Abstract

Green hydrogen is a promising energy vector for industrial applications. However, hydrogen leaks can occur causing greenhouse effects and posing safety risks for operators and local communities, potentially leading to legal liabilities. Industry 4.0 focuses on digital industrial modernization, while Industry 5.0 emphasizes collaborative, human-centered, and sustainable processes. This study developed and analyzed an Industry 5.0 proof of concept as an additional safety layer for hydrogen leak management. The proof of concept was implemented using Raspberry Pi microcomputers, integrated computer vision, and OpenAI GPT-3 for dynamic email communication. A legal liability analysis for Chile and Spain identified potential challenges in transitioning the system into a market-ready product. The findings suggest the system should act as a complementary safety layer rather than a primary detection system to mitigate legal liability risks, as operational deployment without full certification and validation could lead to malfunctions. This study illustrated how hydrogen detection and management can be integrated into Industry 5.0 smart systems. With growing global interest in sustainable engineering and AI regulation, as reflected in Regulation (EU) 2024/1689, legal considerations over technologies like the one presented in this study are becoming increasingly relevant.

1. Introduction

Industry 4.0 (I4.0) is a concept used to describe the latest modernization efforts taking place in industrial environments [1]. I4.0 is different from previous modernization stages, each of which was characterized by certain technologies, such as steam and machinery (I1.0), electrical circuits and machines (I2.0), and control systems (I3.0). The new technologies included in the I4.0 concept are, among others, the Internet of Things (IoT), cloud computing, smart algorithms, computer vision, and soft sensors [2,3].

Industry 5.0 is a recent concept used by the European Commission to state a possible evolution of industrial transformation, focusing on the synergy between advanced technologies and human creativity. Unlike I4.0, which emphasizes automation and interconnected systems, Industry 5.0 (I5.0) places humans at the center, leveraging collaborative systems and artificial intelligence to enhance, rather than replace, human capabilities. This paradigm shift prioritizes sustainability, resilience, and personalization over technological improvements, aiming to create smarter and more adaptive production systems [4,5].

The legal aspects have to be considered when developing and implementing new technologies. Legal liabilities are one of the main constraints when considering incorporating new and novel automatic control and decision-making systems into critical processes [6,7,8]. Failures in the operation of these systems can have devastating consequences for production, but also the environment and the company’s workers, putting, in some cases, lives at risk. Complex systems, based on the integration of several components, are prone to failure [9]. When a malfunction of industrial equipment, systems, or processes occurs that results in damage to people and the environment, it is very likely that legal litigation processes will take place to determine the liabilities and compensation associated with the failure [8]. In this context, several questions arise about how Industry 4.0, smart systems, and the intelligent industry can comply with the legal requirements when implementing the digital transformation [10].

Green hydrogen is the name given to hydrogen obtained from renewable energy sources [11,12]. Green hydrogen is considered clean due to the absence of CO2 and methane, two greenhouse gases, during its production. The interest in hydrogen has increased in recent times due to its potential use in industrial plants as a source of energy for small transportation vehicles, as an energy vector for storage and transportation, and for conversion into heat or electricity [13]. Hydrogen can be obtained from electrolysis by splitting water or ammonia molecules [14]; however, electrolysis consumes large amounts of energy, which, depending on the source, can have a negative impact on the environment [15], which highlights the benefits of green hydrogen. Although hydrogen alone has not been considered a strong greenhouse gas when liberated into the atmosphere, compared with the unit value of the global warming potential of CO2, the molecular interaction of hydrogen with other gases results in a coefficient 10.9 times higher compared with CO2 [16]; therefore, unnecessary hydrogen release has to be reduced for environmental protection.

Leaks are the primary sources of hydrogen released into the environment. The main sources of hydrogen leaks are storage sites and transport pipelines, with leak estimates exceeding 2.3% of the total hydrogen produced [16]. Hydrogen leaks are problematic not only due to their damage to the environment; they can cause fires, explosions, and oxygen displacement in closed or poorly ventilated areas, leading to potential accidents, injuries, and risk of suffocation for operators [17]. The study of risk analysis on hydrogen leaks is an area of current research interest, for example, in vehicles [18]. Hydrogen is also a highly corrosive and reactive gas that can rust metal pipes and cause leaks, especially when the container material consists of polymers [19].

Chile and Spain are actors in the global energy transition toward green hydrogen. Both countries made public their strategic guidelines with regard to hydrogen in 2020. In Chile, the National Green Hydrogen Strategy aims to position the country as a world leader in green hydrogen production and export. Leveraging its abundant natural resources and low-cost renewable energy potential, Chile aims to be the producer of the cheapest green hydrogen in the world [20]. In Spain, the Hydrogen Roadmap focuses on developing technological and industrial capabilities, promoting investment in infrastructure, and strengthening regulatory frameworks to ensure the sustainable deployment of hydrogen [21]. Like Chile, Spain also seeks to establish itself as a producer and exporter of green hydrogen. In both countries, the respective strategies prioritize the integration of hydrogen into key sectors, such as transportation, industry, and electricity generation, reinforcing their commitment to global decarbonization and economic growth [22].

This research aimed to explore the concepts of Industry 4.0 and 5.0 and the legal aspects of developing and implementing smart detection systems in the context of green hydrogen safety. This initial framework was further specified for the case of hydrogen leak detection in pipes, with the aim of obtaining a proof-of-concept system for the Industry 4.0/5.0 concepts. Then, assuming that this proof of concept could be later improved to reach a market product, a legal analysis focused on Chile and Spain’s legal frameworks was performed in order to elucidate potential challenges for future development and implementation. This research problem is relevant considering that I4.0 and I5.0 hydrogen sensor systems and socially responsible and sustainable system design are emerging global engineering trends and that interest in regulating artificial systems is currently being implemented.

This paper is organized into the following sections, addressing both technical and legal aspects: Section 2 reviews the literature on hydrogen sensor technology, the state-of-the-art advancements in Industry 4.0 and 5.0, their applications in hydrogen systems, and the legal frameworks of Chile and Spain. Section 3 describes the materials and methods for a proof-of-concept development for hydrogen leaks, as well as the considerations for the analysis of legal aspects. In Section 4, the results regarding technological development are described. In Section 5, the technical and legal aspects are discussed. Finally, the conclusions of this work are presented in Section 6.

2. Brief Literature Review

A brief literature review was conducted to outline the key aspects that are later analyzed in the discussion, focusing on hydrogen sensor technology, modernization, and legal considerations within the Chilean and Spanish legal frameworks.

2.1. Technologies for Hydrogen Leak Detection

With regard to technologies for hydrogen leak detection, hydrogen leaks can be detected when these events occur in controlled environments using specialized digital sensors. When a potentially dangerous gas leak is sensed, the affected area should be evacuated, and the source of the leak should be detected and stopped [23]. Identifying the exact location of the hydrogen leak is less straightforward, considering that most hydrogen container surfaces must be tested for the leak. Colorimetric or soap solutions can detect leaks in methane or other gases [24]. Other approaches to detecting gas leaks include inspection, thermographic scanning using infrared, gas detector gauges and sensors, ultrasonic detection, and pressure testing [25]. In open environments, hydrogen leaks are more difficult to identify, considering the rapid gas dilution in the air [26]. The detection of hydrogen leaks in open environments has been partially solved using colorimetric tapes [27]; however, this requires that the tape has direct contact with the gas. In these cases, the color change must be verified manually. An overview of different hydrogen sensor detection technologies is presented.

2.1.1. Mechanical Sensors

Mechanical sensors detect hydrogen by utilizing physical effects, such as deformation, expansion, or stiffness changes in materials when hydrogen is present [28]. These effects can occur due to interactions like hydrogen absorption or hydride formation in specific metals. The mechanical changes are often converted into measurable signals using components like strain gauges or piezoelectric elements. In simple setups, the sensor output may be a direct mechanical response, such as displacement [29,30].

2.1.2. Catalytic/Pellistors

Pellistors are hydrogen sensors that consist of two circuits connected in a Wheatstone bridge configuration with two wires: one coated with a catalytic material, typically platinum (Pt) or palladium (Pd), and the other uncoated [28,31]. Both wires are heated through a controlled circuit, but the wire with the catalyst heats more due to the oxidation reaction facilitated by the catalyst, causing a change in its resistance. The change in resistance, in turn, creates a voltage imbalance in the Wheatstone bridge, which can be measured as an analog voltage output [32].

2.1.3. Thermoelectric Sensors

Thermoelectric sensors measure the effect of varying thermoelectric voltage generated between two materials when exposed to the gas being analyzed. This variation occurs due to changes in thermal conductivity or temperature gradients caused by the gas. The current or voltage output changes proportionally depending on the materials used, such as metals (e.g., platinum and nickel) or semiconductors. These sensors provide an analog output signal, which can be amplified or processed for further analysis [32].

2.1.4. Chemiresistive Sensors

Chemiresistive sensors are made from various materials, which can include pure metals, metal oxides, catalysts, and non-metal oxides. When an electric current passes through the chemiresistive material, the presence of hydrogen causes its electrons to interact with the surface of the sensor [33]. This interaction alters the material’s resistance, leading to a measurable change in the current or voltage. The resulting signal is provided as an analog electrical output [32,33].

2.1.5. Photoresistive Sensors

Photoresistive sensors operate based on the principle that a photosensitive material changes its electrical properties, such as resistance, when exposed to light of a specific wavelength. The interaction with light enhances the sensor’s ability to detect changes in its environment. When a voltage or current is applied, the sensor produces an analog electrical output proportional to the intensity of the incident light [34].

2.1.6. Optical Sensors

Optical sensors are devices that utilize reflective, transmissive, or light-based effects for detection. In active sensors, light is typically emitted using lamps, LEDs, or lasers [35,36,37]. Active optical sensors are often connected to electronic equipment that measures light intensity, with the data being processed by computers or microcontrollers [38,39,40]. When computers are involved, these sensors generally produce an analog electrical output that is converted to digital signals using an analog-to-digital converter. However, not all optical sensors are active or electrically powered. Some rely on chemical reactions involving catalytic materials to detect hydrogen. These reactions cause changes in coloration, which are observable through variations in the absorbance and reflective properties. In such cases, the output of these colorimetric sensors is a non-electrical physical signal [41].

2.2. Industry 4.0/5.0 in Hydrogen Systems

Industry 4.0 describes a digital transformation that is based on various technologies. IoT describes the ability to add an Internet connection to equipment through electronic boards, which can be complemented by services and higher computing performed remotely. Artificial intelligence (AI) is a broad, non-technical term used to describe algorithms, machines, or equipment capable of performing complex tasks that, until recently, could only be performed by humans. In the Industry 4.0 context, AI can be used to create empirical models and systems that can respond to changes in the environment in real-time, predict outcomes, and make decisions autonomously to increase efficiency and productivity [42]. Computer vision and predictive language models are also examples of applied AI [43]. Computer vision deals with how computers can understand the environment using digital images or videos. Computer vision uses signal processing, image processing, deep learning, and computer graphics methods to understand the content of an image or video [44]. Soft sensors are a term for describing analog probes or measuring elements that are coupled with software for estimating variables that are not directly measurable [3,45]. More recent digital technologies are natural language models that allow paragraphs to be written using input data as text strings, from which context patterns are recognized to generate a reasonable response text [46]. Although these models with successful examples, such as GPT-3, -4, and the Bing search application, have not yet been used for industrial applications, they are expected to be incorporated soon [47].

Industry 4.0 has been studied with regard to hydrogen. Among the Industry 4.0 techniques applied to hydrogen-related systems, numerical simulations have been identified as valuable for analyzing vehicle responses under various driving cycles [48]. In the cited work, mathematical models were used with algorithms that integrate variables such as the altitude, road slope, and distance to calculate the vehicle’s response in a simulation. The work concluded by stating the potential use of online data acquisition from sensors with mathematical models for Industry 4.0. Other approaches analyzed the concept of Industry 4.0 to hydrogen, proposing the Hydrogen 4.0 concept. In the cited work, the use of Industry 4.0 was suggested as a possibility in various scenarios, such as energy production efficiency, safety and compliance monitoring, green transport, green hydrogen supply chain, and green manufacturing [31].

Industry 5.0 describes modernization as incorporating aspects of sustainable, human-centric, and resilient technologies. In the context of Industry 5.0, specific models were proposed to estimate the modernization level in various systems quantitatively by considering the concept of technology layers and defining various levels, such as T1.0, which would account for measurements with analog non-electric outputs; T2.0 sensors would have electrical analogical outputs; T3.0 digital outputs; and T4.0 with output information obtained from data processing. In contrast, T5.0 would have contextual intelligence in human language.

2.3. Legal Frameworks of Chile and Spain

The legal traditions and systems in different countries are shaped by the diverse cultural, historical, and social aspects of the societies in question. Globally, the legal systems are categorized into civil law (codified statutes, comprehensive codes, non-precedent-driven), common law (case-based, precedent-driven), religious law (faith-based, sacred texts), and customary law (tradition-driven, community practices). In the United States, the legal system primarily follows the common law tradition, which relies on judicial precedents and case law as key sources of authority. In the European Union, most countries follow the civil law tradition, and this legal system is also prevalent in South America [49].

Chile and Spain follow the civil law tradition, enabling analyses within this legal framework on specific topics and offering broader applicability across various contexts. The Chilean tradition has been heavily influenced by European codes, mainly the French and Spanish models, emphasizing codified statutes and comprehensive legal frameworks. This combination of global influences is integrated with legal principles and new influences, such as the emergence of the dogmatism of fundamental rights, the constitutional aspects, case law, and the influence of the United States’ tradition and international treaties, which is exemplified, for example, in how contracts are negotiated [50,51]. In the case of Spain, legal sources are the law, the costume, and the general principles of the law. The costume is applicable only where the law does not explicitly consider the matter [52]. The current Spanish legal system shows the coexistence of autonomous regions with their own legal traditions within a centralized state. Although significant efforts have been made regarding legal unification, this legal unification has never been entirely achieved, and different Spanish legal traditions are in force [53]. Despite this, the Spanish constitution presents preeminence over other sources of law [54].

Civil liability is present in the legal systems of Chile and Spain. Civil liability arises from the breach of a contract, the commission of a civil offense or quasi-offense, or as mandated by law. For liability to exist, harm must be caused to another person or their property, whether by violating a pre-existing obligation or committing an unlawful act. Civil liability is classified into two main types based on its source: contractual liability, which arises when the liable party and the victim are connected by a prior contractual obligation, with the liability stemming from total, partial, or delayed non-compliance; and non-contractual liability, which occurs when an unlawful act is committed, arising from a civil offense or quasi-offense. Contractual liability entails compensating the creditor for damage that resulted from the breach or inadequate fulfillment of the contract, whereas non-contractual liability requires compensating the victim for harm caused by the offense or quasi-offense. The legal doctrine further categorizes non-contractual liability into subjective and objective liability. Subjective liability is based on the intent or negligence of the agent, while objective liability is founded on risk. In subjective liability, compensation is required because the agent is at fault for the harm caused. In objective liability, compensation is owed solely because the person caused the harm. The Chilean civil liability system is primarily based on subjective liability, although it includes specific cases of objective liability [55]. Researchers who investigated the case for Spain agree with the latter, stating, “The typical characteristic of environmental civil liability should be the obligation of the causer to respond for the damage, even when no unlawful act has been committed if the environment is affected. In these cases, objective civil liability should prevail, along with two fundamental environmental principles: the “polluter pays” principle and the precautionary principle, the latter consisting of measures that must be adopted in the face of an environmental risk threat” [56].

2.3.1. Specific Laws in Chile

Chile has regulations regarding electronic and digital technologies. Law 19,799 of 2022 regulates electronic documents and signatures, ensuring their secure use [57]. It establishes the legal validity of electronic documents and signatures, equating them with paper documents, except in specific circumstances. The law also outlines certification service providers’ roles and obligations in issuing electronic signature certificates. It defines user rights and responsibilities and the accreditation process for providers.

In Chile, Law 19,300 of 1994 has a General Environmental Law that establishes a framework for environmental protection and sustainable development based on principles such as the right to a pollution-free environment, sustainable development that balances quality of life with environmental care, and accountability for environmental damage [58]. This law emphasizes public participation in protecting the environment, providing access to information and involvement in Environmental Impact Assessments. The law established key environmental aspects, such as the polluter has to pay for the damages, and mechanisms like Strategic Environmental Assessments, environmental quality and emission standards, and prevention and decontamination plans. The law also prohibits project fragmentation to avoid evaluation evasion, enforces penalties for damage, simplifies processes for small companies, and ensures compliance through the Ministry of the Environment and the Superintendency of the Environment. Concerning access to environmental information, Article 31 bis states that the Environmental Assessment Service has to ensure the right of all individuals to access environmental information held by the administration, as outlined in the Constitution and Law 20,285 of 2008 on Access to Public Information [59]. Environmental information includes any written, visual, auditory, electronic, or otherwise recorded data related to specified environmental matters in the administration’s possession.

The Chilean Law 20,417 of 2010 [60] primarily institutes the creation of key institutions for environmental law enforcement, such as the Ministry of the Environment, which is the central body responsible for environmental policy; the Environmental Assessment Service (SEA) created to administer the Environmental Impact Assessment System; and finally, the Superintendency of the Environment (SMA) as a supervisory body to monitor compliance with environmental regulations. Among these aspects, Article 2 highlights the concept of Best Available Techniques, which in Article 40 is considered a criterion for determining the values or parameters required by the regulation, where applicable. This law aligns with Chilean Law 19,799 by enabling digital submissions for Environmental Impact Assessments, allowing project proponents to submit digital documents to provide observations via digital platforms.

Finally, Chilean Law 2,222 of 1978 [61], which pertains to navigation and the specific cases of hydrocarbon and other harmful substances leakage, establishes clear accountability in cases of leaks. Article 142(2) specifies that responsibility lies with both the shipowner and the operator and Article 144 states that civil responsibilities are applicable and that compensation for damage caused by a spill must be paid. Law 2,222 is also important because it is an early example of the regulation of automated or smart systems in Chile, such as autopilots. This law states in Article 29 that as a fundamental safety measure, autopilot is permitted only under the strict supervision of the ship’s captain, master, or commanding officer. Ships subject to this law and equipped with autopilot must have a surveillance camera and recording system to ensure that the person responsible for navigation is paying proper attention to external conditions. The Maritime Authority will establish the technical standards that the surveillance system must meet.

2.3.2. Specific Laws in Spain

Spain has established regulations for electronic and digital technologies. Law 6/2020 governs electronic trust services, including electronic signatures, ensuring their secure implementation [62]. It grants legal validity to electronic documents and signatures, equating them with paper documents under Regulation (EU) 910/2014 (eIDAS) [63]. The law also outlines the responsibilities of certification service providers in issuing electronic signature certificates, while defining user rights, obligations, and the accreditation process for providers.

Spain has a comprehensive environmental legal framework designed to protect natural resources and promote sustainable development. The Spanish Law 34/2007 of Air Quality and Atmospheric Protection regulates air pollution by establishing emission limits for industries [64]. Subsequently, Royal Decree 102/2011 set air quality objectives, pollutant standards, and maximum allowable levels to safeguard public health and the environment [65]. Law 21/2013 of Environmental Assessment ensures public participation in decision-making through Environmental Impact Assessments (EIAs) and Strategic Environmental Assessments (SEAs), enhancing transparency and environmental protection [66]. Law 22/2011 for Waste and Contaminated Soils implements waste management policies aligned with circular economy principles, ensuring efficient resource use and pollution control [67]. More recently, Law 7/2021 of Climate Change and Energy Transition has driven decarbonization efforts and facilitated the transition to renewable energy sources, reinforcing Spain’s commitment to climate action [68]. Finally, The Royal Decree 376/2022 establishes sustainability criteria and emission reduction requirements for biofuels; bioliquids; and renewable gases, including hydrogen [69]. It defines the system of guarantees of origin to ensure transparency and traceability in the production and use of these energy sources, aligning with Spain’s climate goals and the European Green Deal.

Regulation (EU) 2024/1689 on Artificial Intelligence (AI Act) establishes a legal framework to ensure the safe and ethical development of AI in the European Union [70]. Composed of Chapters I to XIII, Chapter I outlines the general provisions, defining the scope and objectives of the regulation, which aims to promote human-centric AI while ensuring compliance with fundamental rights, democracy, and environmental protection. It also introduces a risk-based classification of AI systems. Chapter II defines and prohibits certain AI practices that pose unacceptable risks, including social scoring by governments, subliminal manipulation, biometric categorization based on sensitive attributes, and real-time remote biometric identification in public spaces for law enforcement (except under strict conditions). These prohibitions aim to prevent AI from undermining human rights, security, and democratic values within the EU. Chapters I and II have applied since 2 February 2025.

3. Materials and Methods

This work involved designing and implementing a proof-of-concept hydrogen leak detection system, followed by a legal analysis of the proposed system within the context of green hydrogen and smart systems. The legal analysis specifically focused on Chile and Spain as examples of countries with a civil law tradition.

3.1. Technical Development

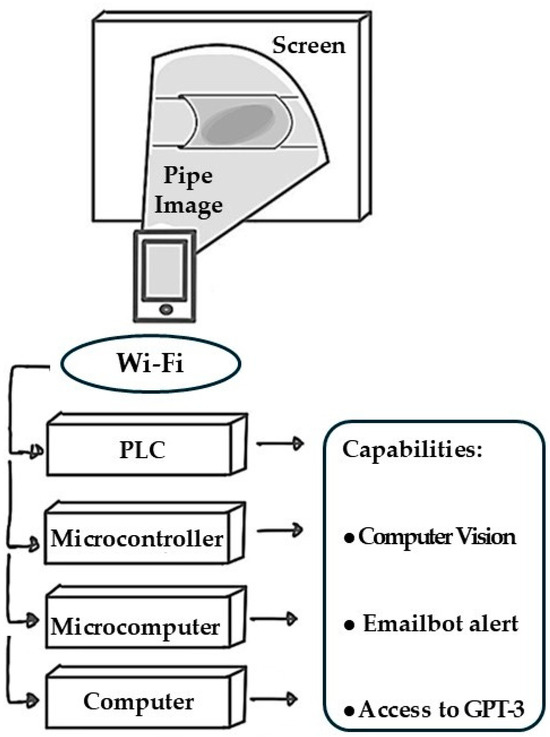

The scenario considered the integration of a hydrogen colorimetric leak sensor tape into a digital management system compatible with the Industry 4.0 and Industry 5.0 frameworks, as seen in Figure 1. This design was proposed to represent hydrogen pipelines located in a semi-open facility with permanent artificial lighting installed with a leak detection system based on colorimetric tapes for detecting the occurrence and location of the eventual leak. To make the system compatible with the Industry 4.0 framework, the design considered developing a system based on computer vision algorithms, IoT devices with wireless communication, and dynamic email messages integrated with a generative language model.

Figure 1.

Schematic diagram of the Industry 5.0 system proof of concept for leak detection.

3.1.1. Characterization of the Hydrogen Leak Detection with Colorimetric Tape

Photographs and a recorded demonstration video from a hydrogen leak tape sensor were obtained from the manufacturer of DetectTape, Element One, Inc., Boulder, CO, USA. The photographs consisted of seven images taken at intervals from 0, when a leak was initiated, up to 30 min, with a sampling interval of 5 min. The photographs were used to provide a qualitative description of changes in the colorimetric tape to characterize the leak.

The video contained a clip with two comparative video shots, describing the test as follows. The first video shot showed a tape-covered tube with no hydrogen leaks. The second video shot showed a connection pipe with a measured leak of 110 mL/min, considering hydrogen at 99% purity, 1 bar, and at an ambient temperature of 22 °C. The test considered the recording from time 0 to time 30 min. The tube portion accounted for less than 50% of the area in the image. The video showed a representative case of leak detection using a video stream captured by a camera that could be transmitted for analysis to a monitoring computer. The video was utilized for a quantitative characterization.

Processing of the video began with the acquisition of the video stream, which had to be separated into different images at a defined sample time. A stable initial condition was then determined, characterized by a condition in which no important changes occurred. RGB codification was used to process the video images, where zero was considered as no light detected by the color sensors and 255 as the maximum color for each red, green, and blue bandwidth. Then, manual highlighting of the areas of the video where the tape was present was made. This highlighting was performed on an iPad Pro tablet (Apple Inc., Cupertino, CA, USA). The image with the highlighted area was then opened with MATLAB R2021a (The MathWorks, Inc., Natick, MA, USA). In this software, an algorithm was programmed and ran to fill in the highlighted area. Then, the highlighted area was selected for image processing. The video was processed by acquiring an individual frame each second of the video stream. The mean pixel value was calculated for each selected area in the video frames and then subtracted from the maximum illumination value of 255. This approach allowed for describing the decrease in illumination on the colorimetric tape due to hydrogen interaction with the tape as an increase in the signal, which facilitated further analysis. The initial test values, recorded in the absence of hydrogen, were used to measure the baseline tape color, which ensured that subsequent coloration changes could be attributed to hydrogen interaction and changes in lighting.

A model was proposed to describe the system’s behavior, which enabled the characterization of its response to specific inputs. This involved analyzing the time response; calculating key parameters, such as the time constant and final value; and accounting for potential perturbations, such as random variations in illumination or external disturbances. The Laplace step response method was applied for the system characterization, using a unitary step input for the leak scenario and no input for the no-leak scenario. For the leak case, a first-order response was analyzed, determining the final value and time constant while considering the impact of perturbations, such as random variations in tape illumination. Noise was defined as the difference between the modeled values of the colorimetric change, and its characterization was performed using the Fast Fourier Transform (FFT).

3.1.2. Simulation of the Leaks Following the Characterization

Following the characterization of the video frames for the computer vision setup, a simulation video was generated. This simulation used two images of the pipe to produce two extended video streams, each representing one hour of data acquisition. The simulation also incorporated the effects of random variations caused by the changes in illumination.

To analyze the feasibility of integrating computer vision with color-changing tape-based hydrogen detection, the experimental setup involved displaying the video on a screen. The images were captured by an IP camera provided by a Redmi Note 8 smartphone (Xiaomi Corporation, Beijing, China), which simulated the real-time acquisition of images from a pipe equipped with hydrogen sensor tape. For designing the alert condition, considerations were made based on the limited available data, while also accounting for conditions applicable to a general use case.

3.1.3. Dynamic Email Alert Integrated with a Language Model

Email capabilities were implemented to send the alert condition. To send the email, the requirement of a library that was simple to use and available in a free platform was considered. In this case, the “smptlib” library was selected due to it being a software package already incorporated in Python 3.12 software (Python Software Foundation, Wilmington, DE, USA). The email used the subject “Hydrogen monitoring system ALERT” as the body of the message, the message obtained from the use of GPT-3 (OpenAI, San Francisco, CA, USA), and the email address of the process supervisor.

GPT-3 was utilized to generate the body of an email as part of the communication system for hydrogen pipeline monitoring using key information regarding the leak detection. The prompt was structured to create a formal and concise email addressed to the “Hydrogen Pipeline Supervisor,” indicating the emergence of a problem, the need for urgent verification, a phrase indicating potential legal implications if the leak is not appropriately handled, and a request for immediate response. Parameters were configured as follows: text-davinci-003 was chosen for its good-quality text generation capabilities and ability to handle complex prompts; a maximum token limit of 2048 ensured the response had sufficient space for detailed information; and a temperature of 0.4 was set to reduce randomness, prioritizing consistency in the tone and content of the generated message. The automated system dynamically incorporated specific contextual details to adapt the message to the situation.

The text for the elaboration of the message was the following: Prompt = (f”Enter a formal body, without subject, send an email to the ’Hydrogen Pipeline Supervisor’\indicate that a problem has arisen”)+text+(“and that urgent verification is required immediately,\y that the response is needed immediately. Please add ’Sincerely, Monitoring System Team’“) For the text response additional parameters were motor=“text-davinci-003”, max_tokens=2048 and, temperature=0.4.

3.1.4. Hardware Comparison for IoT Hydrogen Leak Detection Prototype

Different hardware was compared for the implementation: Siemens S7-1200 PLC (Siemens AG, Munich, Germany), Arduino UNO microcontroller (Arduino LLC, Turin, Italy), Raspberry Pi 2 model B microcomputer (Raspberry Pi Foundation, Cambridge, UK), and HP Envy i7 laptop computer (HP Inc., Palo Alto, CA, USA). The aspects considered in the comparison were the capabilities for image processing, video acquisition, Internet interconnection, connection to remote servers, and the ability to send emails from hardware automatically, as an emailbot. The selected hardware would take into account the minimum price for allowing the mentioned functionalities for the I4.0/I5.0 system.

A second version of the computer vision code was implemented in Octave and Python for testing and integrating its execution on the microcontroller Arduino and the microcomputer Raspberry Pi. Finally, in Raspberry, Python was used from the terminal, and two libraries were used for acquiring and presenting figures, Matplotlib (Matplotlib Development Team, USA) and computer vision CV2 (OpenCV.org, Palo Alto, CA, USA). Each received image consisted of a 600 × 800 image of an IP address. Then, the image would be processed. If a malfunction was detected, the device would send an email to the process supervisor’s and operator’s addresses.

3.2. Legal Responsibilities

A discussion was performed with regard to the design of the system to identify areas of potential error and the potential legal responsibilities. Two types of responsibilities were analyzed: responsibility of means and responsibility of results. This analysis was focused on Chilean and Spanish legislation. In this regard, the responsibility was analyzed by considering the specific context of environmental courts and specific laws in the environmental litigation process. To align with the system’s potential dual impact—on individuals and the environment—two complementary analyses were performed. For the environmental aspects, this study considered the Civil Code of the Republic of Chile of 2000, Chilean Law 19,799 of 2022, Law 19,300 of 1994, and Law 20,417 of 2010. In the case of Spain, for environmental aspects, this study considered the Spanish Civil Code, Law 6/2020 on Electronic Trust Services, Law 21/2013 on Environmental Assessment, Law 34/2007 on Air Quality and Atmospheric Protection, Law 7/2021 on Climate Change and Energy Transition, and Royal Decree 376/2022 on sustainability criteria for renewable gases. This analysis included examining the criteria for preventive measures, monitoring plans, and compliance with environmental regulations. In the case related to potential damage to humans, the discussion explored the applicability of extracontractual liability in high-risk activities and whether the mere occurrence of damage suffices to establish liability. The discussion also addressed the role of automation and artificial intelligence in liability attribution, considering how the system’s autonomous decision-making might interact with the existing human-centered legal responsibility framework. For this analysis, European Regulation (EU) 2024/1689 regarding artificial intelligence-based systems was considered, along with older laws, such as Law 2,222 of 1978 for the case of Chile.

The discussion method was chosen for the legal analysis due to its traditional use in this area. However, recognizing its potential for non-reproducibility and the inclusion of the authors’ opinions, the results of this section were incorporated into the discussion.

4. Results

4.1. Proof of Concept

In the following, the technological development results are presented regarding the proof of concept.

4.1.1. Qualitative Characterization of Hydrogen Leaks with Colorimetric Tape

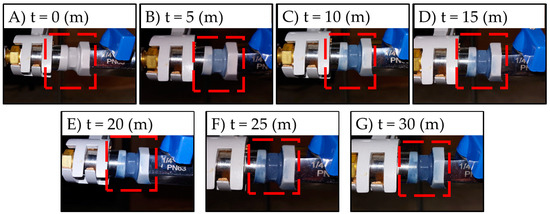

In relation to the qualitative evaluation, the photographs revealed that the colorimetric sensor changed color upon contact with hydrogen, where it transitioned from an initial gray to a dark gray by the end of the 30 min measurement process. It is worth noting that one key aspect for visually evaluating and detecting the color change is the prior knowledge of the tape’s baseline colors—those of the tape without hydrogen exposure and after exposure—since the color change is not contrasted against a standard reference when evaluating the leak detection. When considering this type of tape for integration into image recognition techniques, it is considered necessary to account for the need for a fixed camera position, as this facilitates more accurate comparisons between areas of interest, as small changes in angle can be observed in Figure 2.

Figure 2.

Progression of color change in the hydrogen detection tape (DetetTapeH2) identified through visual color variation within the red square. (A) Initial image at time 0; (G) final image at 30 min. Intermediate images (B–F) represent incremental changes captured every 5 min.

4.1.2. Quantitative Characterization of Hydrogen Leaks with Colorimetric Tape

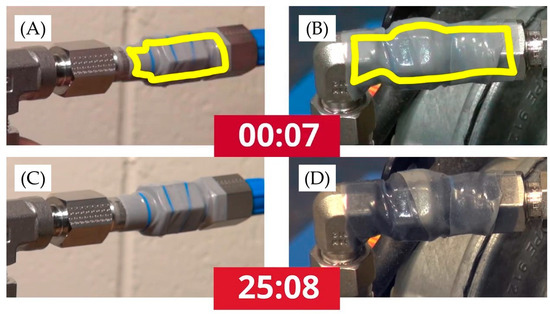

Figure 3A,B illustrates two pipe sections with manually selected monitoring areas at the beginning of the test, where a light gray coloration was observed. In Figure 3A, no hydrogen leak was recorded over a 25 min period. As shown in Figure 3C, the absence of leakage resulted in minimal color variation, which was primarily attributed to changes in lighting. Figure 3B shows the initial condition for hydrogen leak detection, while Figure 3D depicts the final outcome after exposing the tape section to a total hydrogen gas leak volume of 2.75 L under ambient temperature and pressure conditions.

Figure 3.

(A,B) Areas of interest marked in yellow, at the beginning of the test identified by their light gray color. (C) Image of the pipeline area of interest with no color change recorded. (D) Pipe with a discoloration change related to a hydrogen leak.

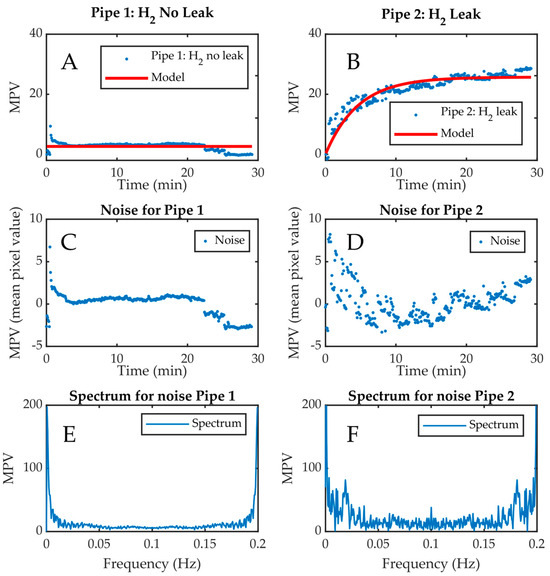

Figure 4 shows the results of analyzing the changes in pixel colors automatically over time inside the initial manually selected areas. Figure 4A shows the results for the leak-free pipeline. At the beginning of the experiment, a rapid decrease in value was recorded, which was soon replaced by new higher values. Upon investigation, this low value was caused by the drastic change in the position of the pipe in the specific frame, which led to covering a larger area with a lower brightness. Drastic changes are also shown in Figure 4B. In this case, the changes were caused by ambient light changes, which caused the tape reflections. The luminosity changes had, on average, a duration close to two minutes, with a luminosity change of less than 10%. Even with variations in the luminosity, a clear trend emerged, showing a continuous increase in pixel values that stabilized over time.

Figure 4.

Normalized pixel values over the highlighted area across frames for (A) no leakage and (B) leakage using a constant and a first-order response model. (C,D) show noise as the difference between the model and pixel values, while (E,F) display the noise spectra for Pipe 1 and Pipe 2, respectively.

Numerically, the function for Pipe 1 was characterized by a constant value of 2.65 (Figure 3A). For Pipe 2, the model was represented by the following function:

where Vmax equals 25.69 and “a” equals 0.2168. This model calculated the stabilization time as 5/a = 23.1 min, with the function reaching a final value of 25.52 units (Figure 4B).

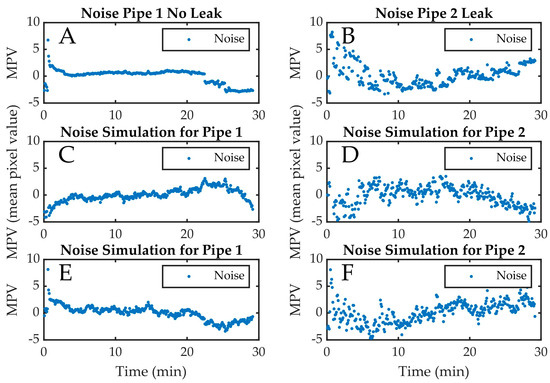

The signal noise was calculated as the difference between the actual data and the model. The noise signals are presented in Figure 4C,D. Figure 4C shows relatively stable noise behavior, with smaller variations compared with those observed in Figure 4D, which exhibited greater dispersion throughout the observation period. Both noise signals were characterized using the Fast Fourier Transform (FFT), and their magnitude spectra are shown in Figure 4E,F.

4.1.3. Visual Simulation of the Hydrogen Leaks Following Characterization

A simulation of the pictures representing pipes with and without leakages was visually generated based on the characterization of the signals. In this simulation, the signal noise was modeled to maintain the initial characteristics of the characterized noise. The magnitude of the frequency spectrum obtained from the FFT was preserved; however, random variations were introduced. Each frequency component was varied randomly within the range [−π, π] radians, and an additional random additive variation was applied uniformly across all frequency components within the range [−1, 1] radians. Following this method, the resulting noise components are presented in Figure 5.

Figure 5.

Noise simulations. (A) Original noise from the signal without a leak. (B) Original noise from the signal with a leak. (C–F) Noises generated based on the characterizations.

For the simulation, the noise signals were added to the simulated coloration change signals for the colorimetric sensor. A 10% random variation was applied to both the final coloration value and the stabilization time to simulate the variability in the colorimetric tape. A 70 min time frame was used for the data generation, which simulated the onset of a leak under the characterized conditions (Figure 6). The leak initiation was set at random intervals: between 0 and 20 min for (A), 20 and 40 min for (B), and 40 and 60 min for (C). A preliminary algorithm for detecting coloration changes was tested on the simulated data, characterized as follows: the initial condition for comparison was defined as the initial value for data within the first 30 min and as the value from 30 min prior for data beyond that timeframe. If a change exceeding the level generated by the double of the time constant of the first-order response persisted for more than one time constant, the alert signal was activated. Given the calculated time constant τ = 1/a ≈ 4.61 and the signal at the double of the time constant of around 22.21 min, the detection times were determined as follows: (A) 12.83 min, (B) 32.08 min, and (C) 57.33 min. It was observed that the alert values varied between the detection times, with (A) 15.18, (B) 17.34, and (C) 22.46, due to the different reference values used in each case.

Figure 6.

Comparison of leak detection for software simulation and proof of concept with camera. (A) The leak initiation between 0 and 20 min. (B) 20 and 40 min. (C) 40 and 60 min.

4.1.4. Proof-of-Concept Implementation

An initial proof of concept showed the feasibility of using a screen and the simulation software for representing the changes in the colorimetric tapes that could, in turn, be analyzed using computer vision and the algorithm for leak detection determined through the characterization of the colorimetric changes. For the representation of the leaks, an initial calibration would be needed to calculate the initial and final colors in the colorimetric tape for the simulation. As can be seen from Figure 6, the changes introduced by the use of the screen mainly accounted for the noise, showing that after the calibration, the algorithm previously defined for detection of the leak condition in the simulation could still be used in the case of the proof of concept that required cameras for the image acquisition.

An alert system was implemented using the SMTP protocol for email communication. The system required the prior configuration of an email account. From the moment the message was sent to the reception, the elapsed time for its retrieval was less than 10 s. The components of the final system configuration were an electronic board, the Internet, a video processing algorithm, interconnection to an OpenAI server, and an SMTP server.

Different hardware was compared for the proof of concept in search of the most economical hardware capable of implementing the detection functionalities already developed for the computer: Siemens S7-1200 PLC, Arduino UNO, Raspberry Pi, and HP Envy i7. The HP computer was capable of image acquisition, processing, data storage, and sending emails with communication with the OpenAI API in close to 5 s. The Siemens S7-1200 PLC was discarded, considering its inability to perform data processing outside of typical control loops. It was verified that the Arduino UNO could not perform the image acquisition since this hardware could not store the video frames of integer values of matrices of 600 × 800 × 3 bytes. Instead, the verified maximum array capable of being stored on the unmodified Arduino was 20 × 20 bytes. Octave 6.3.0 and Python 3.12 codes were successfully tested on the Raspberry Pi and PC. In the case of the Raspberry Pi 2 model B, this hardware could perform video processing using Python following the same steps performed in MATLAB 2021a, which required close to 30 s for the image acquisition, processing, and storing of the results. The capability of using Python for replicating the functionalities of MATLAB would show that in the case studied when considering its implementation, the cost would not require those related to software licenses (Table 1).

Table 1.

Hardware characterization with respect to Industry 4.0 task requirements.

4.2. Estimation of Modernization for Hydrogen Leak Detection Systems

Finally, the proof of concept and the reported hydrogen sensors were classified depending on the output type of the sensors and its corresponding technology layer, which is presented in Table 2. The classification of hydrogen sensor technologies shows that there were mainly technology types T1.0, 2.0, and 3.0 regarding non-electric output, electric analog output, and digital output. No hydrogen system was reported to have been coupled with software for estimating more complex variables, such as in the case of soft sensors.

Table 2.

H2 sensors and their technology types reported in research. Sensor systems T1.0 provides a non-electrical output, T2.0 an analog electric output, T3.0 digital data, T4.0 information, and T5.0 contextual intelligence.

5. Discussion

5.1. Technical Aspects

Industry 4.0 emphasizes the integration of digital technologies in industrial production, while Industry 5.0 prioritizes sustainability, human-centered technologies, and resilient systems.

This study explored the integration of tapes and computer vision for detecting hydrogen leaks. Four types of hardware were compared for their suitability in implementing the systems to detect and manage hydrogen leaks. Due to its design limitations, the PLC was unable to perform data-intensive tasks, such as image processing. While Arduino demonstrated limited data-processing capabilities, it surpassed the PLC in terms of processing and storage capabilities and showed potential for specific applications that required low processing data volumes. The Raspberry Pi microcomputer and the laptop both successfully handled video processing and email integration, differing only in the task execution time. The microcomputer’s speed was found suitable for monitoring image-based systems, as the analyses could be performed in 30 s, which was less than the time of stabilization of the color change in the colorimetric sensor calculated as 23.1 min. Experimental analysis showed that the coloration changes could be distinguished from the noise caused by abrupt pipe movements and fluctuations in ambient light.

In the system presented in this work, the aspects of Industry 4.0 and those of Industry 5.0 can be clearly identified. The computer vision coupled with the color-changing tape constitute a soft sensor, considering the definition in which a soft sensor adds a software layer to analog sensors, as defined by others. The software sensor, in turn, has been considered part of the Industry 4.0 modernization stage. On the other hand, sensing emails while reporting the area of leakages in human language, enhancing the collaboration between process information systems and the operator, and ensuring sustainable and resilient operation of the hydrogen process constitutes an example of Industry 5.0 through Emailbots. The technical development can be considered aligned with the principles defined in the Industry 5.0 literature, which considers human-centered technology for process cooperation and sustainability, as the system is designed as a tool for human and environmental safety for hydrogen systems.

When evaluating the development stage of the solution, the starting point presented in this work can be classified between the TRL 2 technology concept formulated due to the innovative use of computer vision added to the detection tape and the TRL 3 experimental proof-of-concept level due to the implementation using real cameras, according to the scale defined by others [72]. This indicates that transitioning to industrial implementation would require progression through several stages, six at least, starting with the validation of each component under laboratory conditions, followed by simulated environments, and eventually real-world operating conditions. At the proof-of-concept stage, the system functions effectively in a controlled simulated environment but cannot guarantee specific detection accuracy. Achieving defined detection reliability would necessitate additional testing to ensure the system’s proper functioning into a functional prototype. In its current stage of development, meeting the same functionality, a manufacturing entity cannot guarantee a specific detection accuracy. Detection should ideally meet a guaranteed threshold and a detection percentage upon implementation. At the same time, the various subsystems that make up the system increase the risk of malfunction, as any of them can cause failure. For example, the present system, as proposed, requires the use of the Internet. The system can no longer send and receive email notifications if the Internet connection fails. Dependency on the Internet and communication with remote servers that could require unexpected updates in the communication protocols would render the development unusable at certain moments, which can cause a malfunction. Concerning the integration of ChatGPT-like models for writing part of the email communications, this tool presents uncertainty regarding the type of responses it can generate. This implies the possibility of inappropriate or imprecise wording, which could lead to wrong decisions. Although at the proof-of-concept level, this technology could be further analyzed, considering that maturity may eventually be reached. An interesting aspect to explore would be the legal context, as such an analysis could help anticipate whether the legal framework favors or limits its development—an assessment that is particularly useful for potential private investors or public stakeholders in this emerging technology.

5.2. Legal Aspects

The legal tradition shared by Chile and Spain requires a thorough examination of the legal codes, constitutional principles, and doctrinal interpretations for legal analysis, as case law is not considered a binding source of law within these countries. Our discussion started with the theme of hydrogen and its environmental impact.

5.2.1. Hydrogen Regulation as a Contaminant

With respect to sustainable development, a critical analysis is important when considering the use of hydrogen in its multiple applications. The essential question is whether it is possible to implement hydrogen technologies without compromising the environment or the well-being of future generations. This risk must be carefully analyzed to determine whether it is acceptable and at which level. From a technical point of view, the use of hydrogen as an energy source and vector is viable; however, its use must guarantee the absence of unwanted emissions since these uses, even at low volumes, could cause a more serious environmental impact than other fuels, as stated by others [16]. Furthermore, it is crucial to consider its complete effect on the ecosystem and human societies to evaluate its true sustainability.

As the atmosphere is a globally shared medium, hydrogen, as a potential air contaminant, requires legal considerations on a global scale. It is important to emphasize that hydrogen leaks affect the global community, so addressing this issue within a broader international legal framework is necessary. If certain countries have lax legislation or impose minimal fines, these regions could become unregulated pollution centers despite the global repercussions of such environmental damage. This phenomenon has already been observed with natural gas leaks from oil fields in producing countries, which are considered one of the most significant contributors to global warming. This underscores the urgent need for a coordinated international approach to regulate and mitigate such environmental risks effectively.

Currently, neither Chile nor Spain has a specific law regulating hydrogen. As with other specialized matters, it is important to assess whether hydrogen should be governed under a dedicated law, considering the high costs of environmental repair in the case of important leaks due to the technical complexity or the literal impossibility of capturing leaked hydrogen. This represents a considerable burden for the victim, in this case, the environment, especially if it involves irrecoverable damage, such as the release of gases into the atmosphere. Furthermore, hydrogen is highly corrosive to various materials, which means that there will always be constant small leaks at a theoretical level due to its chemical properties. This highlights the need to incorporate a more scientific perspective from a chemical standpoint on the global context of green hydrogen, complemented by new monitoring technologies for data acquisition and processing. These systems, inherent to Industry 5.0, could be valuable for integration into legislation or consideration in judicial proceedings.

5.2.2. Opportunities for Hydrogen 5.0: Legal Frameworks of Chile and Spain

The Chilean Law 19,300 of 1994 that protects the access to environmental information and the public participation in environmental matters considers spaces where Industry 5.0 could bring solutions. For example, these new digital technologies and the human and sustainable approach would allow for access to connected monitoring systems (IoT) that could send real-time alerts not only to operators, as shown in the proof of concept, but also to the community. This is a technically feasible possibility that could improve transparency and access to information, thereby enabling more informed participation of local communities when environmental assessment processes are performed. In this regard, a legal framework has already been established that could be leveraged for the benefit of society.

For this same law, regarding the prohibition of project fragmentation to avoid evaluation evasion, developing prototypes as part of integrated systems would allow for a comprehensive evaluation of the project’s overall impact, ensuring stricter compliance with the law. Furthermore, Industry 5.0 could greatly contribute to mechanisms such as measuring deviations from environmental quality and emission standards through the acquisition of data for modeling and simulation integrated with smart systems to measure and anticipate impacts and design more effective mitigation strategies. It must also be considered that as the law requires avoiding fragmentation, monitoring and control systems would need to be integrated into existing installations and should not be treated as separate entities. This, in turn, would align with the principles of Industry 5.0 and modernization models, where an intelligent technological layer is added to existing processes to enhance their performance as a collaborative tool for the human user.

The integration of Industry 5.0 into the framework of the Chilean Law 20,417 of 2010 offers opportunities to enhance environmental management through advanced technologies. As this law expanded environmental assessments, systems akin to IoT, including technologies such as image acquisition, data collection, and real-time monitoring, that are directed toward environmental protection could improve the accuracy and efficiency of these administrative duties. AI-powered tools, such as those provided by OpenAI, could be considered to analyze complex datasets and streamline economic and social evaluations. Later, they could be incorporated as part of the concept of Best Available Techniques for implementing industrial processes. Emailbots and automated notification systems can facilitate communication between the industry, members of the society, and state regulators, enabling efficient digital submissions and real-time feedback during the Environmental Impact Assessment process. By leveraging these technologies, the law’s implementation can become more interactive, transparent, and effective, advancing sustainability goals with data-driven precision, as the legal framework defined instances where developing new technology could bring new solutions.

With regard to Chilean Law 19,799 of 2002, the focus was on regulating digital documents, electronic signaturing, and services for the certification of the signatures. In this sense, Chile already has the proper means of legally certificating the authenticity of electronics documents and communications, which could have been an initial consideration for the implementation of automatic data reporting through electronics channels. However, the requirement for the report to be signed by a responsible party would still apply. The use of electronic signatures, which enable the signing of contracts, could leverage new digital technologies to implement smart contracts with an environmental focus. Secure electronic transactions, data collection and analysis, and public participation are areas where Industry 4.0 and 5.0 principles and technologies can drive innovation, improving the efficiency and effectiveness of environmental oversight.

In the case of Spain, the legislation allows for the electronic signing and certification of documents, ensuring their legal validity as stablished in Law 6/2020 and Regulation (EU) 910/2014. This regulatory framework also enables the generation and validation of documents signed electronically, including those produced through automated systems. The possibility of using electronic signatures with the same legal effect as handwritten signatures under specific conditions can be useful if incorporated into automatic monitoring systems that would incorporate reports that can be verified.

In Spain, regarding environmental protection laws, Law 21/2013 implements mechanisms to verify compliance with environmental regulations. Law 26/2007 addresses pollution and environmental damage, specifically regarding soil, water, coastal areas, and estuaries. However, since hydrogen pollution primarily occurs through leaks into the air, it does not significantly impact soil or water, making this law largely inapplicable in this context. Notably, Spanish Law 26/2007 shares common principles with Chilean environmental law, particularly the “polluter pays” principle. Meanwhile, Law 34/2007 sets limits on air pollution and explicitly regulates 14 atmospheric pollutants, including hydrocarbons, oxides, particulate matter, and ozone-depleting substances. However, hydrogen is not explicitly listed among these pollutants, nor is it mentioned elsewhere in this law. As a result, hydrogen emissions are currently unregulated under this framework. On the other hand, Law 7/2021 aims to regulate and promote decarbonization, explicitly encouraging the integration of renewable gases into the energy matrix, including biogas, biomethane, hydrogen, and other fuels produced exclusively from renewable energy sources. This law references Royal Decree 102/2011; however, while this decree focuses on air quality improvement, it does not contain specific regulations addressing hydrogen pollution. Instead, it refers to hydrogen compounds that do not share the same physical and chemical properties as molecular hydrogen. As a result, green hydrogen is being promoted in Spain without explicit regulatory considerations regarding its leakage into the environment.

Additionally, Spanish Law 22/2011 addresses pollution, waste recycling, and soil contamination, making it inapplicable to hydrogen pollution concerns. In contrast, Royal Decree 376/2022 regulates sustainability criteria and greenhouse gas emissions reductions, an area where hydrogen could be relevant. However, the decree explicitly applies to biofuels, bioliquids, and biomass-based fuels, along with the guarantee of an origin system for renewable gases. This decree specifically states that renewable gases, including hydrogen, can contribute to decarbonization, particularly in sectors where electrification faces technical or economic challenges. One of its key mechanisms for promoting renewable gas deployment is the Guarantee of Origin System, which certifies the use of renewable sources in their production. Despite research indicating that hydrogen can act as an indirect greenhouse gas, the decree does not acknowledge its environmental impact in this regard. While the regulation ensures the traceability of renewable sources, which could potentially enable monitoring systems, leak detection is not explicitly considered within Spain’s environmental regulatory framework.

Finally, Regulation (EU) 2024/1689 began its implementation in February 2025, with Chapters I and II addressing unacceptable risks in AI-based systems. Upon reviewing these prohibited risks, hydrogen-related monitoring systems are not explicitly mentioned. However, the regulation does establish environmental protection as one of its core objectives. Article 3 of the regulation defines a “serious incident” as one that causes serious harm to property and the environment, which could theoretically be relevant in the cases of major hydrogen leaks. Nevertheless, Chapter II details prohibited AI practices, none of which are directly applicable to hydrogen-leak-monitoring systems. Thus, while the regulation emphasizes environmental protection, it does not directly regulate hydrogen emissions or leakage detection through AI systems.

Based on the above, it can be concluded that Spain’s regulatory framework does not contain explicit provisions that prevent the development and implementation of hydrogen-monitoring prototypes, except in the cases of non-contractual liability due to malfunctions that result in harm to individuals or the environment. Additionally, Spain’s legislation actively promotes the integration of green hydrogen without addressing potential environmental risks associated with hydrogen leakage. The absence of specific regulations regarding hydrogen emissions means that potential indirect environmental impacts remain unregulated. Finally, current AI regulations do not explicitly prohibit or impose restrictions on hydrogen-leak-monitoring systems, indicating that their development and deployment would not contradict existing AI legislation.

Although the previously discussed laws do not use Industry 4.0/5.0 terminology, their provisions on electronic processes, digital signatures, and technological solutions create a foundation for adopting Industry 4.0 technologies within environmental management and compliance, which could be further developed by incorporating Industry 5.0 aspects. In summary, the development of Industry 4.0 solutions, and those of Industry 5.0 focused on environmental sustainability for industrial applications, aligns with applicable laws and regulations in Chile. Still, further analysis is required to assess the implications of potential malfunctions if such systems are implemented. Although focused on Chile and Spain, this discussion can be extrapolated to other legal systems, provided the applicable environmental laws and regulations on digital technologies are established, along with determining whether these regulations account for the use of technology in their enforcement.

5.2.3. Malfunction of the System: Legal Liabilities in Chile and Spain

In Chile and Spain, the legal systems structure their entire responsibility framework on human conduct. This principle applies equally to individuals and companies. For companies, the legal system attributes responsibility to legal entities, assuming that human actions ultimately drive their operations. In this context, the legal fiction is that the legal entity acts, but it is still human individuals who perform the actions. Therefore, a solution was needed to determine how responsibility is attributed to legal entities within a framework that fundamentally considers human behavior. Along the same line, the individual is the personification of the legal entity. The legal entity is an object that is capable of acquiring responsibilities and rights. Responsibility, therefore, even in the case of a legal entity, ultimately always points to the action or omission carried out by a human person. Faced with this situation, complexities arise in how responsibility could be attributed to technologies that could be autonomous and capable of making decisions, as is the case analyzed for the system presented in this work, where automation and artificial intelligence technologies are incorporated.

From a legal perspective, the primary challenges for a company developing and implementing an autonomous safety system in the event of a malfunction causing environmental or human damage could arise from unforeseen liabilities. Two key types of responsibility are recognized in the literature: obligation of means and obligation of result. The obligation of means refers to the requirement of a party to act diligently, using all available resources to ensure that tasks are executed properly. This is typically demonstrated in court through certifications related to materials, manufacturing processes, durability, and similar factors, showing that reasonable precautions were taken. The obligation of results, on the other hand, requires the product or service to achieve a specific, guaranteed outcome, as verified through extensive testing to prevent malfunctions. Additional measures, such as regular calibration by certified entities, are also necessary to ensure reliability. In Chile and in Spain, there is also the objective extracontractual liability, which is based on the fact that the legislator has established that in certain activities that report risks, a liability regime concurs in which it is not necessary to prove fault or fraud, but only the materialization of the damage.

Environmental repair is understood as the action of restoring the natural environment to a quality similar to that which existed before the accident or at least re-establishing its basic characteristics. Whoever causes environmental damage, whether through negligence or intent, is responsible for repairing it in Chile, or covering the cost of remediation as in Spain. However, if the damage is accidental, there would technically be no intent to harm the environment. In most cases, the burden of proof falls on the victim, who must demonstrate negligence or intent in court. However, identifying a specific injured party becomes significantly more complex when the victim is the environment. In this case, it can be alleged that anyone could exercise the action. It is also important to mention that some authors propose a different approach with regard to who has the burden of proof. They argue that all commercial activities should be presumed capable of causing pollution or damage. Based on this premise, the potential pollutant party must prove their non-liability for any harm [46].

In Chile, according to Article 10, letter ñ, of Law 19,300, projects related to the production, storage, transportation, disposal, or reuse of toxic, explosive, radioactive, flammable, corrosive, or reactive substances must undergo an environmental impact evaluation system. Likewise, other activities listed in the same article may require a supervisory guide by the Superintendency of the Environment, which also acts as a regulatory body. The indicated projects will need an environmental impact study if they correspond to at least one of the categories shown in the law. Considering this, hydrogen is regulated through Law 19,300 in Chile, thus requiring compliance with environmental law through studies that can benefit from monitoring systems.

In the case of Spain, since the regulatory body for environmental and chemical contamination explicitly defines specific pollutants, including establishing measurement methods and objective compliance levels, and considering that hydrogen has not been classified as a pollutant, the regulations do not explicitly require the implementation of studies nor monitoring systems. Although extracontractual liability could apply, without monitoring systems in place, the community would have fewer tools to prove contamination and its implications. However, as mentioned, in environmental cases, it has been considered reasonable for the burden of proof to fall on the accused, which ultimately balances the situation. The existence of publicly accessible records of potential contamination and leaks would help address community concerns, as well as facilitate the provision of evidence of compliance for potentially polluting companies.

Broader considerations for analyzing liability in the use of hydrogen control and monitoring systems include the feasibility or impossibility of environmental recovery following hydrogen contamination. Courts typically rule that the environment must be restored in Chile, or that financial compensation for its repair is required in Spain, ordering studies to assess the before and after conditions and the improvements implemented. Therefore, in cases where recovery is feasible, reliable measurements would be required to implement restorative measures. Conversely, when environmental recovery is not possible, fines or sanctions tend to be more severe. In the case of hydrogen, recovering a gas that has been released into the atmosphere and the environment is extremely difficult. This challenge justifies the need to implement technologies and systems that ensure the prevention of leaks as a priority measure that could be economically justified.

For the specific case of the proof of concept developed in this work, our analysis suggests that its most practical application at this stage would be as a backup solution. When implementing this system, to ensure clarity with regard to contractual liabilities, the contract between the industry and the system provider should explicitly state the intended use, for example, as a testing tool of a monitoring system, and specify that the system’s installation does not exempt the industry from its own safety and maintenance obligations. Still, extracontractual responsibilities would apply both in Chile and Spain if the proof of concept is deployed.

In terms of the extracontractual responsibility, the considerations regarding the environmental aspects would mean that an obligation of results rather than an obligation of means would be deemed appropriate. This implies that due diligence, defined as taking all reasonable actions and measures regardless of the system’s ultimate success, would not suffice. Instead, the emphasis would be on guaranteeing specific outcomes, particularly preventing environmental harm. Failure to achieve these outcomes would require appropriate compensation for any resulting damage. Regarding the extracontractual responsibilities due to malfunctions in the monitoring system for green hydrogen leakages with potential harm to individuals would invoke an obligation of means rather than an obligation of results. This implies that due diligence—taking all reasonable actions and measures regardless of the system’s success—would suffice. Legal discussions would likely focus on whether diligent conduct was followed. The company that acquires a system or software assumes liabilities for its use since any damage derived from its operation will fall on it. However, this does not exclude the possibility of additional liabilities arising from the contract with the technology provider.

5.2.4. Regulation of Smart Systems

From a legal perspective, there are no documented experiences in which OpenAI has been used with concrete judicial results. There have also been no reported cases where OpenAI or ChatGPT has been involved in activities with a high risk of causing harm to people, but this is because of the tool’s recent emergence and examples could appear in the near term. So far, ChatGPT has been used mainly in educational settings but not in industrial contexts or in services that involve considerable risks to people or the environment. A simple analysis would suggest that the use of this tool should always have some kind of supervision, and that responsibility has to be attributed to a supervisor if necessary. However, this supervision could be incompatible with its implementation in automated processes, which could limit its progress to merely demonstrative levels and restrict its use in non-critical industrial environments. We consider it reasonable that a potential solution would be to establish clear limits for text generation, allowing the specification of the tenor, vocabulary, and form of the generated interactions to be reliably predicted. This would contribute to characterizing and predicting the content produced with greater certainty, increasing confidence in the system. From a legal perspective, this solution would require an expert to sign a liability document when configuring and adjusting the system to comply with these restrictions.

The design and development of new prototypes can greatly benefit from integrating legal analysis from the early stages, considering a progressive evolution toward full implementation. This approach allows for anticipating potential regulatory limitations and identifying opportunities for innovation and deployment that have an economic impact on the companies investing in new technologies.

Legal analysis may serve as a distinctive element that characterizes Industry 5.0. Within the framework of Industry 5.0, which prioritizes human-centered systems, the legal frameworks governing individuals could become a critical factor in the development of Industry 5.0 technologies. Given that Industry 5.0 remains in its developmental and conceptual phase, the integration of legal compliance analysis could represent a significant area of development and research for other technologies. This perspective aligns with recent regulatory developments, such as the European AI Act 2024/1689, which, in Chapter 3 (not yet in force), outlines an iterative development cycle for prototype validation until reaching market readiness. These regulatory frameworks emphasize the importance of structured validation processes, ensuring that Industry 5.0 systems comply with legal and ethical standards before deployment.

6. Conclusions

This study presented an interdisciplinary approach to Green Hydrogen Gas Leak detection in the context of Industry 4.0/5.0, smart systems, industry modernization, and legal considerations. The main contributions are as follows:

- A software sensor, as an example of Industry 4.0 technologies, was developed at the proof-of-concept level, integrating a computer vision algorithm with a hydrogen leak detection tape to bridge the physical and digital aspects of the system. The visual sensor processed images to detect tape color changes within a given period, triggering email alerts if changes fell below a defined threshold.