Study on Optimization of 3DP Rock Elastoplastic Properties: Coupling Experimental and DEM Simulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation and Experimental Setup

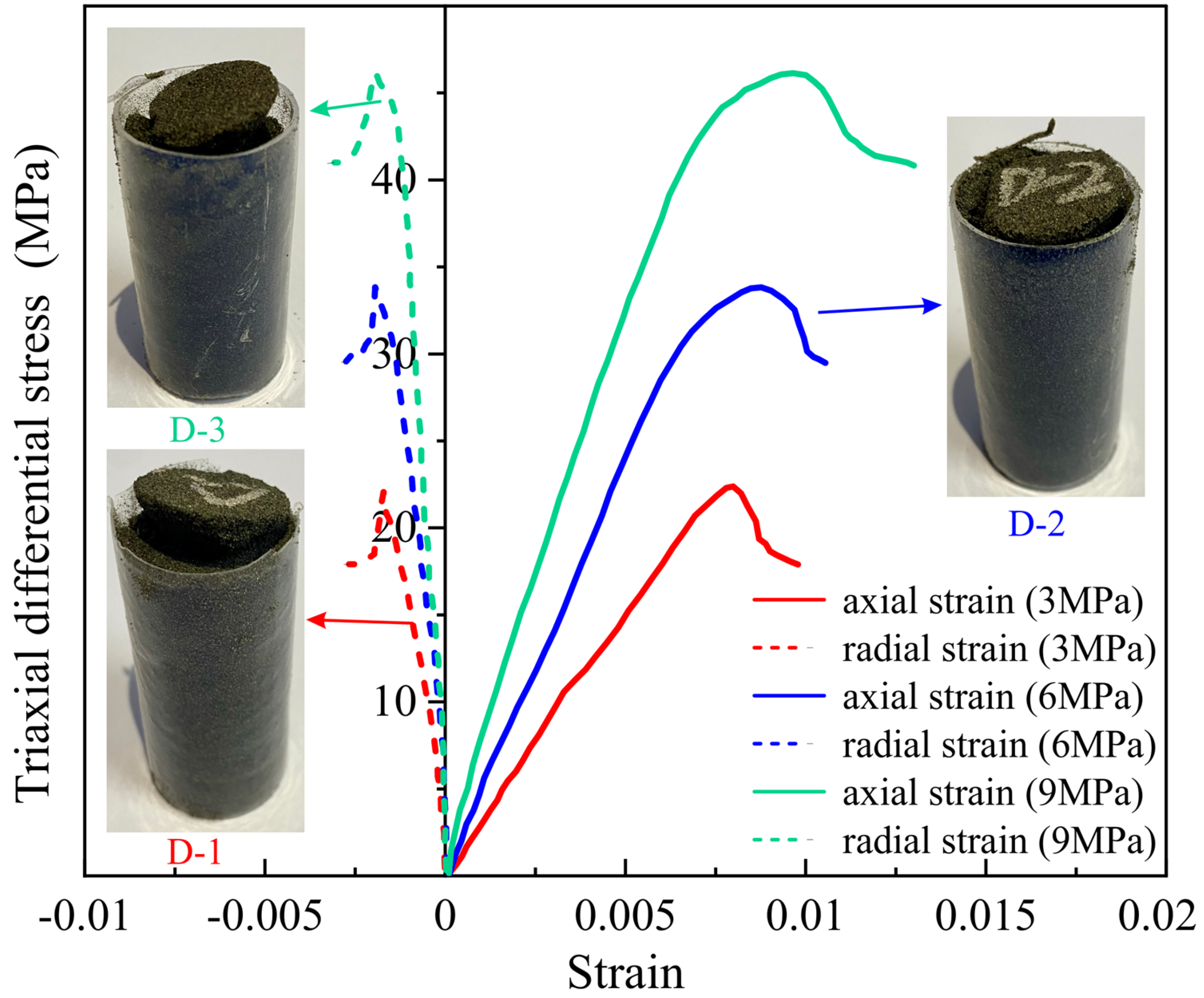

2.2. Analysis of Experimental Results

3. Numerical Simulation of Rock Mechanics Based on DEM

3.1. Numerical Simulation Methodology of DEM

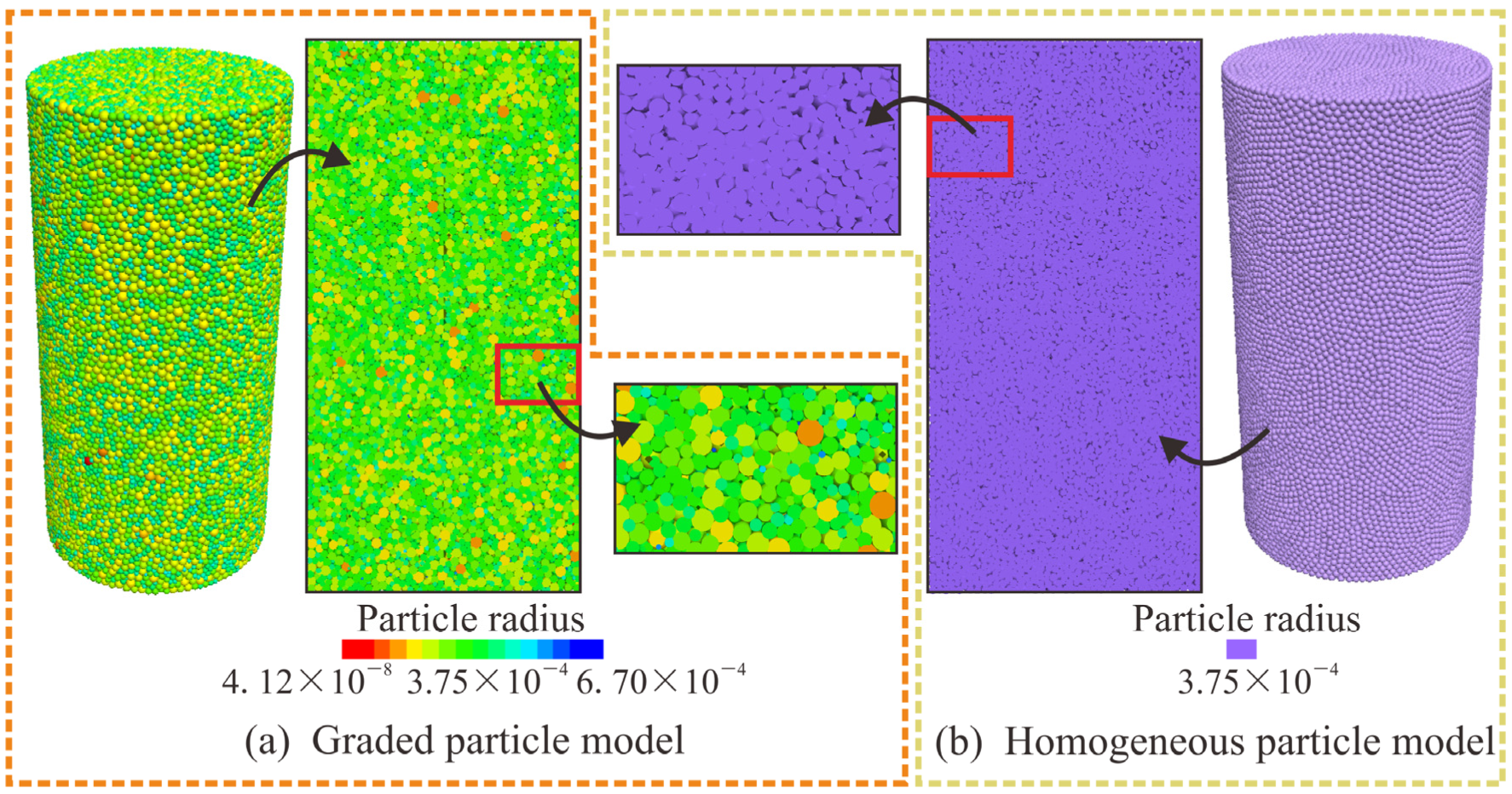

3.2. Modeling and Validation

3.3. Relationship Between Binder and Cohesion in 3DP Rock Samples

4. Microscopic Parameter Analysis

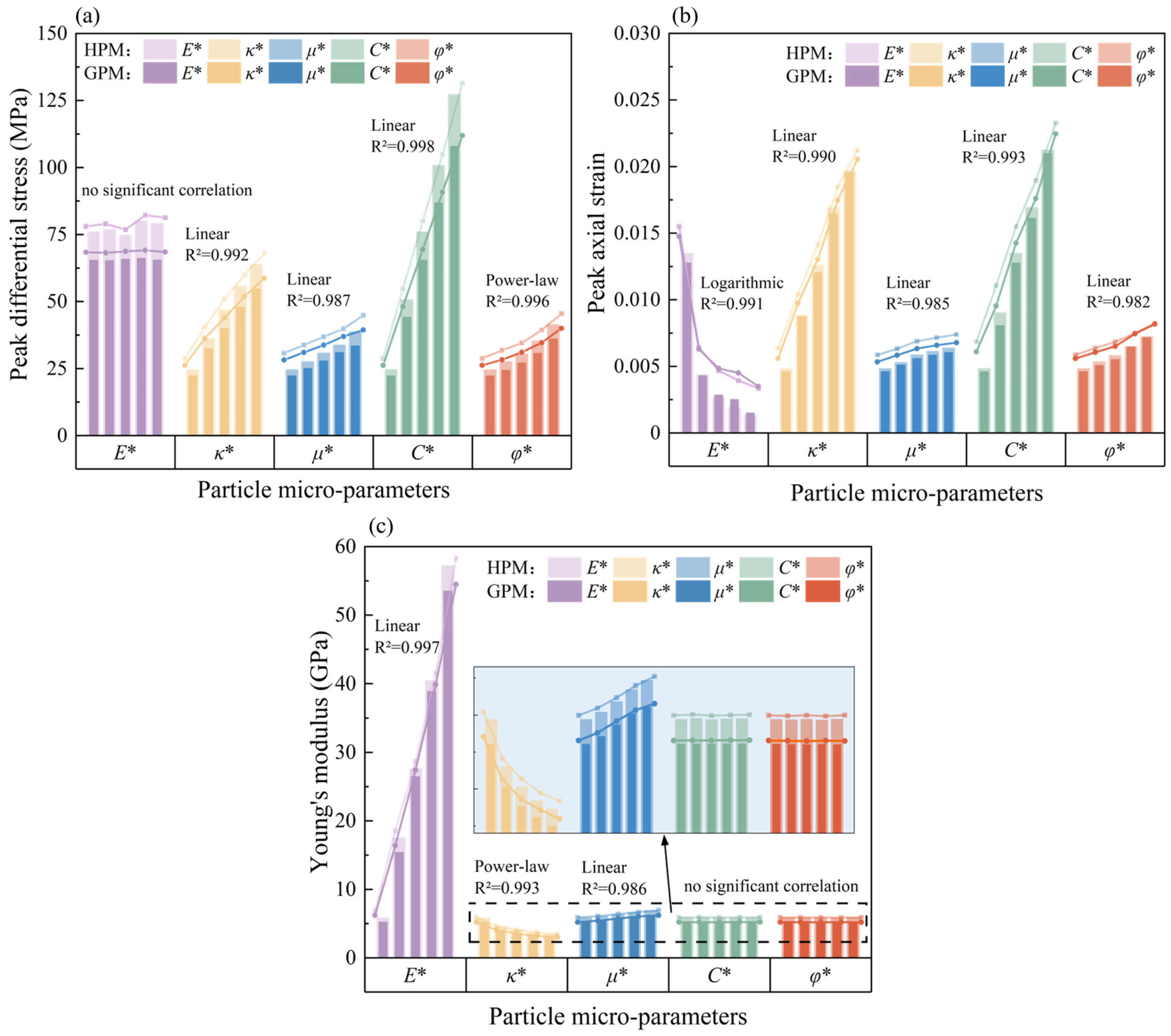

4.1. Bond Effective Modulus

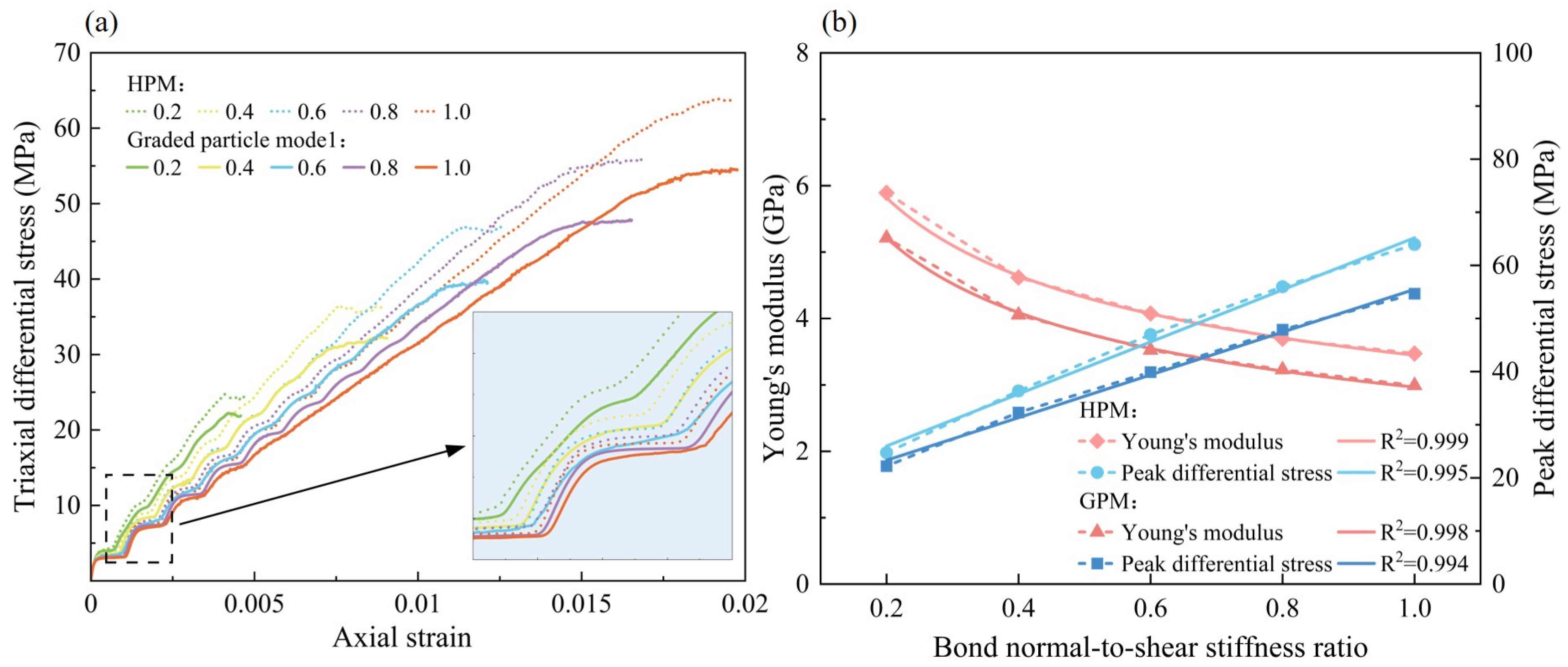

4.2. Bond Stiffness Ratio

4.3. Friction Coefficient

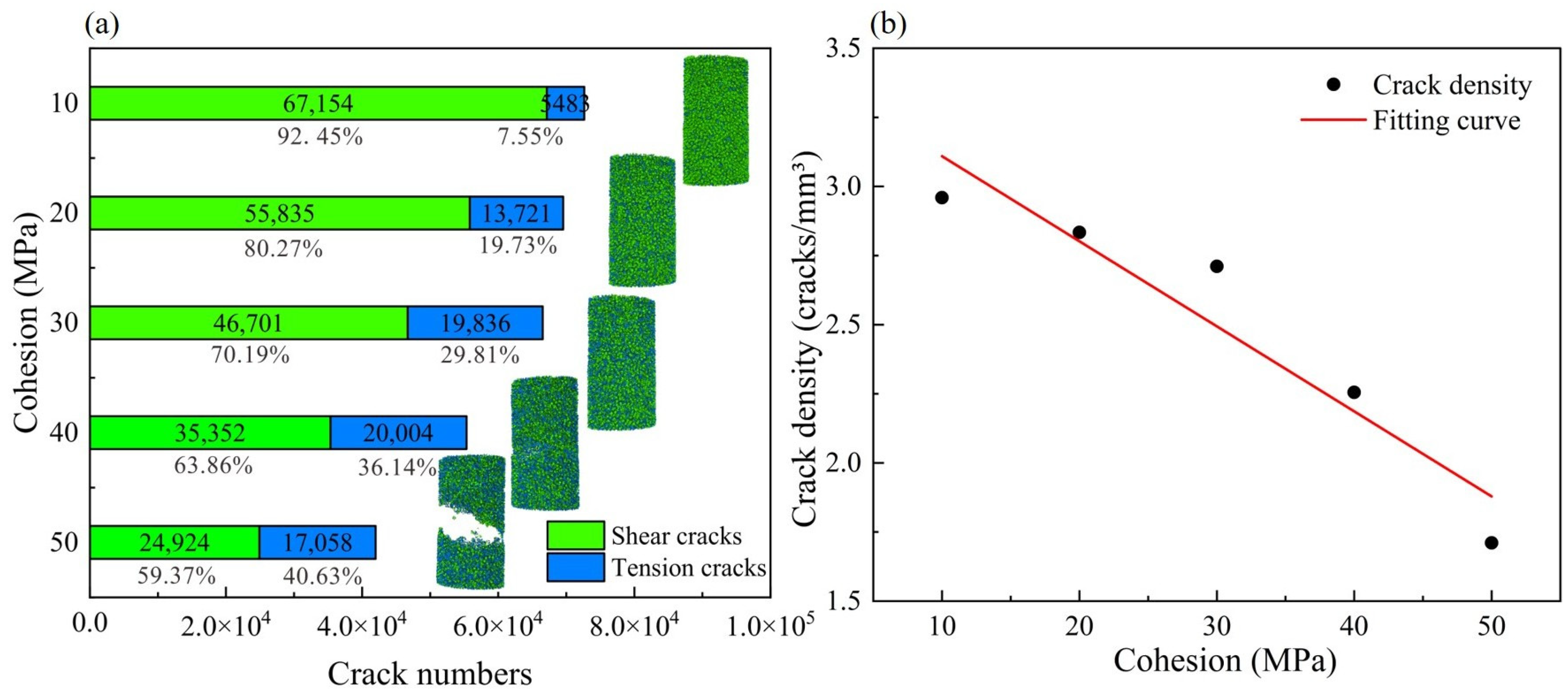

4.4. Cohesion

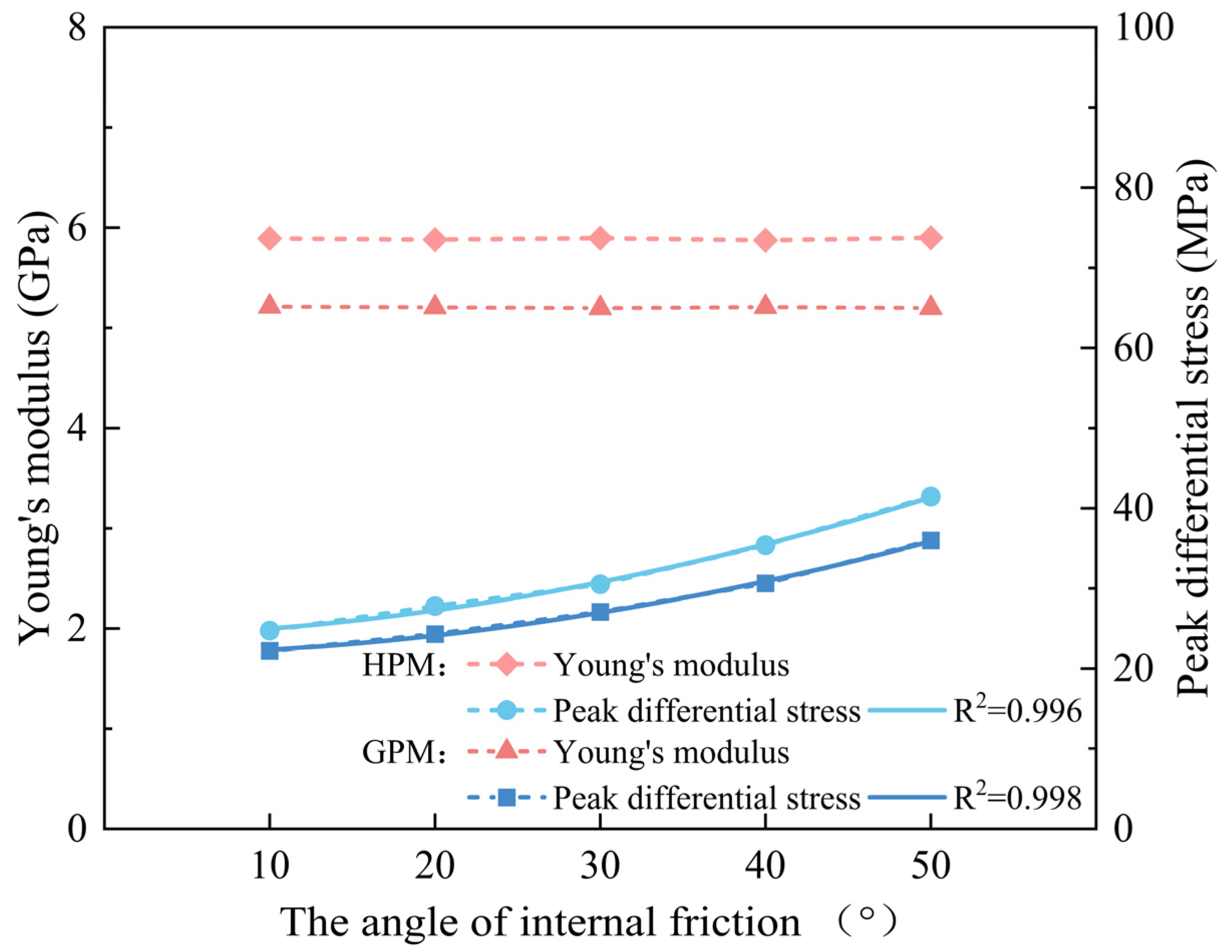

4.5. Angle of Internal Friction

5. Conclusions

- The GPM constructed based on the actual PSD closely matched the experimental data, with an average peak strength error of 1.13%, validating DEM’s reliability in characterizing heterogeneous 3DP rocks with plastic-dominated failure.

- Cyclic saturation post-processing with silica sol effectively improved mechanical properties, with peak strength and Young’s modulus increased to 52.84 MPa and 1.66 GPa, respectively. The power-law relationship between saturation cycles, microscopic cohesion, and macroscopic strength clarified the binder penetration strengthening mechanism.

- The DEM simulations indicated that the bond effective modulus dominates Young’s modulus (elastic stage), while cohesion and the bond stiffness ratio are the primary factors controlling peak strength and shear failure (plastic stage). The friction coefficient and internal friction angle have minor effects.

- The established experimental DEM framework can provide customized 3DP rocks, solving the problems of natural rock sample scarcity and parameter dispersion, and supporting its potential application in the rock mechanics experiments of UGS reservoirs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, J.J.; Yang, C.H.; Song, R. Advances of Geological Storage Engineering and Technology. GeoStorage 2025, 1, 1–26. [Google Scholar] [CrossRef]

- Sharafisafa, M.; Aliabadian, Z.; Tahmasebinia, F.; Shen, L. A comparative study on the crack development in rock-like specimens containing unfilled and filled flaws. Eng. Fract. Mech. 2021, 241, 107405. [Google Scholar] [CrossRef]

- Jiang, X.; Zhu, H.H.; Yan, Z.G.; Zhang, F.S.; Ye, F.; Li, P.N.; Zhang, X.H.; Dai, Z.R.; Bai, Y.; Huang, B.S. A state-of-art review on development and progress of backfill grouting materials for shield tunneling. Dev. Built Environ. 2023, 16, 100250. [Google Scholar] [CrossRef]

- Shakor, P.; Chu, S.H.; Puzatova, A.; Dini, E. Review of binder jetting 3D printing in the construction industry. Prog. Addit. Manuf. 2022, 7, 643–669. [Google Scholar] [CrossRef]

- Chu, S.H.; Li, L.G.; Kwan, A.K.H. Development of extrudable high strength fiber reinforced concrete incorporating nano calcium carbonate. Addit. Manuf. 2021, 37, 101617. [Google Scholar] [CrossRef]

- Ishutov, S.; Hasiuk, F.J. 3D Printing Berea Sandstone: Testing a New Tool for Petrophysical Analysis of Reservoirs. Petrophysics 2017, 58, 592–602. [Google Scholar]

- Song, R.; Wang, Y.; Tang, Y.; Peng, J.J.; Liu, J.J.; Yang, C.H. 3D Printing of natural sandstone at pore scale and comparative analysis on micro-structure and single/two-phase flow properties. Energy 2022, 261, 125226. [Google Scholar] [CrossRef]

- Ju, Y.; Xi, C.D.; Zheng, J.T.; Gong, W.B.; Wu, J.H.; Wang, S.J.; Mao, L.T. Study on three-dimensional immiscible water–Oil two-phase displacement and trapping in deformed pore structures subjected to varying geostress via in situ computed tomography scanning and additively printed models. Int. J. Eng. Sci. 2022, 171, 103615. [Google Scholar] [CrossRef]

- Chu, S.H.; Lam, W.L.; Li, L.; Poon, C.S. Packing density of ternary cementitious particles based on wet packing method. Powder Technol. 2022, 405, 117493. [Google Scholar] [CrossRef]

- Zhou, T.; Zhu, J. An Experimental Investigation of Tensile Fracturing Behavior of Natural and Artificial Rocks in Static and Dynamic Brazilian Disc Tests. Procedia Eng. 2017, 191, 992–998. [Google Scholar] [CrossRef]

- Jiang, Q.; Feng, X.T.; Song, L.B.; Gong, Y.H.; Zheng, H.; Cui, J. Modeling rock specimens through 3D printing:Tentative experiments and prospects. Acta Mech. Sin. 2016, 32, 101–111. [Google Scholar] [CrossRef]

- Almetwally, A.G.; Jabbari, H. Experimental investigation of 3D printed rock samples replicas. J. Nat. Gas Sci. Eng. 2020, 76, 103192. [Google Scholar] [CrossRef]

- Ishutov, S.; Hasiuk, F.J.; Harding, C.; Gray, J.N. 3D printing sandstone porosity models. Interpret. A J. Subsurf. Charact. 2015, 3, SX49–SX61. [Google Scholar] [CrossRef]

- Liu, P.; Ju, Y.; Ranjith, P.G.; Zheng, Z.M.; Wang, L.; Wanniarachchi, A. Visual representation and characterization of three-dimensional hydrofracturing cracks within heterogeneous rock through 3D printing and transparent models. Int. J. Coal Sci. Technol. 2016, 3, 284–294. [Google Scholar] [CrossRef]

- Ishutov, S.; Gray, J.N.; Harding, C.; Hasiuk, F.J.; Buono, A.S.; Fullmer, S.M. Resurrection of a reservoir sandstone from tomographic data using three-dimensional printing. AAPG Bull. 2017, 101, 1425–1443. [Google Scholar] [CrossRef]

- Feng, X.; Gong, Y.; Zhou, Y.; Li, Z.; Liu, X. The 3D-Printing Technology of Geological Models Using Rock-Like Materials Rock. Mech. Rock Eng. 2019, 52, 2261–2277. [Google Scholar] [CrossRef]

- GuoWei, M.; Li, W.; Yang, J. State-of-the-art of 3D printing technology of cementitious material—An emerging technique for construction. Sci. China (Technol. Sci.) 2018, 61, 475–495. [Google Scholar]

- Gao, Y.-T.; Wu, T.-H.; Zhou, Y. Application and prospective of 3D printing in rock mechanics: A review. Int. J. Miner. Metall. Mate 2021, 28, 1–17. [Google Scholar]

- Kharat, V.J.; Singh, P.; Raju, G.S.; Yadav, D.K.; Gupta, M.S.; Arun, V.; Majeed, A.H.; Singh, N. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Mater. Today Proc. 2025, in press. [Google Scholar] [CrossRef]

- Zhou, T.; Zhu, J. Identification of a Suitable 3D Printing Material for Mimicking Brittle and Hard Rocks and Its Brittleness Enhancements. Rock Mech. Rock Eng. 2018, 51, 765–777. [Google Scholar] [CrossRef]

- Song, R.; Wang, Y.; Sun, S.; Liu, J. Characterization and microfabrication of natural porous rocks: From micro-CT imaging and digital rock modelling to micro-3D-printed rock analogs. J. Pet. Sci. Eng. 2021, 205, 108827. [Google Scholar] [CrossRef]

- Song, R.; Wang, Y.; Ishutov, S.; Zambrano-Narvaez, G.; Hodder, K.J.; Chalaturnyk, R.J.; Sun, S.Y.; Liu, J.J.; Gamage, R.P. A Comprehensive Experimental Study on Mechanical Behavior, Microstructure and Transport Properties of 3D-printed Rock Analogs. Rock Mech. Rock Eng. 2020, 53, 5745–5765. [Google Scholar] [CrossRef]

- Primkulov, B.E.A.; Chalaturnyk, J.; Chalaturnyk, R.; Zambrano Narvaez, G. View Correspondence. 3D printed sandstone strength: Curing of furfuryl alcohol resin-based sandstones. 3D Print. Addit. Manuf. 2017, 4, 149–155. [Google Scholar] [CrossRef]

- Ardila, N.; Zambrano-Narvaez, G.; Chalaturnyk, R.J. Wettability Measurements on 3D Printed Sandstone Analogues and Its Implications for Fluid Transport Phenomena. Transp. Porous Media 2019, 129, 521–539. [Google Scholar] [CrossRef]

- Gomez, J.S.; Chalaturnyk, R.J.; Zambrano-Narvaez, G. Experimental Investigation of the Mechanical Behavior and Permeability of 3D Printed Sandstone Analogues Under Triaxial Conditions. Transp. Porous Media 2018, 129, 541–557. [Google Scholar] [CrossRef]

- Sharafisafa, M.; Shen, L.; Xu, Q. Characterisation of mechanical behaviour of 3D printed rock-like material with digital image correlation. Int. J. Rock Mech. Min. Sci. 2018, 112, 122–138. [Google Scholar] [CrossRef]

- Zhang, K.; Ye, J.; Liu, X. Exploration of Stereolithography Apparatus 3D Printing Technology in the research of Complex Fractured Rock Mass. Mater. Rep. 2022, 36, 122–127. [Google Scholar]

- Vogler, D.d.e.c.; Walsh, S.D.C.; Dombrovski, E.; Perras, M.A. A comparison of tensile failure in 3D-printed and natural sandstone. Eng. Geol. 2017, 226, 221–235. [Google Scholar] [CrossRef]

- Ahmed, W.F.; Sghaier, M.B.H.; Allaoui, S. Investigation of the effect of three-point bending testing parameters on the behavior of 3D printed sand. Int. J. Adv. Manuf. Technol. 2022, 121, 1415–1428. [Google Scholar] [CrossRef]

- Hodder, K.J.; Sanchez-Barra, A.J.; Ishutov, S.; Zambrano-Narvaez, G.; Chalaturnyk, R.J. Increasing Density of 3D-Printed Sandstone through Compaction. Energies 2022, 15, 1813. [Google Scholar] [CrossRef]

- Zhu, J.B.; Zhou, T.; Liao, Z.Y.; Sun, L.; Li, X.B.; Chen, R. Replication of internal defects and investigation of mechanical and fracture behaviour of rock using 3D printing and 3D numerical methods in combination with X-ray computerized tomography. Int. J. Rock Mech. Min. Sci. 2018, 106, 198–212. [Google Scholar] [CrossRef]

- Hodder, K.J.; Nychka, J.A.; Chalaturnyk, R.J. Improvement of the unconfined compressive strength of 3D-printed model rock via silica sand functionalization using silane coupling agents. Int. J. Adhes. Adhes. 2018, 85, 274–280. [Google Scholar] [CrossRef]

- Ju, Y.; Wang, H.; Yang, Y.; Hu, Q.; Peng, R. Numerical simulation of mechanisms of deformation, failure and energy dissipation in porous rock media subjected to wave stresses. Sci. China-Technol. Sci. 2010, 53, 1098–1113. [Google Scholar] [CrossRef]

- Carrier, B.; Granet, S. Numerical modeling of hydraulic fracture problem in permeable medium using cohesive zone model. Eng. Fract. Mech. 2012, 79, 312–328. [Google Scholar] [CrossRef]

- Wu, M.Y.; Liu, J.J.; Lv, X.F.; Shi, D.; Zhu, Z.W. A study on homogenization equations of fractal porous media. J. Geophys. Eng. 2018, 15, 2388–2398. [Google Scholar] [CrossRef]

- Chen, Z.; Bunger, A.P.; Zhang, X.; Jeffrey, R.G. Cohesive zone finite element-based modeling of hydraulic fractures. Acta Mech. Solida Sin. 2009, 22, 443–452. [Google Scholar] [CrossRef]

- Muliadi, A.R.; Litster, J.D.; Wassgren, C.R. Modeling the powder roll compaction process: Comparison of 2-D finite element method and the rolling theory for granular solids (Johanson’s model). Powder Technol. 2012, 221, 90–100. [Google Scholar] [CrossRef]

- Zhang, X.; Jeffrey, R.G.; Thiercelin, M. Deflection and propagation of fluid-driven fractures at frictional bedding interfaces: A numerical investigation. J. Struct. Geol. 2006, 29, 396–410. [Google Scholar] [CrossRef]

- Kresse, O.; Weng, X. Numerical Modeling of 3D Hydraulic Fractures Interaction in Complex Naturally Fractured Formations. Rock Mech. Rock Eng. 2018, 51, 3863–3881. [Google Scholar] [CrossRef]

- Liu, X.; Liu, S.; Ji, H. Numerical research on rock breaking performance of water jet based on SPH. Powder Technol. 2015, 286, 181–192. [Google Scholar] [CrossRef]

- Lecampion, B.; Bunger, A.; Zhang, X. Bunger and X. Zhang, Numerical methods for hydraulic fracture propagation: A review of recent trends. J. Nat. Gas Sci. Eng. 2018, 49, 66–83. [Google Scholar] [CrossRef]

- Jiang, H.X.; Zhao, H.H.; Gao, K.D.; Wang, O.G.; Wang, Y.X.; Meng, D.G. Numerical investigation of hard rock breakage by high-pressure water jet assisted indenter impact using the coupled SPH/FEM method. Powder Technol. 2020, 376, 176–186. [Google Scholar] [CrossRef]

- Jia, L.H.; Chen, M.; Zhang, W.; Xu, T.; Zhou, Y.; Hou, B.; Jin, Y. Experimental study and numerical modeling of brittle fracture of carbonate rock under uniaxial compression. Mech. Res. Commun. 2013, 50, 58–62. [Google Scholar] [CrossRef]

- Wang, T.; Zhou, W.B.; Chen, J.H.; Xiao, X.; Li, Y.; Zhao, X.Y. Simulation of hydraulic fracturing using particle flow method and application in a coal mine. Int. J. Coal Geol. 2014, 121, 1–13. [Google Scholar] [CrossRef]

- Zhou, Z.Y.; Zhang, F.S.; Fu, H.F.; Xiu, N.L.; Guan, B.S.; Cai, B. A thermal–mechanical coupled DEM model for deep shale reservoir: The effects of temperature and anisotropy. Rock Mech. Rock Eng. 2024, 57, 3707–3726. [Google Scholar] [CrossRef]

- Xia, Y.; Yang, Y. Modeling the failure process of rock masses using a 3D nodal-based continuous-discontinuous deformation analysis method. Comput. Methods Appl. Mech. Eng. 2024, 425, 116968. [Google Scholar] [CrossRef]

- Lisjak, A.; Kaifosh, P.; He, L.; Tatone, B.S.A.; Mahabadi, O.K.; Grasselli, G. A 2D, fully-coupled, hydro-mechanical, FDEM formulation for modelling fracturing processes in discontinuous, porous rock masses. Comput. Geotech. 2017, 81, 1–18. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, G.; Zhou, W.; Wei, D.H.; Zhao, Q.; Zou, Y.X.; Grasselli, G. An enhanced tool for probing the microscopic behavior of granular materials based on X-ray micro-CT and FDEM. Comput. Geotech. 2021, 132, 103974. [Google Scholar] [CrossRef]

- Potyondy, D.O.; Cundall, P.A. A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar] [CrossRef]

- Yang, S.; Tian, W.; Huang, Y.; Ranjith, P.; Ju, Y. An Experimental and Numerical Study on Cracking Behavior of Brittle Sandstone Containing Two Non-coplanar Fissures Under Uniaxial Compression. Rock Mech. Rock Eng. 2016, 49, 1497–1515. [Google Scholar] [CrossRef]

- Haeri, H.; Sarfarazi, V.; Zhu, Z.; Hedayat, A.; Nezamabadi, M.; Karbala, M. Simulation of crack initiation and propagation in three point bending test using PFC2D. Struct. Eng. Mech. 2018, 66, 453–463. [Google Scholar] [CrossRef]

- Hou, B.; Jin, Y.; Li, S.; Zeng, C. Failure mechanisms of borehole wall rocks in gravel beds with different grain sizes. Nat. Gas Ind. 2015, 35, 66–70. [Google Scholar] [CrossRef]

- Liu, G.; Sun, W.C.; Lowinger, S.; Zhang, Z.H.; Huang, M.; Peng, J. Coupled flow network and discrete element modeling of injection-induced crack propagation and coalescence in brittle rock. Acta Geotech. 2019, 14, 843–868. [Google Scholar] [CrossRef]

- Huang, L.; Liu, J.; Zhang, F.; Dontsov, E.; Damjanac, B. Exploring the influence of rock inherent heterogeneity and grain size on hydraulic fracturing using discrete element modeling. Min. Miner. Depos. 2023, 17, 176–177. [Google Scholar] [CrossRef]

- Li, G.; Liu, S.Q.; Ma, F.S.; Guo, J. A multilevel parallel bonded-grain based model (Multi Pb-GBM) accounting for microstructure failures of typical crystalline rocks. Bull. Eng. Geol. Environ. 2022, 81, 475. [Google Scholar] [CrossRef]

- Vasyliev, L.; Malich, M.; Vasyliev, D.; Katan, V.; Rizo, Z. Improving a technique to calculate strength of cylindrical rock samples in terms of uniaxial compression. Min. Miner. Depos. 2023, 17, 43–50. [Google Scholar] [CrossRef]

- An, M.; Zhang, F.; Dontsov, E.; Elsworth, D.; Zhu, H.; Zhao, L. Stress perturbation caused by multistage hydraulic fracturing: Implications for deep fault reactivation. Int. J. Rock Mech. Min. Sci. 2021, 141, 104704. [Google Scholar] [CrossRef]

- Holt, R.M.; Kjølaas, J.; Larsen, I.; Li, L.; Pillitteri, A.G.; Sønstebø, E. Comparison between controlled laboratory experiments and discrete particle simulations of the mechanical behaviour of rock. Int. J. Rock Mech. Min. Sci. 2005, 42, 985–995. [Google Scholar] [CrossRef]

- Donval, E.; Schneider, M.; Grimm-Strele, H.; Godehardt, M.; Burger, R.; Lechner, P.; Günther, D.; Andrä, H. A directional contraction method to model sand-based binder jet 3D printed materials. Int. J. Solids Struct. 2025, 312, 113260. [Google Scholar] [CrossRef]

- Ma, G.; Hu, T.; Li, Z. Binder jetting 3D printing rock analogs using magnesium phosphate cement. Constr. Build. Mater. 2024, 420, 135620. [Google Scholar] [CrossRef]

- Tabbakhzadeh, M.N.; Esmaeilzadeh, F.; Zabihi, R.; Mowla, D. Experimental study of chemical sand consolidation using epoxy and furan resins for oil wells: Experimental design models. Int. J. Rock Mech. Min. Sci. 2020, 135, 104486. [Google Scholar] [CrossRef]

- Gandini, A.; Belgacem, M.N. Furans in polymer chemistry. Prog. Polym. Sci. 1997, 22, 1203–1379. [Google Scholar] [CrossRef]

- Zhuang, D.; Ning, Z.; Chen, Y.; Li, J.; Li, Q.; Xu, W. Investigation on mechanical properties regulation of rock-like specimens based on 3D printing and similarity quantification. Int. J. Min. Sci. Technol. 2024, 34, 573–585. [Google Scholar] [CrossRef]

- Tian, W.; Wang, X.; Yun, W.; Cheng, X. Mechanical properties of sand 3D printed rock-like samples based on different post-processing methods. Rock Soil Mech. 2023, 44, 5. [Google Scholar]

| Parameter Name | Value Range | Calibrated Value |

|---|---|---|

| Particle density | 2650 kg/m3 | 2650 kg/m3 |

| Particle radius range | 200–1200 μm | 200–1200 μm |

| Bond effective modulus | 1–9 GPa | 5 GPa |

| Bond stiffness ratio | 0.2–1.0 | 0.7 |

| Friction coefficient | 0.2–1.0 | 0.6 |

| Cohesion | 10–50 MPa | 22.5 MPa |

| Angle of internal friction | 10–50° | 21.5° |

| Normal critical damping ratio | 0.7 | 0.7 |

| Tangential critical damping ratio | 0.7 | 0.7 |

| Wall stiffness | 100 GPa | 100 GPa |

| Wall friction coefficient | 0.0 | 0.0 |

| Sample Number | Cyclic Saturation Cycles | Young’s Modulus (GPa) | Peak Strength of Experiments (MPa) | Peak Strength of Numerical Simulations (MPa) | Error (%) |

|---|---|---|---|---|---|

| GR-1 | 0 | 0.36 | 5.6976 | 5.7525 | 0.9636 |

| GR-2 | 1 | 0.46 | 10.1290 | 10.2109 | 0.8086 |

| GR-3 | 2 | 0.64 | 13.5838 | 13.5435 | 0.2967 |

| GR-4 | 3 | 1.24 | 23.3534 | 23.3046 | 0.2090 |

| GR-5 | 5 | 1.66 | 52.8409 | 53.1131 | 0.5151 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, J.; Liu, J.; Song, R. Study on Optimization of 3DP Rock Elastoplastic Properties: Coupling Experimental and DEM Simulation. Processes 2025, 13, 3940. https://doi.org/10.3390/pr13123940

Song J, Liu J, Song R. Study on Optimization of 3DP Rock Elastoplastic Properties: Coupling Experimental and DEM Simulation. Processes. 2025; 13(12):3940. https://doi.org/10.3390/pr13123940

Chicago/Turabian StyleSong, Jiecheng, Jianjun Liu, and Rui Song. 2025. "Study on Optimization of 3DP Rock Elastoplastic Properties: Coupling Experimental and DEM Simulation" Processes 13, no. 12: 3940. https://doi.org/10.3390/pr13123940

APA StyleSong, J., Liu, J., & Song, R. (2025). Study on Optimization of 3DP Rock Elastoplastic Properties: Coupling Experimental and DEM Simulation. Processes, 13(12), 3940. https://doi.org/10.3390/pr13123940