Abstract

This study investigates magnetohydrodynamic (MHD) heat and mass transport in a water-based ternary hybrid nanofluid flowing past an exponentially accelerated vertical porous plate. Two critical scenarios are analyzed: (i) uniform heat flux with variable mass diffusion and (ii) varying heat source with constant species diffusion. The model integrates thermal radiation, heat sink/source, thermal diffusion, and chemical reaction effects to assess flow stability and thermal performance. Governing equations are non-dimensionalized and solved analytically using the Laplace transform method, with results validated against published data and finite difference method outcomes. Ternary hybrid nanofluids exhibit a significantly higher Nusselt number compared to hybrid and conventional nanofluids, demonstrating superior heat transfer capabilities. Magnetic field intensity reduces fluid velocity, while porosity enhances momentum transfer. Thermal radiation amplifies temperature profiles, critical for energy systems. Concentration boundary layer thickness decreases with higher chemical reaction rates, optimizing species diffusion. These findings contribute to the development of advanced thermal management systems, such as solar energy collectors and nuclear reactors, enhance energy-efficient industrial processes, and support biomedical technologies that require precise heat and mass control. This study positions ternary hybrid nanofluids as a transformative solution for optimizing high-performance thermal systems.

1. Introduction

The study of unsteady magnetohydrodynamic (MHD) flow problems is crucial for advancing technologies in diverse sectors such as aerospace, nuclear energy, and electronics. The incorporation of thermal radiation, thermal diffusion, heat sinks/sources, chemical processes, and porous media into fluid flow studies considerably complicates the analysis while simultaneously enhancing its applicability to sophisticated technological applications [1]. Many researchers have contributed to the understanding of these complex phenomena. Rajesh and Varma [2] conducted research to investigate the optimal solution for an unsteady flow problem across an infinite vertical plate with exponential acceleration. This study considered the effects of variable mass diffusion and uniform heat flux while analyzing a homogeneous first-order chemical reaction. Kumar et al. [3] conducted an exact analysis using the Laplace transform method to solve the problem of unsteady MHD flow of a chemically reacting elasto-viscous fluid past an infinite vertical plate through a porous medium, considering radiation absorption and a transverse magnetic field. Their findings indicate that as the radiation absorption parameter increases, the velocity of the elasto-viscous fluid decreases. However, in the case of a viscous fluid with plate cooling, the opposite effect is observed. Islam and Ahmed [4] investigated the heat and mass transfer effects on unsteady MHD free convection flow of an electrically conducting viscous fluid past a moving, infinite, isothermal vertical plate. Their study considered the influence of a transverse magnetic field, the Soret effect, chemical reactions, heat sources, and thermal radiation. Goud et al. [5] explored unsteady MHD free convection flow with mass and heat transfer past an inclined plate subjected to exponential acceleration. The inclined plate was situated within a saturated porous medium characterized by uniform permeability while both concentration and temperature varied. This investigation examined the intricate dynamics of fluid flow influenced by magnetic fields, thermal radiation, and heat absorption. Shankar and Dharmendra [6] analyzed the effects of radiation and heat absorption in the unsteady natural convective MHD flow of a non-gray Newtonian optically thin fluid along an infinitely long straight porous plate. This study considered plate velocity and ramped wall temperature while incorporating the Soret effect and a first-order chemical reaction. The results indicated that as the thermal radiation parameter increased, the thermal boundary layer thickness decreased. Bafakeeh et al. [7] examined unsteady free convective electromagnetic heat and mass transfer of an incompressible electrically conducting viscous fluid flowing over a vertical plate situated in a porous medium, considering the effects of chemical processes and thermal radiation. The impacts of the Soret effect, rotation parameter, and Hall current were also explored. Their study observed that a decreasing heat source parameter reduced temperature dispersion, leading to a lower overall temperature. Narmatha and Kavitha [8] studied the rotational flow of an unsteady MHD heat and mass transfer process driven by convection over a vertical porous semi-infinite plate. Their research revealed significant trends in fluid behavior. Specifically, fluid velocity increased as the Grashof number, modified Grashof number, and Soret number rose. Conversely, it decreased with lower values of the magnetic field parameter, Prandtl number, and Schmidt number. Abbas and Nazar [9] investigated the influence of the Hall current on the multiphase thermal transfer of an incompressible electrically conducting Jeffrey fluid flowing over an infinitely long vertical plate. Their study considered the effects of heat absorption and chemical reactions. The analysis employed extended versions of Fourier’s and Fick’s laws combined with the recently introduced constant proportional Caputo (CPC) fractional operator.

Conventional fluids such as ethylene glycol, engine oil, and water have relatively low thermal conductivity, limiting their effectiveness in applications requiring advanced thermal management. This drawback has led to increased interest in nanofluids—colloidal suspensions of nanoparticles (such as metals, metal oxides, or carbides) dispersed in base fluids. Nanofluids are known for their enhanced thermal conductivity and stability, offering significant advantages in a wide range of applications. Researchers have conducted extensive studies on nanofluid flow over various surfaces, including vertical plates and stretched sheets, to understand how these geometric configurations impact heat transfer efficiency. Choi and Eastman [10] are credited with pioneering the concept of nanofluids in the mid-1990s. Their ground-breaking research marked a significant advancement in understanding the thermal properties of fluids containing suspended nanoparticles. They demonstrated that even low concentrations of nanoparticles could improve the thermal conductivity of base fluids, leading to enhanced heat transfer potential. Following Choi’s breakthrough study, the field of nanofluids has seen a surge of interest, with researchers exploring their applications across a wide range of thermal systems. Sedki [11] investigated the synergistic effects of thermophoresis, Brownian motion, thermal radiation, and chemical reactions on mixed convective heat and mass transport in a moving magneto-nanofluid boundary layer induced by a stretching, permeable surface within a porous medium with heat generation. Studies have shown that the thermal boundary layer thickness is lower than that of the momentum and mass transfer layers, and it is influenced by factors such as mixed convection, chemical processes, nanoparticle volume fraction, surface nonlinearity, and the presence of a porous medium. The numerical analysis by Reddy et al. [12] examined the effects of heat radiation on the boundary layer of MHD flow of a Williamson nanofluid across an expanding surface within a porous medium, considering velocity and thermal slip conditions. Their findings indicated that increasing the Williamson parameter elevated both the temperature and concentration of the nanofluid. Sudarsana and Sreedevi [13] analyzed heat and mass transfer properties in both steady and unsteady nanofluid flow over a stretched surface embedded in a porous medium. Their study incorporated factors such as thermal radiation, chemical reactions, thermal stratification, magnetic fields, and solutal stratification. Results showed that temperature profiles decreased with an increase in the thermal stratification parameter, while concentration profiles diminished as the solutal stratification parameter increased. Dharmaiah et al. [14] explored the impact of an imposed magnetic field on bio-convection patterns in an electrically conducting, two-dimensional Maxwell nanofluid containing gyrotactic microorganisms. Their study highlighted how slip effects influence thermal phenomena. Kodi et al. [15] investigated the effects of diffusion-thermo and radiation absorption on the free convective heat and mass transfer of an incompressible MHD Jeffrey nanofluid across a slanted plate embedded in a porous material under fluctuating boundary conditions. Their analysis revealed that increasing radiation absorption correlated with improved velocity and temperature profiles, whereas diffusion-thermo parameters led to opposing behavior in velocity and temperature variations. Raghunath [16] examined unsteady MHD nanofluid flow along a stretching sheet, considering Soret effects and thermal radiation under a transverse magnetic field. This study found that – water nanofluid exhibited higher velocity than – water nanofluid. Additionally, results indicated that increasing thermal radiation caused decreases in both temperature and velocity. Ramesh et al. [17] focused on Carreau nanofluid flow within a microchannel, incorporating Joule heating, electro-osmosis, and chemical reactions. Their analysis concluded that an increase in the Hartmann number (magnetic parameter) led to a decline in velocity. Furthermore, parameters such as the Schmidt number, Prandtl number, radiation term, and chemical reaction term contributed to an increase in solutal nanoparticle concentration. Venkateswarulu et al. [18] conducted a numerical analysis of the heat transfer efficiency of nanofluids used as coolants in prismatic batteries. Their study examined various nanofluids in a base fluid composed of 50% water and ethylene glycol. The results indicated that and nanofluids significantly enhanced heat transfer rates by approximately 40.42% and 42.13%, respectively. Further, aluminum nanoparticles exhibited a heat transfer rate that was 4.06% higher than that of copper nanoparticles. Galal et al. [19] investigated heat and mass transfer rates in three-dimensional magnetohydrodynamic (MHD) nanofluid flow. Their study incorporated chemical reactions and thermal radiation effects occurring across two elastic surfaces while considering the influence of inclined magnetization and viscous dissipation. Dharmaiah et al. [20] examined the effects of a magnetic dipole on a nonlinear, thermally radiative ferromagnetic liquid flowing across an extended surface under the influence of thermophoresis and Brownian motion. Their research demonstrated that the combination of nanoparticle properties and magnetic dipole effects enhanced the thermal conductivity of nanofluids, leading to improved heat transfer. Rahman et al. [21] studied the impact of nanoparticle characteristics such as concentration, size, and shape on nanofluid properties. Their findings revealed that increasing nanoparticle volume concentration enhanced heat transfer efficiency up to a certain threshold. However, exceeding the optimal concentration led to reduced Brownian motion due to increased viscosity and density. Basit et al. [22] focused on examining the enhancement of heat and mass transfer rates due to the presence of motile microorganisms in Carreau nanofluid flow through an inclined, stretchable cylinder, considering the effects of activation energy and thermal radiation. Their results indicate that the velocity profile increases with the augmentation of the curvature parameter. The thermal profile becomes more pronounced as the thermophoresis parameter increases, while the nanoparticle concentration profile smoothens as the temperature coefficient rises. Saleem et al. [23] investigated the influence of viscous dissipation, magnetohydrodynamics, and mixed convection on the flow of Casson nanofluid thin films over a vertical stretching surface, considering unsteady, two-dimensional conditions. Their problem formulation assumed incompressible flow and applied boundary layer approximations, resulting in a system of partial differential equations (PDEs). Waseem et al. [24] conducted a numerical analysis of viscoelastic Casson nanofluid flow over a Darcy–Forchheimer exponential sheet. The Casson model was used to capture the non-Newtonian behavior of the nanofluid, while the Darcy–Forchheimer formulation accounted for the effects of a permeable medium. Results indicated that temperature profiles increased with a higher magnetic parameter, whereas an increase in the Prandtl number and thermal radiation led to a decrease in temperature profiles.

The development of hybrid nanofluids involves the combination of two types of nanomaterials with a conventional heat transfer base fluid. This innovative approach results in a fluid with enhanced energy transfer capabilities compared to both traditional fluids and standard nanofluids. Hybrid nanofluids have attracted significant attention from researchers, who have extensively studied their distinctive properties and explored their applications across various thermal systems. Using the Buongiorno model, Mishra and Upreti [25] investigated the heat and mass transfer behavior of / and / hybrid nanofluids in the presence of viscous dissipation, chemical reactions, and heat absorption/generation. Their findings indicate a correlation between the temperature profiles of hybrid nanofluids and the increasing values of heat generation/absorption, viscous dissipation, and thermophoresis parameters. Lone et al. [26] examined the MHD flow of mixed convective micropolar / hybrid nanofluid over a flat surface. Their study reveals that thermal flow behavior improves with an increase in the radiation factor, magnetic effects, heat source strength, and Eckert number. Mebarek et al. [27] conducted a numerical analysis of /water, hybrid nanofluid flow within a porous elliptical cavity, focusing on the thermal system’s performance under a magnetic field by evaluating heat transfer characteristics and entropy generation. Their results demonstrate an improvement in the thermal and dynamic behavior of the hybrid nanofluid as the shape factor, concentration, Darcy number, and porosity increase. Shamshuddin et al. [28] made a significant contribution by thoroughly examining heat and mass transfer phenomena in a nanofluid system consisting of / under the influence of an exponentially stretching velocity. Their investigation explores the complex interactions between gyrotactic microorganisms and convective boundary conditions within this system. The research by Khan et al. [29] leverages the superior performance of hybrid nanofluids to investigate the flow dynamics and thermal properties of a kerosene oil-based hybrid ferrofluid. This study focuses on modified versions of two critical models—the Yamada–Ota and Xue models. The findings conclude that the enhanced Yamada–Ota model provides more effective results compared to the Xue model. Agbaje et al. [30] conducted a study on the free convection behavior of a micropolar hybrid nanofluid, using water as the base fluid with diamond and copper nanoparticles as solid components. Their investigation incorporates the thermal relaxation effect by applying the Cattaneo–Christov heat flux model to the energy equation. Also, this study considers the impact of Darcy–Forchheimer inertial drag along with an irregular heat sink/source. Ishaq et al. [31] provided valuable insights into optimizing thermal management in industrial heat transfer and energy systems using Casson hybrid nanofluids. By incorporating radiative effects and convective boundary conditions, their study demonstrates the potential for enhancing the efficiency of thermal systems, including heat exchangers and solar collectors. Their findings contribute to the advancement of industrial cooling systems, where improved heat transfer characteristics play a crucial role in enhancing operational stability and extending equipment lifespan.

Tri-hybrid nanofluids represent a specialized class of nanofluids containing three distinct types of nanoparticles suspended in a base fluid. These nanofluids have demonstrated remarkable effectiveness in various applications, particularly in magnetohydrodynamic (MHD) flows. In the fields of drug delivery and tissue engineering, tri-hybrid nanofluids play a crucial role in regulating temperature during targeted hyperthermia treatments. They can locally activate therapeutic agents through chemical reactions within the fluid and ensure consistent drug release profiles via controlled mass diffusion. Research highlights that tri-hybrid nanofluids enhance drug delivery efficiency by improving the solubility of hydrophobic drugs and enabling precise targeting through functionalization with ligands or antibodies. In the aerospace and defense sectors, MHD tri-hybrid nanofluids are highly effective in managing rapidly changing thermal loads in critical components such as turbine blades, avionics, and rocket engine nozzles. Their ability to maintain uniform heat flux and regulate mass diffusion allows these components to operate within safe temperature ranges despite fluctuating conditions. Due to their diverse applications across multiple fields, researchers have extensively studied ternary nanofluid flows. The study by Oweidi et al. [32] investigates the effects of ternary nanoparticles on heat transfer and fluid movement, focusing on the thermal properties of tri-hybrid nanofluids. The nanofluids analyzed in this research consist of aluminum oxide , copper oxide , silver , and water as the base fluid. The results indicate that the rate of entropy generation increases with rising magnetic field strength and radiation parameters. Conversely, entropy production decreases as the Brinkman number and Hall current parameter become more pronounced. In their study, Alshahrani et al. [33] assessed the impacts of heat radiation, slip boundary conditions, and uniform magnetic strength on the flow of three different types of nanofluids over a spinning disk. This research combined aluminum oxide , carbon nanotubes , and zirconium dioxide to create tri-hybrid nanocomposites. This study found that an increase in the slip coefficient significantly reduces the velocity field, while higher values of the heat source term and thermal radiation parameter enhance the thermal profile. Vinutha et al. [34] reviewed the implications of the Soret effect, heat sink/source, and the Dufour effect on the flow of tri-hybrid nanofluids across a wedge. Their findings indicate that altering the dynamic wedge parameter reduces the temperature profile while increasing the magnetic constraint boosts velocity. Furthermore, adjusting the heat source/sink, Soret, and Dufour parameters leads to higher temperature and concentration profiles. A study by Madhukesh et al. [35] analyzed the performance of tri-hybrid nanofluid flow in an inclined leaky cylinder/plate system. The results showed that plate geometry performed better than cylindrical geometry when maintaining a stable volume fraction. The rate of heat transfer in the cylinder increased from 2.08% to 2.32%, while in the plate, it rose from approximately 5.19% to 10.83% as the porous material fraction increased from 0.1 to 0.5. Several researchers [36,37,38,39] have conducted studies on ternary hybrid nanofluids, focusing on convective heat transport and various geometric configurations. Gopinath Mandal [40] established the presence of a double solution in radiative mixed convective tri-hybrid nanofluid MHD flow within a Darcy–Forchheimer porous medium over a rapidly diminishing surface. This study also considered the influence of velocity and thermal slip, as well as surface suction effects. An analysis was conducted on three fluid categories: -mono nanofluid, -/-hybrid nanofluid, and --/-tri-hybrid nanofluid, across various flow fields. The primary objective of the study by Khan et al. [41] was to investigate the flow and heat transfer characteristics of a blood-based composite nanofluid composed of , , and in a Sutterby fluid over a bidirectional porous stretching surface. The graphical results indicate that, in the presence of the Darcy–Forchheimer effect, there is a significant reduction in fluid velocity for both tri-hybrid and unary nanofluids. A similar trend is observed for the slip parameter. Jamrus et al. [42] performed numerical computations to explore heat transfer and fluid flow dynamics in the stagnation region of mixed convection involving ternary hybrid nanofluids with thermal stratification. Their study examined the effects of magnetohydrodynamics, velocity slip, and a permeable sheet capable of stretching or shrinking. Chandel et al. [43] investigated a novel ternary nanofluid dispersed in a shear-thinning fluid (ethylene glycol) over an exponentially stretching sheet. The fluid’s rheology was analyzed using a power-law fluid model, with flow influenced by an inclined magnetic field. The results demonstrated that increasing the nanoparticle volume fraction enhances both fluid temperature and Nusselt number distributions. The study by Saleem et al. [44] examined the properties of a Casson ternary nanofluid over a stretching sheet under Thomson and Troian slip conditions, while also considering the effects of electro-magnetohydrodynamics (EMHD). The findings indicated that the temperature of the ternary Casson nanofluid increased with higher concentrations of silver, copper, and titanium dioxide nanoparticles.

Building on the framework established by Rajesh and Varma [2], who studied the unsteady flow past an infinite vertical exponentially accelerated plate with uniform heat flux, variable mass diffusion, and a first-order homogeneous chemical reaction, this study extends their work to ternary nanofluids. In addition to uniform heat flux and variable mass diffusion, it incorporates a varying heat source and constant species diffusion. A key enhancement is the inclusion of thermal radiation, thermal diffusion, and a heat sink/source, providing a more comprehensive understanding of ternary nanofluid flows. This investigation is significant for its potential to enhance thermal stability and control, crucial for various industrial applications. The inclusion of additional effects enhances heat transfer efficiency by reducing thermal boundary layers and increasing mass transfer rates. Ternary nanofluids offer the advantage of optimizing thermal properties through strategic nanoparticle combinations, improving both conductivity and stability. Moreover, the analysis of varying heat sources and constant species diffusion provides insights into how different boundary conditions affect ternary nanofluid behavior, which is essential for designing efficient systems across diverse operating conditions.

This study mainly aims to address the following key research questions:

- How do flow parameters, such as Grashof numbers and the porosity parameter, affect the velocity profiles of water-based ternary hybrid nanofluid?

- What is the impact of increasing thermal radiation on temperature profiles?

- How does the heat absorption parameter influence the rate of heat transfer?

- What role does thermo-diffusion play in mass transfer rates?

- What are the unique findings and contributions of this research?

2. Mathematical Model

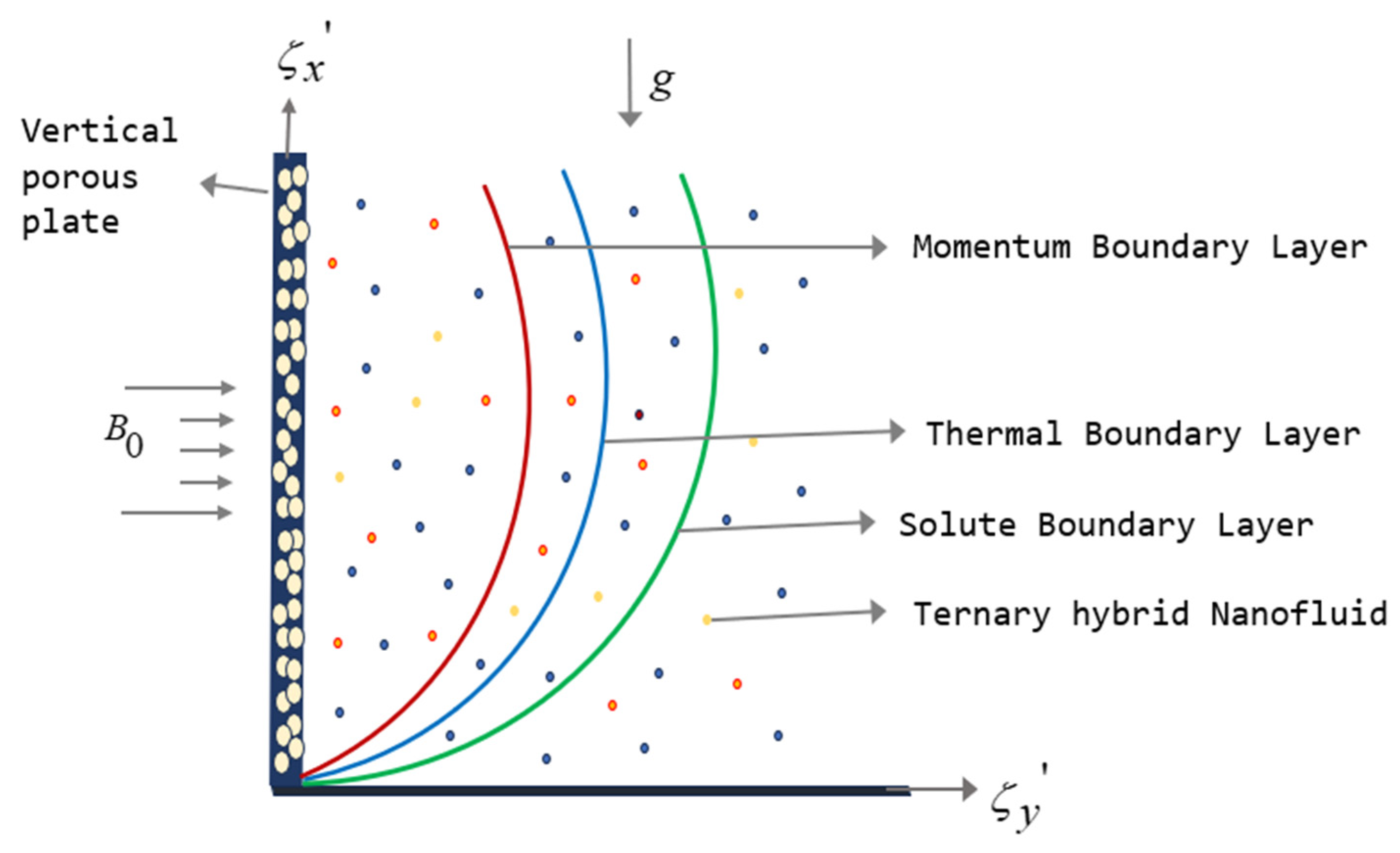

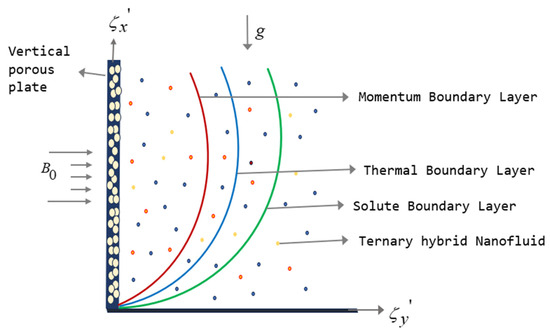

Unsteady MHD natural convective, heat, and mass transfer flow of viscous incompressible ternary hybrid nanofluid along infinite vertical porous plate influenced by Soret effect and thermal radiation is considered. Figure 1 illustrates the problem’s physical model.

Figure 1.

Physical model; modified from [3].

The way the coordinate system is considered is that, along the plate, the axis is positioned, and fluid is flowing past it. Perpendicular to it is the axis. Initially, at time , the plate and fluid remain stationary. They are held at temperature. At any point inside the fluid and on the surface of the plate, species concentration is . At > 0, the plate is accelerated exponentially with velocity against the gravitational field within its own plane. In a direction parallel to , , a uniform magnetic field, is applied. We examine two cases: In Case I, the concentration level close to the plate rises linearly over time, while the plate’s temperature rises at a uniform rate. In Case II, the concentration is elevated to , and the temperature increases linearly with respect to time. All physical parameters are considered to be functions of and only, as the flow of fluid is presumed to occur in the direction of axis . Also, it is assumed that pressure gradient, viscous dissipation, Hall effects, and Ohmic heating are all neglected. Although the fluid is gray, optically thick, absorbing, and producing radiation, it is considered a non-scattering medium. All colored circles are Ternary hybrid nanofluid. The magnetic field induced is disregarded, given that the fluid flow’s magnetic Reynolds number is considered to be relatively low. The momentum equation incorporates magnetic field and porous effects, while the energy equation includes thermal radiation and heat sink/source terms. The concentration equation accounts for the thermal diffusion term.

Under these assumptions and Boussinesq’s approximation, momentum, energy, and concentration governing equations are as follows [2,4]:

Momentum equation

Energy equation

Species diffusion equation

Boundary and initial conditions are as follows:

Case I:

Case II:

Radiative heat flux for an optically thick fluid can be calculated using Rosseland approximation, as follows:

Simplifying the Taylor series for about and neglecting higher-order terms, successive results are acquired, as follows:

Substituting (7) in (6) and differentiating with respect to , we obtain the following:

By replacing (8) in (2), the energy equation is simplified to the following:

We present the subsequent dimensionless quantities as follows:

After applying the transformations (10), Equations (1), (9), and (3) take the following form:

The boundary and initial conditions relevant to this situation are as follows:

Case I:

Case II:

Table 1 and Table 2 present the thermo-physical properties and their corresponding equations for ternary nanofluids.

Table 1.

Thermo-physical properties (Gopinath [40]).

Table 2.

Thermo-physical properties equations of ternary nanofluid (Gopinath [40]).

3. Methodology

The Laplace transform technique is an effective technique for resolving specific ordinary differential equations (ODEs) and partial differential equations (PDEs). It simplifies the process by transforming a differential equation into an algebraic equation, which is typically easier to handle. After solving the algebraic equation, the inverse transform is used to retrieve the original solution. Furthermore, the Laplace transform has widespread applications in various fields, including electrical circuit analysis, NMR spectroscopy, and signal processing.

The steps involved in the Laplace transform technique are as follows:

- (i)

- Take the Laplace transform of the equation.

- The Laplace transform of a function is as follows:

- Where is the Laplace parameter

- (ii)

- Transform the differential equation into an algebraic equation.

- Convert the differential equation into an algebraic equation in terms of

- (iii)

- Solve for in the Laplace Domain.

- The inverse Laplace transform is applied to retrieve the physical solutions in the time domain =

Case I:

By applying conditions (14), the dimensionless governing Equations (11)–(13) are solved using an analytical approach (i.e., the Laplace transform method). The consequent solutions are for velocity, temperature, and concentration fields (Appendix A):

Velocity

Temperature

Concentration

Case II:

The non-dimensional governing Equations (11)–(13) are solved using an analytical approach (i.e., the Laplace transform) with conditions (15). Following are mathematical expressions for velocity, temperature, and concentration (Appendix A):

Velocity

Temperature

Concentration

4. Results and Discussions

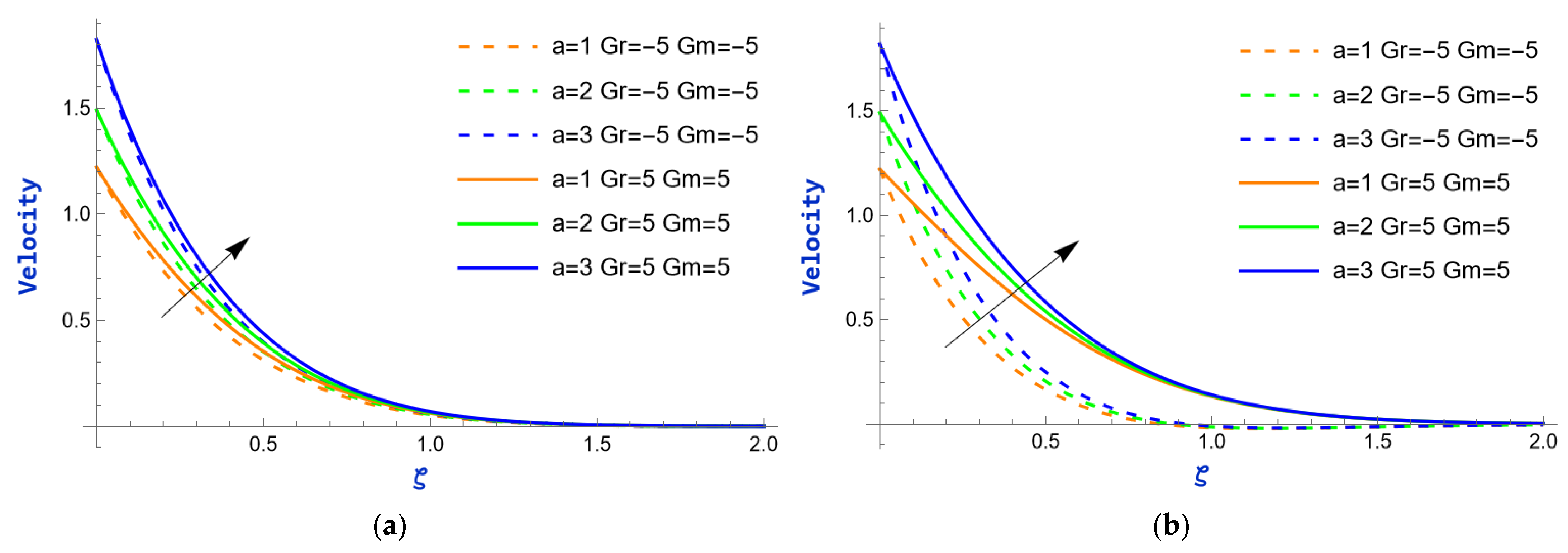

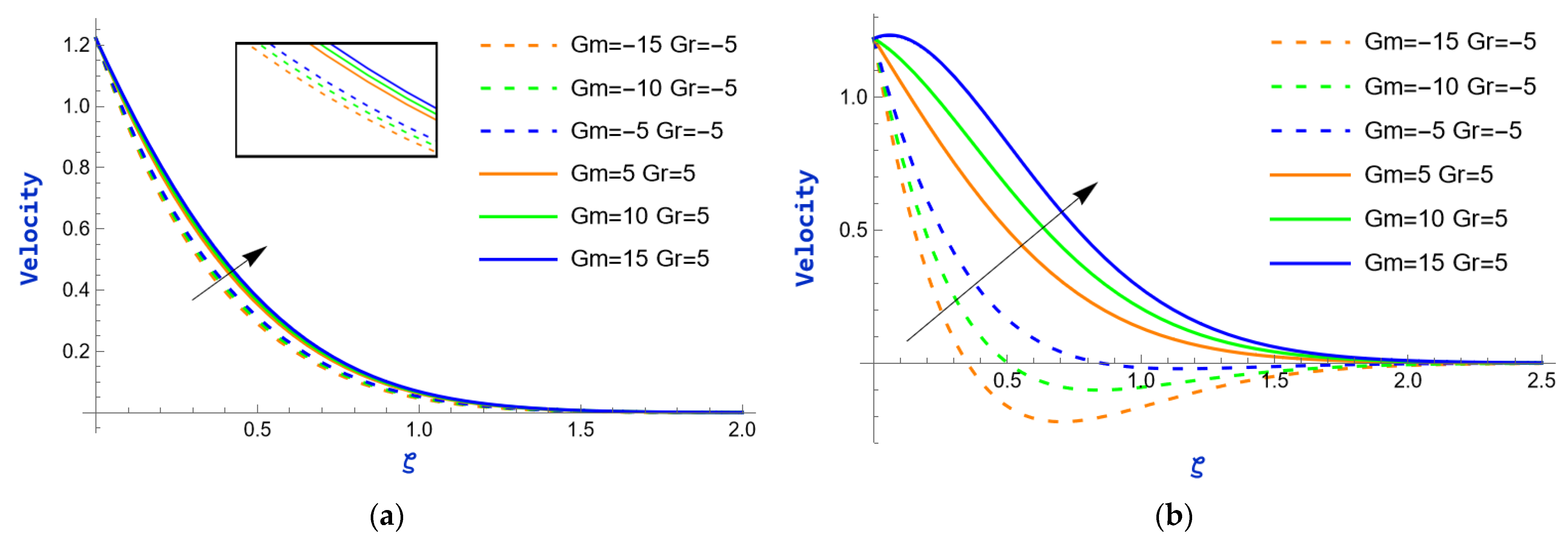

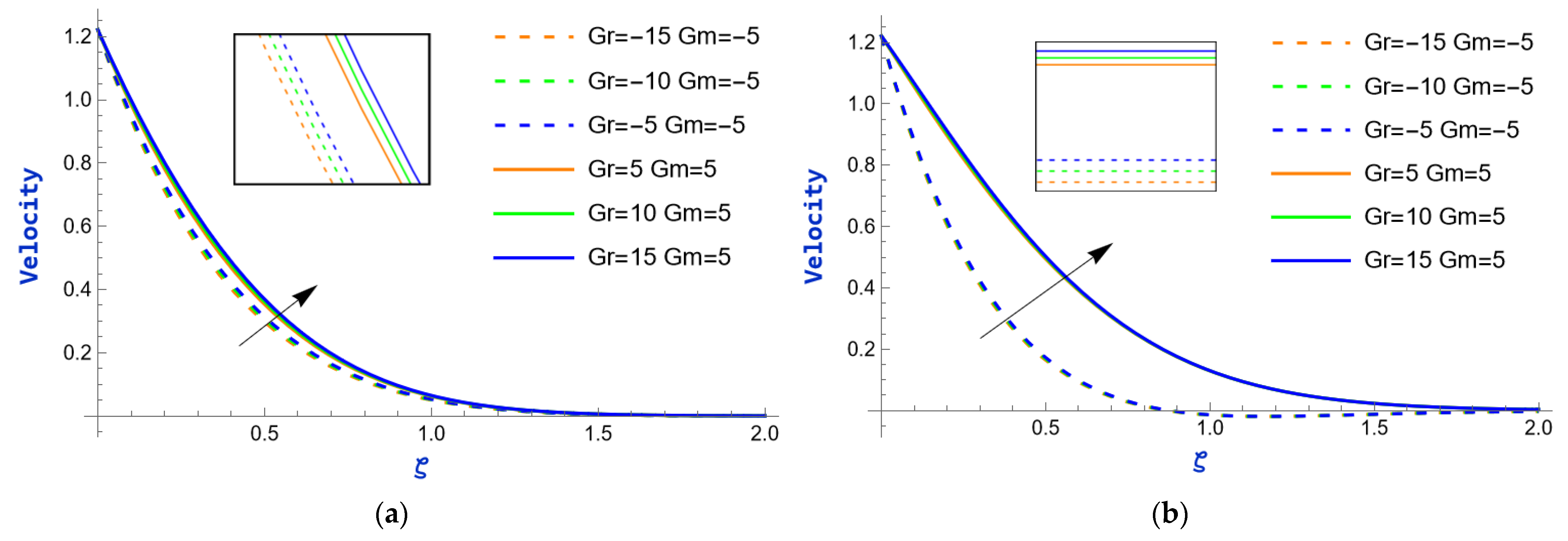

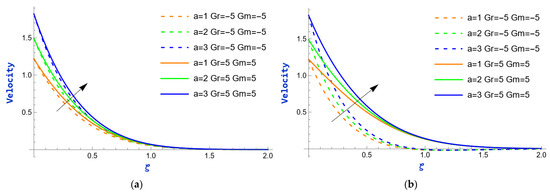

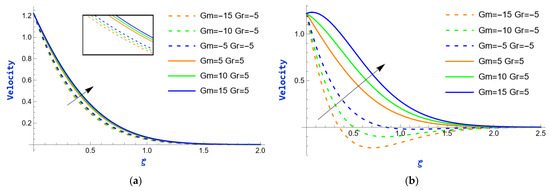

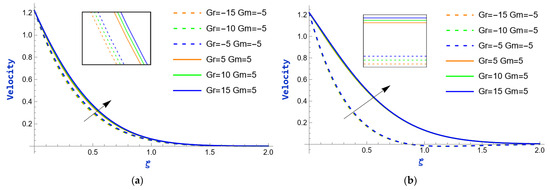

This section is dedicated to examining the numerical computations and the impact of relevant non-dimensional parameters on the distributions of velocity, temperature, and concentration. The results are illustrated graphically in figures, while non-dimensional derived quantities are discussed through tabulated values. Acknowledged for its symbolic computing power, Mathematica is utilized to analytically resolve the intricate system of mathematical equations. To find the numerical resolution of the equations, MATLAB (2025a) software is used. Figure 2a, Figure 3a, Figure 4a, Figure 5a, Figure 6a, Figure 7a, Figure 8a, Figure 9a, Figure 10a, Figure 11a, Figure 12a, Figure 13a, Figure 14a and Figure 15a illustrate the profiles of velocity, temperature, and concentration for Case I, while Figure 2b, Figure 3b, Figure 4b, Figure 5b, Figure 6b, Figure 7b, Figure 8b, Figure 9b, Figure 10b, Figure 11b, Figure 12b, Figure 13b, Figure 14b and Figure 15b present the corresponding profiles for Case II. In the current investigation, calculations are carried out using the following default parameter values: = ±5, = ±5, = 1, = 0.5, = 0.5, = 0.6, = 1, = 0.01, = 0.02, and = 0.03.

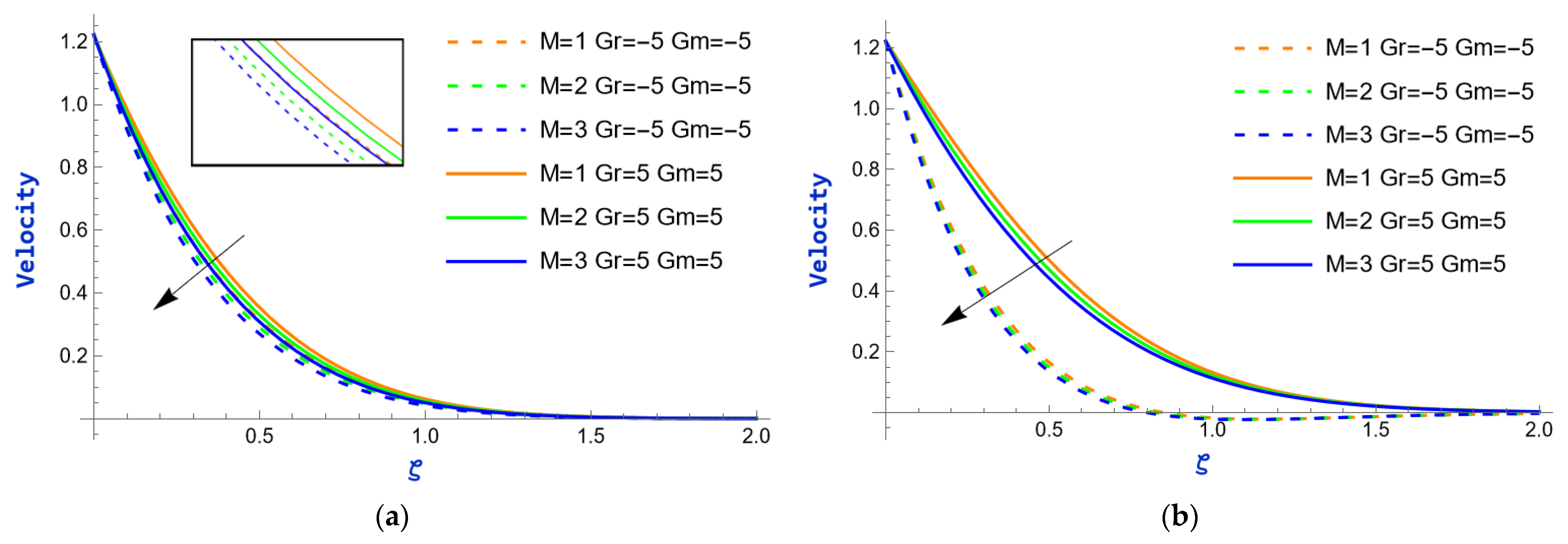

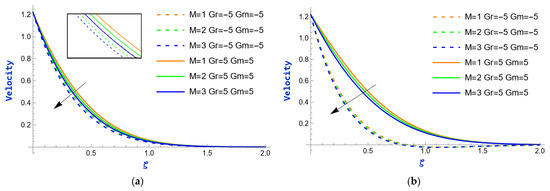

Figure 2.

Velocity against different in Case I (a) and II (b).

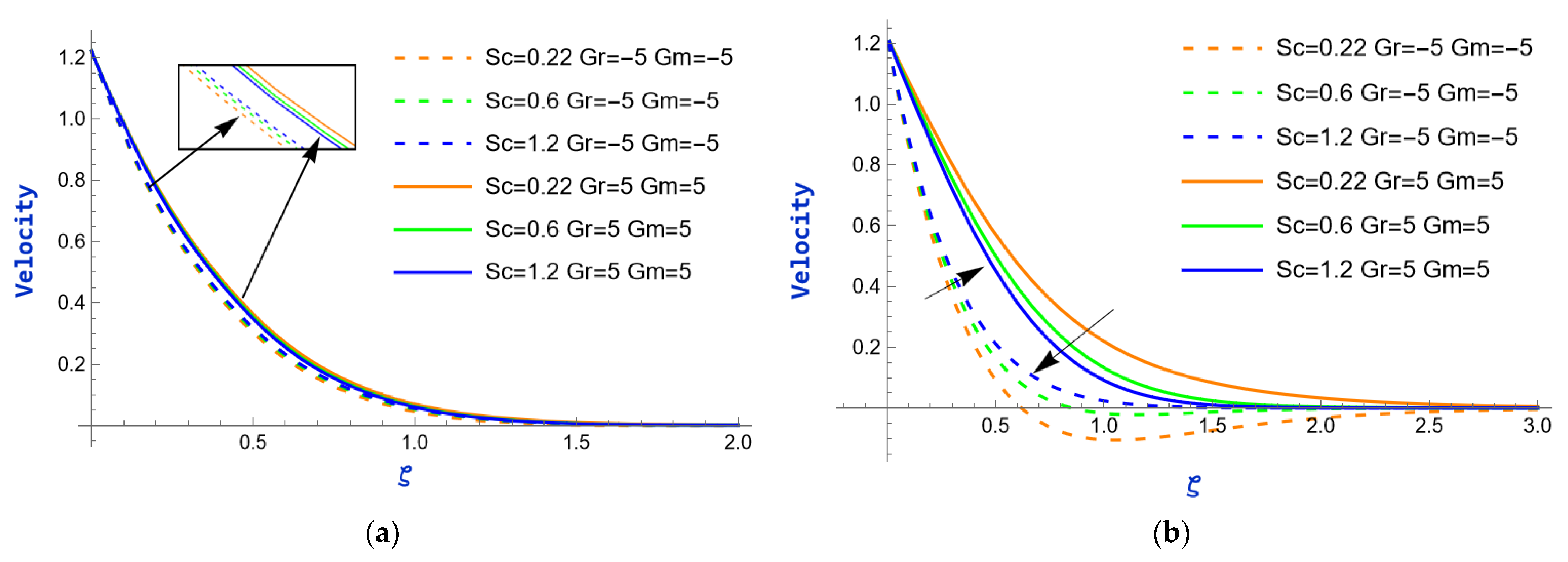

Figure 3.

Velocity against different in Case I (a) and II (b).

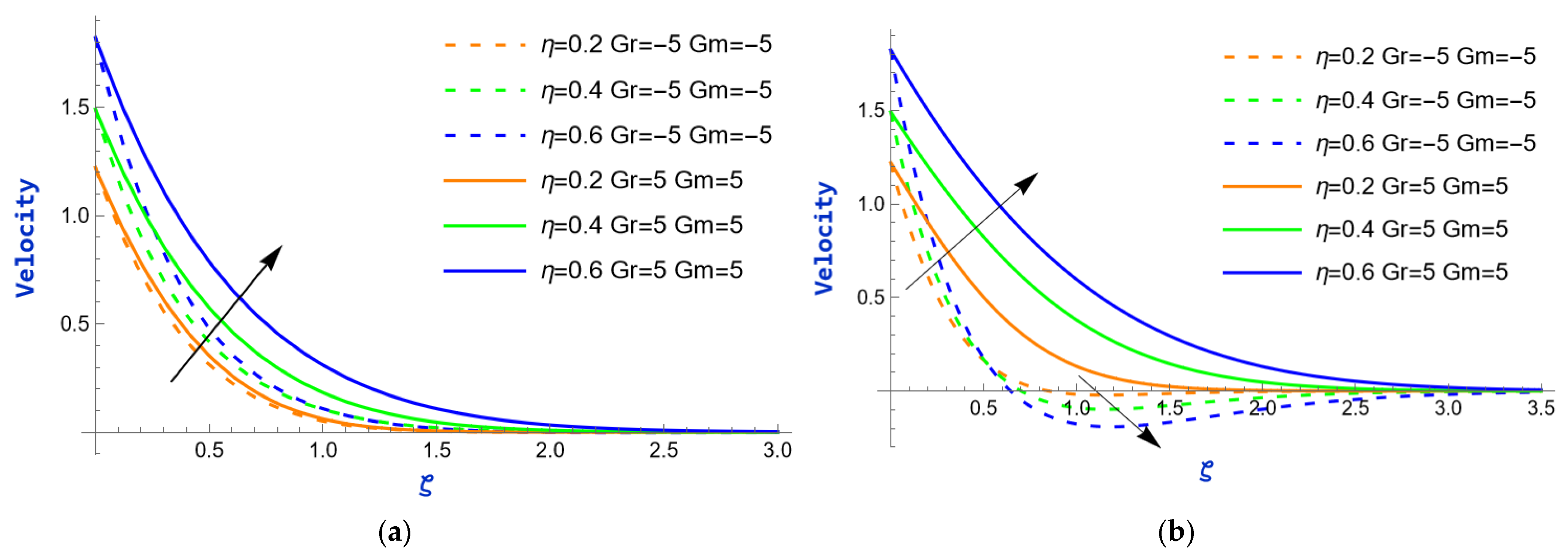

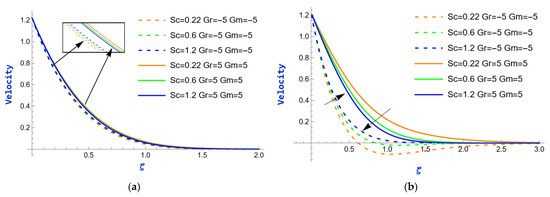

Figure 4.

Velocity against different in Case I (a) and II (b).

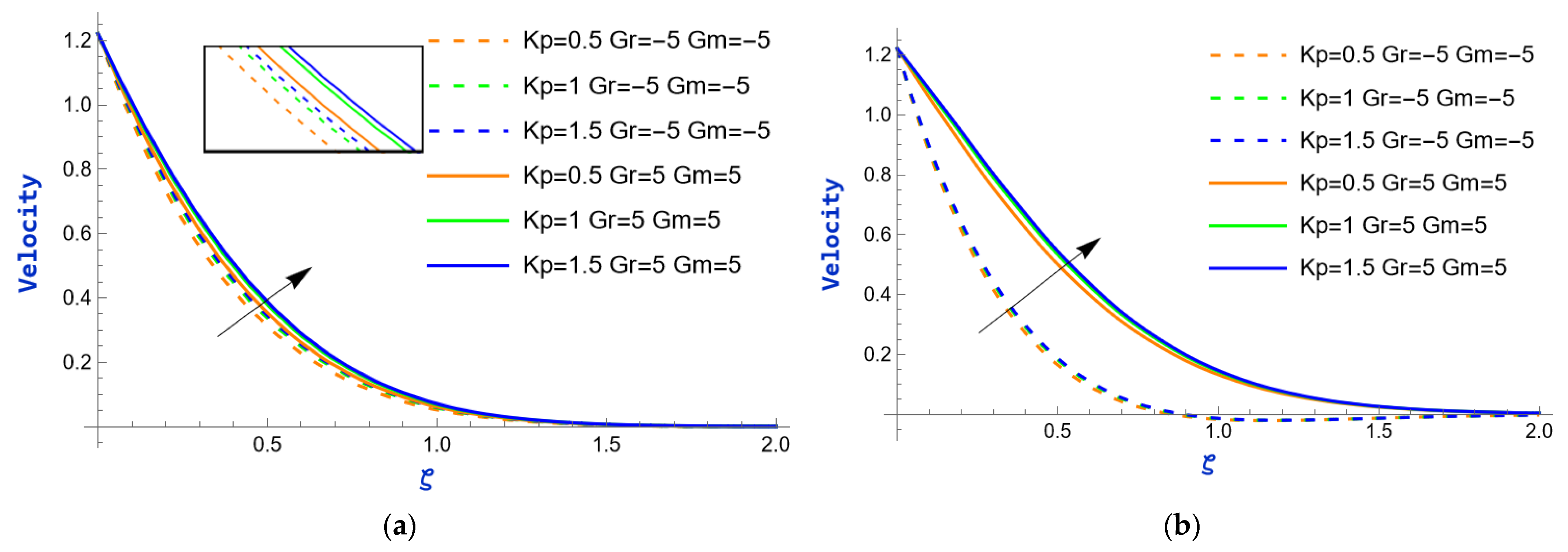

Figure 5.

Velocity against different in Case I (a) and II (b).

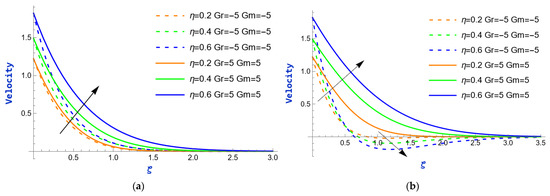

Figure 6.

Velocity against different in Case I (a) and II (b).

Figure 7.

Velocity against different in Case I (a) and II (b).

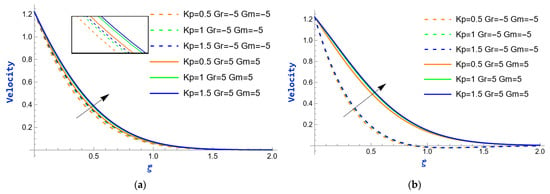

Figure 8.

Velocity against different in Case I (a) and II (b).

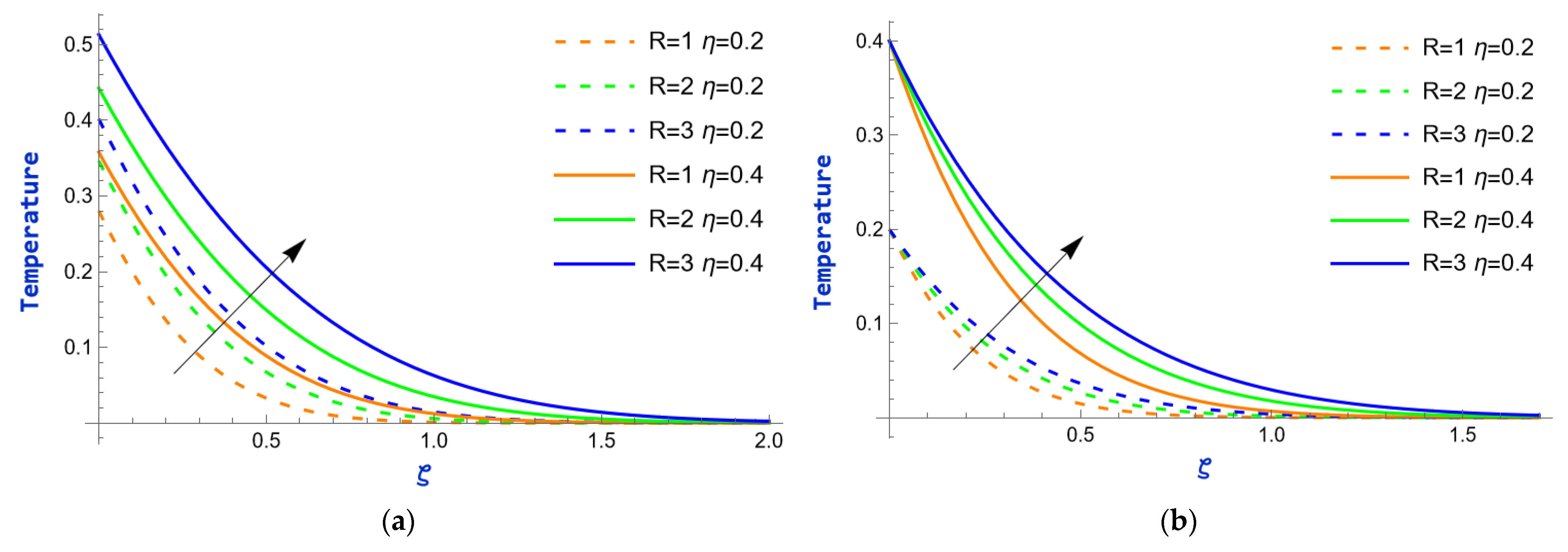

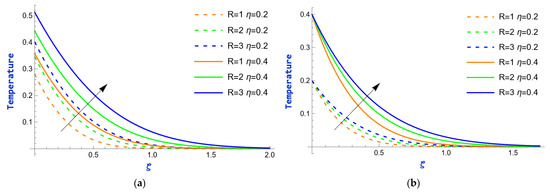

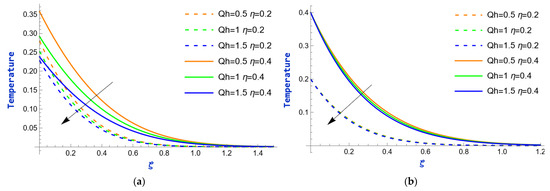

Figure 9.

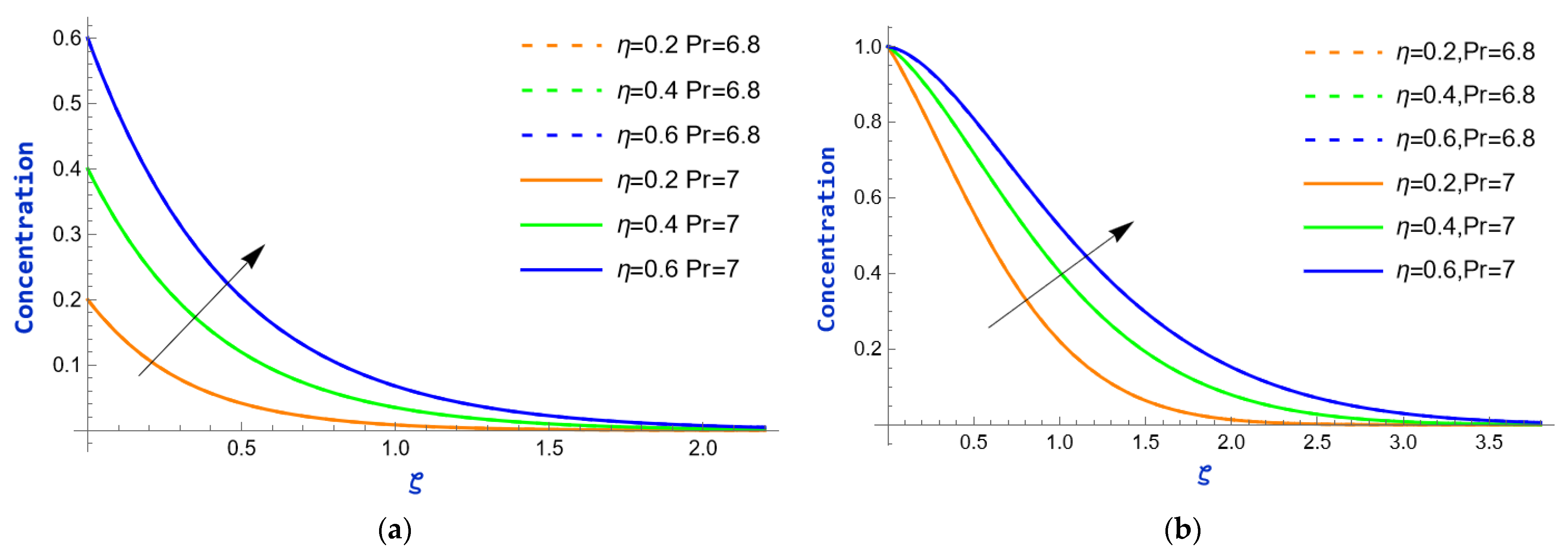

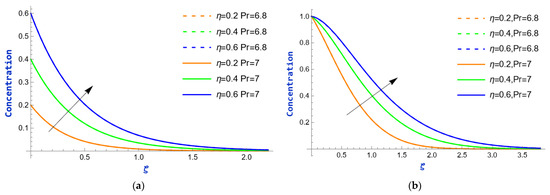

Temperature against different in Case I (a) and II (b).

Figure 10.

Temperature against different in Case I (a) and II (b).

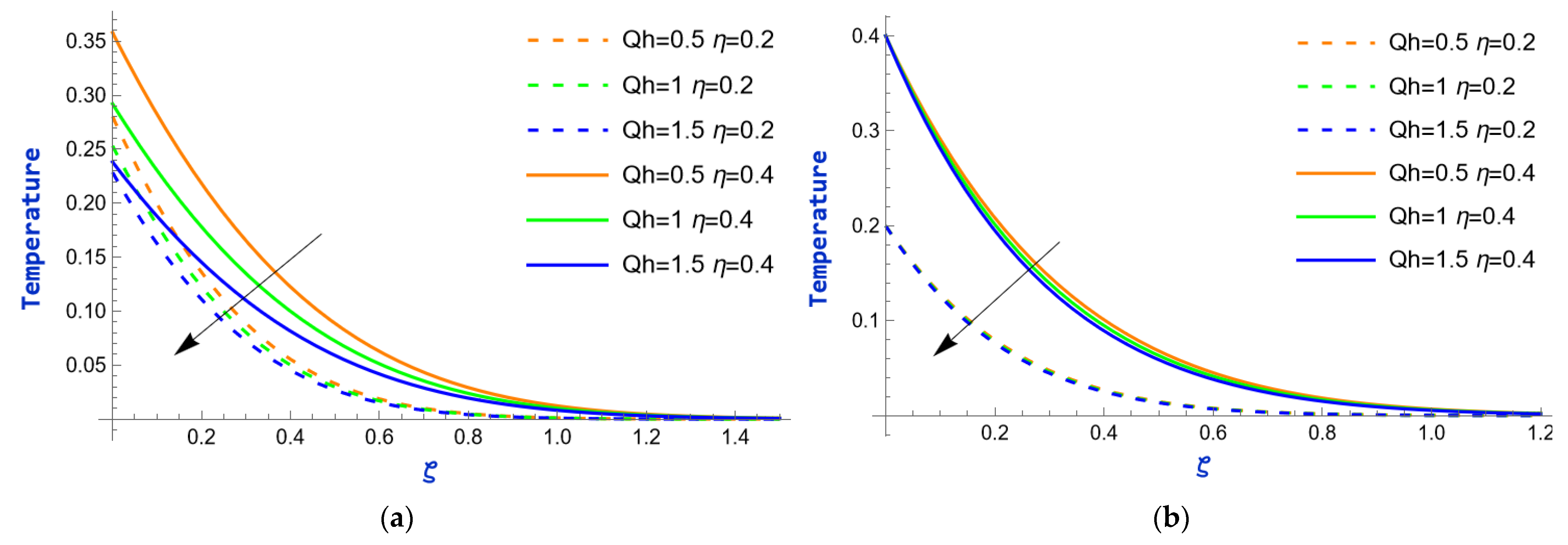

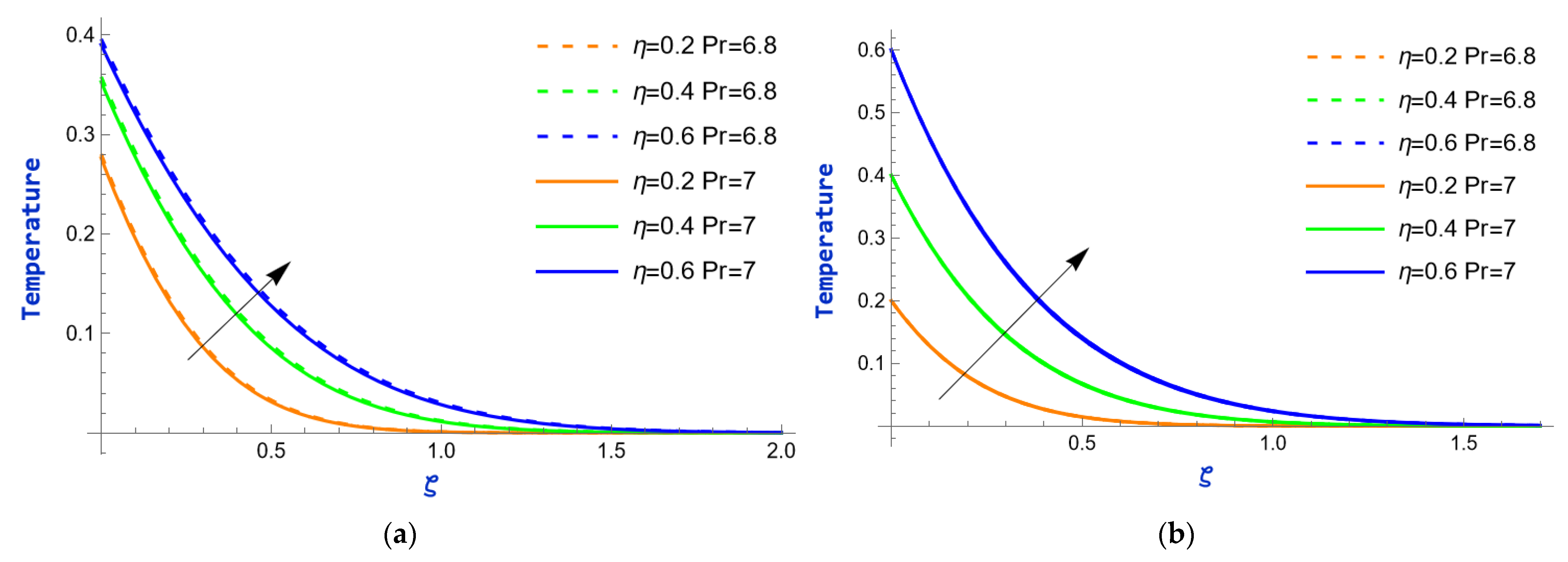

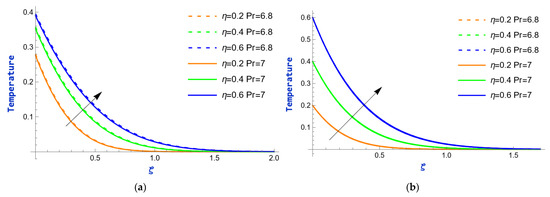

Figure 11.

Temperature against different in Case I (a) and II (b).

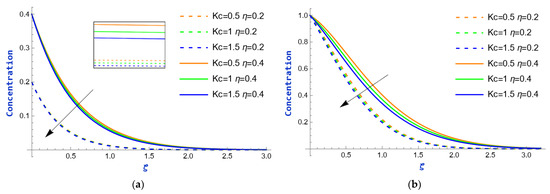

Figure 12.

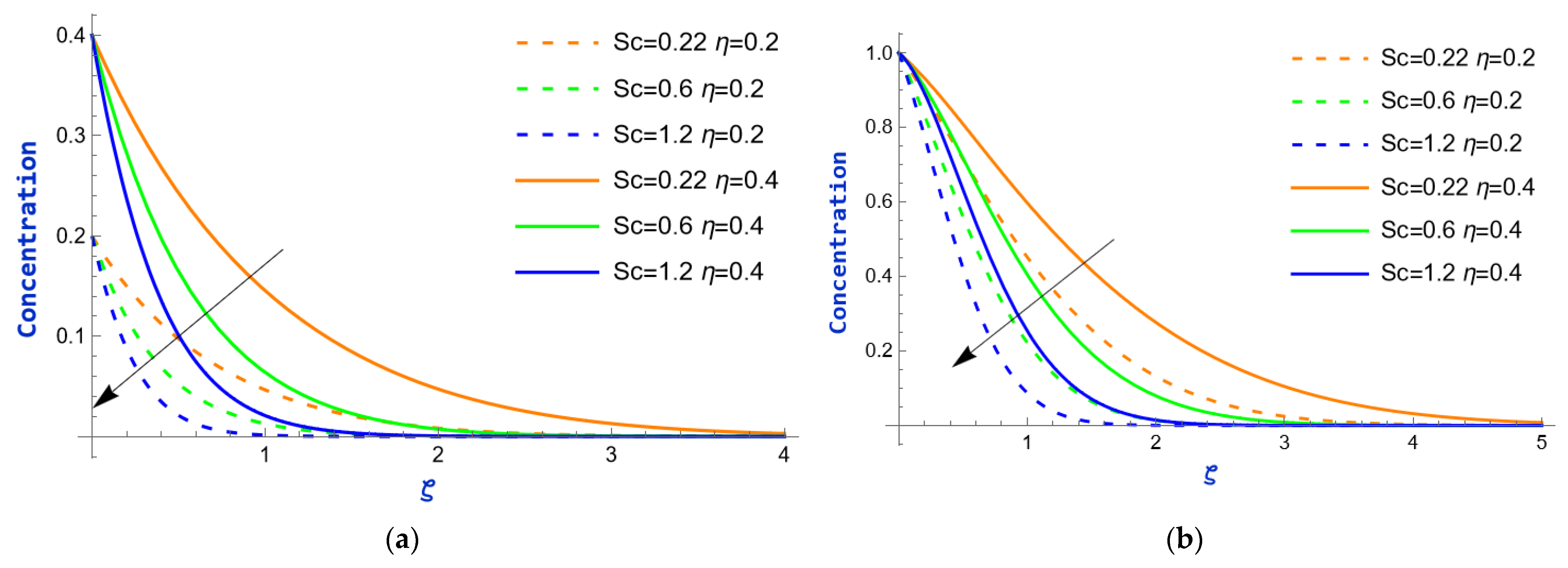

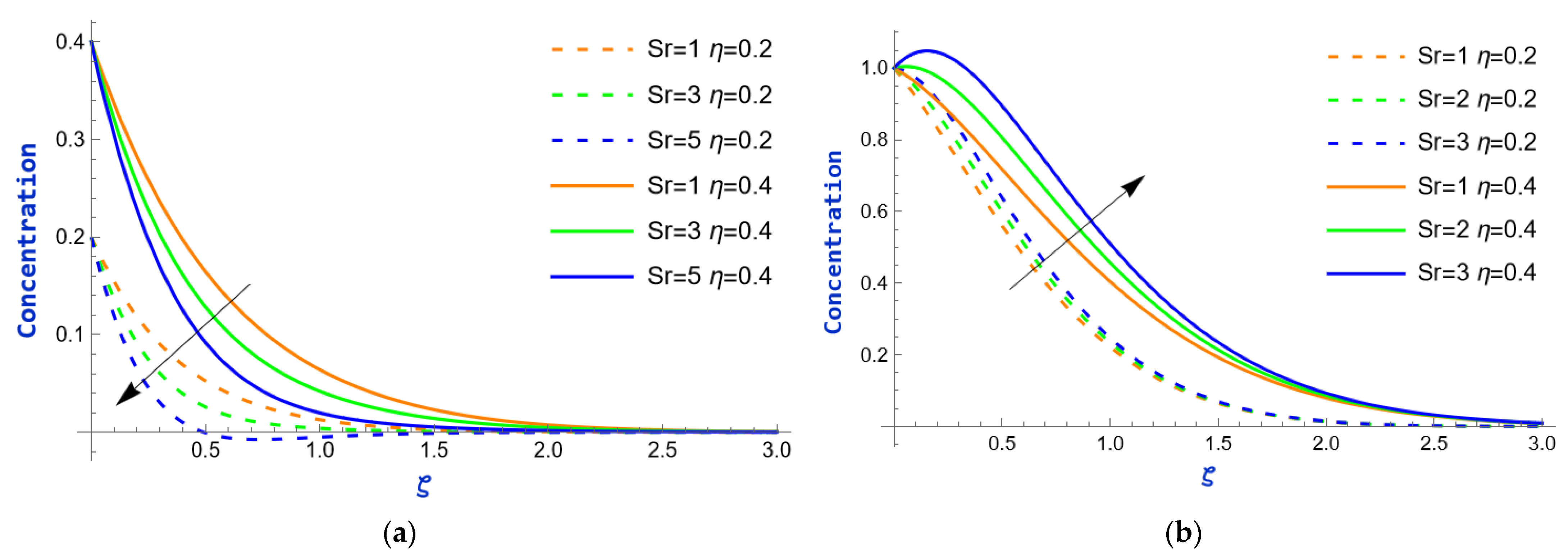

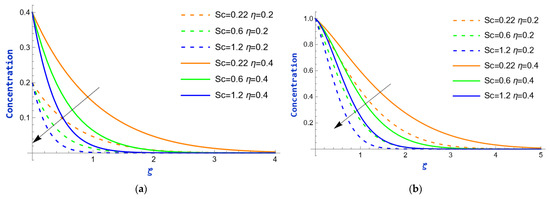

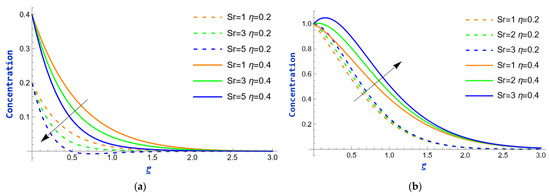

Concentration against different in Case I (a) and II (b).

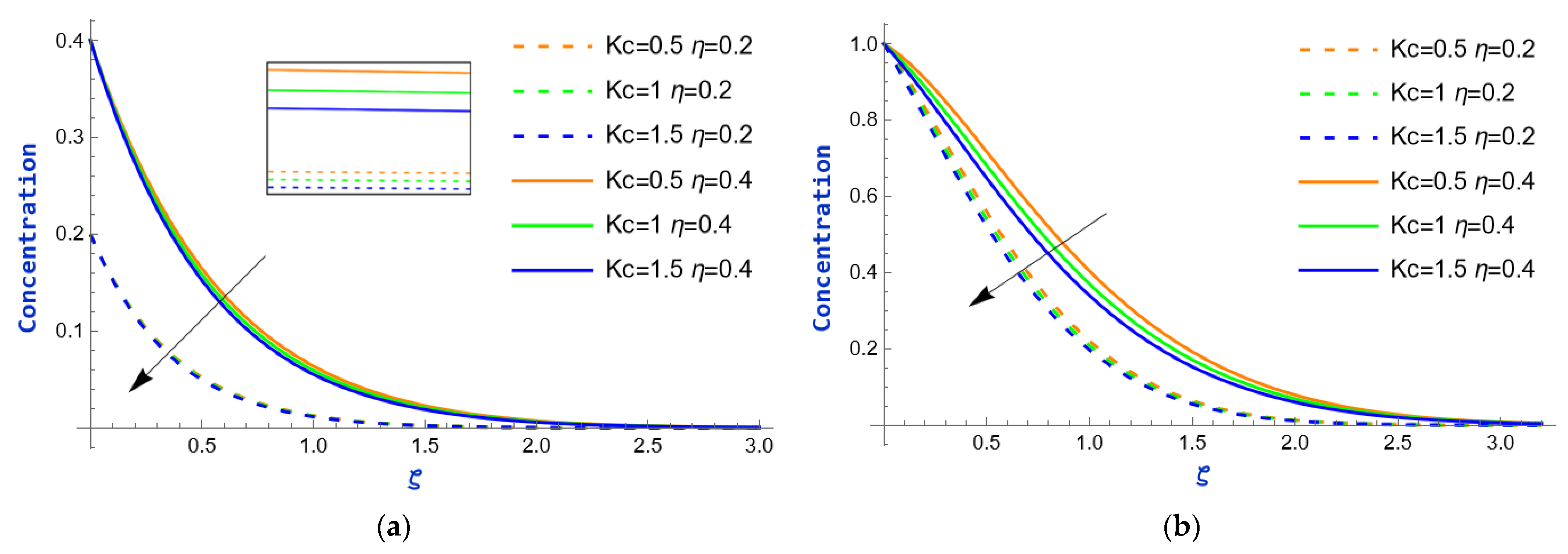

Figure 13.

Concentration against different in Case I (a) and II (b).

Figure 14.

Concentration against different in Case I (a) and II (b).

Figure 15.

Concentration against different in Case I (a) and II (b).

The velocity variation caused by the exponential parameter during heating and cooling (i.e., and ) of the plate is shown in Figure 2. In both figures, it is evident that the velocity exhibits an upward trend as the values of rise. This is because, at the boundary layer, where viscosity has a disproportionately large impact, the velocity profile frequently exhibits a sharp increase as the exponential parameter rises. The consequences of the mass Grashof number () on velocity profiles for fixed values of (i.e., ) are depicted in Figure 3. The mass Grashof number is a non-dimensional number that characterizes the relative effects of buoyancy and viscous forces in fluid flow due to mass transfer. When is high, it indicates that buoyancy forces (due to differences in concentration or temperature) are dominant compared to viscous forces. This dominance results in an augmentation of flow velocity because buoyancy forces promote fluid motion, causing it to accelerate. Consequently, in both scenarios, as strengthens, the velocity rises. Additionally, there is a significant increase in the momentum boundary layer thickness. The impact of the thermal Grashof number () on velocity profiles is observed in Figure 4, while the values of are held constant (i.e., ). The thermal Grashof number, , is a dimensionless term that measures the relative importance of thermal buoyancy forces to viscous forces in fluid flow, particularly in natural convection scenarios. The velocity enhances as increases. This relationship arises because a higher denotes a stronger influence of thermal buoyancy forces compared to viscous forces. As thermal buoyancy becomes more significant, viscous forces are diminished, reducing resistance. This facilitates the fluid’s movement, resulting in higher velocity profiles within the flow.

Figure 5 illustrate the consequence of the magnetic parameter, , on velocity profiles associated with the processes of plate heating and cooling. As the magnetic parameter’s intensity increases, the velocity declines in both cases. The generation of a retarding force, known as the Lorentz force, occurs due to an increase in the magnetic parameter. The Lorentz force opposes the direction of fluid flow when charged particles are exposed to electric and magnetic fields. This opposition leads to a larger slowdown of the flow. Figure 6 highlight the consequence of the Schmidt number, , on velocity profiles for < 0, < 0, > 0, and > 0. , the Schmidt number, measures the ratio of momentum diffusivity (viscosity) to mass diffusivity in a fluid. The behavior of velocity profiles with varying depends on whether the Grashof numbers ( and ) are positive or negative, as these numbers represent the influence of buoyancy forces due to temperature and concentration gradients, respectively. For positive Grashof numbers, an increase in the Schmidt number reduces velocity profiles due to lower momentum transfer efficiency. Conversely, for negative Grashof numbers, a higher Schmidt number increases velocity profiles as buoyancy forces enhance flow, even with thicker boundary layers. This pattern is evident in both scenarios. Figure 7 represent the changes in fluid velocity at different time intervals during the heating and cooling processes of the plate. In Figure 7a, velocity is augmented with a rise in for both positive and negative Grashof numbers. This is often a result of combined effects like momentum transfer, thermal expansion, and the interaction of external forces in the flow system. In Figure 7b, velocity expands for increasing values of for > 0 and > 0 in the vicinity of the plate. For < 0, < 0, velocity rises up to the point of separation, and beyond this point, in the succeeding flow region, we observe a reduction in velocity for higher values of . The initial increase in velocity is due to the establishment of flow and momentum transfer, while the subsequent decrease can result from boundary layer effects, flow separation, changes in fluid properties, or external influences that alter the flow dynamics.

The profiles of velocity for various values of the permeability parameter,, under both heating and cooling conditions of the plate are presented in Figure 8. The corresponding figures indicate that a spike in the value of contributes to an increase in the momentum boundary layer thickness. Due to an advancement in the porosity parameter, the permeability of the medium improves, meaning there is less obstruction to fluid motion within the pores. This allows the fluid to move more freely, thus increasing the velocity within the boundary layer. The impact of the radiation parameter, , on temperature profiles at = 0.2 and = 0.4 is depicted in Figure 9. Thermal radiation is the release of energy from a body’s surface in the form of electromagnetic waves, mostly infrared. An increment in the thermal radiation parameter causes the amount of heat energy radiated to the surrounding fluid to increase, thus contributing additional energy to the system. This energy is absorbed by the fluid, which raises the temperature. Figure 10 provides an analysis of the influence of the heat absorption parameter, , on temperature profiles. An increase in the heat absorption parameter typically indicates that more heat is being removed from the system. This greater heat extraction will cause a reduction in the overall temperature of the fluid, as the energy available to raise the temperature is diminished. So, as increases, the temperature decreases. Figure 11 exemplify the effect of time, , on the temperature field for the values of = 6.8 and = 7. Observations indicate that the temperature rises rapidly as the value of increases.

Figure 12 depict the concentration distribution as a function of , considering the relevance of the chemical reaction parameter, , at = 0.2 and = 0.4, respectively. A first-order chemical reaction is a reaction where the rate of reaction is directly proportional to the concentration of a single reactant. In both cases, an increase in displays a contrasting effect on concentration, indicating that the fluid’s concentration progressively declines as the value of augments. The reason behind this is that as expands, the consumption of the species accelerates, resulting in a considerable drop in its concentration. The effect of the Schmidt number, , on concentration profiles at = 0.2 and = 0.4 is displayed in Figure 13. An upsurge in appears to lead to a decrease in both concentration distribution and its boundary layer thickness. From the perspective of physics, the Schmidt number , a dimensionless quantity used in fluid mechanics and mass transfer, is expressed as the ratio of kinematic viscosity (momentum diffusivity) to mass diffusivity. As a result, when increases, the diffusion of the solute or species becomes less effective relative to momentum transfer, leading to a decrease in concentration over time. Figure 14 depicts the consequence of the Soret effect parameter, , on the concentration fields of flow. The Soret effect, also termed thermal diffusion, refers to the phenomenon in which a temperature gradient causes the movement of species or particles in a mixture, leading to a concentration gradient. Usually, higher thermal diffusion drives the species away from the region, reducing the overall concentration. Thus, in Case I, a rise in culminates in a reduction in the thickness of the concentration boundary layer. However, in Case II, a surge in concentration profiles is observed with enhancing values of . The reason is that, as increases, the concentration rises because a stronger Soret effect causes species to migrate more efficiently from hotter regions to cooler regions, leading to a higher accumulation of species in the cooler regions. The repercussions of time on the concentration field are portrayed in Figure 15 for = 6.8 and = 7. In each case, it is observed that the concentration exhibits an upward trend as the values of grow.

4.1. Skin Friction Coefficient, Nusselt Number, and Sherwood Number

Skin friction coefficient, at .

Nusselt number, at .

Sherwood number, at .

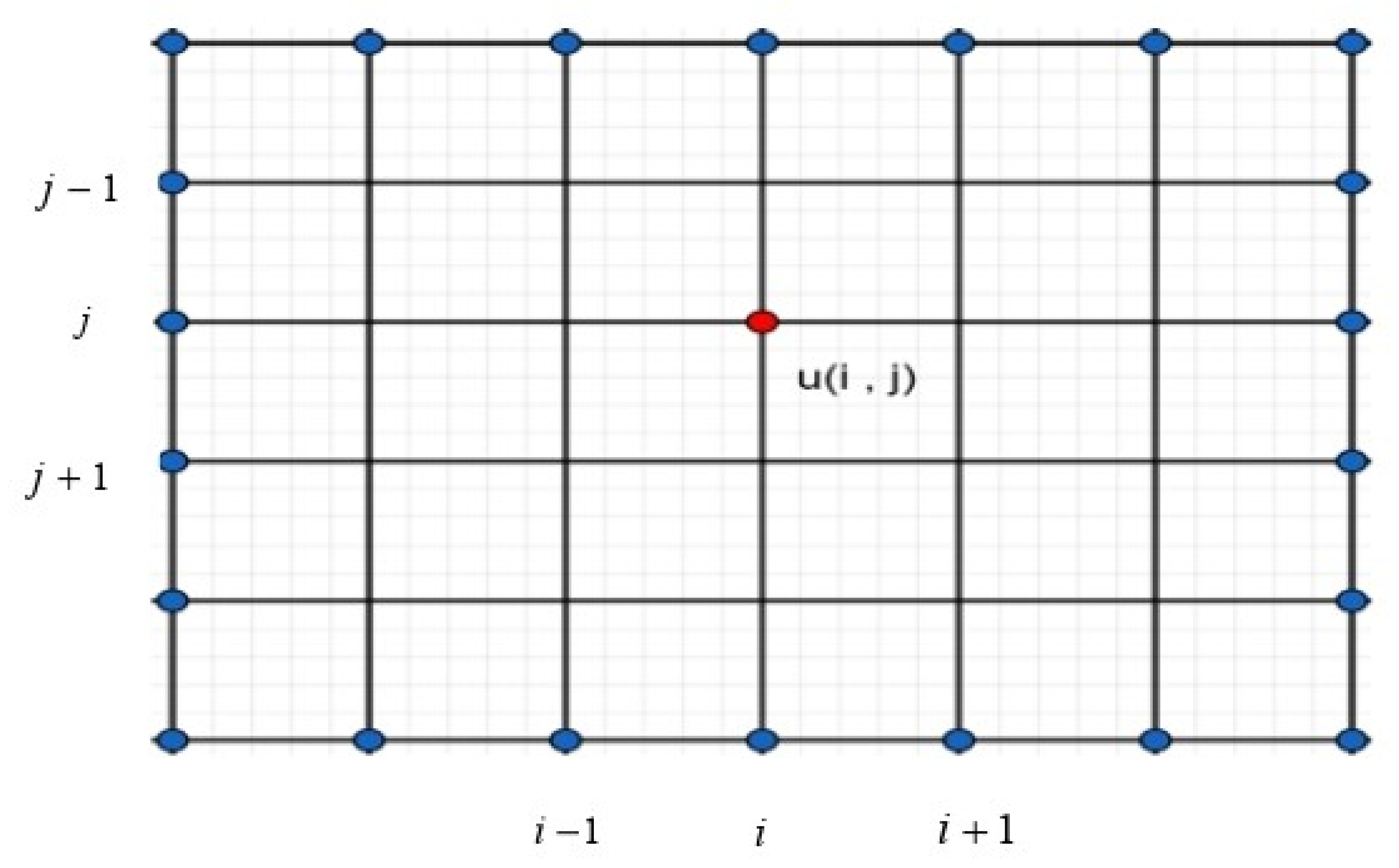

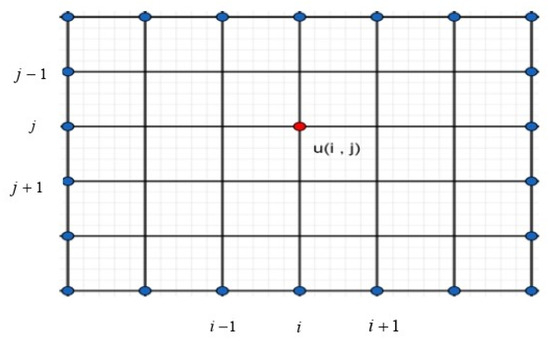

4.2. Finite Difference Method

The finite difference method (FDM), recognized as a stable and convergent approach, is a numerical technique that solves differential equations by approximating derivatives using finite differences. This approach transforms differential equations into a system of algebraic equations, making it easier to compute solutions. FDM is used in this research to validate Case II Sherwood number results by comparing values from these numerical simulations with those produced using analytical techniques.

The following are the finite difference approximations for Equations (11)–(13):

The initial and final conditions (15) are expressed as follows:

Index : ; index : .

The finite difference grid used for numerical computations is illustrated in Figure 16.

Figure 16.

Finite difference grid.

Table 3 provides the validation of the Sherwood number for both cases, while Table 4, Table 5 and Table 6 present the skin friction coefficient, Nusselt number, and Sherwood number, respectively, as computed in the current study.

Table 3.

Sherwood number validation.

Table 4.

Skin friction.

Table 5.

Nusselt number.

Table 6.

Sherwood number.

This table presents a comparison of the Sherwood numbers obtained in Case I with those reported by Rajesh and Varma [2]. For Case II validation, it compares the Sherwood numbers derived from both the FDM and Laplace transform approaches. Here, = 0.71, = 0, = 0, = 0, and = = = 0

This table displays the skin friction coefficient for various pertinent physical parameters.

Table 5 presents the Nusselt number and heat transfer rate for various relevant physical parameters.

The Sherwood number and mass transfer rate for various pertinent physical parameters are displayed in Table 6.

4.3. Contour Plots

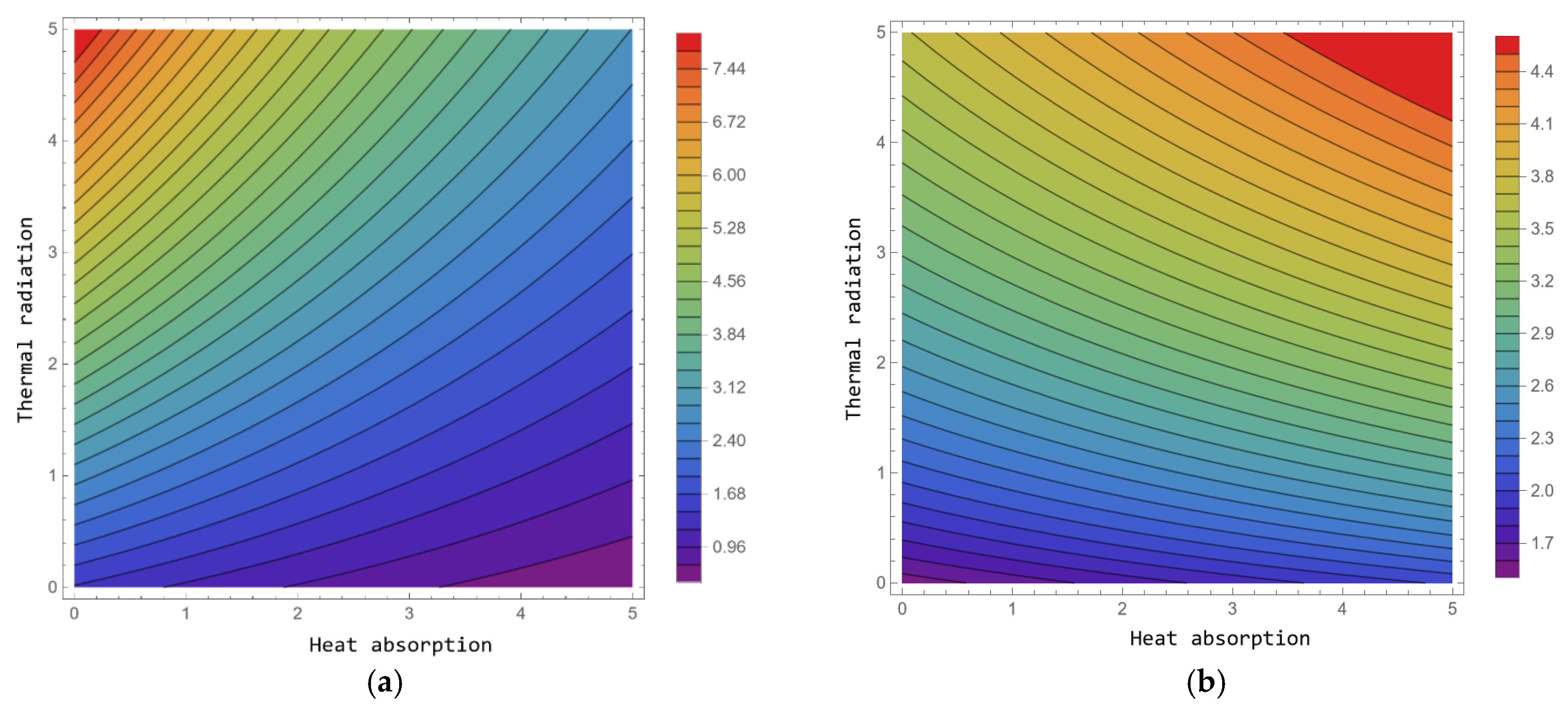

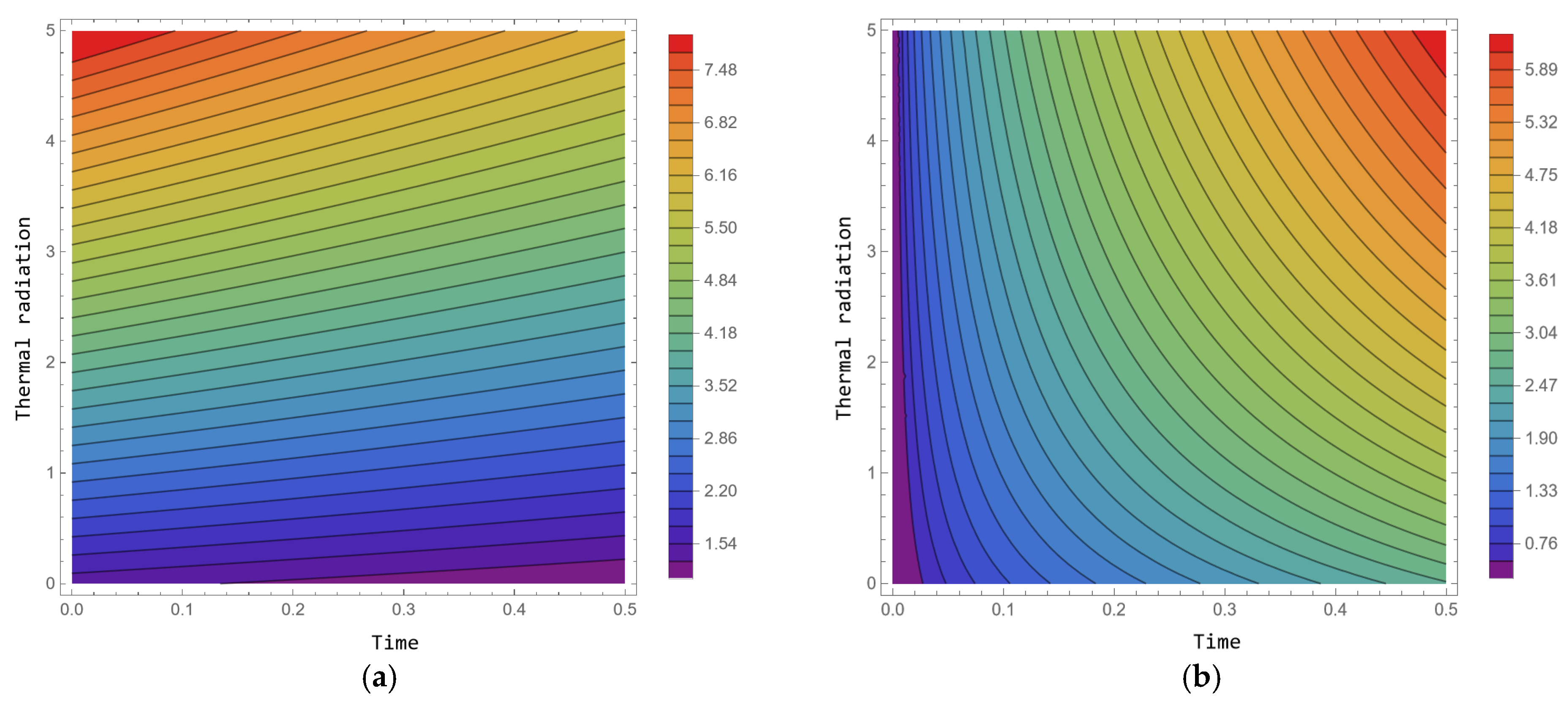

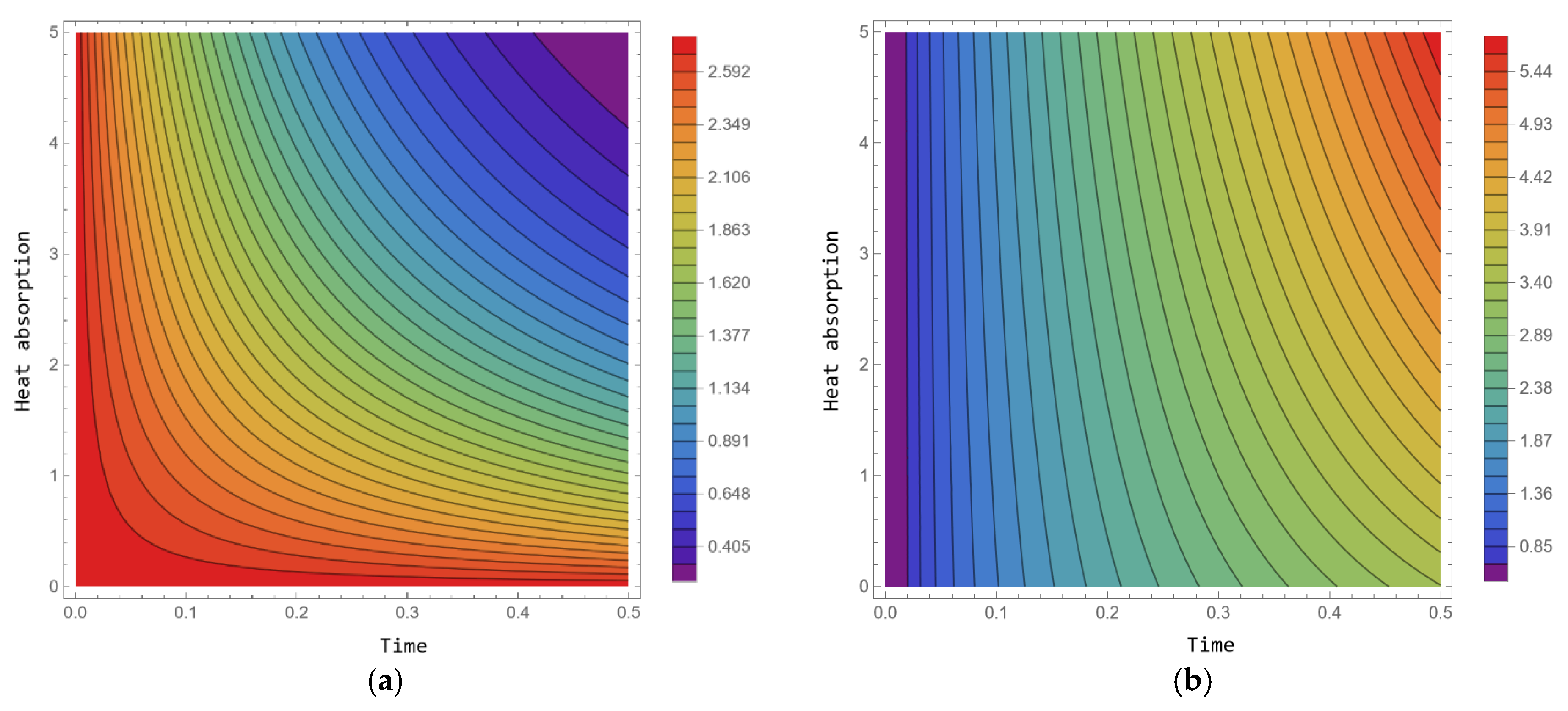

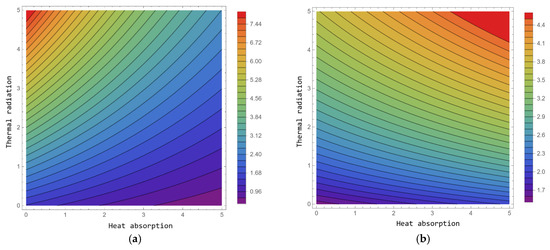

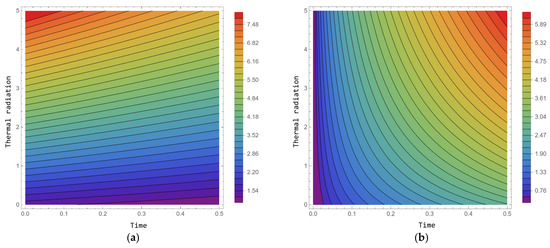

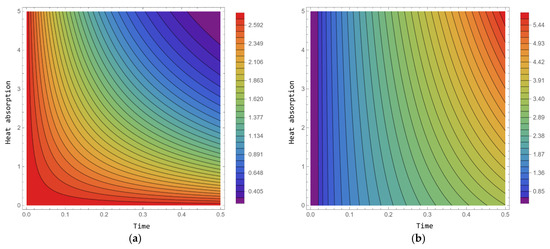

Contour plots for the Nusselt number, , are valuable tools for understanding the relationship between this dimensionless number and various parameters affecting heat transfer. It is a critical factor that indicates the relative dominance of convection over conduction in a given heat transfer scenario. Figure 17, Figure 18 and Figure 19 depict the contour plots of the Nusselt number concerning various active parameters (, , and ) in both scenarios.

Figure 17.

Contour plot of with varying and in Case I (a) and II (b).

Figure 18.

Contour plot of with varying and in Case I (a) and II (b).

Figure 19.

Contour plot of with varying and in Case I (a) and II (b).

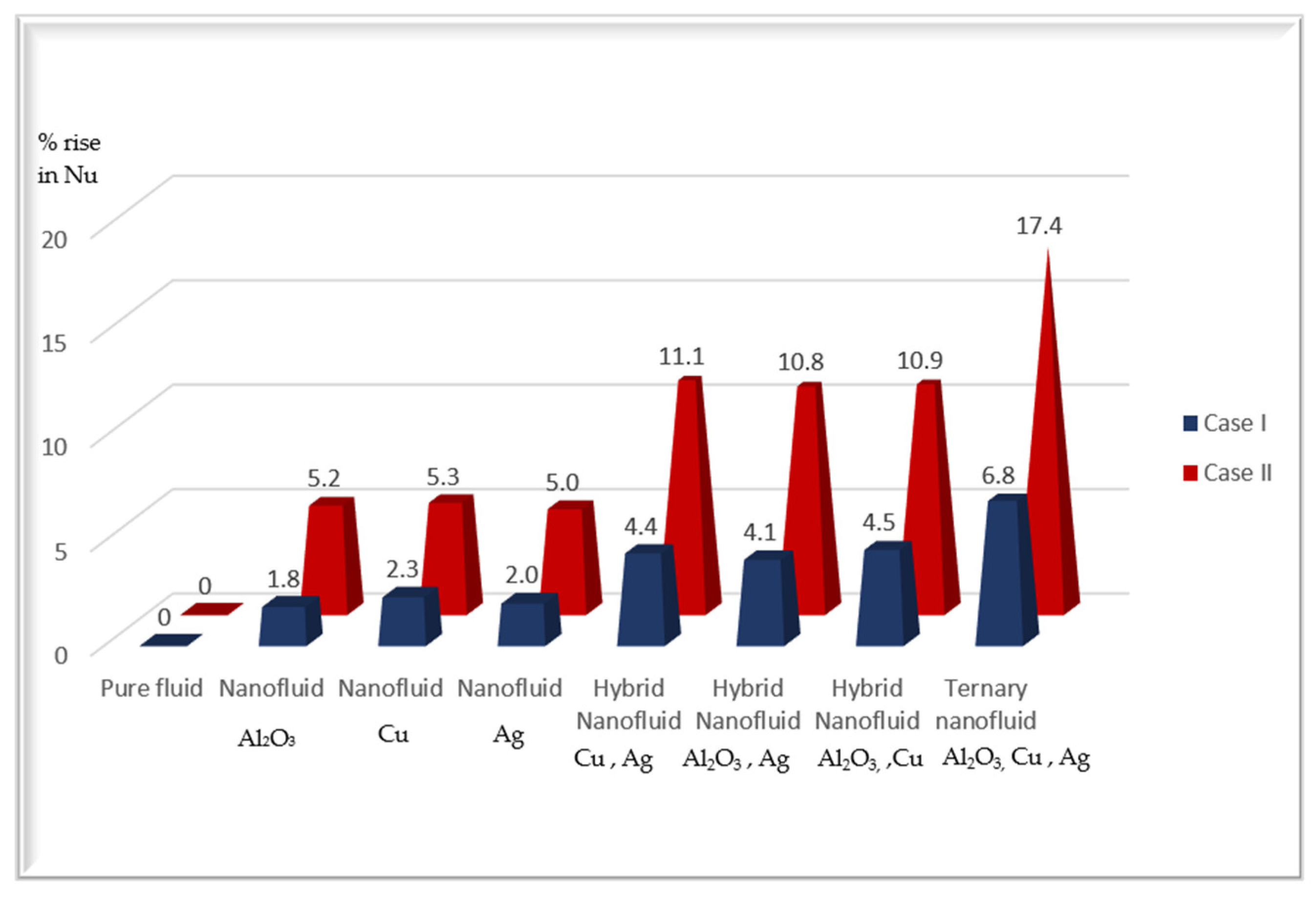

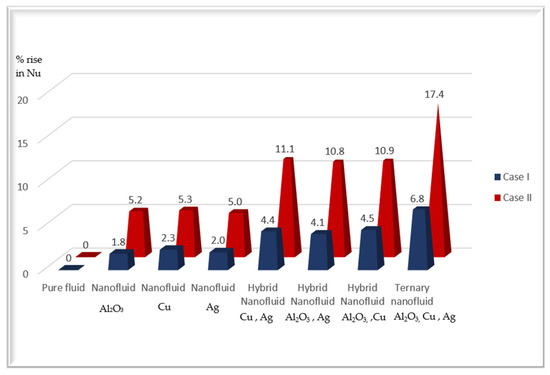

Figure 20 illustrates the percentage increase in the Nusselt number for pure fluid, nanofluid, hybrid nanofluid, and ternary nanofluid. The figure clearly demonstrates that the rate of heat transfer is lowest for the pure fluid and progressively increases with the addition of nanoparticles.

Figure 20.

Percentage rise in the rate of heat transfer with the inclusion of nanoparticles.

5. Conclusions

An investigation is conducted into the time-dependent free convective MHD flow of a ternary hybrid nanofluid adjacent to an infinitely long, vertical porous plate that is exponentially accelerated, focusing on two distinct cases. This flow model has several practical applications across various engineering and industrial fields. Some notable applications include thermal management in electronic devices, cooling systems in nuclear reactors, spacecraft thermal protection, pollutant removal in environmental engineering, chemical and petrochemical engineering, biological and medical applications, and air–water purification.

This research highlights several critical outcomes, notably the following:

- The flow field increases with a rise in the exponential parameter, as well as with the thermal and mass Grashof numbers. However, an increase in the magnetic parameter has a detrimental effect on the flow.

- The temperature field increases with the thermal radiation parameter but decreases as the heat absorption parameter rises. In contrast, the concentration field decreases with higher values of the chemical reaction parameter.

- Both the thermal and mass Grashof numbers significantly impact the skin friction coefficient, leading to a reduction in shear stress rates within fluid flows.

- The heat transfer rate is enhanced by the presence of thermal radiation, while the heat sink causes a considerable reduction in fluid temperature.

- The Soret effect has a varying influence on the rate of mass transfer, depending on specific conditions. In Case I, it causes an increase in the Sherwood number, while in Case II, it leads to a decreasing trend.

- The increase in heat transfer rates reveals that tri-hybrid nanofluids offer the most significant improvement in thermal conductivity, while hybrid nanofluids show notable enhancements, and mono nanofluids provide the least improvement among the three types.

- The Sherwood number for various material parameters is validated through a comparison of numerical data under specific conditions with previously reported results and results obtained using the FDM. This comparison confirms the accuracy of the numerical method.

Author Contributions

Writing—original draft, R.S.; Methodology, R.S.; Software, B.S.; Validation, S.S.K.R.; Investigation, R.S. and F.H.H.A.M.;, Writing—review & editing, S.S.K.R., F.H.H.A.M. and B.S.; Supervision, R.B.T. and S.V.K.V.; Funding acquisition, F.H.H.A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Deanship of Scientific Research, Vice Presidency for Graduate Studies and Scientific Research, King Faisal University, Saudi Arabia [Grant No. KFU251200].

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors have declared no conflict of interest.

Correction Statement

This article has been republished with a minor correction to the reference 32. This change does not affect the scientific content of the article.

Nomenclature

| dimensionless exponential parameter | |

| external magnetic field {A/m} | |

| dimensionless skin friction | |

| specific heat at constant pressure {J kg−1 K−1} | |

| concentration of dimensions {kg m−3} | |

| fluid content at the plate {kg m−3} | |

| fluid concentration at a distance from the plate {kg m−3} | |

| non-dimensional concentration | |

| chemical molecular diffusivity | |

| thermal diffusivity {m2 s −1} | |

| error function | |

| complementary error function | |

| gravity {m s−2} | |

| Grashof number related to temperature | |

| Grashof number related to mass | |

| chemical reaction term | |

| porosity parameter | |

| magnetic field strength | |

| rate of heat transfer | |

| Prandtl number | |

| coefficient of heat absorption | |

| radiative heat flux | |

| heat flux | |

| thermal radiation parameter | |

| Schmidt number | |

| Soret effect | |

| Sherwood number | |

| dimensional temperature {K} | |

| temperature of the fluid at the plate {K} | |

| ambient temperature {K} | |

| fluid velocity in direction {ms−1} | |

| plate velocity {ms−1} | |

| non-dimensional velocity | |

| coordinate axis positioned along vertical surface | |

| coordinate axis perpendicular to plate | |

| non-dimensional coordinate axis perpendicular to plate | |

| Greek Symbols | |

| dimensionless temperature | |

| coefficient of viscosity {kgm−1 s−1} | |

| thermal conductivity of the fluid {Wm−1s−1} | |

| density of the fluid {kgm−3} | |

| volume fraction of nanoparticle | |

| volume fraction of nanoparticle | |

| volume fraction of nanoparticle | |

| kinematic viscosity {m2s−1} | |

| electrical conductivity {sm−1} | |

| volumetric coefficient of thermal expansion | |

| volumetric coefficient of expansion with concentration | |

| time {s} | |

| dimensionless time | |

| Subscript | |

| plate conditions | |

| conditions of free stream | |

| base fluid | |

| nanofluid | |

| hybrid nanofluid | |

| ternary hybrid nanofluid | |

| nanoparticle | |

| nanoparticle | |

| nanoparticle | |

Appendix A

Case 1:

Velocity:

, , , ,

, , ,

, , , ,

, , , ,

,

,

, , , , , , , , , , , , ,

Temperature:

Concentration:

, , , ,

,

, , ,

, , ,

, , ,

Case 2:

Velocity:

Concentration:

References

- Carnahan, B.; Luther, H.A.; Wilkes, J.O. Applied Numerical Methods; John Wiley & Sons: New York, NY, USA, 1969. [Google Scholar]

- Rajesh, V.; Varma, S.V.K. Chemical reaction effects on free convection flow past an exponentially accelerated vertical plate. Ann. J. Eng. 2010, 13, 181–188. [Google Scholar]

- Kumar, A.V.; Kumaresan, E.; Varma, S.V.K. An exact analysis of unsteady MHD free convective chemically reacting elasto-viscous fluid flow past an impulsively started infinite vertical plate through porous medium in the presence of radiation absorption. Int. J. Appl. Comput. Math. 2017, 3, 2257–2274. [Google Scholar] [CrossRef]

- Islam, S.H.; Ahmed, N. Effect of thermal diffusion and chemical reaction on MHD free convective flow past an infinite isothermal vertical plate with heat source. Ital. J. Pure Appl. Math. 2019, 42, 559–574. [Google Scholar]

- Goud, B.S.; Babu, B.S.; Shekar, M.R.; Srinivas, G. Mass transfer effects on MHD flow through porous medium past an exponentially accelerated inclined plate with variable temperature and thermal radiation. Int. J. Thermofluid Sci. Technol. 2019, 6, 19060402. [Google Scholar] [CrossRef]

- Goud, B.S.; Reddy, Y.D. Chemical reaction and Soret effect on an unsteady MHD heat and mass transfer fluid flow along an infinite vertical plate with radiation and heat absorption. J. Indian Chem. Soc. 2022, 99, 100762. [Google Scholar] [CrossRef]

- Bafakeeh, O.T.; Raghunath, K.; Ali, F.; Khalid, M.; Tag-ElDin, E.S.M.; Oreijah, M.; Guedri, K.; Ben Khedher, N.; Khan, M.I. Hall current and Soret effects on unsteady MHD rotating flow of second-grade fluid through porous media under the influences of thermal radiation and chemical reactions. Catalysts 2022, 12, 1233. [Google Scholar] [CrossRef]

- Narmatha, M.; Kavitha, R. Analysis of unsteady heat and mass transfer in rotating MHD convection flow over a porous vertical plate. Arch. Thermodyn. 2024, 45, 179–187. [Google Scholar] [CrossRef]

- Abbas, S.; Nazar, M. Fractional analysis of unsteady magnetohydrodynamics Jeffrey flow over an infinite vertical plate in the presence of Hall current. Math. Methods Appl. Sci. 2025, 48, 253–272. [Google Scholar] [CrossRef]

- Choi, S.U.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles; No. ANL/MSD/CP-84938; CONF-951135-29; Argonne National Laboratory (ANL): Argonne, IL, USA, 1995. [Google Scholar]

- Sedki, A.M. Effect of thermal radiation and chemical reaction on MHD mixed convective heat and mass transfer in nanofluid flow due to nonlinear stretching surface through porous medium. Results Mater. 2022, 16, 100334. [Google Scholar] [CrossRef]

- Reddy, Y.D.; Mebarek-Oudina, F.; Goud, B.S.; Ismail, A.I. Radiation, velocity and thermal slips effect toward MHD boundary layer flow through heat and mass transport of Williamson nanofluid with porous medium. Arab. J. Sci. Eng. 2022, 47, 16355–16369. [Google Scholar] [CrossRef]

- Sudarsana Reddy, P.; Sreedevi, P. Impact of chemical reaction and double stratification on heat and mass transfer characteristics of nanofluid flow over porous stretching sheet with thermal radiation. Int. J. Ambient Energy 2022, 43, 1626–1636. [Google Scholar] [CrossRef]

- Dharmaiah, G.; Mebarek-Oudina, F.; Prasad, J.R.; Rani, C.B. Exploration of bio-convection for slippery two-phase Maxwell nanofluid past a vertical induced magnetic stretching regime associated for biotechnology and engineering. J. Mol. Liq. 2023, 391, 123408. [Google Scholar] [CrossRef]

- Kodi, R.; Ali, F.; Khalid, M.; Abdullaeva, B.S.; Altuijri, R.; Khan, M.I. Heat and mass transfer on MHD flow of Jeffrey nanofluid based on Cu and TiO2 over an inclined plate and diffusion-thermo and radiation absorption effects. Pramana 2023, 97, 202. [Google Scholar] [CrossRef]

- Raghunath, K. Study of heat and mass transfer of an unsteady magnetohydrodynamic (MHD) nanofluid flow past a vertical porous plate in the presence of chemical reaction, radiation and Soret effects. J. Nanofluids 2023, 12, 767–776. [Google Scholar] [CrossRef]

- Ramesh, K.; Mebarek-Oudina, F.; Ismail, A.I.; Jaiswal, B.R.; Warke, A.S.; Lodhi, R.; Sharma, T. Computational analysis on radiative non-Newtonian Carreau nanofluid flow in a microchannel under the magnetic properties. Sci. Iran. 2023, 30, 376–390. [Google Scholar] [CrossRef]

- Venkateswarlu, B.; Kim, S.C.; Joo, S.W.; Chavan, S. Numerical investigation of nanofluid as a coolant in a prismatic battery for thermal management systems. J. Therm. Sci. Eng. Appl. 2024, 16, 031003. [Google Scholar] [CrossRef]

- Galal, A.M.; Alharbi, F.M.; Arshad, M.; Alam, M.M.; Abdeljawad, T.; Al-Mdallal, Q.M. Numerical investigation of heat and mass transfer in three-dimensional MHD nanoliquid flow with inclined magnetization. Sci. Rep. 2024, 14, 1207. [Google Scholar] [CrossRef]

- Dharmaiah, G.; Mebarek-Oudina, F.; Balamurugan, K.S.; Vedavathi, N. Numerical analysis of the magnetic dipole effect on a radiative ferromagnetic liquid flowing over a porous stretched sheet. Fluid Dyn. Mater. Process. 2024, 20, 293–310. [Google Scholar] [CrossRef]

- Rahman, A.; Hasnain, S.M.M.; Pandey, S.; Tapalova, A.; Akylbekov, N.; Zairov, R. Review on nanofluids: Preparation, properties, stability, and thermal performance augmentation in heat transfer applications. ACS Omega 2024, 9, 32328–32349. [Google Scholar] [CrossRef]

- Basit, M.A.; Imran, M.; Mohammed, W.W.; Ali, M.R.; Hendy, A.S. Thermal analysis of mathematical model of heat and mass transfer through bioconvective Carreau nanofluid flow over an inclined stretchable cylinder. Case Stud. Therm. Eng. 2024, 63, 105303. [Google Scholar] [CrossRef]

- Saleem, M.; Al-Zubaidi, A.; Tufail, M.N.; Fiaz, Z.; Saleem, S. Exploration of numerical simulation for unsteady Casson nanofluid thin film flow over stretching surface with mixed convection effects using Buongiorno’s nanofluid model. Zamm 2024, 104, e202400165. [Google Scholar] [CrossRef]

- Waseem, M.; Jawad, M.; Aldalbahi, M.M.; Naeem, S.; Gull, H.; Majeed, A. Statistical and mathematical modeling of viscoelastic 3D Casson nanofluid flow with activation energy and motile microbes induced by exponential sheet bounding with Darcy-Forchheimer porous medium. Multiscale Multidiscip. Model. Exp. Des. 2025, 8, 14. [Google Scholar] [CrossRef]

- Mishra, A.; Upreti, H. A comparative study of Ag–MgO/water and Fe3O4–CoFe2O4/EG–water hybrid nanofluid flow over a curved surface with chemical reaction using Buongiorno model. Partial Differ. Equ. Appl. Math. 2022, 5, 100322. [Google Scholar]

- Lone, S.A.; Alyami, M.A.; Saeed, A.; Dawar, A.; Kumam, P.; Kumam, W. MHD micropolar hybrid nanofluid flow over a flat surface subject to mixed convection and thermal radiation. Sci. Rep. 2022, 12, 17283. [Google Scholar] [CrossRef]

- Mebarek-Oudina, F.; Chabani, I.; Vaidya, H.; Ismail, A.A.I. Hybrid-nanofluid magneto-convective flow and porous media contribution to entropy generation. Int. J. Numer. Methods Heat Fluid Flow 2024, 34, 809–836. [Google Scholar] [CrossRef]

- Shamshuddin, M.D.; Saeed, A.; Mishra, S.; Katta, R.; Eid, M.R. Homotopic simulation of MHD bioconvective flow of water-based hybrid nanofluid over a thermal convective exponential stretching surface. Int. J. Numer. Methods Heat Fluid Flow 2024, 34, 31–53. [Google Scholar] [CrossRef]

- Khan, M.N.; Aldosari, F.M.; Wang, Z.; Yasir, M.; Afikuzzaman, M.; Elseesy, I.E. Overview of solar thermal applications of heat exchangers with thermophysical features of hybrid nanomaterials. Nanoscale Adv. 2024, 6, 136–145. [Google Scholar] [CrossRef]

- Agbaje, T.M.; Panda, S.; Mishra, S.R.; Baithalu, R. Free convection of Cattaneo-Christov heat flux model for the micropolar hybrid nanofluid through permeable stretching surface with inertial drag and irregular heat sink/source. Multiscale Multidiscip. Model. Exp. Des. 2025, 8, 184. [Google Scholar] [CrossRef]

- Ishaq, M.; Khan, S.U.; AL Garalleh, H.; Sowayan, A.S.; Tlili, I. Thermal performance of casson hybrid nanofluid with radiative effects and convective conditions: Applications to energy systems and industrial heat transfer. Multiscale Multidiscip. Model. Exp. Des. 2025, 8, 141. [Google Scholar] [CrossRef]

- Al Oweidi, K.F.; Shahzad, F.; Jamshed, W.; Usman; Ibrahim, R.W.; El Din, E.S.M.T.; AlDerea, A.M. Partial differential equations of entropy analysis on ternary hybridity nanofluid flow model via rotating disk with hall current and electromagnetic radiative influences. Sci. Rep. 2022, 12, 20692, [Label Retracted]. [Google Scholar] [CrossRef]

- Alshahrani, S.; Ahammad, N.A.; Bilal, M.; Ghoneim, M.E.; Ali, A.; Yassen, M.F.; Tag-Eldin, E. Numerical simulation of ternary nanofluid flow with multiple slip and thermal jump conditions. Front. Energy Res. 2022, 10, 967307. [Google Scholar] [CrossRef]

- Vinutha, K.; Nagaraja, K.V.; Sajjan, K.; Khan, U.; Madhukesh, J.K.; Kolli, U.C.; Muhammad, T. Thermal performance of Fe3O4, SWCNT, MWCNT and H2O based on magnetohydrodynamic nanofluid flow across a wedge with significant impacts of Soret and Dufour. Nanoscale Adv. 2023, 5, 5952–5964. [Google Scholar] [CrossRef]

- Madhukesh, J.K.; Sarris, I.E.; Prasannakumara, B.C.; Abdulrahman, A. Investigation of thermal performance of ternary hybrid nanofluid flow in a permeable inclined cylinder/plate. Energies 2023, 16, 2630. [Google Scholar] [CrossRef]

- Mahmood, Z.; Khan, U.; Saleem, S.; Rafique, K.; Eldin, S.M. Numerical analysis of ternary hybrid nanofluid flow over a stagnation region of stretching/shrinking curved surface with suction and lorentz force. J. Magn. Magn. Mater. 2023, 573, 170654. [Google Scholar] [CrossRef]

- Souayeh, B.; Ramesh, K. Numerical scrutinization of ternary nanofluid flow over an exponentially stretching sheet with gyrotactic microorganisms. Mathematics 2023, 11, 981. [Google Scholar] [CrossRef]

- Ramzan, M.; Kumam, P.; Lone, S.A.; Seangwattana, T.; Saeed, A.; Galal, A.M. A theoretical analysis of the ternary hybrid nanofluid flows over a non-isothermal and non-isosolutal multiple geometries. Heliyon 2023, 9, e14875. [Google Scholar] [CrossRef]

- Vishalakshi, A.B.; Mahabaleshwar, U.S.; Laroze, D.; Zeidan, D. A study of mixed convective ternary hybrid nanofluid flow over a stretching sheet with radiation and transpiration. Spec. Top. Rev. Porous Media Int. J. 2023, 14, 33–51. [Google Scholar] [CrossRef]

- Mandal, G. Stability analysis and multiple solutions of MHD mixed convective Cu–Ag-Al2O3/H2O ternary hybrid nanofluid over an exponential permeable shrinking surface with radiation and slip impacts: An estimation of entropy production. Res. Sq. 2023. [Google Scholar] [CrossRef]

- Khan, M.N.; Ahmad, S.; Alrihieli, H.F.; Wang, Z.; Hussien, M.A.; Afikuzzaman, M. Theoretical study on thermal efficiencies of Sutterby ternary-hybrid nanofluids with surface catalyzed reactions over a bidirectional expanding surface. J. Mol. Liq. 2023, 391, 123412. [Google Scholar] [CrossRef]

- Jamrus, F.N.; Waini, I.; Khan, U.; Ishak, A. Effects of magnetohydrodynamics and velocity slip on mixed convective flow of thermally stratified ternary hybrid nanofluid over a stretching/shrinking sheet. Case Stud. Therm. Eng. 2024, 55, 104161. [Google Scholar] [CrossRef]

- Chandel, S.; Sharma, D. Ternary nanofluid dynamics in stagnated flow with exponential heat and inclined magnetic field: Applications in advanced cooling and aerospace system. Int. J. Heat Fluid Flow 2024, 109, 109508. [Google Scholar] [CrossRef]

- Saleem, M.; Al-Zubaidi, A.; Radwan, N.; Saleem, S.; Adawi, H. Thermal effects of ternary Casson nanofluid flow over a stretching sheet: An investigation of Thomson and Troian velocity slip. Case Stud. Therm. Eng. 2025, 65, 105561. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).