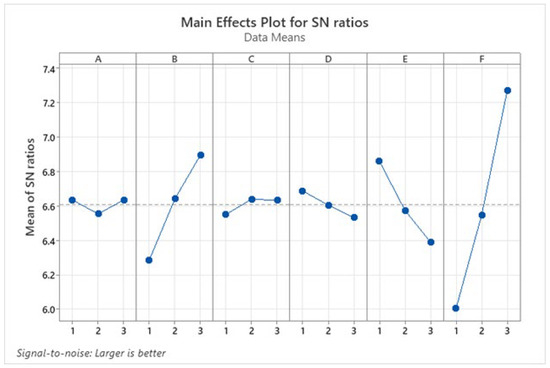

Theoretical COP results according to the Taguchi method are shown in Table 6. After performing the analysis and evaluation according to the Taguchi method, the results as shown in Table 7 and Figure 4. It is noted that the factors (A–F) are from Table 2 and Table 3.

Table 6.

Theoretical COP results according to the Taguchi method.

Table 7.

Response table for signal to noise ratio.

Figure 4.

Influence according to SN value.

Based on the results in Table 7 and Figure 4, it indicates the influence on the COP of each factor in the cascade refrigeration system. Classifying in order of rank from 1 to 6 and corresponding to the above rank, we can see that the evaporation temperature factor is the factor that most affects the COP. Accordingly, the impact order of parameters affecting COP is Te_R744 > Te_R134a > Tc_R744 > Tsc_R744 > Tsh_R744 > Tsc_R134a. The parameters corresponding to the Taguchi method are F > B > E > C > A > D. According to the values of Table 6, the most optimal set of factors for the system is A_3 B_3 C_2 D_1 E_1 F_3. Applying this set of factors can give the most optimal COP value from Taguchi’s analysis. The operating condition of the system is as follows: Tsh_R134a = 7 °C; Te_R134a = 5 °C; Tsc_R744 = 3 °C; Tsc_R134a = 4 °C; Tc_R744 = 6 °C; and Te_R744 = −23 °C. The highest COP obtained corresponding to the above set of factors is 2.560.

Continuing to use the Minitab software v22.2.2 and analyzing using the ANOVA method, the data obtained are shown in Table 8 and Table 9.

Table 8.

Analysis of variance in the ANOVA table for COP.

Table 9.

Variance components from ANOVA analysis.

According to the ANOVA variance analysis for the COP in Table 8, the larger the value of F, the higher the influence of that factor on the COP. Based on the ANOVA analysis table, the F-value of the evaporation temperature at LTC factor is the highest (536.82) and the lowest is the F-value of the HTC subcooling temperature factor is the lowest (0.18). From the ANOVA variance analysis table, the COP based on the given factors will change the total calculated value, and it can predict the change in the COP based on the above factors.

In addition, the rate of impact on the COP are shown in Table 9. We can see that the largest influencing parameter is the LTC evaporation temperature with an impact percentage of 69.18%. This is followed by the HTC evaporation temperature with an impact percentage of 18.65%, the LTC condensation temperature of 7.54%, the LTC supercooling temperature of 2.14%, the LTC superheat temperature of 0.49%, and the insignificant HTC supercooling temperature. It is concluded that the LTC evaporation temperature has a significant effect on the COP while that the HTC subcooling temperature has less affect to the COP. The factors affecting the COP value are based on the F-value as follows, F > B > E > C > A > D, and this order similarity to the results of Taguchi’s analysis is shown in Table 7.

3.2. Taguchi and ANOVA Calculation Results in Experiment

Based on the operating parameters mentioned in the Taguchi L27 table, 27 cases were evaluated on the system, as shown in Figure 3. Conducting experiments and fixing the operating parameters were performed by adjusting the hand throttle valve in both cycles, refilling, or reducing the amount of refrigerant. This control is to adjust the mass flow rate in accordance with the evaporation and condensation temperature to reach the state point parameter closest to the theoretical cycle. The COP is obtained and calculated based on the adiabatic compression at two compressors at LTC and HTC. The cooling capacity is collected at LTC. The condensation temperature at HTC is considered a noise factor, and each experiment will be conducted at three different times during a day. A typical thermodynamic state points statistics for Case 1 in experimental operation are shown in Table 10. COPmean represents the average value mentioned in Table 11.

Table 10.

Thermodynamic state points for Case 1.

Table 11.

Experimental COP results according to the Taguchi method.

Applying the ANOVA variance analysis method to the experiment, the same results are also obtained in Table 12 and Figure 5, after running the analysis based on the Taguchi method. It indicates the F-value of the evaporation temperature at HTC factor is the highest (218.80) and the lowest is the F-value of the HTC subcooling temperature factor is the lowest (0.07).

Table 12.

Response table for signal to noise ratios from Taguchi method based on experimental data.

Figure 5.

Influence according to SN value diagram.

From the ANOVA analysis method, the rate of impact on the COP was determined. According to the results in Table 13, it indicates that the largest influencing parameter is the LTC evaporation temperature with an impact percentage of 69.18%. The LTC subcooling temperature factor and the LTC superheating temperature factor have less effects on the COP of the system. We can conclude that the order of the factors affecting the based COP and the F-value is as follows, F > B > E > D > C > A, and these orders are consistent with the results of the Taguchi analysis in Table 10. However, this arrangement is slightly different from the theoretical analysis. It can be observed that the percentage contribution in Table 14 was determined according to the ANOVA analysis method. The three factors D, C, and A have almost similar contribution percentages, so there is an order change between the above three factors with the least impact on COP 0% for factors A and C and 0.41% for the corresponding D factor. The change in the rank level of the factors of the subcooling and superheating temperatures is derived from the major influence of the ambient temperature and the error of the measuring device during the experiment.

Table 13.

Analysis of variance by ANOVA method based on experiment.

Table 14.

Contribution of variance based on ANOVA analysis with experiment data.

3.3. Predicting COP Using Linear Regression

The actual and theoretical results indicate that the common point of both Rank 1 results is the LTC evaporation temperature. This factor has greatly affected the COP change in the cascade refrigeration system.

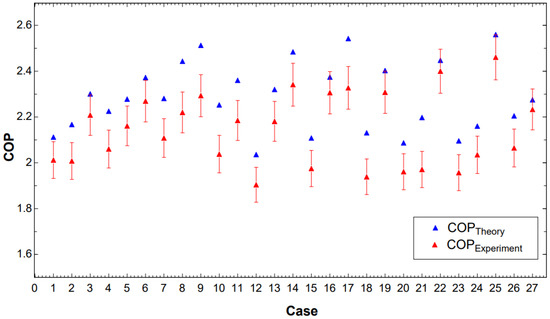

From Figure 6, the theoretical results and the experimental results are almost similar. The case with the highest COP results achieved in the L25 experiment in the Taguchi table was 2.56 in theory and 2.461 in the experiment, respectively. According to the results from the two ANOVA analyses of theory and experiment, both make a percentage contribution to the COP, and both methods give the percentage of LTC evaporation temperature as the highest at 69.18% and have the greatest influence. Moreover, it shows that the HTC subcooling temperature and the HTC superheating temperatures have a disproportionate percentage of contribution so there is less impact on the COP.

Figure 6.

Diagram of comparison table between COPTheory and COPActual.

From the ANOVA variance analysis table, the COP is evaluated based on the given factors; the changes in the factors will change the calculation results. The results can predict the change in the COP based on the above factors. Furthermore, a regression equation can predict the COP based on the change in the F-value and the p-value and predict the COP based on the thermodynamic parameters of the cycle. Linear regression equations of both actual and theoretical cases are as follows:

- In theory: COP = 1.9008 − 0.01491A + 0.07763B + 0.02759C + 0.00272D − 0.04950E + 0.14946F.

- With R2 = 0.9745.

- In actual: COP = 1.8126 + 0.0029A + 0.0754B + 0.0092C − 0.0191D − 0.0582E + 0.1562F.

- With R2 = 0.9383.

From the above two equations, the COP can be predicted in advance under operating conditions. Table 15 shows the COP which can be predicted by the regression equation and the degree of difference between the theory calculation and the prediction by the regression equation in the ANOVA method.

Table 15.

Results comparing COPExperiment and COPTheory with predicted COPActual.

From Table 15, the prediction results and the analysis results obtained by the experimental method are almost the same. Prediction has different percentages, with the smaller calculated COP representing the more accurate results; the equation depends heavily on the noise of the calculated parameters. The highest in predicting the results was in the L17 case and in the theoretical case it was L12. From Taguchi’s analysis a set of setting data was obtained as A3B3C2D1E1F3 at the highest and an optimal COP of 2.457 corresponding to the case L25: Tsh_R744 = 7 °C, Te_R134a = 5 °C, Tsc_R744 = 3 °C, Tsc_R134a = 4 °C, Tc_R744 = 6 °C, and Te_R744 = −23 °C. Based on the thermodynamic parameters presented in Table 2, this study has developed a regression equation with a relatively high R2 value, indicating strong correlation. The deviation between theoretical predictions and experimental results remains within acceptable limits. The refrigeration system utilizing R134a/R744 can reliably apply the theoretical regression equation to interpolate the coefficient of performance (COP) under given operating conditions.

3.4. Verify

From Table 11, based on the evaluation level of each individual factor, the combination set of A3B3C2D1E1F3 gives the COP value according to S/N; it is the most optimal parameter from Taguchi’s analysis. Corresponding to that value, the operating conditions of the system are as follows:

With the most optimal dataset from the experiment: Tsh_R744 = 7 °C, Te_R134a = 5 °C, Tsc_R744 = 3 °C, Tsc_R134a = 4 °C, Tc_R744 = 6 °C, and Te_R744 = −23 °C. After collecting data and analyzing the results of five tests based on the above optimal set of parameters in the changing HTC condensation temperature during a day, the COP results are shown in Table 16 as below.

Table 16.

Experimental results for the most optimal combination.

4. Conclusions

Based on theoretical and experimental analysis by the Taguchi method and ANOVA variance analysis, according to the L27 orthogonal table and conducting experiments in 27 corresponding cases, the influence factors on the COP of the cascade refrigeration system have been shown.

Through the calculation and analysis of data according to both the Taguchi and ANOVA methods, it is indicated that the evaporating temperature at LTC is the factor with the greatest influence on the COP with a 1st rank and a contribution percentage of 69.18%. In addition, the results show that the subcooling temperature of HTC and the superheating temperature of HTC have affected insignificantly on the COP.

Based on the experimental dataset, the research has given a set of data for the highest COP of 2.461 corresponding to the L25 case within the set A3B3C2D1E1F3.

This study has given a regression equation for the influence of operating modes both in theory and in experiments. Experimental verification with theory-based optimization has the highest error of 3.54%.

For future research directions, the algorithm employed in this study can be further applied for optimization by incorporating an auxiliary thermoelectric cooling device. Additionally, evaluating the isentropic compression efficiency and exergy efficiency under operational conditions influenced by ambient temperature, humidity, and solar radiation is recommended. Furthermore, a comparative analysis of environmental performance indicators such as the Total Equivalent Warming Impact (TEWI) and Economic Analysis should be conducted across different refrigerant pairs.

Author Contributions

Conceptualization, writing—review and editing, supervision, T.D.; software, validation, formal analysis, writing—original draft preparation, H.N.; methodology, H.-S.D. All authors have read and agreed to the published version of the manuscript.

Funding

The project No. T2024-47 (sponsored by the HCMC University of Technology and Education, Vietnam).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| The absolute temperature (°C) | |

| Mass flow rate (kg/s) | |

| Work of adiabatic compression (W) | |

| Coefficient of performance | |

| Mean square | |

| Mean square error | |

| i | Experiment number |

| The data observed in experiment number i | |

| The i-th response value | |

| The number of the levels | |

| Cooling capacity (W) | |

| Condensing capacity (W) | |

| Enthalpy of fluid (kJ/kg) | |

| The signal to noise | |

| The total degree of freedom | |

| n | The number of experiments |

| The average response value | |

| F | The F_value |

| The number of factors | |

| Tsh_R744 | Superheating temperature of low temperature cycle () |

| Tsc_R744 | Subcooling temperature of low temperature cycle () |

| Te_R744 | Evaporating temperature of low temperature cycle () |

| Tc_R744 | Condensing temperature of low temperature cycle () |

| Tsh_R134a | Superheating temperature of high temperature cycle () |

| Tsc_R134a | Subcooling temperature of high temperature cycle () |

| Te_R134a | Evaporating temperature of high temperature cycle () |

| Tc_R134a | Condensing temperature of high temperature cycle () |

| LTC | Low temperature cycle |

| HTC | High temperature cycle |

References

- Sanz-Kock, C.; Llopis, R.; Sánchez, D.; Cabello, R.; Torrella, E. Experimental evaluation of a R134a/CO2 cascade refrigeration plant. Appl. Therm. Eng. 2014, 73, 41–50. [Google Scholar] [CrossRef]

- Getu, H.M.; Bansal, P.K. Thermodynamic analysis of an R744–R717 cascade refrigeration system. Int. J. Refrig. 2008, 31, 45–54. [Google Scholar] [CrossRef]

- Dubey, A.M.; Kumar, S.; Agrawal, G.D. Thermodynamic analysis of a transcritical CO2/propylene (R744–R1270) cascade system for cooling and heating applications. Energy Convers. Manag. 2014, 86, 774–783. [Google Scholar] [CrossRef]

- Dubey, A.M.; Agrawal, G.D.; Kumar, S. Thermodynamic analysis of a transcritical CO2/propylene cascade system with split unit in HT cycle. J. Braz. Soc. Mech. Sci. Eng. 2014, 37, 1365–1378. [Google Scholar] [CrossRef]

- Lee, T.-S.; Liu, C.-H.; Chen, T.-W. Thermodynamic analysis of optimal condensing temperature of cascade-condenser in CO2/NH3 cascade refrigeration systems. Int. J. Refrig. 2006, 29, 1100–1108. [Google Scholar] [CrossRef]

- Amaris, C.; Tsamos, K.M.; Tassou, S.A. Analysis of an R744 typical booster configuration, an R744 parallel-compressor booster configuration and an R717/R744 cascade refrigeration system for retail food applications. Part 1: Thermodynamic analysis. Energy Procedia 2019, 161, 259–267. [Google Scholar] [CrossRef]

- Massuchetto, L.H.P.; do Nascimento, R.B.C.; de Carvalho, S.M.R.; de Araújo, H.V.; d’Angelo, J.V.H. Thermodynamic performance evaluation of a cascade refrigeration system with mixed refrigerants: R744/R1270, R744/R717 and R744/RE170. Int. J. Refrig. 2019, 106, 201–212. [Google Scholar] [CrossRef]

- Messineo, A. R744-R717 Cascade Refrigeration System: Performance Evaluation compared with a HFC Two-Stage System. Energy Procedia 2012, 14, 56–65. [Google Scholar] [CrossRef]

- Tsamos, K.M.; Amaris, C.; Mylona, Z.; Tassou, S. Analysis of Typical Booster Configuration, Parallel-Compressor Booster Configuration and R717/R744 Cascade Refrigeration System for Food Retail Applications. Part 2: Energy Performance in Various Climate Conditions. Energy Procedia 2019, 161, 268–274. [Google Scholar] [CrossRef]

- Akan, A.E.; Ünal, F.; Özkan, D.B. Investigation of efficiency of R717 refrigerant single stage cooling system and R717/R744 refrigerant cascade cooling system. Turk. J. Eng. 2021, 5, 58–64. [Google Scholar] [CrossRef]

- Jeon, M.-J. Experimental Analysis of the R744/R404A Cascade Refrigeration System with Internal Heat Exchanger. Part 1: Coefficient of Performance Characteristics. Energies 2021, 14, 6003. [Google Scholar] [CrossRef]

- Jeon, M.-J. Experimental Analysis of the R744/R404A Cascade Refrigeration System with Internal Heat Exchanger. Part 2: Exergy Characteristics. Energies 2022, 15, 1251. [Google Scholar] [CrossRef]

- Son, C.-H.; Moon, C.-G. Performance analysis of a R744 and R404A cascade refrigeration system with internal heat exchanger. J. Power Syst. Eng. 2012, 16, 38–43. [Google Scholar] [CrossRef]

- Oh, H.-K.; Son, C.-H.; Jo, H.; Jeon, M.-J. Mass flow rate ratio analysis for optimal refrigerant charge of a R744 and R404A cascade refrigeration system. J. Korean Soc. Mar. Eng. 2013, 37, 575–581. [Google Scholar] [CrossRef]

- Song, Y.; Li, D.; Yang, D.; Jin, L.; Cao, F.; Wang, X. Performance comparison between the combined R134a/CO2 heat pump and cascade R134a/R744 heat pump for space heating. Int. J. Refrig. 2017, 74, 592–605. [Google Scholar] [CrossRef]

- Wang, B.; Wu, H.; Li, J.; Xing, Z. Experimental investigation on the performance of NH3/CO2 cascade refrigeration system with twin-screw compressor. Int. J. Refrig. 2009, 32, 1358–1365. [Google Scholar] [CrossRef]

- Queiroz, M.V.A.; Panato, V.H.; Antunes, A.H.P.; Parise, J.A.R. Experimental comparison of a cascade refrigeration system operating with R744/R134a and R744/R404A. In Proceedings of the International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 11–14 July 2016; p. 1785. [Google Scholar]

- Dopazo, J.A.; Fernández-Seara, J. Experimental evaluation of a cascade refrigeration system prototype with CO2 and NH3 for freezing process applications. Int. J. Refrig. 2011, 34, 257–267. [Google Scholar] [CrossRef]

- Bhattacharyya, S.; Mukhopadhyay, S.; Kumar, A.; Khurana, R.K.; Sarkar, J. Optimization of a CO2–C3H8 cascade system for refrigeration and heating. Int. J. Refrig. 2005, 28, 1284–1292. [Google Scholar] [CrossRef]

- Ma, M.; Yu, J.; Wang, X. Performance evaluation and optimal configuration analysis of a CO2/NH3 cascade refrigeration system with falling film evaporator–condenser. Energy Convers. Manag. 2014, 79, 224–231. [Google Scholar] [CrossRef]

- Dopazo, J.A.; Fernández-Seara, J.; Sieres, J.; Uhía, F.J. Theoretical analysis of a CO2–NH3 cascade refrigeration system for cooling applications at low temperatures. Appl. Therm. Eng. 2009, 29, 1577–1583. [Google Scholar] [CrossRef]

- Bhattacharyya, S.; Garai, A.; Sarkar, J. Thermodynamic analysis and optimization of a novel N2O–CO2 cascade system for refrigeration and heating. Int. J. Refrig. 2009, 32, 1077–1084. [Google Scholar] [CrossRef]

- Yari, M.; Mahmoudi, S.M.S. Thermodynamic analysis and optimization of novel ejector-expansion TRCC (transcritical CO2) cascade refrigeration cycles (Novel transcritical CO2 cycle). Energy 2011, 36, 6839–6850. [Google Scholar] [CrossRef]

- Cabello, R.; Andreu-Nácher, A.; Sánchez, D.; Llopis, R.; Vidan-Falomir, F. Energy Comparison Based on Experimental Results of a Cascade Refrigeration System Pairing R744 With R134a, R1234ze(E) and the Natural Refrigerants R290, R1270, R600a. Int. J. Refrig. 2023, 148, 131–142. [Google Scholar] [CrossRef]

- Zhao, Z.; Luo, J.; Song, Q.; Yang, K.; Wang, Q.; Chen, G. Theoretical Investigation and Comparative Analysis of the Linde–Hampson Refrigeration System Using Eco-friendly Zeotropic Refrigerants Based on R744/R1234ze(Z) for Freezing Process Applications. Int. J. Refrig. 2023, 145, 30–39. [Google Scholar] [CrossRef]

- Ojeda, F.W.A.B.; Queiroz, M.V.A.; Pico, D.F.M.; dos Reis Parise, J.A.; Bandarra Filho, E.P. Experimental Evaluation of low-GWP Refrigerants R513A, R1234yf and R436A as Alternatives for R134a in a Cascade Refrigeration Cycle With R744. Int. J. Refrig. 2022, 144, 175–187. [Google Scholar] [CrossRef]

- Ye, W.; Liu, F.; Yan, Y.; Liu, Y. Application of Response Surface Methodology and Desirabilit Approach to Optimize the Performance of an Ultra-low Temperature Cascade Refrigeration System. Appl. Therm. Eng. 2024, 239, 122130. [Google Scholar] [CrossRef]

- Rodríguez-Jara, E.Á.; Sánchez-De-La-Flor, F.J.; Expósito-Carrillo, J.A.; Salmerón-Lissén, J.M. Thermodynamic Analysis of Auto-cascade Refrigeration Cycles, With and Without Ejector, for Ultra Low Temperature Freezing Using a Mixture of Refrigerants R600a and R1150. Appl. Therm. Eng. 2022, 200, 117598. [Google Scholar] [CrossRef]

- Turgut, M.S.; Turgut, O.E. Comparative investigation and multi objective design optimization of R744/R717, R744/R134a and R744/R1234yf cascade rerfigeration systems. Heat Mass Transf. 2018, 55, 445–465. [Google Scholar] [CrossRef]

- Sobieraj, M. Development of novel wet sublimation cascade refrigeration system with binary mixtures of R744/R32 and R744/R290. Appl. Therm. Eng. 2021, 196, 117336. [Google Scholar] [CrossRef]

- Das, I.; Samanta, S. Comparative Energetic and Exergetic Analyses of a Cascade Refrigeration System Pairing R744 with R134a, R717, R1234yf, R600, R1234ze, R290. In Advances in Air Conditioning and Refrigeration; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- Canbolat, A.S.; Bademlioglu, A.H.; Arslanoglu, N.; Kaynakli, O. Performance optimization of absorption refrigeration systems using Taguchi, ANOVA and Grey Relational Analysis methods. J. Clean. Prod. 2019, 229, 874–885. [Google Scholar] [CrossRef]

- Kaya, A. Thermodynamical study and Taguchi optimization of a two-stage vapor compression refrigeration system. Therm. Sci. 2022, 26, 3951–3963. [Google Scholar] [CrossRef]

- Ustaoglu, A.; Kursuncu, B.; Alptekin, M.; Gok, M.S. Performance optimization and parametric evaluation of the cascade vapor compression refrigeration cycle using Taguchi and ANOVA methods. Appl. Therm. Eng. 2020, 180, 115816. [Google Scholar] [CrossRef]

- Keshtkar, M.M. Multi-objective optimization of a r744/r134a cascade refrigeration system: Exergetic, economic, environmental, and sensitive analysis (3ES). J. Therm. Eng. 2019, 5, 237–250. [Google Scholar] [CrossRef]

- Bejan, A.; Kraus, A.D. Heat Transfer Handbook; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).