Numerical Simulation on the Transport and Displacement Patterns of Proppant in Hydraulic Fractures Considering the Effect of Rough Fracture Surfaces

Abstract

1. Introduction

2. Theoretical Basis

2.1. Characterization of Fracture Roughness

2.2. Mathematical Model

3. Material and Methods

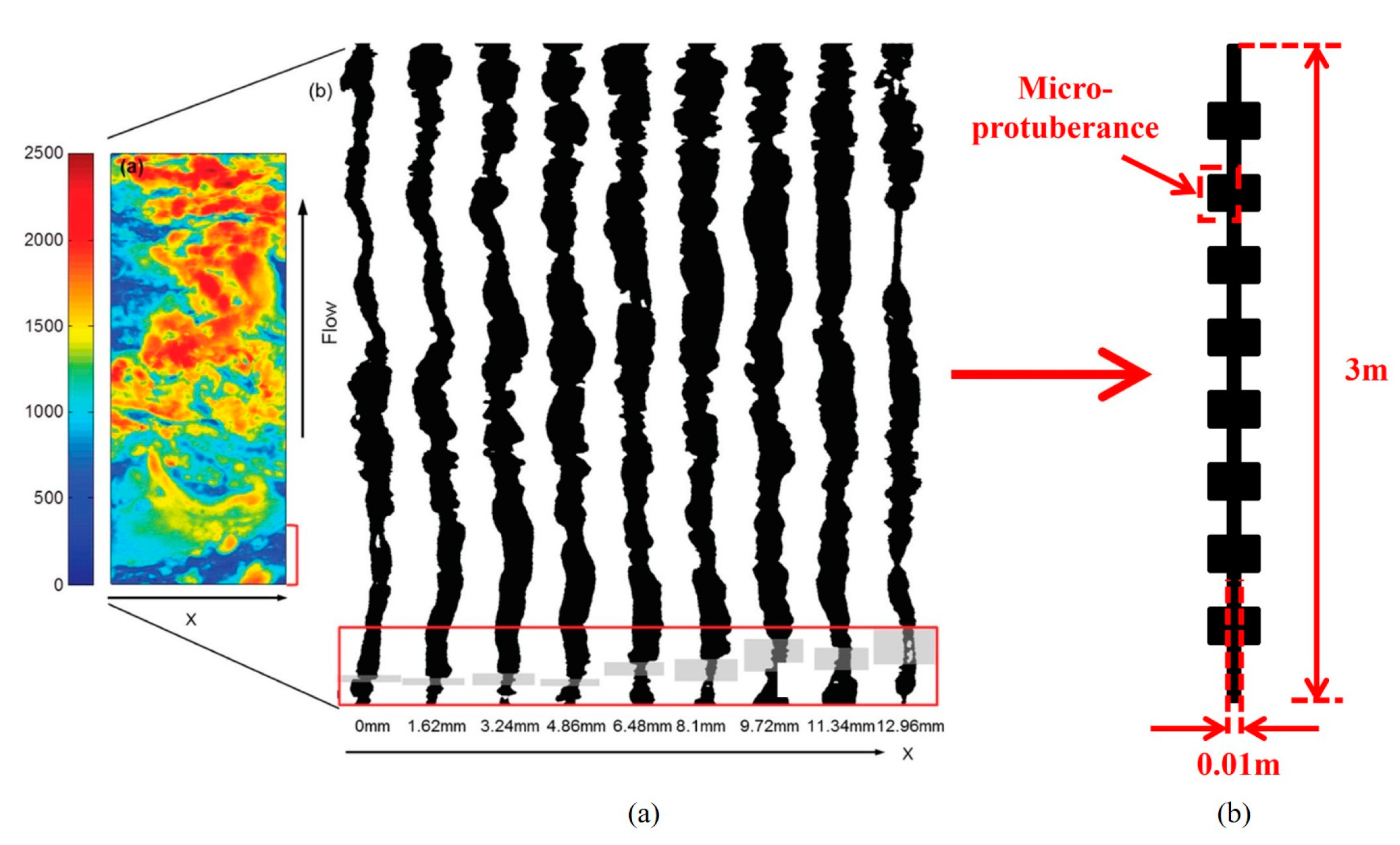

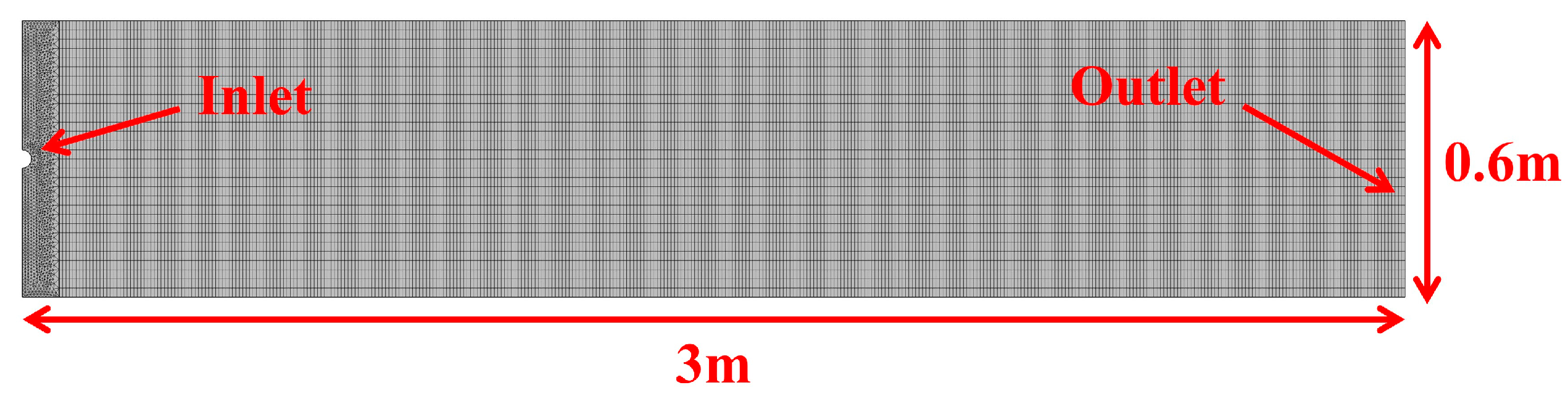

3.1. Geometric Model

3.2. Assumptions

- (1)

- The fracturing fluid is regarded as a Newtonian fluid.

- (2)

- The fluid loss in the fracture is neglected, assuming that the flow of the fracturing fluid within the fracture will not be diminished due to adsorption by the fracture walls.

- (3)

- Due to the turbulent flow regime of the fracturing fluid carrying proppant within the fracture, the standard k-ε model is employed.

- (4)

- The proppant particles are considered to be uniform and of the same size, and no phase transformation occurs within the proppant particles.

- (5)

- During the flow of the fracturing fluid, there is a mutual coupling between the fluid and the proppant phase. The fracturing fluid exerts buoyancy and drag forces on the proppant, and the acceleration of the solid particles exerts an apparent mass force on the fluid. Other interphase forces are considered negligible.

3.3. Model Validation

4. Results and Discussion

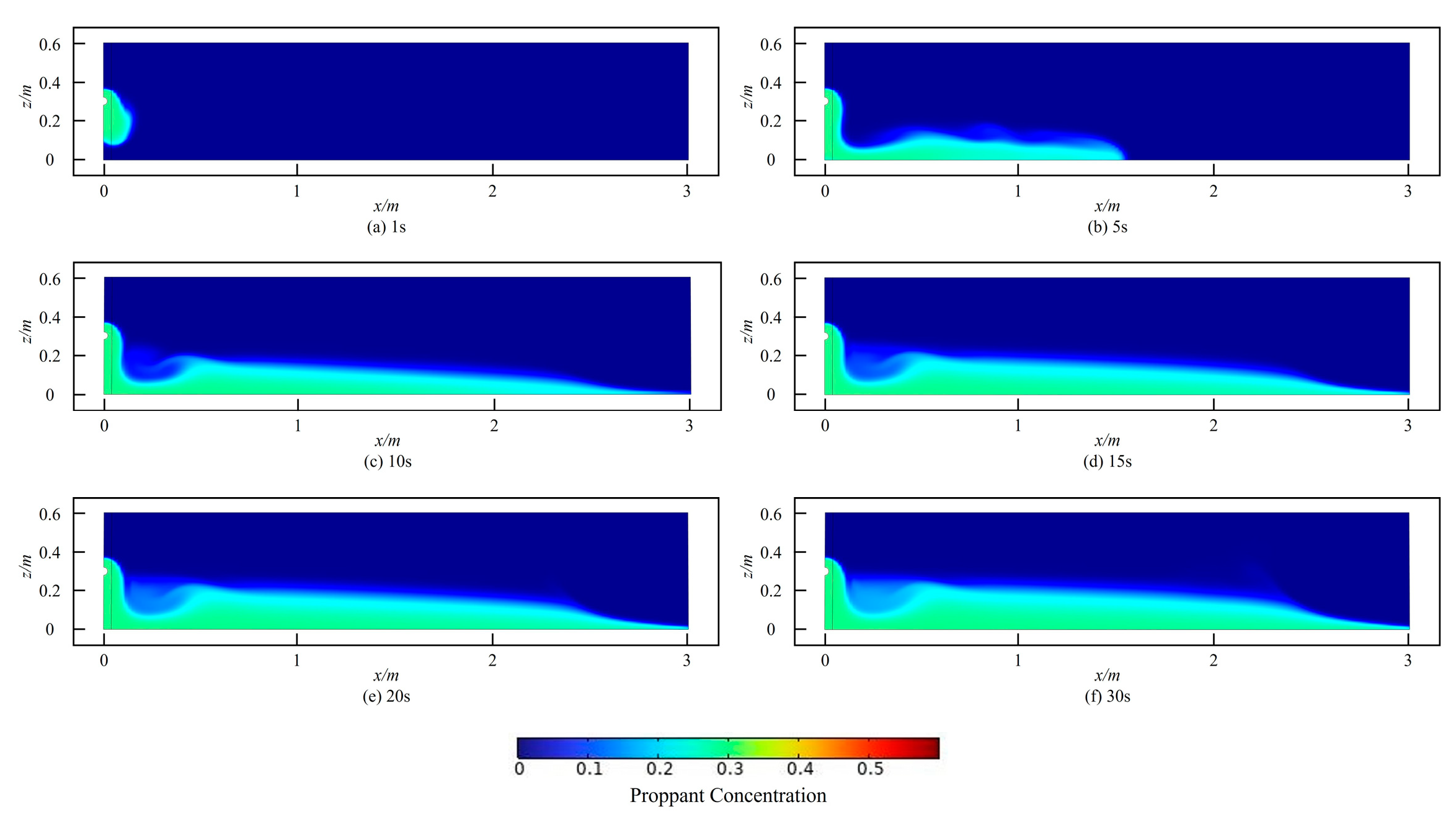

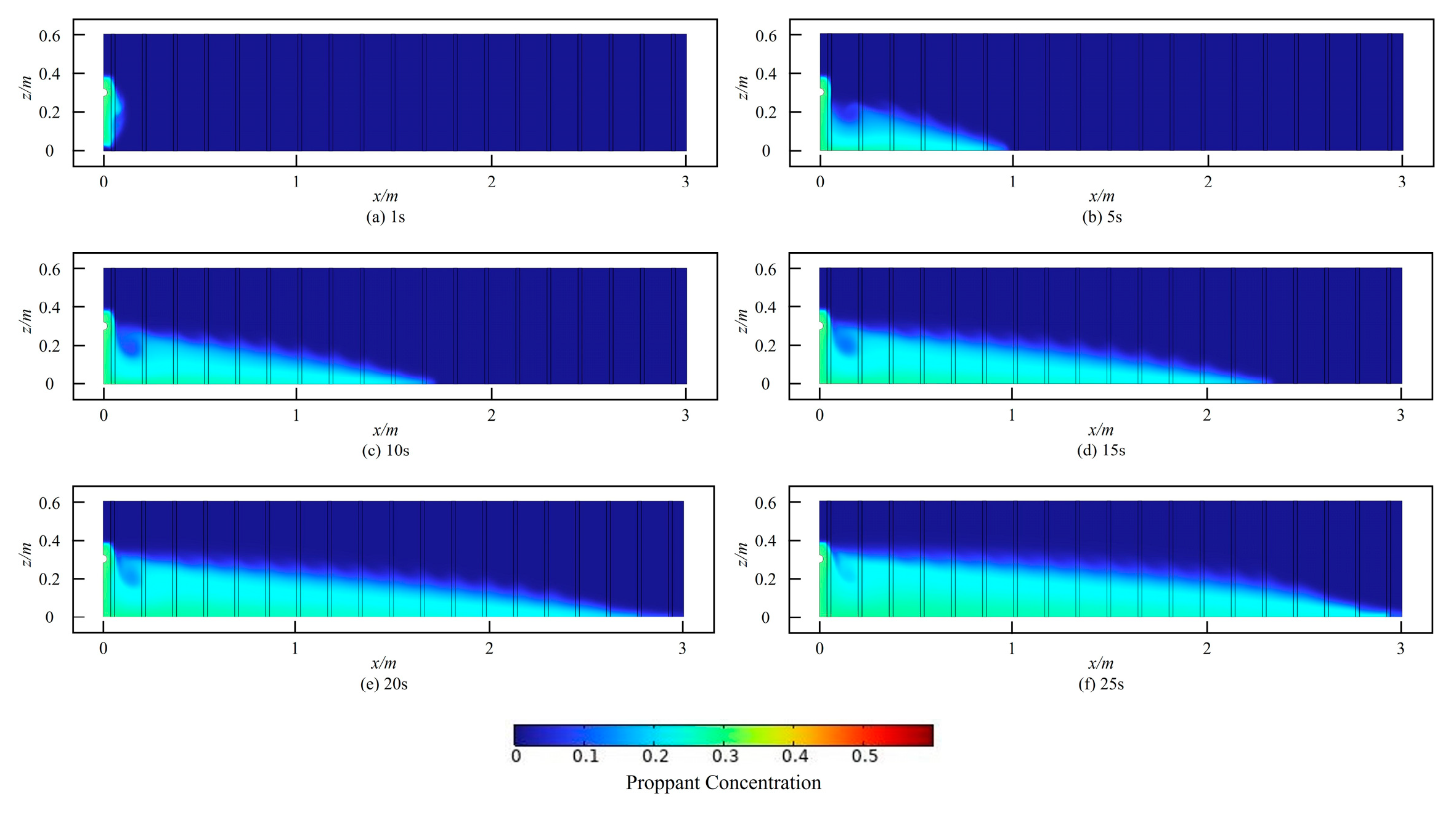

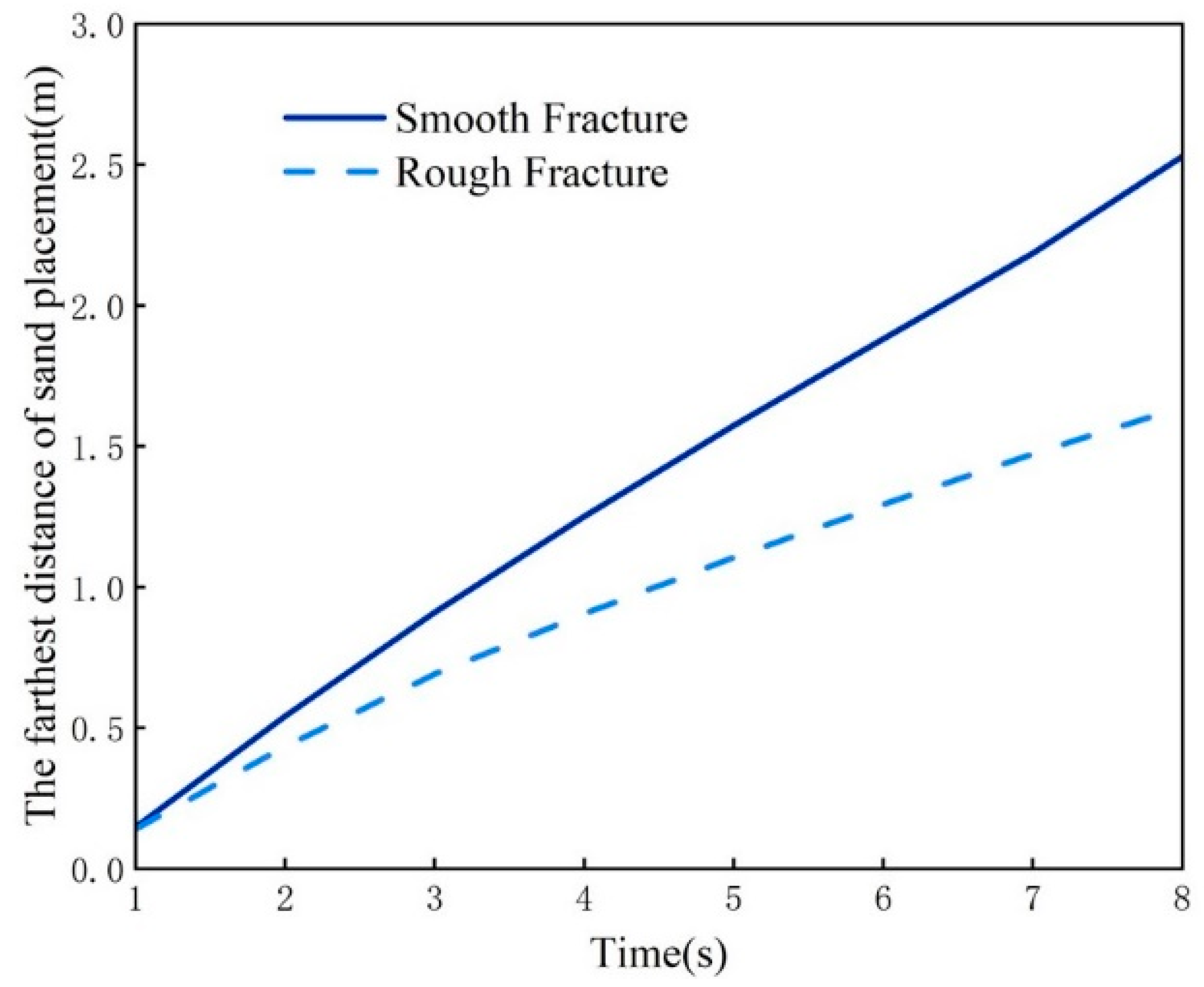

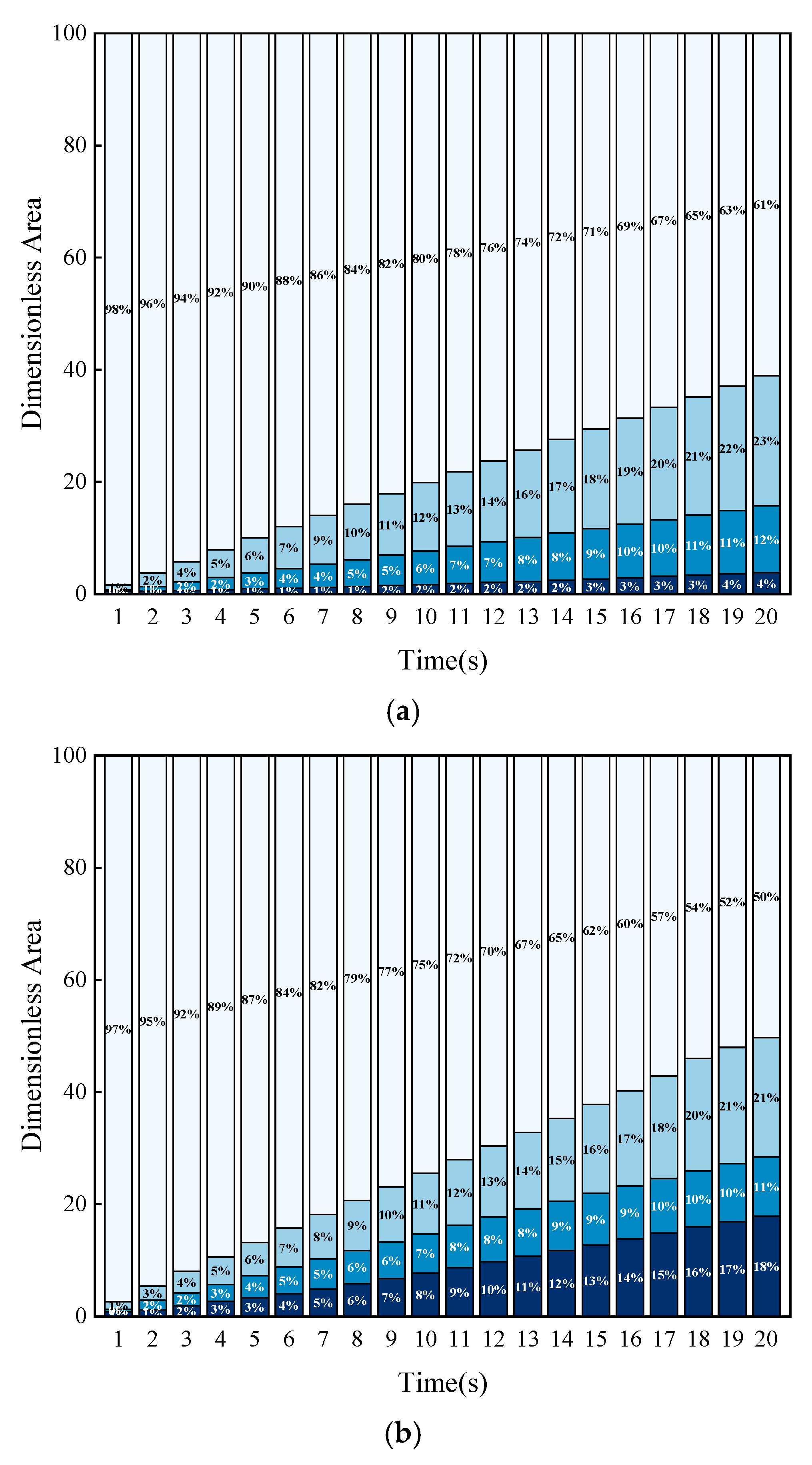

4.1. Comparison of Proppant Placement Morphology in Smooth and Rough Fractures

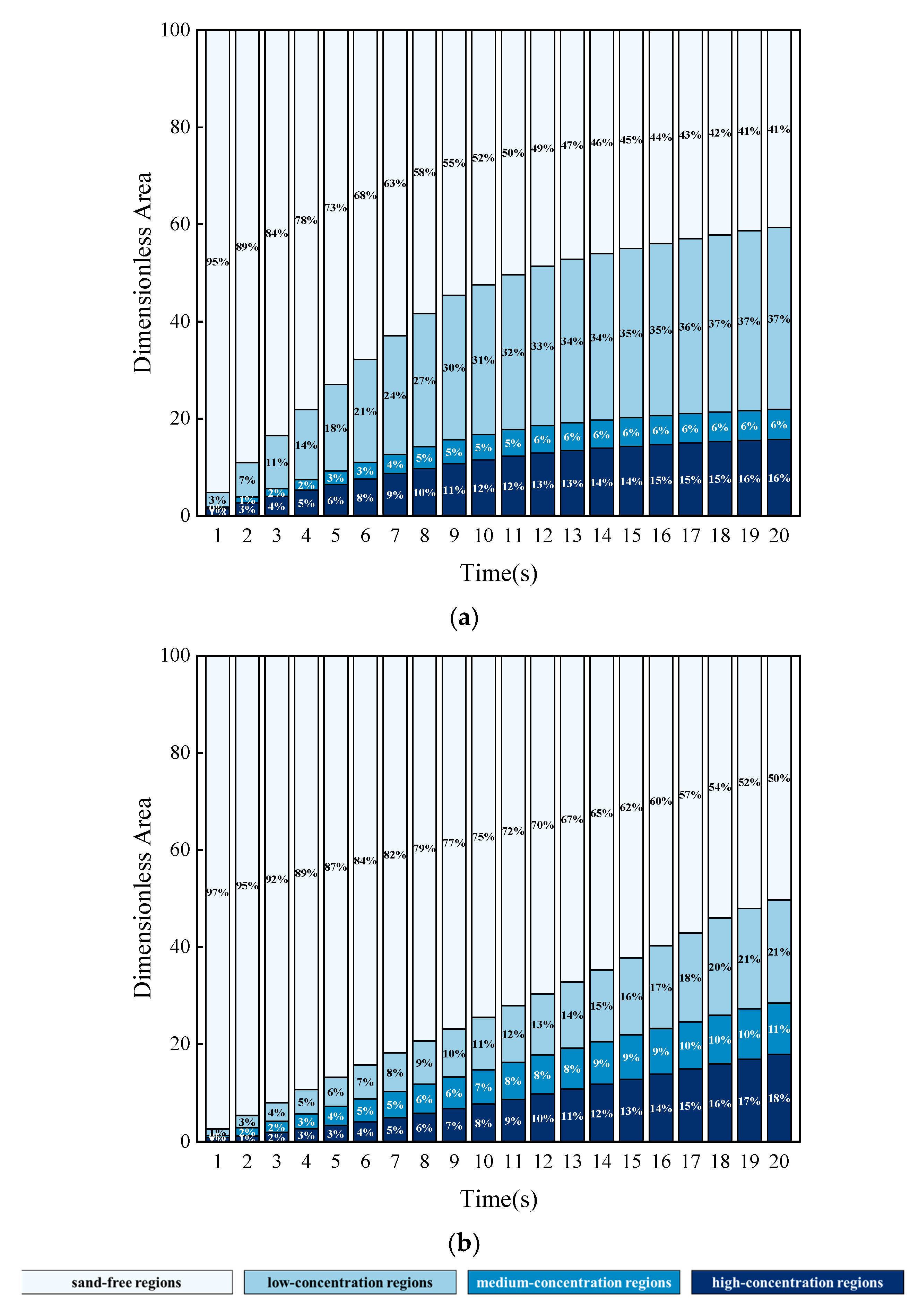

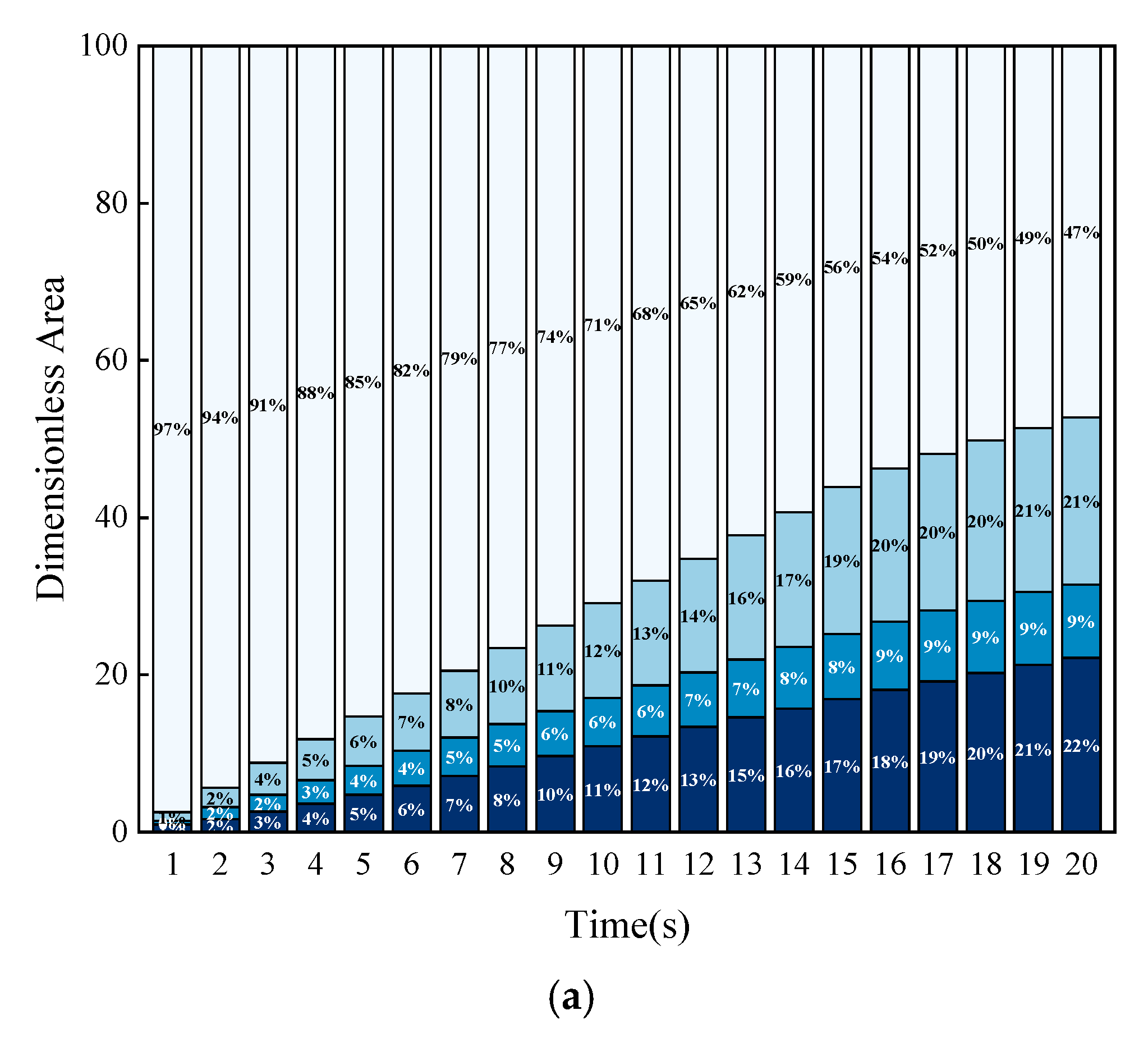

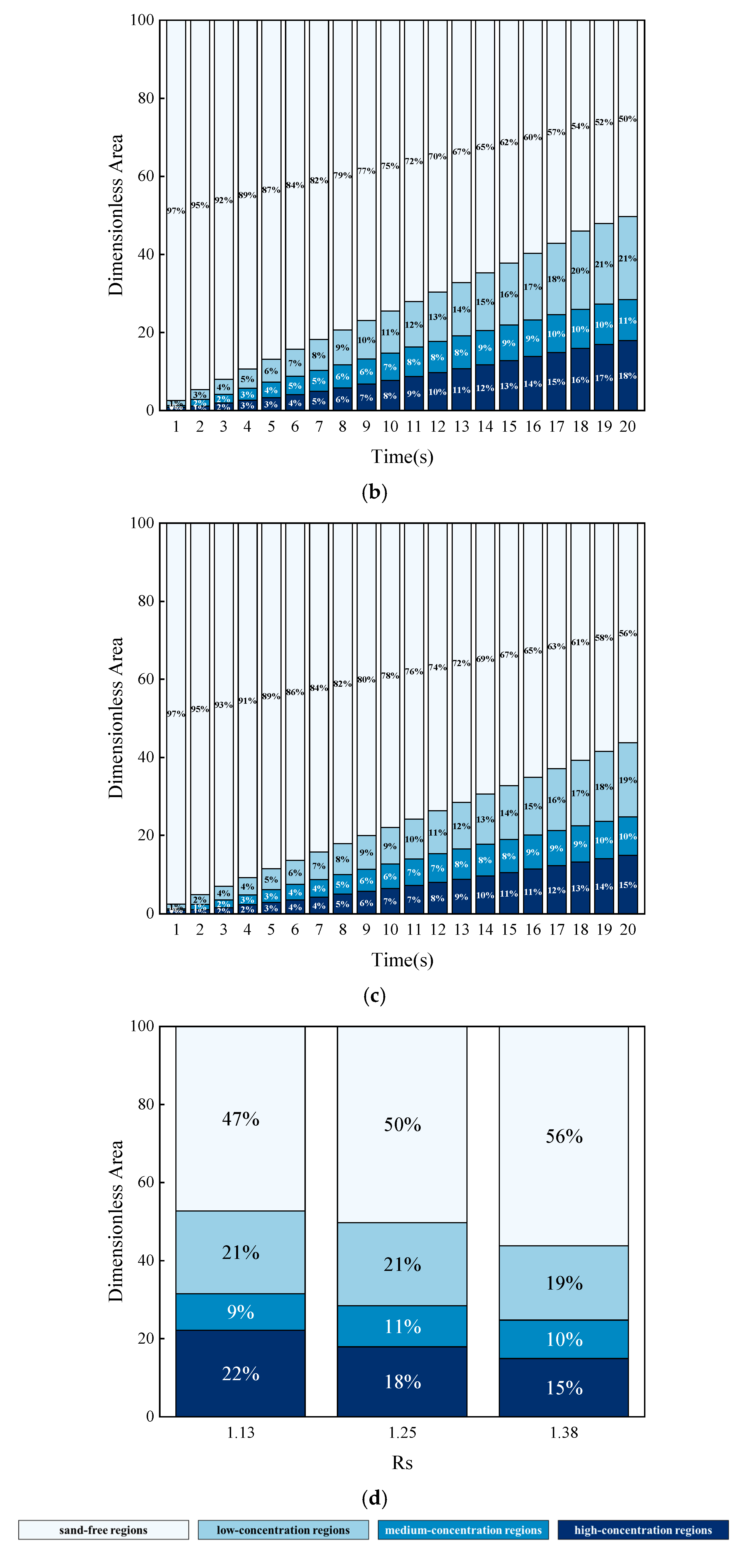

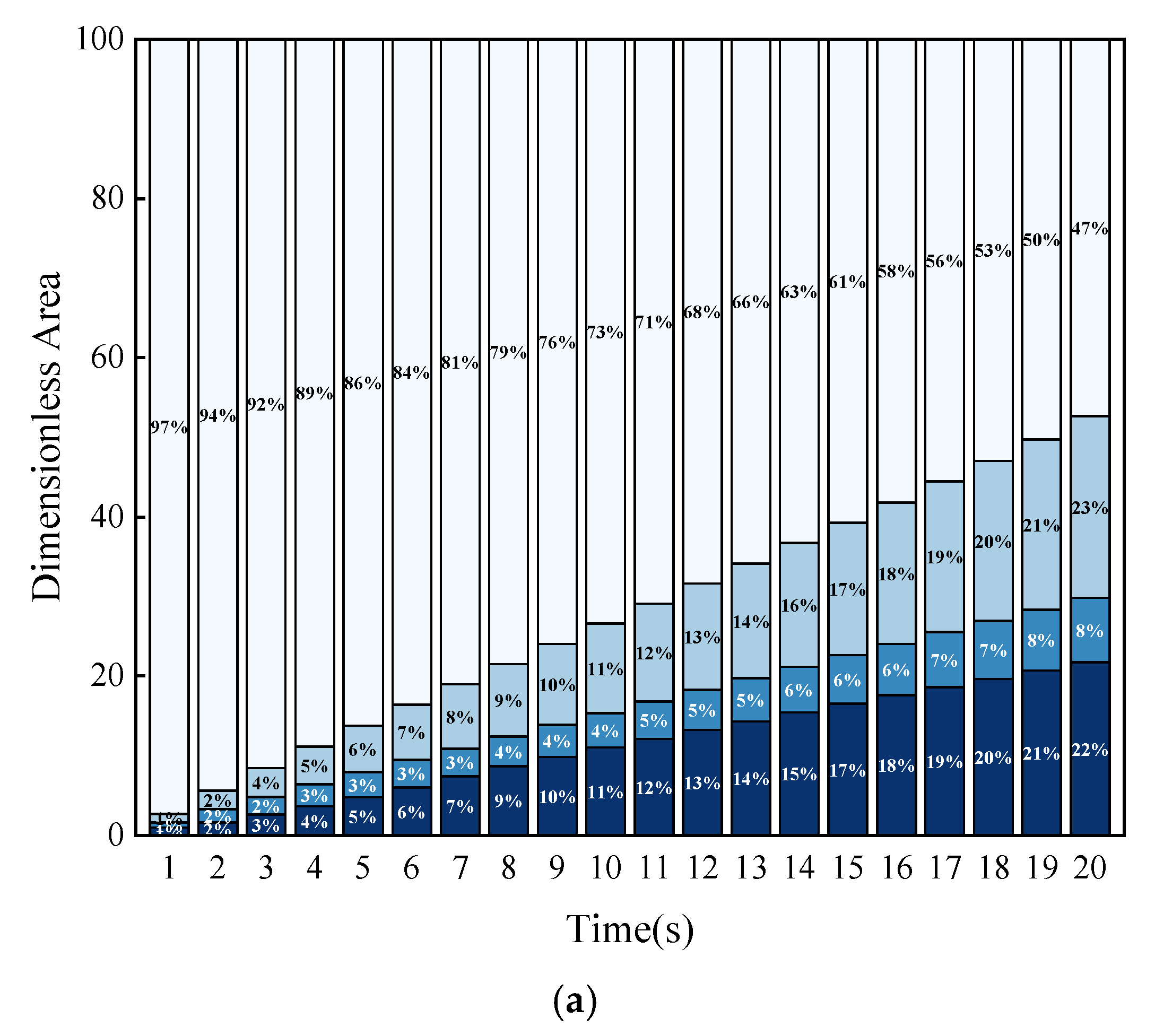

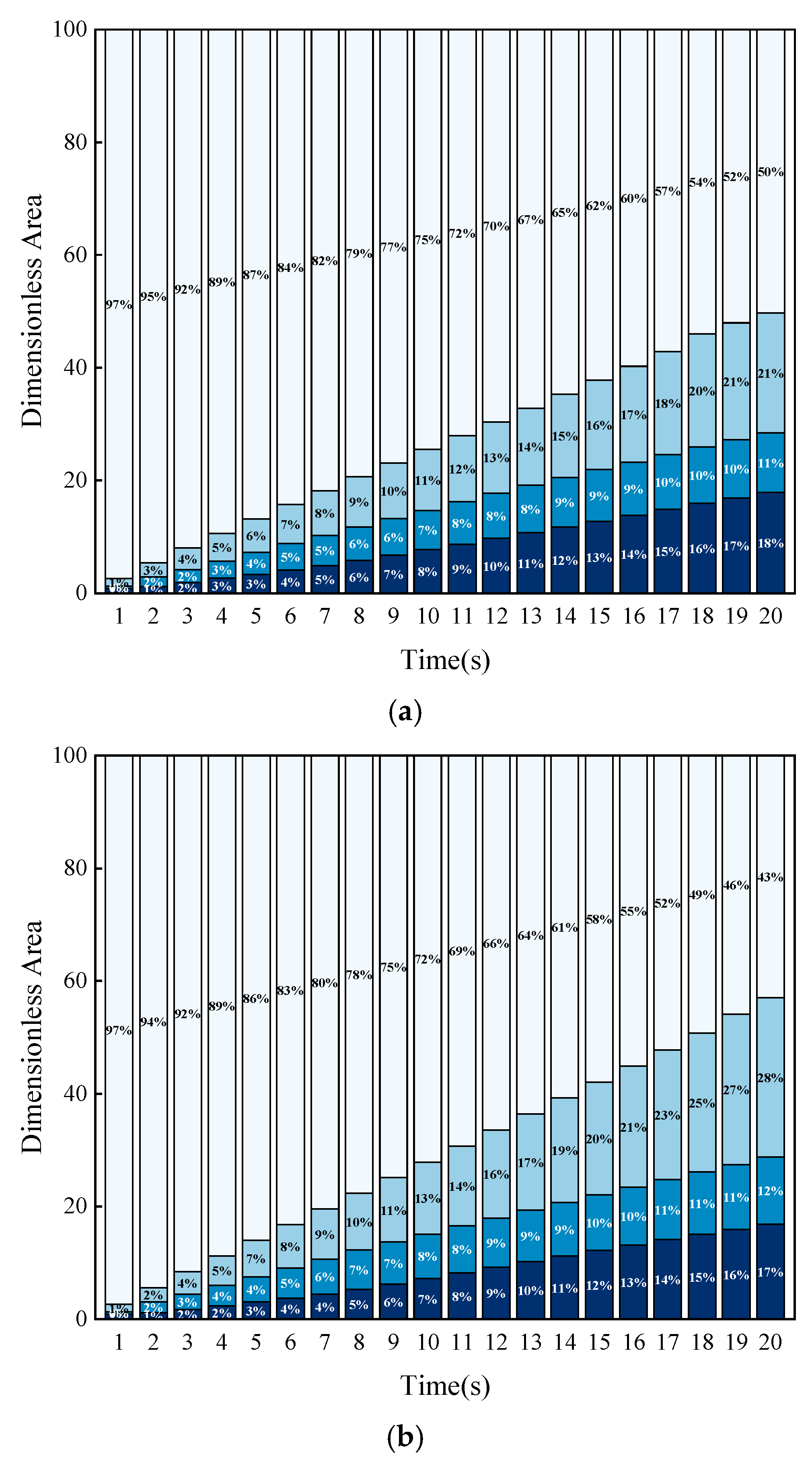

4.2. The Impact of the Number of Micro-Protuberances

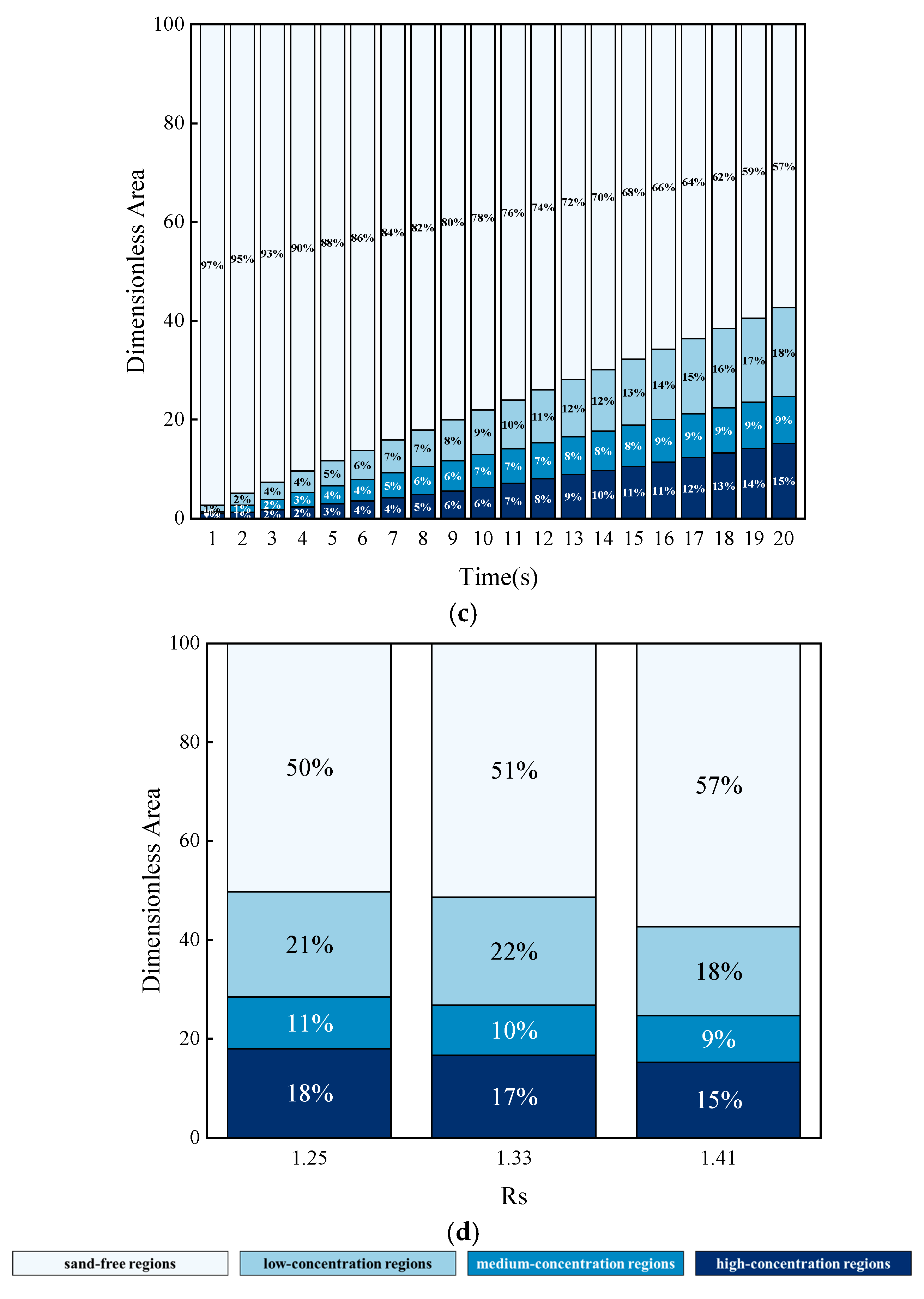

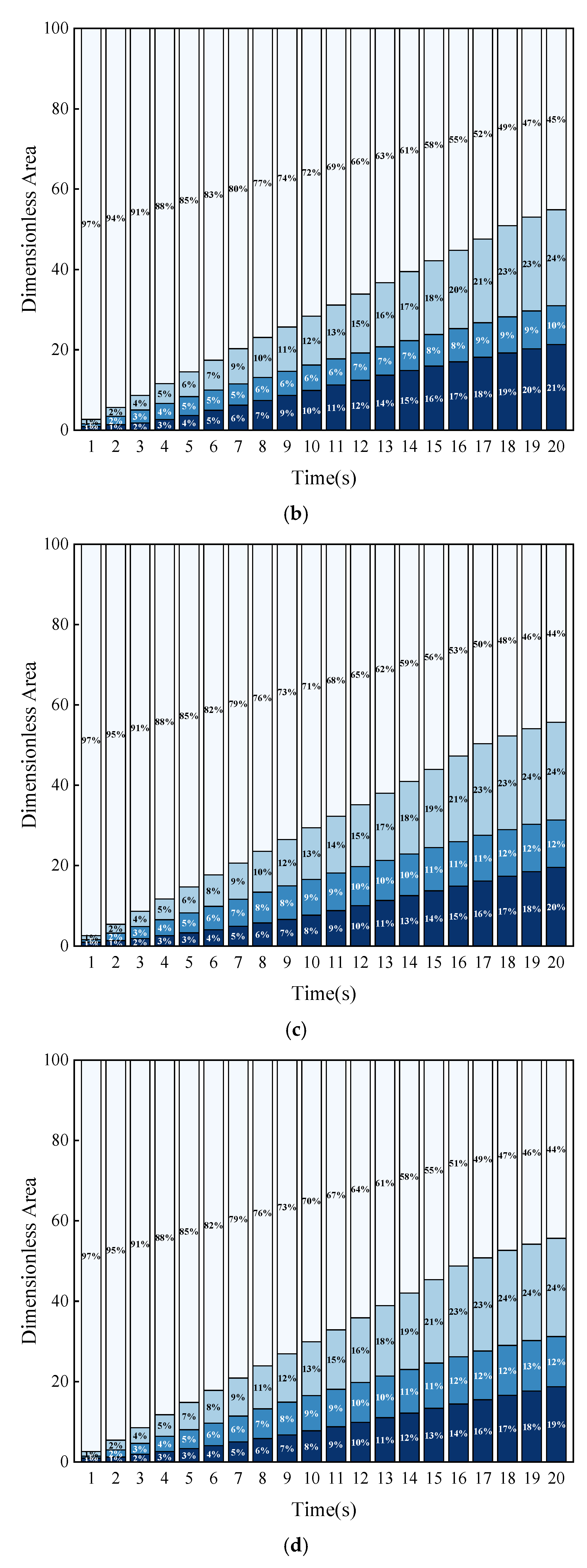

4.3. The Impact of the Height of Micro-Protuberances

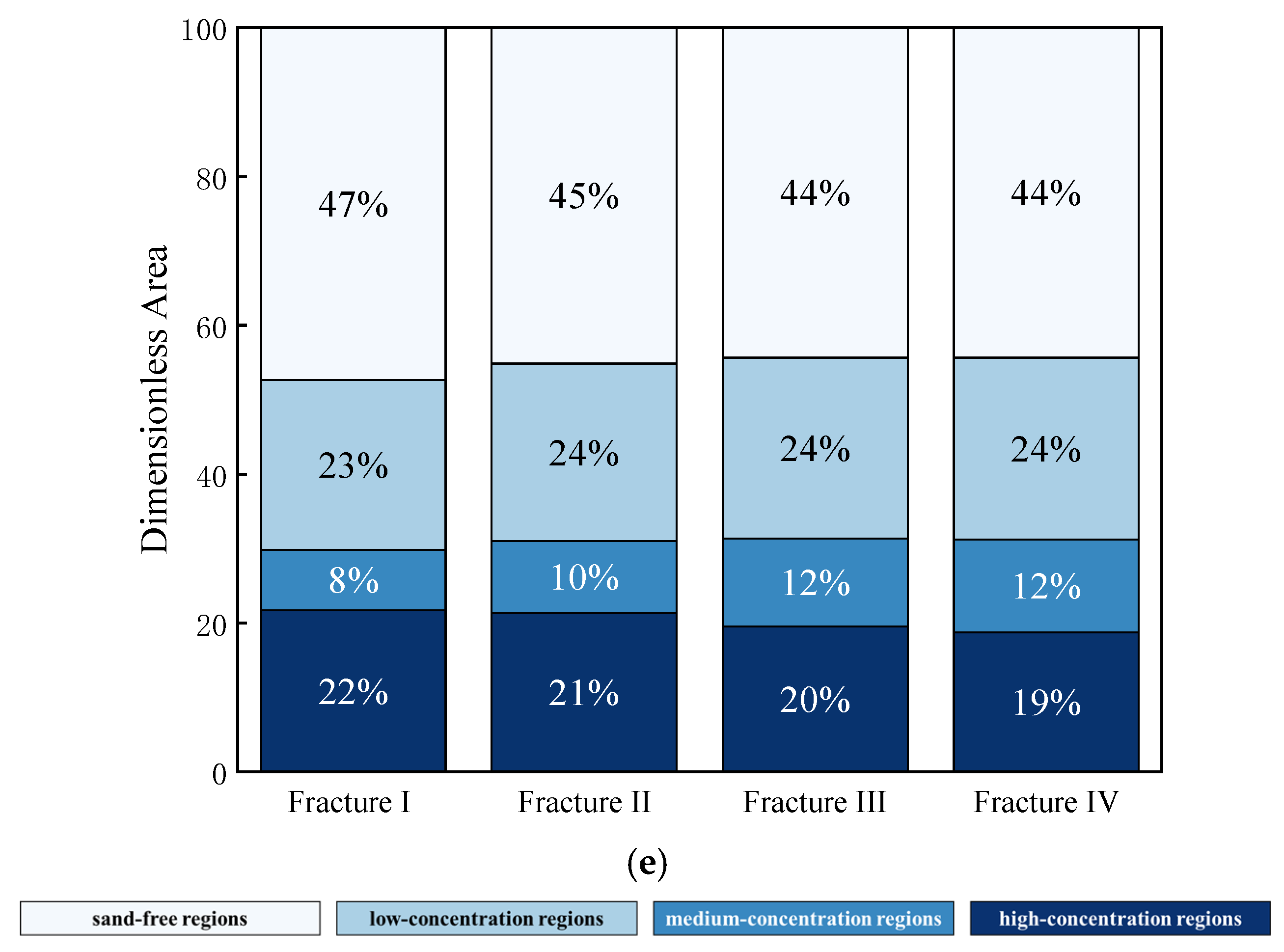

4.4. The Impact of Different Roughness Morphologies

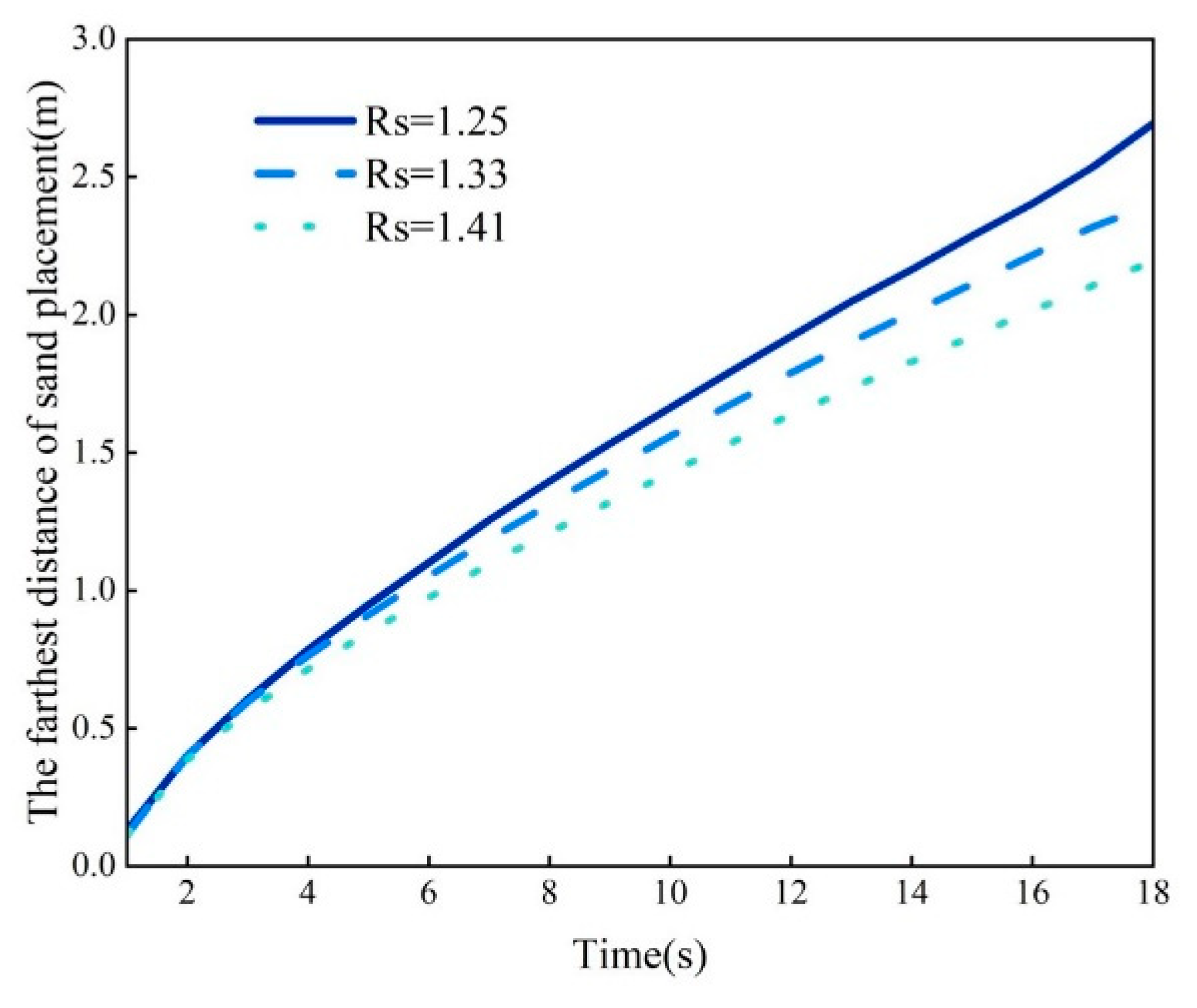

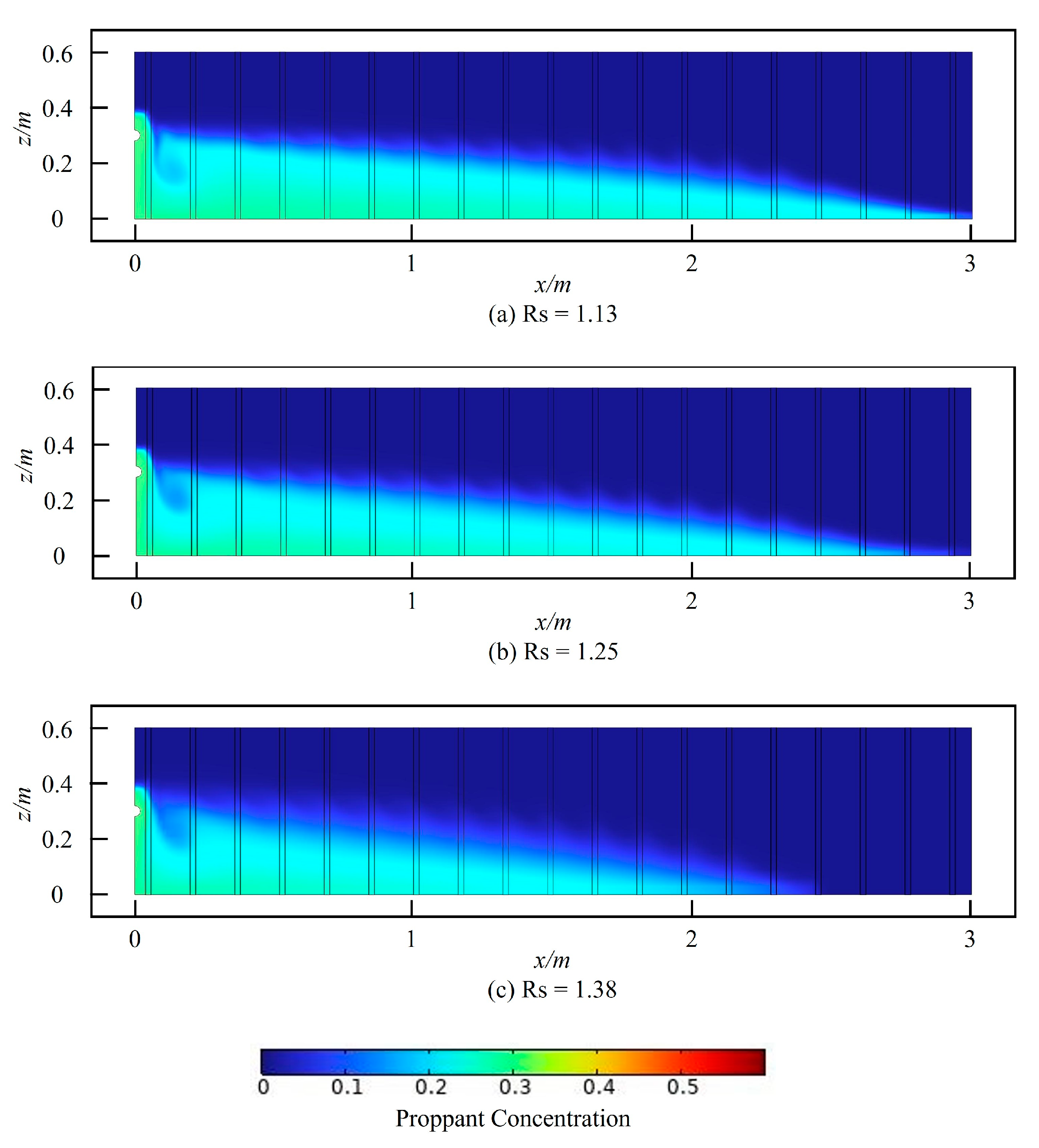

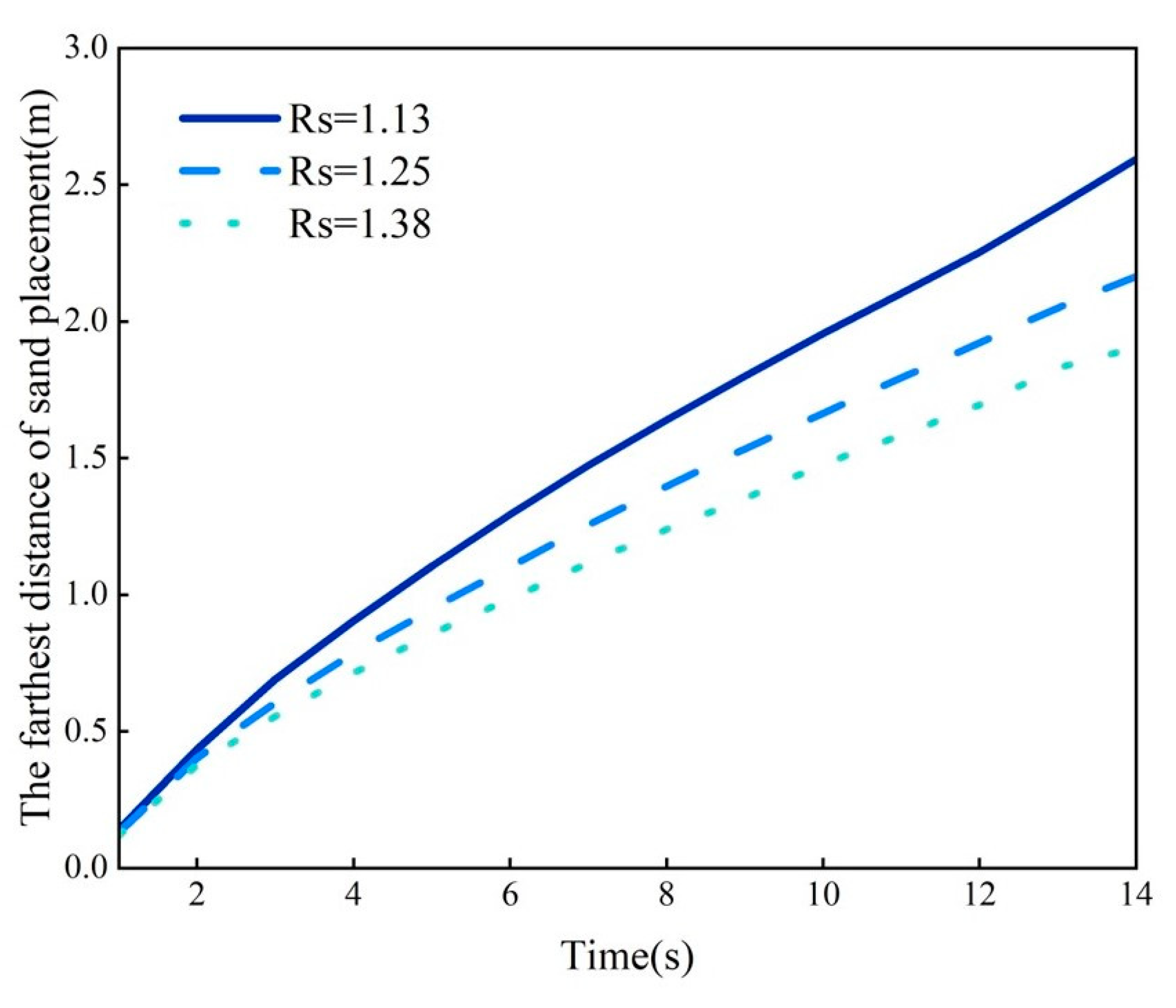

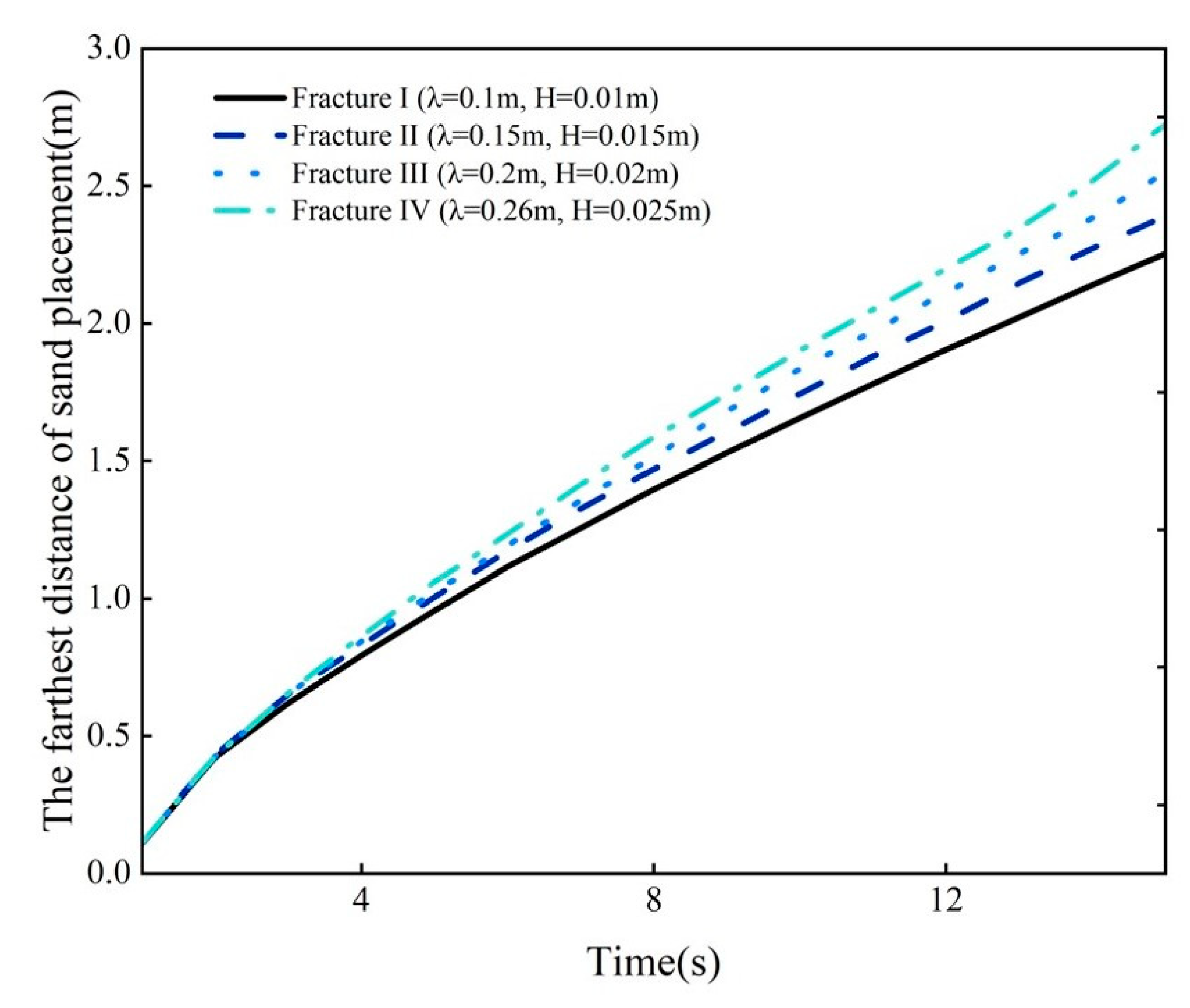

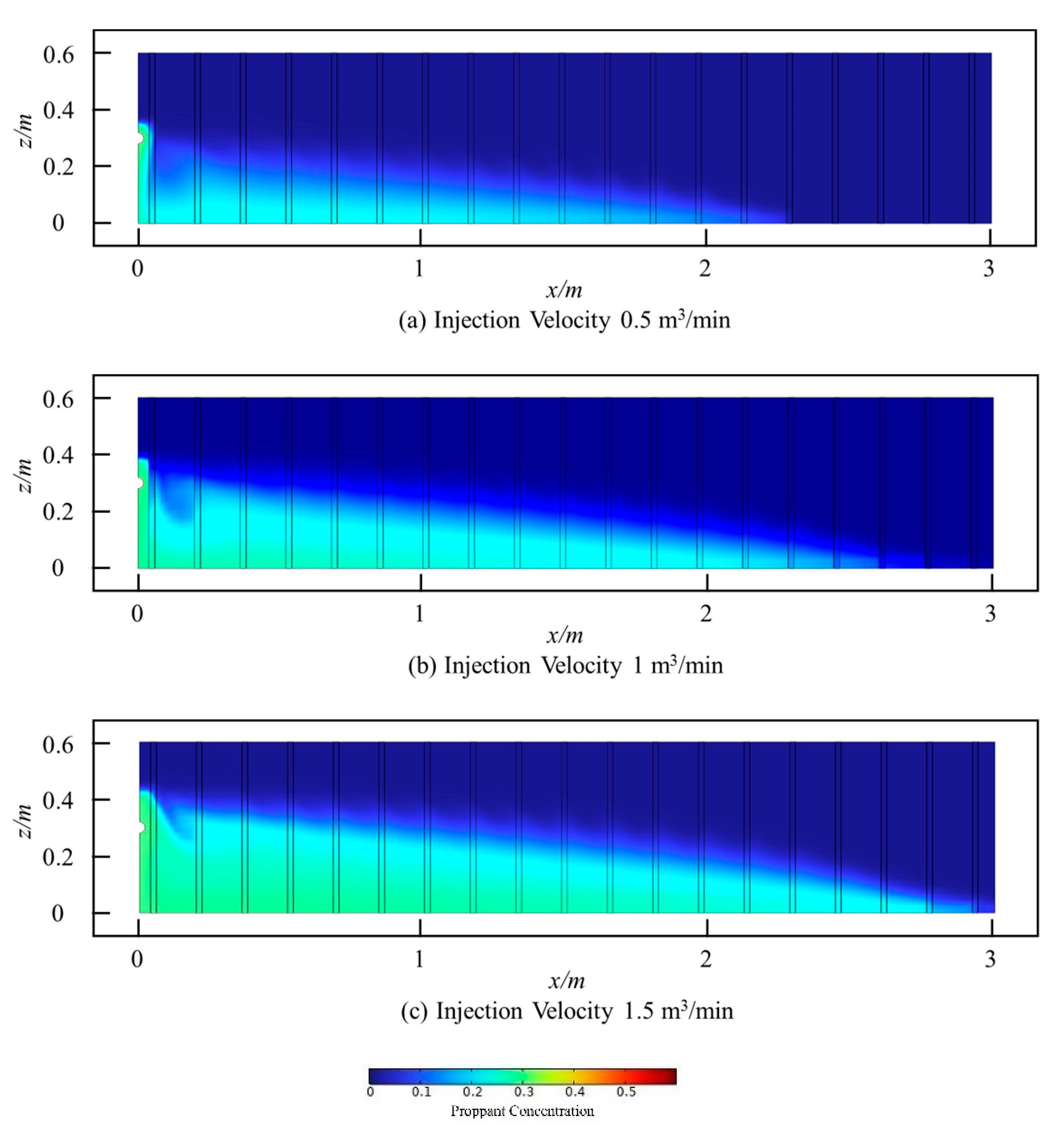

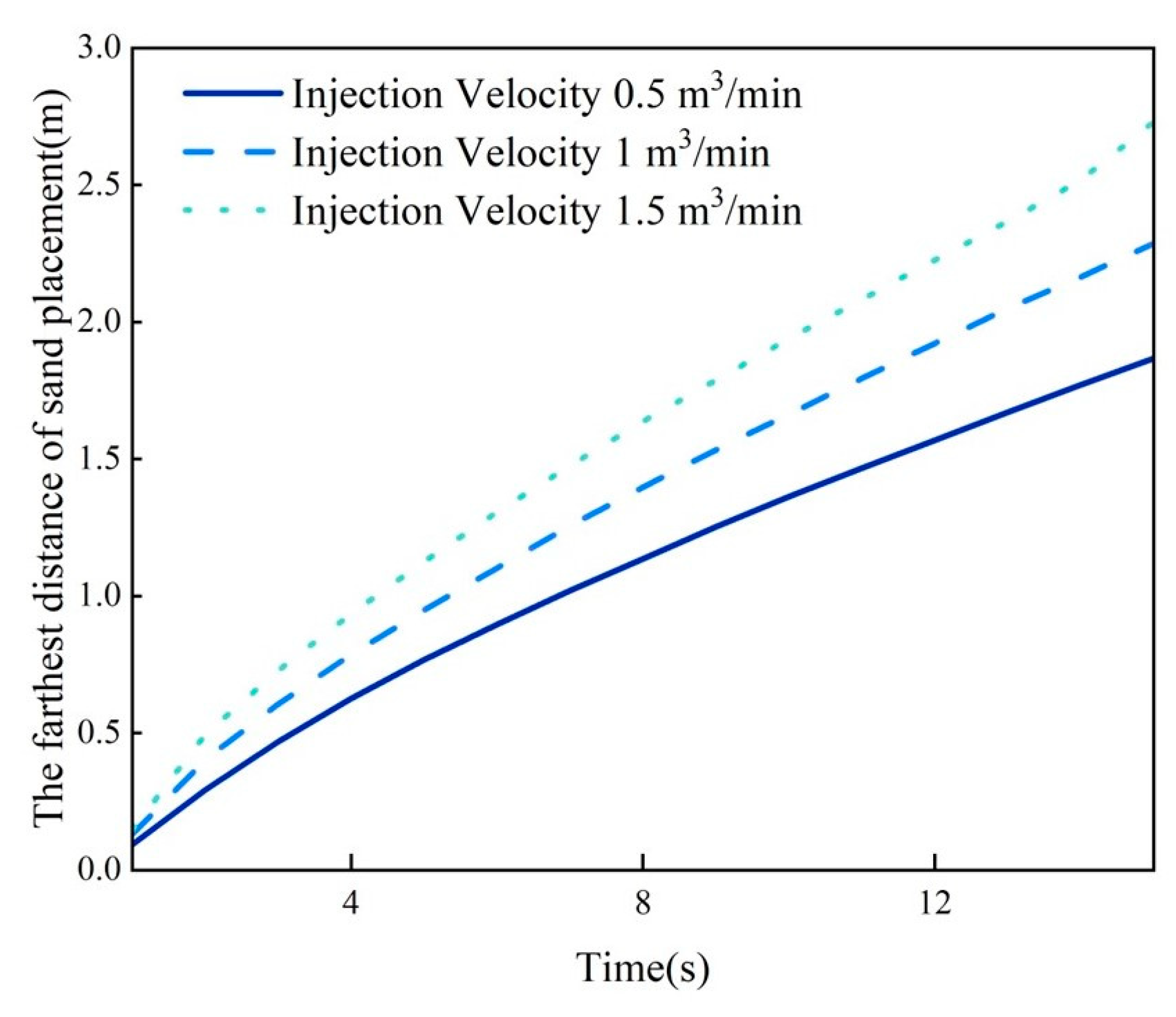

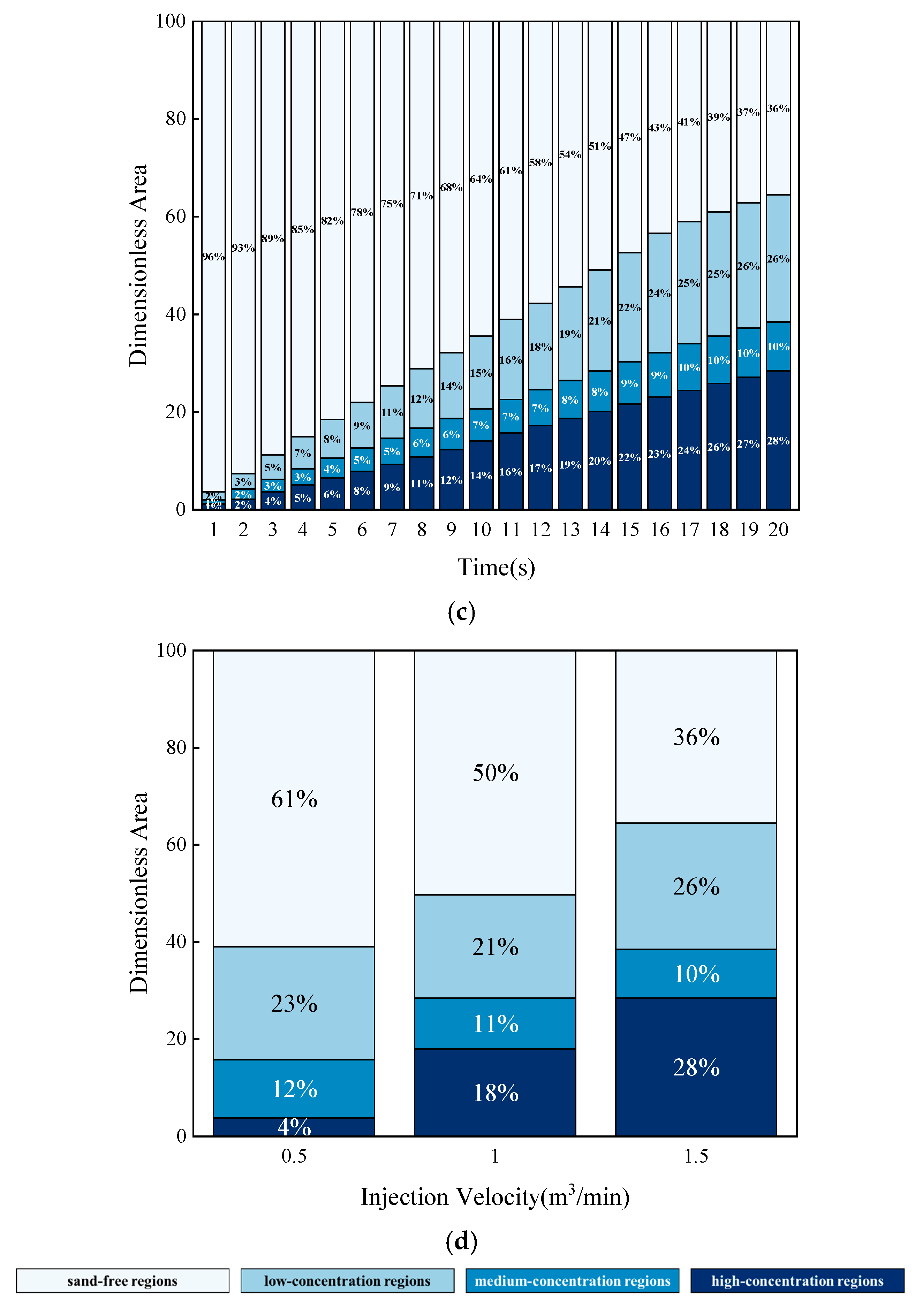

4.5. The Impact of Injection Velocity

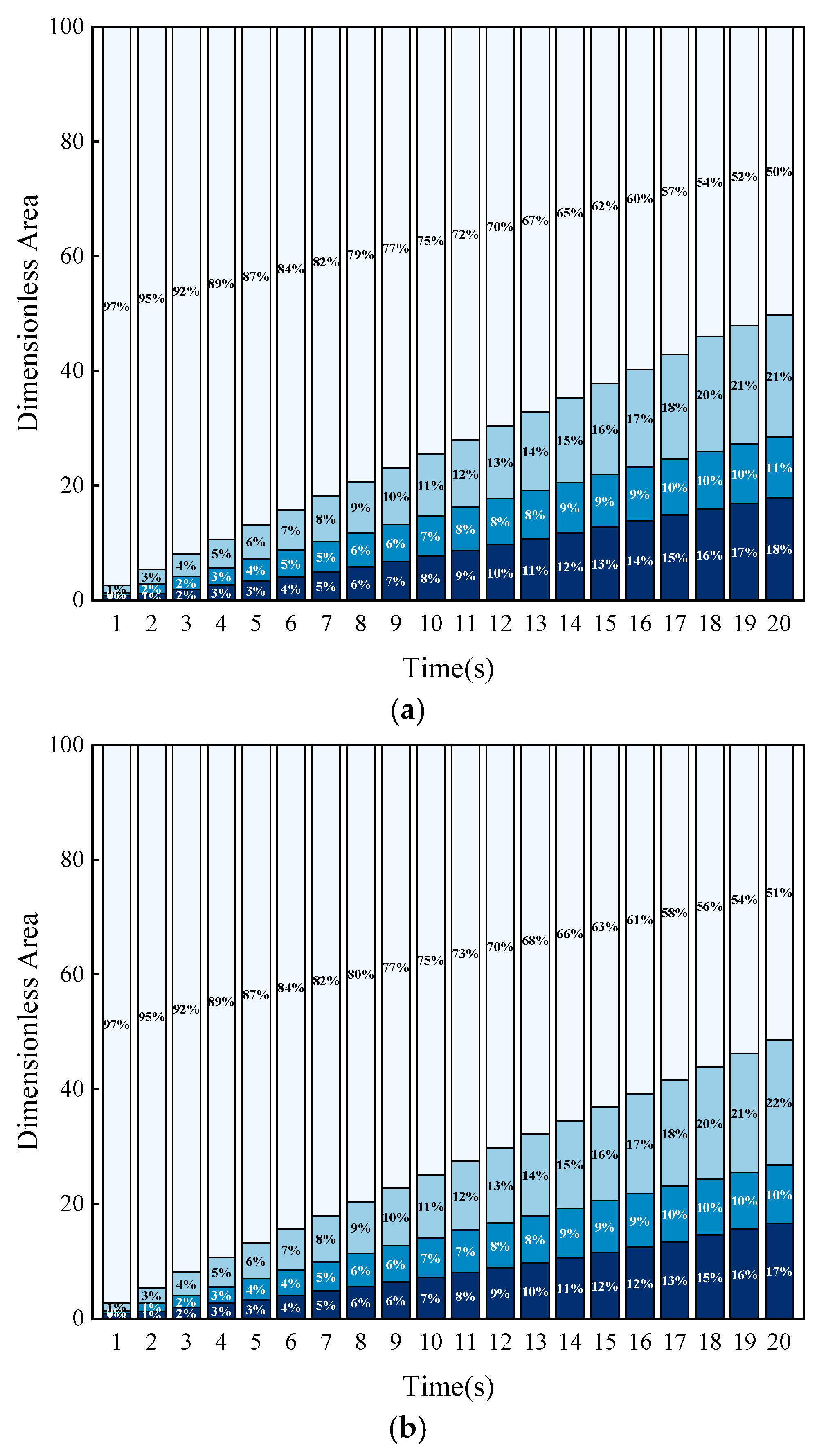

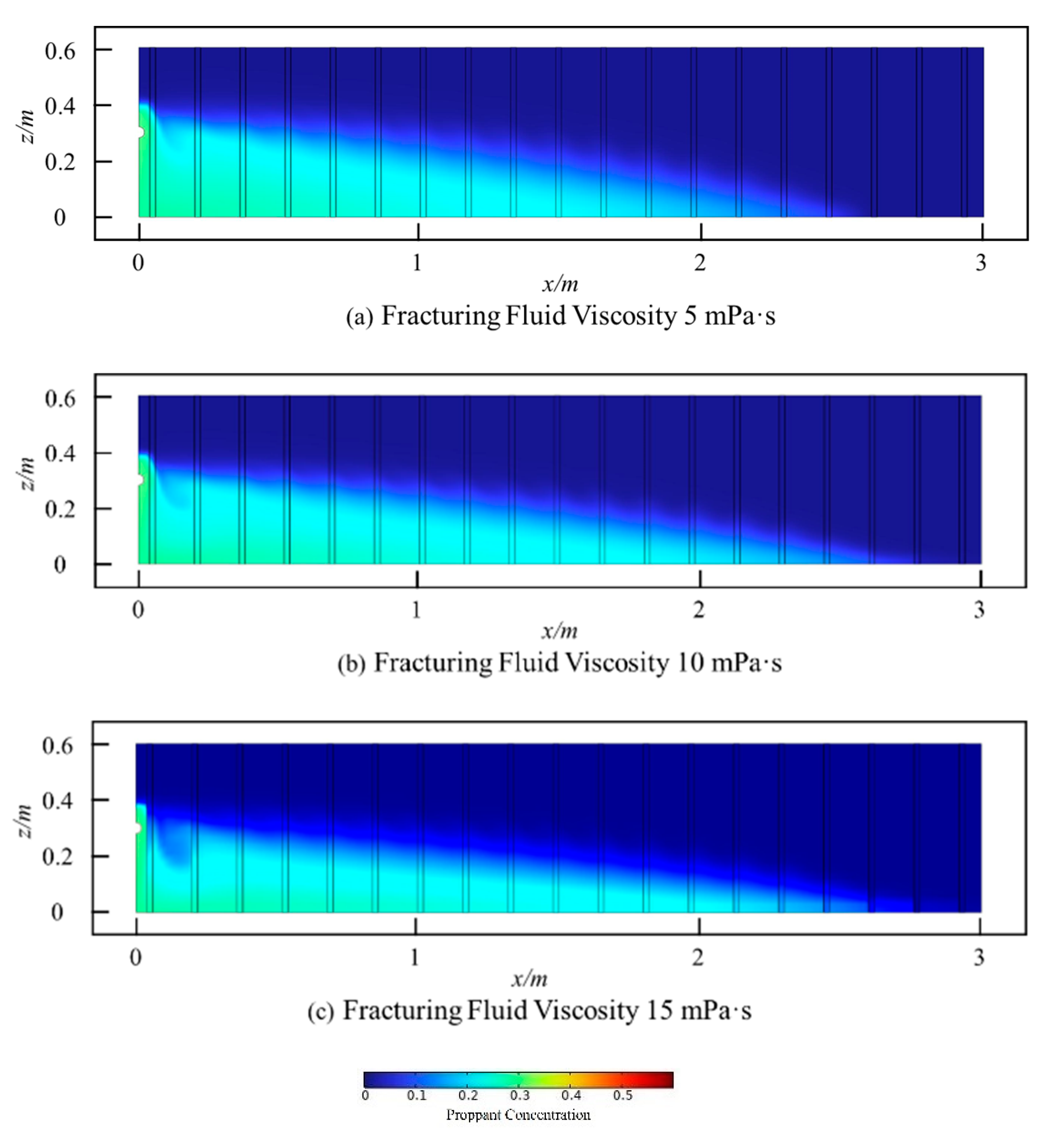

4.6. The Impact of Fracturing Fluid Viscosity

5. Conclusions

- (1)

- The rough and complex spatial structure of fractures can hinder the migration of proppant, leading to reduced support efficiency. The edges of rough fractures are serrated, and the sedimentation near the wellbore is significant, forming sand plugs. The furthest distance of proppant placement in rough fractures is only 55.2% of that in smooth fractures.

- (2)

- The increased roughness of fractures enhances the retarding effect. Both the quantity and height of micro-protrusions contribute to the increase in fracture roughness, but the changes in these two types of roughness have different impacts on the morphology of the sand ridge. An increase in the number of micro-protrusions weakens the serrated degree of the sand ridge edge, while an increase in the height of micro-protrusions leads to an enhanced serrated degree at the edge.

- (3)

- Higher injection rates are conducive to the transport of proppant in rough fractures, carrying the proppant deep into the fractures for effective support. The furthest distance of proppant placement at an injection velocity of 0.5 m3/min is only 68.4% of that at an injection velocity of 1.5 m3/min. The increase in fracturing fluid viscosity primarily serves to elevate the height of the sand ridge, promoting the suspension behavior of the proppant.

6. Limitations

- (1)

- In actual reservoirs, natural fractures and bedding planes are often extensively developed. After hydraulic fracturing treatments, complex fracture networks are typically formed. However, this study has only conducted preliminary research on the transport and placement of proppants in rough single fractures. In the future, we will expand the scope of our research to further investigate the transport and placement behavior of proppants in complex fracture networks with rough walls. This research will provide an important theoretical basis and practical guidance for optimizing fracturing designs and selecting relevant parameters.

- (2)

- This study employs the Eulerian–Eulerian model to simulate the transport behavior of proppants in rough fractures. The model treats both the solid and liquid phases as continuous media, enabling efficient characterization of macroscopic flow features with relatively low computational costs, making it suitable for large-scale numerical simulations. However, as both phases are considered continuous, the model cannot precisely describe the trajectories of individual particles and their interactions. Consequently, it faces limitations in optimizing proppant parameters. In future research, simulations will be conducted using higher-precision models based on the large-scale fracture model.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, G.X.; Lei, Z.D.; Dong, W.H.; Wang, H.; Zheng, X.; Tan, J. Progress, challenges and prospects of unconventional oil and gas development of CNPC. China Pet. Explor. 2022, 27, 1. [Google Scholar]

- Wu, Y.H.; Wen, Q.Z.; Zhang, Y.X.; Sun, Q.Q.; Zhang, Y.X.; Wang, L.; Guo, S.T. Control optimization on proppant spiting. Fault-Block Oil Gas Field 2012, 19, 662–665. [Google Scholar]

- Zhao, J.Z.; Ren, L.; Shen, C.; Li, Y. Latest research progresses in network fracturing theories and technologies for shale gas reservoirs. Nat. Gas Ind. B 2018, 5, 533–546. [Google Scholar] [CrossRef]

- Wan, H.B.; Li, T.Z. Research status and prospect of deposition and transport of propellant in shale pneumatic fracture. Contemp. Chem. Ind. 2019, 48, 1775–1778. [Google Scholar]

- He, X.; Wei, D.; Yu, H.; Bai, B.; Chen, A.; Liang, T. Proppant Migration within a Rough Hydraulic Fracture. J. Porous Media 2023, 26, 1–15. [Google Scholar] [CrossRef]

- Zhu, W.Y.; Zhang, Q.T.; Yue, M.; Zhang, L. Effect of uneven distribution of proppant in fracture network on exploitation dynamic characteristics. Chin. J. Eng. 2020, 42, 1318–1324. [Google Scholar]

- Jiang, C.B.; Li, Q. Understanding and field practice of deep shale reservoir stimulation. J. Jianghan Pet. Univ. Staff Work. 2020, 33, 28–30. [Google Scholar]

- Xu, J.H.; Wen, S.C. Gel breaking performance evaluation and field application of clean fracturing fluid for development of low temperature coal bed gas. Contemp. Chem. Ind. 2018, 47, 520–523. [Google Scholar]

- Wang, X. Analysis of factors affecting proppant settlement in fractures. Petrochem. Ind. Technol. 2017, 24, 292. [Google Scholar]

- Huang, H.; Zheng, Y.; Wang, Y.; Wang, H.; Ni, J.; Wang, B.; Yang, B.; Wang, W. Characteristics of proppant transport and placement within rough hydraulic fractures. Pet. Explor. Dev. 2024, 51, 453–463. [Google Scholar] [CrossRef]

- Zhou, H.; Guo, J.; Zhang, T.; Gou, H.; Chen, C.; Wang, S.; Tang, T. Numerical study of the wall-retardation effect on proppant transport in rough fractures. Comput. Geotech. 2023, 159, 105425. [Google Scholar]

- Huang, H.; Babadagli, T.; Li, H.; Develi, K.; Zhou, D. A visual experimental study on proppants transport in rough vertical fractures. Int. J. Rock Mech. Min. Sci. 2020, 134, 104446. [Google Scholar] [CrossRef]

- Li, J.; Liu, P.; Kuang, S.; Yu, A. Visual lab tests: Proppant transportation in a 3D printed vertical hydraulic fracture with two-sided rough surfaces. J. Pet. Sci. Eng. 2021, 196, 107738. [Google Scholar] [CrossRef]

- Guo, T.K.; Luo, Z.L.; Zhou, J.; Gong, Y.Z.; Dai, C.L.; Tang, J.; Yu, Y.; Xiao, B.; Niu, B.L.; Ge, J.J. Numerical simulation on proppant migration and placement within the rough and complex fractures. Pet. Sci. 2022, 19, 2268–2283. [Google Scholar] [CrossRef]

- Zhou, M.; Yang, Z.; Xu, Z.; Song, X.; Wang, B.; Zheng, Y.; Zhou, Q.; Li, G. CFD-DEM modeling and analysis study of proppant transport in rough fracture. Powder Technol. 2024, 436, 119461. [Google Scholar] [CrossRef]

- YIN, B.; Zhang, C.; Wang, Z.; Sun, B.; Gao, Y.; Wang, X.; Bi, C.; Zhang, Q.; Wang, J.; Shi, J. Proppant transport in rough fractures of unconventional oil and gas reservoirs. Pet. Explor. Dev. 2023, 50, 712–721. [Google Scholar] [CrossRef]

- Huang, X.; Yuan, P.; Zhang, H.; Han, J.; Mezzatesta, A.; Bao, J. Numerical study of wall roughness effect on proppant transport in complex fracture geometry. In SPE Middle East Oil and Gas Show and Conference; SPE: Kuala Lumpur, Malaysia, 2017; p. D021S012R001. [Google Scholar]

- Wang, T.; Zhong, P.; Li, G.; Sheng, M.; Wen, H.; Tian, S. Transport pattern and placement characteristics of proppant in different rough fractures. Transp. Porous Media 2023, 149, 251–269. [Google Scholar] [CrossRef]

- Zhang, B.; Gamage, R.P.; Zhang, C.; Wanniarachchi, A. Hydrocarbon recovery: Optimized CFD-DEM modeling of proppant transport in rough rock fractures. Fuel 2022, 311, 122560. [Google Scholar] [CrossRef]

- Deng, H.; Ellis, B.R.; Peters, C.A.; Fitts, J.P.; Crandall, D.; Bromhal, G.S. Modifications of Carbonate Fracture Hydrodynamic Properties by CO2-Acidified Brine Flow. Energy Fuels 2013, 27, 4221–4231. [Google Scholar]

- Lance, D.A.; Jennings, H.M.; Shah, S.P. Relationship between fracture surface roughness and fracture behavior of cement paste and mortar. J. Am. Ceram. Soc. 1993, 76, 589–597. [Google Scholar]

- Krieger, I.M.; Dougherty, T.J. A Mechanism for Non-Newtonian Flow in Suspensions of Rigid Spheres. Trans. Soc. Rheol. 1959, 3, 137–152. [Google Scholar] [CrossRef]

- Rao, R.; Mondy, L.; Sun, A.; Altobelli, S. A numerical and experimental study of batch sedimentation and viscous resuspension. Int. J. Numer. Methods Fluids 2002, 39, 465–483. [Google Scholar] [CrossRef]

- Subia, S.R.; Ingber, M.S.; Mondy, L.A.; Altobelli, S.A.; Graham, A.L. Modelling of concentrat ed suspensions using a continuum constitutive equation. J. Fluid Mech. 1998, 373, 193–219. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, K.J.; Fu, S.S.; Xu, H.L.; Zhang, L.J.; Jiang, H.S. Migration and settlement laws of proppant in multi-scale fractures during the fracturing in the unconventional reservoirs. Nat. Gas Ind. 2024, 44, 109–119. [Google Scholar]

| Parameter | Value |

|---|---|

| Solid Phase Volume Fraction | |

| Solid Phase Mass Fraction | |

| Fluid | |

| Fluid |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, B.; Li, H.; Wei, C.; Zhu, W.; Song, T.; Yue, M. Numerical Simulation on the Transport and Displacement Patterns of Proppant in Hydraulic Fractures Considering the Effect of Rough Fracture Surfaces. Processes 2025, 13, 461. https://doi.org/10.3390/pr13020461

Xiao B, Li H, Wei C, Zhu W, Song T, Yue M. Numerical Simulation on the Transport and Displacement Patterns of Proppant in Hydraulic Fractures Considering the Effect of Rough Fracture Surfaces. Processes. 2025; 13(2):461. https://doi.org/10.3390/pr13020461

Chicago/Turabian StyleXiao, Bo, Hongzhu Li, Chaoran Wei, Weiyao Zhu, Tianru Song, and Ming Yue. 2025. "Numerical Simulation on the Transport and Displacement Patterns of Proppant in Hydraulic Fractures Considering the Effect of Rough Fracture Surfaces" Processes 13, no. 2: 461. https://doi.org/10.3390/pr13020461

APA StyleXiao, B., Li, H., Wei, C., Zhu, W., Song, T., & Yue, M. (2025). Numerical Simulation on the Transport and Displacement Patterns of Proppant in Hydraulic Fractures Considering the Effect of Rough Fracture Surfaces. Processes, 13(2), 461. https://doi.org/10.3390/pr13020461