Abstract

Deep shale reservoirs in the Luzhou Block are characterized by developed fractures and complex structure. Accurate identification and characterization of natural fractures in reservoirs are crucial for shale gas exploration and development. In this paper, the main development characteristics of natural fractures in the target layer were clarified based on core observation data and imaging logging data, and then the natural fractures were identified by combining the R/S analysis method. Furthermore, due to the different orientations of different fractures, there are differences in fracture activation pressure and drilling fluid leakage, which have a significant impact on the identification of risk zones. The results showed that low-angle and east–west oriented fractures are not easily activated because their orientation relative to the maximum horizontal principal stress is unfavorable, resulting in lower shear stress on the fracture planes. Moreover, after fracture activation, the opening deformation decreases with increasing inclination, leading to differential changes in the leakage rate. The 60° inclination angle fracture is the critical value for high-risk leakage compared to the low-risk leakage. The research results can provide important guidance for further drilling optimization and development of deep shale gas in the Luzhou Block.

1. Introduction

Deep shale gas resources in China are widely distributed, which is of great significance to the new situation of shale gas exploration and development in China [1,2,3]. At present, there is no unified definition for the boundary division of the deep layer. Here, the standard issued by the Ministry of Land and Resources and China National Petroleum Corporation is adopted. It is considered that the depth of 3500–4500 m is the deep layer, and the depth over 4500 m is the super deep layer [2]. Shale is both a reservoir and a hydrocarbon source rock, and fractures play an important role in reservoir and production [4]. The engineering practice shows that the key to the effective exploitation of shale gas lies in the natural fractures and hydraulic fracturing technology [5,6,7]. Natural fractures develop at different scales in shale reservoirs, and fractures play positive and negative roles in the construction of shale gas reservoirs. Moderately developed natural fractures can provide storage space and seepage channels for shale gas, and facilitate the communication of hydraulic fractures during fracturing to form a complex fracture network. However, if the fractures are overdeveloped, it is often unfavorable for the preservation of shale gas reservoirs [8,9,10,11]. In addition, it is often unfavorable for drilling fluid circulation and wellbore stability [12,13]. However, there are significant differences in the difficulty of activating fractures of different orientations and the risk of drilling fluid leakage under their influence. There are many studies on fracture activation, while there is relatively little research on the risk of leakage under different fractures, which still shows a huge research space. Then, fracture prediction, as a geological index to evaluate the drilling quality of shale gas, becomes particularly important. At present, the methods of fracture identification and characterization mainly include geological and petrological methods, logging methods, drilling and logging, and production performance data methods [14]. Among them, core observation and imaging logging technology are the most widely used because they are more intuitive [15,16]. Additionally, the R/S analysis method can be used to determine the fracture location by the slope variation on some logging curves [16].

During actual drilling operations in the Luzhou Block, lost circulation incidents occur frequently and have become a critical bottleneck restricting drilling efficiency and economic performance. According to field statistics, a single severe lost circulation event requires 5 to 7 days for remediation, with drilling fluid losses reaching 500 to 1000 m3. This not only results in significant economic losses and time delays but also leads to more profound implications: substantial drilling fluid invasion into the formation may cause irreversible damage to the reservoir, adversely affecting subsequent fracturing performance and ultimate recovery; meanwhile, pressure imbalance in the loss zones may trigger wellbore instability and other complications, posing significant challenges to the design and safe execution of adjacent wells. Therefore, achieving accurate prediction and proactive prevention of lost circulation risks, particularly those controlled by fractures, has become an urgent core issue to ensure safe and efficient drilling in this block.

Conventional research has predominantly focused on the static geological characterization of fractures or the isolated assessment of their mechanical activation potential, failing to establish an integrated predictive framework that links geological characteristics, mechanical behavior, and engineering risks. This often results in delayed and imprecise evaluation of drilling fluid loss risks. To address this issue systematically, this study innovatively develops an integrated evaluation system of ‘log responses—fracture mechanical behavior—leakage risk.’ This research fills the gap in the systematic integration of multi-scale fracture characterization, differential activation mechanics, and quantitative leakage prediction in the context of deep shale gas.

In this study, we first conducted a systematic and comprehensive study of the fractures in the Longmaxi Formation in the study area based on core observation data and imaging logging data to fully understand the fracture development characteristics. Then, based on the fractal theory, variable-scale extreme difference analysis was performed for AC logging, DEN logging, GR logging, and RT logging. Furthermore, the finite element method (FEM) and Mohr-Coulomb criterion were combined to obtain the fracture’s activity evaluation. Based on FEM, a numerical model for characterizing the drilling fluid leakage of a wellbore with fracture development characteristics was established, and the fluid loss results under different fracture development characteristics were obtained. Compared with the fracture activity and drilling fluid loss results of the study area, a better identification and prediction effect was achieved. Through the integrated evaluation system of “log response—fracture prediction and characterization—stress deformation—leakage risk,” this study has established a quantitative technical pathway that translates readily acquired conventional logging signals into precise early warning of lost circulation risks. This framework not only achieves a transition from static geological description to dynamic engineering risk prediction but, more importantly, elucidates the impact mechanisms of fracture development characteristics on drilling safety. Consequently, it provides more targeted technical support for fracture prediction and drilling risk control in deep shale formations. The obtained results are expected to provide more geological references for efficient drilling construction.

2. Geological Setting

The Luzhou Block is located in the south of the Sichuan Basin, with the Weiyuan Block in the north and the Changning Block in the south, covering an area of about 1500 km2. The buried depth in the study area is generally between 3500 and 4500 m, and gradually deepening from north to south (Figure 1a). Tectonically, the Luzhou Block is located at the junction of the low-steep structural belt in southern Sichuan and the low-fold structural belt in southwest Sichuan [17,18]. The northeast part is close to the tectonic transition zone, where the fold strength is strong and many low-steep anticlines are developed, and the synclinal structure is wide and gentle (Figure 1b).

Figure 1.

(a) Location of the Southern Sichuan Basin and Luzhou Block. (b) Structural map of the study area.

The reservoirs in the Luzhou Block are mainly deep shale reservoirs of the Wufeng–Longmaxi Formation of the Lower Paleozoic. The study area is located in the center of deep-water shelf deposition during the deposition period of the Wufeng–Longmaxi Formation. The Longmaxi Formation contacts conformably with the lower Wufeng or Guanyinqiao Formation (Figure 2). The lithology of the Longmaxi Formation is gray/black, black and gray mud shale. The Wufeng Formation is gray/black siliceous shale, and the Guanyinqiao Formation is biomass limestone. A certain difference in target layer thickness is observed in the Luzhou area, which is mainly determined by the regional structure (Figure 1a).

Figure 2.

Stratigraphic column of the Longmaxi Formation in the Sichuan Basin [4].

The research methodology of this study is illustrated in Figure 3.

Figure 3.

Workflow Diagram.

3. Fracture Characteristics and Numerical Modeling

3.1. Fracture Characteristics in Cores

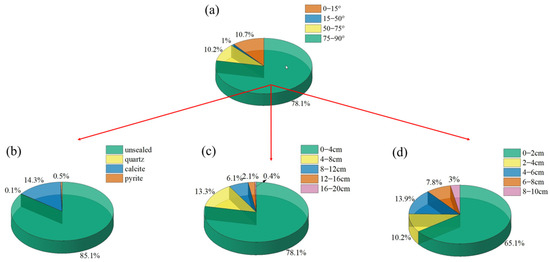

Core fracture observation is an intuitive method to analyze the development characteristics and rules of underground reservoir fractures [19,20,21,22,23]. The fine description of the fractures in the cores of the Wufeng–Longmaxi Formation in the Luzhou Block reveals that three types of fractures are mainly developed in the study area: tensile fractures, shear fractures, and bedding fractures. Among them, shear fractures are fractures formed by shear rupture under the action of tectonic stress, which are generally stable in occurrence and flat in fracture surface (Figure 4a–c). Bed-parallel slip fracture is a kind of shear fracture, and the fracture is nearly the same as the rock formation, with a smooth and flat surface, often accompanied by obvious scratches and step characteristics [24,25] (Figure 4f). Tensile fracture is a kind of fracture type formed by relative expansion along the minimum principal stress of shale under tectonic extrusion stress. This kind of fracture has short extension and is mostly filled by minerals in the later stage [26,27] (Figure 4e). Bedding fractures are mainly low-angle or near-horizontal fractures. After being removed from the underground to the surface, some cores open along the bedding plane, and some are filled with calcite and pyrite (Figure 4d,e). Natural fractures are divided into four categories based on the dip angle differences: horizontal fractures (0–15°), low-angle fractures (15–45°), high-angle fractures (45–75°), and vertical fractures (75–90°) [4]. The statistical results of underground core fractures show that the fractures in the study area are mainly vertical fractures, accounting for 78.1% of all observed fractures. Among the vertical fractures, 85.1% of the fractures are unfilled fractures, and the longitudinal extension is short, and the fracture opening between 1 and 2 cm accounts for 65.1% (Figure 5).

Figure 4.

Photos of natural fractures. (a) High dip-angle shear fractures with no filling; (b) high dip-angle shear fractures with no filling; (c) vertical fractures with no filling; (d) bedding fractures filled with calcite or pyrite [4]; (e) bedding fractures and tensile fractures filled with calcite; (f) bed-parallel slip fracture with scratches.

Figure 5.

Fracture occurrence observed in the cores [4]. (a) Dip-angle. (b–d) are fracture filling, longitudinal extension, and fracture spacing, respectively.

3.2. Fracture Characteristics of Image Logs

Compared with core analysis, electrical imaging logging can identify fractures in the entire target interval [28]. The main basis for imaging logging to identify fractures is based on the difference in resistivity between the fracture development site and the surrounding rock. This difference is represented by chromaticity light/dark features of the graduated image (bright colors for high resistivity, dark colors for low resistivity), which can be used to identify lithology, bedding, fractures, and other geological phenomena near the borehole wall [29]. In the process of drilling, the resistivity of unfilled fractures is significantly lower than that of the surrounding rocks due to mud intrusion. The imaging logging image shows a continuous or semi-closed dark sinusoid curve. However, fractures filled with minerals result in higher resistivity than that of the surrounding rock, which shows continuous or semi-closed bright sine wave curves on the imaging logging images [30,31].

Based on the fracture identification criteria, the fractures of the two wells in the study area were identified and statistically analyzed. It was found that low-angle fractures (51.79%) and high-angle fractures (44.64%) were mainly developed in the study area, and they were mainly unfilled (Figure 6) and the strike of fractures was mainly NE-SW and ~E-W (Figure 7). There is a difference between the statistical results of imaging logging fractures and core fractures. The core fractures are mainly densely developed vertical fractures, followed by high-angle fractures and low-angle fractures, while the imaging logging fractures are mainly high-angle fractures and low-angle fractures, and the vertical fractures are not developed. This is mainly due to the large number of fractures observed in the core with vertical development and small longitudinal extension (Figure 6c). Such fractures, as a main fracture type, cannot be identified in the electrical imaging logging, causing the statistical differences.

Figure 6.

Photos of the image log. (a,b) Image log of well L2. (c,d) Image log of well Y7. (Red lines for high resistivity fractures, green lines for low resistivity fractures).

Figure 7.

Fracture occurrence in the Longmaxi Formation of the Luzhou Block. (a,c) Fracture occurrence of well L2. (b,d) Fracture occurrence of well Y7.

3.3. Prediction Results of Fracture Development

The accurate identification of natural fractures in deep shale reservoirs serves as the cornerstone for optimizing drilling programs and evaluating wellbore stability. Although preliminary observations based on core and electrical imaging logs have provided direct evidence for fracture identification, their application is constrained by cost and availability. To overcome this limitation and achieve a comprehensive evaluation of the study area, utilizing conventional logging data (AC, DEN, GR, and RT)—which are extensively acquired in existing wells—for fracture prediction has become a necessary and feasible supplement and extension. The Rescaled Range Analysis (R/S) method, grounded in fractal theory, provides a powerful tool to address this challenge.

The R/S analysis method is a nonlinear statistical method, which was first used by Hurst to study the year-to-year variation in the Nile’s water [32]. The R/S analysis method was initially formulated by Hurst (1951) and has been subsequently validated as an effective technique for analyzing one-dimensional fractal variables. Its core principle lies in utilizing the ratio of the range (R) to the standard deviation (S) of a data series to unveil its inherent patterns and self-similarity [16,33,34]. The fundamental premise for its application here is that fracture development markedly enhances the vertical heterogeneity of a reservoir. This increased heterogeneity causes conventional logging curves (e.g., AC, DEN, GR, and RT) to exhibit more complex fluctuations across fractured intervals. R/S analysis quantitatively captures this complexity and has been successfully applied in fracture prediction for oil and gas reservoirs [35]. Building upon and extending this methodology, our study selects four conventional logging parameters—AC, DEN, GR, and RT, which are sensitive to fracture responses—as one-dimensional time series for R/S analysis. In Equations (1)–(3), is the one-dimensional time series, , ; n is the total number of sampling points of conventional logging data in the analyzed zone; is the sampling number increasing from 0 to n; is the extreme difference, which is the difference between the maximum cumulative deviation and the minimum cumulative deviation, and represents the complexity of the time series; is the standard deviation, and represents the average trend of the time series; represents the relative fluctuation intensity of dimensionless time series.

Taking the logarithm of both sides of Equation (3), we can obtain:

where H is the Hurst exponent; a is a constant; D = 2 − H, D is the fractal dimension, which reflects the complexity of Z(t) in one-dimensional space [36,37,38]. If and have an obvious double log-linear relationship, then the reservoir parameter sequence has the fractal character of self-scaling similarity.

In this study, AC, DEN, GR, and RT were selected as the target formation logging parameters for fracture identification. As shown in Figure 8, the four selected logging parameters have obvious fractal characteristics, and the Pearson correlation coefficients are 0.953, 0.9011, 0.9592, and 0.9351, respectively. As abovementioned, parameter D can reflect the complexity of the logging sequence with depth (i.e., the vertical heterogeneity of the reservoir). In the fractured section, the reservoir heterogeneity becomes stronger, the D value increases (i.e., the H value decreases), and the slope of the curve decreases, so the fractures can be identified by distinguishing the concave and convex shapes of the curve. Although this method is more intuitive, it is mainly obtained through observation, and inevitably, there will be omissions. Here, we further adopt the FDM to quadratically derive the curve and numerically transform the curve change trend, which greatly improves the recognition efficiency. Before the derivation, the parameters need to be normalized so that each parameter is in the range of 0–1 and is dimensionless to facilitate the subsequent uniform comparison. The formula is as follows:

Figure 8.

Double log curve of R/S and n for Well Y7. (a) Sonic jet lag; (b) density; (c) Natural gamma; (d) Resistivity.

After normalizing the parameters, the obtained parameters are differentiated twice, as shown in Equations (6) and (7):

When the step size is 1, Equation (7) becomes Equation (8):

Here, the K value corresponds to the second derivative of . The concave and convex parts of the curve can be distinguished by the K value, where the convex part corresponds to a K value less than 0, which is defined as 0 here, and the concave part is greater than 0, which corresponds to the fracture development part. As shown in Figure 9, it can be seen that the positive value of K corresponds to the concave part of the curve, verifying the reliability of the studied method. In this study, each curve can represent the degree of fracture development. However, each curve has a different sensitivity to fractures, and the entropy weight method is used here to calculate the weights of the four conventional logging curves. The formula is as follows:

where is the redundancy, is the information entropy, and is the weight value. The natural fracture development factor Q is derived based on four sets of conventional logging data (AC, DEN, GR, and RT), as shown in Equation (14):

where Q is the fracture development index.

Figure 9.

Comparison between the K value and slope of the lg(R/S) curve. (a) Sonic jet lag; (b) density; (c) Natural gamma; (d) Resistivity.

In this study, four sets of one-dimensional time series parameters (AC, DEN, RT, and GR) were selected for R/S analysis, and then the fracture prediction results were compared and analyzed based on the imaging logging and core observation data. As shown in Figure 10, the imaging log results of well Y7 show that the fractures are mainly developed in four sections, 4115–4119 m, 4121–4123.5 m, 4127–4131.5 m, and 4136–4140 m, and are mainly bedding fractures. The R/S prediction results show that eight fracture development zones (defined as Q > 0.2 for fracture development) mainly exist in well Y7. In the Well L2 (Figure 11), the imaging logging results show that there are four fracture development sections: high-angle shear fractures are mainly developed in 4288–4296 m and 4203–4310 m, and bedding fractures are mainly developed in 4299–4301 m and 4313–4317 m. The prediction results also show that four fracture development sections appear in the Well L2. In general, the visual observation results are consistent with the logging identification results based on R/S.

Figure 10.

Comparison of fracture development sections and parameter Q in Longmaxi shale of the Well Y7 (the red box represents the predicted fracture development segment, the imaging logging image shows bias in fracture occurrence due to longitudinal compression).

Figure 11.

Comparison of fracture development sections and parameter Q in Longmaxi shale of the Well L2 (the red box represents the predicted fracture development segment, the imaging logging image shows bias in fracture occurrence due to longitudinal compression).

To further confirm the reliability of the R/S analysis method, the correlation analysis between parameter Q and fracture linear density was carried out (Table 1). It was found that the linear correlation coefficient () between Q value and fracture linear density interpreted by imaging logging reached 80.84% after removing abnormal points (Figure 12). The outliers are found in section 4121–4123.5 of well Y7 and section 4299–4301 of well L2, both of which are densely developed with bedding fractures, while the other sections are developed with high-angle and low-angle fractures, indicating the limitations of this method for horizontal fracture identification [35].

Table 1.

Fracture density and Q of well Y7 and well L2.

Figure 12.

Correlation between Q and the fracture linear density (red dots represent outliers).

There are still some errors in the identification of reservoir fractures using the R/S analysis method, and there is a mismatch between the parameter Q and the fracture line density interpreted by imaging logging in some sections. As mentioned above, in the 4121–4123.5 m section of well Y7 and the 4299–4301 m section of well L2, imaging logging explained that multiple bedding fractures are developed in this section, but the Q value is relatively small. In addition, in the 4302–4311 m interval in Figure 10, imaging logging explained the development of multiple high-angle fractures, but the corresponding Q-value response is not obvious. In view of these mismatches, the reasons are analyzed, which are mainly divided into the following aspects: (i) The basic principle of the R/S method for identifying fractures is based on the longitudinal heterogeneity of reservoirs. The reason for the enhancement of reservoir heterogeneity is not only fracture development, but also influenced by lithology and the intensity of structural deformation. Therefore, the variation in reservoir heterogeneity caused by some non-fracture factors will increase the Q value. (ii) The occurrence of fractures also affects their response to the Q value. Since sound waves travel along the shortest time path, low-angle fractures have a greater impact on the acoustic time difference, while medium- and high-angle fractures have a smaller impact on the acoustic time difference, and vertical fractures have almost no effect. In addition, the filling characteristics of fractures can also affect the interpretation results. Some fully filled fractures do not respond to conventional logging. For unfilled or partially filled fractures, the response will be weakened due to drilling mud intrusion. (iii) The fracture information obtained by intuitive means (imaging, logging, and core observation) is scarce and only limited to the diameter of the borehole. However, the detection range of conventional logging is larger in the underground monitoring process, so some fractures that cannot be observed by intuitive means can be detected by conventional logging. (iv) The calculation of fracture density in this paper is based on the results of imaging logging interpretation, which has limitations and poor ability to identify the densely developed jointed fractures mentioned above, but these fractures will generate responses on conventional logging curves, resulting in a mismatch between the two methods.

3.4. Analysis of Fracture Stress and Activity

The formation of fractures or faults is the result of underground rock rupture. The fracture process is rather complex and is a comprehensive manifestation of the relationship between all the stresses acting on the rock and the rock’s own strength. This process of action can be described by the normal stress and shear stress on the rock on the fracture surface. When most rocks are subjected to stress, the normal stress and shear stress on their fracture surfaces satisfy the Mohr–Coulomb criterion.

When fractures are formed under the stress of the rock, the cohesive force on the fracture surface is relatively small. At this time, the characteristics of the fractures are controlled by the effective normal stress and shear stress on the fracture surface, and the effectiveness of the fractures is reflected in the friction coefficient:

The friction coefficient reflects the possible state of fractures on the surface and directly controls the changes in primary fractures. Therefore, the effectiveness of fractures can be intuitively judged through the friction coefficient.

The Mohr circle is a commonly used tool for analyzing the stress state of fracture surfaces. Given the magnitude of the stress on the rock, the orientation of the 3D fracture determines its position on the Mohr circle and the stress state it resides in.

The principal stresses in the three orthogonal directions in space are denoted as , , and , respectively. The pore pressure is denoted as , and the effective principal stress of the rock is denoted as

In the effective principal stress coordinate system, as shown in Figure 13a, the magnitudes of the normal stress and shear stress on the fracture surface can be calculated by combining the fracture dip angle and azimuth angle , as shown in Figure 13b.

Figure 13.

Stress analysis on the seam surface under a triaxial stress state.

The normal unit vector of the fracture surface is as follows:

By projecting the effective principal stress tensor (which is a diagonal matrix) onto the normal direction of the fracture, the stress vector on the fracture surface can be obtained.

By projecting onto the normal direction of the fracture, the normal stress on the fracture surface can be obtained as follows:

Correspondingly, the shear stress on the fracture surface is as follows:

When the working fluid is injected into the reservoir, the fracture will undergo displacement in both opening and shearing directions under the action of external fluid.

In order to evaluate the fracture activity of the L2 well, a stress characteristic profile based on shale characteristics was established using logging data and the TIV model, as shown in Figure 14.

Figure 14.

Comprehensive histogram and geostress results for L2 well logging.

The results in Figure 14 show that the Luzhou block as a whole exhibits a strike slip stress mechanism, and the activation pressure of fractures with different angles shows significant differences in the longitudinal direction due to the influence of stress differences. The fracture activation pressure at different approximation angles shows an overall trend of 90° > 60° > 30° in the longitudinal direction. However, at a depth of 4308 m, the activation pressure at a fault approach angle of 30° is similar to the result at 60°, and the same feature appears in the Wufeng formation. This indicates that once the injection pressure reaches the activation strength in the Wufeng formation, the fractures are activated, and the distribution range of activated fracture characteristics is wider and relatively more numerous, resulting in a more complex distribution of activated fractures.

A fracture activity evaluation chart is established based on the reservoir fracture characteristics interpreted by imaging logging, and the basic geological parameters used are shown in Table 2. Due to varying degrees of fracture cementing or filling in the reservoir, two states—fully open and fully filled—are defined as boundary conditions for in-depth analysis. Through experimental measurements, the tensile mechanical strength of the shale matrix is determined to be 12 MPa, while the mechanical strength of cemented shale is 1/4 of the matrix strength. These mechanical parameters are then substituted into the Mohr-Coulomb criterion to evaluate fracture activity; other parameters within the reservoir are shown in Table 1, and the results are shown in Figure 15.

Table 2.

Geological parameters of Well L2.

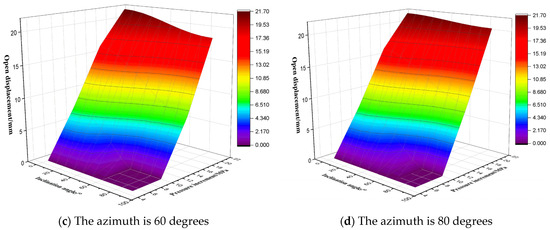

Figure 15.

Lower Hemisphere stereoscopic network diagram of fracture activation distribution results under different net pressure for fractures of different handover types.

When the drill bit breaks the rock to form the wellbore, a small amount of the liquid column pressure in the wellbore will invade the formation, causing an increase in the pore pressure near the wellbore, which will have a significant impact on the opening of the fractures around the wellbore. Even a small amount of water in the oil-based drilling fluid, after activating the seepage channels of the fractures and invading deeper formations, can cause wellbore collapse accidents. As shown in Figure 15, all fractures are in a stable state under the in situ stress condition. When the fluid pressure around the wellbore increases by 15 MPa, the fully filled fractures remain stable, and none of the current fractures are activated; however, about 50% of the open fractures become unstable and activated, significantly increasing the risk of wellbore instability. When the fluid pressure around the wellbore increases by 20 MPa, approximately 50% of the fully filled fractures become unstable and activated, while about 90% of the open fractures become unstable and activated. In addition, from the perspective of inclination distribution, compared to low-angle fractures and horizontal fractures, high-angle seams and vertical fractures have better activity. And from the characteristics of the fracture direction, the distribution pattern of its activity is significantly affected by the direction of stress. The larger the angle between the fracture direction and the horizontal maximum principal stress direction, the worse the activity. The fracture directions with better activity are concentrated in the ENE-WSW and WNW-ESE directions, which are approximately parallel to the horizontal maximum principal stress direction. Overall, the activity gradually decreases from WNW-ESE to NNE-SSW.

This indicates that under a fixed in situ stress state, both the fracture filling type and the increment of pore fluid pressure have significant influences on the activity of fractures around the wellbore and the risk of wellbore instability.

3.5. Evaluation of Displacement of the Activated Fractures

For the stress state of reservoir fractures, according to the complex variable function [39], the Westergaard stress function (Figure 16) for I + II composite superimposed fractures is as follows:

Figure 16.

Plane strain model of I+II composite superimposed fracture.

Based on the fracture displacement calculation method derived by Muskhelishvili et al., the I + II composite superimposed fracture displacement field can be expressed as follows:

Then, the relative displacement of the I + II composite superimposed fracture can be obtained as follows:

In order to further analyze the drilling fluid loss rate under different fracture orientations, a numerical model of fractured boreholes was constructed using the finite element platform COMSOL 6.3. The evaluation of fracture-induced fluid loss under in situ stress conditions was conducted. By incorporating the calculated results of opening displacements under various activated fractures into the finite element model (Figure 17), a study on predicting fluid loss was carried out.

Figure 17.

Results of fracture opening displacement under different orientations. (figures a, b, c, and d represent the imaging logging results, wellbore fracture morphology extraction results, fracture attitude measurement methods, and fracture wellbore finite element model, respectively).

To address the fluid properties and rheology for the COMSOL simulations, the parameters of the KCl polymer drilling fluid used in the model are defined in Table 3. Additionally, key geological parameters governing the fracture behavior and fluid flow are summarized in Table 4.

Table 3.

Basic parameters of the KCl polymer drilling fluid in the COMSOL model.

Table 4.

Basic geological parameters.

The drilling fluid leakage risk mapping was carried out using the COMSOL platform. In the calculation model, the maximum size of the mesh size was 0.05 m and the minimum mesh size was 0.01 m, and the cell grids were divided into free tetrahedral grids. The time step is 0.02 min, the relative tolerance is set to 0.002, and a transient solver is used for iterative operation. The results are shown in Figure 18, Figure 19, Figure 20, Figure 21 and Figure 22.

3.6. Discussion

Shale is a composite formation formed by sedimentation and tectonic processes. The early tectonic movement compressed rocks and formed structural fractures with different morphological characteristics. When drilling into such shale formations, many fractures are activated and opened due to the imbalance of the wellbore fluid column pressure, leading to serious drilling fluid leakage accidents, wellbore collapse, and shale strength deterioration in deep formations. The method for evaluating the activation and opening deformation of cracks quantitatively analyzed the leakage risk of cracks with different dip angles under the characteristics of geostress and geological parameters in the study area, revealing the critical value for the transition of cracks from high-risk dip angles to low-risk dip angles. In addition, this article proposes an integrated evaluation method for fracture prediction, fracture modeling, fracture activation evaluation, fracture stress and deformation analysis, and fracture leakage risk assessment. This systematic method can provide theoretical guidance for predicting the risk of drilling fluid leakage and provide guidance for subsequent drilling optimization.

However, in the actual drilling process, there is a scientific problem of fluid structure coupling and iterative deformation between the wellbore fluid column pressure and the fracture rock system. Although this article uses fixed parameters to reveal the leakage risk of fractures with different inclinations to a certain extent, it cannot capture the dynamic evolution process under the wellbore–fractures–rock coupling system. Therefore, building a fluid–solid coupling near wellbore simulation system is the future key research work, which has important research value for more precise prediction of drilling fluid leakage.

4. Results

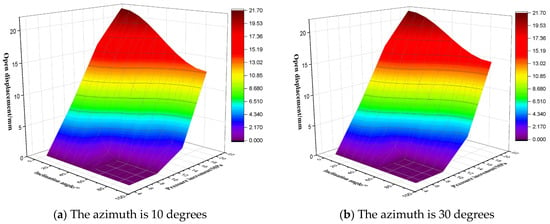

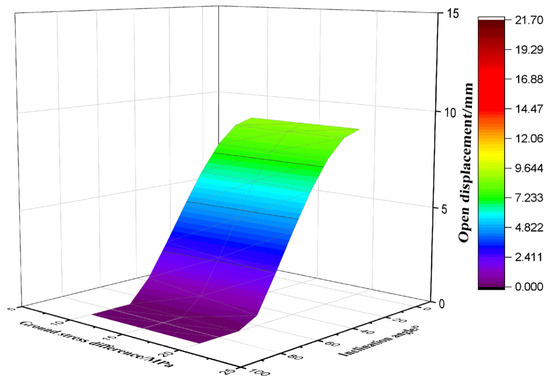

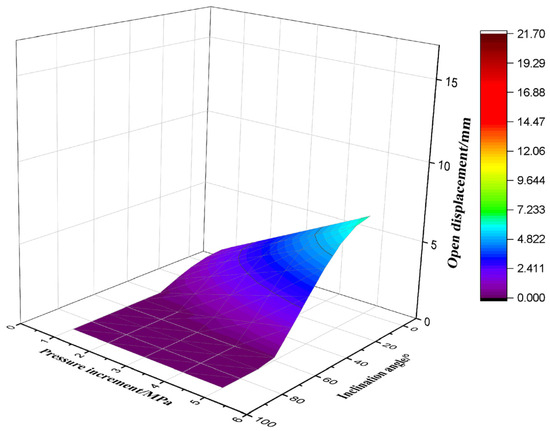

The change in the opening of all fractures varies with the change in fluid pressure inside the fractures. And the normal stress varies with the change in fracture inclination angle and azimuth angle, which has a significant impact on the fracture opening. Then, the influence of pressure increment, fracture inclination angle, and azimuth angle on fracture opening is analyzed by using the parameters in Table 2, and the calculated fracture opening displacement results are as follows.

According to Figure 18, it can be concluded that when the study block is in a strike-slip stress state, as the wellbore liquid column pressure increases, that is, the net pressure of the injected fluid increases, the opening displacement of the activated fractures shows an increasing trend. When the azimuth angle is small, as the dip angle increases, the opening displacement of the fractures shows a decreasing trend. By comparing the four subgraphs, it can be seen that as the strike angle increases, the difference in opening displacement caused by the fracture dip angle gradually decreases. That is, under a larger strike angle, the opening displacement of the fractures is almost not affected by the dip angle. This result, to some extent, reveals the leakage risk degree of different fractures in the wellbore and has guiding significance for optimizing drilling operations.

Figure 18.

Results of fracture opening displacement under different orientations.

With a constant net pressure of 15 MPa as the inlet condition in the wellbore and fixed boundary constraints on the outer surface, an analysis was conducted using super-hydrostatic pressure. The geometric dimensions of the model are 10 m × 10 m × 10 m, and the wellbore penetrates a circular fracture with a radius of 4 m. In this scenario, the formation and outer surface pressures were set at 0 MPa. By using the volume percentage of drilling fluid as a reference and analyzing the fracture azimuth at 10°, the percentage of drilling fluid within a single fracture in the wellbore wall was obtained.

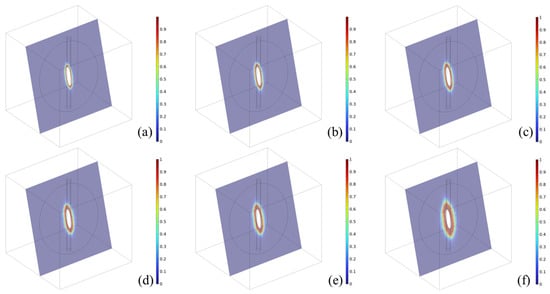

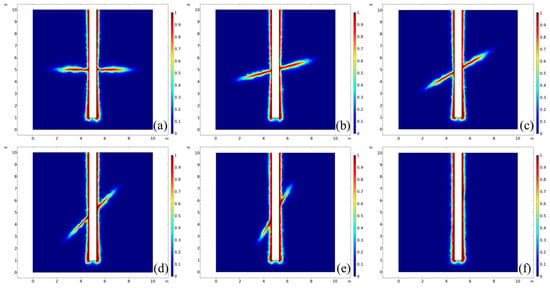

Figure 19, Figure 20 and Figure 21 show the simulation results of the proportion of drilling fluid leakage in wellbore fractures with a fracture inclination of 0°, including the longitudinal section, fracture plane, and invasion front, respectively. Figure 22 and Figure 23 show the calculation results at a 75° fracture inclination angle for the longitudinal section and fracture plane, respectively.

Figure 19.

The invasion front of drilling fluid at different times in the longitudinal section with a 0° dip fracture (figures a, b, c, d, e, and f represent the injection time of 1, 2, 3, 4, 5, and 10 min, respectively).

Figure 20.

The invasion front of drilling fluid at different times in the fracture plane section with a 0° dip fracture (figures a, b, c, d, e, and f represent the injection time of 1, 2, 3, 4, 5, and 10 min, respectively).

Figure 21.

Results curves of drilling fluid intrusion radius position for the 0° fractured model.

Figure 22.

Longitudinal profile results of drilling fluid leakage at different times with a 75° dip fracture (figures a, b, c, d, e, and f represent the injection time of 1, 2, 3, 4, 5, and 10 min, respectively).

Figure 23.

Distribution results of the leading edge of drilling fluid leakage on the fracture surface at different times with a 75° dip fracture (figures a, b, c, d, e, and f represent the injection time of 1, 2, 3, 4, 5, and 10 min, respectively).

According to Figure 21, it can be seen that in the 0° angle fractured formation, the invasion rate of drilling fluid shows a uniform trend, and the invasion front exhibits a linear variation characteristic with time.

According to Figure 22 and Figure 23, it can be seen that in the wellbore model with a fracture angle of 75°, there is no significant invasion depth on either the fracture surface or the wellbore.

As can be seen from Figure 24 and Figure 25, comparing the results of drilling fluid leakage at the front position of 0° to 75° fractures, it can be seen that under the same boundary parameters, the leakage rate and risk of horizontal fractures are significantly higher than those of high-angle fractures. This provides a basic understanding for identifying and preventing drilling risk accidents.

Figure 24.

Longitudinal sectional results of drilling fluid leakage at different fracture dip angles with 10 min injection time (figures a, b, c, d, e, and f represent the fracture dip angle of 0°, 15°, 30°, 45°, 60°, and 75°, respectively).

Figure 25.

Distribution results of drilling fluid leakage leading edge on the fracture surface at different fracture dip angles with 10 min injection time (figures a, b, c, d, e, and f represent the fracture dip angle of 0°, 15°, 30°, 45°, 60°, and 75°, respectively).

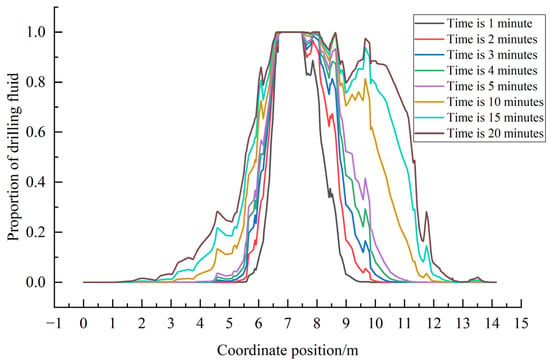

According to the results in Figure 26, it can be seen that under the same boundary conditions and invasion time, as the inclination angle of the fracture increases, the invasion depth of the fracture exhibits a nonlinear decreasing characteristic. Among them, the 60° angle fracture is a significant boundary, and the calculation results show that the 75° angle has the lowest risk of drilling fluid leakage.

Figure 26.

Results curves of drilling fluid intrusion radius position for different fractured models at 5 min.

As shown in Figure 27, Figure 28, Figure 29 and Figure 30, with the fixed wellbore fluid column pressure remaining constant, and within the range of in situ stress and rock mechanics parameters in the research block, by changing these parameters (σHmax, σhmin, σv, μ, E, and ν), the overall fracture opening is still divided at a 60° angle. Beyond 60°, the fracture becomes difficult to open, and the risk of drilling fluid loss decreases. Only by considering the influence of different pore pressures, that is, when the net pressure in the fracture is less than 5 MPa, the critical value of the fracture dip angle decreases to 40°.

Figure 27.

Fracture opening displacement under different elastic modulus of rocks.

Figure 28.

Fracture opening displacement under different Poisson’s ratios of rocks.

Figure 29.

Fracture opening displacement under different horizontal principal stress differences.

Figure 30.

Fracture opening displacement under different pore pressures.

According to Figure 31 and Figure 32, it can be seen that in complex fractured formations, the leading edge of drilling fluid leakage exhibits dynamic changes over time, that is, the deeper the fracture penetrates from the wellbore to the formation, and the better the connectivity of deep formation fractures, the faster the change in the leading edge of leakage, and the deeper the invasion into the formation.

Figure 31.

The invasion front of drilling fluid at different times in the longitudinal section (figures a, b, c, and d represent the injection time of 1, 5, 10, and 20 min, respectively).

Figure 32.

Results curves of drilling fluid intrusion radius position for different times.

5. Conclusions

In this study, based on imaging logging and core observation data, further combined with the R/S analysis method and FDM, the deep shale fractures in the Luzhou Block were identified and predicted. Furthermore, the force analysis, activation risk, and opening displacement of 3D fractures under the increase in internal hydraulic pressure were obtained, and the degree of leakage risk of the fractured wellbore was evaluated accordingly. This study has established an integrated evaluation methodology that effectively links “log responses, fracture prediction and characterization, and leakage risks.” This methodology provides practical guidance for preventing and controlling drilling fluid loss and for optimizing drilling operations in fractured deep shale reservoirs. And the following conclusions can be drawn:

- (1)

- The observation results of the core of Longmaxi Formation in the Luzhou Block show that a large number of vertical fractures are developed in this area, with short longitudinal extension and small opening, accounting for 78.1%. Due to the limited accuracy of imaging logging identification, this type of fracture cannot be accurately identified. The fractures are mainly characterized by high-angle fractures (51.79%) and low-angle fractures (44.64%), and most of them are unfilled, and the fracture strike is mainly NE-SW and ~E-W. This characterization offers a geological basis for understanding the potential pathways for drilling fluid invasion in the Luzhou Block.

- (2)

- The R/S analysis method mainly determines the fracture development location by detecting the mutation points on conventional logging curves, and further obtains the fracture development index Q by combining the FDM and entropy weight method. The results show that the value of this parameter ranges from 0 to 0.6 in the Longmaxi Formation. The linear relationship between parameter Q and fracture linear density is obvious, and the correlation coefficient can reach 80.84%, indicating that the fracture development index can represent the degree of fracture development. This method provides a cost-effective alternative for preliminary fracture identification when image logs are unavailable.

- (3)

- In the Fuji syncline, two groups of natural fractures dominate: Set A (~NE-SW trending) and Set B (~NW-SE trending), and NW-SE direction is the dominant fracture orientation, When drilling or fracturing, pore pressure increment larger than 15–20 MPa is easy to maintain a high natural fracture opening ratio of the reservoir, which is conducive to shale gas production and efficiency while the unfavorable to lead to the risk incident of drilling fluid loss and wellbore collapse. This pressure window serves as a critical reference for managing bottomhole pressure to balance productivity and safety.

- (4)

- Based on the results of imaging logging, the error analysis of the R/S fracture identification results is carried out. It is concluded that the reasons for the mismatch of R/S fracture identification results mainly lie in the longitudinal heterogeneity of the reservoir, the occurrence of fractures, and the interpretation accuracy of identification methods. However, the R/S method is still a convenient and effective way to identify the degree of reservoir fracture development, because the conventional logging parameters are easy to obtain and have strong continuity, and the entropy weight method can combine multiple logging parameters to comprehensively analyze and predict reservoir fractures. Therefore, it presents a practical and cost-efficient approach for preliminary fracture evaluation in areas with limited data availability.

- (5)

- The activity of fractures varies with the occurrence of fractures and the degree of cementation. With the parameters of research block geostress, the degree of cementation, north–south fractures, and fracture angle between 30°~45° have poorer fracture activity and are more stable. These results establish a foundational understanding for evaluating the geomechanical stability of fractured shale reservoirs.

- (6)

- Under the action of increasing geostress and fluid pressure inside the fracture, the displacement of fracture opening varies with the dip angle and fracture azimuth, resulting in significant differences in the rate and degree of drilling fluid leakage. The risk of high-angle fracture leakage is in the low value zone. This understanding is crucial for informing the strategic design of drilling fluid systems in complex fractured formations.

Author Contributions

Writing—original draft preparation, C.W. and Z.L.; writing—review and editing, S.L.; validation, Y.X. and Z.T.; data curation, X.Z. and H.C.; visualization, Z.L. and Z.T. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge the support provided by the National Key Research and Development Program of China: Research and Application of Key Technologies for High-Precision Measurement of Reservoir Geological Parameters (No. 2023YFF0615402).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Chunhua Wang, Yunlong Xu and Xiaoqing Zheng were employed by the company Daqing Oilfield Drilling Engineering Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Shen, W.; Ma, T.; Li, X.; Sun, B.; Hu, Y.; Xu, J. Fully coupled modeling of two-phase fluid flow and geomechanics in ultra-deep natural gas reservoirs. Phys. Fluids 2022, 34, 43101. [Google Scholar] [CrossRef]

- Zhang, J.; Tao, J.; Li, Z.; Wang, X.; Li, X.; Jiang, S.; Wang, D.; Zhao, X. Prospect of deep shale gas resources in China. Nat. Gas Ind. 2021, 41, 15–28. [Google Scholar]

- Ma, X.; Wang, H.; Zhou, S.; Shi, Z.; Zhang, L. Deep shale gas in China: Geological characteristics and development strategies. Energy Rep. 2021, 7, 1903–1914. [Google Scholar] [CrossRef]

- Han, L.; Li, X.; Guo, W.; Ju, W.; Cui, Y.; Liu, Z.; Qian, C.; Shen, W. Characteristics and Dominant Factors for Natural Fractures in Deep Shale Gas Reservoirs: A Case Study of the Wufeng-Longmaxi Formations in Luzhou Block, Southern China. Lithosphere 2022, 2022, 9662175. [Google Scholar] [CrossRef]

- Liu, Z.; Pan, Z.; Li, S.; Zhang, L.; Wang, F.; Han, L.; Zhang, J.; Ma, Y.; Li, H.; Li, W. Study on the effect of cemented natural fractures on hydraulic fracture propagation in volcanic reservoirs. Energy 2022, 241, 122845. [Google Scholar] [CrossRef]

- Wang, L.; Dong, Y.; Zhang, Q.; Duan, R. Numerical simulation of pressure evolution and migration of hydraulic fracturing fluids in the shale gas reservoirs of Sichuan Basin, China. J. Hydrol. 2020, 588, 125082. [Google Scholar] [CrossRef]

- Mohammed, A.I.; Oyeneyin, B.; Bartlett, M.; Njuguna, J. Prediction of casing critical buckling during shale gas hydraulic fracturing. J. Pet. Sci. Eng. 2020, 185, 106655. [Google Scholar] [CrossRef]

- Zeng, L.; Lyu, W.; Li, J.; Zhu, L.; Weng, J.; Yue, F.; Zu, K. Natural fractures and their influence on shale gas enrichment in Sichuan Basin, China. J. Nat. Gas Sci. Eng. 2016, 30, 1–9. [Google Scholar] [CrossRef]

- Ding, W.; Li, C.; Li, C.; Xu, C.; Jiu, K.; Zeng, W.; Wu, L. Fracture development in shale and its relationship to gas accumulation. Geosci. Front. 2012, 3, 97–105. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, W.; Hu, Q.; Zhai, G.; Wang, R.; Xu, X.; Meng, F.; Liu, Y.; Bai, L. Developmental characteristics and controlling factors of natural fractures in the lower paleozoic marine shales of the upper Yangtze Platform, southern China. J. Nat. Gas Sci. Eng. 2020, 76, 103191. [Google Scholar] [CrossRef]

- He, Z.; Nie, H.; Zhang, Y. The main factors of shale gas enrichment of Ordovician Wufeng Formation-Silurian Longmaxi Formation in the Sichuan Basin and its adjacent areas. Earth Sci. Front. 2016, 23, 8–17. [Google Scholar]

- Li, X.; Yang, H.; Wei, Y.; Feng, Y.; Yang, H.; Yan, W.; Fu, L. Wellbore instability in naturally fractured formations: Experimental study and 3D numerical investigation. Gas Sci. Eng. 2024, 124, 205265. [Google Scholar] [CrossRef]

- Wang, W.; Schmitt, D.; Li, W. A program to forward model the failure pattern around the wellbore inelastic and strength anisotropic rock formations. Int. J. Rock Mech. Min. Sci. 2022, 151, 105035. [Google Scholar]

- Liu, J.; Ding, W.; Xiao, Z.; Dai, J. Advances in comprehensive characterization and prediction of reservoir fractures. Prog. Geophys. 2019, 34, 2283–2300. [Google Scholar]

- Xu, H.; Ju, W.; Niu, X.; Feng, S.; You, Y.; Yang, H.; Liu, S.; Luan, W. Prediction of natural fracture in shale oil reservoir based on R/S analysis and conventional logs. Front. Earth Sci. 2021, 15, 705–718. [Google Scholar] [CrossRef]

- Zhang, H.; Ju, W.; Yin, G.; Liu, X.; Wang, Z.; Liu, J.; Wang, K.; Yang, H.; Xu, K.; Luan, W. Natural fracture prediction in Keshen 2 ultra-deep tight gas reservoir based on R/S analysis, Kuqa Depression, Tarim Basin. Geosci. J. 2021, 25, 525–536. [Google Scholar]

- Yang, H.; Zhao, S.; Liu, Y.; Wu, W.; Xia, Z.; Wu, T.; Luo, C.; Fan, T.; Yu, L. Main controlling factors of enrichment and high-yield of deep shale gas in the Luzhou Block, southern Sichuan Basin. Nat. Gas Ind. 2019, 39, 55–63. [Google Scholar]

- Jiang, Z.; Liang, Z.; Shen, Y.; Tang, X.; Wu, W.; Li, Z.; Xue, Z.; Shi, X.; Guo, J. Coupling key factors of shale gas sweet spot and research direction of Geology-engineering integration in southern Sichuan. Earth Sci. 2022, 48, 110–129. [Google Scholar]

- Gu, Y.; Ding, W.; Tian, Q.; Xu, S.; Zhang, W.; Zhang, B.; Jiao, B. Developmental characteristics and dominant factors of natural fractures in lower Silurian marine organic-rich shale reservoirs: A case study of the Longmaxi formation in the Fenggang block, southern China. J. Pet. Sci. Eng. 2020, 192, 107277. [Google Scholar] [CrossRef]

- Ju, W.; Sun, W. Tectonic fractures in the Lower Cretaceous Xiagou Formation of Qingxi Oilfield, Jiuxi Basin, NW China Part one: Characteristics and controlling factors. J. Pet. Sci. Eng. 2016, 146, 617–625. [Google Scholar] [CrossRef]

- Wang, R.; Ding, W.; Zhang, Y.; Wang, Z.; Wang, X.; He, J.; Zeng, W.; Dai, P. Analysis of developmental characteristics and dominant factors of fractures in Lower Cambrian marine shale reservoirs: A case study of Niutitang formation in Cen’gong block, southern China. J. Pet. Sci. Eng. 2016, 138, 31–49. [Google Scholar] [CrossRef]

- Zhao, G.; Ding, W.; Sun, Y.; Wang, X.; Tian, L.; Liu, J.; Shi, S.; Jiao, B.; Cui, L. Fracture development characteristics and controlling factors for reservoirs in the Lower Silurian Longmaxi Formation marine shale of the Sangzhi block, Hunan Province, China. J. Pet. Sci. Eng. 2020, 184, 106470. [Google Scholar] [CrossRef]

- Zeng, L.; Li, X. Fractures in sandstone reservoirs with ultra-low permeability: A case study of the Upper Triassic Yanchang Formation in the Ordos Basin, China. AAPG Bull. 2009, 93, 461–477. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, F.; Yang, H.; Li, Z.; Liu, L.; Chen, L.; Du, Z. Development characteristics of fractures in Jurassic tight reservoir in Dibei area of Kuqa depression and its reservoir-controlling mode. Acta Pet. Sin. 2015, 36, 102–111. [Google Scholar]

- Wu, J.; Zhao, S.; Fan, C.; Xia, Z.; Ji, C.; Zhang, C.; Cao, L. Fracture characteristics of the Longmaxi Formation shale and its relationship with gas-bearing properties in Changning area, southern Sichuan. Acta Pet. Sin. 2021, 42, 428–446. [Google Scholar]

- Zhu, L.; Weng, J.; Lyu, W. The significance and characteristics of natural fractures of the Shale in Changning area, Sichuan province. Geol. Surv. Res. 2016, 39, 104–110. [Google Scholar]

- Ma, S.; Zeng, L.; Shi, X.; Wu, W.; Tian, H.; Xue, M.; Luo, L. Characteristics and main controlling factors of natural fractures in marine shale in Luzhou area, Sichuan Basin. Earth Sci. 2022, 48, 2630–2642. [Google Scholar]

- Qu, H.; Zhang, F.; Wang, Z.; Yang, X.; Liu, H.; Ba, D.; Wang, Q. Quantitative fracture evaluation method based on core-image logging: A case study of Cretaceous Bashijiqike Formation in ks2 well area, Kuqa depression, Tarim Basin, NW China. Pet. Explor. Dev. 2016, 43, 425–432. [Google Scholar] [CrossRef]

- Tong, H. Application of imaging well logging data in prediction of structural fractures. Nat. Gas Ind. 2006, 26, 58–61. [Google Scholar]

- Gou, Q.; Xu, S.; Hao, F.; Lu, Y.; Shu, Z.; Wang, Y. Research on mud shale fractures based on image logging: A case study of Jiaoshiba area. Bull. Geol. Sci. Technol. 2020, 39, 193–200. [Google Scholar]

- Liu, Z.; Cui, H.; Han, L.; Hou, L.; Bai, J.; Wang, C.; Zhan, H. Determination and Application of Stress States Based on Finite Element Techniques: A Case Study of the Longmaxi Formation in the Luzhou Block, Sichuan Basin. ACS Omega 2024, 9, 44347–44364. [Google Scholar] [CrossRef]

- Xiao, Z.; Ding, W.; Liu, J.; Tian, M.; Yin, S.; Zhou, X.; Gu, Y. A fracture identification method for low-permeability sandstone based on R/S analysis and the finite difference method: A case study from the Chang 6 reservoir in Huaqing oilfield, Ordos Basin. J. Pet. Sci. Eng. 2019, 174, 1169–1178. [Google Scholar] [CrossRef]

- Beretta, A.; Roman, H.E.; Raicich, F.; Crisciani, F. Long-time correlations of sea-level and local atmospheric pressure fluctuations at Trieste. Phys. A Stat. Mech. Its Appl. 2005, 347, 695–703. [Google Scholar] [CrossRef]

- Miranda, J.G.V.; Andrade, R.F.S. Rescaled Range analysis of pluviometric records in Northeast Brazil. Theor. Appl. Climatol. 1999, 63, 79–88. [Google Scholar] [CrossRef]

- Pang, J.; North, C.P. Fractals and their applicability in geological wireline log analysis. J. Pet. Geol. 1996, 3, 339–350. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, Z.; Li, L.; Chen, W.; He, Y. Application of the variable scale fractal technique in fracture prediction and reservoir evaluation. Oil Gas Geol. 2008, 29, 31–37. [Google Scholar]

- Zhang, L.; Shi, L.; Liang, W. Application of R/S analysis method in reservoir fracture prediction: A case study of Chang-73 reservoir in Dingbian Dongrengou. Unconv. Oil Gas 2020, 7, 91–96. [Google Scholar]

- Hu, Z. Application of R/S analysis in the evaluation of vertical reservoir heterogeneity and fracture development. Exp. Pet. Geol. 2000, 22, 382–386. [Google Scholar]

- Han, L.; Li, X.; Liu, Z.; Duan, G.; Wan, Y.; Guo, X.; Guo, W.; Cui, Y. Influencing factors and prevention measures of casing deformation in deep shale gas wells in Luzhou block, southern Sichuan Basin, SW China. Pet. Explor. Dev. 2023, 50, 979–988. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).