1. Introduction

The generation of organic waste is closely connected with global trends regarding population growth and economic development, both of which contribute to the continuous increase in waste production. This has since become a critical challenge, demanding sustainable management approaches that not only address its disposal but also contribute to the broader goals of sustainable environmental and energy management. These approaches, which include regeneration of waste into useful products, use of renewable energy sources, etc., are widely recognized for their role in promoting energy security, mitigating the effects of climate change, and offering strategies for the effective utilization of organic wastes. Connected to this are the concepts of circular economy and net-zero emissions that have emerged as crucial frameworks for sustainable development. Within these frameworks, anaerobic digestion (AD) has been extensively employed as a multi-waste management strategy for decades, providing a proven means of generating renewable energy while managing diverse organic substrates [

1,

2].

Building on this foundation, AcoD was introduced and it has received significant attention in recent years. Compared to conventional AD, AcoD offers clear advantages in terms of methane production, nutrient recovery, and overall system stability. By combining multiple feedstocks with complementary characteristics, AcoD allows for more balanced nutrient availability, better biodegradability, and enhanced process robustness [

3,

4]. These advantages highlight why AcoD is considered one of the most promising approaches for advancing sustainable bioenergy generation while simultaneously addressing the global challenge of organic waste management.

Alongside the growing interest in AcoD, artificial intelligence (AI) has become increasingly integrated into the study and operation of biological systems. In recent years, AI methods have been applied to AD for purposes such as process prediction, optimization, control, and real-time monitoring [

5,

6]. Unlike classical models, which often struggle to fully capture the nonlinear and dynamic nature of biological processes, AI—particularly machine learning (ML)—is capable of detecting hidden patterns and modeling complex system behaviors that defy traditional approaches [

7,

8]. This makes AI-based algorithms ideally suited for advancing the AcoD process, where optimization potential is high and where efficient energy recovery aligns with global priorities such as sustainability, energy security, and climate change mitigation.

As a result, substantial research has been dedicated to developing AI-driven models for AcoD. Various algorithms have been employed, including multivariate statistical analyses (MSA) [

9], tree-based ML methods [

10], nature-inspired optimization algorithms [

11], support vector machines (SVM) [

12], and ANN [

13]. The ANN models, in particular, have been extensively studied, both in standalone form [

14,

15] and as hybrid models [

16,

17], and have demonstrated strong performance in predicting outcomes such as biogas yield and composition in AcoD systems. Beyond prediction, intelligent frameworks for system monitoring and control have also been developed, incorporating models such as principal component analysis (PCA) [

9], partial least squares (PLS) [

18], multiple linear regression (MLR) [

19], and ANN [

20].

Optimization has also become an important focus of AI applications in AcoD. Advanced algorithms such as genetic algorithms (GA) and particle swarm optimization (PSO) have been employed to optimize critical process parameters. These include co-substrate mixing ratios [

21], biogas yields [

22], and operational factors such as temperature, pH, hydraulic retention time, total solids, and volatile solids [

23]. Altogether, these studies show the potential of AI-driven optimization to improve AcoD processes at different scales, from laboratory experiments [

13] to pilot-scale [

16] and industrial-scale operations [

24].

Despite these successes, however, the broad application of AI in AcoD remains constrained by a set of challenges [

25]. The most significant of these include the limited availability of high-quality datasets (those containing a sufficiently large number of representative experimental data obtained from a well-designed experiment), which restrict the training and validation of models (in the absence of sufficient numbers or unrepresentative experimental data), and the poor generalizability of standalone AI approaches, which often fail to adapt effectively to previously unseen data [

26,

27,

28,

29,

30]. Another key limitation arises from the “black-box” character of many ML models, particularly ANN, which makes them difficult to interpret and reduces the trust of operators in their predictions. The lack of transparency and interpretability is one of the main barriers to the more widespread adoption of AI in AD and AcoD modeling and process control.

Several recent reviews have discussed these issues in detail. For instance, Rutland et al. (2023) [

31], in a systematic review based on 57 references, emphasized the challenges and potential of applying ML to AD systems, particularly the scarcity of training data and the inherent variability of AD processes. Their review explored how ML is currently being used in AD and highlighted both its benefits and the challenges of implementation. Another review, based on 115 references, provided a broader examination of AI applications in AcoD [

32]. This work critically assessed the most commonly used AI algorithms, their advantages, drawbacks, and applicability in modeling AcoD. It also presented a comparison between standalone and hybrid AI approaches. Importantly, the review introduced the concept of hybrid frameworks in which AI algorithms are guided by conventional modeling techniques, and conversely, conventional approaches are enhanced by AI guidance. Such hybrid models were presented as complementary methods for improving AcoD process modeling.

Other reviews have considered the feasibility of practical implementation. For example, one study [

4] critically evaluated co-digestion systems based on operational conditions, kinetic modeling, and nutrient recovery. This review also identified compatible co-feedstocks for organic waste management and suggested practical steps for future research directions. In addition, the study highlighted the potential role of AI algorithms in optimizing, controlling, predicting unknown input and output parameters, and real-time monitoring of AcoD processes. Furthermore, it presented a comparison of standalone and hybrid AI models applied to AcoD, identifying future research priorities such as data preprocessing, model interpretation, validation, and the development of grey-box models.

A more recent review [

33] drew attention to the limitations of conventional AD of livestock manures, emphasizing the benefits of co-digestion with carbon-rich substrates. This paper also discussed global livestock manure management practices, underlining the advantages of co-digestion strategies and examining progress and challenges in this field.

These reviews are intended primarily for AI specialists and are more likely to illustrate the possibilities of applying individual ML algorithms to AD and AcoD than to the actual benefit to AD and AcoD processes.

In our review, based on more than 110 references including our own results, we discuss the applications of AI in AD and AcoD in areas such as process optimization, control, prediction of unknown input/output parameters, and real-time monitoring. Moreover, we present a comparison of classical approaches with standalone and hybrid AI algorithms, identifying the strengths and weaknesses of each. Importantly, our paper emphasizes the need for further research into data preprocessing, model interpretation, validation, with the focus being placed primarily on the processes of AD and AcoD themselves, rather than on the algorithms that are used.

2. Process Description

The AD is a complex biochemical process consisting of the following four main stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis [

1]. Each of these steps is facilitated by specific groups of microorganisms, which act synergistically to decompose the major organic compounds present in the feedstock and convert them into biogas and digestate [

1,

10,

34].

Traditionally, AD has often relied on conventional AD, in which a single type of feedstock is used. However, conventional AD frequently encounters limitations associated with the intrinsic characteristics of individual feedstocks. Issues such as nutrient imbalance, suboptimal carbon-to-nitrogen (C/N) ratios, and the presence of inhibitory compounds can reduce process efficiency and stability. Co-digestion, in contrast, involves the simultaneous digestion of multiple feedstocks, providing opportunities to overcome these challenges. By combining materials with complementary properties, co-digestion can enhance the degradability of substrates that are otherwise resistant to digestion, improve nutrient balance, and increase overall process robustness. For instance, mixing nitrogen-rich feedstocks with carbon-rich co-substrates helps optimize the C/N ratio, thereby promoting microbial activity and ensuring stable process performance [

34,

35,

36].

Extensive research and development efforts have underlined the inherent benefits of co-digestion. These advantages include improved digestibility as a result of synergistic interactions between co-substrates, enhanced process stability due to balanced nutrient availability, and higher fertilizer value of the resulting co-digestate. Consequently, AcoD is broadly defined as the simultaneous digestion of two or more substrates in combination with co-substrates. The diversity of feedstocks involved typically makes the digestion process more resilient to fluctuations in composition or operating conditions [

3,

4,

9,

17].

Given these advantages, numerous studies have explored co-digestion strategies using different combinations of organic waste from diverse sources. Researchers have investigated AcoD with a wide range of materials, including industrial by-products, agricultural residues, livestock manure, food waste, and municipal solid waste. The broad interest in co-digestion reflects its potential as a flexible and sustainable approach to improving the efficiency of anaerobic digestion systems while simultaneously addressing the growing global challenge of organic waste management [

15,

17,

22].

The main objective of the AcoD process is to enhance the generation of biogas and methane. Additionally, AcoD contributes to better process stability, improved nutrient equilibrium, and greater synergistic interactions among microbial communities, while simultaneously reducing greenhouse gas emissions and operational expenses. Several key factors—including the physicochemical properties of co-substrates, potential inhibitory effects arising from co-substrate combinations, and the organic loading rate—can have a considerable impact on the overall performance of an AcoD system. When selecting co-substrates, the transportation costs from the source to the AcoD facility must also be taken into account, as these can significantly influence economic feasibility. Furthermore, in order to maximize synergistic effects and methane productivity, careful selection of compatible co-substrates and determination of their optimal mixing ratios are of critical importance [

3,

10].

In recent years, AcoD has received increasing attention for its proven ability to enhance methane generation, promote nutrient recovery, and sustain the long-term stability of digesters. Compared with conventional AD, the AcoD process presents multiple advantages, such as higher methane yields and improved reactor stability, resulting from the synergistic interaction of diverse co-substrates, balanced nutrient supply, and a resilient microbial community, while simultaneously mitigating toxicity through dilution effects [

4]. Despite these advantages, AcoD systems can still experience instability when unsuitable co-substrates or unfavorable operational parameters are applied, which often leads to reduced methane production. Therefore, the efficient operation of an AcoD system requires a comprehensive understanding of several critical operational parameters, including the proportion and composition of co-substrates, the volatile fatty acids to alkalinity ratio, the organic loading rate, and both solids and hydraulic retention times [

23,

33].

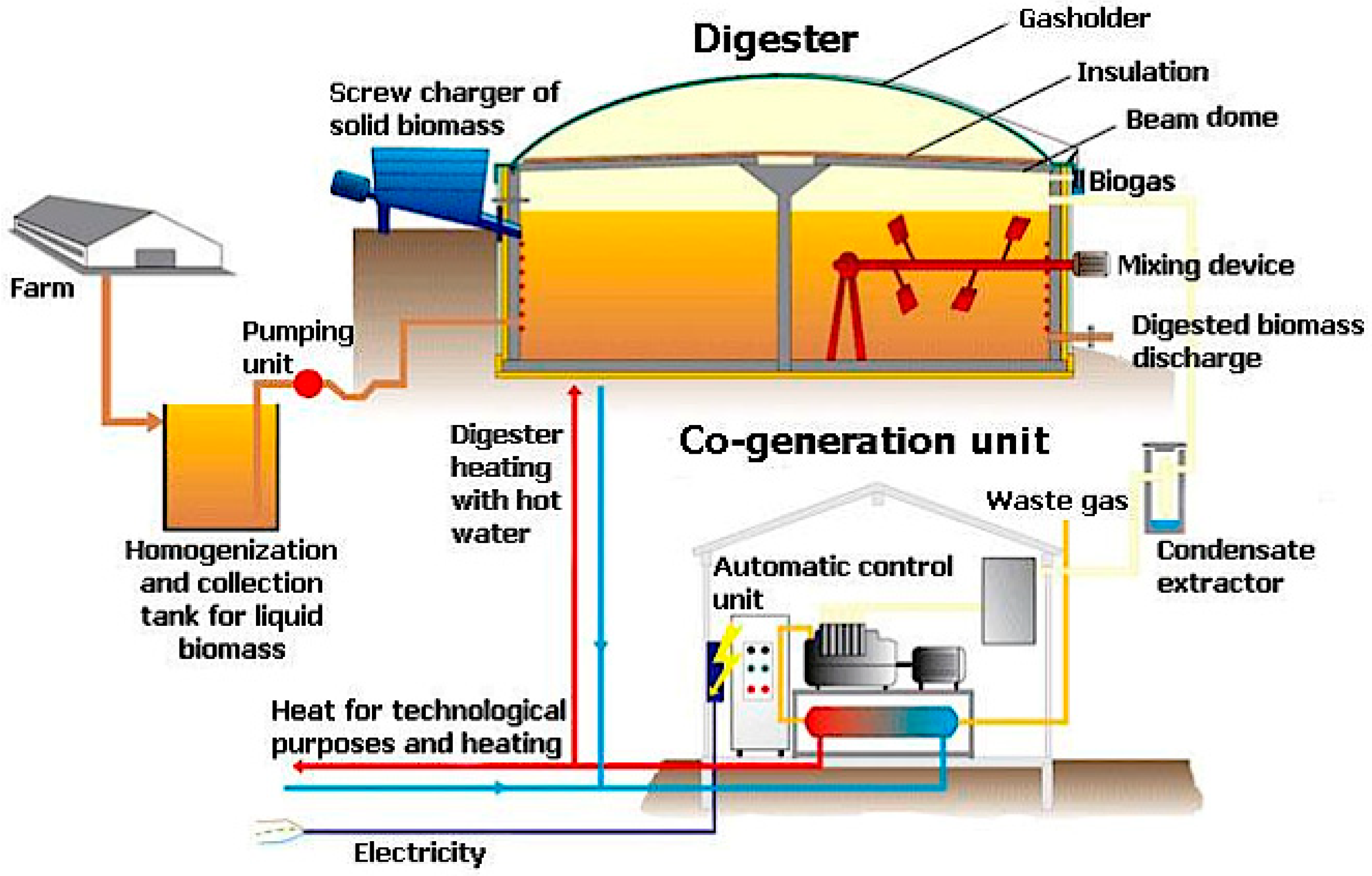

Both AD and AcoD produce biogas and natural fertilizer as main products. Generally, biogas is used for production of electricity and heat using co-generation unit (

Figure 1).

Nevertheless, the AcoD system frequently exhibits instability when inappropriate co-substrates or unsuitable operational conditions are employed, resulting in diminished methane production [

3,

38,

39,

40]. The inherent complexity of the process, coupled with the involvement of nonlinear parameters and multidimensional biochemical conversions, necessitates the application of mathematical modeling approaches. Such models serve as valuable tools for real-time process monitoring, control, and optimization, and can also be utilized to predict key performance indicators and operational efficiencies [

8,

40,

41]. In this context, several theoretical modeling frameworks (cone and modified Gompertz with second order equation models for conventional AD and AcoD systems) have been proposed to assess the AcoD process [

39], estimate biogas generation [

42], and elucidate mechanisms of process inhibition [

43]. However, these conventional modeling techniques for AD and AcoD not only demand extensive prior knowledge and calibration but are also inherently complex, computationally demanding, and generally limited in their applicability to specific operational conditions [

7,

41].

The properties of various types of bioreactors for AD and AcoD have been developed and studied, with the most widespread being BRs with continuous stirring (CSTR) [

1,

34].

There are several particularly important factors influencing the AD and AcoD processes [

36]—temperature, pH, rH and stirring in the bioreactor, buffer capacity of the medium, concentration of VFA, and carbon/nitrogen ratio. In terms of temperature, two operating modes are known that guarantee maximum biogas production—mesophilic and thermophilic.

Unfortunately, currently, a limited number of factors are directly measurable in real time—temperature, pH, ORP and stirring in the bioreactor, flow rate and composition of the biogas produced, flow rate of the supplied solution. Some variables are determined with analytical equipment (e.g., the concentration of VFA with a gas chromatograph), others—only with manual analyses (e.g., concentration of organics). However, some of the most important variables related to the microbial community (concentration of different types of microorganisms, their specific growth rates and some of the intermediate products of anaerobic digestion) are very difficult to determine or not measurable at all. Recently, intensive work has been carried out on the development of so-called “software sensors” to determine these variables [

44,

45,

46,

47,

48,

49] which are good as theoretical results, but more work is needed to implement them in industrial practice.

3. Machine Learning, Artificial Intelligence and Artificial Neural Networks

The application of ML techniques in AD has become increasingly widespread, enhancing the ability to interpret the complex interconnection among system parameters and thereby improving process control, operational efficiency, and optimization.

In recent years, both ML and AI have gained significant attention and become prominent topics in scientific and engineering research. Although the two terms are often used interchangeably, they are not identical. Machine learning can be regarded as one of the most significant implementations of artificial intelligence or ML represents a methodological approach through which AI can be achieved. Essentially, ML involves supplying large datasets to computational systems, enabling them to “learn” to perform specific tasks without explicit programming. An ML algorithm, therefore, is a computational tool designed to analyze input data and identify underlying relationships or patterns. Through statistical modeling and data classification, ML algorithms are capable of discerning correlations within data and making probabilistic predictions or informed estimations based on learned experiences. Furthermore, many ML models possess adaptive capabilities that allow them to improve their predictive accuracy over time by learning from prior errors, progressively becoming more robust and intelligent [

5,

6,

50].

In general, ML algorithms can be grouped into four main categories: supervised learning, unsupervised learning, semi-supervised learning, and reinforcement learning [

5,

6].

Deep learning refers to a class of algorithms designed to analyze data through layered logic structures that mimic the way humans reason and draw conclusions. Among the most representative methods in this category is the ANN approach. This is a ML technique inspired by the functioning of the human nervous system, where neurons serve as the basic processing units. The architecture of an ANN replicates the biological neural network of the human brain, enabling a learning process significantly more sophisticated than that of conventional ML models. Data are introduced as inputs to multiple interconnected layers of artificial neurons; similar to how biological neurons transmit signals through synapses, the output from one layer becomes the input for the next. When such a network includes a large number of interconnected layers, it is referred to as deep learning or a deep neural network (DNN). Deep learning algorithms are thus considered a mathematically advanced and computationally intensive evolution of traditional machine learning techniques [

4,

5].

The AI, on the other hand, encompasses the broader concept of developing intelligent systems capable of executing tasks that normally require human cognitive abilities. Machine learning represents a subfield of AI focused on creating algorithms that enable machines to learn autonomously from data. Deep learning, in turn, is a further subset of ML that attains artificial intelligence capabilities through the use of artificial neural network principles. In essence, deep learning currently represents the most advanced and realistic approximation of true artificial intelligence achieved to date [

4,

5].

AI as a discipline lies at the intersection of computer science, mathematics, and engineering, with its central aim being the design of systems that can emulate human-like reasoning, decision-making, and adaptive learning. Although the idea of machines capable of thinking and acting like humans has existed for centuries in myth and speculative fiction, the realization of this vision has only become possible in recent decades due to advances in computational power, data availability, and algorithmic design. Over time, AI has evolved far beyond its computer science origins and now finds practical applications across a vast range of disciplines. Its rapid development continues to expand its potential for implementing advanced cognitive principles, thereby improving system performance, increasing workplace productivity, and augmenting human capabilities [

5,

8].

Within the field of AD, traditional ML techniques ANN remain the most widely utilized tools for process modeling and prediction. An ANN consists of an extensive network of artificial “neurons” systematically organized into multiple layers, where information processing and learning occur iteratively [

7,

8].

The ANN consist of multiple layers of interconnected neurons. Within a single layer, neurons do not connect to one another; however, every neuron in one layer forms connections with all neurons in the adjacent layer. A typical neural network comprises three primary layers [

6,

8]:

Input layer: Neurons in the input layer do not perform computations or transformations; their role is solely to relay incoming data to the first hidden layer.

Hidden layers: One or more hidden layers may be present, each consisting of multiple neurons. The number of neurons in each hidden layer is considered a hyperparameter, which can be adjusted to optimize model performance.

Output layer: The final layer of the network generates outputs that are subsequently compared with the expected values using a loss function during the training process.

Although various types of neural networks exist, this discussion focuses on feedforward neural networks, where information flows from input to output without any feedback loops. Networks with feedback mechanisms are known as recurrent neural networks (RNNs). In a feedforward ANN, the input layer transmits information to the first hidden layer, where each neuron receives inputs from all neurons in the preceding layer. The inputs, combined with the weights of each connection, are used to calculate the output of each neuron in the hidden layer. These outputs are then propagated forward and compared with the target values through a loss function. The computed loss is employed to adjust the weights and biases of all layers via the backpropagation algorithm, starting from the output layer and moving backward to the input layer. After multiple training epochs, the network becomes capable of capturing complex relationships between inputs and outputs, ultimately enabling accurate predictions [

6,

8].

4. Modeling of the Anaerobic Digestion

The application of mathematical models represents a powerful approach for investigating, optimizing, and controlling anaerobic biodegradation processes [

44,

51,

52,

53].

A wide variety of modeling techniques exist, each tailored to specific objectives and levels of detail. From a general perspective, these approaches can be broadly categorized into two primary classes, depending on the purpose and methodology of the modeling [

45,

52]:

Mass balance models: They consist of sets of nonlinear ordinary differential equations (ODE) and describe more accurately all microbiological and biochemical phenomena during the AD processes.

Black box models: They represent only the relationships between the input and output variables of a given object of modeling and control and are built on the basis of available relevant data acquired usually from planned experiments. Black box models can be linear (parametric or non-parametric) or nonlinear (AI models).

The biggest spread for AD processes has received the dynamical type of models, based on mass balances and, especially those created CSTR mode [

45,

52]. The vast majority of these models are sets of ODE involving many unknown coefficients. Their exact determination for each specific case represents a complex problem to solve mainly because of the few measurable process variables [

45,

53].

The most complex basic model is Anaerobic Digestion Model No. 1 (ADM1) [

51], developed more than 20 years ago by an interdisciplinary team at the International Water Association (IWA). ADM1 has had a number of additions and developments in recent years [

54]. The ADM1 encompasses the principal biochemical and physicochemical processes that take place during anaerobic digestion. This model includes 26 dynamic state concentration variables, 19 biochemical kinetic processes, 3 gas–liquid transfer kinetics, and 8 implicit algebraic variables [

51]. Collectively, these components provide a global representation of 32 dynamic state concentrations along with 6 additional acid–base kinetic processes [

51]. However, it contains over 30 nonlinear ordinary differential equations (ODEs) with an exceeding number of coefficients. It is of the mass balance type and describes the main possible processes and limitations in AD processes. Due to its complexity, a large number of simpler models with a significantly smaller number of unknown coefficients, which are determined for each specific case, have been developed on its basis [

53]. For example, Kegl et al. (2024) [

55] presented a very interesting study, which ended with a practical implementation in an industrial biogas plant with significant improvement of some parameters.

But even with them, this is not easy mainly because of the small number of measurable process variables [

53].

For AD, various ANN-based and hybrid modeling frameworks have been developed to estimate and predict specific process components [

20,

24,

26,

27,

56,

57].

Considerable research efforts have focused on modeling AD and AcoD with the aim of improving process efficiency, productivity, and overall performance. Compared to traditional modeling techniques, AI algorithms have substantially simplified the representation of nonlinear, mathematically complex, labor-intensive, and time-consuming processes [

8]. A wide range of AI approaches have been investigated for AcoD modeling, including MSA [

9], tree-based machine learning algorithms [

10], nature-inspired optimization methods [

11], support vector machines (SVM) [

12], and ANN [

13]. These methods have been extensively explored to capture the intricate dynamics of AcoD processes and to support enhanced predictive accuracy and operational optimization.

Numerous studies have successfully applied both standalone ANN [

14,

15,

28,

29,

30,

56] and hybrid ANN models [

16,

17,

26] to predict biogas yield and composition in AcoD processes. Additionally, advanced intelligent frameworks have been developed for effective monitoring and control of AcoD using models based on PCA [

9], partial least squares (PLS) [

18], MLR [

19], and ANN [

20]. Furthermore, the integration of sophisticated optimization techniques, such as GA and PSO, has facilitated the optimization of co-substrate mixing ratios [

21], biogas production [

22], and critical operational parameters, including temperature, pH, HRT, total solids, and volatile solids [

23]. The potential of AI-driven modeling has also been demonstrated at laboratory [

13], pilot [

16], and industrial [

24] scales, underscoring its applicability across different operational scenarios. Nevertheless, the widespread adoption of AI algorithms in AD and AcoD modeling is limited by challenges such as small datasets, poor generalizability of standalone models, the black-box nature of machine learning algorithms, and the lack of interpretability of developed AI models [

7,

8,

29].

Neural models for single-input single-output (SISO) and multiple-input multiple-output (MIMO) configurations have been developed for AD of organic waste stimulated by glucose [

58] or other carbohydrate-rich substrates, based on laboratory-scale experiments using cattle dung and synthetic data generated from nonlinear AD models with glucose addition [

28,

30]. Training and testing of these neural models in our studies were conducted using the specialized software package NNSYSID20 in MATLAB 5.3 [

28,

29,

30]. The actual inputs to the models were considered as the dilution rate for influent organics (D

1), the dilution rate for added glucose (D

2), and glucose concentration (S

10). Outputs included biogas yield (Q) and the integrated pollution index, COD, of the reactor effluent. The unmeasurable “on-line” perturbation, corresponding to the concentration of polluting organics in the influent (S

0i), was also incorporated as an input perturbation.

Two types of neural network structures have been studied [

26,

28,

56]:

- 1.

SISO case:

- (a)

the control action D1 is assumed as the input, Q—as the output;

- (b)

the control action D1 is assumed as the input, COD—as the output;

- (c)

the control action S10 is assumed as the input, Q as the output;

- (d)

the control action S10 is assumed as the input, COD as the output;

- (e)

S0i is assumed as the input, Q as the output.

- 2.

2MIMO case:

- (a)

two inputs (S10 and S0i) and one output (Q);

- (b)

two inputs (S10 and SOi) and two outputs (Q and COD).

In our studies, all ANN models employed two layers, with the hidden layer typically containing six neurons determined experimentally. Hyperbolic tangent functions were used for activation in the hidden layer, while a linear function was applied to the output layer. Model validation yielded excellent results, with negligible static error and minimal dynamic error, demonstrating the models’ capacity to predict biogas yield and support process control for cattle dung digesters [

26,

27,

28,

29,

30,

56].

Almomani has extensively modeled AcoD process using standalone ANN models for the prediction of the biogas yield and composition [

59]. An ANN architecture consisting of three layers with fifteen neurons was developed as a model. The ANN model was trained over 260 epochs to accurately predict the performance of AcoD involving agricultural solid waste (ASWs) and cow manure (CM) under various operational conditions [

59]. The algorithm was specifically designed to model and optimize cumulative methane production (CMP) from ASWs, CM, and their mixtures under both mesophilic and thermophilic conditions. The results indicated that a 70:30 mixture of ASWs to CM produced the highest CMP of 334 ± 4 NL/kgVS, compared to 230 ± 10 NL/kgVS for mono-digested substrates. This study confirms the capacity of the ANN model to predict the behavior of AcoD and identify the optimum conditions in a short time [

59].

5. Product Yield and Composition Prediction

The AI based algorithms have significantly facilitated the modeling of AcoD processes, enabling accurate prediction and optimization of biogas and methane yields [

16,

59,

60,

61,

62] as well as gas composition, including CH

4, CO

2, and H

2 [

63,

64]. Standalone ANN models, in particular, have been extensively applied for forecasting both biogas yield and composition in AcoD processes [

13,

14,

15,

59,

60,

65,

66,

67].

Comparisons among different neural network types have demonstrated that backpropagation neural networks (BPNN) often outperform generalized regression neural networks (GRNN) and radial basis function neural networks (RBFNN) in predicting cumulative biogas production [

68]. However, many ANN studies relied on a single training algorithm [

13,

14,

15,

59,

60,

65,

66,

67], highlighting the need for careful interpretation of the results. A comprehensive evaluation of twelve distinct ANN training algorithms—including Levenberg–Marquardt, Bayesian Regularization, BFGS Quasi-Newton, Resilient Backpropagation, Scaled Conjugate Gradient, Conjugate Gradient variants, One Step Secant, Variable Learning Rate Gradient Descent, and Gradient Descent with Momentum—revealed superior performance of Bayesian Regularization with 50 neurons for methane yield prediction [

69].

Fajobi et al. (2025) [

70] applied ANN to model experimental data from the anaerobic co-digestion of cow dung, mango pulp, and

Chromolaena odorata, using temperature and pressure as inputs and biogas yield as the output. Thirty-three network architectures were evaluated, and the optimized topology was selected based on minimal training error and a high coefficient of determination, achieving predictions with at least 99.8% accuracy.

Long et al. (2021) [

71] assessed six machine learning algorithms using genomic data and operational parameters to predict methane yield. Random forest (RF) achieved classification accuracies of 0.77 with operational parameters alone and 0.78 when including genomic data at the bacterial phylum level. Combining both types of data improved predictive accuracy, while regression using neural networks yielded a low root mean square error of 0.04 (relative root mean square error = 8.6%). Feature importance analysis identified

Chloroflexi,

Actinobacteria,

Proteobacteria,

Fibrobacteres, and

Spirochaeta as the top five influential phyla, providing guidance for proactive microbial management.

Despite their effectiveness, ANN models have limitations, particularly when handling collinearity and a large number of input variables, such as co-substrates and their interactions [

72]. Integrating ANN with PCA addresses this challenge by transforming original datasets into uncorrelated principal components, reducing dimensionality while retaining most of the original information. PCA-based ANN models (ANN-PCA) have demonstrated superior performance in predicting biogas and methane yields compared to conventional ANN approaches. This is because PCA helps to remove the collinearity issues and reduce the number of input parameters [

72,

73].

Once an ANN model with sufficient generalization capability is established, its input space can be optimized to identify process variables that maximize biogas and methane production. Various nature-inspired metaheuristic algorithms have been used to fine-tune both ANN models, as well AD and AcoD operational parameters [

17,

74,

75,

76,

77,

78,

79]. A lot of studies employed such an approach in which the ANN model was first developed for the prediction of biogas yield and the resulting ANN model was then combined with the optimization method, where it served as the fitness function for the optimization of AD and AcoD processes (i.e., biogas yield) [

16]. The hybrid ANN model and advanced optimization algorithms can effectively model the nonlinear dependencies of the AD and AcoD process due to substrate complexity, biochemical reactions, and microbial dynamics [

74,

78]. During ANN model development, the selection of optimized ANN architecture (number of layers and the number of neurons per layer) and parameters (weights, biases, learning rate, etc.) is critically important [

6]. Specifying too many neurons results in an overfitting problem while too few neurons limit the modeling capabilities of ANN [

6]. Traditional trial-and-error selection is computationally intensive [

13,

14,

59,

80]. Recently, studies have successfully coupled ANN models with nature-inspired optimization algorithms for selecting optimum ANN architecture [

68,

78,

79] and AcoD parameters [

16,

75,

76,

77]. For instance, Zaied et al., (2023) [

80] used the integrated framework of ANN and PSO for optimizing the ANN parameters (weights and biases) while other studies used GA [

78], moth flame optimization (MFO) algorithm [

81], and seagull opti-mization algorithm (SOA) [

74] in selecting optimal ANN architecture for predicting biogas yield. Furthermore, studies have successfully applied an adaptive neuro-fuzzy inference system (ANFIS) for predicting biogas yield during AcoD of various co-substrates with R

2 values over 0.994 [

82,

83,

84]. Although ANN models performed well in modeling AD and AcoD system, the major limitation of these models is their “black-box” nature, thereby making them difficult to interpret. Neural networks tend to yield high prediction accuracy, but they rely on large amounts of training data and hyperparameter optimization. Furthermore, overfitting, high computational cost, and poor generalization issues need to be considered while applying ANN models.

Mukasine et al. (2024) [

72] proposed a novel methodology to enhance the accuracy of biogas yield prediction through a stacking ensemble MLapproach. This strategy combines three distinct ML algorithms—light gradient-boosting machine (LightGBM), categorical boosting (CatBoost), and an evolutionary optimization strategy—to achieve improved performance and predictive precision. The model was evaluated using environmental datasets obtained from operational biogas production facilities. By leveraging optimal parameter selection and the stacking ensemble framework, the approach demonstrated superior accuracy and reduced variability in predictions. Furthermore, the proposed model was benchmarked against alternative ML techniques, including k-nearest neighbor (KNN), RF, and decision tree (DT). Results from this comparative analysis indicated that the stacking ensemble model outperformed all tested conventional models, confirming its effectiveness for biogas yield prediction [

72].

Tree-based machine learning approaches are generally easier to implement compared to other algorithms. These methods typically require minimal data preprocessing, and missing predictor values can be handled efficiently due to the inherent structure of the models. Additionally, tree-based techniques allow straightforward assessment of feature importance, which enhances model interpretability, improves predictive performance, and facilitates a clearer understanding of the relationships within the dataset [

6]. Numerous studies have successfully employed tree-based models for predicting biogas yield and composition during AcoD [

10,

24,

32,

85,

86,

87]. For example, Clercq et al. (2020) [

24] compared elastic net RF, and extreme gradient boosting (XGBoost) for predicting daily biomethane production in an industrial-scale AcoD facility. The results demonstrated superior performance of RF and XGBoost over elastic net. However, these models were primarily based on feedstock input data and did not incorporate operational parameters. To address this limitation, Wang et al. (2021a,b) [

10,

88] included both operational conditions and feedstock information to develop and compare a novel tree-based pipeline optimization tool (TPOT) with ANN models for industrial-scale AcoD modeling. Their findings indicated that the TPOT approach outperformed the ANN model in accurately predicting biogas yield, highlighting the advantage of incorporating operational data alongside feedstock characteristics.

Several studies have conducted comparative evaluations of various AI algorithms for modeling the anaerobic co-digestion (AcoD) process [

89,

90,

91,

92,

93]. For example, ANN have been compared with fuzzy logic [

94], response surface methodology (RSM) [

95], ANFIS and logistic regression [

96], as well as fuzzy Mamdani models combined with RSM [

97] for predicting biogas yield and composition. In addition, other investigations have compared linear regression, support vector machines (SVM), RF, extreme gradient boosting (XGBoost), and KNN [

85], as well as RF, XGBoost, and ANN [

87] for the same predictive purposes.

In summary, ANNs remain the most commonly applied AI algorithms for forecasting biogas yield and composition in AcoD. However, due to challenges associated with their interpretability, tree-based models are often preferred for AcoD modeling, as they provide interpretable structures that effectively capture relevant information from the data. Key input variables consistently used for predicting biogas yield and composition include temperature, hydraulic retention time (HRT), carbon-to-nitrogen (C/N) ratio, and pH. Since the majority of studies have focused on laboratory-scale batch systems, there is a clear need to further explore AI-based modeling approaches for commercial-scale, continuous AcoD operations to ensure their practical applicability.

6. Monitoring and Control

Current monitoring systems for key process parameters in AD and biogas plants, such as volatile fatty acids (VFAs) concentration, alkalinity, or microbial populations, are often prohibitively expensive and demand substantial maintenance [

44,

45]. Typically, only a limited number of variables such as pH, T, flow rates, and the composition of gaseous outflow are feasible for online measurement and automation due to cost-effectiveness [

34]. An alternative approach involves using mathematical models of the AD process combined with a restricted set of available online sensor data to estimate the temporal evolution of critical process variables through so-called software sensors, or virtual sensors [

44,

45]. The fundamental principle of a software sensor is to leverage easily accessible online data together with a process model to infer values of crucial variables that are otherwise difficult, costly, or impossible to measure in real time [

46].

Software sensors are generally classified into two categories: model-driven and data-driven. Model-driven sensors, based on classical, require a thorough understanding of the process mechanisms. In biochemical processes, classical models are typically formulated using mass balance equations coupled with kinetic expressions for substrate consumption and microbial growth rates [

44,

45,

46,

47]. Specifically, for AD, various model-based software sensor strategies have been reported, ranging from classical Kalman filters and adaptive observer schemes to nonlinear asymptotic, interval observers, and high-order sliding mode approaches [

44,

45,

46,

47,

48]. Nevertheless, model-based software sensors present inherent challenges, including the costs and complexity associated with deriving suitable kinetic structures that accurately reflect the intricate interactions occurring in the bioprocess [

45]. Furthermore, these sensors often suffer from limited predictive capabilities due to the inherent limitations of classical bioprocess models [

46,

48].

The main advantage of software sensors is their simplicity of implementation as they rely on inexpensive and readily available online measurable signals [

98]. Data-driven models are constructed solely from historical datasets obtained from the process (online and offline) [

6,

98]. They can be developed quickly without requiring prior knowledge of the complex biochemical phenomena underlying the system [

6,

49].

Conversely, the primary advantage of data-driven approaches lies in their straightforward implementation, relying on inexpensive and readily available online measurements [

98]. These models are developed solely from historical datasets collected from the process, both online and offline, and can be established rapidly without requiring detailed knowledge of the complex biochemical phenomena involved. For example, Wang et al. (2018) [

20] developed an ANN-based software sensor for online monitoring of alkalinity in an anaerobic co-digestion system. A backpropagation feedforward ANN was constructed using available online measurements, including pH, oxidation-reduction potential, and electrical conductivity. Similarly, Dewasme (2009) [

98] designed a radial basis function neural network (RBFNN) software sensor to estimate VFAs, alkalinity, and biogas composition in an AD system treating brewery wastewater, based on measured parameters such as electrical conductivity, temperature, pH, redox potential, suspended solids, and influent and effluent flows. In another study, Clercq et al. (2020) [

24] applied different machine learning regression techniques, including random forest and extreme gradient boosting, to model and forecast biomethane production as a function of various organic waste inputs in an industrial-scale anaerobic co-digestion plant.

However, to the best of the authors’ knowledge, the integration of typical online measurements such as T, pH, flow rates, and biogas composition into machine learning-based software sensors for estimating key parameters of biogas plants remains an open research area. Such developments could significantly enhance operation, monitoring, and automation in biogas facilities.

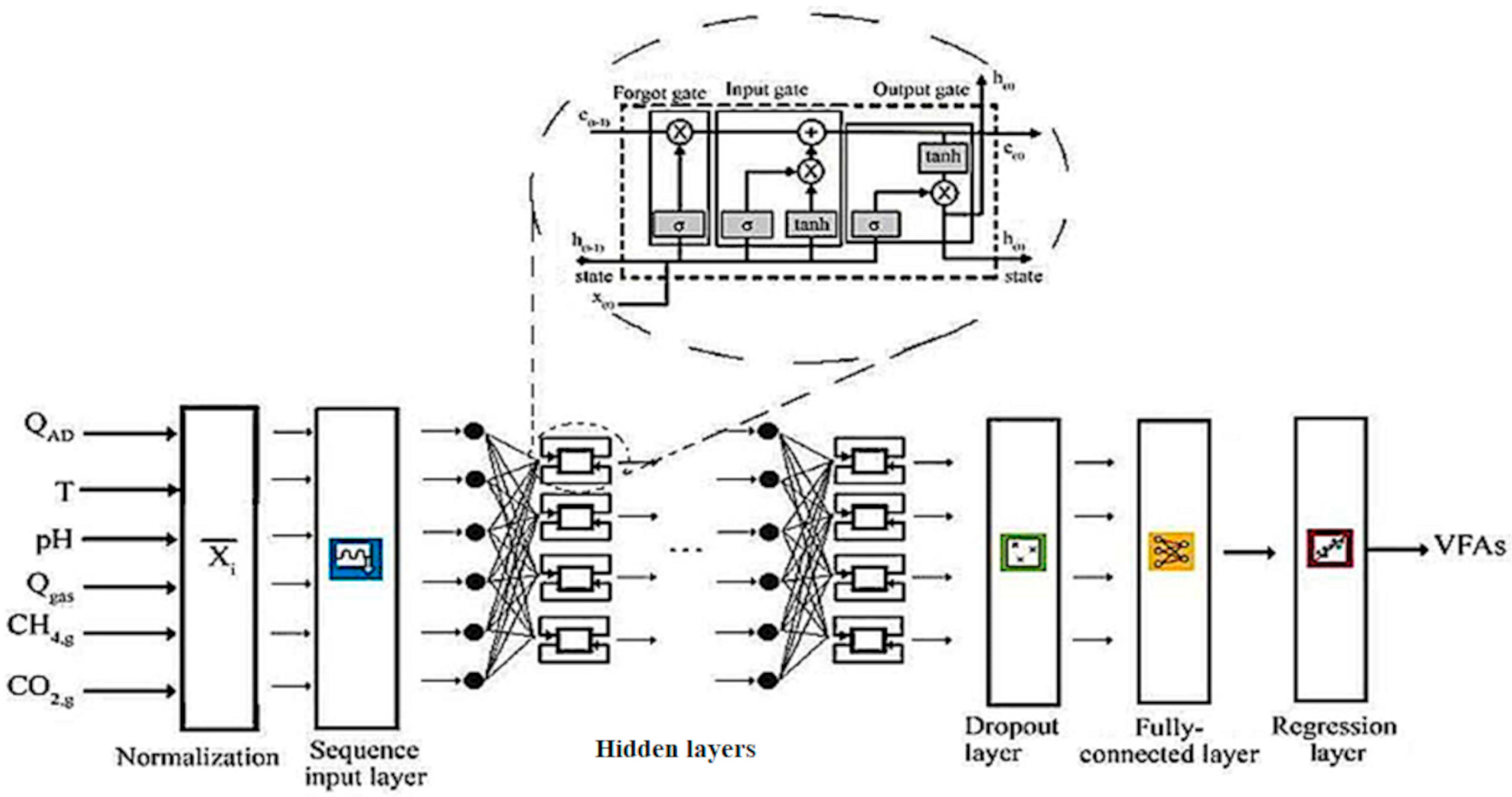

Lara-Cisneros (2024) [

49] proposed data-driven software sensors capable of estimating VFAs online using readily available sensor data from municipal wastewater treatment biogas plants. The study utilized online measurements, including T, pH, flow rates (Q

AD and Q

gas), and biogas composition (CH

4.g and CO

2.g) as input variables, with VFAs concentration serving as the target output. Based on these inputs, two distinct modeling approaches were developed: Principal Component Analysis combined with Non-linear Support Vector Regression (PCA-NSVR) and a Long Short-Term Memory (LSTM) recurrent neural network, as illustrated in

Figure 2.

The dataset was generated from numerical simulations using the International Water Association (IWA) Benchmark Simulation Model No. 2 (BSM2) [

99], which incorporates ADM1 with dynamic influent data and noisy sensor signals. The simulations were conducted over a 180-day period on the BSM2 platform, considering online measurements recorded every 30 min for variables such as temperature, pH, flow rates, and biogas composition, alongside daily offline samples for VFAs concentration. The performance of both software sensor approaches was assessed using the mean-root square error applied to the testing dataset. Results indicated that the LSTM recurrent neural network was particularly effective in capturing the sequential dynamics of the input data, making it more efficient for online estimation of VFAs. The ability of LSTM networks to represent complex temporal patterns allows for improved modeling of the dynamic behavior of biogas plants, providing accurate estimates of critical process components. Nevertheless, these findings are theoretical, and further research is required to validate and implement the approach in practical operational settings.

The AcoD process is generally more stable than conventional AD; however, factors such as variability in co-substrates, their mixing ratios, and diverse operating conditions can lead to the accumulation of inhibitory compounds, potentially causing digester failure [

4,

9,

17]. Consequently, process monitoring and control have become critical for maintaining stability and maximizing methane production. Given the susceptibility of AcoD systems to fluctuations in loading and co-substrate composition, identifying and monitoring key operational parameters is essential for effective process control [

9,

17,

20]. The absence of suitable process indicators can result in insufficient control and suboptimal performance of the AcoD system [

100,

101]. Typical indicators for monitoring AcoD include biogas production and composition, volatile solids reduction, pH, alkalinity, oxidation–reduction potential (ORP), chemical oxygen demand (COD), VFA, VFA/total alkalinity (TA) ratio, ammonia/ammonium (NH

3/NH

4+), and microbial community structure and activity [

102,

103]. An ideal performance indicator should not only reflect the current state of the process but also be straightforward and reliable to measure. Moreover, it should exhibit a pronounced response to process disturbances relative to background fluctuations [

100,

104].

Conventional monitoring methods for AD processes rely heavily on labor-intensive and time-consuming chemical and physical analyses, which limits their applicability for real-time process monitoring and control. Additionally, effective digester management requires sophisticated instrumentation and equipment, along with skilled operators to obtain reliable measurements of critical process variables. This approach is not only expensive but also subject to limitations such as measurement delays and reduced precision [

12,

20,

105]. Consequently, data-driven AI-based soft sensor modeling has been increasingly explored to predict parameters that are otherwise difficult to measure, leveraging the hidden interdependencies among input variables to enable real-time monitoring, optimization, and control of the AcoD process [

12,

106].

The VFA concentration represents a key monitoring parameter in AD and AcoD, as excessive accumulation can lead to digester instability and failure [

12,

34]. Online monitoring of VFAs has been successfully implemented using sequential and orthogonalized partial least squares (SO-PLS) regression [

18], as well as various machine learning-based soft sensors, including RF, ANN, extreme learning machines (ELM), SVM, and Gaussian processes (GP), based on simulated datasets [

12]. To further advance ML-based soft sensors for VFA monitoring, a study [

107] introduced novel DNN models and random standard deviation sampling (RSDS)-based approaches, employing RSDS as a data augmentation technique to generate synthetic data from limited experimental datasets.

Similarly, alkalinity represents a critical parameter for monitoring AD and AcoD processes [

19,

20]. Online measurement of TA is essential for maintaining optimal pH levels in digesters, while partial alkalinity (PA) has been found to be more sensitive than TA for detecting early signs of digester instability. Xue et al. (2017) [

19] reported that multiple linear regression (MLR) outperformed simple linear regression (SLR) in predicting both TA and PA; however, their study was limited by a small dataset of 60 samples. Therefore, larger-scale comparative studies are necessary to draw robust conclusions regarding the relative performance of MLR and SLR in such applications. Moreover, MLR and SLR are often sensitive to outliers and prone to overfitting. In contrast, ANN have been shown to be more reliable and accurate for predicting alkalinity in AcoD systems, based on deviation metrics such as bias, mean absolute error, and RMSE [

20]. Overall, ANN models are adaptive, robust, and fault-tolerant, capable of handling high-dimensional data; however, their performance requires optimization when alkalinity values exceed expected ranges due to changes in co-substrates or other operational conditions [

19,

20].

The PCA has also been applied for online monitoring of AcoD system stability. For instance, Awhangbo et al. [

9] used a PCA model to track shifts from acetolactic methanogenesis to syntrophic acetate oxidation and hydrogenotrophic methanogenesis. Methanogenic pathways and potential microbial community changes were inferred by analyzing fluctuations in biogas production kinetics with PCA. Early-warning detection was particularly challenging at low concentrations of long-chain fatty acids (LCFAs, 522 mg/L), VFAs (189 mg/L), and ammonia/ammonium (NH

3/NH

4+, 160 mg-N/L), which are critical to prevent a shift toward hydrogenotrophic methanogenesis and potential system failure.

Due to its inherent advantages, including the ability to rapidly adapt to new conditions through transfer learning, deep learning-based frameworks have been applied for real-time monitoring of the AcoD process [

108]. State and performance variables were tracked using convolutional neural networks (CNN) and bidirectional LSTM models. Among these, a hybrid CNN-LSTM model demonstrated greater robustness compared to individual CNN or LSTM models in terms of validation performance, reduced overfitting risk, and training efficiency, enabling accurate prediction of critical process parameters such as pH, alkalinity, VFA, COD, soluble COD (sCOD), TS, volatile solids (VS), and methane production rate and composition in biogas [

108].

Gurubel et al. (2019) [

109] proposed an inverse optimal neural control strategy for nonlinear anaerobic bioprocess models aimed at simultaneous hydrogen and methane production under disturbances. Leveraging the fundamental system properties, a passivity-based approach was employed to guarantee asymptotic stability. A recurrent high-order neural network was designed to estimate unmeasurable state variables under unknown bounded disturbances and parameter uncertainties, which are directly linked to biofuel production. Optimal control laws derived from the neural model ensured overall system passivation. Simulation results demonstrated that the proposed neural control strategy effectively stabilized hydrogen and methane production along desired trajectories, even in the presence of disturbances.

Ghanavati et al. (2021) [

110] proposed a fuzzy supervisory control approach integrated with an adaptive model predictive controller (AMPC) to enhance the productivity of AD processes while maintaining operational stability. In this hierarchical control framework, the set-point for the inner loop is provided by a supervisory controller. Within the inner loop, the AMPC regulates the feed flow rate to achieve the desired methane production rate. The AMPC is designed based on an auto-regressive moving average (ARMA) model, with parameters updated at each sampling interval to increase robustness against external disturbances and model uncertainties. At the supervisory level, a fuzzy logic system adjusts the lower-level controller’s set-point based on real-time measurements of total VFA concentration. An override control mechanism is implemented to prevent excessive VFA accumulation by maintaining the total VFA concentration within a safe range. The widely accepted ADM1 model was used to simulate the AD process, and simulation studies were conducted to evaluate the proposed control strategy. Results demonstrated that this hierarchical approach can maximize methane production while effectively handling external disturbances and model mismatches.

Over the last decade, control and monitoring strategies have significantly advanced; however, the techno-economic and management aspects of automated process control and instrumentation in AD plants still require thorough investigation.

7. Optimization

Synergistic interactions in the AcoD process, aimed at maximizing productivity (e.g., methane yield and volatile solids reduction) while maintaining system stability (pH and alkalinity), can be achieved through careful optimization of co-substrate selection, including types, mixing ratios, and temporal and spatial availability [

11,

111]. Achieving this manually is challenging due to the high variability of available co-substrates and their possible combinations. Consequently, optimizing the AcoD process is complex, with no single definitive solution; rather, a set of holistic solutions are required to address multiple objectives simultaneously, such as optimal co-substrate mixing ratios, pH balance, C/N ratio, minimal energy input, and production of high-quality biogas and digestate [

15,

16,

111]. Traditional optimization approaches typically rely on laboratory-scale batch experiments with varying co-substrate mixing ratios to identify conditions that enhance digestibility and methane yield [

40,

112]. These methods are labor-intensive, time-consuming, and costly. To overcome these limitations, several mathematical and analytical techniques, including kinetic models, statistical approaches, and the ADM1 framework, have been developed to optimize key process parameters, such as organic loading rate, retention time, and co-substrate ratios, ultimately improving biogas and methane production [

2,

40,

112,

113]. Álvarez et al. (2010) [

114] introduced a linear programming-based optimization strategy by defining constraints on waste mixture characteristics, assuming improved biodegradation potential through optimal waste combinations; however, the study did not consider the availability of diverse co-substrates. Effective AcoD optimization must address both mixing ratios and the temporal and spatial availability of co-substrates. Verdaguer et al. (2016) [

115] proposed an ant colony optimization (ACO) algorithm for real-time process optimization based on co-substrate composition and availability, also addressing logistical challenges associated with co-substrate supply [

21]. In a more recent study, the same authors compared ACO, genetic algorithm (GA), and PSO for optimizing centralized AcoD plant networks with multiple waste sources and receptors. While ACO and GA aimed to maximize biogas production by pushing constraints (e.g., COD, total nitrogen, total alkalinity) to their limits, PSO focused on optimizing process stability under these restrictions [

11].

Process control and monitoring technologies for AD systems are advancing rapidly, enabling more precise management and optimization of AcoD process parameters, which is essential for enhancing biogas production. Various AI-based optimization models have been successfully developed and applied for this purpose, including central composite design–response surface methodology (CCD-RSM) [

22] and artificial neural network–response surface methodology (ANN-RSM) [

23]. For instance, Jiménez et al. (2015) [

116] utilized an RSM model to investigate the effects of co-substrate concentrations and their potential interactions on specific methanogenic activity (SMA), highlighting the importance of understanding co-substrate synergism for optimizing methane production.

In summary, nature-inspired optimization algorithms offer a promising alternative to traditional, labor-intensive, and time-consuming approaches for optimizing AcoD process parameters. These algorithms not only enable the identification of optimal conditions to maximize biogas yield but also enhance the predictive performance of AI models employed for simulating AcoD processes. Furthermore, nature-inspired algorithms can assist in selecting the most relevant input variables for AI-based modeling, improving model accuracy and reducing computational complexity, thereby supporting more efficient process design and operation.

8. Challenges and Prospects

Studies investigating the application of AI algorithms have highlighted multiple advantages in predicting, monitoring, controlling, and optimizing the AD and AcoD processes. However, several challenges and limitations remain that need to be addressed to fully exploit the potential of these algorithms. Most AI-based modeling studies for AD and AcoD rely on limited datasets, due to the lack of cheap and reliable sensors for online measurements of a large part of the main variables (concentration of different types of microorganisms and some intermediate products), as well as the difficult, slow and expensive analyses of another part of these variables (VFA, alkalinity, enzyme activity) in these processes. The development of robust data-driven models requires comprehensive datasets that incorporate both quantitative and qualitative aspects. When only small datasets are available, overfitting can occur, producing models with high training accuracy but poor generalization and testing performance [

20]. Generating sufficient data is often time-consuming and resource-intensive, making data scarcity a frequent constraint in applying AI algorithms to model AD and AcoD processes. To mitigate this issue, strategies such as generating synthetic data from the original dataset using advanced techniques like generative adversarial networks, or employing AI algorithms that perform well on limited datasets such as SVM and DT, can be applied. Additionally, the challenge of small datasets for AcoD modeling can be addressed by creating simulated datasets using established mechanistic models, such as ADM1.

The predictive performance of AI algorithms in modeling AD and AcoD processes can be further enhanced by integrating them with advanced optimization techniques. These techniques aid in selecting the most important process features and determining the optimal hyperparameters for AI models [

21,

31,

53,

115]. By identifying critical variables and eliminating redundant or irrelevant parameters, feature selection not only improves model accuracy but also strengthens the generalizability and predictive capabilities of the AI algorithms.

Another critical challenge in applying AI algorithms to model AD and AcoD processes is the lack of interpretability. Interpretable AI models are regarded as understandable and trustworthy, as they provide insights into the underlying mechanisms driving the model outputs [

24]. Incorporating techniques such as feature importance analysis, sensitivity analysis, or model-agnostic approaches can significantly enhance model explainability. Despite the recognized value of interpretability, very few studies have conducted feature importance analyses when modeling AD processes. Available research indicates that substrate organic content is the most influential factor affecting biogas yield [

10,

24,

85]. Moreover, these analyses have consistently identified temperature and pH as key features, followed by operational parameters such as organic loading rate (OLR) and HRT or solids retention time (SRT) in AD process modeling [

23,

108,

117].

AI algorithms also have the potential to leverage secondary meta-omics datasets to reveal metagenomic and metabolic changes in microbial interactions within the AcoD process [

88]. This suggests that AI could serve as a powerful tool for understanding the fundamental mechanisms of co-digestion performance, particularly in relation to microbial community structure, function, and metabolic pathways. Furthermore, validating AI models with experimental data or deploying them in real-world settings is essential to assess their robustness and generalizability. However, most studies to date have focused on lab-scale applications, and there is a notable gap in extending these findings to develop AI models suitable for full-scale AD plant operations.

Deep learning (DL) models can be effectively employed for prediction, optimization, monitoring, and control of the AD process. The DL architectures enhance traditional three-layer neural networks by incorporating additional layers and more complex interactions between nodes within layers, thereby increasing the model’s capacity to capture nonlinear relationships [

63,

117]. Compared to conventional ML methods, the structural diversity of DL networks makes them particularly suitable for modeling the AcoD process. For instance, a recent study developed a DNN model to predict biogas yield based on slurry characteristics, where the model training was coupled with a GA for hyperparameter optimization [

63]. Similarly, Jeong et al. (2021) [

117] proposed a hybrid DL framework combining a dual-stage attention-based LSTM network with variable selection networks (VSNs) to accurately predict biogas production. Despite the demonstrated advantages, the application of DL-based approaches in AcoD modeling remains limited.

Traditional first-principle or “white-box” models, such as ADM1, are often complex, time-intensive, and restricted to specific operating conditions. In contrast, AI-based models rely on robust datasets and are capable of simultaneously handling multiple input and output variables. Nevertheless, due to their “black-box” nature, these models provide predictive outputs without offering insight into the internal mechanisms, relying solely on input-output relationships. The “grey-box” modeling approach, which integrates white-box and black-box models, offers a potential solution by combining the interpretability of classical models with the predictive power of AI, thus improving both performance and transparency in AD and AcoD process modeling.

9. Conclusions

This critical review highlighted the applicability of AI algorithms in modeling the AD and AcoD processes for predicting product yield and composition, as well as for process optimization, monitoring, and control. Several challenges limit the widespread application of AI in these processes, including small and limited datasets, poor generalizability of standalone models, the black-box nature of many machine learning approaches, and the interpretability of AI-generated outputs. Although datasets from both laboratory-scale and industrial-scale operations have been used for training AI models, challenges remain due to the diversity of system designs and differences in monitoring equipment. In particular, models trained on laboratory-scale datasets often face difficulties when applied to full-scale, as these systems exhibit higher complexity and variability in microbial communities and operational conditions. Despite these limitations, machine learning approaches can be effectively implemented for real-time predictive modeling in practical applications, helping maintain process stability and enhancing the efficiency of both biogas production and organic waste treatment. In the context of AD, ANN have been the most extensively applied AI approach to date. Nevertheless, our findings indicate that the limited volume of experimental data, which often necessitates additional processing, combined with challenges associated with scaling up from small laboratory bioreactors, restricts the direct applicability of these results in real-world operations, serving primarily as an initial reference point. We argue that leveraging long-term operational data from industrial-scale biogas plants would provide significantly more reliable and practical outcomes.

It is also crucial to acknowledge that most AI models, including ANN-based approaches, function as “black-box” systems. Without a thorough understanding of the underlying biological and biochemical processes, these models may fail to capture critical phenomena such as microbial inhibition or the washout of specific microbial populations, potentially leading to inaccurate or misleading predictions.

At the same time, research continues on the use of mass balance (classical) models to solve a number of problems and mainly to optimize the AD processes. For example, Kegl et al. (2024) [

55] presented a very interesting study, which ended with a practical implementation in an industrial biogas plant with significant improvement of some parameters. The development of complex nonlinear dynamic and AI models of AD and AcoD has been and continues to be the subject of numerous scientific studies. Various mathematical techniques have been used, but unfortunately more often to demonstrate the possibilities of the relevant techniques for the identification of model parameters, synthesis of observers (software sensors) and control algorithms than to solve real problems (including the control of the process). This is largely due to the fact that these studies are conducted by scientists in the relevant field, but without serious in-depth knowledge of AD and AcoD. For obvious reasons, the AD specialists do not understand, but also do not accept the use of such sophisticated algorithms. In this sense, the introduction of some AI methods (e.g., the ANN approach) has real prospects and arouses the interest of specialists because they are simpler and easier to apply. But even in this case, only the joint work of interdisciplinary teams has a real chance of success.

So, in the near future, significant competition should be expected between the use of classical and AI methods to solve the problems of AD and, above all, to spread the obtained results in industrial practice, which for now is too far behind other fields.