Abstract

The moisture content is closely related to the shear creep deformation behavior of soft rock, and the linear creep deformation behavior of soft rock can be described by the classical Nishihara model. However, its accuracy in describing accelerated nonlinear creep characteristics and the effects of moisture content still needs to be improved. The innovation of this paper is to propose an improved Nishihara model that can describe the whole creep process of shale with different moisture content. The model uses a strain-triggered nonlinear sticky pot to describe the process of accelerated creep of rock, and proposes a damage factor to reflect the effect of moisture content on the creep characteristics of rock. The relationship between the moisture content and damage factor is an exponential function, and the damage factor and related model parameters are determined by the shear creep test results under moisture conditions (0%, 0.46%, 0.87%, 1.24%). The shear creep tests were carried out by a self-developed rock shear apparatus. The experimental results show that the shear creep rate decreases first and then increases. The higher the moisture content of shale, the greater the initial shear displacement and stable creep displacement, and the longer it takes to enter the stable creep stage. The improved Nishihara model proposed in this paper can accurately fit the shear creep curves of four groups of shale samples with different moisture contents, and the correlation coefficients all reach 0.99. The fitting effect is better than that of the traditional model, which has good accuracy and practicability.

1. Introduction

Under the long-term action of in situ stress, the rock will undergo creep deformation, and water can deteriorate the mechanical properties of rock and increase the creep deformation of the rock [1,2,3,4]. The classic Nishihara model can only describe the first two stages of rock creep deformation very well [5,6], but its accuracy in describing accelerated creep characteristics and the effects of other factors still needs to be improved. To address this problem, many scholars strive to improve the classic Nishihara model to describe the full process characteristics of rock creep under the influence of various factors [7,8,9,10,11,12,13,14,15].

On the one hand, adding or replacing elements is an important method to improve the constitutive model for describing the nonlinear deformation of rocks. By replacing the dashpot in the Kelvin model with the Abel dashpot and modifying the dashpot in the plastomer model to nonlinear dashpot, Yan et al. [16] established a modified Nishihara model that can better describe the whole process (deceleration creep stage, stable creep stage, accelerated creep stage). Jiang et al. [17] obtained an improved quasi-static Nishihara model of transient and steady-state creep by adding a strain-triggered inertial element in series, which can describe a phase of quadratic accelerating creep. On the other hand, the introduction of damage variables into constitutive models is also the main method for describing the influence of other factors on the creep properties of rocks. For example, in order to study the thermal effect in the creep model, Wang et al. [18] proposed a modified Nishihara rheological model considering the thermal damage and stress coupling effect by introducing a damage variable. Li et al. [19] introduced the hardening variable and damage variable to consider the hardening and weakening effects of the frozen loess and proposed an improved Nishihara model.

In summary, there exists an improved Nishihara model that is not suitable for describing the effect of moisture content on the deformation behavior of rock in the whole process of shear creep. Therefore, we first presented an improved Nishihara model that connected a strain-triggered nonlinear dashpot in series on the classical Nishihara model to describe the whole process of rock creep, and a damage factor was proposed to reflect the effect of moisture on the rock creep characteristics. Then, the shear creep test results of shale with different moisture contents are used to determine the parameters of the improved Nishihara model. Finally, the applicability and accuracy of the improved model are verified by the fitting effect of the experimental data.

2. Rock Shear Creep Experiment

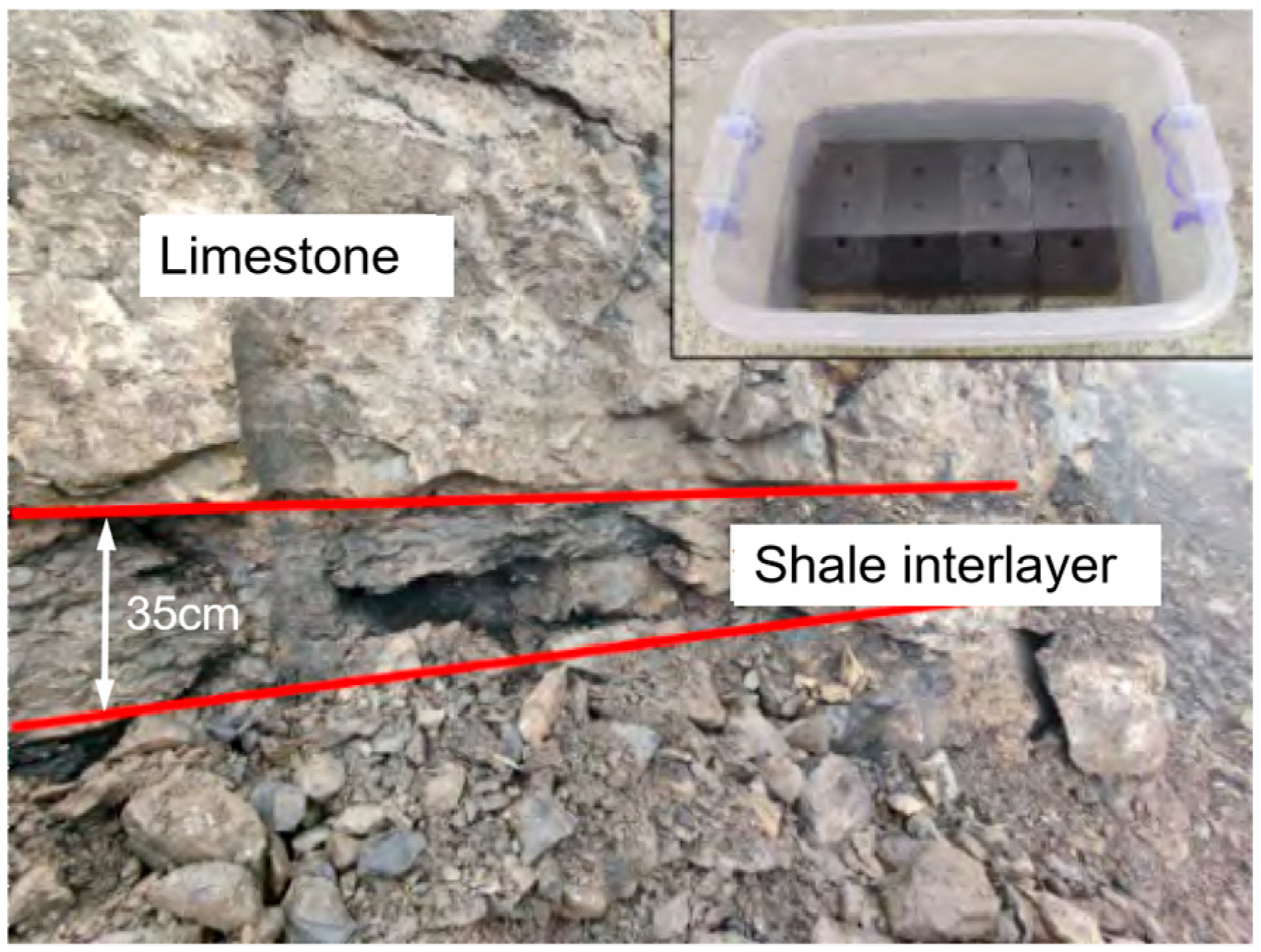

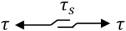

The samples utilized in this study were collected from interlayer shale in a limestone mine in the east of Southwest of China (Figure 1) [20]. The mine area is prone to landslides, and many disasters have been attributed to high moisture contents and major deformation of the weak interlayer after heavy rainfall [21,22,23]. Shale blocks collected from the mine site were transported to the laboratory, and cuboids measuring 150 mm × 75 mm × 75 mm were prepared. Following the preparation, the samples exhibited a polished finish, and the error associated with various dimensions was ±0.02 mm, while the average volumetric weight was 25.6 kN/m3. The composition elements of shale samples (expressed as oxides) were tested by XRD method, including CaO (38.03%), SiO2 (35.83%), MgO (13.03%), and Al2O3 (2.73%).

Figure 1.

Photograph showing the weak interlayer of shale in limestone.

The rock shear apparatus used in this study was independently developed. The apparatus mainly consists of a servo stress loading subsystem, shear box, control subsystem, etc. The host frame is made of high-grade ductile iron with a stiffness of 6 GN/m. The maximum holding time for compressive shear load can reach 2000 h. During the shear creep test, the normal load was set to 0.6 MPa, and shear stress was applied in five incremental steps, which lasted 48 h each. Data were acquired using a frequency of 10 Hz during the deceleration creep stage, followed by 1 Hz during the stable creep stage with sensors [24].

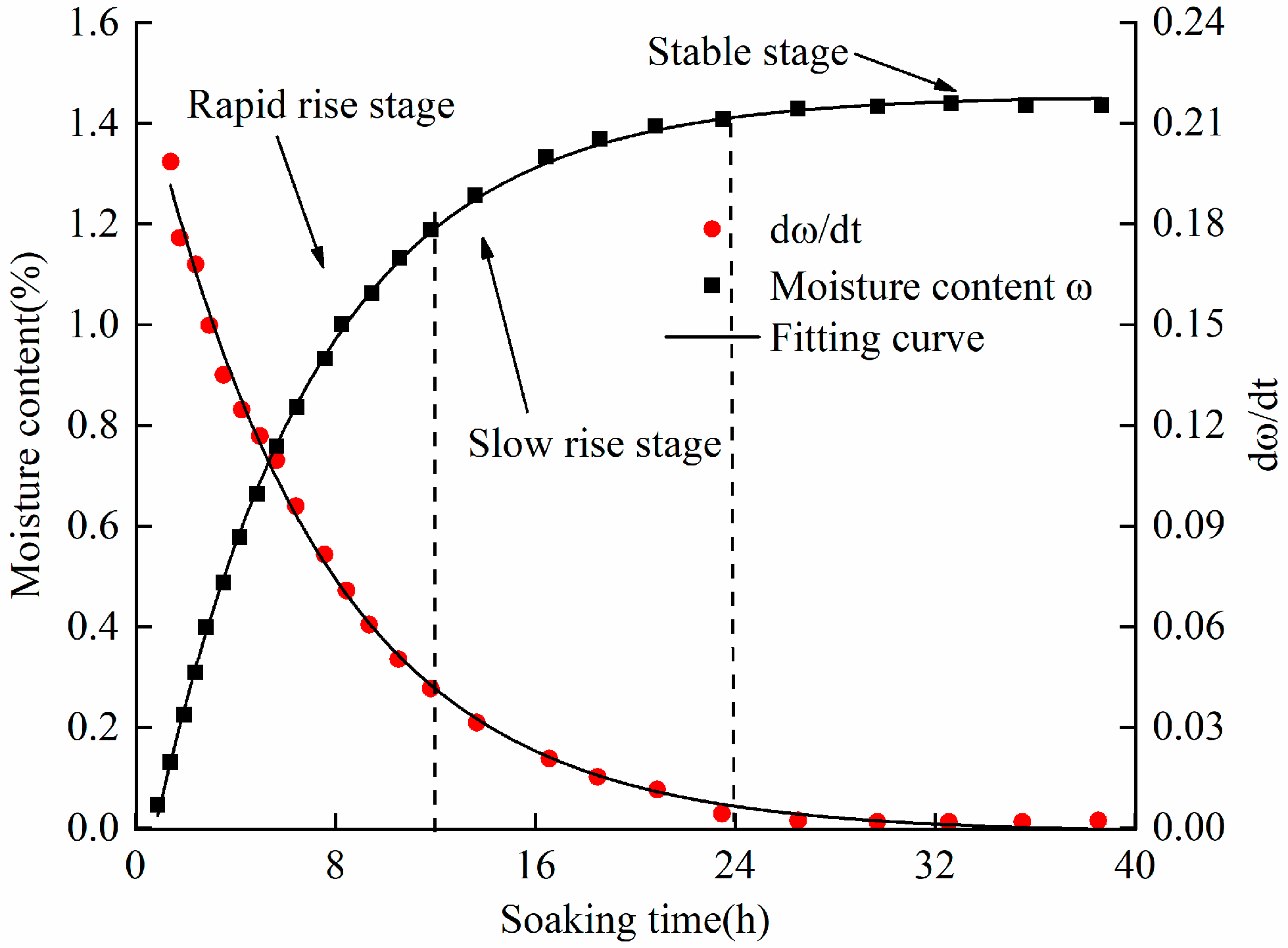

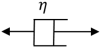

Before the shear tests, shale samples were oven-dried at 110 °C for 24 h and then immersed in water according to the International Society for Rock Mechanics recommendations. The moisture content of each sample was measured at 30 min intervals for a total of 40 h to establish the relationship with time, as depicted in Figure 2 [25]. Before the test, a dry sample was selected, and the moisture contents of the other three samples were measured to be 0.46%, 0.87%, and 1.24% after soaking in water for 4 h, 8 h, and 12 h, respectively. Following the removal of a sample from the water, the surface was slightly dried using a rag. Shear creep tests were then conducted under constant normal stress conditions, and the rest of the samples were wrapped in a waterproof membrane to prevent the loss of moisture. The moisture content of each sample was determined using Equation (1) [26].

where ω denotes the moisture content, m1 represents the weight of the saturated rock sample, and m2 is the weight of the dry rock sample.

Figure 2.

Evolution of moisture content as a function of immersion duration.

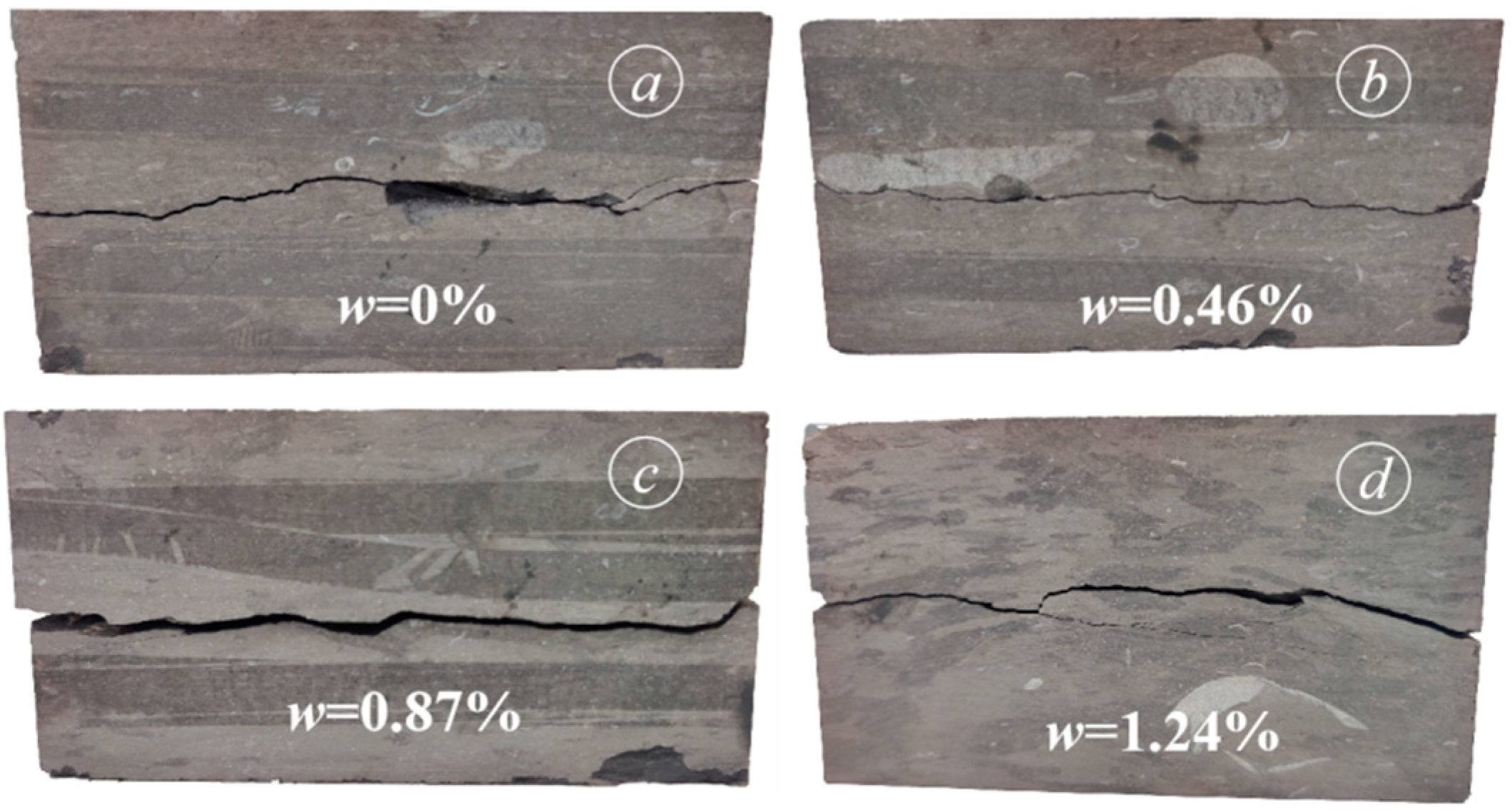

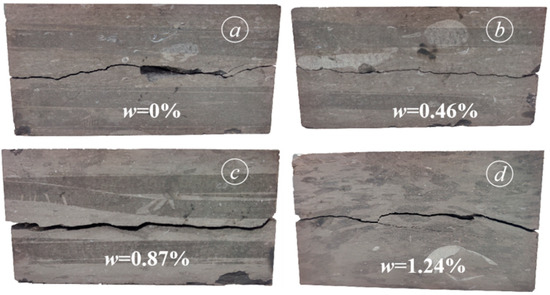

Figure 3 shows samples with different moisture contents that failed during shear creep tests using a normal stress of 2.04 MPa. The shear failure surface mainly develops and extends along the middle of the rock sample.

Figure 3.

Fractures associated with shear creep in samples with different moisture contents.

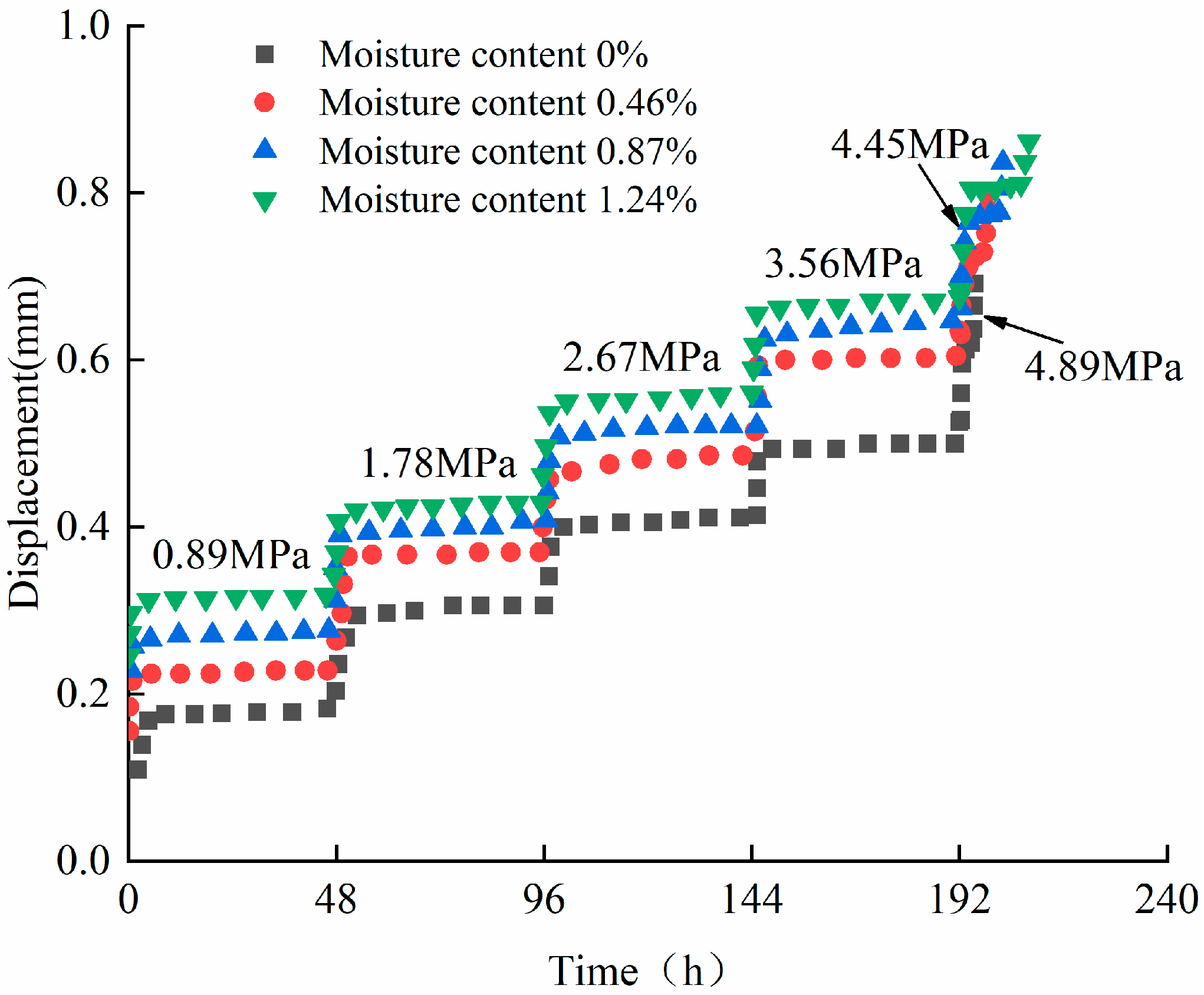

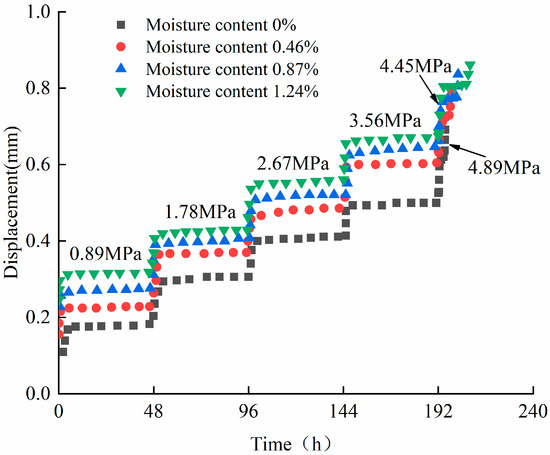

Figure 4 shows the shear creep displacement of samples with four different moisture contents during the five loading steps. The influence of moisture content on the creep characteristics of shale is significant. The larger the moisture content is, the larger the initial displacement and stable creep of the shale sample are. Under the shear force of 0.8 MPa, when the moisture content is 0%, 0.46%, 0.87% and 1.24%, the initial displacements of the samples are 0.10 mm, 0.15 mm, 0.19 mm, and 0.22 mm, respectively, and the displacements in the stable creep stage are 0.18 mm, 0.22 mm, 0.27 mm, and 0.31 mm, respectively.

Figure 4.

Shear creep response of shale samples with four different moisture contents.

In addition, under the first four levels of shear loading, the shear creep evolution characteristics of the samples are similar, and the shear creep of rock samples with different moisture contents only consists of two stages: deceleration and stable creep. Except for the fifth level shear loading stage, under the same shear loading force, the shear deformation value of the rock sample in the stable creep stage increases with the increase in moisture content. This is because the increase in moisture content leads to a decrease in the bonding force between rock particles, resulting in the softening of the shale. Under the fifth level shear loading, samples with different moisture contents enter the accelerated creep stage after experiencing different loading times, and shear deformation increases rapidly and shear failure occurs.

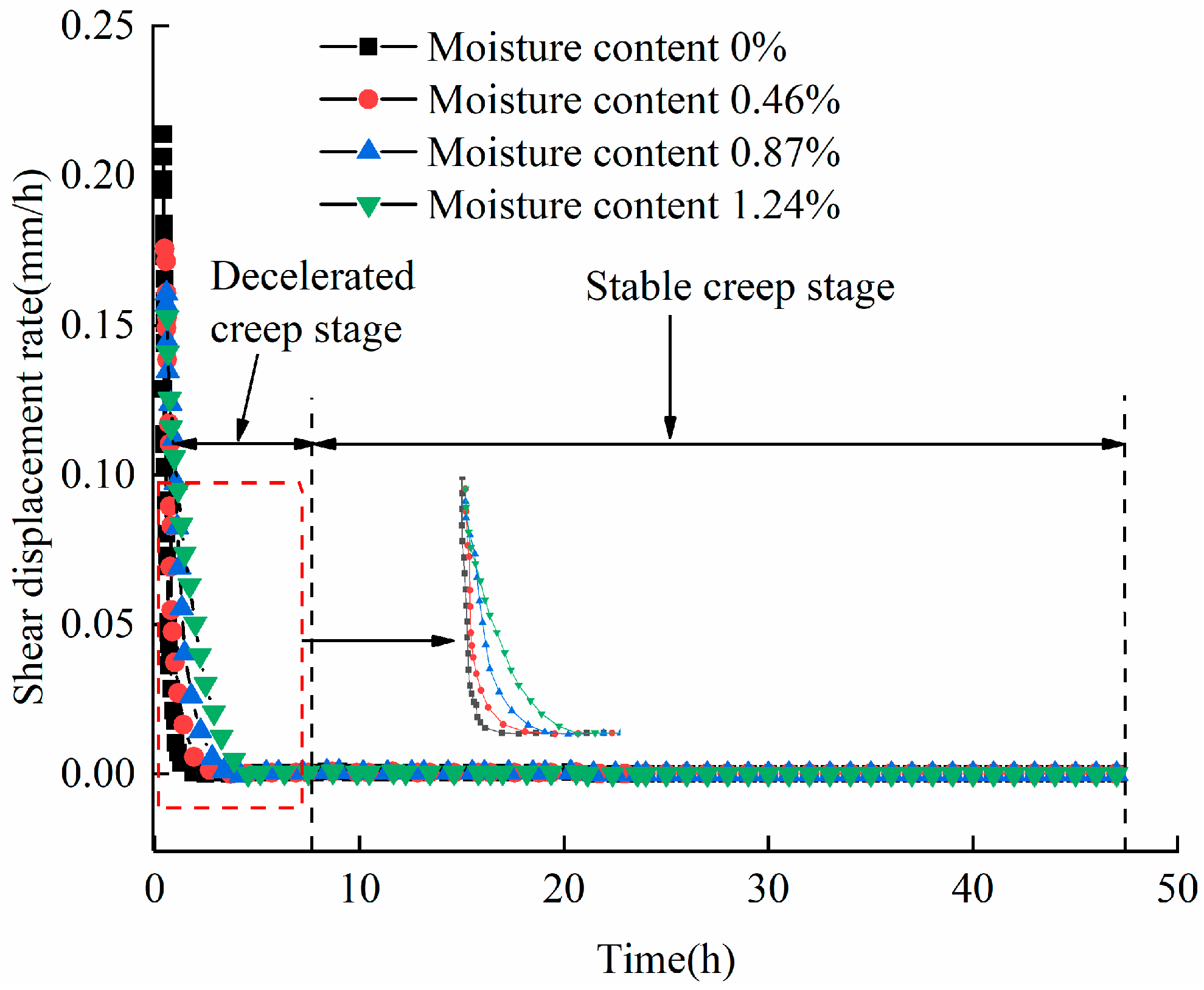

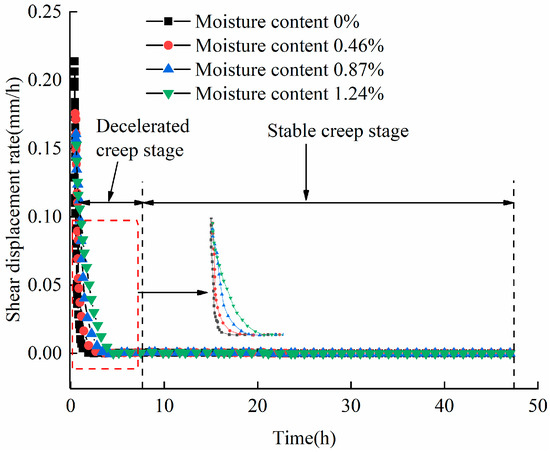

The evolution of the shear displacement rates for samples with different moisture contents under a shear stress of 0.89 MPa is shown in Figure 5. The data in Figure 5 revealed the following: (1) the shear displacement rates of samples with different moisture contents all undergo two stages, including decelerated creep and stable creep; (2) the shear creep rates of the samples were characterized by a monotonically decreasing trend and the values eventually approached zero; (3) the lower the moisture content, the higher the initial shear creep rate and the shorter the duration required to reach the stable creep stage. In summary, it can be inferred that moisture content has a significant impact on the creep rate of shale. When the shear stress is less than the yield limit , the creep deformation of samples with different moisture contents ultimately stabilizes at a certain value. The moisture content of the sample affects the time required for deformation to stabilize at a certain value. Therefore, the moisture content can be regarded as a damage factor affecting the creep deformation of soft rocks.

Figure 5.

Changes in the shear displacement rates of the four samples at a shear stress of 0.89 MPa.

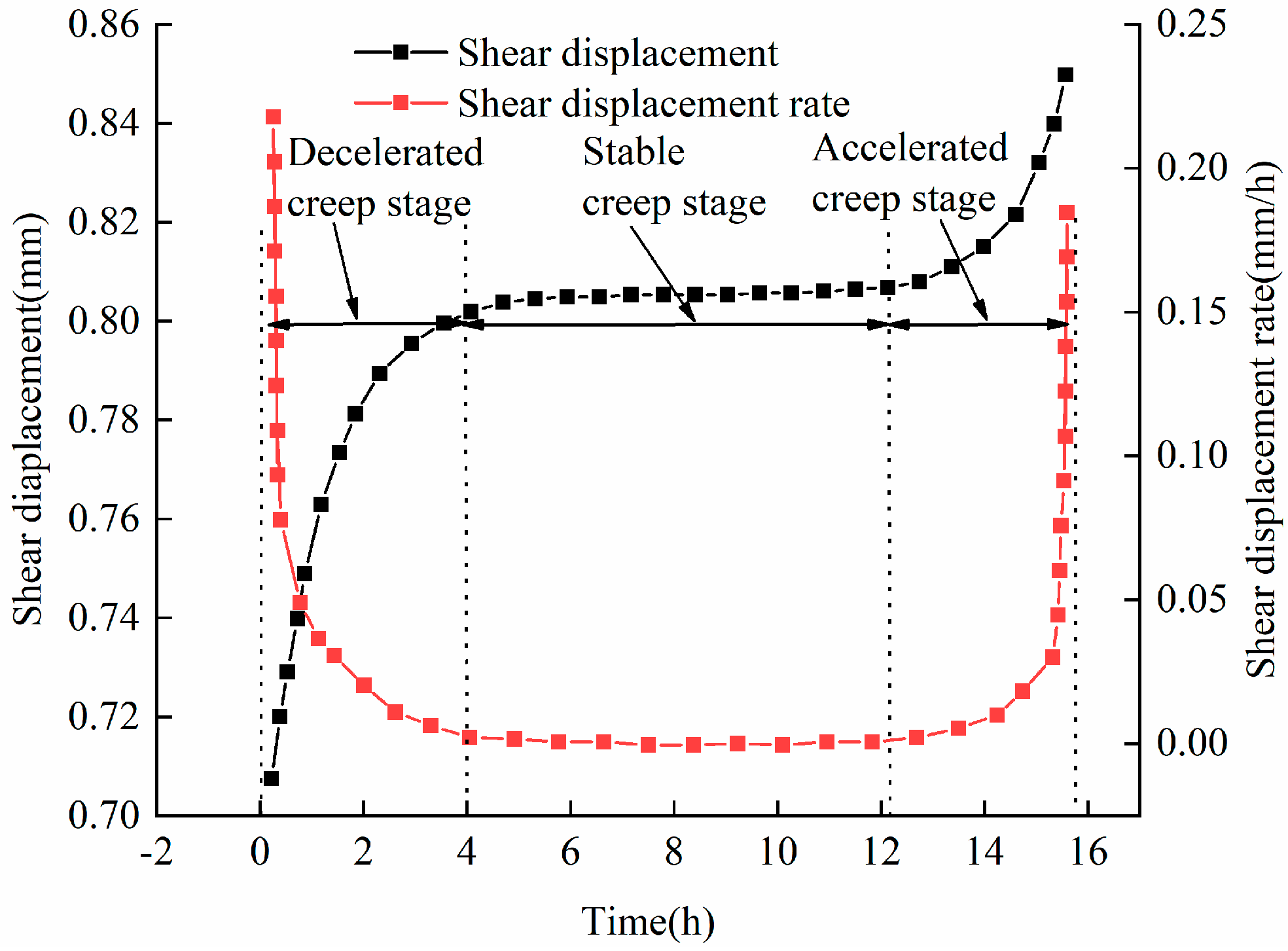

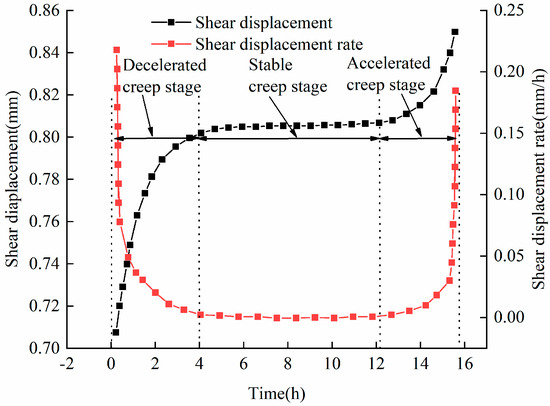

The shear displacement rate of a shale sample with a moisture content of 1.24% under a shear stress of 4.45 MPa is shown in Figure 6. The shear creep of the specimen was characterized by decelerated, stable, and accelerated creep stages. After approximately 12 h, in the accelerated creep stage, the shear deformation of the rock sample suddenly increased and then failure occurred [27]. The shear displacement rate shows a ‘U’ shape with the change in shear stress loading time. Within 4 h of shear loading, the rock sample is in the decelerated creep stage, and the shear displacement rate gradually decreases with the duration of shear loading. In the shear loading of 4~12.1 h, the rock sample is in a stable creep stage, and the shear displacement rate remains stable at about 0. When the shear loading reaches 15.8 h, the rock sample enters the accelerated creep stage, and the shear displacement rate begins to increase continuously. When the rock sample is destroyed, the shear displacement rate rises sharply. In short, the water-bearing rock sample and the dry rock sample have the same shear creep evolution characteristics. When the moisture content is 1.24%, the shale sample still has the characteristics of three stages of shear creep failure.

Figure 6.

Variations in the shear displacement and shear displacement rate for the sample with a moisture content of 1.24%.

3. Improved Nishihara Creep Model

3.1. Classical Nishihara Creep Model

Usually, the classical creep model is mainly composed of elastic elements, plastic elements, and viscous elements. The mechanical models and constitutive equations of the three elements are shown in Table 1. η is the viscosity coefficient. The elastic element fully conforms to Hooke’s law and is an ideal elastic element; the plastic element begins to deform when the shear stress reaches the yield limit , and the shear strain continues to grow when the stress no longer increases; the stress for the viscous element is proportional to the strain rate ; the strain is time-dependent.

Table 1.

The basic elements of the creep model.

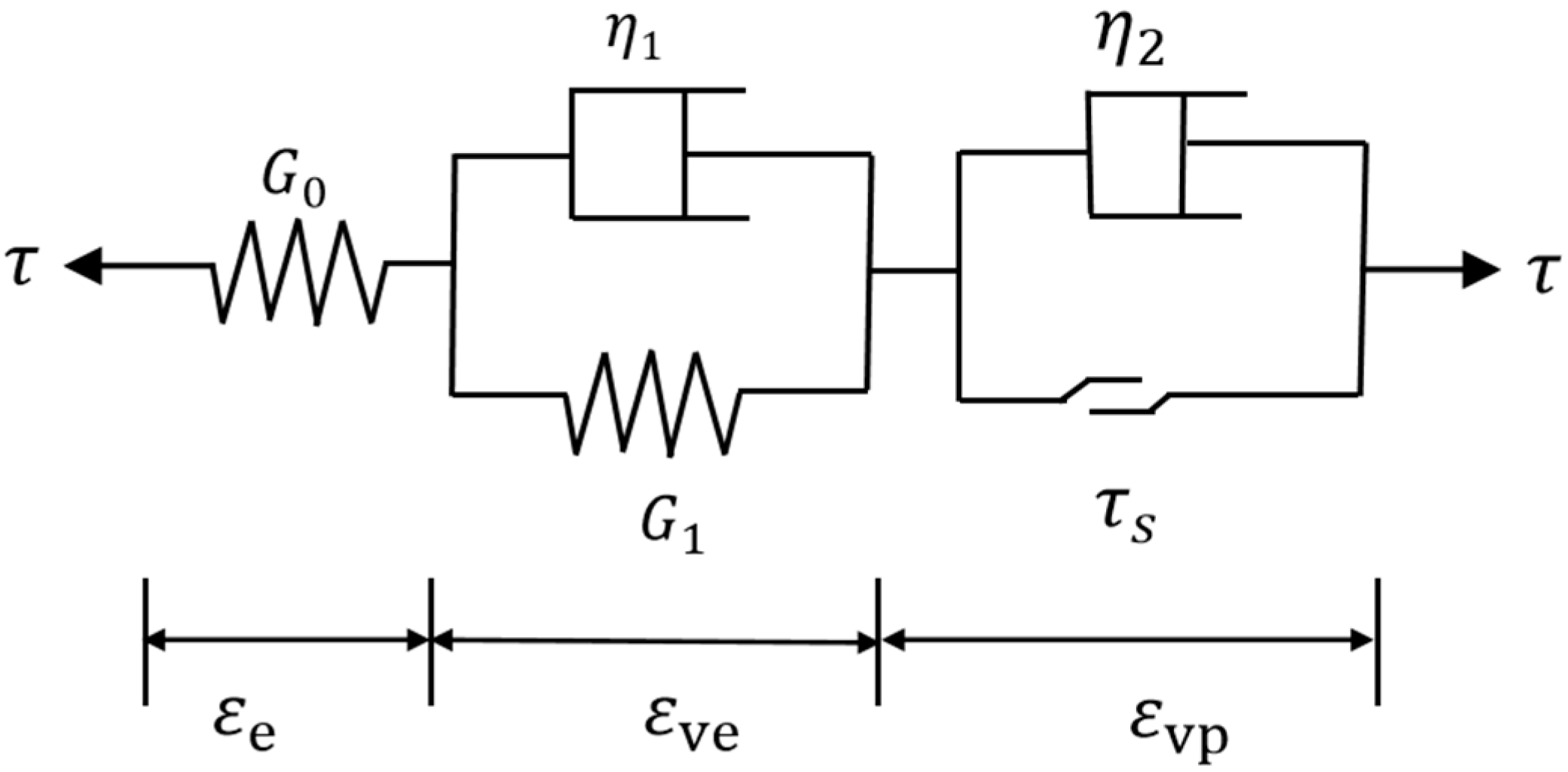

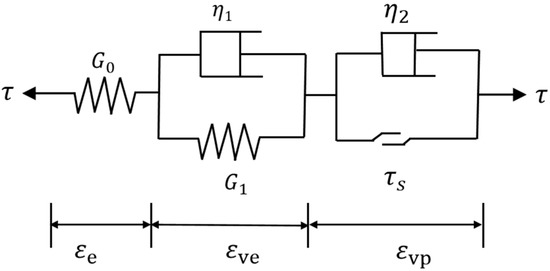

The classical Nishihara model is composed of the Hooke element, Kell element, and ideal visco-plastic element in series, as shown in Figure 7. It is widely used to reflect the linear creep deformation behavior of soft rock under low shear stress. We can obtain the total deformation of soft rocks by adding the deformations of these elements according to Equation (2),

where , , and represent the strains of the Hooke, Kell, and ideal visco-plastic elements, respectively. The constitutive equation of the classical Nishihara model is expressed in Equation (3):

where represents all shear stress values, is the instantaneous shear modulus, is the visco-elasto-plastic modulus, and are viscosity coefficients, and is the total strain associated with various creep elements.

Figure 7.

Components of the classical Nishihara model.

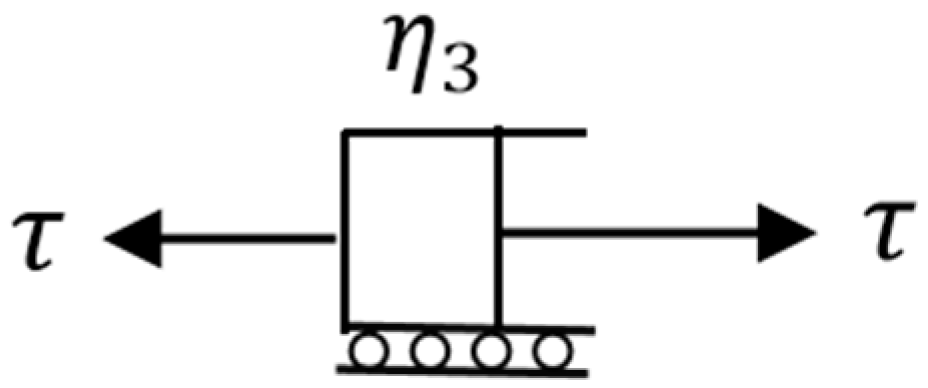

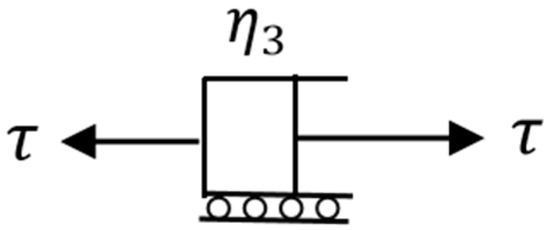

3.2. A Nonlinear Dashpot Triggered by Strain

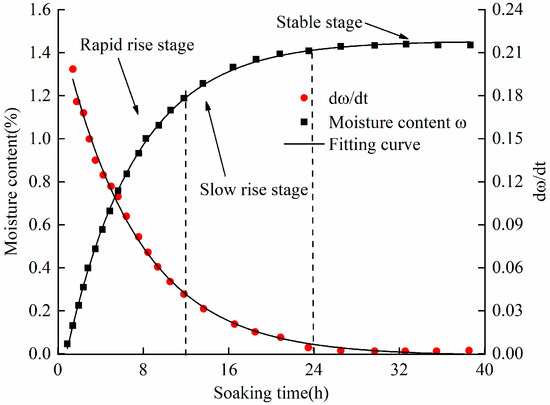

Before landslides occur, the creep deformation of rocks increases rapidly, providing an important reference index for timely landslide disaster prediction. Therefore, based on the classical Nishihara model, we introduced a nonlinear dashpot triggered by strain to describe the deformation characteristics of rocks during the accelerated creep stage. The nonlinear dashpot triggered by strain is shown in Figure 8.

Figure 8.

A nonlinear dashpot triggered by strain.

The parameter is the critical value of shear strain at the start of the accelerated creep stage. If the shear strain , the dashpot is a nonfunctional rigid element. In contrast, if the applied shear stress is larger than the yield strength and the shear strain , the rock enters the accelerated creep stage. The constitutive relationship of the nonlinear dashpot can be expressed as follows:

where is a parameter that requires confirmation based on the shear creep experiment, and represents the viscosity coefficient of the nonlinear dashpot. By integrating Equation (4), the following equation, Equation (5), was obtained:

3.3. Moisture-Related Damage Factor

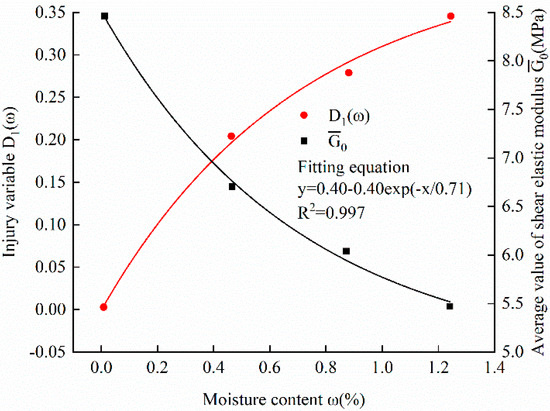

The model parameters are obtained by fitting the results of the shear creep experiments of shale with different moisture contents, and the fitting parameter values are shown in Table 2.

Table 2.

Summarized data for parameters of the Nishihara model obtained under different moisture conditions.

Water can weaken the mechanical strength of the rock and increase the creep deformation of the rock [28,29]. To characterize the influence of moisture content on the shear creep properties of a rock, a damage factor D (ω) was introduced [30]. The relationship given in Equation (6) was established between the moisture content and the instantaneous shear elastic modulus as follows:

where D1 (ω) is the damage variable of the degradation of the instantaneous shear elastic modulus associated with the moisture content, GM (0) represents the instantaneous shear elastic modulus in the dry state, and GK (0) denotes the instantaneous shear elastic modulus after degradation with the moisture content. If the moisture content (ω) is 0, the rock sample is undamaged and D1 (ω) = 0; D (ω) varies as the moisture content changes.

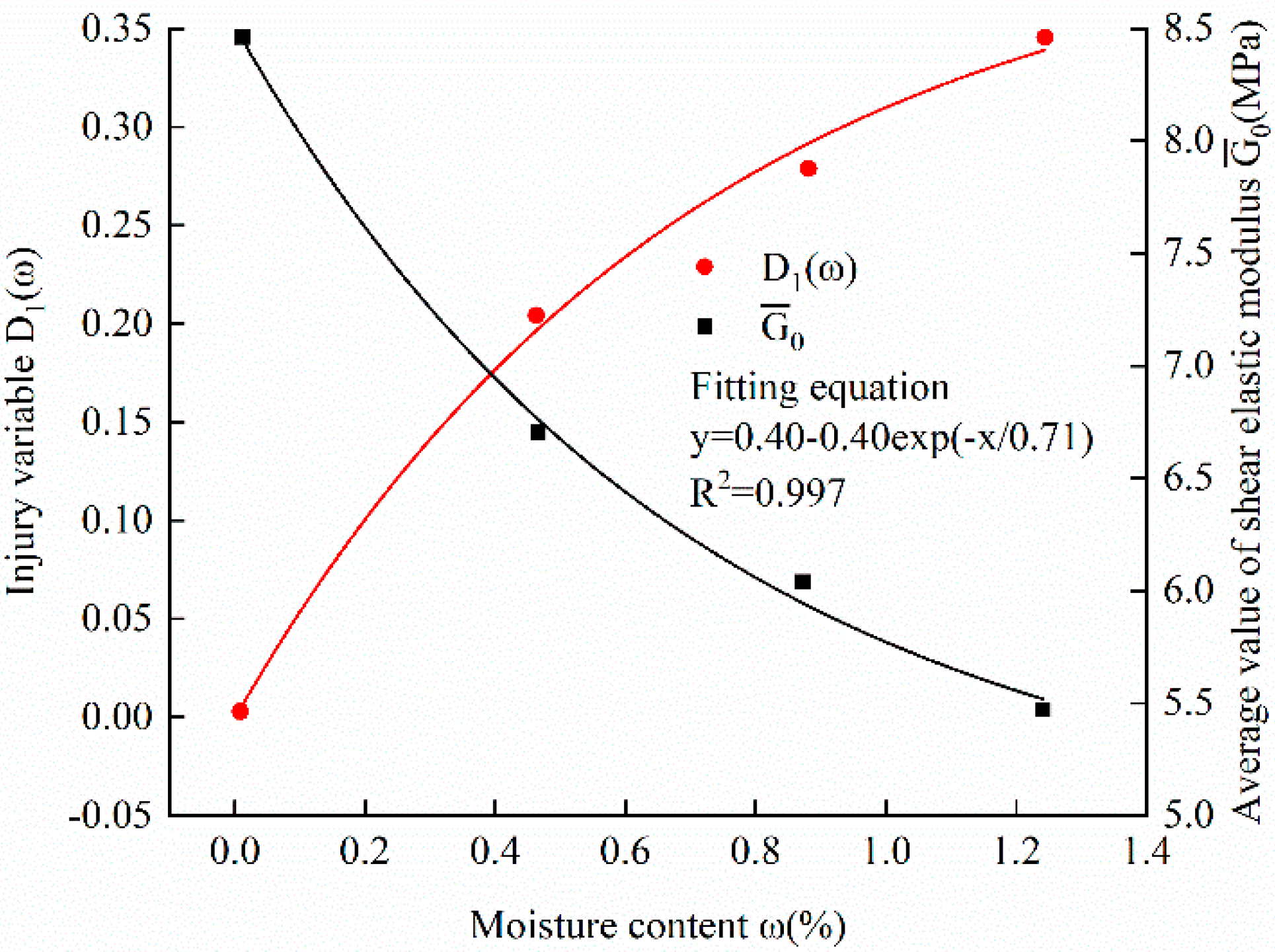

According to the parameter values of the model shown in Table 1, a relationship between the damage variable and the moisture content can be established. The average instantaneous shear elastic modulus , the average visco-elasto-plastic shear modulus , and the average shear viscosity coefficient decrease as moisture content increases. These parameters can be fitted using the least square method, as shown in Figure 9, and the associated fitting results can be expressed by Equations (7)–(9). For example, the calculation results show that the standard deviation of D1 (ω) is only 0.06.

Figure 9.

Fitting involving the damage factor linked to moisture content.

Even if the parameters , , and also affect the fitting results associated with the improved Nishihara model, these parameters start to work typically until the accelerated creep stage, for which the time for rock failure in this stage is short. Thus, the effects of the damage caused by the moisture content linked to these parameters were neglected at the accelerated creep stage in this study.

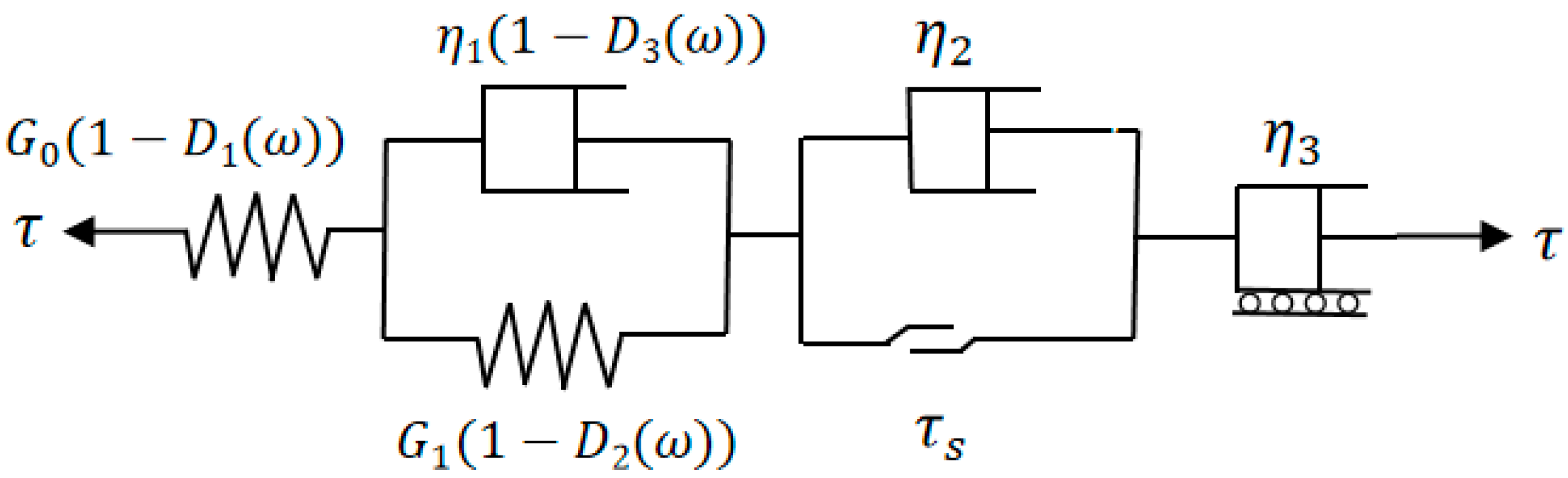

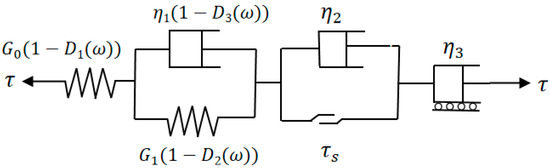

3.4. Establishment of Improved Nishihara Model

The classical Nishihara model is improved by introducing a nonlinear dashpot element and damage factor on moisture content. The improved model is shown in Figure 10. Before entering the accelerated creep stage, the damage factor related to moisture content will affect the average instantaneous shear elastic modulus , the average visco-elasto-plastic shear modulus , and the average shear viscosity coefficient . When the rock sample enters the accelerated creep stage, the shear stress must be greater than the yield stress and the shear strain is greater than the critical value . At this time, a strain-triggered nonlinear dashpot in series on the classical Nishihara model comes into work, and the creep constitutive equation of the improved Nishihara model is shown in Equation (10).

Figure 10.

Improved Nishihara model with damage factor related to moisture content.

4. Validation of Improved Nishihara Model

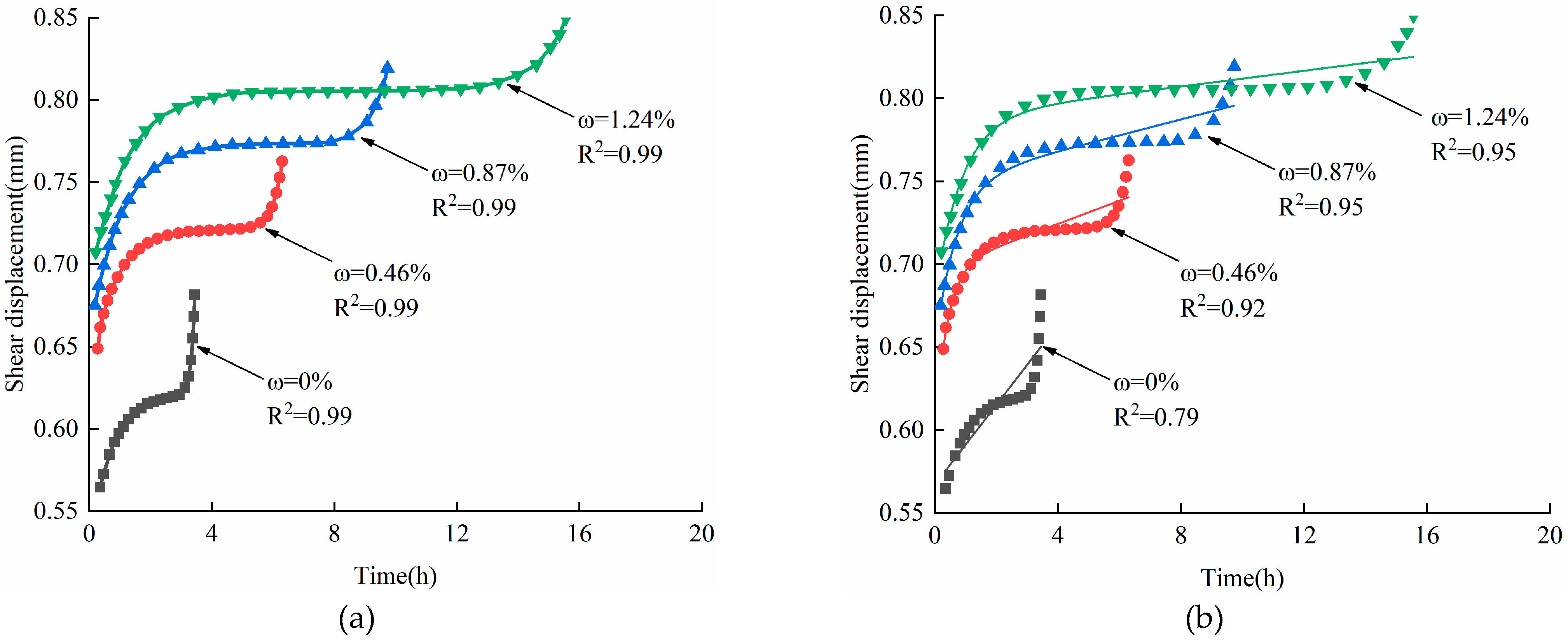

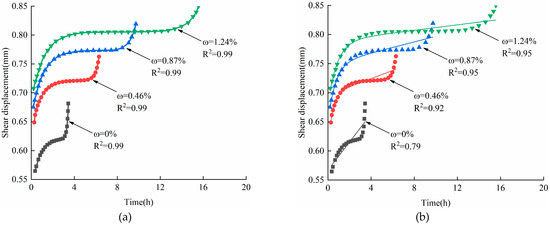

Based on the accelerated creep test results for the samples with different moisture contents, the Levenberg–Marquardt optimization iterative algorithm was used to identify the parameters of the improved creep model. The results for the parameters of the improved Nishihara model in the accelerated creep stage are presented in Table 3. A comparison between the fitting associated with the improved and the classical Nishihara model in the accelerated creep stage is shown in Figure 11. The improved model in Figure 11a adequately described the deformation of the shale with varying moisture contents, and the associated correlation coefficients (R2) were greater than 0.99. Based on the shale shear creep test of the same test apparatus, the fitting correlation coefficient of the nonlinear damage creep constitutive model established by Wei et al. [31] reached 0.95, which indicates that the improved Nishihara model established in this paper has a more accurate fitting effect on the creep deformation of shale.

Table 3.

Creep characteristic values for shale with different moisture contents in the accelerated creep stage based on the improved Nishihara model.

Figure 11.

Fitting effects of the (a) improved and (b) classical Nishihara models on the deformation of shale with different moisture contents during accelerated creep stages.

Figure 11b shows the limitation of the classical Nishihara model in the characterization of the deformation of shale during the accelerated creep stage. In particular, at a low moisture content, the line-of-fit using the classical Nishihara model substantially differed from the test results, and the R2 was 0.79, indicating a poor fitting effect of the deformation characteristics in the accelerated creep stage. These results validated the applicability and accuracy of the improved Nishihara model and demonstrated its superiority relative to the classical Nishihara model.

The improved Nishihara model proposed in this paper can be embedded in numerical simulation software to accurately predict the creep deformation of soft rock with different moisture contents. For example, it can simulate the landslide of slope with weak interlayer under rainfall conditions and predict the deformation of the surrounding rock of a water-rich soft rock tunnel under different ground stress conditions. In the future, the application scope of the improved Nishihara model based on the shale shear creep test needs to be further determined. For example, the fitting effect of the creep deformation of sandstone and slate with different moisture content needs to be discussed. In addition, due to the large number of parameters involved in the model and the correlation between the parameters, this means that the model parameters obtained based on the experimental results are not a fixed single value, which poses a certain challenge to the convenience of using the model. Reducing the model parameters is the need for further research in the future application of the improved Nishihara model.

5. Conclusions

Based on the shear creep test results of shale with different moisture contents, this study innovatively proposes an improved Nishihara creep model that can describe the whole creep process of soft rock with different moisture contents. The conclusions are as follows:

(1) Shale samples with different moisture contents have experienced three stages of attenuation creep, stable creep, and accelerated creep under shear force. The rate of shear displacement decreases first and then increases. The shear displacement rate–time curve is ‘U’ type. The initial displacement and stable creep displacement of shale samples increase with the increase in moisture content and the longer it takes to enter the stable creep stage.

(2) The influence of moisture content on the creep characteristics of shale is significant. The higher the moisture content, the larger the initial displacement and stable creep of the shale sample. Under the shear force of 0.8 MPa, when the moisture content is 0%, 0.46%, 0.87%, and 1.24%, the initial displacements of the samples are 0.10 mm, 0.15 mm, 0.19 mm, and 0.22 mm, respectively, and the displacements in the stable creep stage are 0.18 mm, 0.22 mm, 0.27 mm, and 0.31 mm, respectively.

(3) Under the same shear loading force of the first four stages, the shear deformation value of the rock sample in the stable creep stage increases with the increase in moisture content. Under the action of the fifth-stage shear load, the samples with different moisture contents entered the accelerated creep stage after different loading times, and the shear deformation increased rapidly, and shear failure occurred. The improved Nishihara model proposed in this paper can accurately fit the shear creep curves of four groups of shale samples, and the correlation coefficient reaches 0.99, which is better than the traditional model. This model can provide a reference for the accurate prediction of deformation of soft rock tunnel and slope with weak interlayer under different moisture content conditions.

Author Contributions

Conceptualization, M.L.; formal analysis, L.W.; methodology, B.H.; supervision, J.Z.; validation, Y.Z.; writing—original draft, L.M. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Science and Technology Research Project of China Railway 18 Bureau Group Co. Ltd. (G23-02 and G21-11).

Data Availability Statement

The data used to support the findings of this study are available from the corresponding authors upon request.

Conflicts of Interest

Authors Liyao Ma, Lichuan Wang and Jingjing Zhang were employed by the China Railway 18th Bureau Group Co., Ltd., author Yaqian Zhao was employed by the China General Nuclear Power Corporation. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhang, F.; Zhang, D.; Huang, S. Creep Characteristics and Creep Model of Coal Based on Pore Water Pressure. Processes 2023, 11, 638. [Google Scholar] [CrossRef]

- Chen, C.; Xie, H.; Xu, J.; Peng, S.; Li, C.; Li, M. Creep behavior of sandstone under the coupling action of stress and pore water pressure using three-dimensional digital image correlation. Int. J. Damage Mech. 2024, 33, 147–173. [Google Scholar] [CrossRef]

- Miao, C.; Jiang, M.; Wang, L.; Yang, J.; Sun, X. Experimental Study on Long-Term Strength and Creep Characteristics of Sandstone Under Different Water Content and Confining Pressure. Rock. Mech. Rock. Eng. 2024, 57, 9035–9054. [Google Scholar] [CrossRef]

- Gu, Q.; Tan, Y.; Zhao, G.; Meng, X.; Cheng, X. Creep behavior of dry and saturated medium-grain sandstone and its relationship with conventional mechanical properties. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 52. [Google Scholar] [CrossRef]

- Feng, W.; Qiao, C.; Niu, S.; Yang, Z.; Wang, T. An improved nonlinear damage model of rocks considering initial damage and damage evolution. Int. J. Damage Mech. 2020, 29, 1117–1137. [Google Scholar] [CrossRef]

- Hu, D.; Liang, X.; Li, Y.; Wu, Y.; Jiang, L. Deformation Prediction of Tunnel-Surrounding Rock Considering the Time Effect of the Viscosity Coefficient: A Case of an NATM-Excavated Tunnel. Front. Earth Sci. 2022, 10, 843545. [Google Scholar] [CrossRef]

- Xiu, X.; Wang, Y.; Zhou, Y.; Niu, G.; Zhao, S.; Chang, D. Creep Model and Experimental Verification of Sandstone under the Coupled Effect of Chemical Corrosion and Temperature. Appl. Sci. 2024, 14, 7847. [Google Scholar] [CrossRef]

- Gu, H.; Lai, X.; Tao, M.; Cao, W.; Yang, Z. The role of porosity in the dynamic disturbance resistance of water-saturated coal. Int. J. Rock. Mech. Min. 2023, 166, 105388. [Google Scholar] [CrossRef]

- Deng, X.; Shi, J.; Li, X.; Wang, R.; Zhang, J.; Yang, X. The Secondary Development and Application of the Improved Nishihara Creep Model in Soft Rock Tunnels. Buildings 2023, 13, 2082. [Google Scholar] [CrossRef]

- Wu, L.Z.; Luo, X.H.; Li, S.H. A new model of shear creep and its experimental verification. Mech. Time-Depend. Mat. 2021, 25, 429–446. [Google Scholar] [CrossRef]

- Du, S.; Zhang, C.; Mao, D.; Ruan, B.; Lu, X. A case study of the failure mechanism analysis and support design of a tailrace tunnel in a weak fracture zone containing expansive minerals. B. Eng. Geol. Environ. 2022, 81, 495. [Google Scholar] [CrossRef]

- Li, D.; Du, S.; Zhang, C.; Mao, D.; Ruan, B. Time-dependent deformation behavior of completely weathered granite subjected to wetting immersion. Rock. Mech. Rock. Eng. 2021, 54, 6373–6391. [Google Scholar] [CrossRef]

- Gao, X.; Hu, T.; Su, Z. Nonlinear Nishihara model of soft rock based on damage mechanics and its parameter identification. Mater. Today Commun. 2024, 39, 108715. [Google Scholar] [CrossRef]

- Du, S.; Li, D.; Zhang, C.; Mao, D.; Ruan, B. Deformation and strength properties of completely decomposed granite in a fault zone. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 1–21. [Google Scholar] [CrossRef]

- Du, S.; Li, D.; Ruan, B.; Wu, G.; Pan, B.; Ma, J. Deformation and fracture of circular tunnels under non-tectonic stresses and its support control. Eur. J. Environ. Civ. Eng. 2022, 26, 1654–1677. [Google Scholar] [CrossRef]

- Yan, B.; Guo, Q.; Ren, F.; Cai, M. Modified Nishihara model and experimental verification of deep rock mass under the water-rock interaction. Int. J. Rock. Mech. Min. 2020, 128, 104250. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, D.; Wang, J.; Wang, X.; Cong, Y.; Wang, Z. A nonlinear creep model of rocks based on memory-dependent derivative. Constr. Build. Mater. 2023, 391, 131618. [Google Scholar] [CrossRef]

- Wang, X.; Huang, Q.; Lian, B.; Liu, N.; Zhang, J. Modified Nishihara Rheological Model considering the Effect of Thermal-Mechanical Coupling and Its Experimental Verification. Adv. Mater. Sci. Eng. 2018, 2018, 4947561. [Google Scholar] [CrossRef]

- Li, X.; Liu, E.; Song, B.; Liu, X. An Improved Nishihara Model for Frozen Loess considering the Influence of Temperature. Adv. Mater. Sci. Eng. 2018, 2018, 9073435. [Google Scholar] [CrossRef]

- Cui, K.; Hu, B.; Cui, A.; Li, J.; Wei, E.; Zhang, Z. An extended super/subloading surface model for soft rock considering structure degradation. PLoS ONE 2021, 16, e0258813. [Google Scholar] [CrossRef]

- Yi, X.; Feng, W.; Bai, H.; Shen, H.; Li, H. Catastrophic landslide triggered by persistent rainfall in Sichuan, China: August 21, 2020, Zhonghaicun landslide. Landslides 2021, 18, 2907–2921. [Google Scholar] [CrossRef]

- Zhuang, Y.; Hu, X.; He, W.; Shen, D.; Zhu, Y. Stability Analysis of a Rocky Slope with a Weak Interbedded Layer under Rainfall Infiltration Conditions. Water 2024, 16, 604. [Google Scholar] [CrossRef]

- Basu, S.; Jones, A.; Mahzari, P. Best Practices for Shale Core Handling: Transportation, Sampling and Storage for Conduction of Analyses. J. Mar. Sci. Eng. 2020, 8, 136. [Google Scholar] [CrossRef]

- Li, J.; Hu, B.; Sheng, J.; Zhang, Z. Failure mechanism and treatment of mine landslide with gently-inclined weak interlayer: A case study of Laoyingzui landslide in Emei, Sichuan, China. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 61. [Google Scholar] [CrossRef]

- Liang, X.; Tang, S.; Tang, C.; Wang, J. The influence of water on the shear behaviors of intact sandstone. B. Eng. Geol. Environ. 2021, 80, 6077–6091. [Google Scholar] [CrossRef]

- Wang, X.; Hu, B.; Tang, H.; Hu, X.; Wang, J.; Huang, L. A constitutive model of granite shear creep under moisture. J. Earth. Sci-China 2016, 27, 677–685. [Google Scholar] [CrossRef]

- Ma, C.; Zhang, T.; Yao, W. An Assessment of the Osmotic Pressure Effect on the Creep Properties of Silty Mudstone. Soil. Mech. Found. Eng. 2019, 56, 314–320. [Google Scholar] [CrossRef]

- Lin, H.; Zhang, Q.; Zhang, L.; Duan, K.; Xue, T.; Fan, Q. The Influence of Water Content on the Time-Dependent Mechanical Behavior of Argillaceous Siltstone. Rock. Mech. Rock. Eng. 2022, 55, 3939–3957. [Google Scholar] [CrossRef]

- Zhao, Z.; Dai, W.; Yang, J.; Zhou, M.; Liu, Z. Creep mechanical tests and shear rheological model of the anchorage rock mass under water-rock coupling. PLoS ONE 2023, 18, e0284569. [Google Scholar] [CrossRef]

- Hu, B.; Zhang, Z.; Li, J.; Xiao, H.; Cui, K. Statistical Damage Model of Rock Based on Compaction Stage and Post-Peak Shape under Chemical-Freezing-Thawing-Loading. J. Mar. Sci. Eng. 2022, 10, 696. [Google Scholar] [CrossRef]

- Wei, E.; Hu, B.; Tian, K.; Cen, P.; Zhang, Z.; Wang, Z.; Chang, S. Study on the Nonlinear Damage Creep Model of the Weak Interlayer. Adv. Civ. Eng. 2022, 2022, 3566521. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).