Bubble Dynamics in Sustainable Technologies: A Review of Growth, Collapse, and Heat Transfer

Abstract

1. Introduction

2. Review Method

3. Bubble Growth Studies

3.1. Liquid–Gas Studies

3.2. Solid–Gas Studies

4. Bubble Collapse Studies

5. Bubble Growth and Collapse Studies

6. Evaluation of the Numerical Methods Used in Bubble Growth and Collapse Studies

7. Recommendations for Further Research

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ANOVA | analysis of variance |

| BE | boundary-element |

| BEM | boundary-element method |

| CEL | Coupled Eulerian–Lagrangian |

| CFD | Computational Fluid Dynamics |

| CLBM | Conventional Lattice Boltzmann Method |

| DDF | double distribution function |

| FEM | Finite Element Method |

| HIFU | High Intensity Focused Ultrasound |

| IMCs | intermetallic compounds |

| IPM | Included Phase Model |

| LBM | Lattice Boltzmann method |

| LSM | Level-Set Method |

| MRT-LBM | multi-relaxation-time lattice Boltzmann method |

| ONB | Onset of Nucleate Boiling |

| PDE | partial differential equation |

| PFM | Phase-Field Model |

| PFT | Potential Flow Theory |

| RP | Rayleigh-Plesset |

| SEM | scanning electron microscopy |

| SEMP | Spectral Element Marker Particle |

| SILS | Sharp-Interface Level-Set |

| SPH | Smoothed Particle Hydrodynamics |

| TLBM | Thermal Lattice Boltzmann method |

| UMo | Uranium Monolithic |

| VOF | Volume of Fluid |

| VOFE | Volumetric Optical Force |

References

- Wang, H.; Zhang, C.; Xiong, H. Growth and collapse dynamics of a vapor bubble near or at a wall. Water 2020, 13, 12. [Google Scholar] [CrossRef]

- Mehralizadeh, A.; Shabanian, S.R.; Bakeri, G. Effect of modified surfaces on bubble dynamics and pool boiling heat transfer enhancement: A review. Therm. Sci. Eng. Prog. 2020, 15, 100451. [Google Scholar] [CrossRef]

- Hussein, E.Q.; Rashid, F.L.; Hussein, A.K.; Younis, O. Hydrodynamics of single bubble rising through water column using volume of fluid (VOF) method. J. Therm. Eng. 2021, 7, 2107–2114. [Google Scholar] [CrossRef]

- Mohanty, R.L.; Das, M.K. A critical review on bubble dynamics parameters influencing boiling heat transfer. Renew. Sustain. Energy. Rev. 2017, 78, 466–494. [Google Scholar] [CrossRef]

- Hong, Y.; Ashgriz, N.; Andrews, J.; Parizi, H. Numerical simulation of growth and collapse of a bubble induced by a pulsed microheater. J. Microelectromech. Syst. 2004, 13, 857–869. [Google Scholar] [CrossRef]

- Al-Obaidi, M.A.; Rasn, K.H.; Aladwani, S.H.; Kadhom, M.; Mujtaba, I.M. Flexible design and operation of multi-stage reverse osmosis desalination process for producing different grades of water with maintenance and cleaning opportunity. Chem. Eng. Res. Des. 2022, 182, 525–543. [Google Scholar] [CrossRef]

- Al-Obaidi, M.A.; Alsarayreh, A.A.; Mujtaba, I.M. Reduction of energy consumption of brackish water reverse osmosis desalination system via model based optimisation. J. Tech. 2023, 5, 1–7. [Google Scholar] [CrossRef]

- Avvaru, B.; Venkateswaran, N.; Uppara, P.; Iyengar, S.B.; Katti, S.S. Current knowledge potential applications of cavitation technologies for the petroleum industry. Ultrason. Sonochem. 2018, 42, 493–507. [Google Scholar] [CrossRef]

- Rajoriya, S.; Carpenter, J.; Saharan, V.K.; Pandit, A.B. Hydrodynamic cavitation: An advanced oxidation process for the degradation of bio-refractory pollutants. Rev. Chem. Eng. 2016, 32, 379–411. [Google Scholar] [CrossRef]

- Edwards, D.H.; Jones, I.R. An experimental study of the forces generated by the collapse of transient cavities in water. J. Fluid Mech. 1960, 7, 596–609. [Google Scholar]

- Fujikawa, S.; Akamatsu, T. Experimental investigations of cavitation bubble collapse by a water shock tube. Bull. JSME 1978, 21, 223–230. [Google Scholar] [CrossRef]

- Karri, B.; Pillai, K.S.; Klaseboer, E.; Ohl, S.W.; Khoo, B.C. Collapsing bubble induced pumping in a viscous fluid. Sens. Actuators A Phys. 2011, 169, 151–163. [Google Scholar] [CrossRef]

- Koynov, A.; Khinast, J.G.; Tryggvason, G. Mass transfer and chemical reactions in bubble swarms with dynamic interfaces. AIChE J. 2005, 51, 2786–2800. [Google Scholar] [CrossRef]

- Agarwal, D.K.; Welch, S.W.J.; Biswas, G.; Durst, F. Planar Simulation of Bubble Growth in Film Boiling in Near-Critical Water Using a Variant of the VOF Method. J. Heat Transf. 2004, 126, 329–338. [Google Scholar] [CrossRef]

- Mukherjee, A.; Dhir, V.K. Study of Lateral Merger of Vapor Bubbles During Nucleate Pool Boiling. J. Heat Transf. 2005, 126, 1023–1039. [Google Scholar] [CrossRef]

- Tomar, G.; Biswas, G.; Sharma, A.; Agrawal, A. Numerical simulation of bubble growth in film boiling using a coupled level-set and volume-of-fluid method. Phys. Fluids 2005, 17, 112103. [Google Scholar] [CrossRef]

- Wu, J.; Dhir, V.K. Numerical simulations of the dynamics and heat transfer associated with a single bubble in subcooled pool boiling. J. Heat Transf. 2010, 132, 1–15. [Google Scholar] [CrossRef]

- Marchal, A.; Vergnes, B.; Poulesquen, A.; Valette, R. Competitive growth and rising of bubbles in a yield stress fluid. Consequences on the macroscopic swelling of bitumen drums. J. Nonnewton Fluid Mech. 2016, 234, 162–169. [Google Scholar] [CrossRef]

- Goel, P.; Nayak, A.K.; Kulkarni, P.P.; Joshi, J.B. Experimental study on bubble departure characteristics in subcooled nucleate pool boiling. Int. J. Multiph. Flow 2017, 89, 163–176. [Google Scholar] [CrossRef]

- Zhang, S.; Li, X.; Zhu, Z. Numerical simulation of cryogenic cavitating flow by an extended transport-based cavitation model with thermal effects. J. Cryog. 2018, 92, 98–104. [Google Scholar] [CrossRef]

- Pahk, K.J.; de Andrade, M.O.; Gélat, P.; Kim, H.; Saffari, N. Mechanical damage induced by the appearance of rectified bubble growth in a viscoelastic medium during boiling histotripsy exposure. Ultrason. Sonochem. 2019, 53, 164–177. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Zhang, N.; Ding, Z.; Yang, F.; Hu, Q.; Zeng, L.; Li, J. Bubble growth, intermetallic compounds dissolution and their interactions during heating of an Al-5wt.%Mn alloy by in-situ synchrotron radiography. J. Alloys Compd. 2020, 822, 153554. [Google Scholar] [CrossRef]

- Zeng, X.; Wu, G.; Wang, J.; Yang, C.; Meng, Q.; Chen, G.; Chen, D. Effects of inhibitors on the morphology and kinetics of hydrate growth on surface of bubble. J. Nat. Gas. Sci. Eng. 2020, 74, 103096. [Google Scholar] [CrossRef]

- Allred, T.P.; Weibel, J.A.; Garimella, S.V. The Role of Dynamic Wetting Behavior during Bubble Growth and Departure from a Solid Surface. Int. J. Heat Mass Transf. 2021, 172, 121167. [Google Scholar] [CrossRef]

- Zhao, W.; Liang, J.; Sun, M.; Wang, Z. Investigation on the effect of convective outflow boundary condition on the bubbles growth, rising and breakup dynamics of nucleate boiling. Int. J. Therm. Sci. 2021, 167, 106877. [Google Scholar] [CrossRef]

- Winder, D.; Lin, L.; Mach, J. Incorporating bubble growth volume feedback to improve simulation of the response of a structure containing liquid and gas to sudden energy input. Nucl. Instrum. Methods. Phys. Res. A 2021, 1005, 165371. [Google Scholar] [CrossRef]

- Li, D.; Ren, Z.; Li, Y.; Gong, R.; Wang, H. Thermodynamic effects on the cavitation flow of a liquid oxygen turbopump. Cryogenics 2021, 116, 103302. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, P.; Qi, B.; Zhang, Y.; Wei, J. Effects of micro-pin-fins on the bubble growth and movement of nucleate pool boiling on vertical surfaces. Int. J. Therm. Sci. 2022, 171, 107186. [Google Scholar] [CrossRef]

- Lai, T.; Yan, S.; Zhao, Q.; Zhang, Z.; Ding, W.; Liu, Y.; Hou, Y. Numerical study on thermodynamic growth of single hydrogen bubble in an infinite space. Int. J. Hydrogen Energy 2022, 47, 24406–24420. [Google Scholar] [CrossRef]

- Cheng, N.; Yu, S.; Xiao, J.; Peng, C. Numerical simulation of single bubble growth in vertical rectangular narrow flow channels. Nucl. Eng. Des. 2022, 391, 111749. [Google Scholar] [CrossRef]

- Hu, S.; Setyawan, W.; Beeler, B.W.; Gan, J.; Burkes, D.E. Defect cluster and nonequilibrium gas bubble associated growth in irradiated UMo fuels-A cluster dynamics and phase field model. J. Nucl. Mater. 2020, 542, 152441. [Google Scholar] [CrossRef]

- Zhou, T.T.; He, A.M.; Wang, P. Dynamic evolution of He bubble and its effects on void nucleation-growth and thermomechanical properties in the spallation of aluminum. J. Nucl. Mater. 2020, 542, 152496. [Google Scholar] [CrossRef]

- Arévalo-Cid, P.; Adán-Más, A.; Silva, T.M.; Rodrigues, J.A.; Maçôas, E.; Vaz, M.F.; Montemor, M.F. On the growth mechanical properties of nanostructured cobalt foams by dynamic hydrogen bubble template electrodeposition. Mater. Charact. 2020, 169, 110598. [Google Scholar] [CrossRef]

- Prudil, A.A.; Welland, M.J.; Ofori-Opoku, N. Modelling the growth and evolution of statistically significant populations of intergranular fission gas bubbles by IPM. J. Nucl. Mater. 2022, 566, 153777. [Google Scholar] [CrossRef]

- Gong, S.; Cheng, P. Lattice Boltzmann simulation of periodic bubble nucleation, growth and departure from a heated surface in pool boiling. Int. J. Heat Mass Transf. 2013, 64, 122–132. [Google Scholar] [CrossRef]

- Navarrete, M.; Godínez, F.A.; Castellanos, F.; Mejía-Uriarte, E.V.; Naude, J.L.; Méndez, F. Dynamics and acoustic energy dissipation in conical bubble collapse. Int. J. Multiph. Flow 2015, 76, 86–100. [Google Scholar] [CrossRef]

- Gong, S.W.; Klaseboer, E. Interaction between collapsing bubble and viscoelastic solid: Numerical modelling and simulation. Appl. Math. Model. 2016, 40, 122–132. [Google Scholar] [CrossRef]

- Tang, J.; Yan, C.; Sun, L. Enhanced vapor bubble condensation and collapse with ultrasonic vibration. Exp. Therm. Fluid Sci. 2016, 70, 115–124. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, C.; Fang, X.; Wu, X.; Du, T. On the internal collapse phenomenon at the closure of cavitation bubbles in a deceleration process of underwater vertical launching. Appl. Ocean. Res. 2016, 56, 157–165. [Google Scholar] [CrossRef]

- Qin, Z.; Alehossein, H. Heat transfer during cavitation bubble collapse. Appl. Therm. Eng. 2016, 105, 1067–1075. [Google Scholar] [CrossRef]

- Li, S.; Han, R.; Zhang, A.M.; Wang, Q.X. Analysis of pressure field generated by a collapsing bubble. Ocean. Eng. 2016, 117, 22–38. [Google Scholar] [CrossRef]

- Rowlatt, C.F.; Lind, S.J. Bubble collapse near a fluid-fluid interface using the spectral element marker particle method with applications in bioengineering. Int. J. Multiph. Flow 2017, 90, 118–143. [Google Scholar] [CrossRef]

- Ye, L.; Zhu, X. Analysis of the effect of impact of near-wall acoustic bubble collapse micro-jet on Al 1060. Ultrason. Sonochem. 2017, 36, 507–516. [Google Scholar] [CrossRef] [PubMed]

- Pavlov, P.A. Fast collapse of a vapor bubble. Int. J. Heat Mass Transf. 2017, 104, 627–633. [Google Scholar] [CrossRef]

- Ming, L.; Zhi, N.; Chunhua, S. Numerical simulation of cavitation bubble collapse within a droplet. Comput. Fluids 2017, 152, 157–163. [Google Scholar] [CrossRef]

- Rosselló, J.M.; Urteaga, R.; Bonetto, F.J. A novel water hammer device designed to produce controlled bubble collapses. Exp. Therm. Fluid Sci. 2018, 92, 46–55. [Google Scholar] [CrossRef]

- Phan, T.H.; Ha, C.T.; Park, W.G. Numerical simulation of bubble collapse between two parallel walls and saturated film boiling on a sphere. Int. J. Heat Mass Transf. 2018, 127, 116–125. [Google Scholar] [CrossRef]

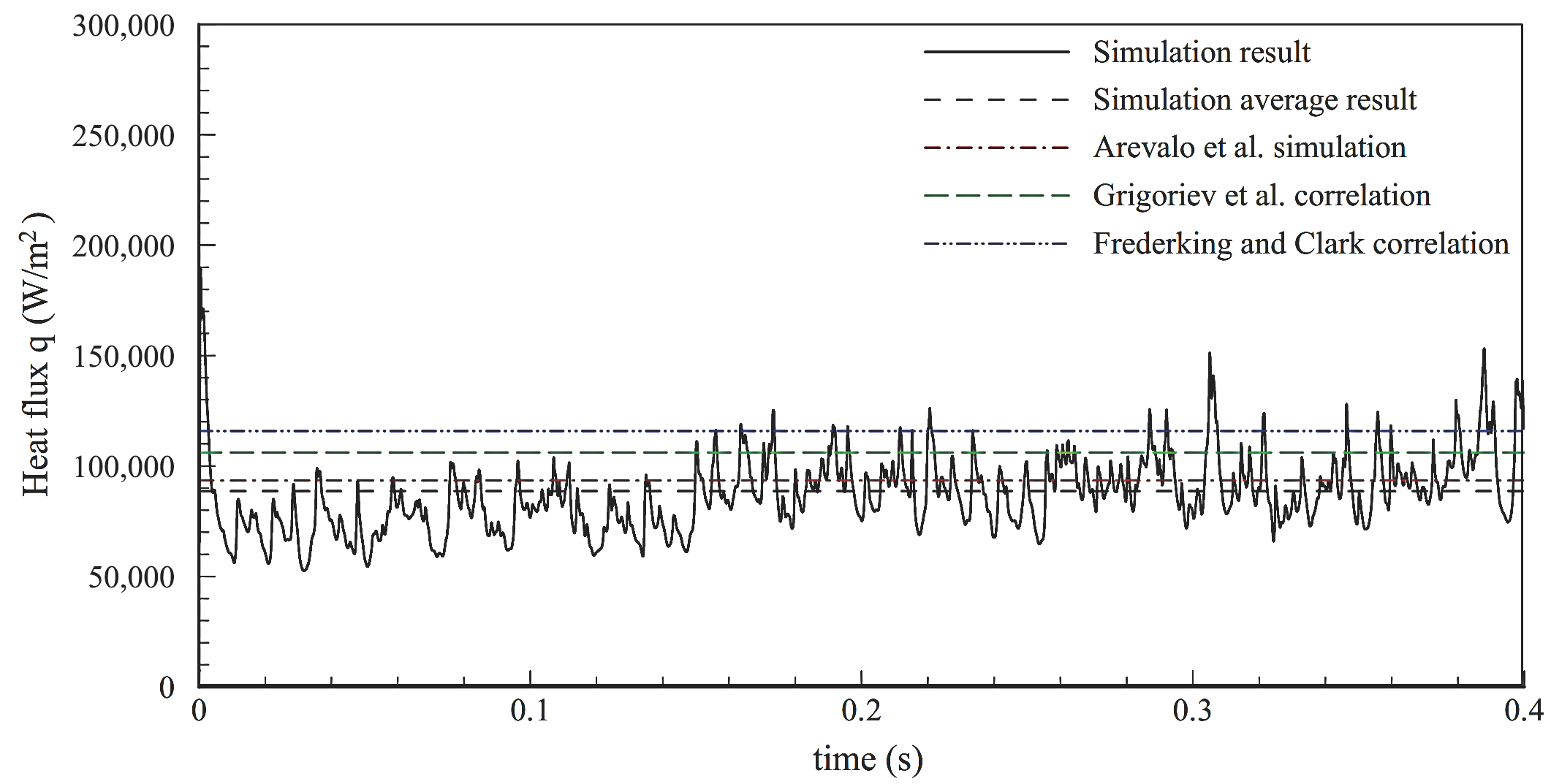

- Arévalo, R.; Antúnez, D.; Rebollo, L.; Abánades, A. Estimation of radiation coupling factors in film boiling around spheres by mean of Computational Fluid Dynamics (CFD) tools. Int. J. Heat Mass Transf. 2014, 78, 84–89. [Google Scholar] [CrossRef]

- Grigoriev, V.A.; Klimenko, V.V.; Shelepen, A.G. Pool film toiling from submerged spheres. In Proceedings of the International Heat Transfer Conference Digital Library, Munich, Germany, 6–10 September 1982; Begel House Inc.: Danbury, CT, USA, 1982. [Google Scholar]

- Frederking, T.H.; Clark, J.A. Natural convection film boiling on a sphere. In Advances in Cryogenic Engineering: Proceedings of the 1962 Cryogenic Engineering Conference University of California Los Angeles, CA, USA, 14–16 August 1962; Springer: New York, NY, USA, 1963; pp. 501–506. [Google Scholar]

- Kerabchi, N.; Merouani, S.; Hamdaoui, O. Depth effect on the inertial collapse of cavitation bubble under ultrasound: Special emphasis on the role of the wave attenuation. Ultrason. Sonochem. 2018, 48, 136–150. [Google Scholar] [CrossRef]

- Joshi, S.; Franc, J.P.; Ghigliotti, G.; Fivel, M. SPH modelling of a cavitation bubble collapse near an elasto-visco-plastic material. J. Mech. Phys. Solids 2019, 125, 420–439. [Google Scholar] [CrossRef]

- Brujan, E.A.; Takahira, H.; Ogasawara, T. Planar jets in collapsing cavitation bubbles. Exp. Therm. Fluid Sci. 2019, 101, 48–61. [Google Scholar] [CrossRef]

- Hopfes, T.; Wang, Z.; Giglmaier, M.; Adams, N.A. Collapse dynamics of bubble pairs in gelatinous fluids. Exp. Therm. Fluid Sci. 2019, 108, 104–114. [Google Scholar] [CrossRef]

- Bardia, R.; Trujillo, M.F. An improved categorization of vapor bubble collapse: Explaining the coupled nature of hydrodynamic thermal mechanisms. Int. J. Heat Mass Transf. 2019, 145, 118754. [Google Scholar] [CrossRef]

- Gan, N.; Yao, X.L.; Liu, L.T.; Xiao, W.; Wang, X.L. Research on overall damage characteristics of a hull girder under explosion bubble collapse. Ocean. Eng. 2019, 188, 106315. [Google Scholar] [CrossRef]

- Chudnovskii, V.M.; Levin, A.A.; Yusupov, V.I.; Guzev, M.A.; Chernov, A.A. The formation of a cumulative jet during the collapse of a vapor bubble in a subcooled liquid formed as a result of laser heating. Int. J. Heat Mass Transf. 2020, 150, 119286. [Google Scholar] [CrossRef]

- Yuan, G.Y.; Ni, B.Y.; Wu, Q.G.; Xue, Y.Z.; Zhang, A.M. An experimental study on the dynamics and damage capabilities of a bubble collapsing in the neighborhood of a floating ice cake. J. Fluids Struct. 2020, 92, 102833. [Google Scholar] [CrossRef]

- Han, S.; Li, Y.; Zhu, H. The similarities and differences between the bubble collapse near a solid wall and in free water. Eur. J. Mech.-B/Fluids 2020, 84, 553–561. [Google Scholar] [CrossRef]

- Fursenko, R.V.; Chudnovskii, V.M.; Minaev, S.S.; Okajima, J. Mechanism of high velocity jet formation after a gas bubble collapse near the micro fiber immersed in a liquid. Int. J. Heat Mass Transf. 2020, 163, 120420. [Google Scholar] [CrossRef]

- Tan, K.L.; Yeo, S.H. Velocity estimation of micro-particles driven by cavitation bubble collapses through controlled erosion experiments. Int. J. Multiph. Flow 2020, 127, 103271. [Google Scholar] [CrossRef]

- Orthaber, U.; Zevnik, J.; Petkovšek, R.; Dular, M. Cavitation bubble collapse in a vicinity of a liquid-liquid interface—Basic research into emulsification process. Ultrason. Sonochem. 2020, 68, 105224. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiu, X.; Zhang, X.; Tang, N. Collapsing dynamics of a laser-induced cavitation bubble near the edge of a rigid wall. Ultrason. Sonochem. 2020, 67, 105157. [Google Scholar] [CrossRef] [PubMed]

- Ezzatneshan, E.; Vaseghnia, H. Simulation of collapsing cavitation bubbles in various liquids by lattice Boltzmann model coupled with the Redlich-Kwong-Soave equation of state. Phys. Rev. E 2020, 102, 053309. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.; Zhang, M.; Han, L.; Ma, X.; Huang, B. Physical investigation of acoustic waves induced by the oscillation and collapse of the single bubble. Ultrason. Sonochem. 2021, 72, 105440. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Zhu, R.; Wang, J.; Fu, Q.; Wang, X.; Zhao, Y.; Zhao, G. Molecular dynamics simulations of the distance between the cavitation bubble and benzamide wall impacting collapse characteristics. J. Clean. Prod. 2022, 352, 131633. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, J.; He, X.; Wang, Y. Thermal pseudo-potential lattice Boltzmann method for simulating cavitation bubbles collapse near a rigid boundary. Comput. Fluids 2021, 217, 104817. [Google Scholar] [CrossRef]

- Trummler, T.; Schmidt, S.J.; Adams, N.A. Effect of stand-off distance and spatial resolution on the pressure impact of near-wall vapor bubble collapses. Int. J. Multiph. Flow 2021, 141, 103618. [Google Scholar] [CrossRef]

- Long, J.; Eliceiri, M.H.; Wang, L.; Vangelatos, Z.; Ouyang, Y.; Xie, X.; Zhang, Y.; Grigoropoulos, C.P. Capturing the final stage of the collapse of cavitation bubbles generated during nanosecond laser ablation of submerged targets. Opt. Laser Technol. 2021, 134, 106647. [Google Scholar] [CrossRef]

- Wang, X.; Ning, Z.; Lv, M.; Sun, C. Machine learning for predicting the bubble-collapse strength as affected by physical conditions. Results Phys. 2021, 25, 104226. [Google Scholar] [CrossRef]

- Gai, S.; Peng, Z.; Moghtaderi, B.; Yu, J.; Doroodchi, E. LBM study of ice nucleation induced by the collapse of cavitation bubbles. Comput. Fluids 2022, 246, 105616. [Google Scholar] [CrossRef]

- Ezzatneshan, E.; Vaseghnia, H. Dynamics of an acoustically driven cavitation bubble cluster in the vicinity of a solid surface. Phys. Fluids 2021, 33, 1075290. [Google Scholar] [CrossRef]

- Xu, W.L.; Li, J.B.; Luo, J.; Zhai, Y.W. Effect of a single air bubble on the collapse direction and collapse noise of a cavitation bubble. Exp. Therm. Fluid Sci. 2021, 120, 110218. [Google Scholar] [CrossRef]

- Nguyen, T.T.P.; Tanabe-Yamagishi, R.; Ito, Y. Effects of liquid depth on the expansion and collapse of a hemispherical cavitation bubble induced in nanosecond pulsed laser ablation of a solid in liquid. Opt. Lasers Eng. 2020, 126, 105937. [Google Scholar] [CrossRef]

- Yang, Y.; Shan, M.; Su, N.; Kan, X.; Shangguan, Y.; Han, Q. Role of wall temperature on cavitation bubble collapse near a wall investigated using thermal lattice Boltzmann method. Int. Commun. Heat Mass Transf. 2022, 134, 105988. [Google Scholar] [CrossRef]

- He, X.; Peng, H.; Zhang, J.; Yuan, H. Multiple vapor cavitation bubble interactions with a thermal lattice Boltzmann method. Ocean. Eng. 2022, 266, 113058. [Google Scholar] [CrossRef]

- Ezzatneshan, E.; Salehi, A.; Vaseghnia, H. Study of micro-heater shape and wettability effects on inception of boiling phenomenon using a multiphase lattice Boltzmann method. Int. J. Therm. Sci. 2023, 184, 107913. [Google Scholar] [CrossRef]

- Ezzatneshan, E.; Salehi, A.; Vaseghnia, H. Numerical study on collapsing cavitation bubble dynamics in cryogenic fluids. Cryogenics 2024, 141, 103879. [Google Scholar] [CrossRef]

- Lee, J.; Son, G. A sharp-interface level-set method for compressible bubble growth with phase change. Int. Commun. Heat Mass Transf. 2017, 86, 1–11. [Google Scholar] [CrossRef]

- Wang, Q.; Yao, W.; Quan, X.; Cheng, P. Validation of a dynamic model for vapor bubble growth and collapse under microgravity conditions. Int. Commun. Heat Mass Transf. 2018, 95, 63–73. [Google Scholar] [CrossRef]

- Sourtiji, E.; Peles, Y. A micro-synthetic jet in a microchannel using bubble growth and collapse. Appl. Therm. Eng. 2019, 160, 114084. [Google Scholar] [CrossRef]

- Sun, B.; Liu, Z.; Wang, Z.; Chen, L.; Li, H.; Duan, W. Experimental and modeling investigations into hydrate shell growth on suspended bubbles considering pore updating and surface collapse. Chem. Eng. Sci. 2019, 207, 1–16. [Google Scholar] [CrossRef]

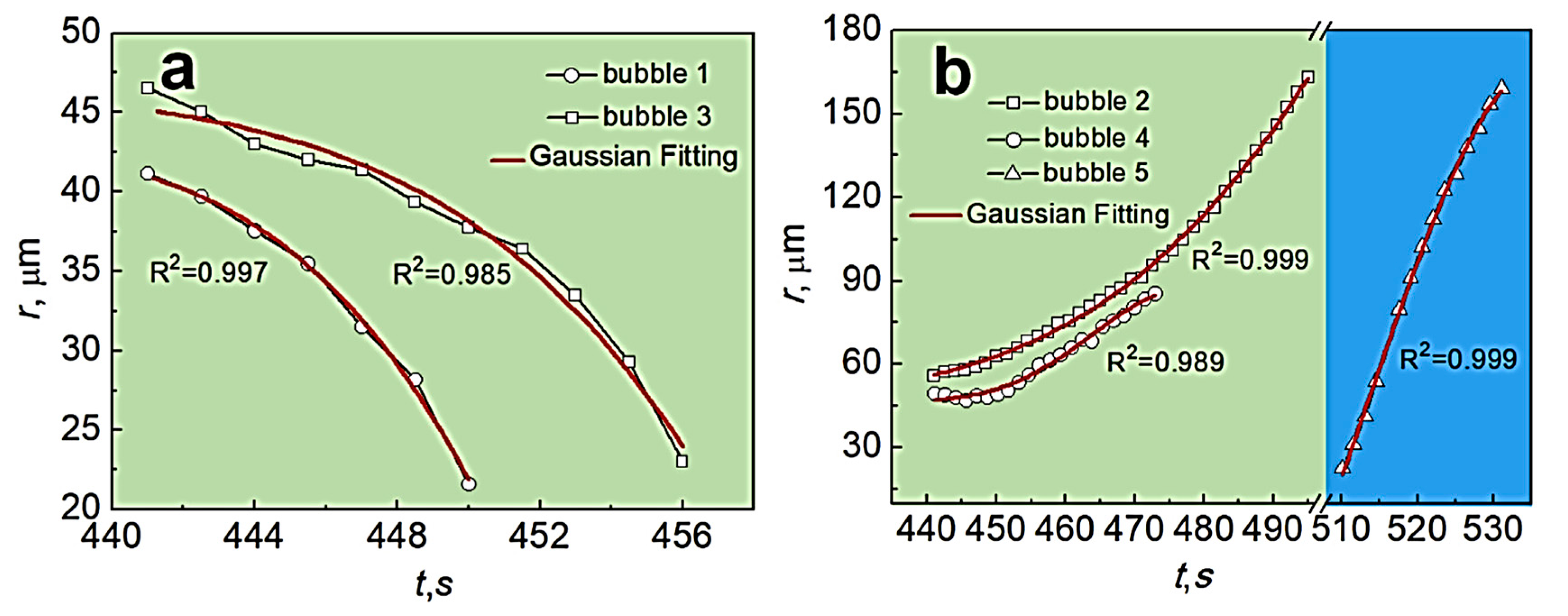

- Zimnyakov, D.A.; Yuvchenko, S.A.; Isaeva, A.A.; Isaeva, E.A.; Tsypin, D.V. Growth/collapse kinetics of the surface bubbles in fresh constrained foams: Transition to self-similar evolution. Colloids Surf. A Physicochem. Eng. Asp. 2019, 579, 123693. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Phan, T.H.; Duy, T.N.; Kim, D.H.; Park, W.G. Modeling of the bubble collapse with water jets and pressure loads using a geometrical volume of fluid based simulation method. Int. J. Multiph. Flow 2022, 152, 104103. [Google Scholar] [CrossRef]

- Puncochar, M.; Ruzicka, M.C.; Simcik, M. Bubble formation and deformation. Chem. Eng. Sci. 2022, 260, 117729. [Google Scholar] [CrossRef]

- Castro, J.M. Modelling and Numerical Simulation of Combustion and Multi-Phase Flows Using Finite Volume Methods on Unstructured Meshes; Universitat Politècnica de Catalunya: Barcelona, Spain, 2018. [Google Scholar]

- Van der Pijl, S.P.; Segal, A.; Vuik, C.; Wesseling, P. A mass-conserving Level-Set method for modelling of multi-phase flows. Int. J. Numer. Methods Fluids 2005, 47, 339–361. [Google Scholar] [CrossRef]

- Alpak, F.O.; Riviere, B.; Frank, F. A phase-field method for the direct simulation of two-phase flows in pore-scale media using a non-equilibrium wetting boundary condition. Comput. Geosci. 2016, 20, 881–908. [Google Scholar] [CrossRef]

- Kono, K.; Ishizuka, T.; Tsuda, H.; Kurosawa, A. Application of lattice Boltzmann model to multiphase flows with phase transition. Comput. Phys. Commun. 2000, 129, 110–120. [Google Scholar] [CrossRef]

- Afzali, S.; Rezaei, N.; Zendehboudi, S.; Chatzis, I. Computational fluid dynamic simulation of multi-phase flow in fractured porous media during water-alternating-gas injection process. J. Hydrol. 2022, 610, 127852. [Google Scholar] [CrossRef]

- Sichani, A.B.; Mehring, C. Generalized pressure-correction for viscous potential flow simulations of multiphase flows using boundary element method. Int. J. Multiph. Flow 2021, 141, 103646. [Google Scholar] [CrossRef]

- Pei, C.; Vahab, M.; Sussman, M.; Hussaini, M.Y. A Hierarchical Space-Time Spectral Element and Moment-of-Fluid Method for Improved Capturing of Vortical Structures in Incompressible Multi-phase/Multi-material Flows. J. Sci. Comput. 2019, 81, 1527–1566. [Google Scholar] [CrossRef]

- Efendiev, Y.; Ginting, V.; Hou, T.; Ewing, R. Accurate multiscale finite element methods for two-phase flow simulations. J. Comput. Phys. 2006, 220, 155–174. [Google Scholar] [CrossRef]

- Sahu, A.; Bhowmick, S. Applications of Lattice Boltzmann in method in multi-component and multi-phase flow: A review. In Proceedings of the AIP, Woodbury, Long Island, NY, USA, 6–7 December 2019. [Google Scholar]

- Szewc, K.; Tanière, A.; Pozorski, J.; Minier, J.-P.A. Study on Application of Smoothed Particle Hydrodynamics to Multi-Phase Flows. Int. J. Nonlinear. Sci. Numer. Simul. 2012, 13, 383–395. [Google Scholar] [CrossRef]

- Kim, M.S.; Lee, W.I.L. A new VOF-based numerical scheme for the simulation of fluid flow with free surface. Part I: New free surface-tracking algorithm and its verification. Int. J. Numer. Methods Fluids 2003, 42, 765–790. [Google Scholar] [CrossRef]

- Han, L.H.; Hu, X.Y.; Adams, N.A. Scale separation for multi-scale modeling of free-surface and two-phase flows with the conservative sharp interface method. J. Comput. Phys. 2015, 280, 387–403. [Google Scholar] [CrossRef]

| Authors (Year) [Reference] | Sector/Area of Process Engineering | Configuration | Medium | Type of Study | Parameters Under Investigation | Highlighted Findings |

|---|---|---|---|---|---|---|

| Agarwal et al. (2004) [14] | Thermal conductivity and specific heat of vapor | Film boiling and bubble formation in water. | Water | Numerical | Effect of film thickness. | It is discovered that the scale and position of minimal film thickness are related to the location and magnitude of greatest heat transfer from the wall surface. |

| Mukherjee and Dhir (2005) [15] | Bubble dynamics and wall heat transfer | Lateral bubble merger throughout transition from partial to fully-developed nucleate boiling. | Water | Numerical | Effect of merger of multiple bubbles. | The overall wall heat transmission is considerably increased when numerous bubbles merge. |

| Tomar et al. (2005) [16] | Incompressible two phase flows with surface tension | Modelling incompressible two phase flows with surface tension. | Water | Numerical | The impact of heat flux on the instability. | When the superheat is reduced from 15 to 10 K for water that is almost at critical condition, oscillations with sub-harmonics affect the length of the ebullition cycle. |

| Wu and Dhir (2010) [17] | Bubble boiling in a sub-cooled pool | Vapor bubble in sub-cooled pool boiling. | Water | Numerical | Effect of gravity. | The heat transfer around the bubble reduces while gravity dropping for a given sub-cooling. |

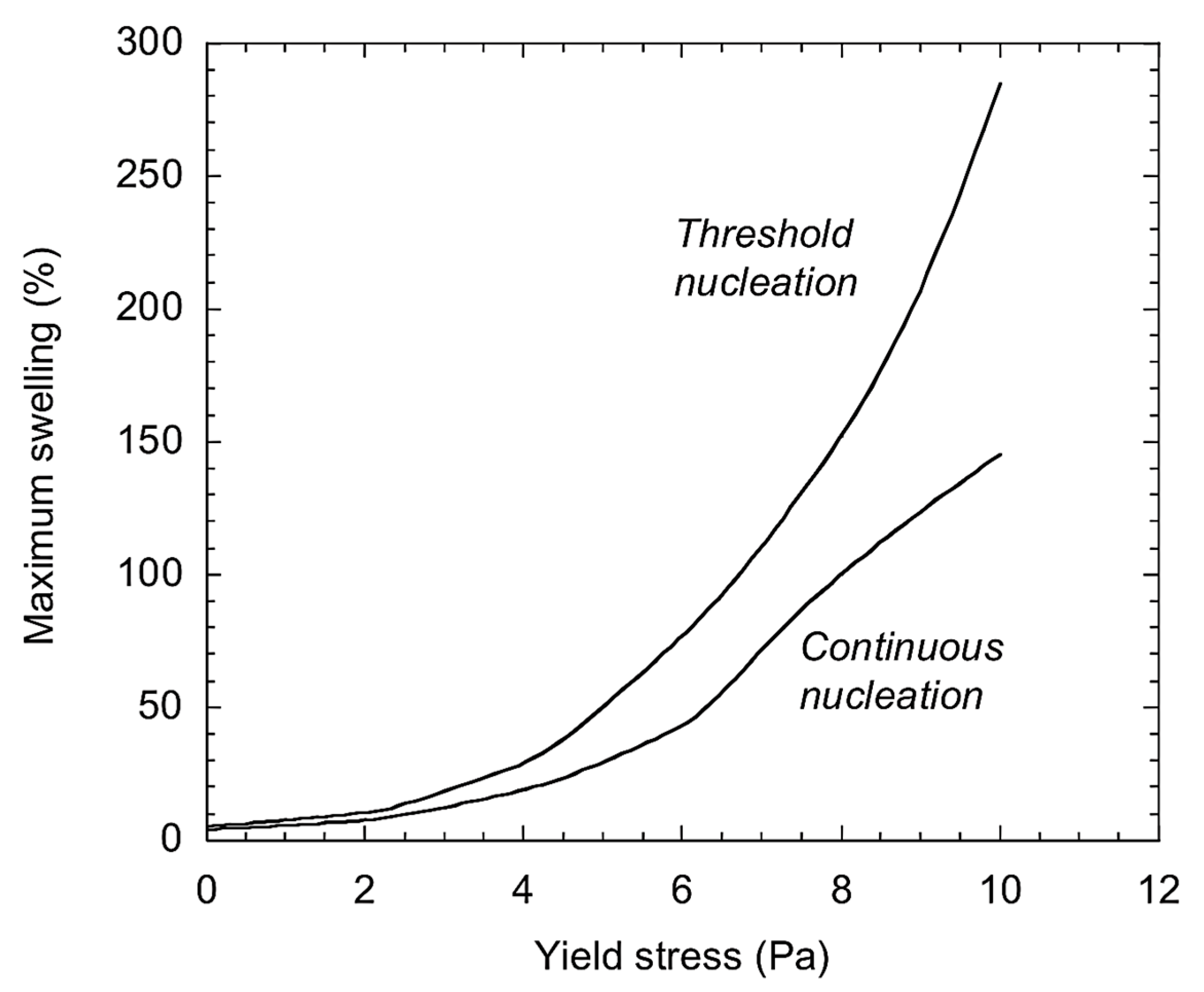

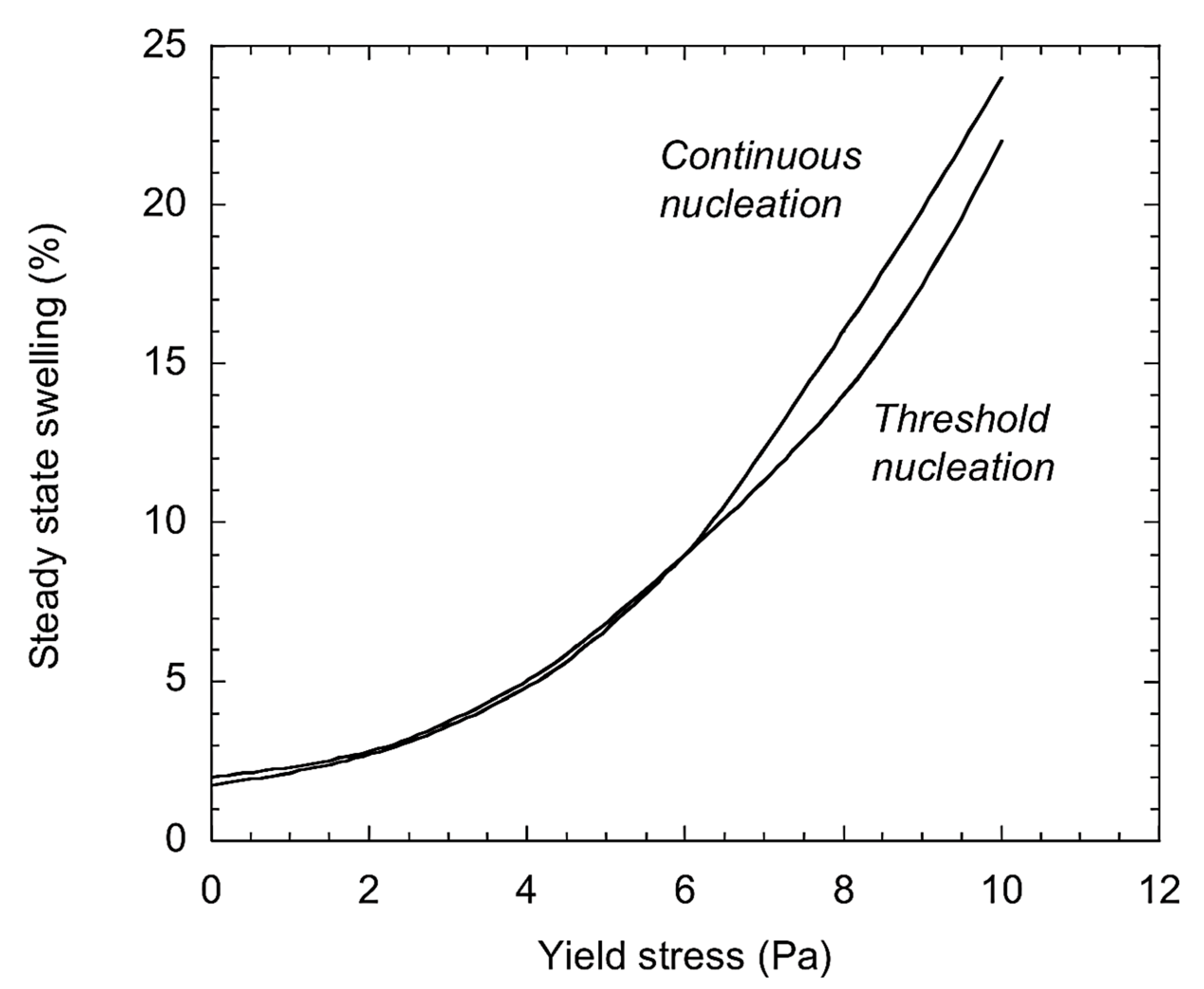

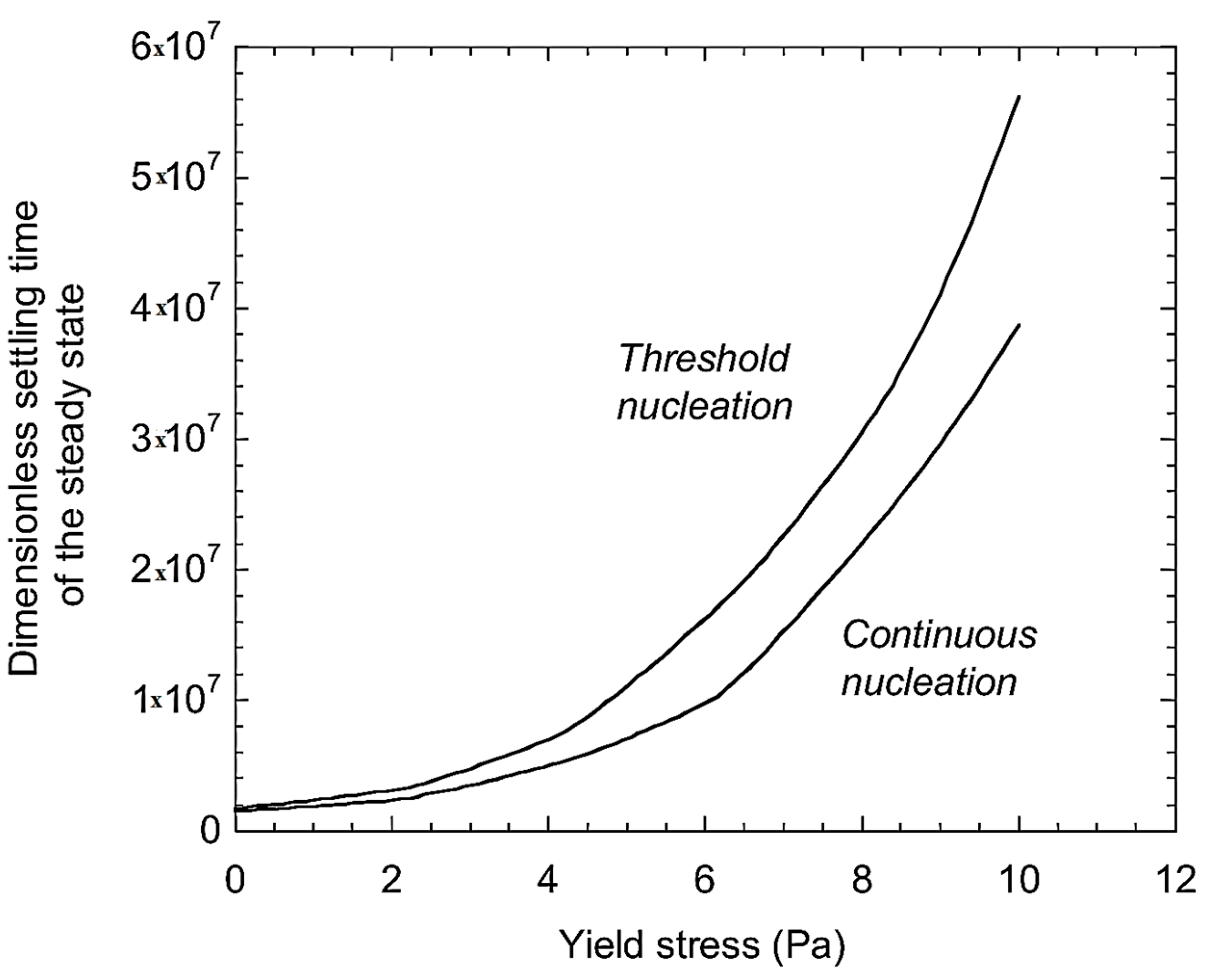

| Marchal et al. (2016) [18] | Macroscopic swelling of bitumen drums | In a fluid matrix under yield stress, consistent gas generation drives the population of bubbles. | Yield stress fluids | Numerical | Impact of yield stress value. | In a static population (no movement owing to buoyancy), bitumen’s yield stress disrupts the conventional state of nucleation, bubble development, and Ostwald ripening in a Newtonian fluid. |

| Goel et al. (2017) [19] | Water pool | Sub-cooled demineralized water at one atmosphere. | Water | Experimental | Effect of wall super-heat, heater size and the inclination angle. | It was discovered that the heater size, inclination angle, and wall superheat all increased the departure diameter while liquid sub-cooling and surface roughness dampened it. |

| Zhang et al. (2018) [20] | Thermal cavitating flows. | Cavitating flows in liquid nitrogen around a 2D hydrofoil. | Liquid nitrogen. | Numerical | Thermal effects. | The cavitation dynamics during the phase-change process are greatly affected by the temperature effect, which may deduce a delay or suppression in the onset and evolution of cavitation behavior. |

| Pahk et al. (2019) [21] | Boiling histotripsy exposure | Boiling histotripsy insolation causes a vapor bubble to boil. | Viscoelastic medium | Experimental and Numerical | Shockwave asymmetry and water vapor transportation. | Asymmetric shockwave and water vapor transfer may cause corrected bubble development, which may cause HIFU-induced tissue decellularization. |

| Lu et al. (2020) [22] | In-situ synchrotron radiography for heating an Al-5 wt.%Mn alloy | In situ synchrotron radiography, bubble development, IMC dissolution, and interactions occur throughout heating of an Al-5 wt.% Mn alloy. | Intermetallic compounds | Experimental | Effects of bubble existence. | A logistic model may explain IMC dissolution, which bubbles can speed up. |

| Zeng et al. (2020) [23] | Hydrates in different reaction systems | On a gas bubble (CH4-C3H8) floating in water with inhibitors, hydrates are thickening in growth. | Kinetic inhibitors added in the water | Experimental | Hydrate growth mode impacts the inhibitor concentration. | Since hydrate particles do not form films, they will not hinder flow substantially. |

| Allred et al. (2021) [24] | Boiling surface wetting | During bubble development, wetting and dewetting processes depend on the dynamic contact angles. | Wetting surface | Numerical | Contact angle. | The early stages of bubble development are controlled by the receding contact angle, which also establishes the greatest contact diameter and departure size as the contact line moves away from the bubble centre. |

| Zhao et al. (2021) [25] | Nucleate boiling | Boiling of the whole nucleate. | Convective and confinement space with solid wall boundary condition | Numerical | The pressure difference. | Coupled pressure from the bubble’s interior and surroundings causes the volume of bubbles in the free outlet domain to increase. |

| Winder et al. (2021) [26] | Sudden energy input | Mercury is filled with helium bubbles to lessen stresses and cavitation in the SNS target module. | Structure containing liquid and gas | Numerical | The energy deposit and helium gas injection into the mercury. | The protons’ deposited energy has the potential to cause harm to the target. It is possible to lessen the harm by injecting helium gas into the mercury. On the other hand, the addition of this gas makes the bodily reaction more complicated. |

| Li et al. (2021) [27] | Turbo-pump. | Cavitation flow of a liquid oxygen turbopump. | Liquid oxygen. | Numerical | The influence of thermodynamic effects. | At low cavitation numbers, the thermodynamic effects significantly decrease the vapor-phase volume fraction of the cavitation zone. Hitherto, at large cavitation numbers, they increase it. |

| Zhou et al. (2022) [28] | Nucleate pool boiling | Experiments on vertical surfaces with pools boiling in subcooled, almost saturated environments. | Vertical surfaces | Experimental and Numerical | Location of the bubble, size of the micro-pin-fins, pin effect, and force of response. | The formation of bubble and motion, as well as its departure time and diameter, are all influenced by the size of the micro-pin-fins. Through the pin effect and response force, micro-pin-fins encourage bubble departure. |

| Lai et al. (2022) [29] | Liquid hydrogen delivery | Liquid hydrogen single bubble growth model with internal temperature distribution. | Liquid hydrogen | Numerical | The impact of ambient pressure and super-heat on the development of a single bubble in liquid hydrogen. | Comparing the crucial times of the various physical indicators outlined above sheds light on the process by which a single bubble might go from experiencing dynamic expansion to experiencing thermal growth. |

| Cheng et al. (2022) [30] | Compact type reactors | Bubble development in small, vertical, rectangular channels. | Vertical rectangular narrow flow channels | Experimental and Numerical | Investigate the behaviour of bubble growth in vertical rectangular narrow channels. | Approximately thirty percent of the entire quantity of evaporation may be attributed to the micro-layer evaporation that occurs at the bubble’s base. |

| Hu et al. (2020) [31] | Polycrystalline UMo fuels | Gas bubble evolution incorporating cluster dynamics based on microstructure. | Irradiated UMo fuels | Numerical | Rates of defect clustering, interstitial emission, defect production, and sinking. | Gas bubble swelling kinetics rises with defect formation, interstitial emission, and clustering rates, but decreases with grain boundary defect sink rates. |

| Zhou et al. (2020) [32] | Spallation of aluminium | During spallation, a helium bubble forms in a single Al crystal. | Aluminium | Numerical | Size, density, and shock resistance of the bubbles. | The bubble prevents the formation and growth of near voids, and its expansion absorbs grown voids. Suppression increases with bubble size or density and decreases with shock strength. |

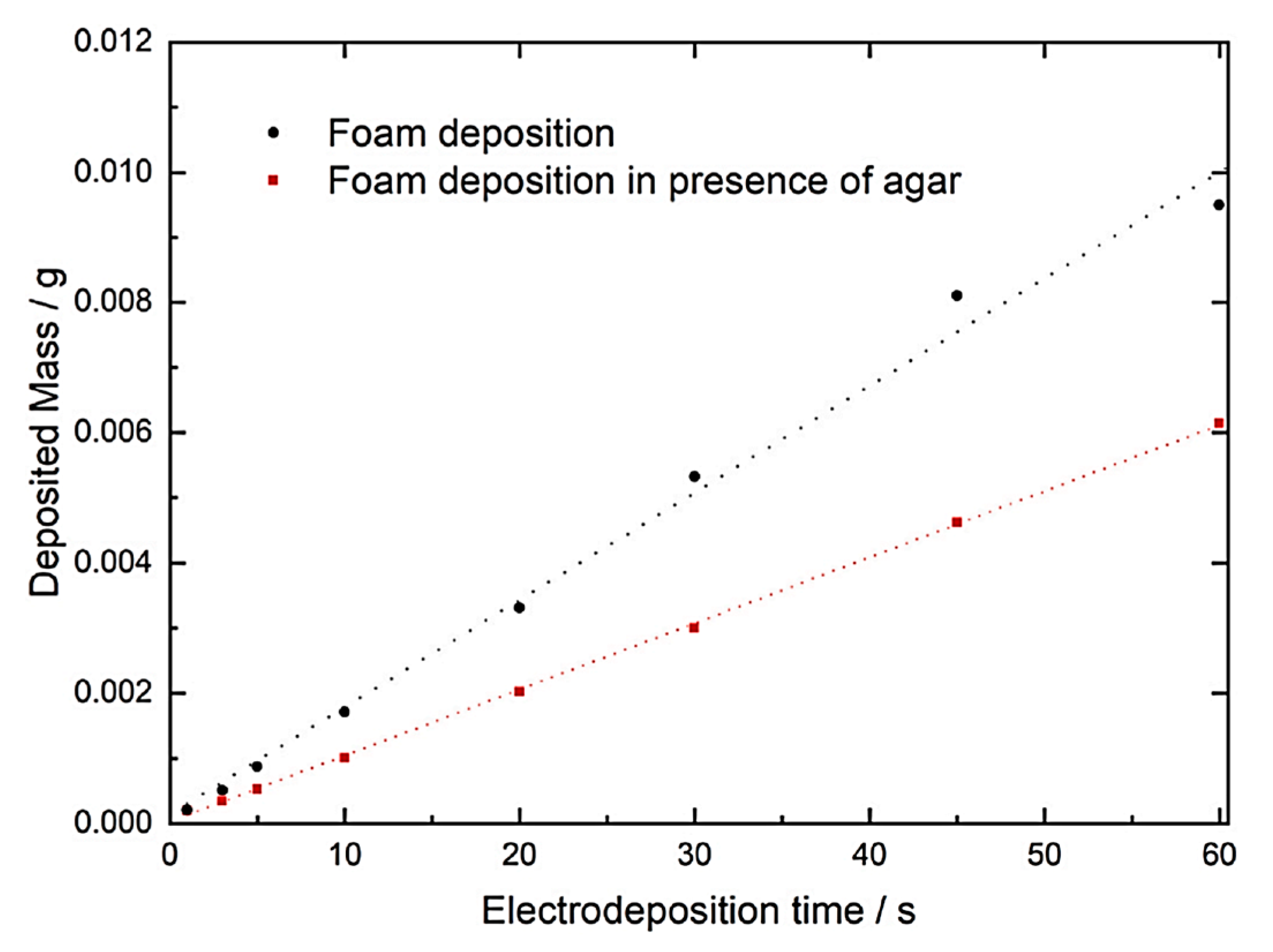

| Arévalo-Cid et al. (2020) [33] | Hydrogen bubble template electrodeposition | Cobalt foams with nanostructures created via hydrogen bubble template electrodeposition. | Nanostructured cobalt foams | Experimental | The addition of agar. | Agar has effectively affected the micro-structure of the final foams, providing a denser porous structure with smaller pore area and slower growth rate, which improves mechanical qualities. |

| Prudil et al. (2022) [34] | Populations of intergranular fission gas bubbles | Bubble development, coarsening, and coalescence lead to connected, high-aspect-ratio bubbles on the grain face. | Oxide fuels | Numerical | Populations of intergranular fission gas bubbles that are significant. | Bubble density is a metric of bubble structure shaped by coalescence, and the two point auto-correlation function records the expansion of a connected network, that might decrease release thresholds. |

| Authors (Year) [Reference] | Sector/Area of Process Engineering | Configuration | Medium | Type of Study | Parameters Under Investigation | Highlighted Findings |

|---|---|---|---|---|---|---|

| Navarrete et al. (2015) [36] | Biomedicine | Collapse of a conical bubble. | The liquid meniscus | Experimental | Effect of collapse on various light emission. | When a conical bubble bursts, a number of light-emitting mechanisms—thermal, chemical, and electrical in nature—are engaged. |

| Gong and Klaseboer (2016) [37] | Biomedicine or marine industry | Interaction between a deforming viscoelastic solid and a bubble that is in the process of bursting. | Viscoelastic solid | Numerical | The standoff distance, bubble size, and form, as well as the viscosity of the plate. | The outcomes showed that standoff distance and bubble size have a substantial impact on viscoelastic solid deformation and bubble collapse. |

| Tang et al. (2016) [38] | Bubble condensation with and without ultrasonic | The process of vapor bubbles condensing and bursting in an otherwise still and cold pool with the application of ultrasonic field. | Vapor bubble surface | Experimental | Impact of capillary wave. | The existence of the capillary wave enlarged the area of the bubble’s contact with the cold bulk and disturbed the thermal boundary layer near the vapor liquid interface, which aided in the condensation process. |

| Wang et al. (2016) [39] | Underwater vertical launching | The axisymmetric projectile experiences a phenomenon known as internal collapse that moves forward from the tail to the head. | Water | Experimental and Numerical | Effect of increasing pressure. | A crucial element that causes a non-linear variation in the cavity length is the pressure rise. |

| Qin and Alehossein (2016) [40] | Water jet drilling and rock cutting | The fluctuation in temperature and the transfer of heat that occurs when a bubble bursts. | Water | Experimental and Numerical | Bubble size and temperature. | The bubble crumbled more quickly as the original maximum bubble size grew. The inside bubble’s maximum temperature rose sharply, and the total transmitted heat also rose greatly. |

| Li et al. (2016) [41] | Ship propellers and hydroturbine | The fluctuating pressure that is caused as a bubble deflates. | Water | Experimental and Numerical | The impacts of the stand-off parameter, which is denoted by γ, the strength parameter, which is denoted by, and the ratio of specific heats, which is denoted by κ. | The maximum pm progressively reduces as γ rises from 1 to 1.4. A crucial standoff parameter, γc, exists. The pressure peak of pg rises as κ rises, whereas the pressure peak of pm falls. |

| Rowlatt and Lind (2017) [42] | Bioengineering | Near a fluid–fluid contact, bubbles collapse. | Stiff wall | Numerical | Interface heights. | Due to the lessened contact between the bubble and stiff wall, the bubble collapsed spherically at increasing interface heights from the rigid wall. |

| Ye and Zhu (2017) [43] | Propeller blades | Acoustic bubble collapse micro-jet near the wall. | Al 1060 | Numerical | Micro-jet velocity. | The wall pressure rises with increasing micro-jet velocity. |

| Pavlov (2017) [44] | Implosion phenomenon | The bursting of a vapor bubble caused by the immediate application of an external pressure. | Water | Numerical | Effect of vapor pressure. | Vapor offers shock absorption to the compression pressure and lengthens the period until the empty bubble bursts. In this situation, the temperature increases rapidly and the vapor pressure peaks. |

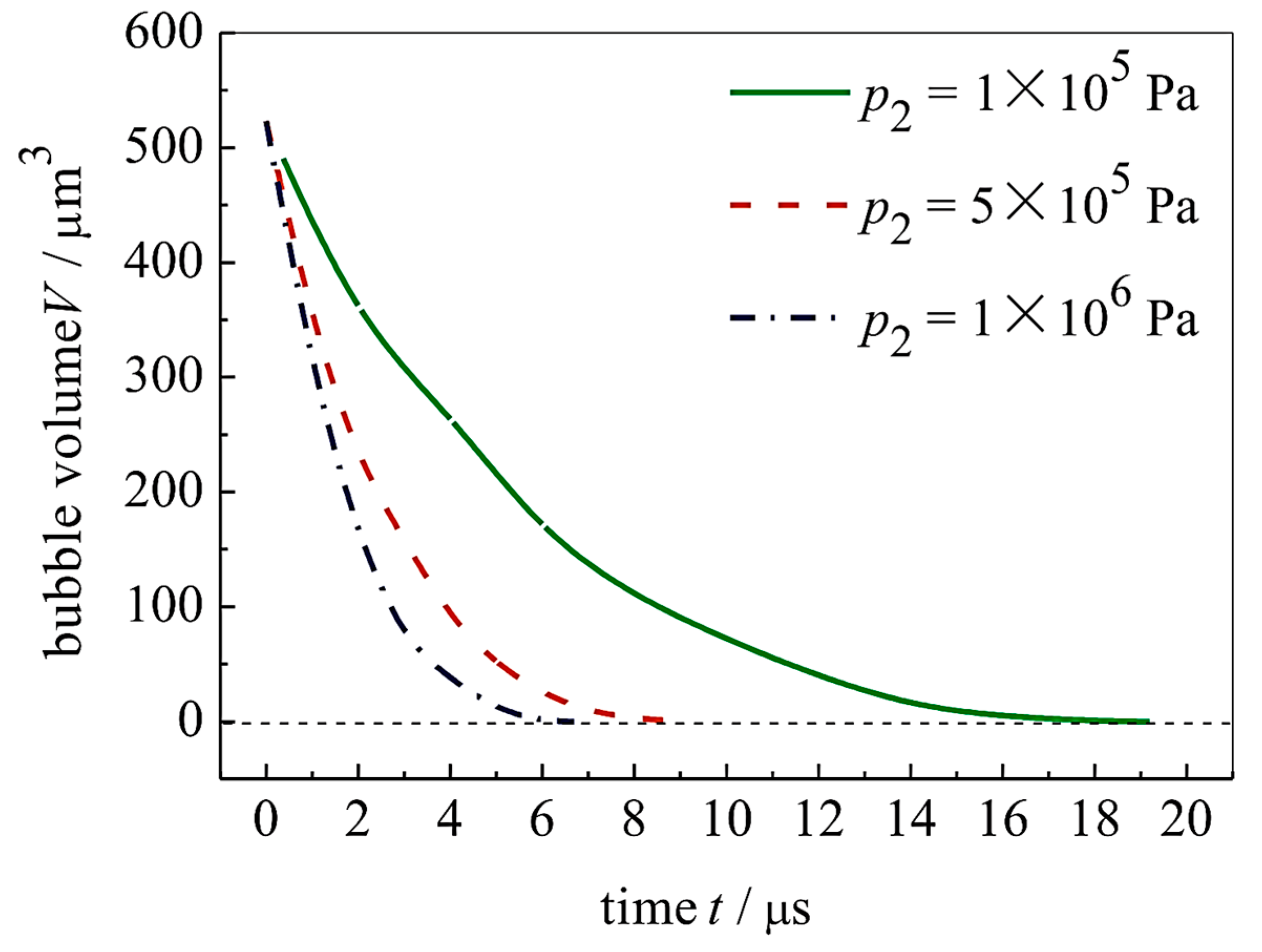

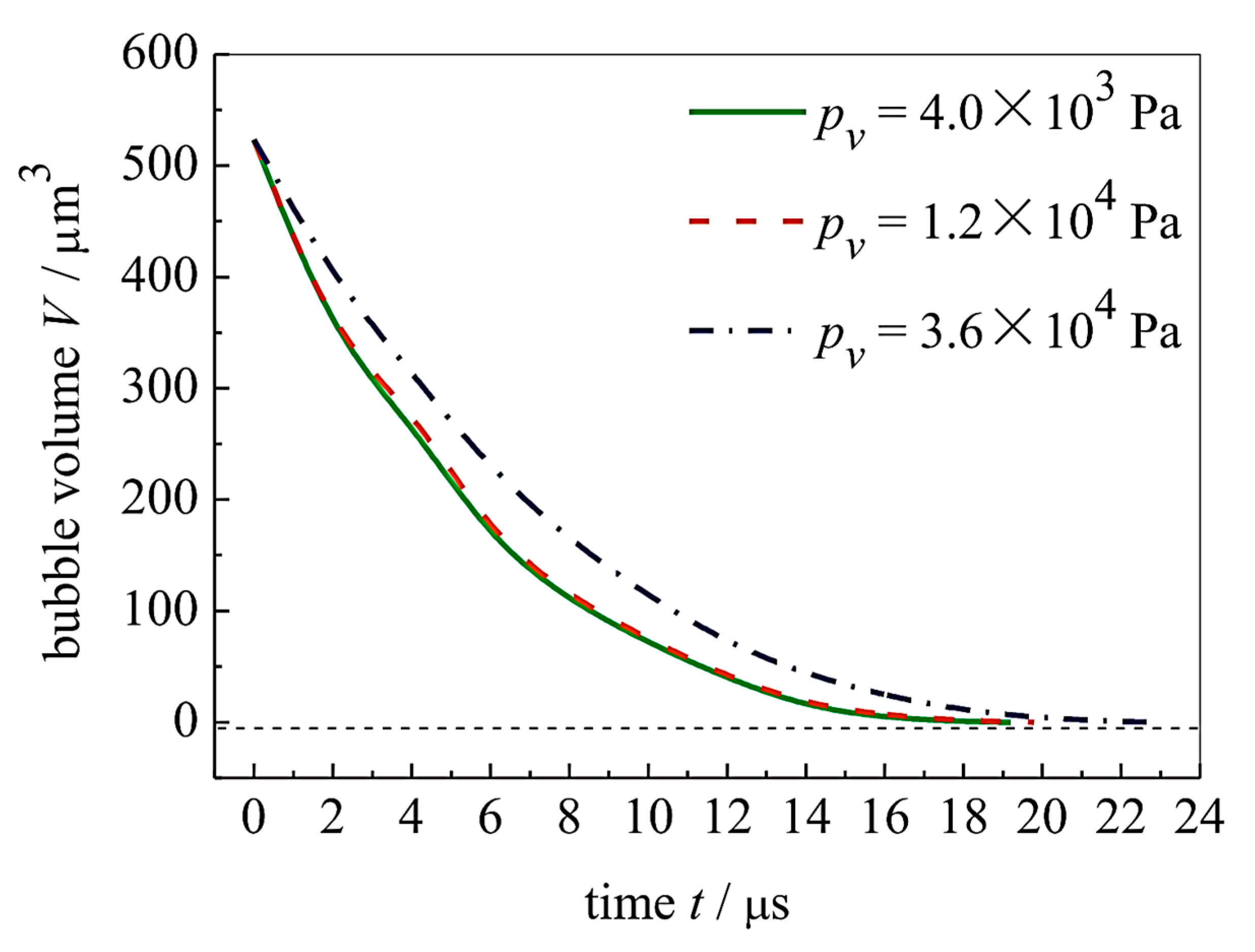

| Ming et al. (2017) [45] | Fuel jet when supercavitation phenomenon | The process of the collapse of the cavitation bubble that was occurring within the diesel droplet. | Water droplet | Numerical | Environmental pressure and saturation vapor pressure. | As ambient pressure rises, the rate of collapse accelerates, while saturation vapor pressure falls, the rate of collapse accelerates. |

| Rosselló et al. (2018) [46] | Water hammering | A device that uses water to create well-ordered collapses of a single cavitation bubble is called a water hammer. | Water | Experimental | The expansion ratio. | The expansion ratio and the equilibrium bubble radius, is the most important metric in relation to collapse strength. |

| Phan et al. (2018) [47] | Free surface flow | Compressible interface flows with and without mass transfers. | Water | Numerical | Superheated wall temperature. | The super-heated wall temperature increases heat flow on the sphere, comparable to previously reported findings. |

| Kerabchi et al. (2018) [51] | Lab-scale sonoreactors | Concentrated acoustic cavitation. | Liquids subjected to ultrasound | Numerical | The influence of depth, ranging from 0 to 10 m, on acoustic cavitation, with a particular emphasis on this factor. | The drop in Tmax and pmax with depth was more severe at 1000 kHz frequency and 10 °C, with 72% losses in Tmax and 94% in pmax at z = 10 m. |

| Joshi et al. (2019) [52] | Cavitation erosion | Cavitation bubble collapsing in close proximity to an elastic-plastic substance. | Elasto-visco-plastic material | Numerical | Shockwave and Strain rate. | Shockwave impacts erode material more than micro-jet impacts. Strain rate overestimates plastic deformation by 60%. |

| Brujan et al. (2019) [53] | Medicine | The dynamics of a cavitation bubble created by a laser in the centre of two hard, horizontal parallel walls. | Microfluidics | Experimental | Size of the bubble, size of the bubble in relation to other bubbles, and the starting position of the bubble. | Planar jet height grows with bubble size relative to stiff wall distance. The jet velocity declines as the bubble size and distance from the vertical wall increase. |

| Hopfes et al. (2019) [54] | Material science to medical applications | Gelatine was filled with air bubbles that were mm-sized and subjected to an immediate pressure rise. | Gelatinous fluids | Experimental | During the collapse, there was motion of single bubbles of gelatine, each of which had a distinct concentration. | Single gelatine bubbles collapse similarly to water bubbles, and gelatine concentration does not influence their behaviour. |

| Bardia and Trujillo (2019) [55] | Heat exchanger and petroleum industries | Intermediate bubble collapse. | Homogeneous surrounding liquid phase | Numerical and Theoretical | Effects of the slow but steady increase in pressure. | Instead of a step shift, a progressive rate of liquid phase pressurization affects the collapse behaviour. |

| Gan et al. (2019) [56] | Underwater explosion | A hull girder that replicates the construction of a genuine warship and is subjected to the stresses of an underwater explosion. | Water | Experimental and Numerical | Examined how the charge weight and the distance from the detonation effect the interactions between loads from an underwater explosion and a hull girder. | Deformation characteristics are the same over a particular charge weight range. |

| Chudnovskii et al. (2020) [57] | Liquid aerosol above the sea surface | Liquid that has been significantly subcooled begins to boil as a result of local heating. | Subcooled liquid | Experimental | Radiation power and duration. | The relationship between maximum bubble size and absorbed radiation power (and time, if pulsed) is nonlinear. |

| Yuan et al. (2020) [58] | Floating ice cake | A bubble bursts close to an ice cake that’s drifting. | Cake | Experimental | Effect of bubble collapse on ice. | Referring to damage degree and crack growth, three damage patterns may be created on ice: crevasse, radial and circumferential, and radial. |

| Han et al. (2020) [59] | Chemical industry and medicine | Two different-sized bubbles interact and the wall affects bubble collapse. | Water | Numerical | The presence of the wall as well as the quantity of the bubbles. | Walls delay bubble collapse. Walls might enhance the collapse and rebound of the bubble. The number of bubbles does not directly affect collapse times. |

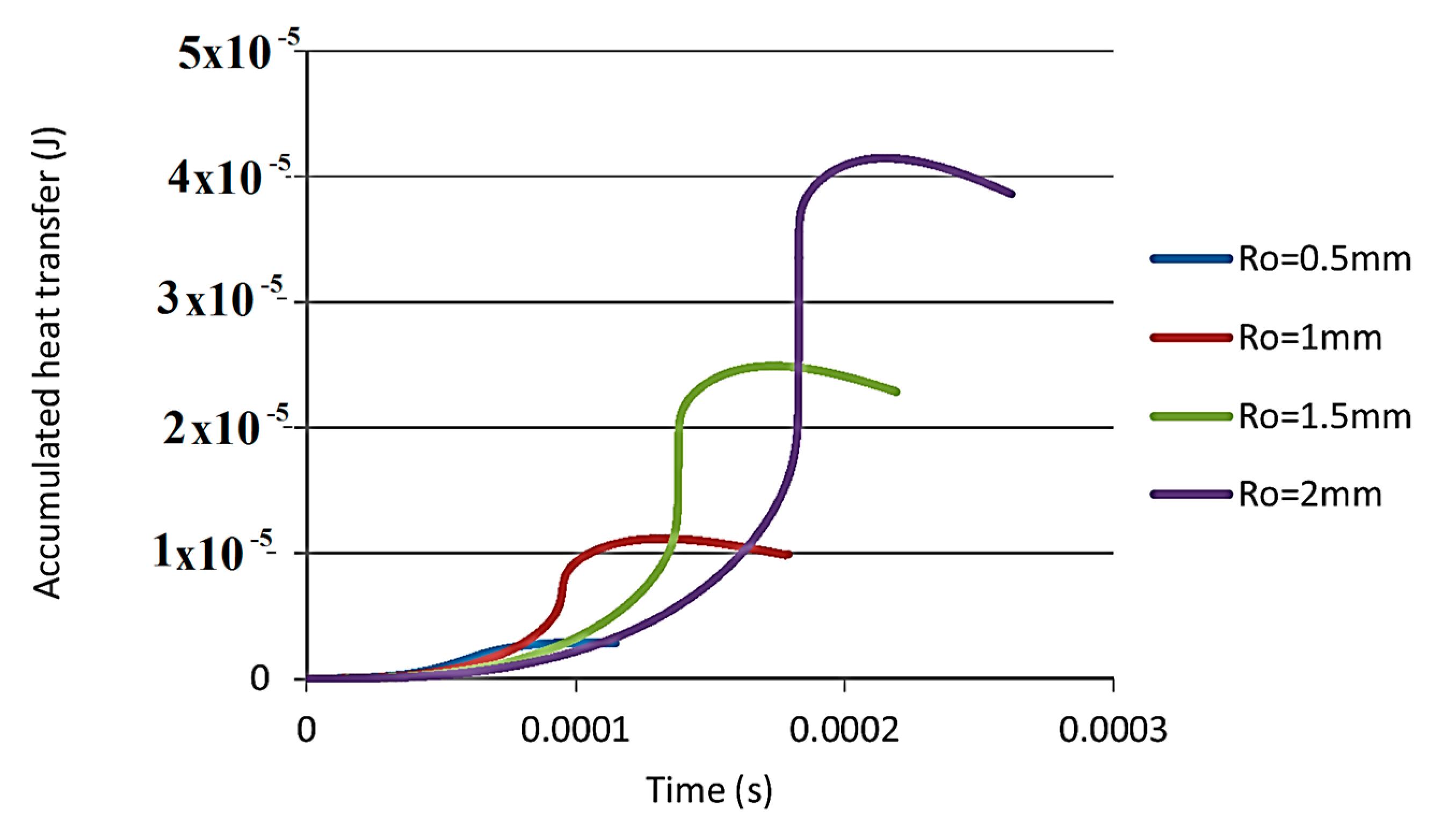

| Fursenko et al. (2020) [60] | Biological tissues and surgery | Near the microfibre submerged in a subcooled liquid, a vapor bubble collapses. | Micro-fibre immersed in a liquid | Experimental | The jet velocity and intensity. | Jet velocity is maximum during formation and declines with time. Jet speed depends on fibre radius. Maximum jet intensity be contingent on initial vapor bubble radius and fibre thickness. Water jet speed directly affects gas bubble volume decrease. |

| Tan and Yeo (2020) [61] | Ultrasonic device | Microabrasive particles with an average diameter of 5 μm to 50 μm were subjected to 20 kHz of strong ultrasonic irradiation in a deionized water medium. | Deionized water medium | Experimental | The influence on particle velocity of both the particle size and the ultrasonic amplitude. | Particle velocity is 8–40 m/s, depending on particle size and ultrasonic amplitude. |

| Orthaber et al. (2020) [62] | Biology, chemistry, and medicine | Dynamics of a single cavitation bubble at the oil–water contact. | Oil-water | Experimental and Numerical | Effect of liquid type (light or dense). | In the bubble develops in the lighter liquid, it jets toward the interface; if the denser liquid, it jets away. |

| Zhang et al. (2020) [63] | Biomedical treatment | Using a high-speed photography equipment, the dynamics of a laser-induced cavitation bubble collapsing close to a stiff wall. | Near the edge of a rigid wall | Experimental | Bubble location. | When a bubble is near to the edge, the interface’s mobility is constrained by a distinct neck in the centre. The edge might delay bubble collapse by 22% of the Rayleigh time. |

| Ezzatneshan and Vaseghnia (2020) [64] | Different wettability conditions | Collapse dynamics of cavitation bubbles of various liquids. | Water, liquid nitrogen, and liquid hydrogen. | Numerical | Wettability effect of the surface. | The water’s cavitation bubble collapses faster due to a powerful liquid jet, whereas the LN2 bubble takes a longer time to collapse due to its bigger bubble radius at the rebound. |

| Huang et al. (2021) [65] | Noise and erosion | The collapse and oscillation of a single bubble produce acoustic waves. | Water | Experimental and Numerical | Rarefaction wave pressure of acoustic waves. | After a shockwave, liquid velocity and pressure rise. Rarefaction waves disperse and lower liquid pressure. Acoustic waves’ pressure and influence on liquid velocity decrease with distance. |

| Xu et al. (2021) [66] | Ships | Air entrainment cavitation bubble collapse to reduce cavitation. | Water | Experimental | The roundness, size, and distance of an air bubble. | The collapse pressure determines the collapse direction. |

| Peng et al. (2021) [67] | Medicine | Single and dual bubbles of cavitation seen in close proximity to a stiff border that has a significant density-to-viscosity ratio. | Near a rigid boundary | Numerical | The impacts of the gap in space between the bubble of cavitation and the solid border. | As the bubble’s distance from the hard boundary grows, so will its maximum collapse pressure, velocity, and temperature. Cavitation bubble lifespan decreases. |

| Trummler et al. (2021) [68] | Ships | The way cavitation bubbles collapse in close proximity to walls when there is a lot of atmospheric pressure. | Vertical wall | Numerical | Effect of stand-off distance. | Stand-off distance affects collapse dynamics, micro-jet generation, rebound, and wall pressure. |

| Long et al. (2021) [69] | Biomedical | Throughout the pulsed laser ablation of sub-merged targets in three liquids, cavitation bubbles were created. | Three organic liquids | Numerical | Effect of liquid media on cavitation. | In ethanol and n-butanol, cavitation-induced reactions produce gaseous gases that prevent bubble collapse. In water, cavitation bubbles may be crushed into a microscopic area, increasing localized temperature and pressure and triggering a second etching. |

| Wang et al. (2021) [70] | Ships | Bubble collapse strength. | Water | Numerical | Viscosity, surface tension, density and sound velocity. | Viscosity and surface tension affect collapse strength more than density and sound speed. |

| Gai et al. (2022) [71] | Ice formation | Ice formation brought on by the cavitation bubble collapsing. | Water | Numerical | The stand-off distance, differential pressure, and initial bubble size on the maximum collapse pressure. | Scenario II’s greater pmax initiates ice nucleation more easily than scenario I. |

| Xu et al. (2022) [73] | Biomedical | Various separations (d) between the cavitation bubble and the benzamide wall. | Benzamide wall | Numerical | Influence of time on maximum pressure. | When one stays in the field of maximum pressure for a longer period of time, the pressure at its peak will be higher. |

| Nguyen et al. (2022) [74] | Ships | Bubble collapse near walls and a free surface: dynamic behaviour of water jets, pressure loads, and bubble collapses. | Water | Experimental and Numerical | Water jets and pressure loads. | The pressure stresses that were produced as a result of the jets colliding with the walls. |

| Yang et al. (2022) [75] | Heating or cooling system | Near the heated/cooled wall, a cavitation bubble develops. | Water | Numerical | The mechanism of influence that the micro-jet and the cavitation bubble itself have on one another. | The values of λ, Δp, R0 and Tw that are ideal may be employed to improve heat transmission and bring about heating or cooling treatments on a variety of various surfaces. |

| Ezzatneshan et al. (2024) [78] | Cryogenic fluids. | Collapse of cavitation bubbles in cryogenic liquids. | Cryogenic liquids | Numerical | The influence of the distance between a cavitation bubble with an adjacent solid wall. | The collapsing bubble cluster’s micro-jet velocity and collapse intensity are both enhanced by raisng the solid surface’s contact angle. |

| Authors (Year) [Reference] | Sector/Area of Process Engineering | Configuration | Medium | Type of Study | Parameters Under Investigation | Highlighted Results/Findings |

|---|---|---|---|---|---|---|

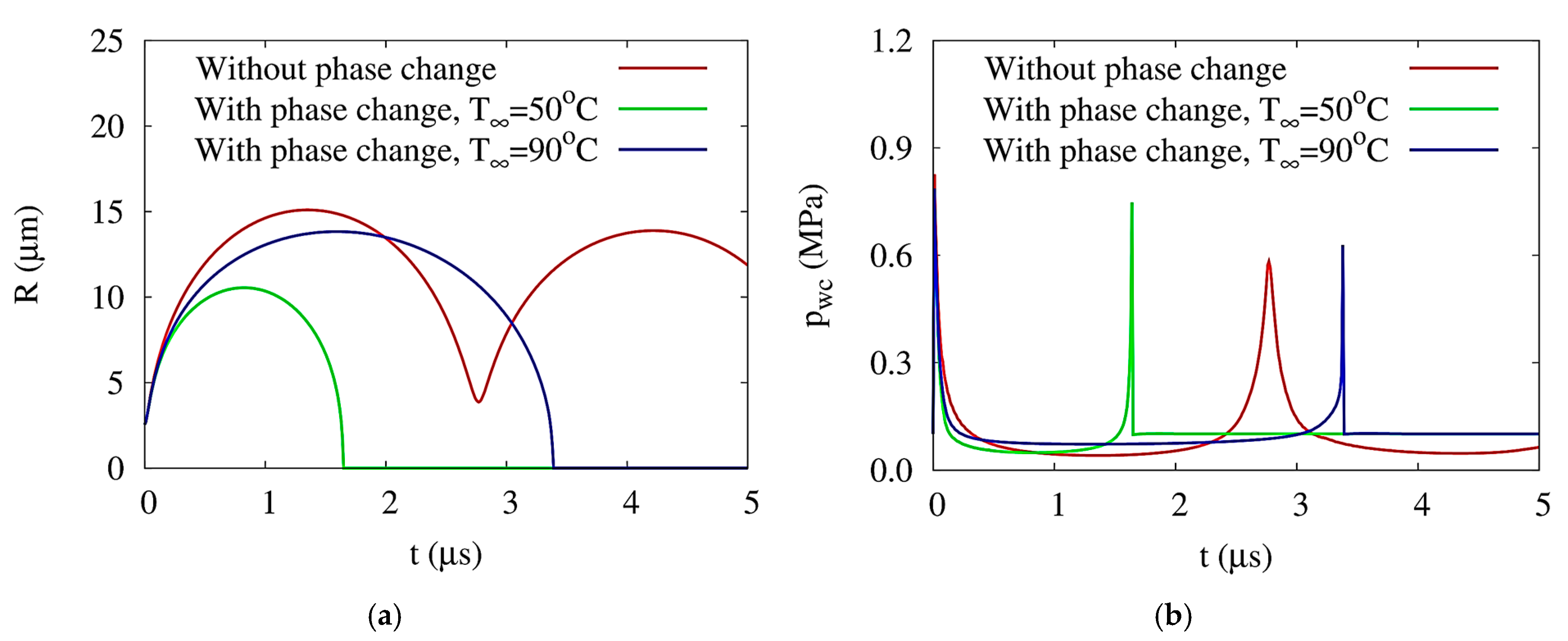

| Lee and Son (2017) [79] | Ultrasonic cleaning and medical treatment | The expansion and subsequent deflation of a compressible vapor bubble. | Liquid-vapor phase change | Numerical | The influence of the ambient temperature, the phase shift, and the wall on the development and collapse of the compressible bubble. | It was demonstrated that the ambient temperature had a substantial influence on the bubble formation and collapse patterns. Additionally, it was noted that throughout the bubble growth phase, the bubble pressure did not descent lower the comparable saturation pressure. |

| Wang et al. (2018) [80] | Subcooled boiling | The expansion and contraction of bubbles when subjected to microgravity. | Water | Numerical | Behaviour of bubble radii. | The bubble radii exhibited some “variations” throughout the early stages of bubble collapse, which may be ascribed to the “re-bound effect” of pressure balance in the bubble due to the starting condition of a sharp decrease in temperature. |

| Sourtiji and Peles (2019) [81] | Microbiology and micro-sensors | Micro synthetic jets that function by using bubble development and collapse throughout a spectrum of operational frequencies (0.1–2.5 Hz) and heating powers. | Microfluidics | Experimental | Operating frequencies. | The average value is greater than unity over a wide range of operational frequencies, proposing that this jet may advance the functionality of a number of micro-systems, including micro-mixing in microfluidic devices. |

| Sun et al. (2019) [82] | System sub-cooling | Variation in the morphology of the hydrate shell that forms on methane bubbles floating in supersaturated water. | Water | Experimental | Effect of continuous collapse and hydrate shell. | The opposition between the hydrate shell’s critical collapse pressure and the bubbles’ differential pressure has a significant impact on how frequently continuous collapse occurs. |

| Zimnyakov et al. (2019) [83] | Fresh constrained foams | The surface film cells that are located at the interface between the new liquid foam and the confining wall. | Liquid foam | Numerical and Analytical | Effect of splitting process. | The averaged specific rate of local re-arrangements in the surface film cells and clusters of bulk bubbles decays exponentially during the splitting process until it reaches a constant value. This happens as the rate of re-arrangements in the clusters of surface film cells and bulk bubbles slows down. |

| Nguyen et al. (2020) [84] | Nanoparticles synthesis | A nanosecond pulsed laser is used to ablate a solid at varying depths of a finite liquid, which causes a bubble of cavitation to form. | Finite liquid | Experimental | liquid depth. | The secondary shockwaves grow more concentric as the liquid depth rises, and a larger impulse is produced into the solid target as a result of this change. |

| Puncochar et al. (2022) [85] | Water desalination | Process of bubble production and subsequent deformation. | Water | Numerical | Buoyancy, inertia, elasticity. | The principle of energy conservation is used throughout the detachment process in order to define the association that exists between the final form of the bubble and its Weber number. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rashid, F.L.; Al-Obaidi, M.A.; Hussein, A.K.; Ahmad, S.; Albdeiri, M.S.; Mujtaba, I.M. Bubble Dynamics in Sustainable Technologies: A Review of Growth, Collapse, and Heat Transfer. Processes 2025, 13, 38. https://doi.org/10.3390/pr13010038

Rashid FL, Al-Obaidi MA, Hussein AK, Ahmad S, Albdeiri MS, Mujtaba IM. Bubble Dynamics in Sustainable Technologies: A Review of Growth, Collapse, and Heat Transfer. Processes. 2025; 13(1):38. https://doi.org/10.3390/pr13010038

Chicago/Turabian StyleRashid, Farhan Lafta, Mudhar A. Al-Obaidi, Ahmed Kadhim Hussein, Shabbir Ahmad, Mahmood Shaker Albdeiri, and Iqbal M. Mujtaba. 2025. "Bubble Dynamics in Sustainable Technologies: A Review of Growth, Collapse, and Heat Transfer" Processes 13, no. 1: 38. https://doi.org/10.3390/pr13010038

APA StyleRashid, F. L., Al-Obaidi, M. A., Hussein, A. K., Ahmad, S., Albdeiri, M. S., & Mujtaba, I. M. (2025). Bubble Dynamics in Sustainable Technologies: A Review of Growth, Collapse, and Heat Transfer. Processes, 13(1), 38. https://doi.org/10.3390/pr13010038