Abstract

Based on the analysis of the motion law of 3D five-directional circular transverse braided fibers, this paper obtains the angle calculation formula between fibers and the local polar coordinate system in various cell models by transforming the position coordinates of fiber nodes. The stress transformation matrix between the local coordinate system and the global coordinate system of any fiber in the circular braided single cell is derived without considering the physical force on the single-cell micro-hexahedron unit. The calculation formulas of braided parameters such as the overall stiffness matrix and fiber volume content of the circular braided composite material after considering the matrix are derived by using the volume average method; the length of braided knuckles is 2 mm, the inner diameter of inner cells is 7 mm, the number of radial and axial braided yarns is 80, the height of inner cells is 0.5 mm, and the filling coefficient is 0.61. Comparing the results of the numerical prediction model with the experimental results in reference, it is found that the error of the numerical prediction model deduced in this paper is small. Therefore, this model can be used to fully study the effects of braided parameters such as cell inner diameter, cell height, and node length on the mechanical properties of composites.

1. Introduction

The 3D braided composites have a specific geometric position relationship between braided fibers and matrix by pre-setting the braiding mode of fibers, so as to ensure that the materials have excellent mechanical properties in a specific direction and show good performance with designable characteristics. In recent years, with the improvement in braiding technology and the reduction in manufacturing cost, 3D braided composites have been widely used in aviation, aerospace, navigation, transportation, medical care, sports, and civil engineering [1,2,3].

In order to obtain 3D braided composites with different structures, the braiding methods can be divided into rectangular braiding and circular braiding according to the structural differences of preforms. In the aspect of reasonable construction of rectangular braided material model, Tian et al. proposed a diversity-oriented particle swarm optimization (DPSO-MLS) with multilevel learning strategy, which can be used to optimize the composite structure [4]. Zhang and Xu, based on the analysis of braiding laws of 3D five-directional and all five-directional braided composites, divided the studied materials into three kinds of cell models: inner, surface, and corner. By introducing reasonable boundary conditions, they predicted the effective stiffness characteristics of the materials, and compared the detailed mechanical properties of the three cell models. In addition, the effects of braiding angle and fiber volume fraction on the elastic properties of the composites were also analyzed [5,6,7]. Inspired by the slub fiber structure, Wang et al. designed and prepared a new type of three-dimensional six-way braided composite pipe [8].

In the aspect of mechanical properties of rectangular braiding, Ji et al. [9] analyzed the geometric model of composite materials with the help of finite element analysis software Abaqus 15.0, and obtained the elastic modulus, shear modulus, and Poisson’s ratio of composite materials corresponding to different braiding angles. The influence of fiber volume fraction on the elastic properties of composite element is also studied, and the bending properties of braided composite material are evaluated by the multi-scale model in finite element analysis. The experimental results show that the predicted results are basically consistent with the experimental results. In order to study the progressive damage behavior and strength characteristics under uniaxial tension, Kang et al. established a finite element and progressive damage analysis model, and compared the finite element analysis results with experimental data [10]. Sun et al. [11] studied the effects of fiber fracture defects and corrugation defects on compressive fatigue behavior and damage evolution process of three-dimensional multiaxial braided composites.

The above research focuses on rectangular braiding. Compared with rectangular braiding, the micro-geometric structure of circular braiding is more complicated than that of rectangular preform, and it is more difficult to analyze its structure and mechanical properties theoretically [12,13,14]. Zhao and Li et al. [15,16] selected a micro-geometric cell, and found that the curvature of annular pipe has great influence on braided composites. The elastic modulus of braided composites of annular pipe was predicted by mathematical models, and the predicted results were found to be reasonable by comparing with the literature data. Shen [17] tested the compression and torsion mechanical properties of 3D, 4D, and 5D braided tubular members through experiments, and found that the compression properties of 5D materials were greatly improved compared with 4D materials, but the shear modulus was not significantly improved. Comparing the experimental data with the prediction data of FGM model, it was concluded that the prediction results of FGM simulation were lower. Zhang [18] applied braided composite materials to two-stage gear transmission system, realizing the design goal of lightweight gear transmission system.

As can be seen from the above literature, most of the research on braided composites is focused on rectangular braiding and circular braiding, but there are few research papers on the prediction of mechanical properties of 3D five-way circular braiding. Because of the anisotropy of mechanical properties of 3D five-way circular braided composites, the research in this paper provides the possibility for the special performance requirements of materials, such as the application of composites subjected to radial force, which is of great value.

The paper is divided into seven sections. In Section 2, the motion law of 3D five-directional circular braiding fiber is analyzed, and the composite material is divided into three microscopic cells. In Section 3, the formulas for calculating the overall stiffness matrix and fiber volume content of 3D five-directional circular braided composites are derived, and the mechanical properties of the composites can be obtained by inverting the overall stiffness matrix of the composites. In Section 4, the prediction model derived in this paper is used to further numerically analyze the mechanical properties of cells. In Section 5, there is numerical analysis of the influence of braiding parameters on the mechanical properties of cells. In Section 6, on the basis of the above analysis, the parametric study is completed. In Section 7, we state the main conclusions. In this paper, the numerical prediction model for mechanical properties of 3D five-directional circular braided composites fully considers the braiding parameters such as cell inner diameter, cell outer diameter, cell height, and knuckle length, and can quantitatively analyze the influence of different braiding parameters on the mechanical properties of composites.

2. The 3D Circular Braided Three-Cell Structure Analysis

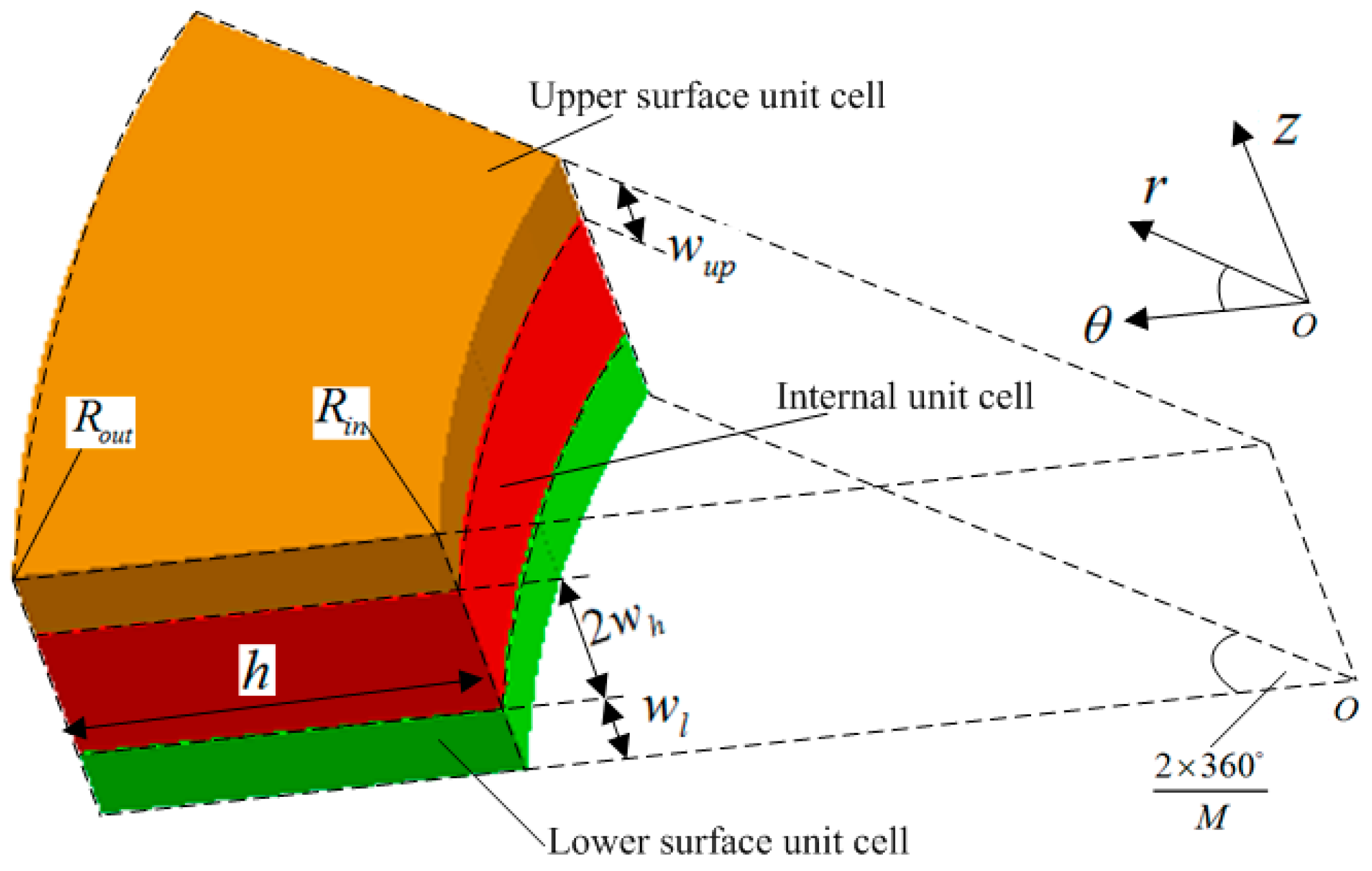

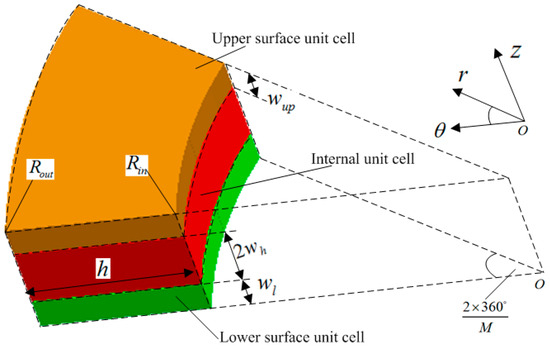

The micro-structure of 3D annular braided preform should have good periodicity. In order to improve the modeling efficiency, according to Figure 1, the smallest research unit of 3D five-way annular braided composites is divided into three forms: internal cell, upper surface cell, and lower surface cell [19,20].

Figure 1.

Three cell divisions.

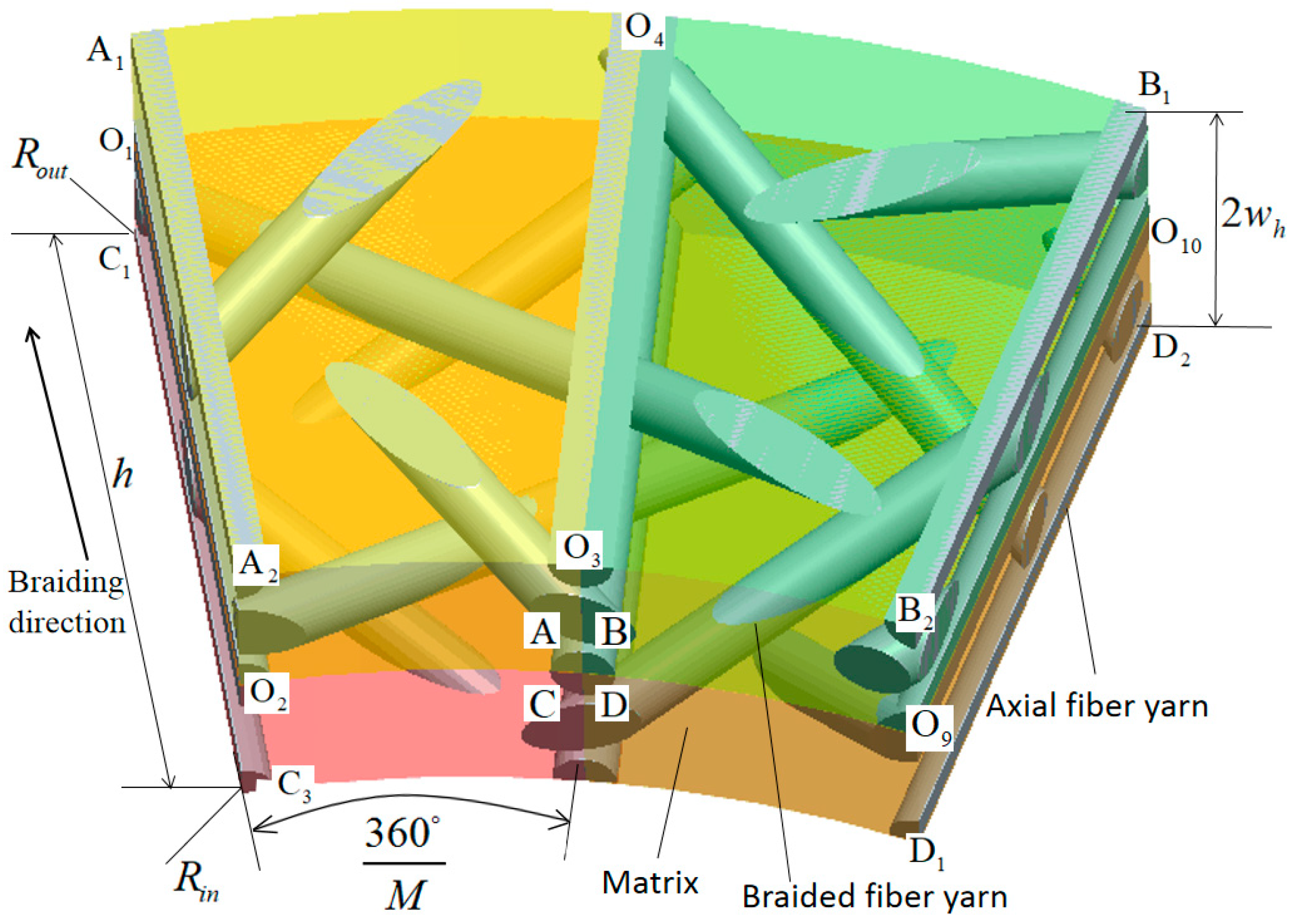

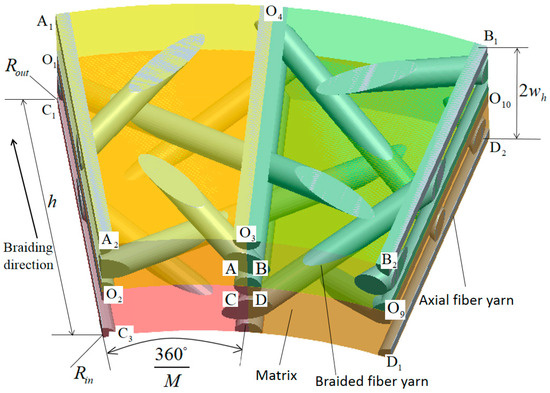

As shown in Figure 2, the inner cell can be further subdivided into four sub-regions: A, B, C, and D, which extend periodically outward along the radial braiding direction. In Figure 2, h is the length of braiding knuckles, is the inner diameter and is the outer diameter of the inner cell, M and N are the number of radial and axial braiding fibers, respectively, and is the height of the inner cell.

Figure 2.

Internal unit cell matrix and fiber.

3. The Solving the Stress Transformation Matrix of Circular Braiding

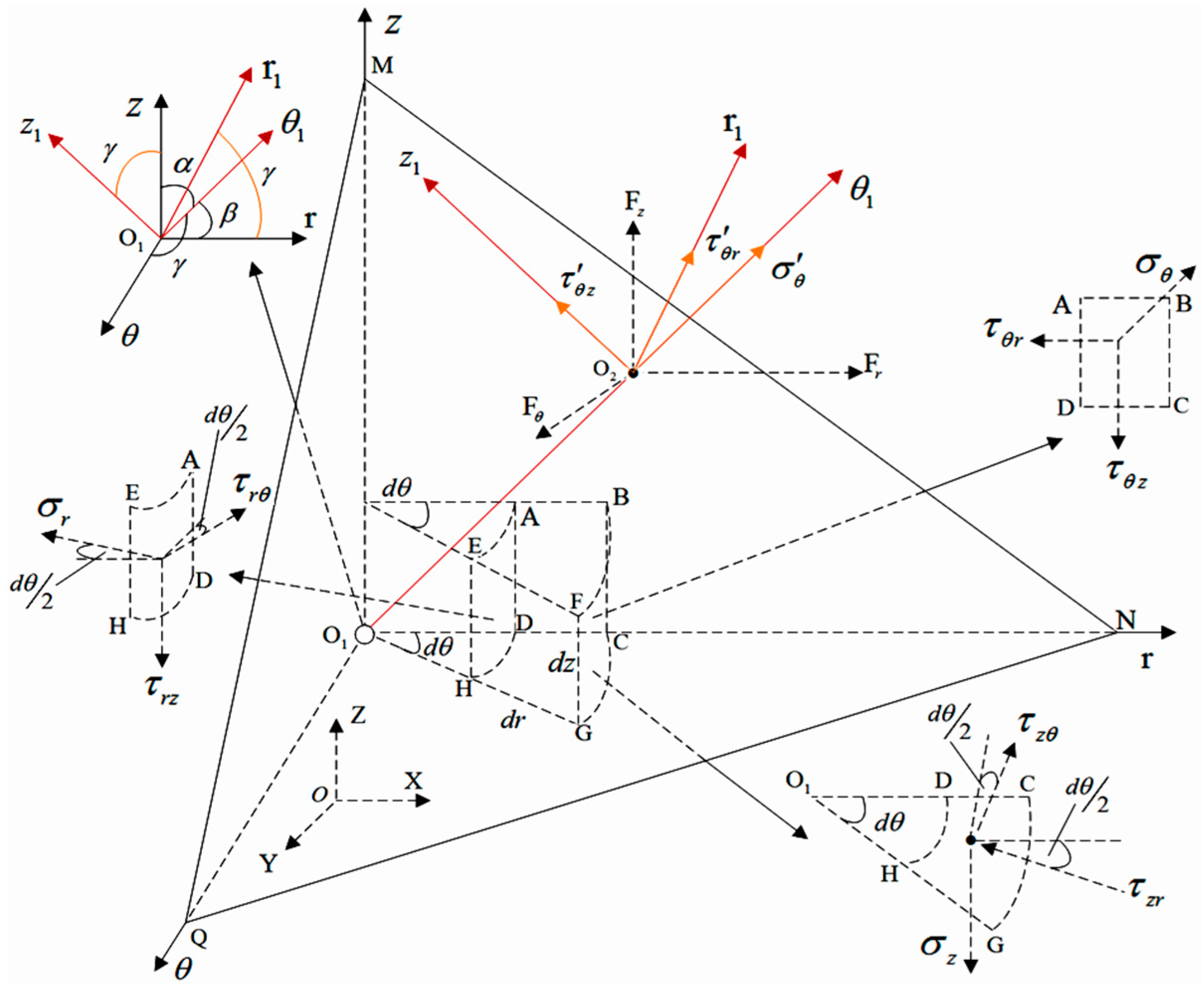

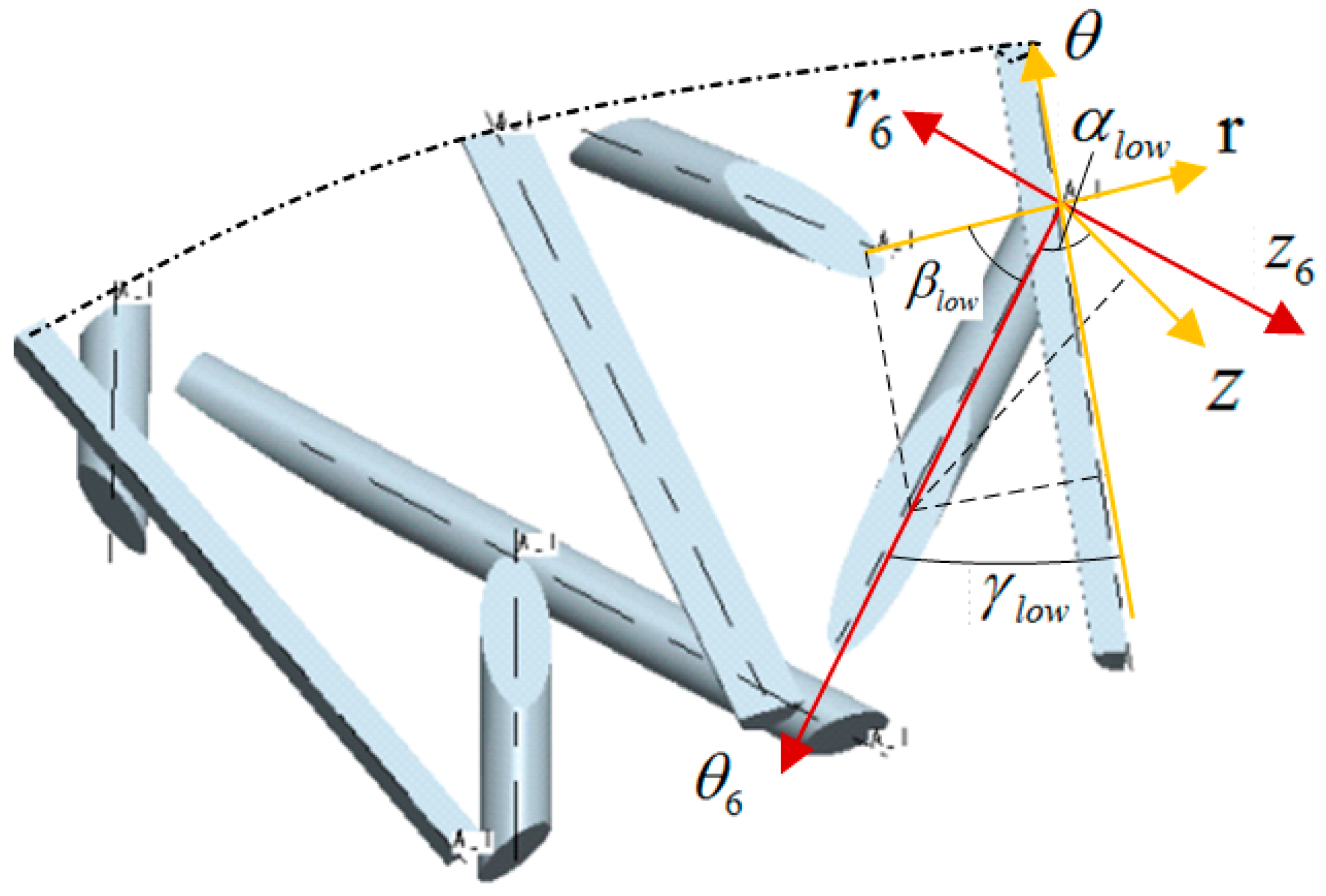

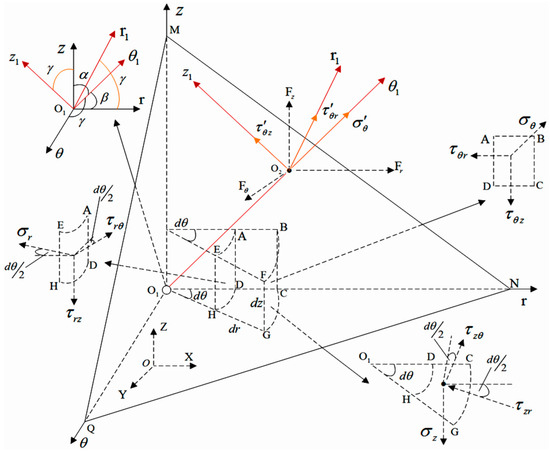

In the process of 3D five-directional circular braiding, the fiber movement is carried out in the polar coordinate system in Figure 3, and the braiding angle is calculated under the global coordinate rectangular system in Figure 3. The polar coordinate system is located on the inclined section of MNQ, and the axis is parallel to the outer normal of plane MNQ, and the coordinate axis and are on plane MNQ.

Figure 3.

Three-direction stress on inclined section perpendicular to axis.

In Figure 3, when M, N, and Q points approach infinitely to the origin of polar coordinate system along the opposite directions of , , and axes, respectively, the stress on the annular hexahedron element shown in Figure 3 is approximately equal to the stress on the inclined section MNQ.

Assuming that the force on the circular-shaped micro hexahedron element is not considered, the area of the inclined section will be projected on the three coordinate axes of the polar coordinate system , and the relationship between the areas is obtained: , , .

Assume that the total stress on the inclined section MNQ is F, and the components of F along the coordinate axis in polar coordinate system are expressed by, and respectively.

According to the equilibrium conditions , , and , and in the annular hexahedron element in Figure 3, we can obtain:

The moment balance condition , , and are applied to the center of gravity coordinate axis of the annular hexahedron in Figure 3, we can obtain , and .

The force in Formula (1) is decomposed along the three coordinate axes of polar coordinate system , and according to the angle relationship shown in Figure 3, the stress , , and on the inclined section MNQ is:

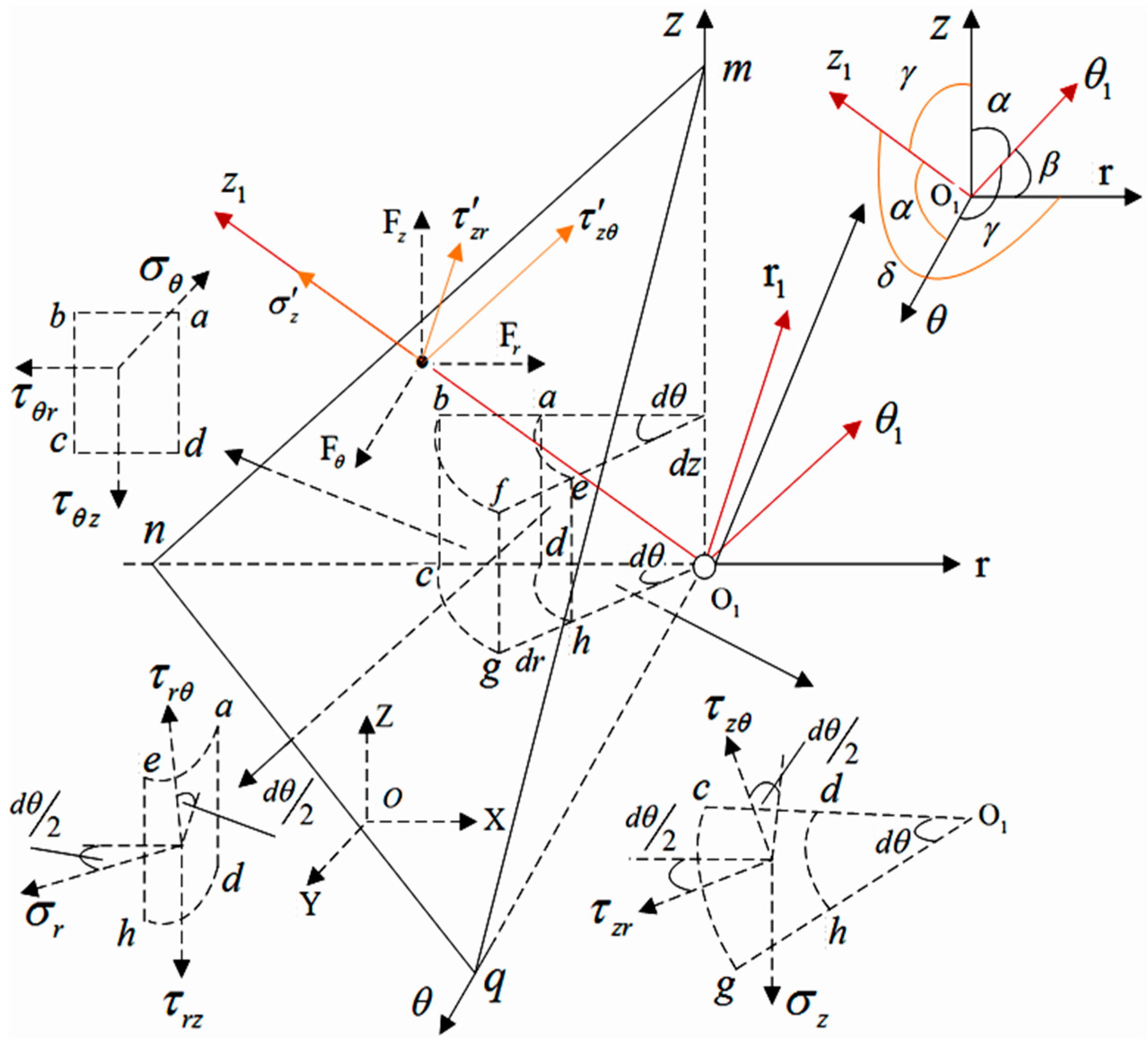

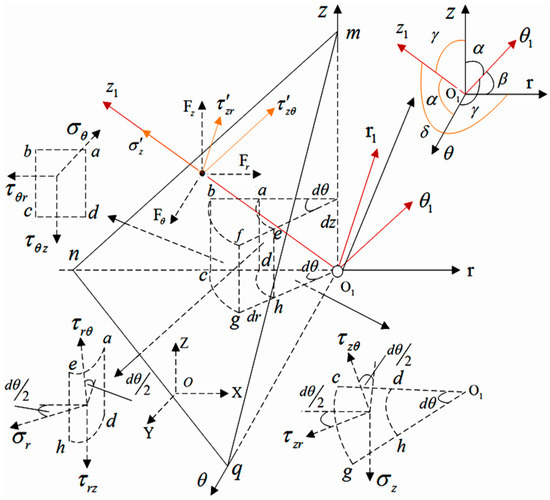

In Figure 4, the axis is parallel to the outer normal of the plane , is the angle between the axes and ; according to the angle relationship in Figure 4, we can obtain .

Figure 4.

Three-direction stress on inclined section perpendicular to axis.

Let the area of inclined section be , and project on three coordinate axes plane of polar coordinate system , and obtain the relationship between areas , , . According to the equilibrium conditions in the annular hexahedron unit in Figure 4:

The force in Formula (3) is decomposed along three coordinate axes of polar coordinate system , according to the angular relationship shown in Figure 4, the stresses , , and on the inclined section are obtained as follows:

In the same way, can be obtained when the inclined section is parallel to the outer normal of the axis. By using Formulas (2) and (4), the relationship matrix of stress components on the inclined section of the annular hexahedron element in polar coordinate system can be obtained as follows:

In Formula (5), is the spatial transformation matrix of circular braiding stress, is a 6 × 6 matrix, which is given in Appendix A.

4. The Equivalent Stiffness Matrix of Cells

4.1. Solving the Equivalent Stiffness Matrix of Internal Cells

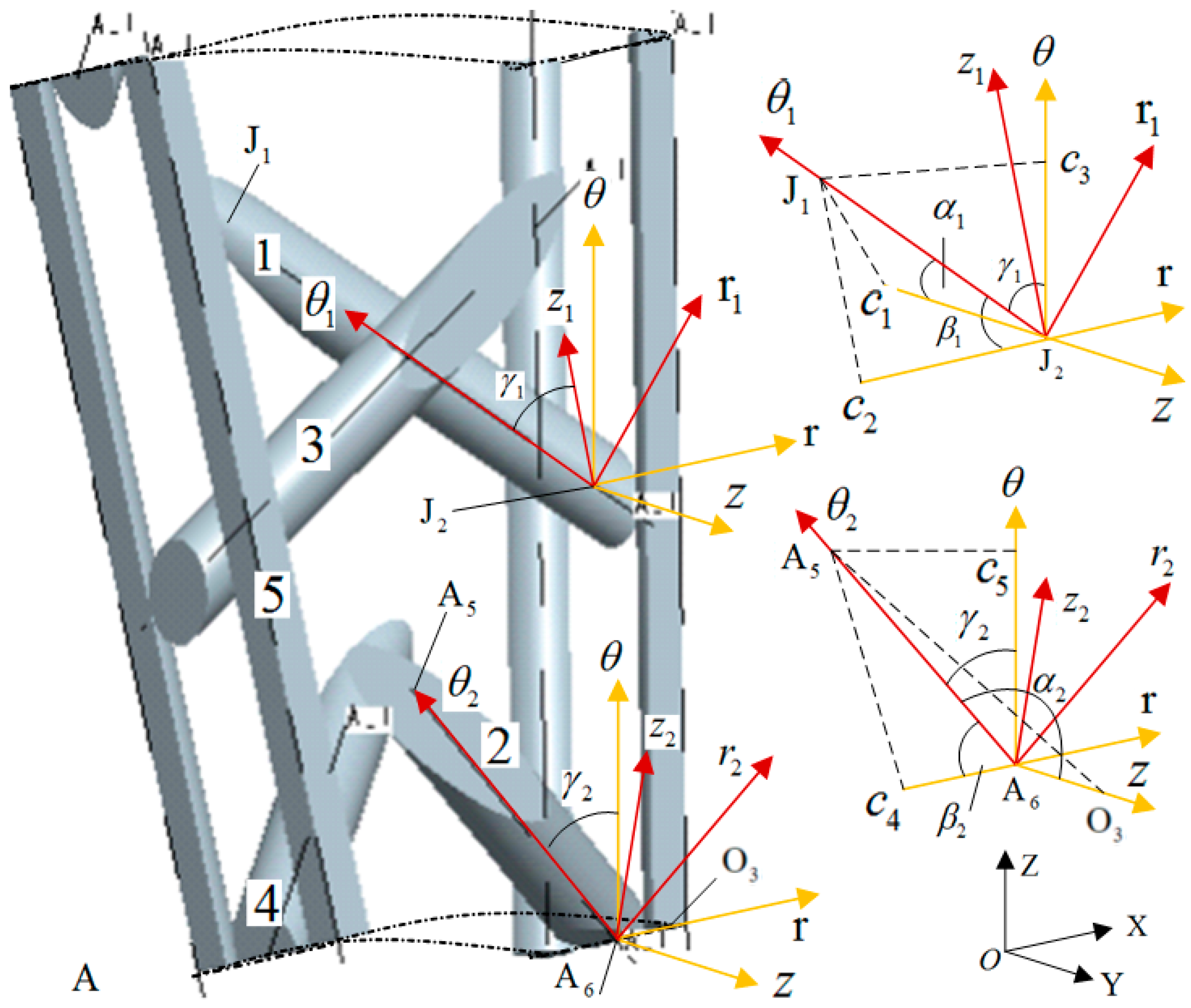

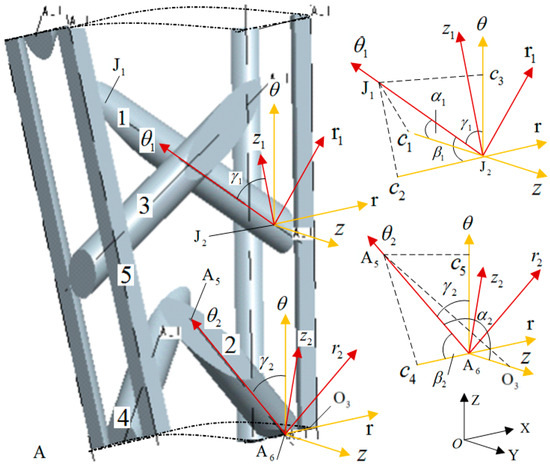

Figure 5 shows the fiber angle relationship in the inner cell A, and the coordinates of and points in the cylindrical coordinate system in Figure 5 are:

Figure 5.

Angle relationship of fibers in inner cell A.

Therefore, the coordinates of the and points in the rectangular coordinate system are:

According to the relationship between cylindrical coordinate system and rectangular coordinate system , in Figure 5, the distance between and points in rectangular coordinate system is:

The distance between the and points in the cylindrical-coordinate system is:

Therefore, the coordinates of the and points in rectangular coordinate system are:

Therefore, according to the positional relationship between the two coordinate systems, in Figure 5, the distance between the and points in the rectangular coordinate system is , the distance between and is [21]:

According to the positional relationship shown in Figure 5, the formulas for calculating the angle between the axis and the three coordinate axes on fiber 1 in inner cell A can be obtained:

In Formula (12), the angle between the inner braiding fiber and the braiding direction is defined as the inner braiding angle, and is the inner braiding angle of the outer layer fiber of inner cell A.

In the same way, according to the positional relationship shown in Figure 5, the formulas for calculating the angle between the axis on fiber 2 in inner cell A and the three coordinate axes of can be obtained:

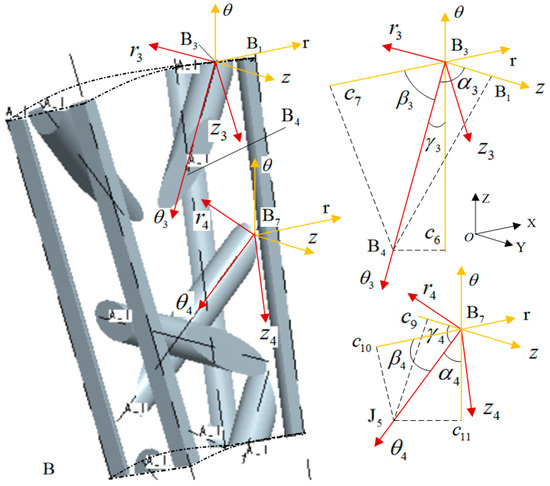

In the same way, according to the positional relationship shown in Figure 6, the formulas for calculating the angle between axis and three coordinate axes on fiber 1 in inner cell B can be obtained:

Figure 6.

Angle relationship of fibers in inner cell B.

In the same way, the formulas for calculating the angle between axis and three coordinate axes on fiber 2 in inner cell B can be obtained:

In Formulas (14) and (15),

There are five kinds of fibers with different orientations in inner cell A. According to the positional relationship shown in Figure 5, the angles between the five kinds of fibers in inner cell A and the coordinate axis are shown in Table 1.

Table 1.

Fiber angle in inner cell A.

In the same way, there are five kinds of fibers with different directions in inner cell B. According to the positional relationship shown in Figure 6, the angles between the five kinds of fibers in inner cell B and the coordinate axis can be obtained, as shown in Table 2.

Table 2.

Fiber angle in inner cell B.

Because of the symmetry of inner cell structure, the angle between fiber and coordinate axis in inner cell D is the same as that in inner cell A, and the angle between fiber and coordinate axis in inner cell C is the same as that in inner cell B.

Therefore, the stiffness matrix of inner cell A is:

In Formula (16), is the fiber volume ratio of fiber in inner cell A to inner cell A, is the stress transformation matrix of fiber in inner cell A, and the angles in Table 1 are brought into Formula (5). According to Formulas (13) and (15), the stress transformation matrix of inner cell A can be obtained. is the stiffness matrix of fiber in local coordinates [16,17].

In Formula (17), , in the same way, the stiffness matrices , , and of internal cells B, C, and D can be obtained.

In Formula (18),

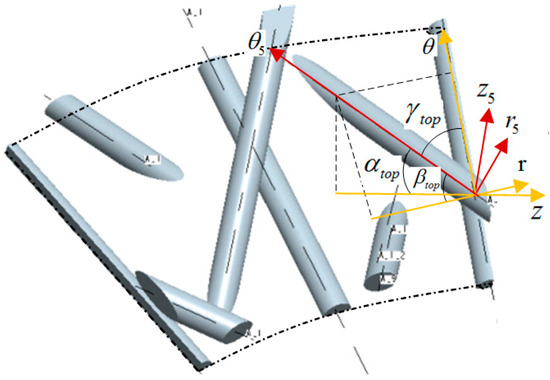

4.2. Solving the Equivalent Stiffness Matrix of Upper Surface Cells

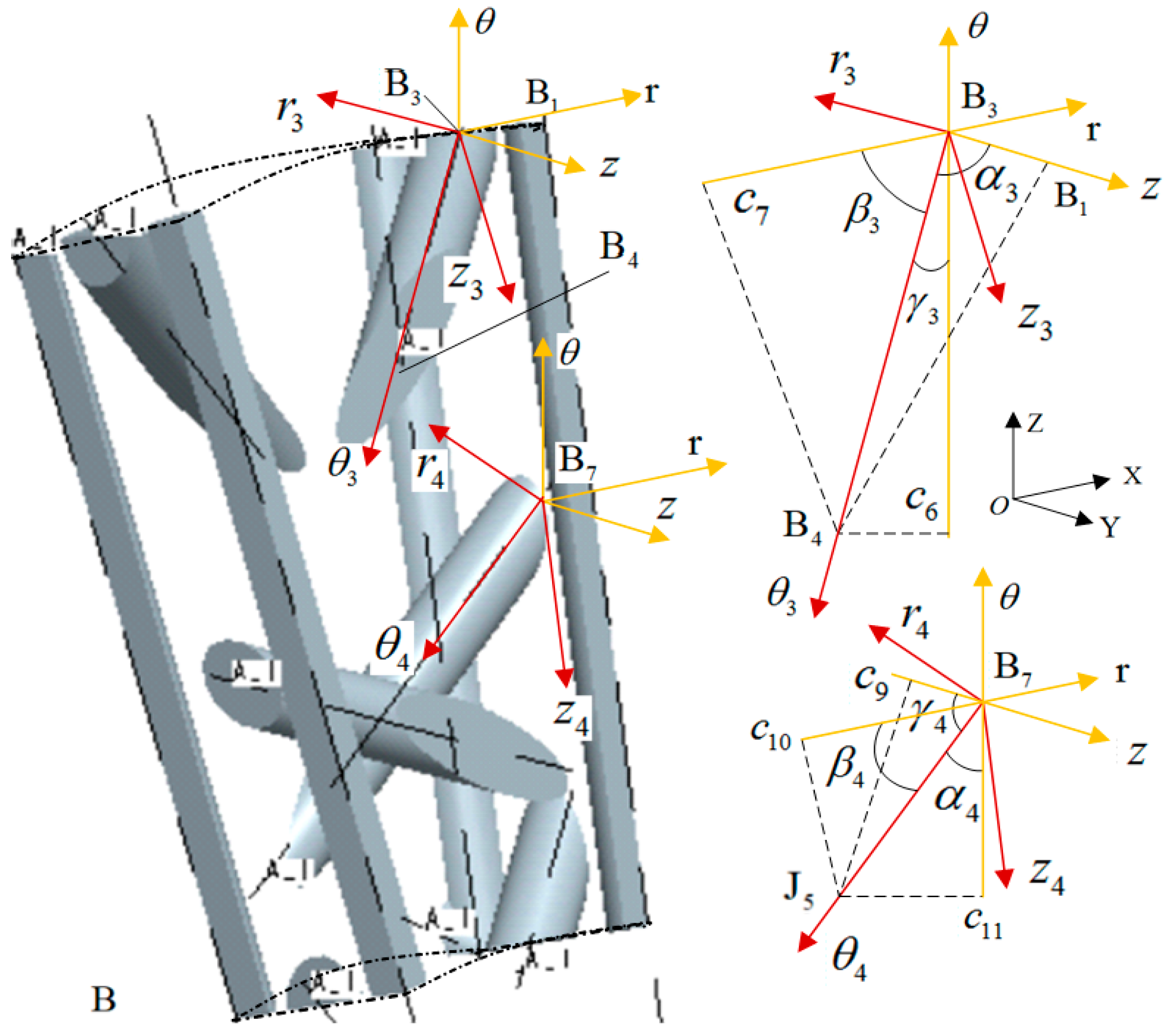

Figure 7 shows the fiber angle relationship in the upper surface cell. Similarly, according to the position relationship shown in Figure 7, the calculation formulas of the angles between axis and axis on the fiber in the upper surface cell can be obtained:

Figure 7.

Angle relationship of fiber in upper surface cells.

In Formula (19), .

In the same way, the equivalent stiffness matrix of the upper surface cell is:

In Formula (20), , .

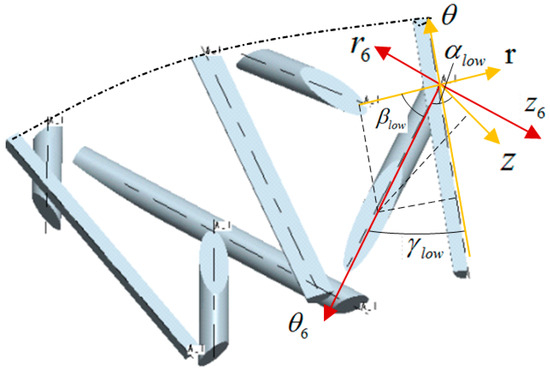

4.3. Solving the Equivalent Stiffness Matrix of Lower Surface Cells

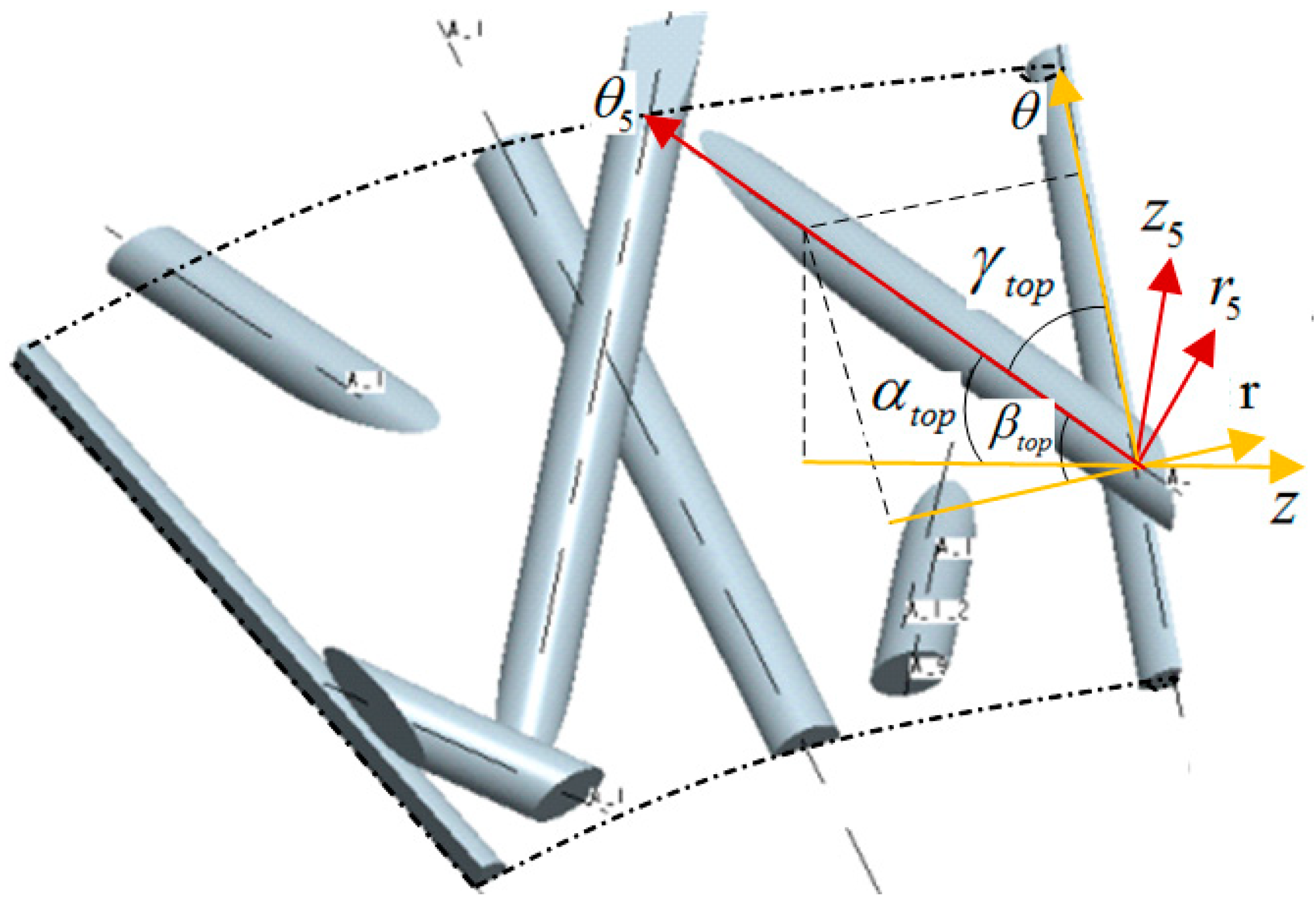

Figure 8 shows the angle relationship of fibers in the lower surface cells. Similarly, according to the position relationship shown in Figure 8, the calculation formulas of the angle between axis and axis on the fiber in the lower surface cells can be obtained:

Figure 8.

Angle relationship of fiber in lower surface cells.

In Formula (21), .

In the same way, the equivalent stiffness matrix of the lower surface cell is:

In Formula (22), , .

Therefore, the overall stiffness matrix of all fibers of the whole annular braided composite material is:

In Formula (23), , , .

The overall stiffness matrix of that 3D and five-direction annular braided composite material considering the matrix is as follows:

In Formula (24), is the fiber volume fraction, is matrix of matrix stiffness.

The calculation formulas of fiber volume fraction is as follows [21]:

In Formula (25), is the total volume of internal cells, is the volume of fibers in the inner cell, is the cross-sectional area of braided fiber bundle, and the cross-sectional shape of braided fiber is oval, , the half of major axis of ellipse is , the half of the minor axis of ellipse is . is the cross-sectional area of the axial fiber, the cross-sectional shape of the axial fiber is square , the side length is , is the cross-sectional dimension coefficient of axial fiber [17,18,21].

Table 3 gives the mechanical property parameters of fibers and matrix in carbon fiber braided composites. Because the 3D five-directional circular transverse braided materials approximately meet the conditions of transverse isotropy in a certain radial range in the plane perpendicular to the Z axis, the elastic modulus satisfies: , the shear modulus meets the following requirements: , and Poisson’s ratio meets the following requirements: . Because the matrix is an isotropic material, the shear modulus of the matrix meets the following requirements: .

Table 3.

Material parameters of fiber and matrix.

According to the parameters of composite fibers and matrix in Table 3, the mechanical parameters of fiber bundles in composite materials in all directions can be calculated by using Chamis mechanical formulas shown in Formula (26) [21,22].

In Formula (26), is the elastic modulus of fiber bundle in direction, is the filling coefficient of matrix and fiber in fiber bundle, is the elastic modulus of matrix, is the elastic modulus of fiber in direction, is the shear modulus of fiber bundle in planes, is the shear modulus of fiber in planes, is Poisson’s ratio of fiber bundle in planes, is Poisson’s ratio of fiber in direction [18,21].

5. Numerical Analysis of the Influence of Braiding Parameters on the Mechanical Properties of Cells

The matrix parameters in Table 3 and the parameters of fiber bundles obtained by Formula (26) are brought into Formula (24), and the overall stiffness matrix of 3D five-directional annular braided composites can be obtained. By inverting the overall stiffness matrix, the engineering elastic constant of 3D five-directional annular braided composites can be obtained as shown in Formula (27).

In Formula (27), is the overall flexibility matrix of composite materials, is the elastic modulus of the composite material in the direction, is the shear modulus of the composite in the planes, is Poisson’s ratio of composite materials in planes.

The length of braiding knuckles h = 2 mm, inner cell diameter = 7 mm, M and N are radial and axial braided fibers M = N = 80, respectively. The height of internal cells = 0.5 mm, the filling factor .

The numerical results calculated by Formula (27) are compared with the experimental results in reference [17], and the results are shown in Table 4. It is found that the relative error between the numerical prediction model deduced in this paper and the experimental results is 6.6%.

Table 4.

Comparison of numerical results and experimental measurement results.

In order to further analyze the influence of braiding parameters on the mechanical properties of 3D five-directional circular braided composites, the mathematical model described in this paper is used to numerically analyze the influence of braiding parameters on the mechanical properties of cells.

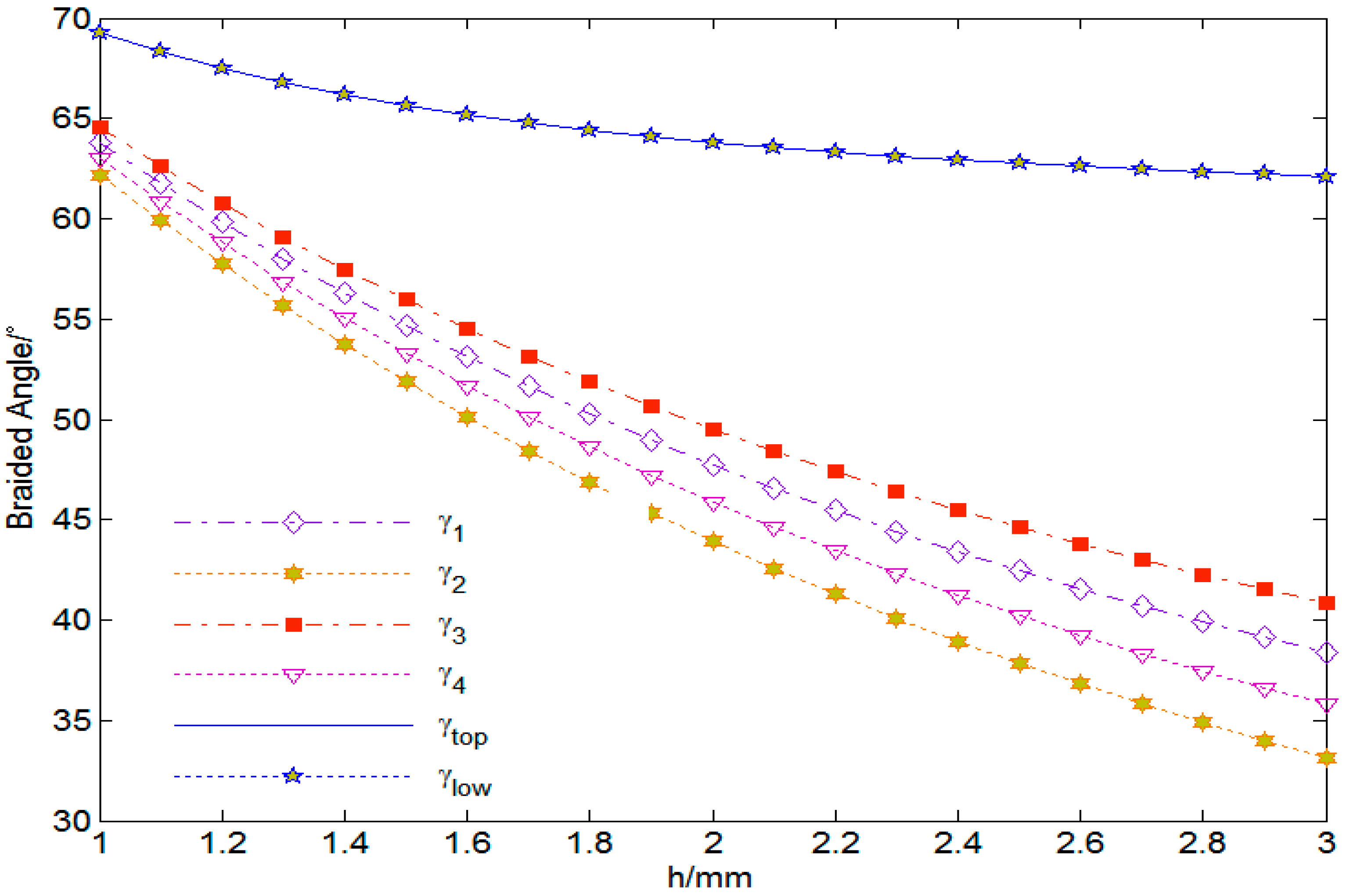

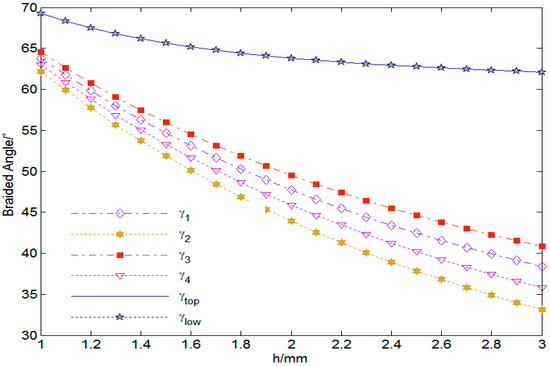

The relationship between that braiding angle γ and the knuckle length h of the 3D circular braiding material is shown in Figure 9, in which the cell inner diameter , the height of the inner cell , the number of radial and axial braiding fibers . It can be seen from Figure 9 that the braiding angles of the four internal cells are relatively close, that is, . With the increase in the length h of the knuckle, the braiding angles of each cell decrease, and the braiding angles of the four inner cells decrease the most; when that knuckle length increases from 1 mm to 3 mm, the braiding angle of the four inner cells is reduced by 38%~46%. With the increase in the length h of the knuckle, the braiding angle of the upper and lower surfaces decreases slightly, that is, ; when that knuckle length increases from 1 mm to 3 mm, the braiding angle of the upper and lower surfaces is reduced by 7.1%.

Figure 9.

Relationship curve between braiding angle and knuckle length.

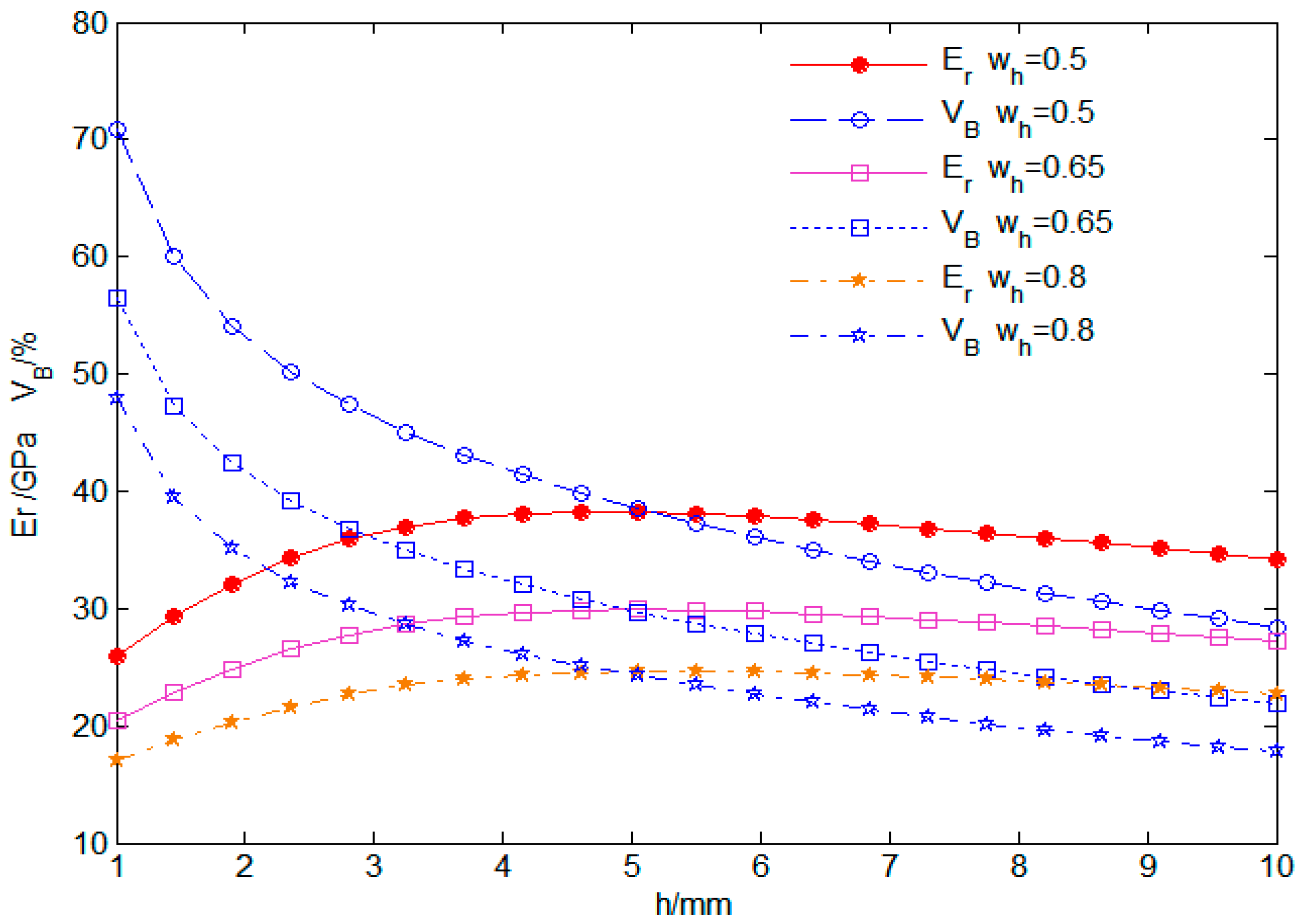

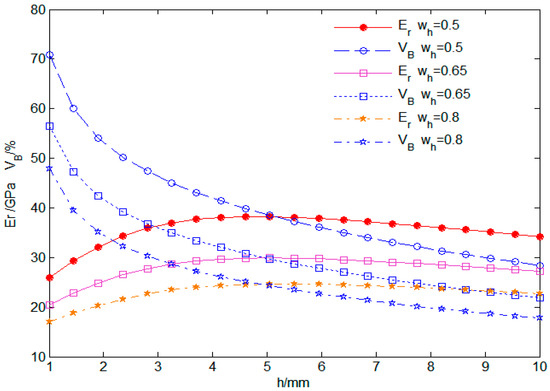

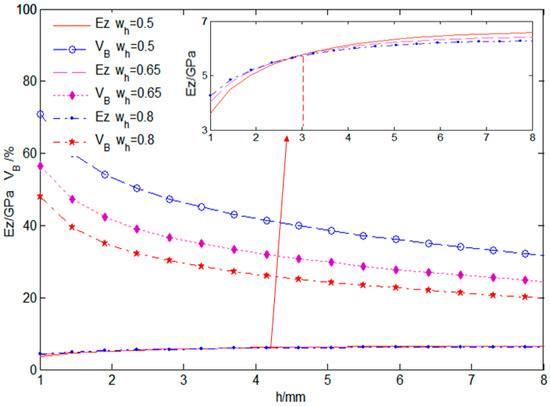

Figure 10 shows the influence curve of cell height and knuckle length h on fiber volume content and transverse elastic modulus . It can be seen from Figure 10 that with the increase in knuckle length h and cell height , the fiber volume content of 3D five-directional annular braided composites decreases; when that knuckle length increase from 1 mm to 10 mm, the fiber volume content is reduced by 57.1%. With the increase in knuckle length h, the transverse elastic modulus first increases and then decreases slowly, and with the increase in cell height , the transverse elastic modulus decreases. This is mainly because fiber volume content decreases due to the increase in knuckle length and cell height, and the number of carbon fibers per unit volume decreases, which, in turn, leads to a decrease in transverse elastic modulus.

Figure 10.

Influence curve of cell height and knuckle length on fiber volume content and transverse elastic modulus.

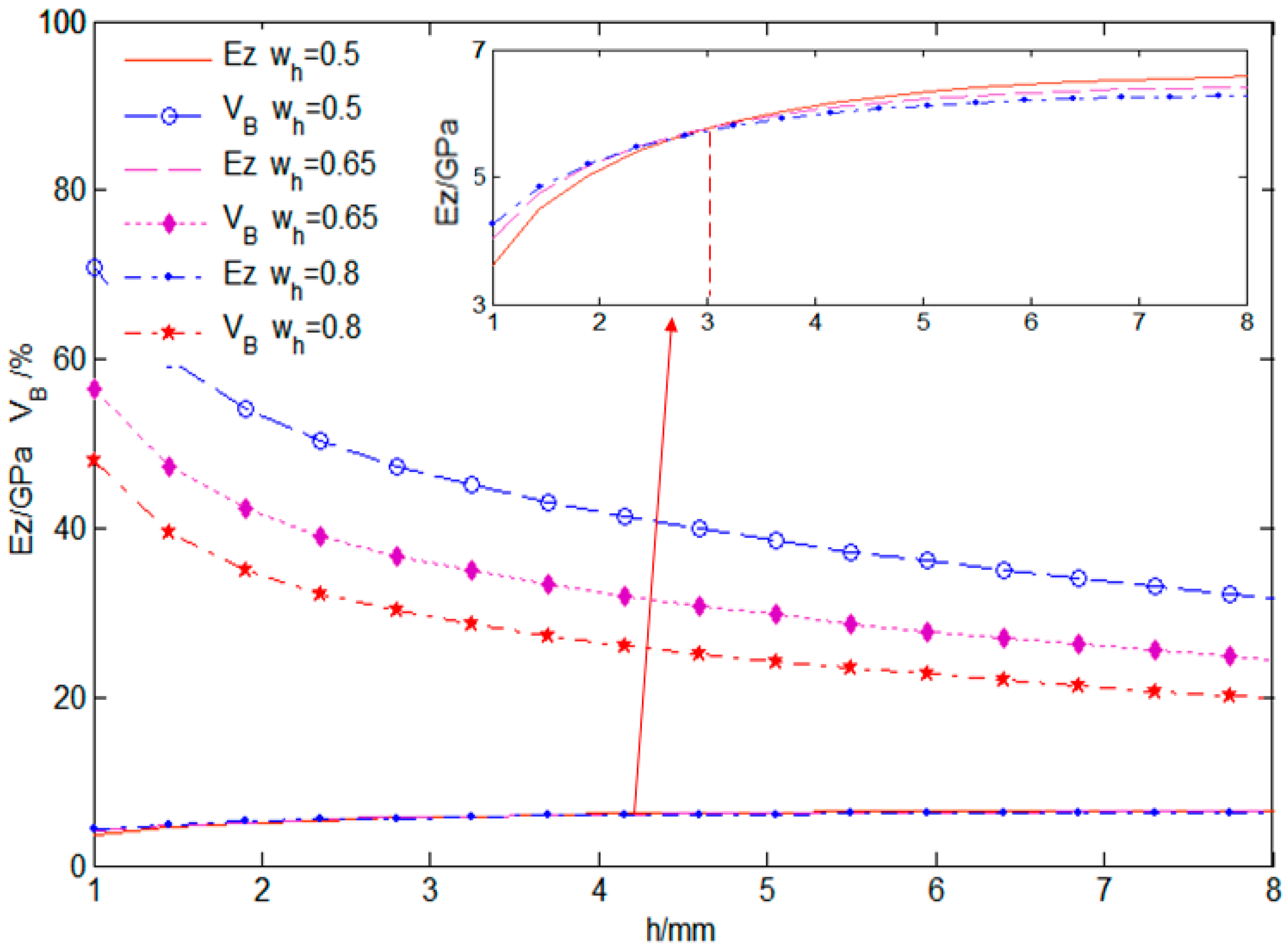

Figure 11 shows the influence curve of cell height and knuckle length on fiber volume content and longitudinal elastic modulus . It can be seen from Figure 11 that with the increase in knuckle length and cell height , the fiber volume content of 3D five-directional annular braided composites decreases. The longitudinal elastic modulus increases rapidly when the length of knuckle , and increases slowly when . When the knuckle length , the longitudinal elastic modulus increases with the increase in the cell height . When the node length , the longitudinal elastic modulus decreases with the increase in cell height . The above results show that the cell height has less influence on longitudinal elastic modulus and more influence on fiber volume content.

Figure 11.

Influence curve of cell height and knuckle length on fiber volume content and longitudinal elastic modulus.

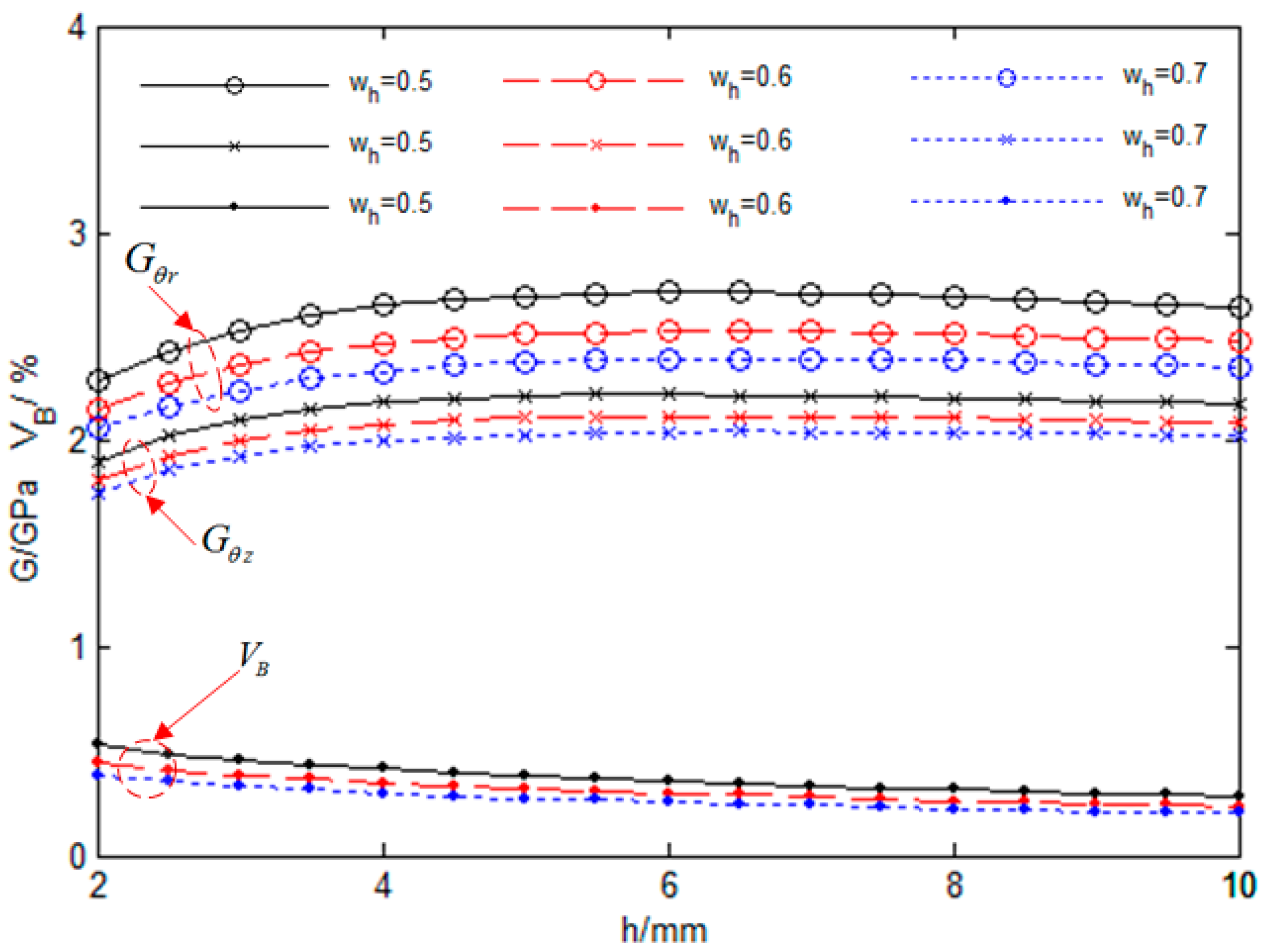

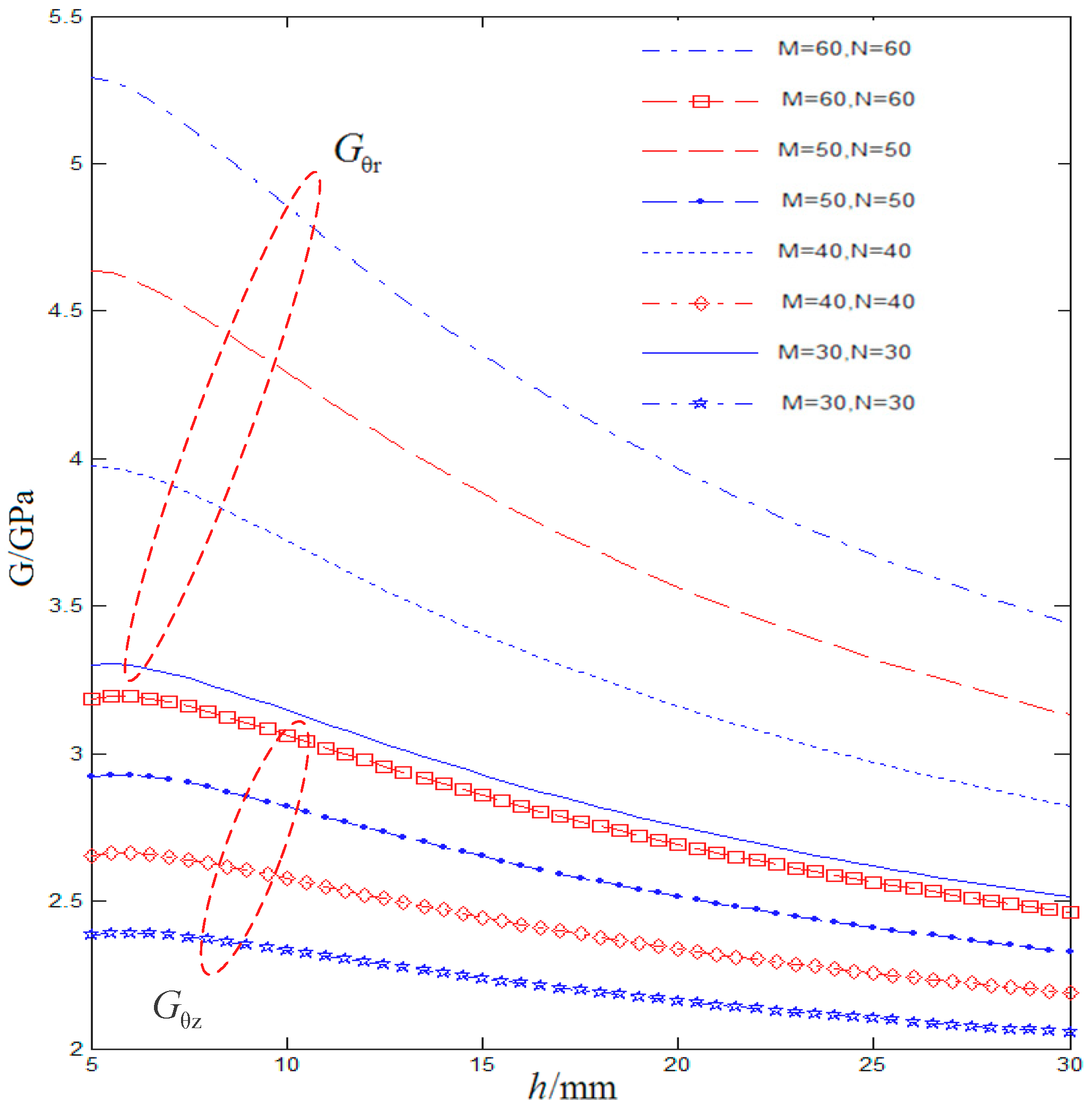

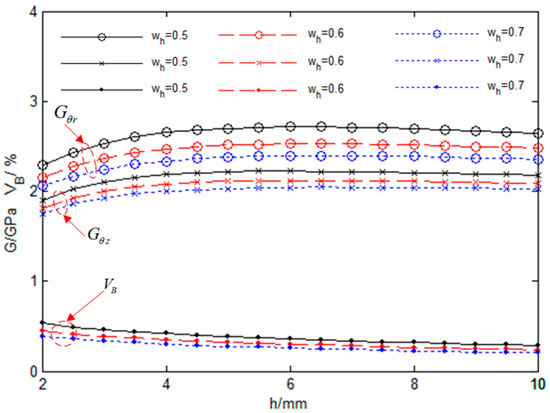

It can be seen from Figure 12 that with the increase in knuckle length h, the fiber volume content decreases, and the shear modulus first increases and then decreases. With the increase in cell height , the fiber volume content and elastic modulus decrease linearly. The above results show that the shear modulus is greater than the shear modulus , and this is mainly because the mechanical properties of materials along the braiding direction are the best.

Figure 12.

Relationship curve of cell height, knuckle length, fiber volume content, and shear modulus.

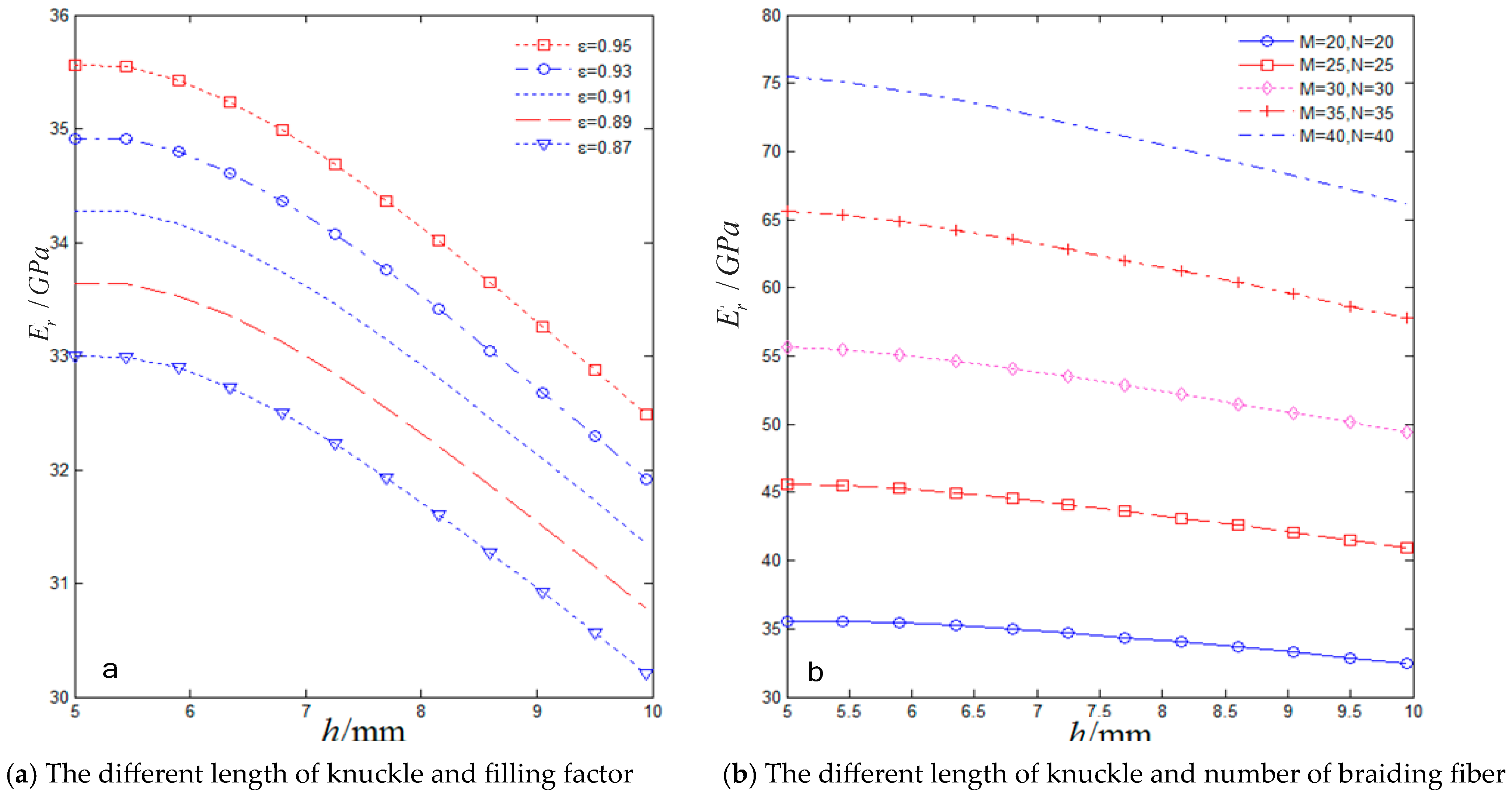

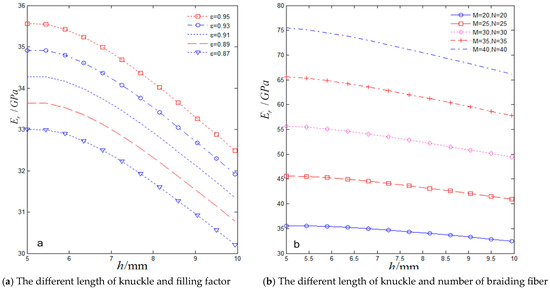

It can be seen from Figure 13 that with that knuckle length increase from 5 mm to 10 mm, the transverse elastic modulus is reduced by 8.6%; when the filling factor increases from 0.87 to 0.95, the transverse elastic modulus is increased by 7.5%; when the number of braiding fibers increases from 20 to 40, the transverse elastic modulus is increased by 114%.

Figure 13.

Influence curve of braiding parameters and transverse elastic modulus.

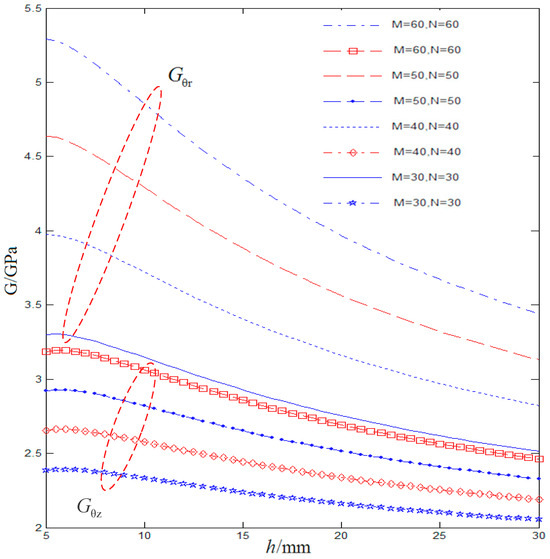

It can be seen from Figure 14 that with that knuckle length increase from 5 mm to 30 mm, the shear modulus is reduced by 33%, the shear modulus is reduced by 31%, and when the number of braiding fibers increases, the shear modulus is increased.

Figure 14.

Relationship curve between knuckle length and shear modulus under different yarn numbers.

6. Future Work

Through the above analysis, it can be found that by changing the input design variables such as filling factor, the knuckle length, cell height, and number of braiding fibers, the braiding angle and fiber volume content will be changed, and finally, the mechanical properties such as elastic modulus, shear modulus, and Poisson’s ratio will be affected, that is, the anisotropy index of mechanical properties of composites in different directions can be optimized by changing the input design variables, and the mechanical properties of braided composites can be designed, in order to meet the special requirements of industrial development for materials.

7. Conclusions

In this paper, the mathematical model of mechanical properties of 3D five-way circular braided composites is established, and the mechanical properties of materials are numerically analyzed. The research results show that the cell inner diameter is 5 mm, the cell height is 0.5 mm, and the number of radial yarns and axial yarns is 40. The numerical prediction results show that the braided angles of each cell decrease with the increase in the node length, and the braided angles of the four internal cells decrease the most. When that knuckle length increases from 1 mm to 3 mm, the braiding angle of the four inner cells is reduced by 38%~46%, and when that knuckle length increases from 1 mm to 3 mm, the braiding angle of the upper and lower surfaces is reduced by 7.1%. The braided angle of the upper and lower surfaces decreases slightly with the increase in the length of the knuckles. When the length of braided knuckles is 2 mm, the inner diameter of inner cells is 7 mm, the number of radial and axial braided yarns is 80, the height of inner cells is 0.5 mm, and the filling coefficient is 0.61. By comparing the numerical prediction model with the experimental results in reference [13], it is found that the error of the prediction model deduced in this paper is small.

Author Contributions

Final draft review, C.L.; overall scheme design L.Y.; writing, W.Z.; chart creation, W.W.; data analysis, L.L.; literature search, C.Z.; data collection, X.Z. All authors have read and agreed to the published version of the manuscript.

Funding

The research was supported by Key research and development projects in Shaanxi Province (grant No. 2024GX-YBXM-570), W.Z.; Key Project of Shaanxi Provincial Department of Science and Technology (Program No. 2024QY2-GJHX-38), L.L.

Data Availability Statement

The author provides the program code of Figure 12 in the paper. (DOCX).

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| The inner diameter of the inner cell. | |

| The outer diameter of the inner cell. | |

| M | The number of radial braiding fibers. |

| N | The number of axial braiding fibers. |

| The height of the inner cell. | |

| The fiber volume ratio of fiber in inner cell A to inner cell A. | |

| The stress transformation matrix of fiber in inner cell A. | |

| The stress transformation matrix of the inner cell A. | |

| The stiffness matrix of fiber in local coordinates. | |

| The total volume of internal cells. | |

| The volume of fibers in the inner cell. | |

| The elastic modulus of fiber bundle in direction. | |

| The filling coefficient of matrix and fiber in fiber bundle. | |

| The elastic modulus of matrix. | |

| The elastic modulus of fiber in direction. | |

| The shear modulus of fiber bundle in planes. | |

| The shear modulus of fiber in planes. | |

| Poisson’s ratio of fiber bundle in planes. | |

| Poisson’s ratio of fiber in direction. | |

| The fiber volume content. | |

| The transverse elastic modulus. | |

| The longitudinal elastic modulus. | |

| h | The knuckle length. |

Appendix A

The stress transformation matrix.

.

, , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , .

References

- Zhang, W.L.; Wang, X.P.; Ji, X.M. Response analysis of 3D braided two-stage gear system excited by different frequency signals. Adv. Mech. Eng. 2021, 13, 1. [Google Scholar] [CrossRef]

- Zhou, X. Construction of nanocomposite interphase with controllable thickness to relieve stress concentration and boost stress transfer from carbon fiber/epoxy resin interface. Chem. Eng. J. 2025, 505, 159542. [Google Scholar] [CrossRef]

- Li, L.; Aliabadi, M.H. Elastic property prediction and damage mechanics analysis of 3D braided composite. Theor. Appl. Fract. Mech. 2019, 104, 102338. [Google Scholar] [CrossRef]

- Tian, D.P.; Xu, Q.; Yao, X.H. Diversity-guided particle swarm optimization with multi-level learning strategy. Swarm Evol. Comput. 2024, 86, 101533. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, X.W.; Chen, K. Application of Three Unit-Cells Models on Mechanical Analysis of 3D Five-Directional and Full Five-Directional Braided Composites. Appl. Compos. Mater. 2013, 20, 803–825. [Google Scholar] [CrossRef]

- Xu, K.; Xu, X.W. Finite element analysis of mechanical properties of 3D five-directional braided composites. Mater. Sci. Eng. A 2008, 487, 499–509. [Google Scholar] [CrossRef]

- Zeng, T.; Fang, D.N.; Ma, L. Predicting the nonlinear response and failure of 3D braided composites. Mater. Lett. 2004, 58, 3237–3241. [Google Scholar] [CrossRef]

- Wang, X.; Sun, J.; Pang, Z.; Qian, K.; Zhang, D. Design and fabrication of bioinspired bamboo-node three-dimensional six-directional braided composite tubes for superior axial compression capacity. Constr. Build. Mater. 2025, 458, 139593. [Google Scholar] [CrossRef]

- Ji, X.B.; Khatri, A.M. Multi-scale simulation and finite element-assisted computation of elastic properties of braided textile reinforced composites. J. Compos. Mater. 2014, 48, 931–949. [Google Scholar] [CrossRef]

- Kang, H.R. Progressive damage analysis and strength properties of fiber-bar composites reinforced by three-dimensional weaving under uniaxial tension. Compos. Struct. 2016, 141, 264–281. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, Y.; Liu, T. Effect of fiber breakage defect and waviness defect on compressive fatigue behavior and damage evolution of 3D multiaxial braided composites. Chin. J. Aeronaut. 2025, 38, 103323. [Google Scholar] [CrossRef]

- Wang, Q. Analysis of Vibration Characteristics for Rotating Braided Fiber-Reinforced Composite Annular Plates with Perforations. Materials 2024, 17, 5402. [Google Scholar] [CrossRef]

- Gao, C.; Sun, H.; Gu, J. Dynamic modeling of a three-dimensional braided composite thin plate considering braiding directions. Appl. Math. Mech. 2025, 46, 123–138. [Google Scholar] [CrossRef]

- Chen, Y.H. Micro-mechanical modelling of the overall response of plain woven polymer matrix composites. Int. J. Eng. Sci. 2019, 145, 103163. [Google Scholar] [CrossRef]

- Zhao, Y.L. Analysis of structures and elastic properties of 3D tubular braided composites. J. Tianjin Polytech. Univ. 2010, 29, 15–18. [Google Scholar]

- Li, D.S.; Lu, Z.X.; Chen, L. Microstructure Analysis and Prediction of the Elastic Properties of 3D and 5-D Tubular Braided Composites. Acta Aeronaut. Astronaut. Sin. 2007, 28, 123–129. [Google Scholar]

- Shen, H.R. Investigation on Mechanical Properties for Three-dimensional Braided Circular Tubes and the Bearing Capacities for the Analogue Structure of a Rocket Linking Stage. J. Natl. Univ. Defense Technol. 1999, 21, 61–66. [Google Scholar]

- Zhang, W.L. Structural design and dynamic characteristics analysis of braided composite two-stage gear transmission system. Sci. Rep. 2024, 14, 1–15. [Google Scholar] [CrossRef]

- Zeng, J.H.; Zhang, Q.L.; Fu, Y.C. Heterogeneous ablation behavior of SiCf/SiC composite by nanosecond pulse laser. Adv. Manuf. 2025, 13, 196–210. [Google Scholar] [CrossRef]

- Fang, G.D.; Liang, J.; Lu, Q. Investigation on the compressive properties of the three dimensional four-directional braided composites. Compos. Struct. 2011, 93, 392–405. [Google Scholar] [CrossRef]

- Zhang, W.L.; Wang, X.P.; Ji, X.M. Parametric characteristics analysis of three cells in 3D five-directional annular braided composites. PLoS ONE 2021, 16, e0254691. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.L.; Li, C.; Zhang, L.Q. Micro-XCT analysis of damage mechanisms in 3D circular braided composite tubes under transverse impact. Compos. Sci. Technol. 2018, 155, 91–99. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).