Abstract

Green and low-carbon transformation has become a global development theme. This paper provides a systematic survey of the literature related to key technologies for green and low-carbon future buildings, including the green design method system of low-carbon future buildings; the low-carbon future buildings construction system and green building materials; the low-carbon future buildings energy system; the low-carbon intelligent operation of buildings and carbon emission control in the operation stage; and the low-carbon future buildings assessment system. This paper analyzes and summarizes the whole chain of “carbon monitoring-carbon accounting-carbon assessment-carbon control” of the whole life cycle of buildings. We systematically surveyed the development overview and the latest development trend of scientific and technological innovation; the existing starting level of science and technology; and the existing intellectual property, competition, and industrialization prospects in each stage of the whole life cycle. We conducted an overall analysis of the characteristics, thematic context, and knowledge evolution of low-carbon future building-related research, both domestically and internationally; referring to the relevant standards and specifications for new types of buildings, such as green buildings, a preliminary theoretical framework for low-carbon future buildings is constructed from the perspective of the entire life cycle.

1. Introduction

Currently, the green and low-carbon transition has become a global development theme [1]. China has announced that carbon emissions are striving to reach a carbon peak by 2030 and striving to achieve carbon neutrality by 2060. China is the world’s top carbon emission country, with a total carbon emission of nearly 10 Gt, accounting for nearly 30% of the world. According to statistics, carbon emissions from the whole process of construction account for 50.6% of China’s carbon emissions and are the main source of China’s carbon emissions. Therefore, the promotion of green and low carbon in the building sector is the key link to achieving the goal of “carbon peak and carbon neutrality” in China [2]. Low-carbon buildings and green buildings have the same value orientation but different connotations. With the double carbon target reduction schedule of each country, the transformation from green to low-carbon buildings is inevitable in the next phase of construction [3]. At present, several studies have been conducted in the field related to low-carbon future buildings in academia; this paper has conducted a systematic research survey of the literature related to key technologies of green and low-carbon future buildings. We have reviewed the depth of current academic research in the planning and design of low-carbon future buildings, green building materials and intelligent construction, building energy systems, intelligent operation and maintenance, and evaluation systems.

At present, academics have already conducted a considerable depth of research and obtained rich results in low-carbon future building planning and design; green building materials and intelligent construction; building energy systems; intelligent operation and maintenance; and evaluation systems [4]. In terms of building planning and design, the use of artificial intelligence and big data for building form generation; the early intervention of energy-saving and emission-reducing elements in the design process; and assisting architects in positive design have become the direction of research on low-carbon future building design [5]. In the direction of green building materials and intelligent construction, new building materials with high performance and low emissions will continue to be developed to meet the needs of the construction industry, and the use of digital technology to enhance assembly-type buildings and intelligent construction is the main direction of future research and development [6]. In the direction of building energy, improving electrification, renewable energy building integration, green power Direct Current (DC) drive equipment, etc., are the main directions of future research and development [7]. In the building operation stage, energy consumption and carbon emission limit control require systematic and in-depth research in the areas of building energy diagnosis; intelligent and optimized operation and carbon emission monitoring; and carbon emission limit. Breakthroughs are made in relevant key technologies to provide a reliable guarantee for low-carbon building operations [8]. In terms of building evaluation systems, European and American countries have taken the lead in carrying out low-carbon building practices, establishing a foundation for the clarification of the concept of low-carbon buildings and the establishment of evaluation systems.

However, there are no accepted methods and mature conclusions for research on low-carbon design, low-carbon construction, low-carbon energy systems, low-carbon operation strategies, and low-carbon evaluation methods for buildings [9]. Most studies have applied the concepts of green building, energy-efficient building, and low-energy building to study low-carbon future buildings, which has brought some trouble to the current development of low-carbon future buildings [10]. Existing green and energy-efficient building construction technologies mainly focus on safety and clean construction, which cannot be directly transposed to low-carbon future buildings, and there is a lack of cutting-edge construction technology research for low-carbon goals [11]. The development requirements of low-carbon future buildings bring serious challenges to the traditional building materials industry, which mostly presents a rough growth mode, and the problem of overcapacity is becoming more and more prominent and lacks perfect guidelines for the transformation of the low-carbon building materials development mode. Renewable energy utilization is the key engine of low-carbon city and building development, but there is still a need to make efforts in source, network, load, and storage, especially with the lack of a multi-energy complementary supply system and active–passive low-carbon technology integration methods for low-carbon cities, building design, and operation and maintenance [12]. The high urbanization rate and large industrial output value in some regions still dominate “high energy consumption and high emissions”, and carbon emissions from building operation and maintenance continue to grow, lacking effective carbon emission control tools and low-carbon- and zero-carbon-oriented intelligent carbon control technologies. The evaluation purpose of low-carbon future buildings is not clear enough; the evaluation index is relatively single; a unified list of basic data, such as energy consumption and carbon emission coefficients in each life stage of buildings and a systematic evaluation system, have not been formed; and an operable and relatively accurate evaluation method has not been formed.

Several studies have been conducted in the field of low-carbon future buildings, resulting in several scientific and technological achievements. This review has conducted a systematic research survey of the literature related to key technologies of green and low-carbon future buildings. The main contributions of this review can be summarized as follows:

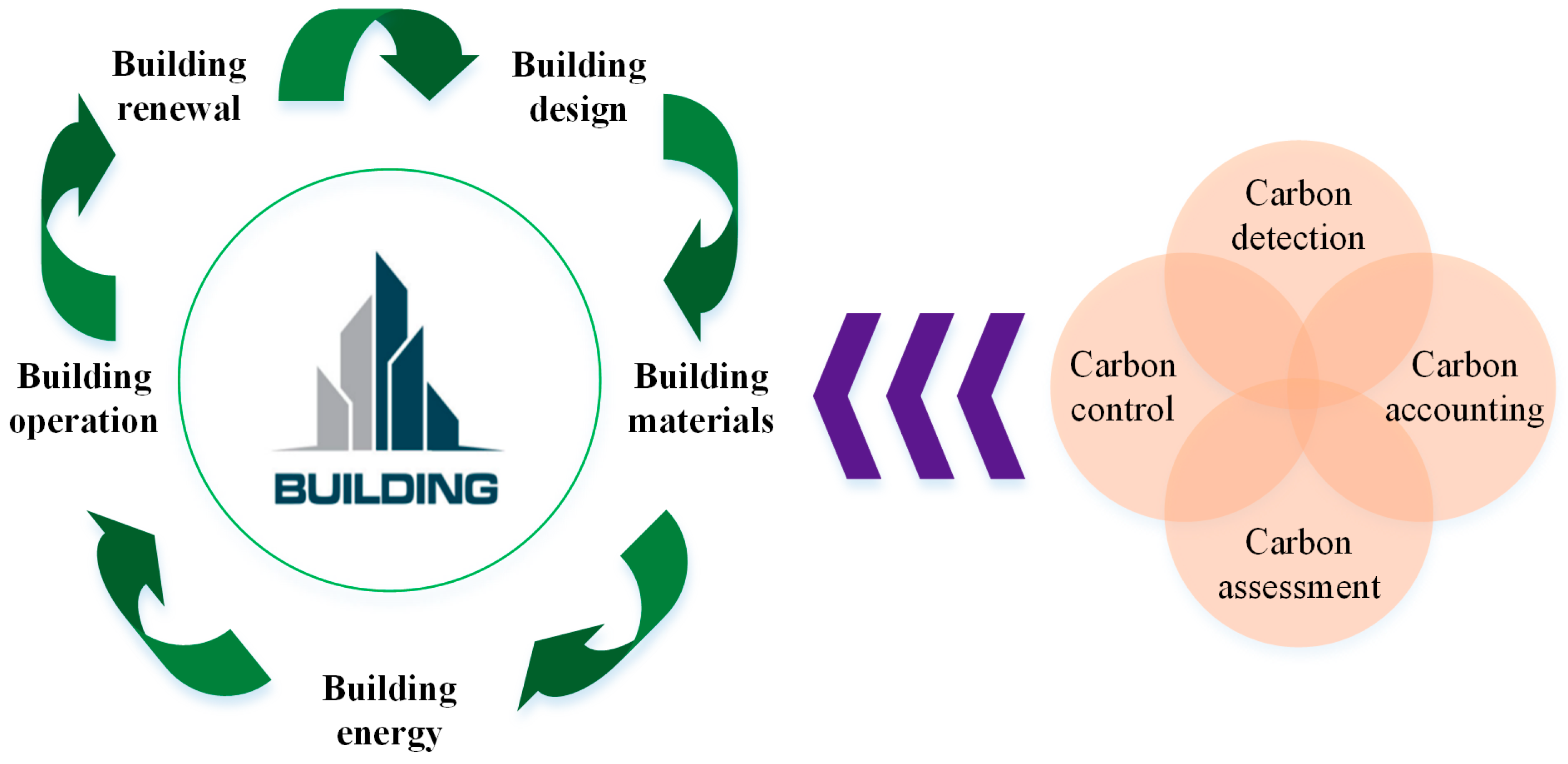

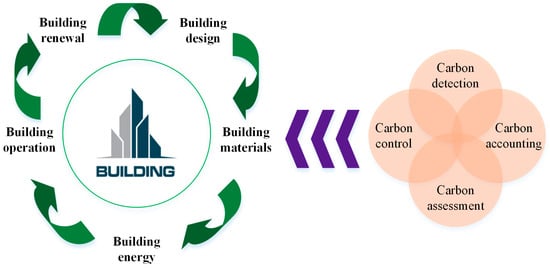

- The research survey of this review will take each stage of the whole life cycle of the building (planning and design, building materials construction, energy system, operation and maintenance management, evaluation system, etc., as shown in Figure 1) as the main focus, and systematically analyze the development overview and latest development trend of science and technology innovation in each stage of the whole life cycle of low-carbon future buildings, the existing starting point of the science and technology level, and the existing intellectual property rights, as well as the global competition and industry prospects.

Figure 1. Carbon emission control mechanism in the whole life cycle of buildings.

Figure 1. Carbon emission control mechanism in the whole life cycle of buildings. - We point out the current troubles of low-carbon future buildings, judge the future development trend of low-carbon future buildings, determine the development goal and implementation path of low-carbon future buildings, and provide support and reference for the development of low-carbon future buildings-related fields.

- We conduct an overall analysis of the characteristics, thematic context, and knowledge evolution of low-carbon future building-related research, both domestically and internationally; referring to the relevant standards and specifications for new types of buildings, such as green buildings, a preliminary theoretical framework for low-carbon future buildings is constructed from the perspective of the entire life cycle.

This paper reviews the characteristics of low-carbon future buildings design; reviews construction, energy, operation, and maintenance systems; points out the current troubles of low-carbon future buildings; examines the future development trend of low-carbon future buildings; determines the development goal and implementation path of low-carbon future buildings; and provides support and reference for the development of low-carbon future buildings-related fields.

The research objectives of this paper are as follows: to comprehensively examine and explore the key technologies and development trends in green and low-carbon buildings and provide a theoretical basis and practical guidance for the sustainable development of the construction industry. Firstly, this article clarifies the basic concept of green and low-carbon buildings, including the relevant definitions and connotations of low-carbon buildings, green buildings, and energy-saving buildings, as well as their relationships and differences. This helps readers have a clear understanding and comprehension of green and low-carbon buildings. By reviewing the development history of green and low-carbon buildings, the entire process of this field from its inception to development can be demonstrated, including key time nodes, important milestone events, and the main factors driving its development. We also explore the future development trends and challenges in green and low-carbon buildings. This includes the direction of technological innovation, the impact of policies and regulations, the reference to international experience, and opportunities for cooperation.

Through these discussions, we can help with understanding the future development direction and potential challenges in green and low-carbon buildings, providing a reference for future research and practice. By comprehensively and systematically introducing and analyzing the key technologies and development trends of green and low-carbon buildings, valuable reference information can be provided for researchers, designers, engineers, and policymakers to better understand and apply green and low-carbon building technologies and promote the sustainable development of the construction industry. The purpose of this article is to comprehensively examine and explore the key technologies and development trends in this field, providing a theoretical basis and practical guidance for the sustainable development of the construction industry. This paper can provide a deeper understanding of the core concepts, development history, key technologies, development trends, and challenges of green and low-carbon buildings, providing reference and inspiration for future research and practice.

2. Materials and Methods

This paper contains an analysis of data from open sources, including publications and data from internet portals, Web of Science, Scopus scientometric databases, websites of patent offices, libraries, and reading rooms.

In the process of analyzing the scientific, technical, and patent-licensed literature, the following were considered: the key technologies for green and low-carbon future buildings, including the green design method system of low-carbon future buildings; the low-carbon future buildings construction system and green building materials; the low-carbon future buildings energy system; the low-carbon intelligent operation of buildings and carbon emission control in the operation stage; and the low-carbon future buildings assessment system. The above key technologies are analyzed from three perspectives: the general situation and the latest development trend of scientific and technological innovation; the existing starting point of the science and technology level and the existing intellectual property rights; and the global competition and industrialization prospects.

In writing this paper, a total of 150 papers (in the past ten years) were analyzed on the development of the key technologies for green and low-carbon future buildings. In this paper, 86 papers were selected for in-depth analysis and summary, including the green design method system of low-carbon future buildings; the low-carbon future buildings construction system; green building materials; the low-carbon future buildings energy system; the low-carbon intelligent operation of buildings and carbon emission control in the operation stage; and the low-carbon future buildings assessment system. The keywords used in the search for scientific and technical information were the following: low-carbon buildings; building design; buildings construction system; green building materials; buildings energy system; intelligent operation of buildings and carbon emission control; and buildings assessment system.

3. Results and Discussion

3.1. Green Design Method System of Low-Carbon Future Buildings

- 4.

- General Situation and the Latest Development Trend of Scientific and Technological Innovation

In terms of low-carbon future buildings design, the 2017 International Energy Agency (IEA) report raised an urgent need to reduce the proportion of carbon emissions from urban construction. In recent years, some scholars have proposed the relationship between the impact of the construction environment and building planning on building carbon emission and urban block comfort [13]. Many Chinese scholars have explored the correlation between urban form, microclimate, and building energy performance and its form generation and optimization strategy [14]. In the direction of building a single design, as early as the beginning of this century, professional institutions in developed countries in Europe and the United States developed a large number of tools for building carbon emission calculations based on ISO 14040 Life Cycle Assessment (LCA) [15], such as BEAT 2002 in Denmark, Eco-Quantum in the Netherlands, GaBi in Germany, etc. However, these tools are all developed based on the carbon emission database of industrial products, and they have some problems in the applicability of buildings, so they have not become mainstream in the construction market. At the same time, the green building evaluation tools based on the scoring and evaluation system represented by Leadership in Energy and Environmental Design (LEED) in the United States have dominated the market. Although such tools are very successful in the commercial market, their scientificity is constantly questioned by professionals. In recent years, countries have developed their own carbon emission calculation standards based on the whole life cycle of the carbon emission calculation method, which has become the basis of [16,17,18] for building carbon emission evaluation. In 2002, the Building Information Model (BIM) technology proposed by the Autodesk company tried to integrate information about building design, construction, and operation. After more than ten years of development, this technology has been gradually improved, providing a technical basis for computing carbon emissions. BIM’s unified format standards provide the basis for secondary development, and commercial tools based on BIM have been developed. In the future, this software will be further integrated with existing mainstream design tools to provide strong support for low-carbon future building design. In addition, the forward design supported by intelligence has also become the latest design development trend.

- 5.

- Existing Starting Point of Science and Technology Level and Existing Intellectual Property Rights

The field of low-carbon future building planning and design is still in its infancy. Researchers have made some achievements in low-carbon urban planning [19,20,21]. In the 2017 International Energy Ownership Report, Thibaut Abergel et al. proposed an urgent need to reduce the proportion of carbon emissions from urban building construction. Abdo Abdullah Ahmed Gassar studied the relationship between the impact of the built environment and building planning on building carbon emissions and urban block comfort [22,23]. Gauch, Hannes L. et al. aimed to evaluate the influence of building design variables on the efficiency of building designs and devised a model that combines parametric optimized design of structural frames with thermal building modeling. In terms of architectural design, it is in the stage of transformation from energy-saving buildings and green buildings to low-carbon future buildings. The research on green buildings is on the rise. China has set up a special project of the “13th Five-Year Plan” on the topic of “Green building and building industrialization” and carried out dozens of special studies related to green building, with fruitful results [24,25,26]. At the same time, many scholars have also begun to actively explore intelligent generation design methods emphasizing the whole chain workflow from data collection to generation design and even related to Computerized Numerical Control (CNC) construction. The current artificial intelligence is from the information integration, mapping modeling, prediction, and decision level of architectural design and generates design methods to make intelligent algorithms involved in the designer’s design thinking and space operation process. It also combines environmental elements, physical elements, and other conditions based on being environmentally friendly as the goal of positive design exploration. In general, these studies are in the early stages, and the research on zero-carbon block planning and design is not comprehensive. Future architectural design methods that are low carbon and based on multi-objective optimization and complex adaptive systems are needed. In addition, there is still a large distance between the industrialization of theory and methodological tools.

- 6.

- Competition and Industrialization Prospects

The research on sustainable building design methods is undergoing the process of conversion from energy-saving buildings and green buildings to low-carbon future buildings. At present, the research on low-carbon future building design methods is still in its infancy, but it is developing rapidly [27,28,29].

The International Energy Agency-Energy in Buildings and Communities (IEA-EBC) has created the Future Buildings Forum (FBF) to explore low-carbon design methods, which has published several collections since its inception and is the authoritative theoretical integration of exploring the methods of future buildings design technology. The Future Cities Laboratory (FCL) at the Singapore-Eidgenössische Technische Hochschule (ETH) Research Center has been continuously researching and developing zero-carbon building models since 2015. Google’s X company is developing computer-aided generation of green building design methods. The International Institute for Sustainable Built Environment (IISBE) has been continuously developing and promoting sustainable building methods and sustainable building tools, such as the Sustainable Building (SB) Method and SB Tool. In addition to scientific research institutions, a large number of commercial companies are also continuing to invest in this field. Autodesk has developed the Green Building Studio based on the Revit platform to analyze the projects’ monthly and annual carbon emissions. Xu Weiguo from Tsinghua University, Yuan Feng from Tongji University, and Li Biao from Southeast University have made important explorations in promoting digital design direction [30,31]. Under the leadership of Academician Cui Kai, the China Academy of Architectural Design has conducted research on green construction design methods. Based on PKPM, the Institute of China Academy of Architectural Sciences continues to develop design software tools with carbon emission computing functions.

In addition to the traditional method of design before simulation, forward design methods based on computing technology are becoming a major trend in low-carbon future architectural design [32,33,34]. The intelligent generation design method emphasizes the whole chain workflow from data collection to generation design and is even related to CNC construction. In recent years, Professor Hovestadt of ETH has developed a digital chain control system for the design of an apartment block with 300 household units, which is an early attempt at the generation design method based on the digital chain system. Southeast University took the lead in China to explore the forward-generation design mode of green public buildings by a programming method and obtained independent intellectual property rights.

In general, exploration has made certain achievements but has mostly stayed at the theoretical level; to be used in practical engineering projects and obtain large-scale application conditions, there are still multiple problems to be solved: first, the existing design method tools use a high threshold—for grass-roots architectural designers, learning these is too difficult. Secondly, the connection with the existing construction engineering system is not smooth enough. As a mature industry, the construction industry has a relatively complete set of workflows and corresponding tools and software. The position of the new tools in the existing system is awkward, and they still have not been widely recognized by relevant practitioners. Finally, the use cost of advanced tools is too high, so a large number of small- and medium-sized design institutions with hundreds of thousands of software use costs cannot afford them, and a large number of construction projects are completed by these small- and medium-sized design agencies, which makes it difficult to apply these research results in engineering practice.

3.2. Low-Carbon Future Buildings Construction System and Green Buildings Materials

- General Situation and the Latest Development Trend of Scientific and Technological Innovation

In terms of low-carbon future building construction technology, the combined carbon emissions of building materials and building construction carbon emissions exceed 50% of the whole process of building carbon emissions. In the Pre-2030 Carbon Peak Action Plan released by China, it is clearly pointed out that green and low-carbon building materials and green construction methods should be promoted, the industrialization of new buildings should be accelerated, prefabricated buildings should be vigorously developed, steel structure housing should be promoted, and the recycling of building materials should be promoted. In terms of building materials production, the high energy consumption and high carbon emission problems in the construction department are largely caused by the extensive production of traditional building materials [35]. Held in 1999, the first green building seminar in China put forward the concept of green building materials, internationally also known as ecological building materials, healthy building materials, or environmental protection building materials. Corresponding to traditional building materials, green building materials use clean production technology and include industrial and agricultural or urban solid waste production, achieving this effect after the recycling cycle, and they can effectively reduce the whole life cycle of building carbon emissions. In the past 20 years, Europe, the United States, Japan, and other developed countries have attached great importance to the development of green building materials and have carried out comprehensive and systematic basic research work, which has also greatly promoted the development of green building materials in China.

At present, green building materials are used in a large number of green building materials production technologies, such as high-quality cement, high-performance concrete, energy-saving doors and windows, and new walls. Green building materials production technology has become a key research field in building carbon emission reduction in the world, which can effectively promote the sustainable, green, and low-carbon development of the whole life cycle of the construction sector [36]. In terms of green construction, prefabricated building technology can reduce on-site operations through standardized design and factory production to effectively reduce energy consumption in the construction stage and achieve carbon emission reduction. The development of Western prefabricated buildings has been relatively mature, and China is also vigorously promoting the development of prefabricated buildings [37]. The development of prefabricated buildings plays a positive role in reducing pollutants and waste emissions and improving labor productivity, and it is also an effective implementation of national policies. It is an important technical path for the construction industry to achieve a “carbon peak” and “carbon neutrality” [38]. A study by Sriskanthan Srisangeerthanan et al. considers modular buildings as those built using prefabricated, fully completed volumetric units called modules, which could be an apartment unit, staircase, structural core component, etc. Such modules are factory-manufactured and fit with mechanical connections for assembly on-site, where they would be stacked vertically and scaled horizontally to form complete buildings. The key structural materials for modules vary among timber, concrete, or steel; however, steel elements are more commonly used.

Intelligent construction, namely digital technology and engineering construction systems, is deeply integrated to form the innovative development mode of engineering construction. Its technology system is mainly built up by artificial intelligence, cloud computing, big data, BIM, and other technologies. Intelligent construction technology can be fully applied to all stages of the whole life cycle of the building, and the use of new information and communication technology can enhance the accuracy of geological analysis in the survey and design stage, strengthen the safety cost progress management in the construction stage, and assist the monitoring and early warning in the building operation and maintenance stage. With the support of new communication technology, intelligent construction technology has effectively improved building production efficiency, land saving, materials saving, and energy saving, and it is also an important means of building carbon emission reduction in various countries.

- 2.

- Existing Starting Point of Science and Technology Level and Existing Intellectual Property Rights

In the field of low-carbon construction, after a series of research and engineering practices, there are now more than 30 regional or national building standards formed. Among them, the prefabricated concrete structure is one of the most important systems of industrial buildings. To follow the existing design method of the cast-in-place concrete structure system, the current prefabricated concrete structure specifications and engineering practice are based on the design concept of “equivalent cast-in-place”, that is, grouting sleeve and other methods are used to connect steel bars at the splice of the prefabricated components and post-cast concrete. In China’s newly released “Prefabricated Concrete Building Technical Standard” (GB/T51231-2016) [39], the “equivalent cast-in-place” design method of prefabricated concrete structure is given, which rapidly promotes the industrialization process of construction industrialization. Transforming the traditional site pouring into factory manufacturing is an important step forward in the low carbonization of buildings. However, due to the small gap between the grouting sleeve and the connecting steel bar, it is difficult to install the prefabricated components. Grout sleeve connection must be carried out in very detailed grouting operations, but because it is buried deep in the prefabricated components, the actual construction quality is difficult to test, resulting in blind spots in quality supervision and causing concern for the government and the owners. Therefore, a large number of vertical components in the current prefabricated building practice do not use prefabricated components. At the same time, there are still a large number of structures that have to be built in cast-in-place mode due to their structural particularity, such as large span, high durability, complex function, and shape [40]. These factors lead to the current low proportion of industrialization, and the actual assembly rate is not high, which affects the low-carbon process of the building construction process.

In addition, in the field of green building materials, cement production involves silicate decomposition and kiln calcination processes, and the carbon dioxide emitted accounts for about 7% of the total global carbon emissions. Seeking new green building materials has become the primary priority of low-carbon emission reduction in the current construction industry [41]. As the largest city source of waste in China, construction waste has an annual output of more than 1.5 Gt, accounting for about one-third of the total municipal waste. At present, the utilization rate of construction waste resources in China is less than 10%. It is particularly important to realize the sustainable development of the construction industry.

Based on China’s “double carbon” strategic goal, current construction waste recycling is mainly for the following: (1) Industrial by-products (such as fly coal, steel slag, etc.) used as cement concrete mineral admixture and fine aggregate to reduce the use of cement; the construction industry also issued a series of technical standards, such as the mineral blending division application technical specification (GB/T51003-2014) [42]. However, in this process, it is still impossible to completely avoid the use of high energy consumption and high carbon emission product cement; thus, real green building material production is not realized. (2) To produce recycled aggregate to replace natural aggregate and reduce the exploitation of natural resources. The conversion rate between construction waste and recycled aggregate is extremely high, and 1 Mt of construction waste can generate 0.88 Mt of recycled aggregate. However, in the production of recycled aggregate, high energy consumption calcination, such as high-temperature crushing and grinding and high-energy drying, cannot achieve low-carbon emission processing.

Therefore, in the development of cement-free green building materials, construction waste should be used to produce low-carbon emission recycled aggregate free from high-temperature calcination to realize the resource utilization of construction waste and to promote the green development of the construction industry. The low-carbon and green development of the construction industry depends not only on the research and development of green building materials but also on the use of green construction technology. Compared with the traditional concrete cast-in-place process, 3D printing technology can achieve formwork-free support in the molding process, saving materials and greatly improving construction efficiency, which has a sustainable development prospect. Using 3D printing and construction technology can reduce the waste of labor and resources in the traditional construction process and promote the transformation of the construction industry to industrialization.

- 3.

- Competition and Industrialization Prospects

The new low-carbon construction mode takes “green” as the goal, “intelligent” as the technical means, “industrialization” as the production mode, project general contracting as the implementation carrier, and green building materials as the material basis to realize the goal of “energy conservation, environmental protection, efficiency, quality, and safety” in the construction process [43].

In recent years, under the guidance of the state and the housing and construction departments policy, China’s construction industrialization process is in full swing. In the current engineering practice, the main industrial building systems that have been adopted all follow the concept of “equivalent cast-in-place” through the bonding of the reinforcement at the end of the component and the post-pouring area or the concrete of the adjacent components. Under the principle of “equivalent cast-in-place”, design and construction technicians can apply standards and design theory to the whole series of cast-in-place structures, effectively promoting the application of prefabricated buildings. This has formed a relatively mature prefabricated concrete shear wall structure and prefabricated frame structure system, which is reflected in the engineering practice of good economic benefits and social and environmental benefits.

While protecting the indoor space and reducing energy loss, the building skin receives renewable energy, such as solar energy and wind energy, recovers rainwater resources, and carries the ecological greening to create the carbon sink [44]. Among the receiving devices for renewable energy for building epidermis structures, solar energy is the most widely used [45]. Professor FelixTrombe, director of the French Solar Energy Laboratory, and his collaborators first proposed and tested the successful Trumber wall, which relies on the interaction of a bilateral epidermis, no mechanical power, no traditional energy consumption, and only the passive collection of solar energy to heat buildings. In addition, by solar collectors, pipes, fans or pumps, heat storage devices, indoor heat dissipation ends, and other active solar energy utilization systems, many countries have developed a lot of new solar thermal utilization products using photovoltaic tiles, photovoltaic wall panels, etc. and the development of buildings combined with photovoltaic technology. In 2002, the United States of America Department of Energy launched and hosted the international Solar Decathlon (SD) competition, combining solar energy, energy saving, and architectural design with a new way of integrating, designing, building, and running a functional, perfect, comfortable, livable, sustainable solar living space and showcasing the world’s latest energy technology achievements.

In terms of technology, many countries have been trying since the 1990s and have relatively mature technology and experience. The “world capital of fashion and design”, Milan, Italy, has built two Ferris “tree towers”, becoming the world’s first pair of green apartments—green from the top and the ground to the vertical wall extension [46]. In recent years, China has also begun to consciously use green epidermis, and relevant research and practice are still in the initial stages, with a lack of standard and technical crossover research. When using it in specific projects, inconsistent design concepts and technologies and even difficult integration occur, most of which still stay in the roof garden mode.

3.3. Low-Carbon Future Building Energy System

- General Situation and the Latest Development Trend of Scientific and Technological Innovation

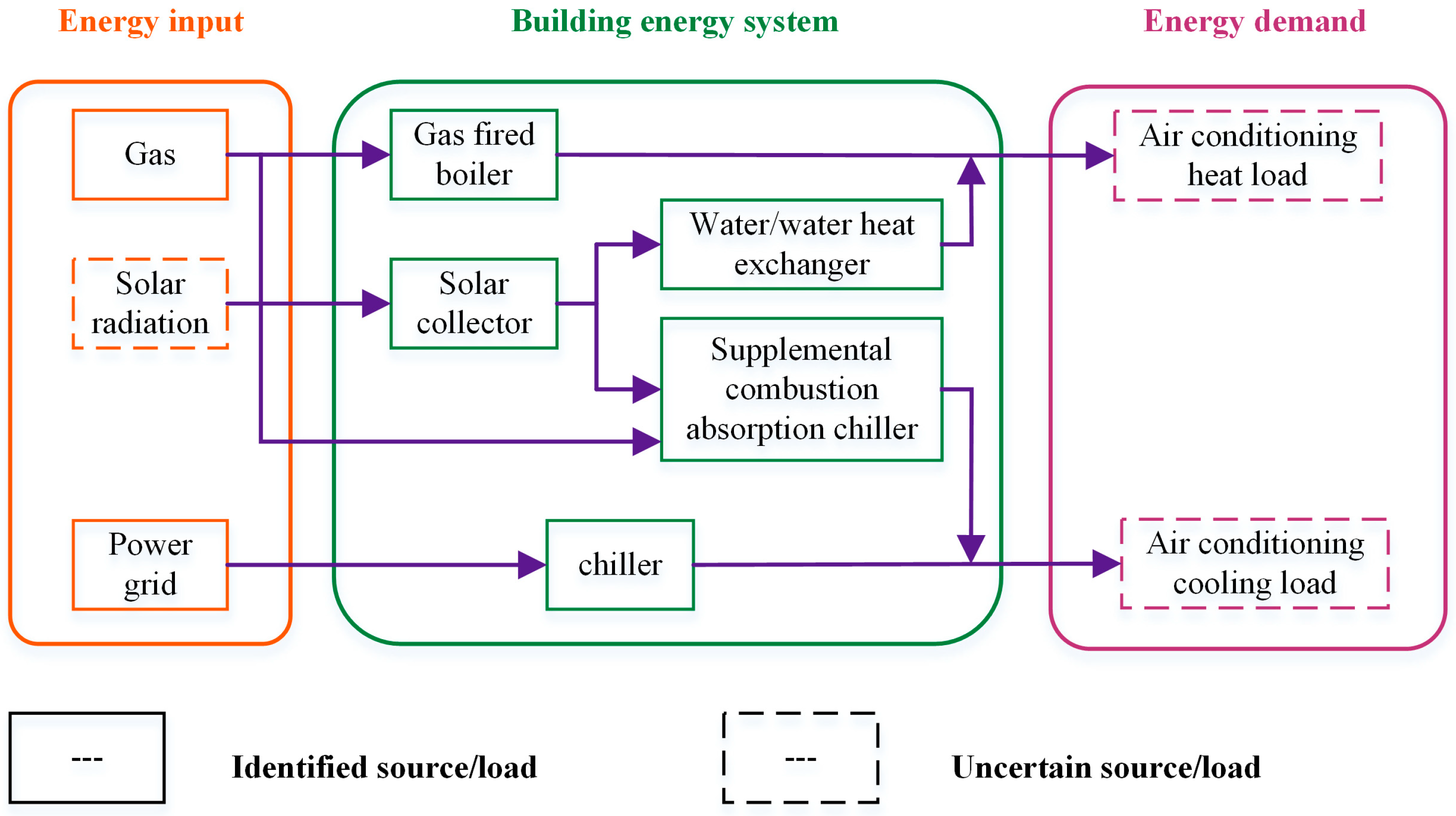

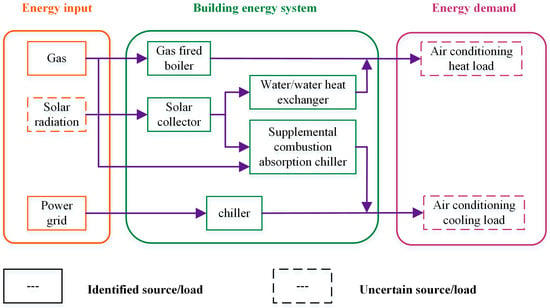

In terms of the low-carbon future building energy system, the building energy system can provide support for the future low-carbon/zero-carbon building in the three major directions of energy efficiency improvement, building production capacity, and building electrification [47]. Figure 2 shows a block diagram of the energy system of a building that uses a composite energy system to provide cooling and heat for the building. In terms of energy efficiency, there are two main methods [48]: first, more use of low-grade renewable energy; countries have successively used ground, water, and air sources in the renewable energy category. Solar photovoltaic photothermal energy, low-grade waste heat-driven refrigeration heating, and power generation technology are increasingly mature; the main bottleneck is how to improve source uncertainty or discontinuity (such as photovoltaic, thermal) and building energy system characteristics and how to overcome the source, water, sewage source, and heat resources constrained by the spatial and temporal distribution problem [49]. At present, new energy storage media and systems are being developed, and the construction method of low-carbon future building energy systems according to local conditions and multi-energy complementary methods is being studied to solve the problem of continuity and the spatial and temporal distribution of renewable low-grade energy [50].

Figure 2.

Block diagram of a building energy system.

In addition, the air source heat pump, as the main building cooling and heating mode in the Yangtze River Basin in China and the main method of clean heating in northern China, is also an important solution. We need to study its winter frost suppression and frost-free and summer efficient operation technology and to develop cold and heat source technology not limited by geographical and geological conditions. Second, with more intelligent and efficient optimization control methods and platforms, more and more buildings have begun to access the energy monitoring platform, mainly to monitor the energy system node parameters and parameter visualization; some have feedback regulation ability according to the outdoor parameters and load, set key parameters to achieve the purpose of energy saving, and in frontier research, have been used for model-based optimization regulation. With big data, artificial intelligence aims to solve the three problems of building load accurate prediction, building energy system modeling, and global optimal control [51]. In terms of load prediction, from the calculation method based on building a thermal model to the actual operation process of the data-driven method, data characteristic engineering, gradient algorithm, and memory network have the building energy consumption prediction level at about 70%. The future higher proportion of renewable energy scenarios, days, and schedules puts forward better requirements for energy consumption prediction.

Building energy system modeling mainly adopts the black box model (data-driven) and white box model (physical model), which are suitable for existing buildings with a large amount of operating data and new buildings with only physical parameters, respectively [52]. The development of a model suitable for the whole cycle of the building is the direction of future development. In terms of optimization control, heuristic algorithms, such as genetic algorithms and particle swarm algorithms, have received more and more attention and application [53]. Under the situation of a large increase in cooling, heat storage, and power storage systems, dynamic planning and other algorithms that can solve multi-stage decision problems will get more and more attention.

Construction production capacity mainly relies on a photovoltaic roof, photovoltaic glass, photovoltaic wall panels, and other realizations. Its research directions are mainly two: (1) Through advanced materials and manufacturing technology, the photoelectric conversion efficiency is constantly improved. At present, the photovoltaic conversion efficiency of photovoltaic panel products has exceeded 20%, and some laboratory efficiency is more than 25%. But for the photovoltaic products integrated with the buildings, such as photovoltaic roofing and photovoltaic wall panels, the efficiency of their commercial products has not exceeded 16% and 12% because of the need to consider the structure and other factors. (2) Through structural design and building design, there can be better implementation of routine building replacements, installation efficiency can be improved, the cost can be reduced, and the payback period can be shortened. The current investment payback period for the photovoltaic roof is 8–10 years; photovoltaic wall panels are still more than 10 years old. In terms of building electrification, comprehensively promoting building electrification is an important way to absorb building production capacity and green power in the power grid under the increasing proportion of renewable energy generation in the future. The consumption of energy in building hot and cold environment construction accounts for about 40% of the total energy consumption; all kinds of electric drive heat pumps combined with low-grade energy can realize the efficient supply of building heating and cooling and are completely consistent with the direction of building electrification. In addition, the development of DC-driven heat pump equipment further reduces loss in the process of power conversion and is an important development direction.

- 2.

- Existing Starting Point of Science and Technology Level and Existing Intellectual Property Rights

In terms of the comprehensive utilization and system construction of low-grade renewable energy in buildings, the model library of TRNSYS 18, MODELICA 4.0, MATLAB 2023b, and other platforms are mainly used for the coupling and simulation of multiple different cold and heat source systems [54]. Combining meteorological parameters and building load, we can evaluate the annual energy consumption and carbon emissions or select the load rate and the system performance parameters under specific working conditions [55]. Most of the above methods can only be used as a reference for scheme design and system construction, and there is still a gap with the actual operation effect, mainly because the load prediction, the dynamic characteristics simulation of the system, and the characteristics extraction of low-grade renewable resources are still not accurate enough [56]. In terms of a universal double high-efficiency frost-free air source heat pump, the FUJIA of Merchantmen University in Japan was the first scholar to propose the use of the solution to achieve the full thermal utilization of air in winter. Research teams from Southeast University, Hunan University, and Tsinghua University combined it with heat pump technology and developed double high-efficiency frost-free air source heat pump technology. Qingdao Haier, Jiangsu Simpson, Jiangsu Yuanze, and other enterprises have also carried out the research and development and production of the technical equipment. At present, it has been applied in Tokyo, Nagoya, Jiangsu, Shandong, Guizhou, Hubei, and other regions. The main bottleneck of this technology is the new cyclic solution with low corrosion and a high-performance, high-efficiency solution regeneration method and system control strategy.

In building capacity and renewable energy building integration, through advanced materials and manufacturing processes, the photoelectric conversion efficiency is constantly being improved. In addition, flexible buildings based on photovoltaic energy storage and DC are also a hot topic of research at present; there have been a small number of demonstrations, such as the future Building R3 module in Shenzhen, but how to configure the building capacity and the energy storage capacity and how to realize DC drive and flexible regulation are still common problems [57].

This is especially true in the scenario of a large proportion of renewable energy access; it can be scheduled between days and even across seasons through load forecasting. During the design or evaluation phase, load forecasting mostly relies heavily on physical model-based platforms, such as DOE2; ENERGY PLUS, funded by the U.S. Department of Energy; DEST, developed by Tsinghua University; and TANGENT, developed by Tianzheng Company. Such software needs to input more building physical parameters, personnel parameters, building schedules, etc. But in practice, these parameters are often more difficult to obtain, and there is large variability; thus, in the operational phase, more data-driven load forecasting methods are needed.

The Building Energy Consumption Forecast Competition hosted by ASHRAE is currently the highest level of competition in the world. Through data feature engineering, gradient algorithms, and memory networks, the level of building energy consumption prediction can be increased to about 70%. Additionally, for new buildings that still lack operational data, Xu Peng’s team at Tongji University began to use the transfer learning method to make predictions. Building energy system modeling mainly uses a black box model (data driven) and white box model (physical model), with the support of experimental data or running data. The above modeling method has reached high accuracy in equipment performance simulation prediction; the main bottleneck is in the absence of the above experiment or test or the absence of a large amount of accurate modeling of operating data [58]. Based on load prediction and equipment modeling, gradient algorithms, genetic algorithms, particle group algorithms, and heuristic algorithms get more and more attention and application. In this direction, the Wang Shengwei team from the Hong Kong University of Technology and the Chen Huanxin team from the Hua Zhong University of Science and Technology have deep knowledge, as the future storage of their heat storage system has increased dramatically. Dynamic planning, which can solve the problem of multi-stage decision-making algorithms, will get more and more attention [59].

- 3.

- Competition and Industrialization Prospects

Low-grade renewable energy relies on heat pump equipment to improve the quality and utilization to achieve the supply of cold and hot water [60]. More efficient compression forms and heat pump units are the main ways to further improve energy efficiency. Currently, the high-efficiency centrifugal unit is mainly used for single cooling. YORK and TRANE were the first to start the development and application of this technology, and Haier and Gree can also manufacture the equipment. However, due to the heating conditions, the pressure ratio of the centrifuge increased substantially, the technical difficulty increased significantly, and the matching of hot and cold abilities between winter and summer is also a new problem, there are very few applications yet. However, for hot summer and cold winter areas, the demand for hot and cold in winter and summer is strong. The development of a new and efficient centrifugal cold water heat pump unit has broad application prospects. It can provide the core equipment for improving the quality and efficiency of low-grade renewable energy sources such as water sources, ground sources, and sewage sources [61].

Air source belongs to the category of low-grade renewable energy. The air source heat pump is in line with the development of building electrification and has become the main/important building cold and heat supply mode in the Yangtze River Basin of China, North China, the United States, Japan, Europe, and other similar climate areas. In terms of air source heat pump defrosting and frost suppression, China Gree, Midea, Haier and Japan DAIKIN, as well as other enterprises, are at the forefront of the world’s enterprises, mainly using electric defrosting, reverse defrosting technology, or a lateral heat exchanger structure and control strategy to achieve it. Wing surface hydrophobic and hydrophilic modification is the current research hotspot. The Cooling Technology Research Center of Purdue University and the Beijing Institute of China are the main research teams in this direction. In recent years, frost-free air source heat pump technology has received more and more attention, and for the actual industrialization application, Southeast University, Hunan University, Tsinghua University, and the Tokyo Merchant University of Japan are the main research teams.

In terms of operation and maintenance regulation and management platforms, the air conditioning enterprise Johnson Controls has launched a building automatic control system, and China Nanrui Group, Nanjing Tianjia, and Keyuan Group have also successively launched building energy conservation management platforms for different segments, such as terminals, rail transit, and industrial construction. For regional-level building energy systems, different operating units have independently developed the corresponding monitoring and management platforms, such as China Energy Conservation, CLP Energy Saving, and other companies. However, the current energy-saving management platform gives priority to monitoring and feedback control. The identification of various equipment characteristics and an intelligent global optimization level remains to be improved, especially the proportion of renewable energy access under increasing conditions, the accurate prediction of building loads, and optimization based on time series regulation demand, which are more urgent [62,63,64].

3.4. Low-Carbon Intelligent Operation and Carbon Emission Control in Operation Stage

- General Situation and the Latest Development Trend of Scientific and Technological Innovation

In terms of the efficient operation of low-carbon buildings in the future, carbon emissions in the operation phase of buildings account for the largest proportion in the whole life cycle of buildings. They are mainly generated through building energy use and can be controlled by further improving energy conservation standards, increasing the promotion of low-carbon future buildings, and promoting the low-carbon operation of buildings [65,66]. There are often various problems that lead to high energy consumption and carbon emissions in building operations, which can be solved through rapid and effective diagnosis, intelligent control, operation optimization, carbon emission monitoring, control, and other measures. In recent years, domestic and foreign scholars have carried out relevant research [67,68]. Huilong Wang and others developed a prototype integration toolbox based on energy consumption data analysis, which can realize the energy consumption diagnosis of a single building floor, system floor, and equipment floor in different periods [69]. Li Zhisheng summarized the fault detection and diagnosis methods for Heating, Ventilation, and Air Conditioning (HVAC) systems [70]. Jiang Yi, Xue Zhifeng proposed a method for energy-saving diagnosis. Jiang Yi, Jiang Ziyan, Wei Qingpeng, etc. proposed a set of energy-saving diagnostic index systems and diagnostic methods for the energy consumption of each energy consumption system and its subsystems [71,72].

The above diagnosis methods need more data to be tested or analyzed and are highly dependent on the professional experience of personnel, so they are difficult to use widely in practical projects. In terms of the low-carbon operation of buildings, with the rise of the Internet of Things, artificial intelligence, big data, and other technologies, the intelligent operation and maintenance of buildings is of wide concern. As building energy use and carbon emissions are affected by climate, building envelope, equipment efficiency, indoor environment, human behavior, and other factors, low-carbon intelligent operation must establish a working platform that enables all systems to connect, interact, and collaborate, and in-depth research also needs to continue to improve the relevant technologies. In terms of building carbon emission monitoring and control, most provinces and cities in China have established building energy consumption monitoring platforms to monitor the energy consumption of a certain number of buildings. The control of building carbon emissions in the operation stage can be achieved through carbon emission monitoring, carbon emission quota formulation, and relevant management means.

- 2.

- Existing Starting Point of Science and Technology Level and Existing Intellectual Property Rights

At present, the research on the low-carbon operation of buildings and carbon emission control in the operation stage has achieved certain results [73,74,75,76].

In terms of building energy consumption diagnosis, the OTI method of energy-saving diagnosis proposed by Jiang Yi and Xue Zhifeng can realize the energy-saving diagnosis of various energy-use systems and subsystems of buildings, and the building energy monitoring platform widely used in China can be used to analyze the energy consumption of various energy consumption systems [77]. Other countries mostly use CAD, Plant3D, Revit, 3dsmax, SketchUp, and other software to realize 3D visualization and BIM model creation. Relevant plug-ins are introduced to assist in the management of building space and equipment systems. Combined with necessary on-site tests, equipment failures are detected, potential risks are prevented, and energy consumption problems are analyzed and diagnosed. At present, China has introduced a large number of relevant software and developed commercial software, such as PKPM and Sell, and research software, such as DEST 2.0.

However, most of this software is used for drawing, modeling, energy consumption simulation, and other calculations and analyses in the design and construction stages. There are few research reports on building energy use dynamic model construction in the operation stage and the rapid diagnosis of building energy use problems using dynamic simulation and testing. In terms of the intelligent low-carbon operation of buildings, the operation adjustment and intelligent management of electromechanical systems is the main development direction. Jiang Yi of Tsinghua University has carried out a more in-depth study on the adjustment of the whole building process. For example, Wei Qingpeng summarized and proposed the operation adjustment method of an air-conditioning system in public buildings based on operation data from the aspects of a cold water system, a two-stage pump multi-stage plate-type hot water exchange system, a chiller, a cooling water system, an all-air variable volume system, etc.; and the Jiangsu Academy of Building Sciences proposed and applied an adjustment method for the electromechanical system in existing public buildings that lays a foundation for building operation optimization. As there are many factors affecting the energy use and carbon emissions of buildings, the factors that have a greater impact include weather, envelope, energy-using equipment, indoor environmental requirements, user behavior, etc. Low-carbon smart operation needs to break down the professional barriers between intelligent subsystems, clarify the logical relationship between control and feedback that reflects the main influencing factors, and establish a smart operation platform to achieve the low-carbon goal. At present, research and practice in this area are still in the initial stage, and there are few reports on relevant standardized technical systems and low-carbon intelligent operation platforms with significant application effects.

- 3.

- Competition and Industrialization Prospects

There has been a lot of research on the low-carbon intelligent operation of buildings and carbon emission control during operation, but the development and application of applicable technologies are still in the initial stage [78]. For example, in the aspect of building energy consumption diagnosis, the diagnosis methods proposed by relevant scholars often require a lot of on-site tests and data analysis. In terms of the research and development of low-carbon intelligent operation technology, some scholars proposed to use 3D laser scanning, BIM, and Internet of Things technology to adjust the building electromechanical system. China has also carried out research and practice on architectural adaptation. Intelligent equipment and products related to intelligent building management are relatively mature, but there are too many subdivisions among intelligent systems, and the information between isolated islands is not interconnected. For this reason, some enterprises have developed relevant platforms, such as Wanda’s “Huiyun” intelligent management platform, which integrates 16 subsystems of five management systems, namely fire protection, security, equipment, operation, and energy conservation, into one operation platform. Tencent, Alibaba, and other Internet enterprises have also gradually launched various smart cities and building platforms, but the application effect remains to be observed.

In terms of building carbon emission monitoring and control, most cities have established online monitoring platforms for public building energy consumption. Some cities and projects have also established carbon emission smart monitoring platforms. For example, Shanghai has proposed a Shanghai building carbon emission smart monitoring platform, and Tsinghua University has applied energy consumption monitoring and carbon emission management platforms to environmental energy-saving buildings that are currently being improved. The relevant research has strong practical needs, solid integration, and strong pertinence and is expected to make a breakthrough. The relevant products will have broad market application prospects.

3.5. Low-Carbon Future Building Evaluation System

- General Situation and the Latest Development Trend of Scientific and Technological Innovation

In terms of the evaluation system of low-carbon future buildings, developed countries (such as Nordic countries and North American countries) lead in the practice of green low-carbon buildings [79,80,81]. The practical experience of developed countries provides a reference for China to explore the development of low-carbon cities and buildings. Most developed countries and regions in the world have successively issued their green and low-carbon building evaluation standards, such as LEED in the United States, BREEAM in the United Kingdom, CASBEEB in Japan, etc. These standards reflect the requirements for sustainable development of buildings and low-carbon energy conservation orientation and run through all aspects of the whole life cycle of building planning and design, construction, and operation management. Countries have standardized the construction and management of green and low-carbon future buildings and promoted the construction of high-level low-carbon and zero-carbon buildings by establishing a green and low-carbon building evaluation system. The development of green and low-carbon buildings in China is progressing in an orderly manner.

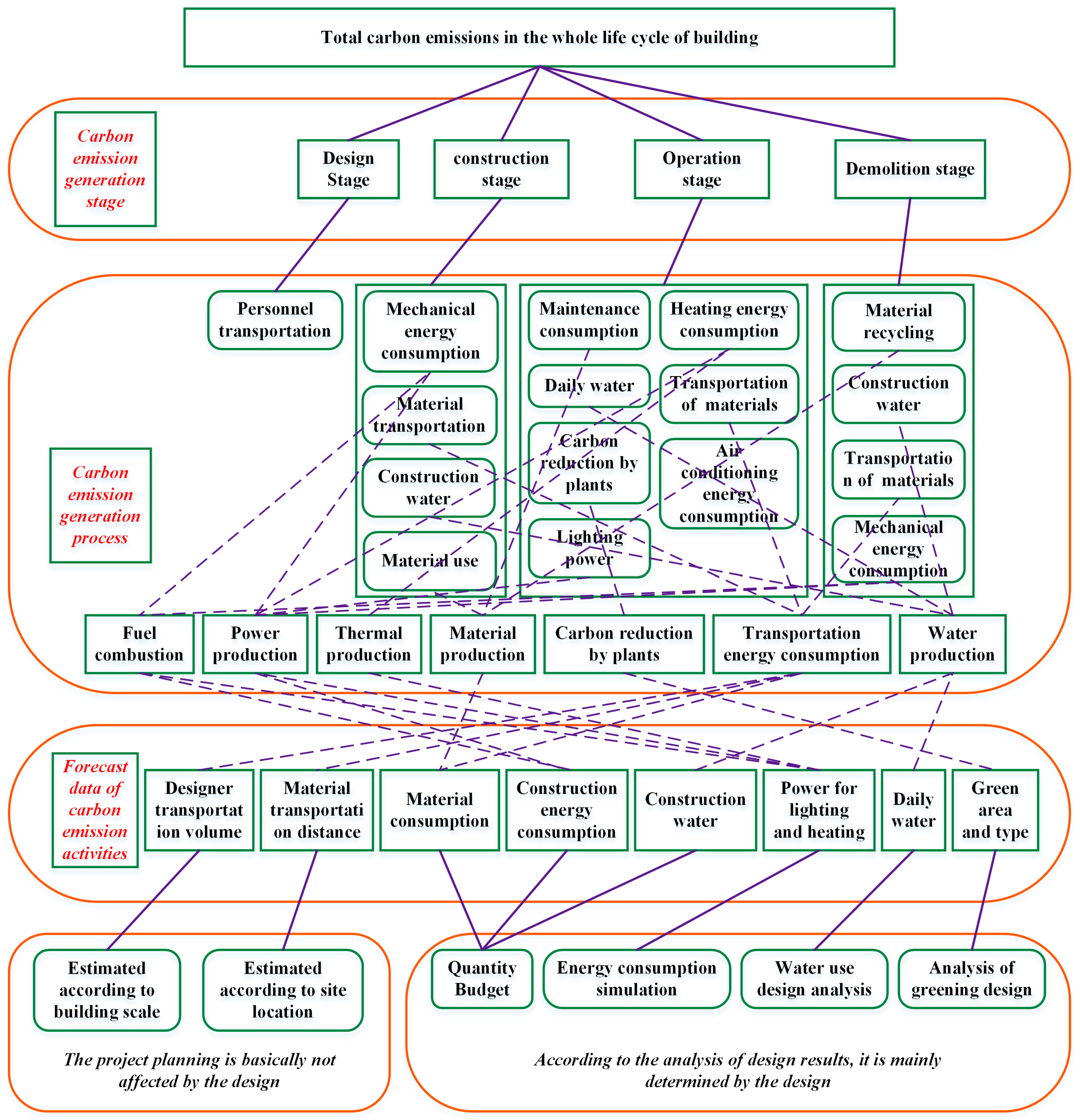

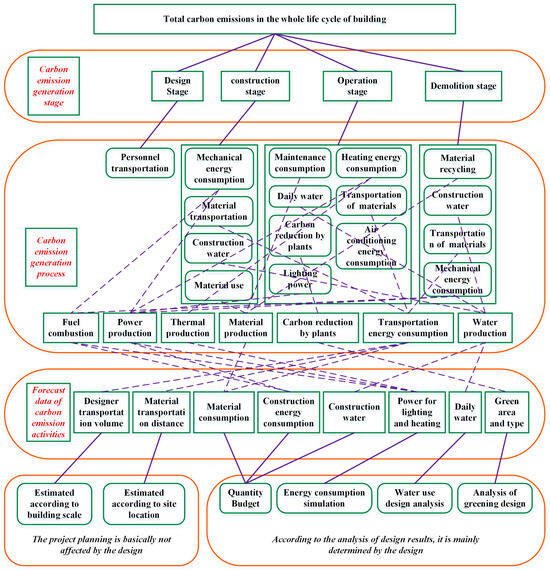

The development goal and path of green buildings have been defined, low-carbon building technologies and evaluation systems are being explored, and high-quality development support systems are gradually being improved [82,83]. At present, a standard system and corresponding indicator system focusing on green buildings and near-zero energy consumption buildings have been formed, which, to some extent, reflects the guidance of the low-carbon development of buildings. However, these standard systems generally focus on the conservation of building resources and energy, and there is still much room for improvement in the comprehensive and systematic aspects of carbon emission control [84]. In combination with the research results of the classification method of carbon emissions in the life cycle of buildings, we have determined the data correlation for each classification method to determine the evaluation factors of the design, and we have determined the factors that are relevant to the design as the basis for evaluating and optimizing the building design. The carbon emission types and data correlation determined by the three classification methods are shown in Figure 3.

Figure 3.

Data correlation in three carbon emission classification methods.

- 2.

- Existing Starting Point of Science and Technology Level and Existing Intellectual Property Rights

In terms of building carbon emission calculation, there are many corresponding carbon emission calculation methods for different stages of carbon emissions. These methods have their advantages and disadvantages, but there is no general method applicable to various situations [85,86,87]. Most studies collect and summarize the energy consumption at each stage of the building life cycle through measurement, estimation, simulation, empirical formula, or standard specifications. They then convert it into carbon emissions according to the carbon emission factor database of energy and consumables. The calculation results of different methods and the carbon emissions of the same building in different regions are quite different.

In terms of low-carbon future building indicator systems, there are relatively mature standard systems and corresponding indicator systems mainly oriented to green buildings and near-zero energy consumption buildings, which, to some extent, reflect the requirements for building energy conservation and emission reduction [88,89,90]. Some countries have formulated technical standards, including indicator systems for zero-carbon buildings, while China has not yet formed building standards and corresponding indicator systems with low carbon as the core. The existing indicator system related to low-carbon future buildings generally focuses on the conservation of building resources and energy. There is still much room for improvement in the comprehensive and systematic aspects of carbon emission control. In addition, the relevant indicator system has not yet conducted targeted research on different building types and different use scenarios.

In terms of low-carbon future building assessment systems, the LCA method is mainly used for research on building carbon emissions [91]. There have been post-evaluation studies and systems for green buildings, but there are no evaluation systems and methods for low-carbon future buildings [92]. Most studies on building carbon emission assessment methods in China and abroad take “carbon emissions per unit area” as an indicator. The indicators are relatively simple. An assessment system covering basic data lists and systems such as building life-cycle energy consumption and carbon emission factors has not been formed, and a highly operable and relatively accurate assessment method has not been formed [93]. At present, there are few building types and a number of cases to be evaluated, and the reliability of the evaluation method needs to be further verified.

In terms of integrated demonstration research, from the methods and research on demonstration project actual measurement research, the focus has been on demonstration project testing research in the fields of building energy efficiency, renewable energy, and green buildings, and the pathway for testing research on this type of demonstration project has been clear. However, there is still a lack of systematic and large-scale demonstration project research in the field of low-carbon future buildings, and there is a lack of engineering guidance on how to comprehensively and systematically test the comprehensive carbon reduction capacity of demonstration projects and the carbon reduction benefits of individual technologies. In addition, Chinese R&D projects often do not combine the findings of technical research with practical engineering applications; the technologies, tools, and products derived from research projects are not well applied in demonstration projects; and there is a lack of relevant verification and analysis of the actual effects of application. Further research and analysis are needed on how to organically combine technical research with engineering applications. Table 1 shows the low-carbon future building demonstration project.

Table 1.

Low-carbon future building demonstration project.

- 3.

- Competition and Industrialization Prospects

Scholars have conducted a lot of research on the assessment and evaluation methods of building carbon emissions [94]. The most mainstream is the research on building life cycle assessment, which originated in the United States in the late 1960s, was initially applied to the assessment of industrial products, and formed international standards such as ISO 14040. In recent years, LCA has attracted much attention in the field of construction, especially in the field of building carbon emission research. Europe and the United States have long taken the post-construction use evaluation as the project evaluation procedure. In addition to the evaluation of technology and economy, it also pays attention to the evaluation of user satisfaction, such as the evaluation of user satisfaction through Key Performance Indicators.

Mature green building evaluation systems around the world, such as LEED in the United States, BREEAM in the United Kingdom, DGNB in Germany, CASBEE in Japan, and GB/T 50378 [95] in China, are being promoted and applied. In terms of the evaluation of low-carbon future buildings, the United Nations Environment Programme proposed the “Common Carbon Emission Indicator System” at the beginning of this century. USGBC released the LEED Zero Energy, LEED Zero Carbon, and LEED Zero Waste evaluation systems in 2020. The International Living Future Institute has developed the Net Zero Energy Building certification system. These two systems are also competing for user recognition worldwide, especially in the United States. To carry out the quantitative assessment of the whole life cycle of buildings, North America, the European Union, Japan, and other countries have developed relevant software and databases for the quantitative assessment of the environmental load of the whole life cycle of buildings, including LCA tools for building materials, LCA tools for buildings, LCA tools combined with CAD, etc. Typical evaluation software includes BEES, INVEST, and AIJ-LCA.

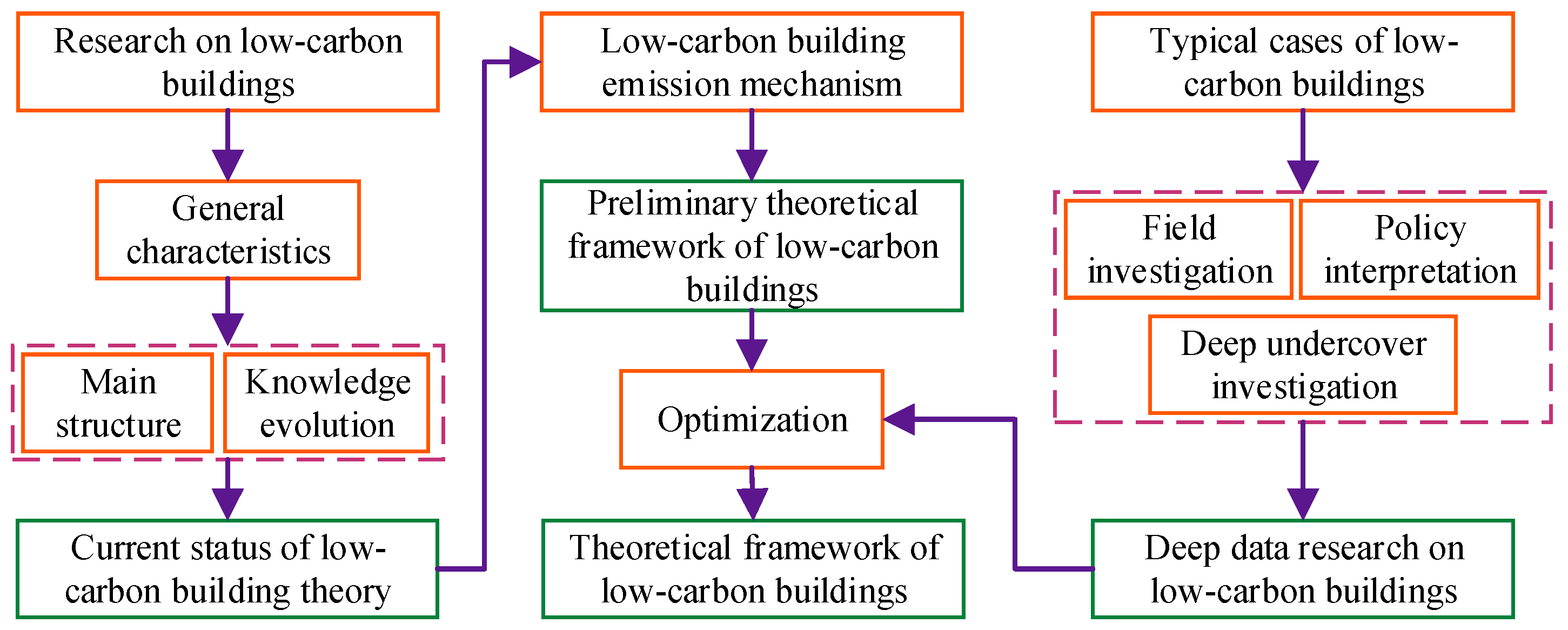

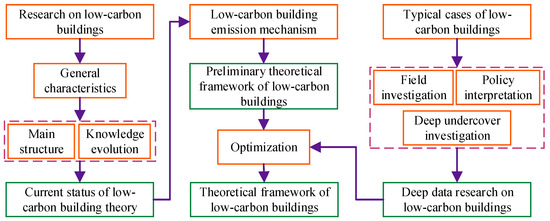

3.6. Construction of Theoretical Framework for Low-Carbon Future Building

We conducted an overall analysis of the characteristics, thematic context, and knowledge evolution of low-carbon future building-related research both domestically and internationally; referring to the relevant standards and specifications for new types of buildings such as green buildings, a preliminary theoretical framework for low-carbon future buildings was constructed from the perspective of the entire life cycle (as shown in Figure 4). Based on typical low-carbon future building cases at home and abroad, this study verifies and analyzes the theoretical framework of low-carbon future buildings through field investigations, policy text interpretation, in-depth interviews, and the mechanism of building carbon emissions and further improves and optimizes the theoretical system.

Figure 4.

Construction of theoretical framework for low-carbon future building.

4. Conclusions

This paper analyzes and summarizes the whole chain of “carbon monitoring-carbon accounting-carbon assessment-carbon control” of the whole life cycle of buildings. It systematically surveys the development overview and the latest development trend of scientific and technological innovation; the existing starting level of science and technology; and the existing intellectual property, competition, and industrialization prospects in each stage of the whole life cycle and provides a reference for the development of low-carbon future buildings. The main conclusions drawn from this paper are as follows:

- In the aspect of building planning and design, using artificial intelligence and big data to generate building forms, involving elements of energy conservation and emission reduction in the design process in advance, and assisting architects in positive design have become the research directions in low-carbon future building design.

- In terms of green building materials and intelligent construction, we will continue to develop new building materials with high performance and low emissions, adapt to the needs of the construction industry, and use digital technology to improve the level of prefabricated buildings; intelligent construction is the main direction of future research and development.

- In the direction of building energy, improving the level of electrification, “light storage, direct and flexible” buildings, building integration of renewable energy, green power DC-driven equipment, etc., are the main research and development directions of the future.

- In terms of building operation, the control of energy consumption and a carbon emission quota in the building operation phase are needed. Systematic and in-depth research needs to be conducted on building energy use diagnosis, intelligent optimization operation, carbon emission monitoring, carbon emission quotas, and other aspects to make breakthroughs in relevant key technologies and provide a reliable guarantee for the low-carbon operation of buildings.

- In terms of building evaluation systems, European and American countries took the lead in carrying out low-carbon building practices, which laid a foundation for the clarification of the concept of low-carbon buildings and the establishment of the evaluation system. Based on the evaluation system, countries are actively developing the construction and evaluation system of green and low-carbon future buildings.

At present, there is a general lack of analysis and even shelving of massive building energy consumption monitoring data in China. With the proposal of the dual carbon target, it is of great significance to explore the data value of building energy consumption monitoring platforms for the establishment of energy consumption and carbon emission quotas, dynamic supervision, and total control. At present, most relevant governments and research institutions are exploring the implementation path of low-carbon transformation in the construction industry from the perspective of top-level design and at a macro level. There is relatively little research on combining the dynamic monitoring of building carbon emissions with regional total control at the macro level. Future research can be conducted in the following aspects:

- It is important to build a method and technical system for building design based on carbon emission measurement and to provide accurate guidance for building design through convenient and rapid carbon emission calculations. Meanwhile, due to the high urbanization rate in some regions of China and the large existing building stock, there is an urgent need to develop low-carbon design methods and evaluation tools suitable for existing buildings.

- The use of renewable energy is a key engine for the development of low-carbon cities and buildings in the province, but there is still a need to make efforts in source, network, load, and storage, especially since there is a lack of a multi-dimensional energy complementary supply system and active and passive low-carbon technology integration methods for low-carbon cities, building design, and operation and maintenance.

- In some regions of China, the urbanization rate is high, the industrial output value is large, and “high energy consumption and high emissions” still dominate. The carbon emissions from building operation and maintenance continue to grow. They lack effective carbon emission control tools and low-carbon, zero-carbon-oriented intelligent carbon control technologies. There is an urgent need to build a building carbon footprint monitoring carbon emission operation and maintenance platform, and there are multiple energy-complementary technologies with core technologies that can be independently grasped.

- The purpose of the assessment and evaluation of low-carbon future buildings is not clear enough; the assessment index is relatively single; a unified list of basic data, such as energy consumption and carbon emission coefficients for each life stage of the building and a systematic assessment system, has not yet been formed; and a highly operable and relatively accurate assessment method has not yet been formed.

Author Contributions

Conceptualization, D.Y. and L.X.; methodology, D.Y. and L.X.; formal analysis, L.X. and J.Z.; investigation, J.Z.; data curation, C.J.; writing—original draft preparation, L.X. and J.Z.; writing—review and editing, D.Y.; visualization, D.Y. and J.Z.; supervision, D.Y.; project administration, J.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research were funded by the National Natural Science Foundation of China, grant number 52075232, the Natural Science Research Project of Higher Education Institutions in Jiangsu Province, grant number 18KJD440001, and the Open Project of Key Laboratory of Aircraft Environmental Control and Life Support, Ministry of Industry and Information Technology, grant number KLAECLS-E-201903.

Data Availability Statement

Data sharing not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhang, J.; Liu, Z. Low carbon economic scheduling model for a park integrated energy system considering integrated demand response, ladder-type carbon trading and fine utilization of hydrogen. Energy 2024, 290, 130311. [Google Scholar] [CrossRef]

- Hosseinian, S.M.; Faghani, M. Assessing the effect of structural parameters and building site in achieving low carbon building materialization using a life-cycle assessment approach. J. Build. Eng. 2021, 44, 103318. [Google Scholar] [CrossRef]

- Bazzocchi, F.; Ciacci, C.; Di Naso, V. Evaluation of Environmental and Economic Sustainability for the Building Envelope of Low-Carbon Schools. Sustainability 2021, 13, 1702. [Google Scholar] [CrossRef]

- Mei, Q.; Liu, L.; Abu Mansor, M.R. Investigation on spray combustion modeling for performance analysis of future low- and zero-carbon DI engine. Energy 2024, 302, 131906. [Google Scholar] [CrossRef]

- Olkkonen, V.; Hirvonen, J.; Heljo, J.; Syri, S. Effectiveness of building stock sustainability measures in a low-carbon energy system: A scenario analysis for Finland until 2050. Energy 2021, 235, 121399. [Google Scholar] [CrossRef]

- Zhou, W.; Moncaster, A.; Reiner, D.M.; Guthrie, P. Developing a generic System Dynamics model for building stock transformation towards energy efficiency and low-carbon development. Energy Build. 2020, 224, 110246. [Google Scholar] [CrossRef]

- Arsenkin, A.M.; Grigorovich, K.V.; Odesskii, P.D.; Tabakov, Y.I.; Zheleznyi, M.V.; Shibaeva, T.V. Structural nonuniformity: Impact on the cold resistance of low carbon microalloyed steel for building constructions. Results Mater. 2020, 8, 100141. [Google Scholar] [CrossRef]

- Watari, T.; Yamashita, N.; Serrenho, A.C. Net-Zero Embodied Carbon in Buildings with Today’s Available Technologies. Env. Sci. Technol. 2024, 58, 1793–1801. [Google Scholar] [CrossRef]

- Usman, M.; Khalid, K.; Mehdi, M.A. What determines environmental deficit in Asia? Embossing the role of renewable and non-renewable energy utilization. Renew. Energy 2021, 168, 1165–1176. [Google Scholar] [CrossRef]

- Guo, Z.; Wei, W.; Chen, L.; Dong, Z.Y.; Mei, S. Impact of Energy Storage on Renewable Energy Utilization: A Geometric Description. IEEE Trans. Sustain. Energy 2021, 12, 874–885. [Google Scholar] [CrossRef]

- Palomba, V.; Borri, E.; Charalampidis, A.; Frazzica, A.; Cabeza, L.F.; Karellas, S. Implementation of a solar-biomass system for multi-family houses: Towards 100% renewable energy utilization. Renew. Energy 2020, 166, 190–209. [Google Scholar] [CrossRef]

- O’Neill, R.; Window, A.; Kenway, S.; Dargusch, P. Integrated operational and life-cycle modelling of energy, carbon and cost for building façades. J. Clean. Prod. 2021, 286, 125370. [Google Scholar] [CrossRef]

- Liu, Y.; Luo, W.; Chen, X. Occupants’ Satisfaction of Indoor Environment Quality in Non-Linear Minimum Buildings in Winter Based on the Role of Different Kinds of Perceptions. Sustainability 2022, 14, 4983. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, Z.; Xiao, J.; Tiong, R. A Conceptual Framework for Estimating Building Embodied Carbon Based on Digital Twin Technology and Life Cycle Assessment. Sustainability 2021, 13, 13875. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework, CEN (European Committee for Standardisation). International Standards Organization ISO: Geneva, Switzerland, 2006.

- Ang, Y.Q.; Berzolla, Z.M.; Reinhart, C.F. From concept to application: A review of use cases in urban building energy modeling. Appl. Energy 2020, 279, 115738. [Google Scholar] [CrossRef]

- Brooks, M.; Abdellatif, M.; Alkhaddar, R. Application of life cycle carbon assessment for a sustainable building design: A case study in the UK. Int. J. Green. Energy 2021, 18, 351–362. [Google Scholar] [CrossRef]

- Wang, J.; Teng, Y.; Chen, Z.; Bai, J.; Niu, Y.; Duan, H. Assessment of carbon emissions of building interior decoration and renovation waste disposal in the fast-growing Greater Bay Area, China. Sci. Total Environ. 2021, 798, 149158. [Google Scholar] [CrossRef]

- Xiaoxiang, Q.; Junjia, Y.; Haron, N.A.; Alias, A.H.; Law, T.H.; Abu Bakar, N. Status, Challenges and Future Directions in the Evaluation of Net-Zero Energy Building Retrofits: A Bibliometrics-Based Systematic Review. Energies 2024, 17, 3826. [Google Scholar] [CrossRef]

- Bottero, M.; Dell’Anna, F.; Morgese, V. Evaluating the Transition Towards Post-Carbon Cities: A Literature Review. Sustainability 2021, 13, 567. [Google Scholar] [CrossRef]

- Huo, Y.; Bouffard, F.; Joos, G. Spatio-Temporal Flexibility Management in Low-Carbon Power Systems. IEEE Trans. Sustain. Energy 2020, 11, 2593–2605. [Google Scholar] [CrossRef]

- Gassar, A.A.A.; Cha, S.H. Energy prediction techniques for large-scale buildings towards a sustainable built environment: A review. Energy Build. 2020, 224, 110238. [Google Scholar] [CrossRef]

- Gassar, A.A.A.; Koo, C.; Kim, T.W.; Cha, S.H. Performance Optimization Studies on Heating, Cooling and Lighting Energy Systems of Buildings during the Design Stage: A Review. Sustainability 2021, 13, 9815. [Google Scholar] [CrossRef]

- Gao, Y.; Jia, R.; Yao, Y.; Xu, J. Evolutionary Game Theory and the Simulation of Green Building Development Based on Dynamic Government Subsidies. Sustainability 2022, 14, 7294. [Google Scholar] [CrossRef]