Abstract

Intelligent production has changed the traditional mode of production. However, how to achieve an improvement in carbon emission efficiency via intelligent production needs to be further explored. This study focuses on the mechanism of how production intelligence affects the equipment manufacturing sector’s carbon emission efficiency. Using data from 247 businesses in the equipment manufacturing sector between 2015 and 2021, this study applies fixed-effects models and statistical analysis methods to explore the correlation between production intelligence and the equipment manufacturing sector’s carbon emission efficiency. The results indicate that intelligent production can effectively improve the carbon emission efficiency of equipment manufacturing businesses and improve the carbon emission efficiency by enhancing the energy utilization rate of enterprises. Environmental regulation has a regulating function in the connection between the production intelligence and carbon emission efficiency of equipment manufacturing enterprises. There are also regional and industrial differences in the effect of intelligent production on carbon emission efficiency. Based on these findings, our study proposes three policy suggestions for policymakers.

1. Introduction

Global climate change has now reached a critical juncture. According to the Intergovernmental Panel on Climate Change (IPCC), the global average temperature has increased by approximately 1.1 degrees Celsius since pre-industrial levels [1]. Being the largest developing nation and a major emitter of greenhouse gases globally, China proposed the “double carbon” objective, which aims to attain a carbon emission peak by 2030 and plans to become carbon-neutral by 2060 [2]. One of the crucial means of fulfilling the “double carbon” and high-quality development objectives is through carbon emission efficiency.

The equipment manufacturing industry has been found to largely contribute to carbon emissions and is the key field to realizing the “double carbon” objective. The equipment manufacturing industry involves many fields [3,4]. For example, in the electronic equipment manufacturing industry, such as computer communication, and the transportation equipment manufacturing industry, such as the railway, ship, and aerospace field, the industry output value scale is huge. However, there are problems, such as obsolete internal production equipment, high energy consumption and emissions, and safety problems, which also need to be solved urgently [5]. In the context of Industry 4.0, intelligent manufacturing has become a key part of industrial transformation and upgrading, leading to a more efficient and environmentally friendly production mode. For example, manufacturing factories can adopt advanced sensors, automation equipment, and intelligent management systems to achieve precise control of the production process and the optimal allocation of resources to reduce energy consumption and waste emissions. Specifically, Afrin et al. [6] found that the application of multi-robot systems can significantly improve energy and cost consumption in factories; Cassettari et al. [7]’s experimental studies found that, by applying intelligent technologies, a factory can significantly reduce energy costs while effectively reducing carbon dioxide emissions. Wang et al. [8] proposed an intelligent system for energy-efficient manufacturing management and successfully achieved approximately 30% energy savings through its experimental implementation in a European factory; Karuppiah et al. [9] also addressed the importance of sustainable manufacturing practices.

The current research focused on the factors affecting carbon emissions, including economic and social factors, demographic factors, and institutional environmental factors—specifically, economic and social factors, such as the grade of economic development [1], technological progress [2], industrial structure optimization [3], and urbanization [10]. The investigation of population factors mainly includes the effect of population size [11], changes in population composition [12], and household consumption patterns [13] on carbon emissions. Institutional environmental factors, such as carbon trading policies [14] and ecological civilization construction [15], etc., have gradually become an important lever for regulating carbon emissions. Some scholars have started to express concern about the effect of high-quality development [16] and the digital economy [17,18,19] on carbon emissions. A small number of studies have explored the carbon emission reduction effects of artificial intelligence or intelligent manufacturing. For example, the study by Huang et al. [20] revealed that artificial intelligence provides technical support for reducing carbon emissions and optimizes resource utilization efficiency to further slow down the increase in carbon emissions. Based on the data of China’s subdivided industries, Mi et al. [21] found that there is a prominent positive correlation between the improvement in industrial intelligence and the reduction in carbon emissions; that is, industrial intelligence possesses a substantial inhibitory influence on carbon emissions. The research by Wang et al. [22] further explored the specific path of robot applications in carbon emission reduction. Geng et al. [23] determined that intelligent manufacturing notably lessened the carbon intensity after carrying out an empirical analysis with cross-national and industry data. Nowadays, due to the social risks introduced by environmental challenges such as climate warming, it is becoming more and more important to seek more sustainable production. Some scholars try to explore its effect on sustainable manufacturing from the perspective of digital intelligence technology empowerment [24].

After a careful scrutiny of the existing literature, we found there is scant literature on the theoretical analysis and empirical test of the effectiveness of intelligent production in reducing carbon emissions based on the standpoint of artificial intelligence patent applications; moreover, the current empirical research on intelligentization-enabled carbon emission reduction is mainly based on the industry level, and there are few works in the literature on intelligentization-enabled low-carbon development at the enterprise level; moreover, previous studies mainly focused on the whole industry or manufacturing industry, and there is a lack of research on the carbon emission efficiency of the equipment manufacturing industry. Moreover, the existing research that links intelligent production with sustainable manufacturing needs to be expanded.

To address the research gap, this study adopts the panel data of equipment manufacturing businesses in 2015–2021 to investigate the effect and mechanism of the enterprise production intelligence level on carbon emission efficiency from the perspective of artificial intelligence patent application and makes contributions in terms of three aspects: (1) we provide specific insights on the effect of intelligent production on the carbon emission efficiency of the equipment manufacturing industry; (2) this paper reveal the internal mechanism of intelligent production influencing firms' carbon emission; (3) the different effects of intelligence on carbon emission reduction from the regional and industry levels are explored.

The organizational structure of this paper is as follows: the following part includes the relevant theoretical analysis and puts forward the research hypothesis. The third part is the model design, which involves the measurement and calculation of variables. The fourth part is the main effect result analysis and mechanism test. The fifth part is the heterogeneity analysis. Finally, we introduce the conclusion, discussion, management enlightenment, and research deficiencies and prospects of this study.

2. Theoretical Analysis and Research Hypothesis

2.1. Intelligent Production and Carbon Emission Efficiency of Equipment

Intelligent production refers to the integration of advanced information technology and manufacturing technology in production activities to realize the automation and intelligent management of the production process [25]. Intelligent production relies on artificial intelligence technology. Artificial intelligence technology is deeply integrated into all production links of corporations, and the production process of corporations is intelligently transformed so that it has a certain ability of self-perception, self-learning, and self-optimization. Masood et al. [26] discovered that artificial intelligence could monitor technology, forecast emissions of carbon monoxide and dioxide, and aid in the detection, aggregation, and organization of carbon-related data, thereby contributing indirectly to the decrease in carbon emissions.

With the help of artificial intelligence technology, enterprises can accurately predict production demand in the production process, optimize production plans, and reduce waiting time and resource idleness in the production process [27], thereby reducing energy consumption and carbon emissions. Secondly, with the help of intelligent means, enterprises can track energy consumption and emissions during the manufacturing process in real-time [28], identify high energy consumption and emission hotspots through data analysis, and provide scientific justification for reducing emissions and conserving energy. Finally, with the improvement in the intelligent level of enterprise production, the transformation of the enterprise production process to automation and intelligence can effectively reduce the error and waste in manual operation, improve the overall production efficiency and resource utilization, and raise the carbon emission efficiency. The following hypothesis is put out in light of the analysis above.

H1.

Intelligent production can improve the carbon emission efficiency of the equipment manufacturing industry.

2.2. Intelligent Production, Energy Efficiency, and Carbon Emission Efficiency of Equipment Manufacturing Enterprises

Energy consumption is an important question in today’s society. Chen [29] pointed out that the promotion of energy efficiency is the main goal of carbon emission reduction. Energy efficiency is a crucial metric to measure the energy efficiency of enterprises, and it is also a key factor affecting carbon emission efficiency. The equipment manufacturing industry is the core part of the industry. It offers equipment for simple reproduction and expanded reproduction of various economic sectors and serves a vital part in economic development. However, it is unrealistic to directly reduce the energy supply of the equipment manufacturing industry because energy is an irreplaceable mode of production. Therefore, improving energy efficiency or reducing energy demand for the same output has become a key way to realize the purpose of reducing energy consumption and sustainable development. In the setting of the new normal of economic development [30], only by accelerating the pace of technological progress and relying on innovation to drive high-quality development can we effectively achieve a notable decrease in the intensity of carbon emissions. The advancement of technology can effectively improve energy efficiency [31,32]. Li [33] showed that intelligent technology can effectively upgrade the energy structure of enterprises and minimize energy use by exerting a scale effect.

By improving the level of production intelligence, enterprises can realize the dynamic management and optimal allocation of energy with the help of intelligent control systems to ensure the efficient utilization of energy in all aspects and improve the energy utilization rate. The efficiency of carbon emissions is closely linked to the rate of energy utilization. Thus, hypothesis H2 is proposed based on the study above.

H2.

Production intelligence can improve the energy utilization rate of the equipment manufacturing industry and improve its carbon emission efficiency.

2.3. The Regulatory Role of Environmental Regulation

In examining the effects of intelligent production on carbon emission efficiency within the equipment manufacturing sector, environmental regulations are considered as a moderating factor. The impact is mainly manifested in the fact that when environmental regulations are strict, they may increase the production costs of enterprises, such as higher taxes and fees imposed by the government, which may force enterprises to adopt cleaner energy technologies, lowering carbon emissions and increasing carbon emission efficiency in the process. Yin et al. [34] showed that with the shift from weak to strict environmental regulations, its “forced emission reduction” effect gradually increases. Berman et al. [35] believed that innovation is “compensated for” by environmental regulations, which make up for the cost burden of environmental governance. Jiang et al. [36] believed that appropriate environmental regulation policies could realize the compensation of innovation performance to input costs and promote the level of technological progress. Environmental regulation can not only compensate for the cost burden of enterprises due to environmental governance but also stimulate the potential of enterprises in sustainable development by promoting technological innovation and operational optimization to help enterprises find a new balance between environmental protection and economic benefits.

According to the Porter hypothesis [37], environmental regulation can inspire the innovation potential of corporations, improve the competitiveness of enterprises through technological innovation, and achieve cost savings while reducing pollution. This means that under the pressure of environmental regulation, enterprises may be more active in adopting artificial intelligence technology to improve the level of intelligent production, thereby improving carbon emission efficiency. The following theory is proposed in light of the analysis above.

H3.

Environmental regulation plays a regulatory role in the relationship between production intelligence and the equipment manufacturing industry.

3. Research Design

3.1. Sample Selection and Data Collection

This study takes China’s A-share equipment manufacturing enterprises as the research sample and 2015–2021 as the study interval, and the samples are screened using the following guidelines: (1) eliminate the samples with missing key variables; (2) exclude ST and * ST company samples; (3) exclude the samples of delisting, suspension of listing, and termination of listing during the study period. After the above screening, 247 enterprises were obtained. The data were derived from CSMAR, the China Statistical Yearbook, the China Energy Statistics Yearbook, and the National Bureau of Statistics.

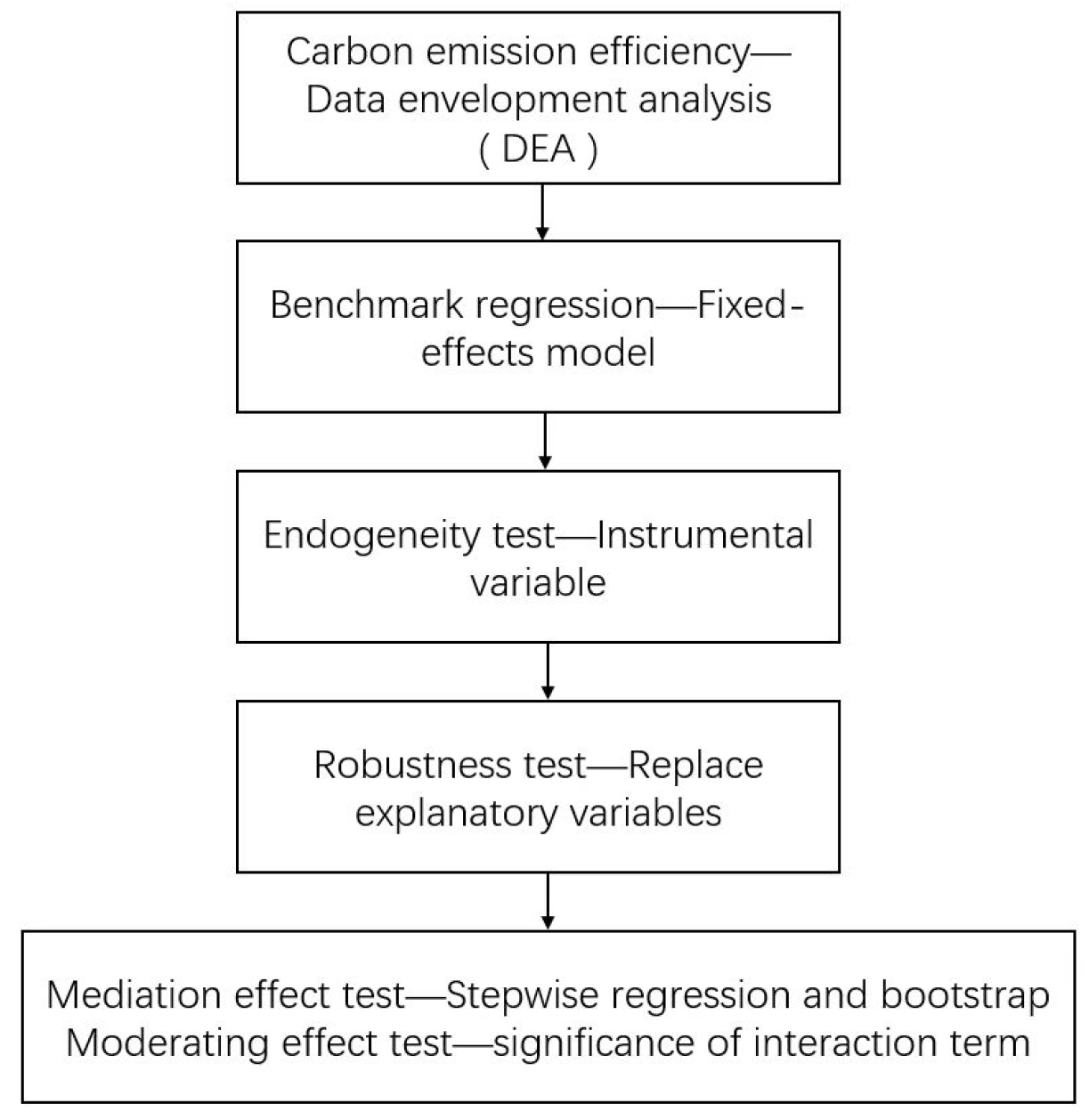

To test our research hypotheses, we conducted several analyses in the following section (see Figure 1). Considering that the carbon emission efficiency of enterprises is the result of multiple input and output factors, and the data envelopment method (DEA) can incorporate a variety of factors into the model calculation, this study uses the data envelopment method to effectively measure the carbon emission efficiency of enterprises. In this study, the two-way fixed effect is used to regress the model to reduce the error of the model, and the instrumental variable method is used to test the endogeneity so as to reduce the resulting error caused by the endogeneity problem. A robustness test is carried out by replacing the explanatory variables to verify the reliability of the model. Finally, the stepwise regression method is used to test the mediating effect of the model, the reliability of the mediating test results is strengthened using the Bootstrap method, and the moderating effect is verified by the significance of the interaction term.

Figure 1.

Data analysis flowchart.

3.2. Variable Measurement

3.2.1. Dependent Variables: Enterprise Carbon Emission Efficiency

The actual production or operation process involves multiple input factors and multiple output outcomes. The DEA method can effectively extrapolate the situation of multiple inputs and outputs [38]. Therefore, it can more comprehensively and objectively reflect the overall efficiency level of economic activities. As a non-parametric method, data envelopment analysis (DEA) uses linear programming technology to determine the effective frontier of production based on the input and output data of decision-making units (DMUs) and determines the technical efficiency by evaluating the distance between each DMU and this frontier. It has been widely used in the evaluation of total factor carbon emission efficiency. However, the traditional DEA model is mostly radial and angular and fails to fully consider the relaxation of input and output, which leads to a large deviation between the evaluation results and the actual economic situation, thus affecting the accuracy of carbon emission efficiency evaluation. In order to effectively make up for this defect, the SBM model proposed by Tone fully considers the slack of undesired output, which can deal with undesired output more effectively; significantly improve the accuracy of estimation; and is closer to the real economic situation. The super-efficiency SBM model based on the SBM model can further rank the efficiency values of the decision-making units, thus further improving the accuracy of the evaluation [39]. Therefore, this paper chooses to use the super-efficiency SBM model to make a more accurate measurement of carbon emission efficiency, including undesired output.

Assume that there are n DMUs, each DMU has m input indicators, expected outputs, and undesired outputs. Let x ∈ , ∈, ∈ . X = [, , , …, ] ∈ , = [, , …, ] ∈ , = , , , …, ] ∈ .

Build the following model:

X, , and are input variables, expected output variables, and unexpected output variables, respectively, and ρ is the efficiency value; i is the input; r is the expected output; t is the undesired output; j is the decision-making unit; k is the decision-making unit; and , , are slack variables of input, expected output, and undesirable output, respectively. This paper selects the net fixed assets of the enterprise, the number of employees, and the energy consumption of the enterprise as input indicators; the operating income as the expected output; and the carbon dioxide emissions of the enterprise as the undesired output.

Since China does not force companies to disclose carbon emission-related information, few companies voluntarily disclose carbon emission data in their annual reports. Considering that companies that are willing to disclose carbon emission information are often those that perform well in carbon emission control, the availability of relevant data in this area is low. This paper draws on the estimation method of enterprise carbon emissions by Shen [40] and uses industry carbon emissions to estimate the carbon emissions of enterprises. The details are as follows:

3.2.2. Independent Variable: Intelligent Production

The number of artificial intelligence patents of enterprises reflects the investment and upgrading of enterprises in intelligent technology. Therefore, this study uses the number of artificial intelligence patents of equipment manufacturing enterprises as a measure of the level of intelligent production of enterprises. By referring to Yin et al. [41], the number of patents with keywords such as artificial intelligence, intelligence, automation, expert system, computer vision, machine learning, and natural language processing in the patent name of the enterprise is selected as the number of artificial intelligence patents of the enterprise. In an effort to lessen data volatility, this study also standardizes the number of patents by adding a logarithm.

3.2.3. Mediator Variable: Energy Efficiency

Based on the practice of Chen [29] and Lyubich et al. [42], this study applies energy productivity to measure the energy utilization rate of enterprises. Concretely, the details are as follows: the energy efficiency (EE) of enterprises is expressed by dividing the operating income of enterprises by the energy input of enterprises. Among them, the energy consumption of enterprises refers to the practice of Shen [40]—that is, the ratio of the main operating cost of the enterprise to the main operating cost of the industry multiplied by the total energy consumption of the industry.

3.2.4. Regulatory Variable: Environmental Regulation

Considering that environmental regulation in this study is used to examine the conduct of micro-industrial enterprises, referring to the research of Zhang et al. [43], this study sets up environmental regulation indicators from the perspective of environmental regulation intensity and makes use of the quotient of finished industrial pollution investment to the added worth of the secondary industry as an indicator of environmental regulation, assessing the yearly strength of environmental regulation intensity in the province where the enterprise is based.

In addition, this essay makes reference to the existing literature to control other factors that may affect the carbon emission efficiency of the equipment manufacturing industry [44,45,46]. It mainly includes (1) enterprise size (Size), which takes the firm’s total yearly assets’ natural logarithm as a stand-in for the enterprise size; (2) asset–liability ratio (Lev), with the year-end ratio of total liabilities to total assets as the proxy variable of asset-liability ratio; (3) net profit margin of total assets (ROA), the total asset–liability ratio’s proxy variable is the enterprise’s net profit divided by the average balance of its total assets; (4) listed years (ListAge), with the year of the enterprise minus the year of listing and a natural logarithm as the proxy variable of the listed years of the corporation; (5) the proportion of the first shareholder (Top1), the proportion between the number of shares held by the first shareholder and all shares as the proxy variable of the proportion of the first shareholder( as Table 1).

Table 1.

Variable explanation.

3.3. Model Setup

To investigate the effects of the enterprise production intelligence level on the carbon emission efficiency of the equipment manufacturing industry, the following regression model is constructed:

is how well the equipment manufacturing sector emits carbon, indicating the carbon emission efficiency of the i enterprise in the t year; indicates the intelligent level of production in the t year of i enterprise; Control represents control variables such as firm size; and represent year-fixed effects and industry-fixed effects, respectively; and is a random disturbance term.

To explore whether the mediating effect of the energy utilization rate in the relationship between production intelligence and carbon emission efficiency of the equipment manufacturing industry is established, the following mediating effect model is constructed:

Among them, Mediator i, t is the intermediary variable—that is, energy utilization rate, indicating that the remaining variables of energy utilization rate in the t year of i enterprise have the same meaning as Formula (1).

To explore whether environmental regulations have a moderating influence on the relationship between production intelligence and the equipment manufacturing industry’s carbon emission efficiency, the following moderating effect model is constructed:

4. Results

In this section, we investigated the mechanism of intelligent production influencing how efficiently corporations emit carbon using regression analysis, and heterogeneity analysis was carried out to explore the different effects of intelligence on carbon emission reduction from the regional and industry levels. Further, robustness of the results was also verified.

4.1. Descriptive Statistical Analysis

The descriptive statistical results are displayed in Table 2. According to Table 2, businesses’ average carbon emission efficiency (CEE) is 0.336, the standard deviation is 0.150, the minimum value is 0.077, and the maximum value is 1.074. Businesses’ carbon emission efficiency varies to some extent. The average value of the degree of intelligent production (PI) is 0.134, the standard deviation is 0.127, the minimum value is 0, and the maximum value is 0.681, which indicates that the degree of intelligent production among enterprises is different, and the level generally needs to be further improved.

Table 2.

Descriptive statistical analysis results.

Table 3 reports the correlation coefficient characteristics of the main variables. Based on the correlation analysis findings of Table 3, the carbon emission efficiency of enterprises is correlated with the production intelligence of enterprises at the level of 10%. Control variables, such as enterprise size Size, the asset–liability ratio (Lev), return on assets (ROA), listed years (ListAge), and the first shareholder’s shareholding ratio column (Top1), are significantly correlated with corporate carbon emission efficiency. Note: * p < 0.1, ** p < 0.05, *** p < 0.01.

Table 3.

Correlation coefficient characteristics of main variables.

4.2. Analysis of Benchmark Regression Results

By calculating the variance inflation factor to identify the multicollinearity of the explanatory variables, the explanatory variable VIF is less than 10, so there is no multicollinearity problem in the panel data. The Hausman test of the panel data strongly rejects the original hypothesis; that is, the fixed effect model should be applied. Therefore, the panel data fixed effect model is employed for empirical analysis, and the benchmark regression results are shown in Table 4. Model (1) only considers the relationship between enterprise carbon emission efficiency (CEE) and production intelligence (PI) and does not add other control variables. At the 1% confidence level, the level of corporate production intelligence is significant. This result indicates that intelligent technology possesses a positive function in improving enterprise carbon emission efficiency, supporting H1. Model (2) adds a fixed effect based on Model (1), taking into account the heterogeneity of industry and time. Although the coefficient of production intelligence has declined, it is still significant at the 1% confidence level. Model (3) further adds control variables. The results indicate that 0.098 is the production intelligence regression coefficient, which at the 1% confidence level is significant, indicating that even after controlling more enterprise characteristics, enhancing manufacturing intelligence’s positive effects on carbon emission efficiency is still robust.

Table 4.

Baseline regression results.

4.3. Endogeneity Test

The level of enterprise production intelligence and its carbon emission efficiency may have endogenous problems caused by reverse causality; that is, the level of enterprise production intelligence of corporations can affect the carbon emission efficiency, but in turn, the carbon emission efficiency of enterprises also influences the level of production intelligence of enterprises. This is because when the carbon emission efficiency of enterprises is too low, it may prompt enterprises to adopt intelligent upgrading measures to improve the carbon emission efficiency of enterprises. This study uses the one-period lag of the explanatory variable as the instrumental variable (IV) and uses the two-stage least squares (2SLS) method to test the endogeneity. The findings are displayed in Table 5. Column (1) is the first-stage regression result, and the coefficient of the instrumental variable is 0.6689, which is significant at the level of 1%, which suggests that there is a strong positive association between the instrumental variable and the explanatory variable. Column (2) is the second-stage regression result. After using the instrumental variable for 2SLS regression, the promotion effect of the enterprise production intelligence level on enterprise carbon emission efficiency is still significant at the 1% level, and the result estimation aligns with the benchmark regression outcome, which further verifies the reliability of the result estimation in this paper.

Table 5.

Endogenous test results.

In terms of the rationality test of instrumental variables, the Kleibergen–Paap rkF statistical value is 639.470, which exceeds the critical value of 10% (16.38) in the Stock–Yogo weak instrumental variable test and rejects the weak instrumental variable hypothesis—that is, instrumental variables and the level of production intelligence possess a strong correlation. The p value of the Kleibergen–Paap rkLM statistic is 0.000, which rejects the underestimation assumption that the instrumental variable identifiability is satisfied. The p value of the Hansen J statistic is 0.000, indicating that the instrumental variables satisfy the exogenousity. The aforementioned findings demonstrate that this paper’s instrumental variable selection is generally sound.

4.4. Robustness Test

The robustness test in this paper is conducted by using the explanatory variable lag one period and the data bilateral tail reduction, respectively. First, because the intelligent production technology introduced by the enterprise in the current period cannot play a role in time, there may be a certain lag effect. Therefore, the explanatory variables undergo first-order lag processing. The outcomes are displayed in Column (1) of Table 6, and the production intelligence is significant at the level of 1%. Secondly, taking into account the impact of extreme values, this study performs a 1% upper-side tail reduction on all variables. The outcomes are displayed in Table 6, column (2). The regression coefficient of production intelligence is 0.098, which is significant at the 1% level, and the hypothesis is still valid.

Table 6.

Robustness test results.

4.5. The Mediating Effect Test of Energy Utilization Rate

Firstly, the stepwise regression coefficient approach is used in this study to test the influence mechanism of production intelligence of equipment manufacturing enterprises on the carbon emission efficiency of enterprises. Models (1), (2), and (3) in Table 7 constitute the mediating effect test model. Model (1) uses carbon emission efficiency as the explained variable to regress the degree of production intelligence. The results show that production intelligence can promote businesses to increase the efficiency of their carbon emissions. Model (2) takes the energy utilization rate as the explained variable to carry out regression analysis on the degree of production intelligence. The results show that the intelligent transformation of corporations in production can promote the energy utilization rate of enterprises. By introducing advanced information technology, automation, and intelligent technology, enterprises can improve the utilization of energy and reduce energy waste to promote the energy utilization rate. Model (3) verifies the mediating effect of the energy utilization rate in the course of production intelligence, improving the carbon emission efficiency of enterprises. The energy utilization rate’s regression coefficient is significant at the level of 10%. Production intelligence can reduce energy consumption per unit output by optimizing production processes and improving equipment operation efficiency, that is, improving the energy utilization rate. Energy consumption is the primary source of carbon emissions. The improvement in the energy utilization rate helps to decrease businesses’ carbon emission intensity in the production process, thus improving carbon emission efficiency.

Table 7.

Test results of mediating effect of energy efficiency.

Table 8 indicates the outcomes of the Bootstrap test to further determine the mediating effect of energy utilization between production intelligence and carbon emission efficiency. In the table, the confidence interval of the indirect effect of production intelligence on enterprise carbon emission efficiency does not include 0, which further verifies that energy utilization plays a mediating role in the relationship between production intelligence and enterprise carbon emission efficiency.

Table 8.

Bootstrap test results.

4.6. The Moderating Effect Test of Environmental Regulation

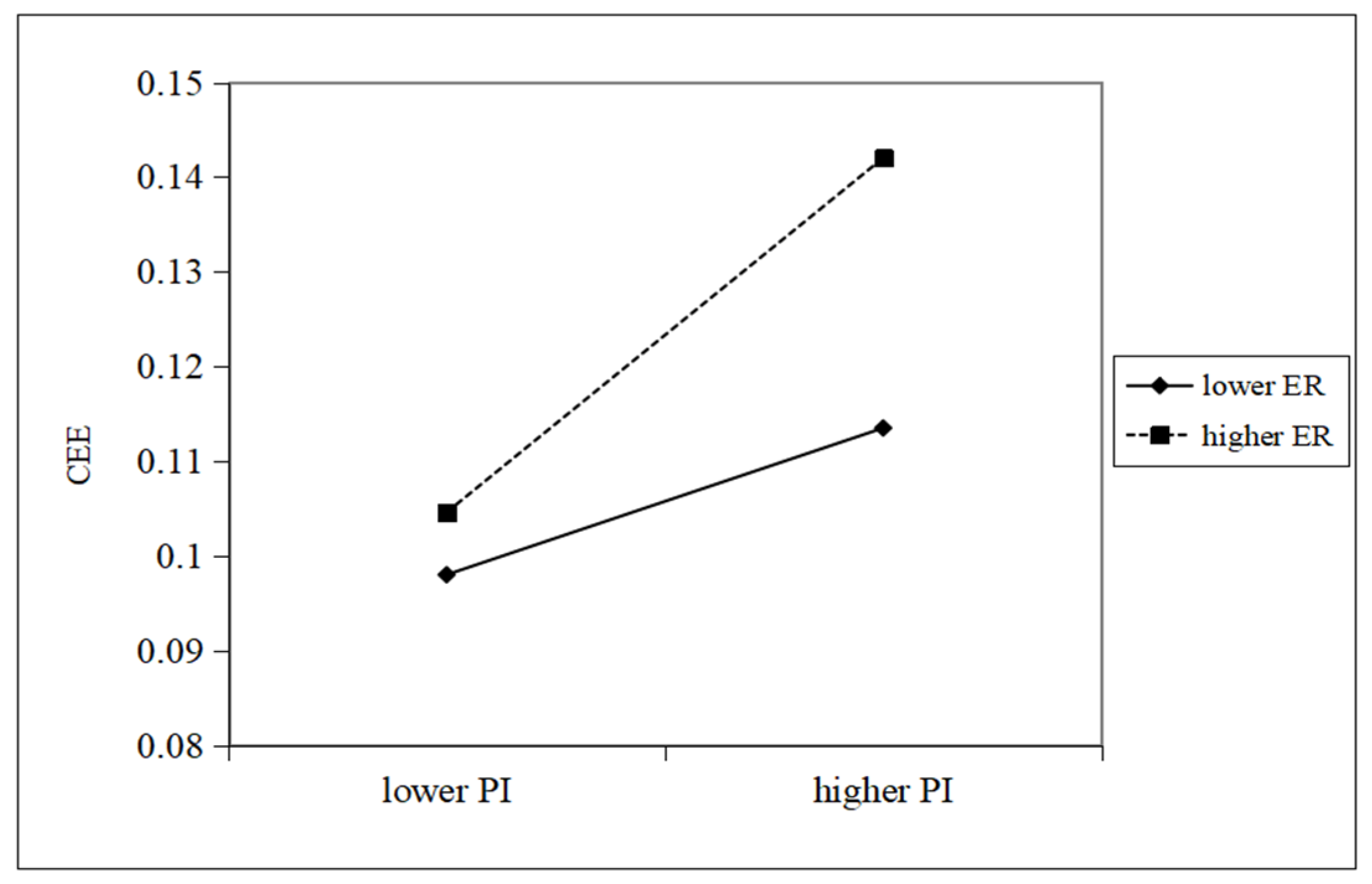

To avoid possible multicollinearity problems, this research centralizes production intelligence (PI) and environmental regulation (ER), and the regression outcomes are displayed in Table 9. Among them, model (1) represents the basic regression, model (2) adds adjustment variables, and model (3) indicates that the coefficient of the interaction between the level of production intelligence and environmental regulation is significantly positive (the coefficient is 0.310, p > 0.1), indicating that environmental regulation strengthens the role of production intelligence in promoting the carbon emission efficiency of equipment manufacturing enterprises. Figure 2 shows the effect of the enterprise production intelligence level on the improvement in the carbon emission efficiency of equipment manufacturing enterprises under different environmental regulation levels. The results show that under the lower level of environmental regulation, the impact of the enterprise production intelligence level on enterprise carbon emission efficiency is relatively small, while under the higher level of environmental regulation, the positive impact of production intelligence level has been strengthened, which indicates that strict environmental regulation may encourage enterprises to pay more attention to and invest in intelligent technology to achieve higher carbon emission efficiency.

Table 9.

Test results of moderating effect.

Figure 2.

Environmental regulation function diagram.

5. Heterogeneity Test

Due to the significant differences in the level of economic development between different regions, economically developed regions may introduce and popularize intelligent technology earlier to achieve the improvement in carbon emission efficiency in the production process, while economically backward regions may not be able to quickly promote the intelligent transformation of enterprises due to the limitations of technology, capital, or talents. The high-tech industry usually has greater technological innovation ability and can introduce and apply intelligent technology faster. This technological advantage helps enterprises to make better use of intelligent technology to improve carbon emission efficiency in the production process with a low production intelligence level and high production intelligence water carbon emission efficiency. In contrast, non-high-tech industries may have more obstacles in technology introduction and application. Therefore, this study analyzes the heterogeneity of regions and industries, respectively.

5.1. Regional Heterogeneity

This study analyzes the regional heterogeneity. The results are shown in Table 10. The intelligent coefficient of production in the eastern region is 0.113, which is significant at the level of 5%, which indicates that the region has achieved certain positive results in the application of intelligent technology. The impact of production intelligence in the western region is positive, with a coefficient of 0.078, but only significant at the level of 10%. This means that there is still much room for improvement in the application of intelligent technology in the western region; in the central region, the impact of intelligent production is not significant (coefficient is 0.071, p > 0.1), which indicates that the application and promotion of intelligent technology in the central region need to be further strengthened. The results show that the effect of intelligent production on the carbon emission efficiency of equipment manufacturing enterprises in the eastern region is obvious, while the effect on the central and western regions is small. The possible reason for the difference is that the eastern region usually has a higher level of economic development and better infrastructure, which is conducive to the promotion and application of intelligent technology to improve the efficiency of carbon emissions.

Table 10.

Results of heterogeneity analysis.

5.2. Industry Heterogeneity

Regarding the comparison between high-tech industries and non-high-tech industries, the results show that for high-tech industries, production intelligence has a significant positive impact on carbon emission efficiency (coefficient is 0.111, p < 0.001), while for non-high-tech industries, the impact of production intelligence is negative (coefficient is −0.060, p < 0.01). This result indicates that high-tech industries may have more advantages in adopting intelligent production technologies, can adopt and integrate intelligent technologies faster, and can use these technologies more effectively to improve carbon emission efficiency. On the contrary, non-high-tech industries may fail to effectively use production intelligence to improve carbon emission efficiency due to the limitation of technical foundation and innovation ability, resulting in a deviation from the original intention.

6. Conclusions and Implications

6.1. Discussion of Research Conclusions

This study takes the application of artificial intelligence patents as the entry point for production intelligence to raise the carbon emission efficiency of the equipment manufacturing industry. Based on the panel data of 247 enterprises in the equipment manufacturing industry from 2015 to 2021, this study examines the effect of production intelligence on the carbon emission efficiency of the equipment manufacturing industry and draws the following conclusions. (1) The results demonstrate that there is a significant positive correlation between enterprise production intelligence and carbon emission efficiency, which is consistent with current research [7,8,9]. When enterprises actively introduce intelligent means to intelligently transform their internal production processes, their carbon emission efficiency can be effectively improved; (2) The mediating effect test results show that production intelligence improves the carbon emission efficiency by improving the energy utilization rate of enterprises; (3) The results of the adjustment effect test show that the intensity of environmental regulation in the region where the enterprise is located plays a regulatory role in the relationship between the intelligent production and the carbon emission efficiency of the equipment manufacturing industry. That is, when the enterprise is in an environment with high environmental regulation, the industry is forced by environmental pressure and is more inclined to introduce intelligent production technology to improve carbon emission efficiency; (4) Heterogeneity analysis shows that there are significant regional and industrial differences in the impact of production intelligence on corporate carbon emission efficiency. The effect is obvious in the eastern region, and the effect in the central and western regions needs to be further improved. In the high-tech industry, the advantage of intelligent production is more significant, while in the non-high-tech industry, it is the opposite.

Compared with the current literature, we contribute in three aspects. First, existing literature has paid little attention to the theoretical analysis and empirical testing of how intelligent production reduces carbon emissions from the perspective of artificial intelligence patent applications. This study uncovers the internal mechanism by explaining the role of artificial intelligence patent applications, filling a gap in understanding the underlying processes. Second, current empirical research on carbon emission reduction through intelligentization mainly operates at the industry level [47,48], with little theoretical effort at the firm level. This research offers detailed insights into the effect of intelligent production on the carbon emission efficiency of the equipment manufacturing industry at the firm level. Third, previous studies have noticed the role of intelligence but lack in-depth exploration. We explore the different effects of intelligence on carbon emission reduction at the regional and industry levels, providing a more comprehensive view.

6.2. Policy Implications

The application of intelligent technology is the key to gaining a long-term competitive advantage and achieving sustainable development for enterprises. The application of these technologies can not only reduce the production cost of enterprises but also promote the improvement in carbon emission efficiency by improving energy efficiency, thereby reducing environmental costs, enabling enterprises to survive under increasingly stringent environmental restrictions and meet consumers’ demand for green products. Therefore, enterprises should face the dual pressures of development and green:

(1) Increase investment in intelligent technology and improve the level of intelligent production.

Enterprises should increase investment in intelligence, actively introduce advanced information technology, automation, and intelligent equipment, and strive to comprehensively optimize and innovate the production process to enhance the level of production intelligence of enterprises. With the help of the powerful power of intelligent technology, an efficient and real-time monitoring system is constructed to realize accurate control of the whole process of production. At the same time, combined with the dynamic management strategy, it can flexibly respond to the changes of field changes and production needs and realize the real-time monitoring and dynamic management of the entire production process. With the gradual penetration of intelligent technology, enterprises can better control energy consumption and emissions in the production process, thereby improving carbon emission efficiency. The application of intelligent technology will help enterprises transform into an eco-friendly and low-carbon form of production and contribute to the realization of sustainable development goals. Enterprises should seize this historical opportunity and actively promote intelligent transformation to lay a solid foundation for the long-term development of enterprises.

(2) Put an emphasis on energy efficiency and promote energy management optimization.

Enterprises should be committed to building a comprehensive and advanced energy management system, deeply integrating intelligent technology, realizing real-time, dynamic monitoring and in-depth analysis of energy consumption data, paying attention to energy utilization rate, and finally realizing energy management optimization. Through intelligent monitoring methods, enterprises can grasp the specific situation of energy consumption in real-time, including key data such as consumption, consumption rate, and consumption period of various energy sources, to provide an accurate basis for subsequent energy management. Based on mastering the data of energy consumption, enterprises should further optimize energy allocation and carry out refined scheduling and management of energy use through intelligent algorithms and models to effectively reduce energy waste, improve energy efficiency, and reduce energy waste. At the same time, enterprises need to continuously promote technological innovation and equipment upgrading and introduce cutting-edge energy-saving technologies and high-efficiency equipment. These innovations can not only improve energy conversion efficiency and reduce losses in the conversion process but also promote the green transformation of production processes.

Through the implementation of these comprehensive measures, enterprises can not only greatly reduce their carbon emissions but also actively respond to the call for national energy conservation and emission reduction policies. They can also establish a green and low-carbon brand image in the fierce market competition and win more consumers’ favor and trust. This will create a strong basis for businesses to grow sustainably and help enterprises occupy a more favorable position in future market competition.

(3) Strengthen the response and utilization of environmental regulation policies.

Enterprises should strengthen the response and utilization of environmental regulation policies and make full use of environmental regulation policies to achieve their own development. In today's global context, green development has become the main theme of economic development, which leads the global economy to a more sustainable and environmentally friendly direction. In this context, as an important participant in economic activities, enterprises must pay close attention to and deeply interpret the environmental protection policies and regulations continuously issued by national and local governments from a forward-looking perspective. This is not only to ensure that the business activities of enterprises can meet the requirements of the national sustainable development strategy but also to fulfill their social responsibilities and show a good corporate image.

Enterprises should respond to environmental regulation with a positive attitude and regard it as a powerful driving force to promote their industrial upgrading and transformation. Through an in-depth study of policy orientation, enterprises can accurately locate the direction and path of green transformation in line with their actual situation to ensure the smooth progress of transformation. In this process, enterprises should make full use of policy incentives, such as tax incentives, green credits, subsidy incentives, etc. These measures can effectively reduce the transformation cost of enterprises and accelerate their progress toward low-carbon and environmentally friendly production models. Transforming environmental pressure into an opportunity to enhance their core competitiveness through green transformation, enterprises can not only promote production efficiency and reduce energy consumption and emissions but also establish a green and environmentally friendly brand image in the market, thus winning the favor of more consumers. In addition, as consumer demand for environmentally friendly products is growing, green transformation will also bring new market opportunities and growth points for enterprises.

Therefore, enterprises should firmly grasp the market opportunities brought by environmental regulation and transform environmental protection pressure into the driving force for their development. By actively responding to environmental regulations, making full use of policy incentives, and further promoting green transformation, enterprises can remain invincible in the fierce market competition and contribute to the cause of global sustainable development.

6.3. Limitation and Future Research

This study has limitations. It finds that intelligent production improves carbon emission efficiency by enhancing energy utilization, but intermediary tests reveal other mechanisms at play in the equipment manufacturing industry. Future research should further explore these internal mechanisms. Additionally, this study only examines environmental regulations’ moderating effect without considering other internal and external factors. Future studies can test various factors’ roles more accurately with a refined theoretical framework and empirical model, supporting enterprises in formulating better energy-saving and emission-reduction strategies. In the process of the data collection process, due to data availability, the data for more recent years were not found and collected; thus, recent changes in industries are not considered. Future research can try to substitute the original measure of the variable and find more data to make the research more convincing.

Author Contributions

Methodology, G.X.; Validation, G.X.; Formal analysis, Y.S.; Writing—original draft, Y.S.; Writing—review & editing, Y.S. and G.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Xu, Y.; Cheng, Y.; Wang, J.; Liu, N. Spatio-Temporal Evolution and Influencing Factors of Carbon Emission Efficiency in Low Carbon City of China. J. Nat. Resour. 2022, 37, 1261–1276. [Google Scholar]

- Churchill, S.A.; Inekwe, J.; Smyth, R.; Zhang, X. R&D Intensity and Carbon Emissions in the G7: 1870–2014. Energy Econ. 2019, 80, 30–37. [Google Scholar]

- Zheng, K.; Deng, H.; Lyu, K. Market Integration, Industrial Structure, and Carbon Emissions: Evidence from China. Energies 2022, 15, 9371. [Google Scholar] [CrossRef]

- Bhalaji, R.K.A.; Sankaranarayanan, B.; Alam, S.T.; Hossain, N.U.I.; Ali, S.M.; Karuppiah, K. A decision support model for evaluating risks in a collaborative supply chain of the medical equipment manufacturing industry. Supply Chain. Forum Int. J. 2022, 23, 227–251. [Google Scholar]

- Fu, H.; Li, G.; Zhu, T. Carbon emissions of China’s manufacturing industry: Industry differences and decomposition from driving factors. Reform 2021, 5, 38–52. [Google Scholar]

- Afrin, M.; Jin, J.; Rahman, A.; Tian, Y.; Kulkarni, A. Multi-objective resource allocation for Edge Cloud based robotic workflow in smart factory. Future Gener. Comput. Syst. 2019, 97, 119–130. [Google Scholar]

- Cassettari, L.; Bendato, I.; Mosca, M.; Mosca, R. Energy Resources Intelligent Management using on line real-time simulation: A decision support tool for sustainable manufacturing. Appl. Energy 2017, 190, 841–851. [Google Scholar]

- Wang, S.; Liang, Y.; Li, W.; Cai, X. Big Data enabled Intelligent Immune System for energy efficient manufacturing management. J. Clean. Prod. 2018, 195, 507–520. [Google Scholar]

- Karuppiah, K.; Sankaranarayanan, B.; Lo, H.W. A systematic literature review on the evolution of sustainable manufacturing practices: Key findings and implications. Clean. Eng. Technol. 2024, 22, 100798. [Google Scholar]

- Wang, X.; Ren, S.; Yuan, B.; Yin, H. The Effect of Urbanization, Consumption Ratio and Consumption Structure on Residential Indirect CO2 Emissions. Econ. Theory Bus. Manag. 2016, 36, 79. [Google Scholar]

- Li, G.; Zhou, M. Dynamic Effects on Carbon Dioxide Emissions of Population and Consumption: An Empirical Analysis Based on Variable Parameter Model. Popul. Res. 2012, 36, 63. [Google Scholar]

- Menz, T.; Welsch, H. Population Aging and Carbon Emissions in Oecd Countries: Accounting for Life-Cycle and Cohort Effects. Energy Econ. 2012, 34, 842–849. [Google Scholar]

- Zhang, H.; Shi, X.; Wang, K. Intertemporal Lifestyle Changes and Carbon Emissions: Evidence from a China Household Survey. Energy Econ. 2020, 86, 104655. [Google Scholar]

- Luo, L.; Leizhu, J. Synergetic Effect of China’s Carbon Market Policies on Pollution Reduction and Carbon Reduction. Ziyuan Kexue 2024, 46, 53–68. [Google Scholar]

- Liu, K.; Wu, Y.; Tao, Y.; Wang, C. The Influence of Ecological Civilization Construction to Carbon Emission Intensity in China’s Provinces. China Popul. Resour. Environ. 2019, 29, 50–56. [Google Scholar]

- Nie, C.; LI, R.; Feng, Y. Analyzing Coupling Coordination of Pollution and Carbon Reduction with High-Quality Economic Development: A Case Study of China’s Yangtze River Economic Belt. Sustainability 2024, 16, 4892. [Google Scholar] [CrossRef]

- Guo, P.; Wang, G. The Synergistic Effect of Digital Economy on Pollution and Carbon Reduction and the Influence Mechanism: An Empirical Test Based on Prefecture-Level City Data. Ziyuan Kexue 2023, 45, 2117–2129. [Google Scholar]

- Tian, J.; Meng, Z. Study on the Effect of Digital Economy Development on Carbon Emissions: Evidence from 30 Provinces in China. Environ. Sci. Pollut. Res. 2023, 30, 126088. [Google Scholar]

- Song, W.; Tang, S. Does the Digital Economy Really Help Reduce Industrial Carbon Intensity? Empirical Evidence from Intermediate Inputs of Digital Products in China. Environ. Sci. Pollut. Res. 2024, 31, 56042–56055. [Google Scholar]

- Huang, H.; Wei, Z.; Ge, Q.; Guo, Q. Analysis of Spatial-Temporal Evolution and Influencing Factors of Carbon Emission Efficiency in Chinese Cities. Front. Environ. Sci. 2023, 11, 1119914. [Google Scholar]

- Mi, T.; Li, T. Industrial Intelligence and Carbon Emission Reduction: Evidence from China’s Manufacturing Industry. Sustainability 2024, 16, 6573. [Google Scholar] [CrossRef]

- Wang, H.; Guo, G.; Yan, Z. Research on the Mechanism and Effect of Robot Application on Urban Carbon Emissions. Res. Financ. Econ. Issues 2023, 5, 52–63. [Google Scholar]

- Geng, W.; Liu, X.; Liao, X. Mechanism analysis of the influence of intelligent manufacturing on carbon emission intensity: Evidence from cross country and industry. Environ. Dev. Sustain. 2024, 26, 15777–15801. [Google Scholar] [CrossRef]

- Xie, J.; Ma, L.; Yang, Y. Effects of digital intelligence technology on sustainable manufacturing and circular economy. Manag. Rev. 2024, 36, 82–95. [Google Scholar]

- Sahoo, S.; Lo, C.Y. Smart manufacturing powered by recent technological advancements: A review. J. Manuf. Syst. 2022, 64, 236–250. [Google Scholar]

- Masood, A.; Ahmad, K. A Review on Emerging Artificial Intelligence (Ai) Techniques for Air Pollution Forecasting: Fundamentals, Application and Performance. J. Clean. Prod. 2021, 322, 129072. [Google Scholar]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Artificial intelligence applications for industry 4.0: A literature-based study. J. Ind. Integr. Manag. 2022, 7, 83–111. [Google Scholar]

- Gao, B.; Kong, X.; Liu, G.; Xiang, T.; Gao, Y.; Luo, S.; Wang, Y. Monitoring high-carbon industry enterprise emission in carbon market: A multi-trusted approach using externally available big data. J. Clean. Prod. 2024, 466, 142729. [Google Scholar] [CrossRef]

- Chen, S. Fluctuating Decline Patterns of Carbon Emission Intensity in China and Economic Explanations. J. World Econ. 2011, 34, 124–143. [Google Scholar]

- Zhang, Y. Impact of Changes in Economic Development Patterns on Carbon Emission Intensity in China. Econ. Res. J. 2010, 45, 120–133. [Google Scholar]

- Su, Y.; Li, D. Interaction Effects of Government Subsidies, R&D Input and Innovation Performance of Chinese Energy Industry: A Panel Vector Autoregressive (Pvar) Analysis. Technol. Anal. Strateg. Manag. 2023, 35, 493–507. [Google Scholar]

- Luo, C.; Li, X. Industrial Structure Upgrading, Technological Progress and Energy Efficiency in China—An Empirical Analysis Based on a Non-Dynamic Panel Threshold Model. Inq. Into Econ. Issues 2019, 1, 159–166. [Google Scholar]

- Li, D. Green Technology Innovation Path Based on Blockchain Algorithm. Sustain. Comput. Inform. Syst. 2021, 31, 100587. [Google Scholar] [CrossRef]

- Yin, K.; Liu, L.; Gu, H. Green Paradox or Forced Emission Reduction—The Dual Effects of Environmental Regulation on Carbon Emissions. Int. J. Environ. Res. Public Health 2022, 19, 11058. [Google Scholar] [CrossRef] [PubMed]

- Berman, E.; Bui, L.T.M. Environmental Regulation and Productivity: Evidence from Oil Refineries. Rev. Econ. Stat. 2001, 83, 498–510. [Google Scholar] [CrossRef]

- Jiang, F.; Zhu, J.W.; Jun, H.B. The Dual Effect of Environmental Regulation on Technological Innovation: An Empirical Study Based on Dynamic Panel Data of Jiangsu Manufacturing Industry. China Ind. Econ. 2013, 7, 44. [Google Scholar]

- Porter, M.E.; Linde, C.V.D. Toward a New Conception of the Environment-Competitiveness Relationship. J. Econ. Perspect. 1995, 9, 97–118. [Google Scholar] [CrossRef]

- Tone, K. A Slacks-Based Measure of Efficiency in Data Envelopment Analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Huang, Z.; Jiang, P. Digital Low-Carbon Road: Industrial Robots and Urban Industrial Carbon Emissions. J. Financ. Econ. 2023, 49, 34–48. [Google Scholar]

- Shen, H. Will the Carbon Emission Trading Scheme Improve Firm Value. Financ. Trade Econ. 2019, 40, 144–161. [Google Scholar]

- Yin, Z.; Cao, A.; Guo, J.; Guo, D. A Study of the Impact of Artificial Intelligence on Employment Based on Patents Data: Evidence from Zhongguancun Enterprises. China Ind. Econ. 2023, 5, 137–154. [Google Scholar]

- Lyubich, E.; Shapiro, J.; Walker, R. Regulating Mismeasured Pollution: Implications of Firm Heterogeneity for Environmental Policy. AEA Pap. Proc. 2018, 108, 136–142. [Google Scholar] [CrossRef]

- Zhang, X.; Hou, Y.; Geng, K. Environmental Regulation, Green Technology Innovation, and Industrial Green Transformation: Empirical Evidence from a Developing Economy. Sustainability 2024, 16, 6833. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Li, B.H.; Hou, B.C.; Yu, W.T.; Lu, X.B.; Yang, C.W. Applications of artificial intelligence in intelligent manufacturing: A review. Front. Inf. Technol. Electron. Eng. 2017, 18, 86–96. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, F. Edge computing and machinery automation application for intelligent manufacturing equipment. Microprocess. Microsyst. 2021, 87, 104389. [Google Scholar] [CrossRef]

- Lv, H.; Shi, B.; Li, N.; Kang, R. Intelligent manufacturing and carbon emissions reduction: Evidence from the use of industrial robots in China. Int. J. Environ. Res. Public Health 2022, 19, 15538. [Google Scholar] [CrossRef]

- Tang, J.; Wang, W.; Ding, W. Research into the Path and Mechanism by Which Intelligent Manufacturing Promotes Carbon Emission Reductions. Energies 2024, 17, 3925. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).