Green and Controllable Crosslinked Gel Plugging Technology Based on Modified Natural Biofibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

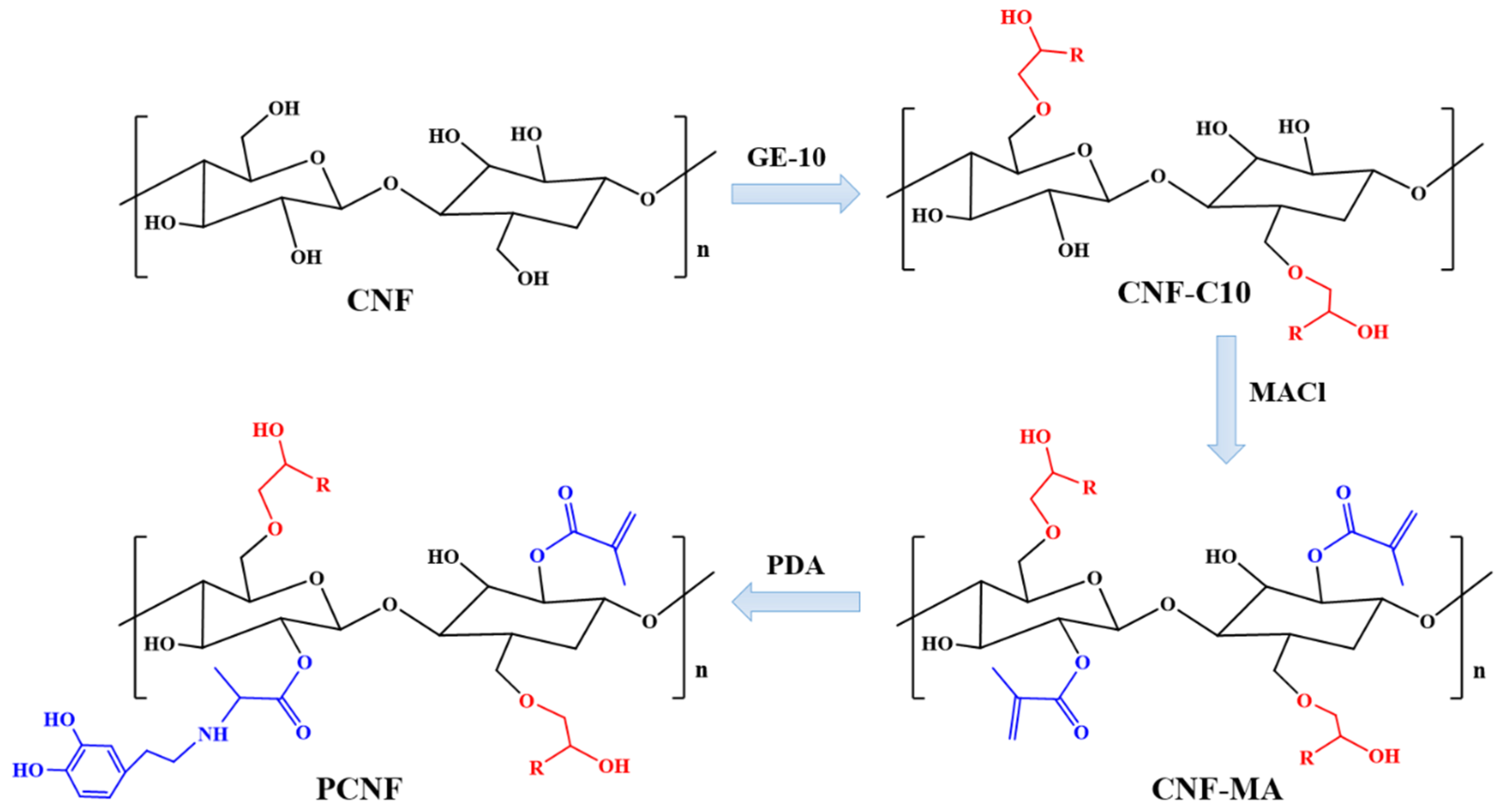

2.2.1. Preparation of Hydrophobically Modified CNF

2.2.2. Grafting of Methacryloyl Groups

2.2.3. Dopamine Modification and Polydopamine Coating

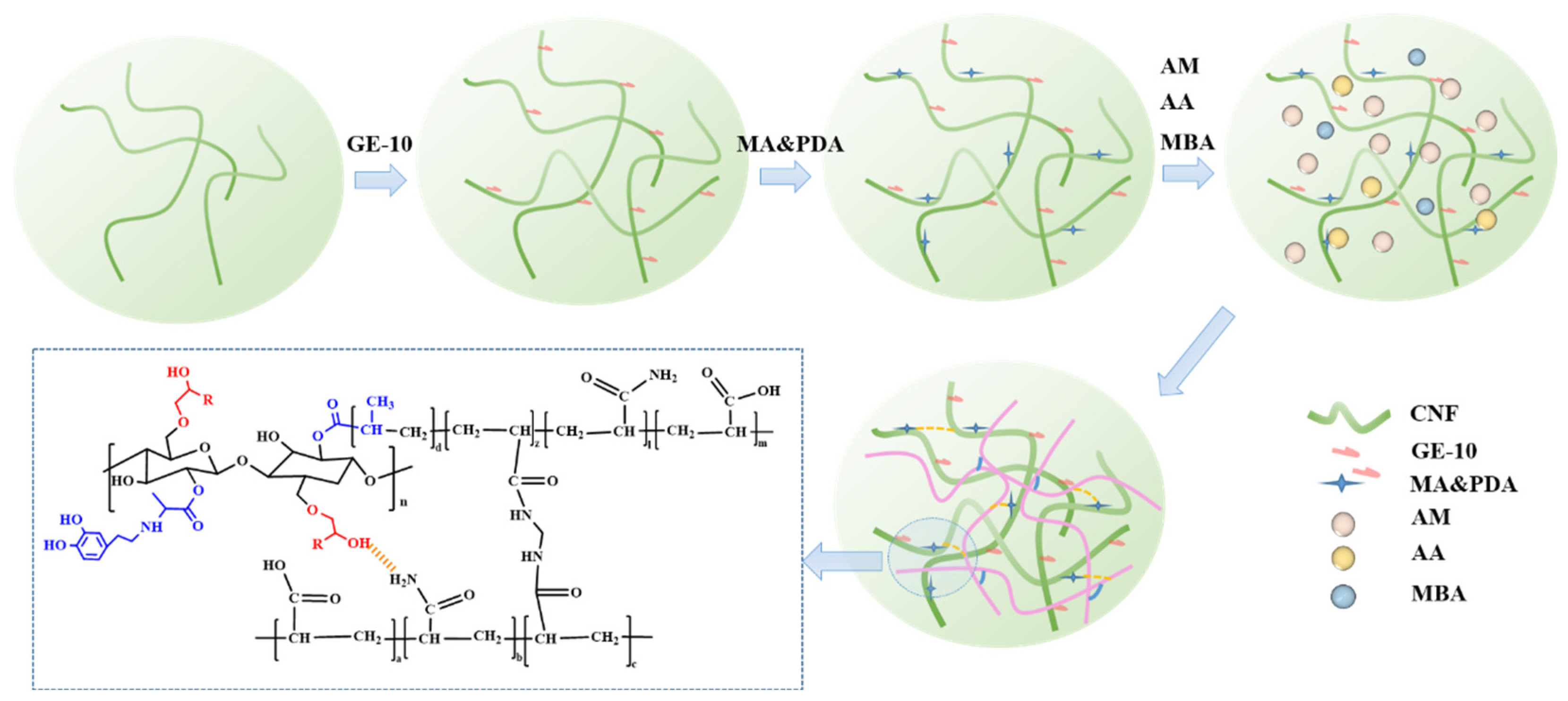

2.2.4. Preparation of Composite Hydrogels

2.3. Characterization

2.4. Rheological Measurements

2.5. Mechanical Properties

2.6. Swelling Behavior

2.7. Texture Analysis

2.8. Plugging Performance Evaluation

3. Results and Discussion

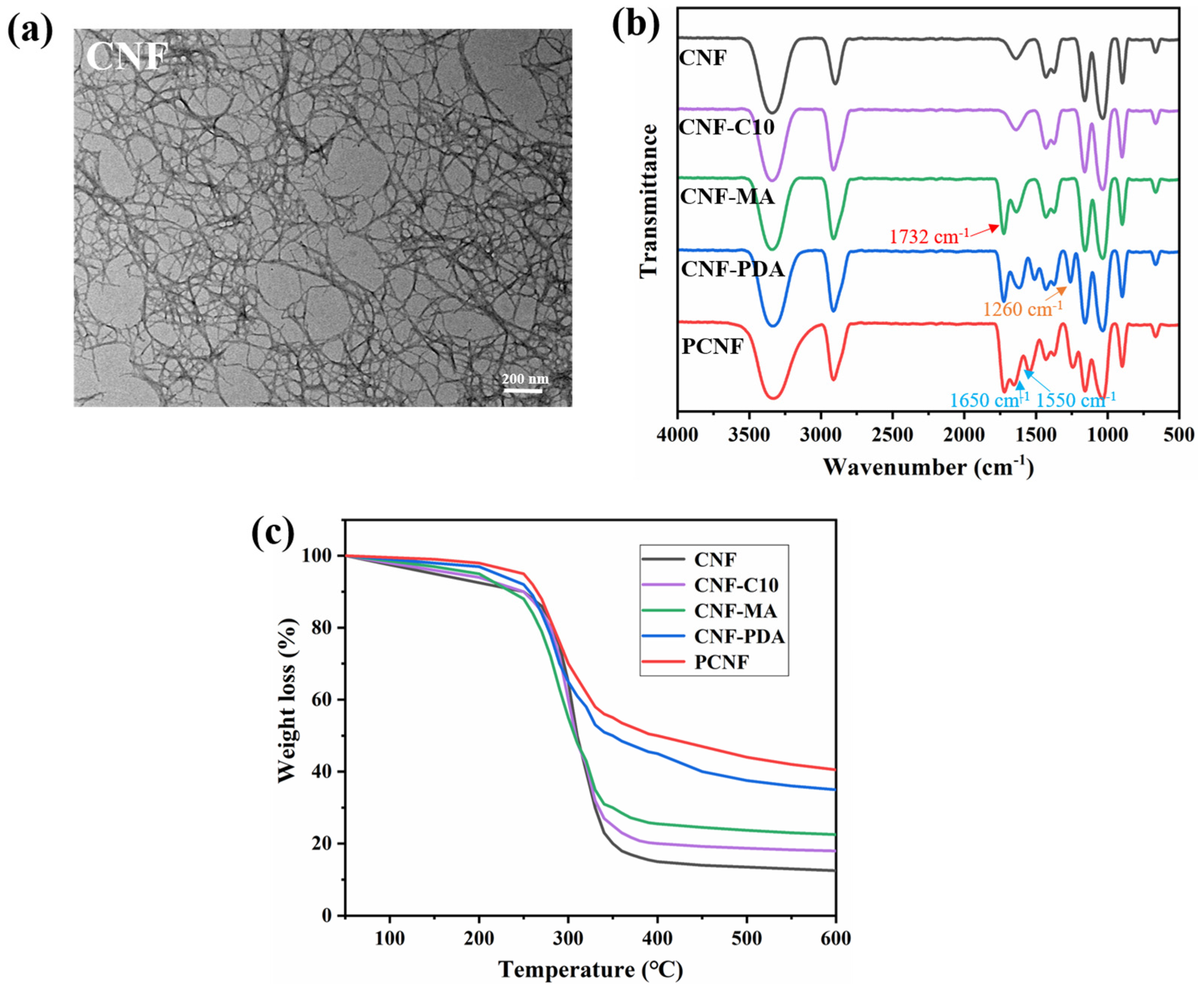

3.1. Structural Characterization

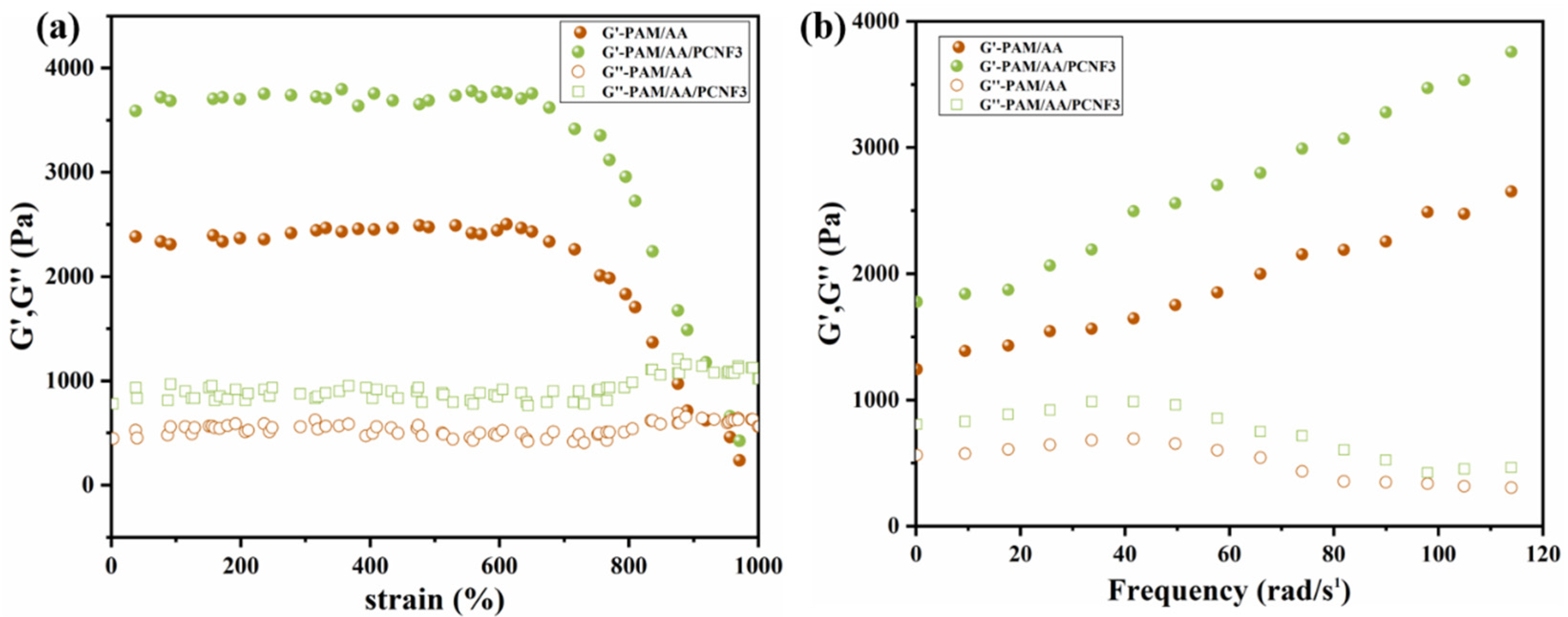

3.2. Influence of PCNF on the Rheological Behavior of Composite Hydrogels

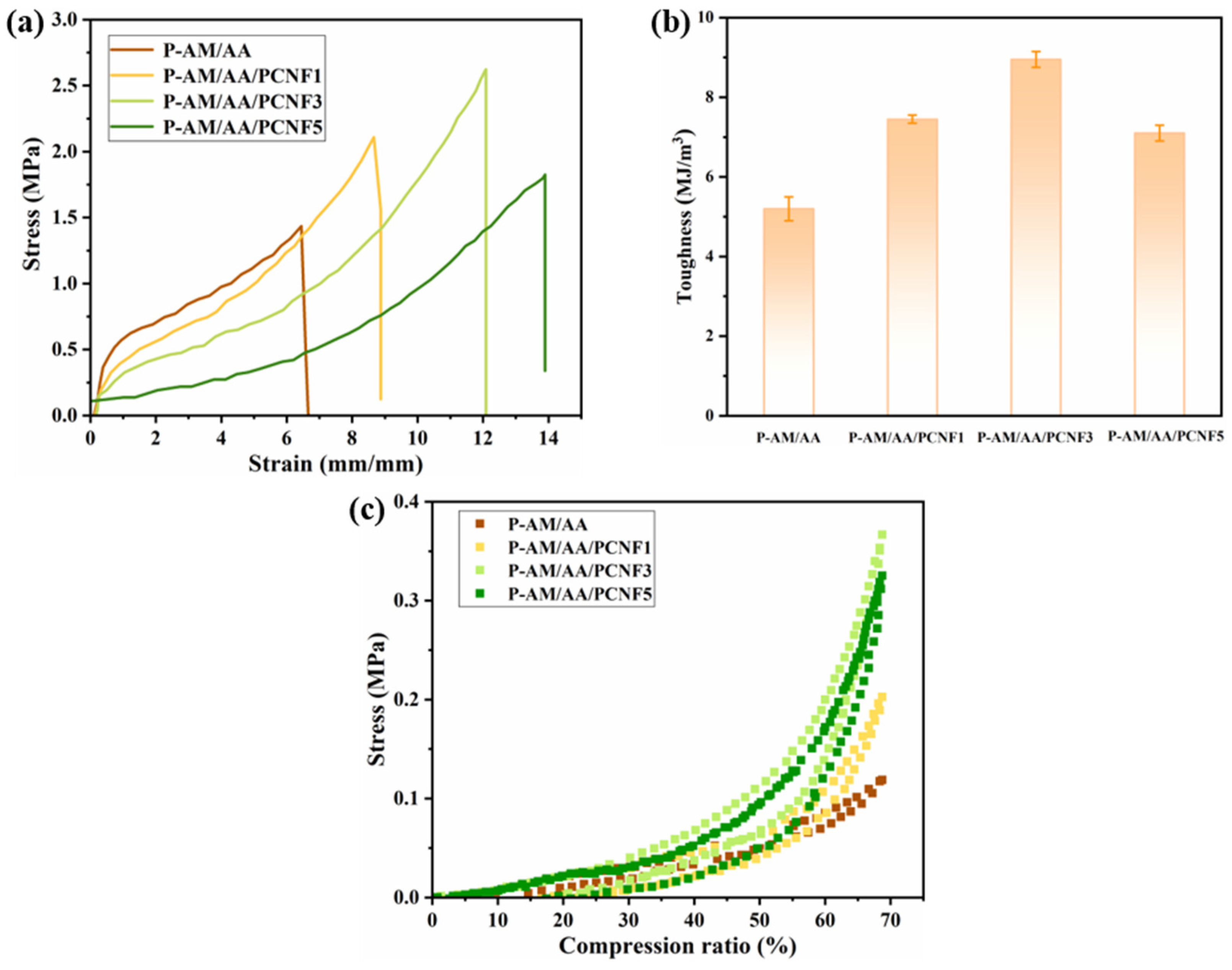

3.3. Mechanical Behavior of Composite Hydrogels with Varying PCNF Content

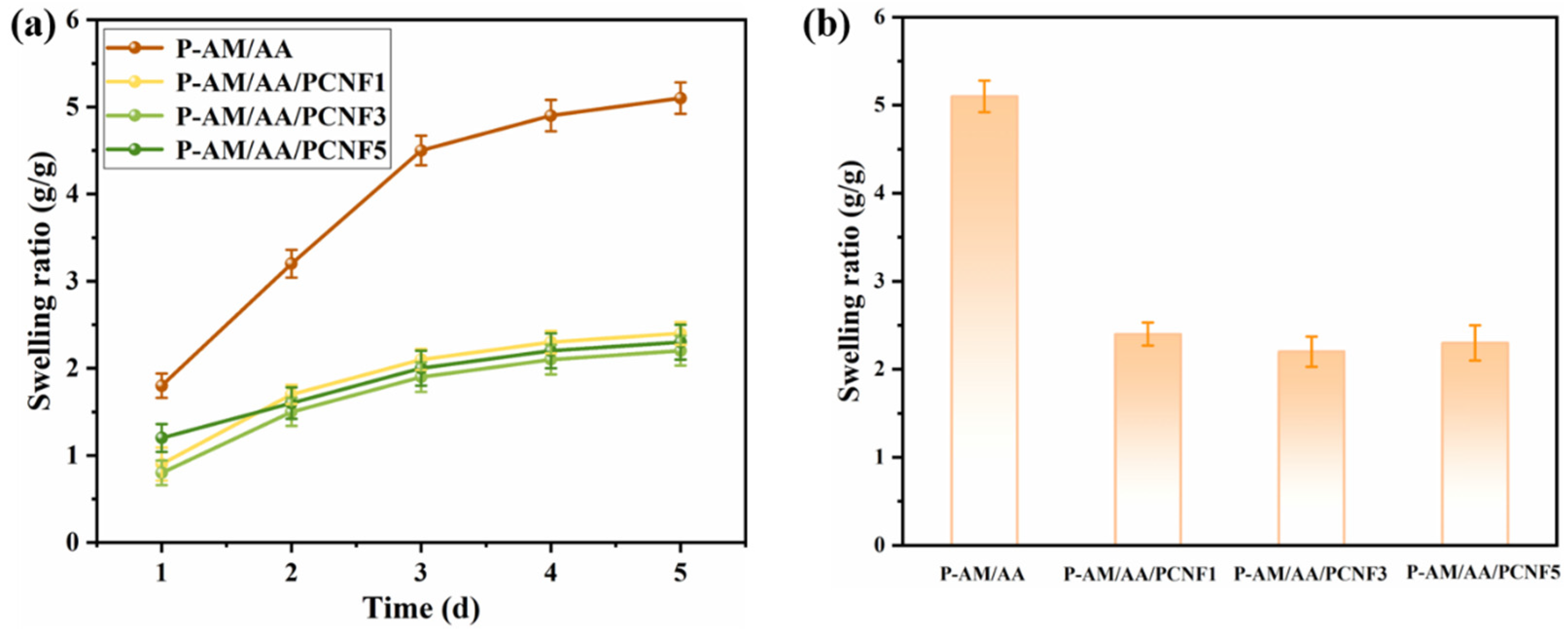

3.4. Impact of PCNF Amount on Hydrogel Swelling Behavior

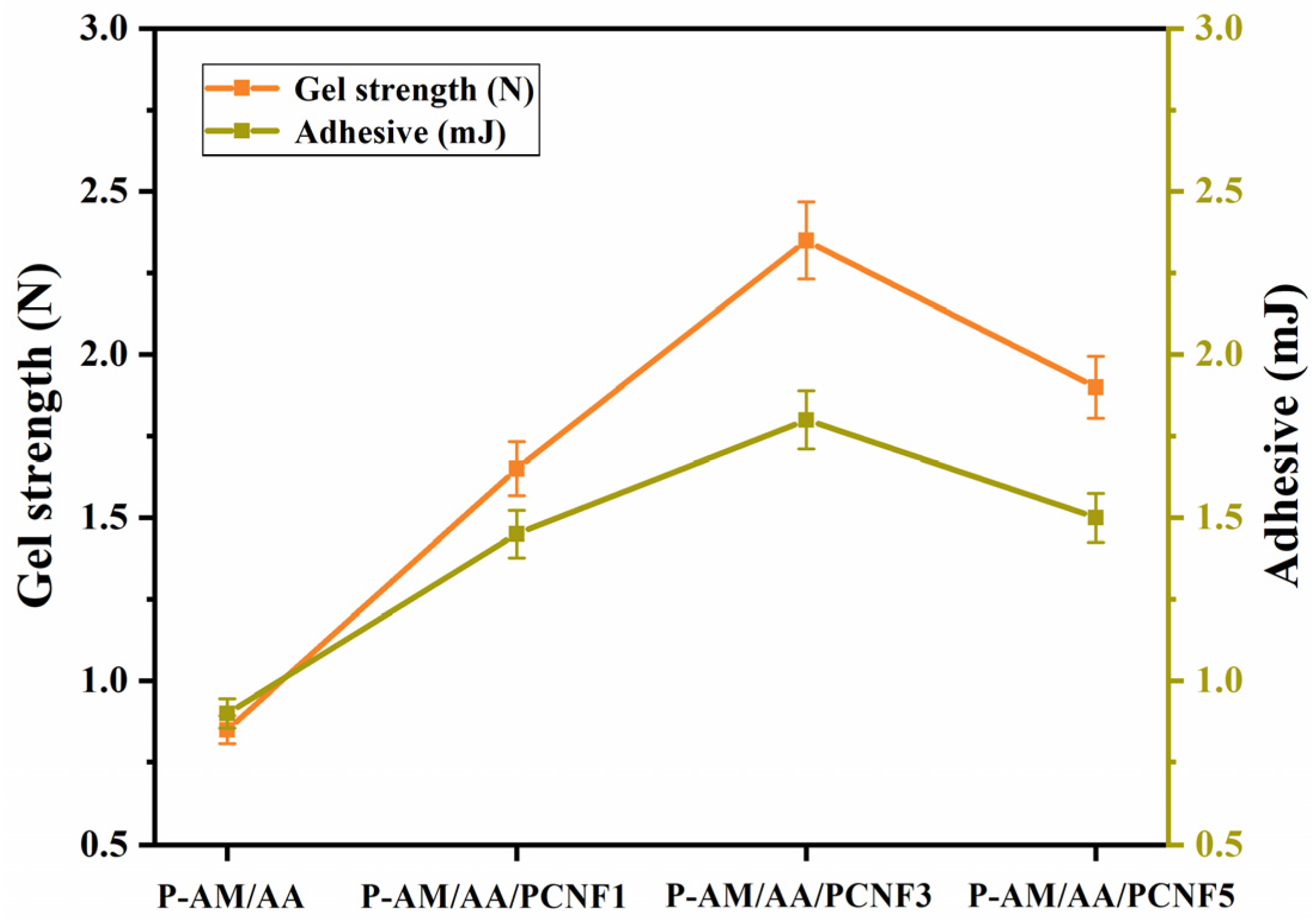

3.5. Impact of PCNF Amount on Hydrogel Texture

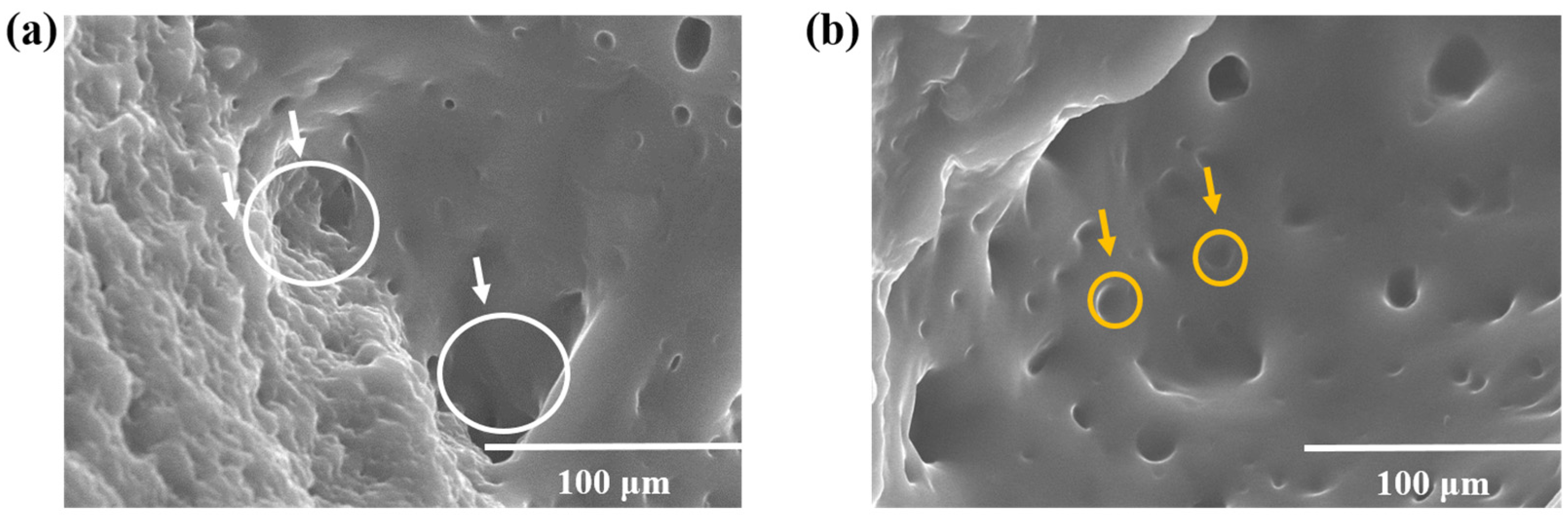

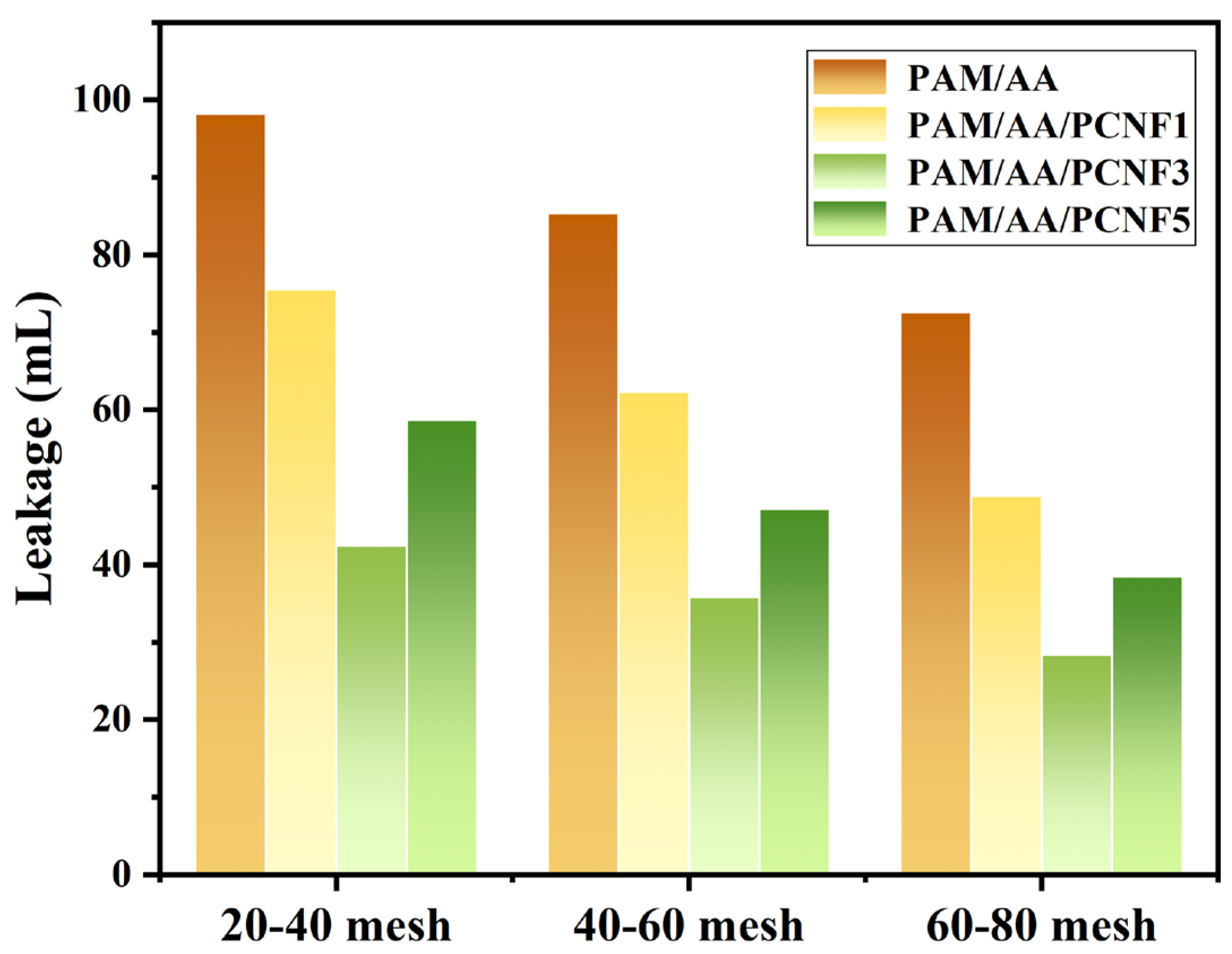

3.6. Effect of PCNF on the Plugging Performance of Composite Hydrogels

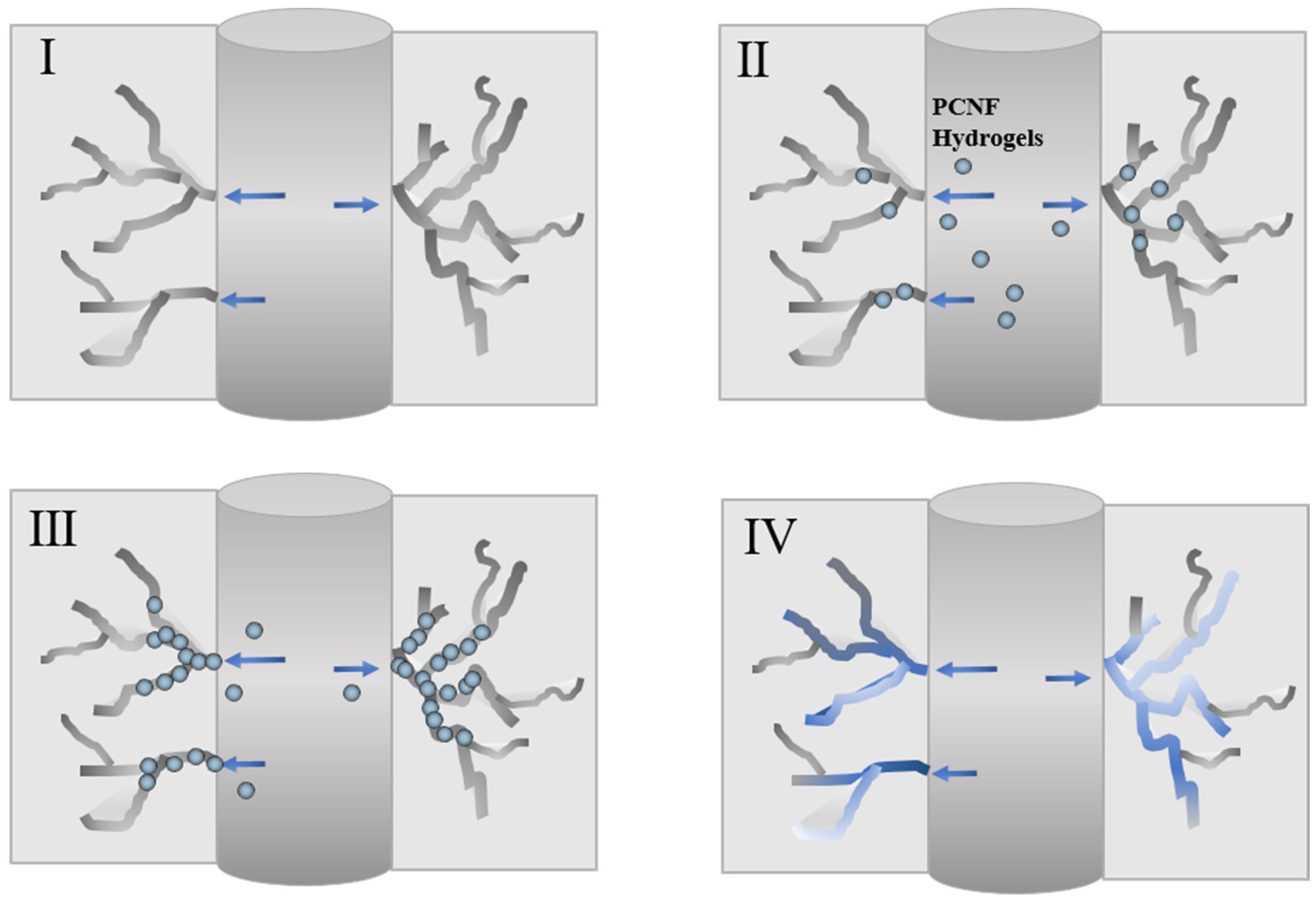

3.7. Plugging Mechanism of PCNF-Reinforced Composite Hydrogels

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, S.; Lin, D.; Xiong, Z.; Spicer, R.; Farnsworth, A.; Valdes, P.; Wang, C.; Cai, F.; Wang, H.; Sun, Y.; et al. A distinctive Eocene Asian monsoon and modern biodiversity resulted from the rise of eastern Tibet. Sci. Bull. 2022, 21, 2245–2258. [Google Scholar] [CrossRef]

- Ma, R.; Dai, L.; Sun, D.; Yang, Y.; Tang, C.; Li, L.; He, Z.; Ni, Y. Nanocellulose/Scleroglucan-Enhanced Robust, Heat-Resistant Composite Hydrogels for Oilfield Water Plugging. Carbohydr. Polym. 2024, 341, 122320. [Google Scholar] [CrossRef]

- Yang, Z.; Ni, R.; Yang, Y.; Qi, J.; Lin, X.; Zhang, Y.; Wang, L.; Wu, Y.; Li, X.; Lu, H. Carboxymethyl Cellulose-Based Supramolecular Hydrogel with Thermo-Responsive Gel-Sol Transition for Temporary Plugging of Oil Pipeline in Hot Work. Carbohydr. Polym. 2024, 324, 121556. [Google Scholar] [CrossRef]

- Liu, H.; Li, X.; Pan, Z.; Dai, L.; Zhang, M.; Shen, F.; Si, C. Lignin-Based Plugging Hydrogel with High-Temperature Resistance and Adjustable Gelation. Adv. Compos. Hybrid Mater. 2025, 8, 111. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, L.; Wan, X.; Tang, Y.; Liu, Q.; Li, W.; Liao, J. Synthesis and Characterization of a Temperature-Sensitive Microcapsule Gelling Agent for High-Temperature Acid Release. ACS Omega 2024, 9, 20849–20858. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.; Cui, X.; Wang, H.; Lou, X.; Yang, S.; Oluwabusuyi, F.F. Research Progress of Intelligent Polymer Plugging Materials. Molecules 2023, 28, 2975. [Google Scholar] [CrossRef] [PubMed]

- Bai, X.; Wang, M.; Chen, Y.; Wu, L.; Yu, J.; Luo, Y. Synthesis and Properties of Self-Healing Hydrogel Plugging Agent. J. Appl. Polym. Sci. 2023, 141, e55005. [Google Scholar] [CrossRef]

- Meng, T.; Liu, R.; Cai, J.; Cheng, X.; He, Z.; Zhao, Z. Breaking structural symmetry of atomically dispersed Co sites for boosting oxygen reduction. Adv. Funct. Mater. 2025, e22046. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, Q.; Sun, J.; Lv, K.; Shang, X.; Liu, C.; Cheng, R.; Wang, F. Self-Healing Hydrogels and Their Action Mechanism in Oil–Gas Drilling and Development Engineering: A Systematic Review and Prospect. Gas Sci. Eng. 2021, 96, 104250. [Google Scholar] [CrossRef]

- Wang, S.; Shi, B.; Shi, Y.; Yang, W.-G.; Zhou, S.; Liu, T.; Yang, D. Core–Shell PAM@PVA Hydrogel with Enhanced Plugging Strength and Controllable Degradation for Petroleum Exploitation. Energy Fuels 2025, 39, 14963–14973. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, S.; Zhu, Q.; Cao, X.; Lv, K.; Feng, Y.; Yin, H. Insights into Polyacrylamide Hydrogels Used for Oil and Gas Exploration: Gelation Time, Gel Strength, and Adhesion Strength. Energy Fuels 2023, 37, 19548–19561. [Google Scholar] [CrossRef]

- Klungtvedt, K.R.; Saasen, A. Comparison of Lost Circulation Material Sealing Effectiveness in Water-Based and Oil-Based Drilling Fluids and under Conditions of Mechanical Shear and High Differential Pressures. J. Energy Res. Technol. 2022, 144, 123011. [Google Scholar] [CrossRef]

- Rong, L.; Zhang, B.; Qiu, H.; Zhang, H.; Yu, J.; Yuan, Q.; Wu, L.; Chen, H.; Mo, Y.; Zou, X.; et al. Significant generational effects of tetracyclines upon the promoting plasmid-mediated conjugative transfer between typical wastewater bacteria and its mechanisms. Water Res. 2025, 287, 124290. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.; Wang, J.; Yang, S.; Fu, J.; Eteme, Y.L. Research Progress of Hydroxyethyl Cellulose Materials in Oil and Gas Drilling and Production. Cellulose 2023, 30, 10681–10700. [Google Scholar] [CrossRef]

- Yang, X.; Wang, L.; Yano, H.; Abe, K. Toughened Hydrogels through UV Grafting of Cellulose Nanofibers. ACS Sustain. Chem. Eng. 2021, 9, 1507–1511. [Google Scholar] [CrossRef]

- Wei, B.; Mao, R.; Tian, Q.; Xiang, H.; Xu, X.; Wood, C. Nanocellulose-Strengthened Particle Gel for Conformance Control in Fractured Tight Formations. Part I: Preparation and Mechanical Stability. Energy Fuels 2020, 34, 5766–5776. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, L.; Zhang, Q.; Ni, C.; Deng, N.; Huang, X. Efficient Adsorptive Removal of Phosphonate Antiscalant HEDP by Mg-Al LDH. Separations 2025, 12, 259. [Google Scholar] [CrossRef]

- Vivas, C.; Salehi, S. Screening of Lost Circulation Materials for Geothermal Applications: Experimental Study at High Temperature. J. Energy Res. Technol. 2021, 144, 033008. [Google Scholar] [CrossRef]

- Wang, J.; Xu, J.; Bai, Y.; Xu, H.; Liao, B.; He, G.; Li, Y.; Li, W. Synthesis and Performance Evaluation of Polymer-Ceramic Composite Microcapsules as Reservoir Protectant for Natural Gas Hydrate Drilling. Sci. Rep. 2024, 14, 22678. [Google Scholar] [CrossRef] [PubMed]

- Sirviö, J.A.; Ukkola, J.; Liimatainen, H. Direct Sulfation of Cellulose Fibers Using a Reactive Deep Eutectic Solvent to Produce Highly Charged Cellulose Nanofibers. Cellulose 2019, 26, 2303–2316. [Google Scholar] [CrossRef]

- Singh, M.; Kaushik, A.; Ahuja, D. Surface Functionalization of Nanofibrillated Cellulose Extracted from Wheat Straw: Effect of Process Parameters. Carbohydr. Polym. 2016, 150, 48–56. [Google Scholar] [CrossRef] [PubMed]

- Guo, C.; Xu, Y.; Deng, N.; Huang, X. Efficient degradation of organophosphorus pesticides and in situ phosphate recovery via NiFe-LDH activated peroxymonosulfate. Chem. Eng. J. 2025, 524, 169107. [Google Scholar] [CrossRef]

- Guo, C.; Jiang, G.; Guan, J.; Huang, S.; Guo, Y.; He, Y.; Yang, L.; Dong, T. Preparation and Performance Evaluation of a Thixotropic Polymer Gel for Loss Circulation Control. Fuel 2024, 371, 132148. [Google Scholar] [CrossRef]

- Zhao, Z.; Sun, J.; Liu, F.; Bai, Y.; Wang, R. A Laboratory Study of Self-Healing Hydrophobic Association Gels Used as Lost Circulation Material. Colloids Surf. A 2022, 646, 128964. [Google Scholar] [CrossRef]

- Chen, J.; Qiu, H.; Djouonkep, L.D.W.; Lv, J.; Xie, B. Preparation, Evaluation and Field Application of Thermally Induced Crosslinked Polymer Gel Leakage Plugging Agent. J. Polym. Environ. 2024, 32, 5677–5688. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, C.; Sun, J.; Shang, X.; Lv, K.; Zhu, Y.; Wang, F. High Temperature Resistant Polymer Gel as Lost Circulation Material for Fractured Formation during Drilling. Colloids Surf. A 2022, 637, 128244. [Google Scholar] [CrossRef]

- Yang, H.; Iqbal, M.W.; Lashari, Z.A.; Cao, C.; Tang, X.; Kang, W. Experimental Research on Amphiphilic Polymer/Organic Chromium Gel for High Salinity Reservoirs. Colloids Surf. A 2019, 582, 123900. [Google Scholar] [CrossRef]

- Li, J.; Wen, M.; Yang, J.; Liu, Y.; Jiang, Z.; Chen, J. Synthesis and analysis of magnetic nanoparticles within foam matrix for foam drainage gas production. Geoenergy Sci. Eng. 2024, 238, 212887. [Google Scholar] [CrossRef]

- Jiang, Q.; Xu, P.; Xu, J.; Hou, M.; Liu, Q.; Dai, B. Preparation and Evaluation of Composite Hydrogel for Reducing the Leakage Rate of Lost Circulation. Polymers 2023, 15, 4218. [Google Scholar] [CrossRef]

- Zhu, J.; Lou, E.; Zhang, S.; Lu, H.; Wang, Z. Preparation and Performance of Resin-Gel–Rubber Expandable Lost Circulation Material Blend. Gels 2023, 9, 862. [Google Scholar] [CrossRef]

- Ni, C.; Zhang, Q.; Xu, B.; Deng, N.; Huang, X. The Role of Solid Electrolytes in Suppressing Joule Heating Effect for Scalable H2O2 Electrosynthesis. ACS Sustain. Chem. Eng. 2025, 13, 17958–17968. [Google Scholar] [CrossRef]

- Bai, Y.-R.; Dai, L.-Y.; Sun, J.-S.; Jiang, G.-C.; Lv, K.-H.; Cheng, R.-C.; Shang, X.-S. Plugging Performance and Mechanism of an Oil-Absorbing Gel for Lost Circulation Control While Drilling in Fractured Formations. Pet. Sci. 2022, 19, 2941–2958. [Google Scholar] [CrossRef]

- Pan, X.; Huang, X.; Deng, N. Short-Chain Carboxylic Acids Influencing Mineralization Mechanisms of Ferrihydrite Transformation to Hematite and Goethite. Environ. Sci. Technol. 2025, 59, 12910–12919. [Google Scholar] [CrossRef] [PubMed]

| Sample | Characteristic Bands (cm−1) | Assignment | Interpretation of Chemical Changes |

|---|---|---|---|

| CNF | 3340, 1058 | O–H stretching; C–O–C vibration | Native cellulose backbone |

| CNF-C10 | 2920, 2850 (new) | –CH2– asymmetric/symmetric stretching | Successful grafting of epoxide-decyl groups, introducing long alkyl chains |

| CNF-MA | 1732, 1635 (new) | Ester C=O; C=C stretching | Methacryloylation with methacryloyl chloride, introducing polymerizable double bonds |

| CNF-PDA | 1505–1600, 1260 (new) | Aromatic ring skeletal vibration; phenolic C–O | Successful dopamine/polydopamine coating |

| PCNF hydrogel | 1635 (markedly decreased) | C=C stretching | Polymerizable double bonds consumed during copolymerization |

| 1650, 1550 (new) | Amide I and II bands | Successful polymerization of acrylamide monomers |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Z.; Liu, J. Green and Controllable Crosslinked Gel Plugging Technology Based on Modified Natural Biofibers. Processes 2025, 13, 3743. https://doi.org/10.3390/pr13113743

Ma Z, Liu J. Green and Controllable Crosslinked Gel Plugging Technology Based on Modified Natural Biofibers. Processes. 2025; 13(11):3743. https://doi.org/10.3390/pr13113743

Chicago/Turabian StyleMa, Zhe, and Junyi Liu. 2025. "Green and Controllable Crosslinked Gel Plugging Technology Based on Modified Natural Biofibers" Processes 13, no. 11: 3743. https://doi.org/10.3390/pr13113743

APA StyleMa, Z., & Liu, J. (2025). Green and Controllable Crosslinked Gel Plugging Technology Based on Modified Natural Biofibers. Processes, 13(11), 3743. https://doi.org/10.3390/pr13113743