1. Introduction

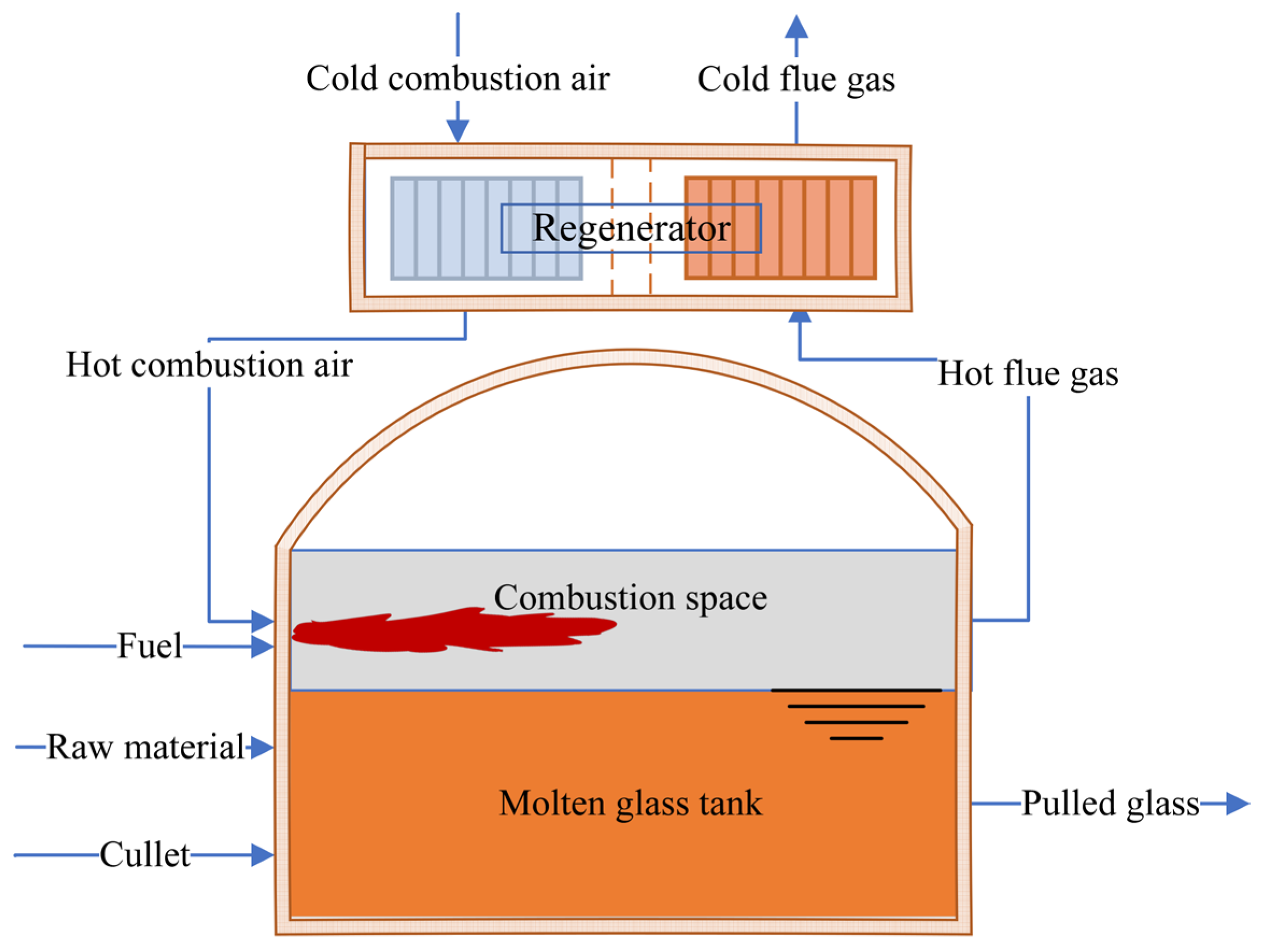

The glass production sector is considered energy-intensive due to its high operating temperatures and the requirement for continuous production. Within this sector, glass furnaces are the most energy-demanding components and serve as the core of the manufacturing process [

1,

2,

3]. These furnaces account for a significant portion of the total energy consumption in the industry (ranging from 70% to 90%). Increasing energy costs and high energy consumption have encouraged many industries around the world to use more efficient and optimized energy systems [

4,

5]. Moreover, increasing environmental degradation and commitments to reduce greenhouse gas emissions have made energy system optimization necessary [

6]. Therefore, enhancing the energy performance of glass furnaces is critical not only for economic efficiency but also for environmental sustainability.

Traditionally, furnace performance has been improved through experimental observations, physical modelling, and engineering experience. However, these traditional methods often fail to produce sufficient results due to the variability and complexity of glass production processes such as variations in substance flow rates, cullet ratios, and air leaks. This situation highlights a critical need for data-driven approaches that can effectively process and interpret the vast datasets generated during production.

In recent years, statistical methods such as data-driven approaches have become an important tool for energy performance analysis [

7]. In this context, techniques like stepwise linear regression can clearly identify relationships between process parameters and energy consumption, enabling accurate prediction and optimization of furnace performance. Ultimately, by combining these statistical models with optimization algorithms, it is possible to determine suitable operating conditions that ensure minimum energy consumption.

Improving the energy performance of glass furnaces has long been a critical topic for research. Traditional methods like mass and energy balance analysis [

8] and physical process simulations [

9] are widely used due to their high accuracy, and these techniques are based on fundamental physical principles. However, these methods have limitations in industrial applications, especially under dynamic process conditions such as variations in raw material flow rates, cullet ratios, and air leaks. These factors often render static physical models insufficient to reflect actual system behavior. Energy efficiency optimization is vital for reducing energy consumption, improving operational performance, and minimizing environmental impact. Strategies involving the influence of operational variables and the integration of advanced technologies into furnace design have led to significant progress toward more sustainable and cost-effective production processes.

The literature covers a broad range of topics concerning energy systems in glass production, including physical limits [

10,

11], the effect of changing electrode positions [

12], and the use of solar energy in the melting process [

13]. Other noteworthy studies include monitoring and control of glass furnaces with smart measurement methods [

14], the effect of regenerator on energy performance [

15], the effect of insulation of glass furnaces on energy performance [

16], and the development of oxy-combustion systems instead of traditional combustion [

11]. Energy systems encompass the technical and economic components used to convert energy from sources like natural gas, coal, or solar power [

17]. Detailed comparisons of the performance of glass furnaces in general terms were first carried out by Beerkens et al. [

18] and Sardeshpande et al. [

1].

Performance analysis relies heavily on accurate data collection. In glass furnaces, high temperatures pose significant challenges to measurement. Measurements are usually made to determine mass flow rate, temperature, and pressure. Moreover, due to technical limitations and economic considerations, it is not possible to measure all variables in many systems [

19]. In addition, each physical measurement may contain uncertainties such as random errors and systematic errors [

20]. Many studies have been conducted to reduce these measurement uncertainties. For example, Zhou et al. [

21] investigated the effect of measurement uncertainty of operating conditions on performance evaluation parameters in thermodynamic systems.

The process model of glass furnaces can be established both on a physical basis (thermodynamic laws, mass-energy balance) and on an empirical or statistical basis. Physical models are based on basic sciences such as thermodynamic laws, heat transfer, combustion kinetics, and fluid dynamics, while empirical or statistical models are based on the relationships between input–output variables, using real business data. Studies on the physical modelling of glass furnaces from the past to the present have been reviewed by Sardeshpande et al. [

1], Sardeshpande et al. [

2], Raič et al. [

22], and Kodak et al. [

8]. Yet, such models can provide valuable insights if the data quality and variable selection are robust.

Given the complexity of furnace operations, advanced data processing techniques like data reconciliation and gross error detection are essential for ensuring measurement accuracy [

23]. These methods not only improve data reliability but also allow for the estimation of unmeasured variables. Recent studies have shown that the importance of optimization techniques based on data consensus in industrial processes has been increasing [

24]. Technical advances in error detection, reconciliation, and efficiency analysis have enabled researchers to identify and correct data inconsistencies, resulting in better-quality analysis of energy efficiency. For example, in the study conducted by Adhi and Saputro [

25], the importance of data reconciliation and gross error detection methods in industrial processes was emphasized, highlighting their importance in process efficiency analysis, process status monitoring, and operational optimization processes. With these methods, the accuracy and reliability of the information used in the evaluation of energy efficiency are slightly increased by contributing to the detection and regulation of errors in process data.

For example, Yuan et al. [

26] used Bayesian methods for simultaneous gross error detection and data reconciliation and showed that the use of these methods increased the data accuracy and enhanced the ability to detect errors. Dumont et al. [

27] conducted an analysis of cooling and power cycles of positive energy buildings using data reconciliation techniques. The innovative idea of using simulation techniques in processes such as optimizing the repositioning of electrodes in glass furnaces demonstrates the glass industry’s commitment to using advanced technologies to increase the energy efficiency of glass furnaces in industrial processes [

12]. In addition, an issue that is currently relevant is the inclusion of electric-boosted units in glass furnaces to meet the challenges of increasing glass melting quality, energy efficiency, and production capacity without major changes in glass furnaces [

28,

29].

Statistical modeling methods are among the alternatives that can provide estimations of fuel consumption in energy systems. These are among the preferred methods in energy systems research in terms of understanding the relationships between variables more clearly, transparency of the model, and ease of application, especially with regard to linear regression analysis. Thanks to regression analysis, the key variables affecting energy consumption can be identified, energy systems can be modelled numerically, and the operation and behavior of processes can be predicted. There are many statistical studies in the literature. For example, Ma et al. [

30] applied the use of machine learning algorithms to increase energy efficiency. Fialko et al. [

31] used exergy analysis and statistical methods to optimize the geometric parameters of a glass furnace and improve energy efficiency. Using these models and optimization techniques, suitable operating conditions can be determined to enhance systems’ energy performance.

Numerous studies have focused on optimizing the energy performance of glass furnaces. Studies such as the optimization of process parameters [

32] and improving energy performance [

31] have attracted attention. For example, Reddy and P [

33] measured some parts of energy systems using wireless sensors and used advanced optimization techniques such as ant colony optimization and firefly swarm optimization to optimize the energy efficiency of systems. Basso et al. [

34] increased the energy efficiency of the glass furnace in the case study by optimizing operational parameters such as burner settings in oxygen-gas fired glass furnaces to increase the overall efficiency. Li [

35] investigated the optimization of the residence time of the raw material in the glass furnace to increase the energy performance and carried out a computer simulation.

When the above studies are examined, a significant research gap still exists in the literature regarding the optimization of the energy performance of glass furnaces. A more efficient glass furnace can be achieved through the use of advanced data collection techniques, detailed process modelling, data reconciliation, linear regression models, and optimization algorithms. By combining these approaches, the challenges associated with increasing the energy performance of glass furnaces can be substantially mitigated. As a result, the effort to enhance energy efficiency in glass furnaces through data reconciliation and optimization methods represents a crucial step toward the sustainability of the glass industry.

The main contribution of this study is to reveal the basic process variables affecting energy consumption, through a regression model developed using the operational data obtained from a real electric-boosted natural gas furnace, and to determine the most appropriate operating parameters to increase the energy performance of this glass furnace by using these models. In this way, data-driven modeling can be performed and optimization can be conducted based on this model. In addition, this study makes a unique contribution to the literature in terms of presenting an integrated approach in which statistical modeling and process optimization are used together.

This study aims to identify the basic process variables affecting energy consumption in an electric-boosted natural gas glass melting furnace, to model the relationships between these variables and energy consumption using the linear regression method, and to optimize these relationships to determine the ideal operating conditions that enhance the energy performance. This study is also a continuation of our previous work [

8], where a robust data reconciliation technique was employed to generate reliable and consistent datasets. For this purpose, a process model of a glass furnace was created. Subsequently, reconciled data were obtained using the process model and data reconciliation methodology. Based on the raw data and reconciled, two stepwise linear regression models were developed, and optimization of energy performance was realized. Then, the reliability of these models and optimization results was compared with each other. Leaving some parameters constant, the combustion heat and specific energy consumption values were examined according to the raw material and cullet variables. As a result, the evaluation of energy performance with optimization methods provides valuable insights into improving operational performance and reducing energy consumption. Furthermore, sustainable production and reduction of environmental impacts can also be achieved through these methods.

3. Results and Discussion

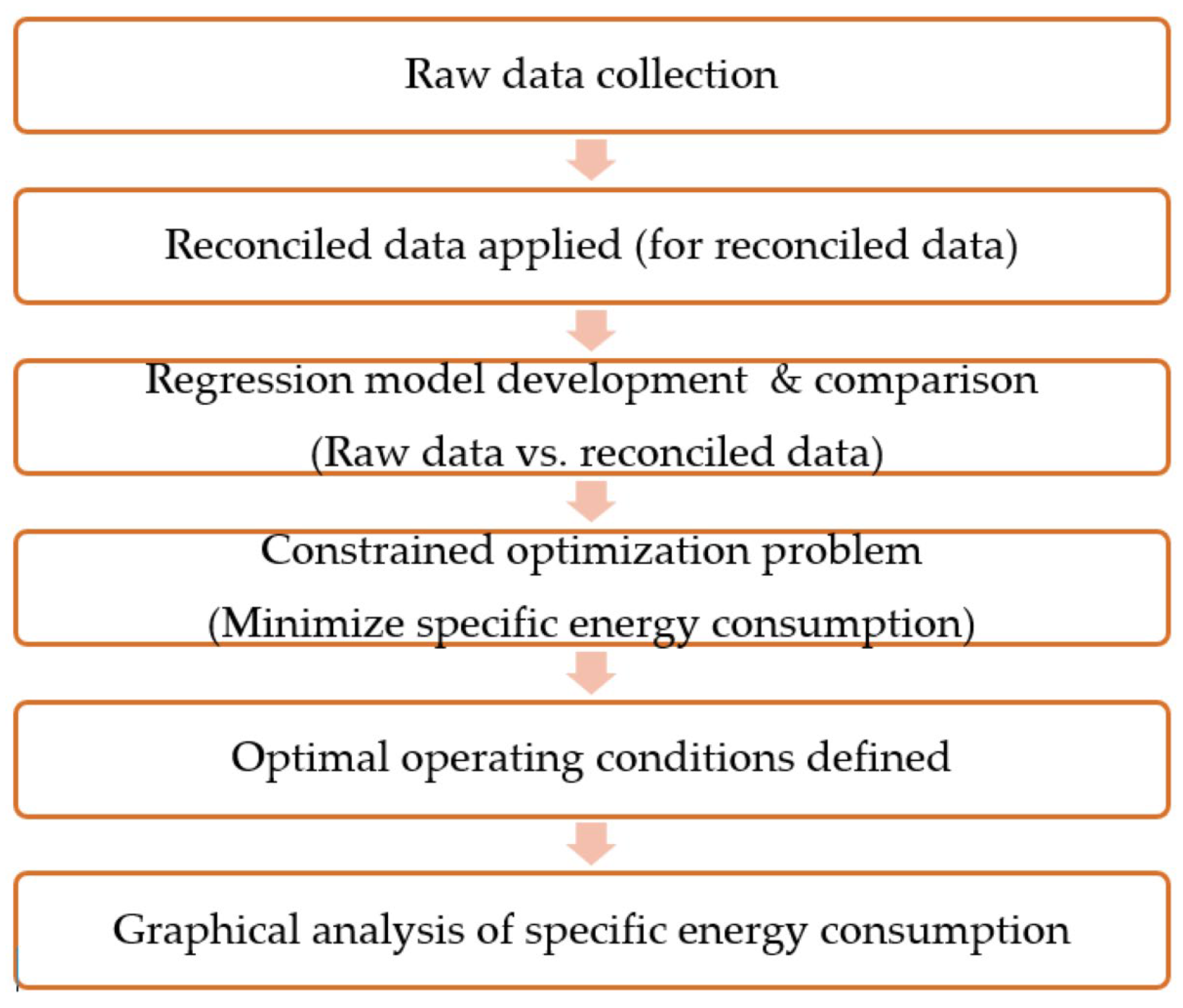

To optimize the energy performance of glass furnaces, a process model of a glass furnace was developed. Then, reconciled data were obtained through this process model and data reconciliation and gross error detection techniques. From these reconciled datasets, specific variables were selected as predictor and response variables for the linear regression model. Based on these variables and the dataset, the stepwise linear regression model was established. After these model parameters were determined, an optimization process was performed on this regression model. The required steps for the optimization process are illustrated in

Figure 2.

3.1. Data Reconciliation and Performance Indicators Results

The process model of the glass furnace (including mass and energy balance) was created, and a data reconciliation methodology was applied using this process model and measurement data. Using the process model and data reconciliation methods, a reconciled dataset for 151 days was obtained. The reconciled dataset included variables such as mass flow rates, temperatures, mass fraction, electric boosting, furnace, and specific energy consumption. Descriptive statistics (mean, minimum, and maximum) of the raw and reconciled data are presented in

Table 2.

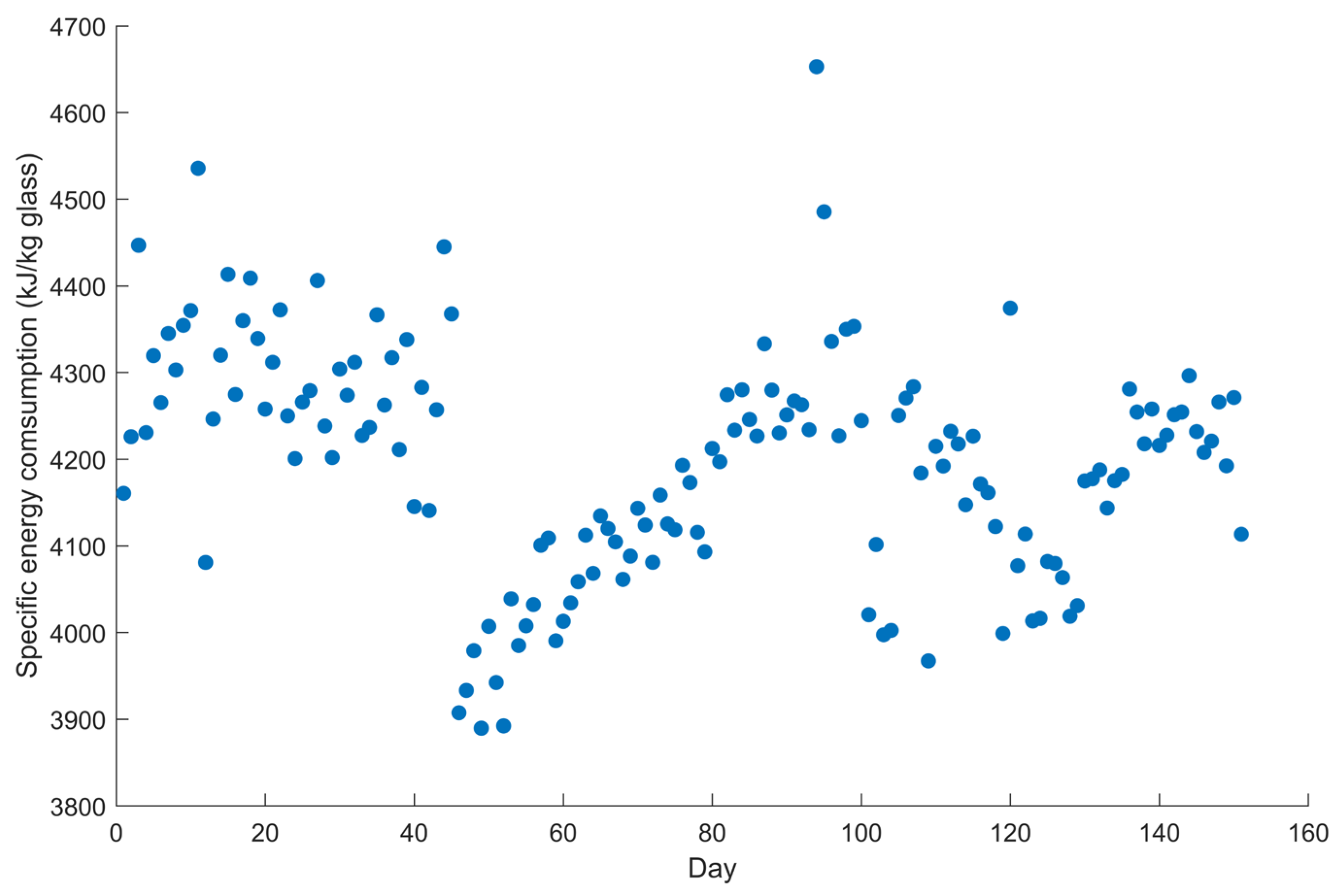

The most important performance indicator for glass furnaces is specific energy consumption. Here, the specific energy consumption ranged from 3880.87 to 4644.10 kJ/kg-glass. This variation was mainly due to daily fluctuations in raw material usage, glass production rates, utilization of electric boosting, and the mass flow rate of the cullet. As a result, the specific energy consumption exhibited considerable daily variability.

3.2. Statistical Analysis of Data Reconciliation Results

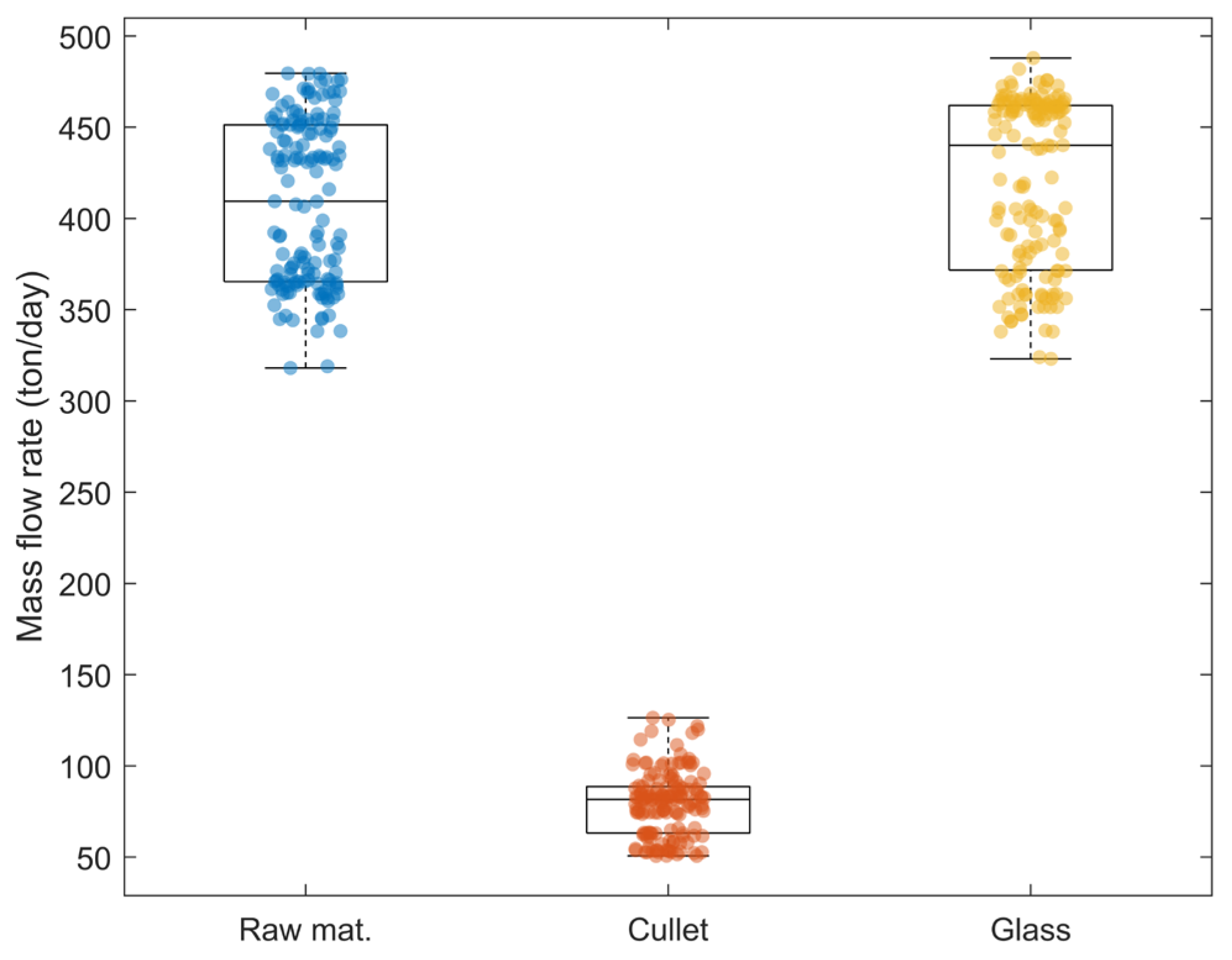

Statistical analysis involves interpreting and drawing conclusions from data. A box plot is a statistical graphic that is used to visualize the distribution of a dataset. This graphic enables a quick assessment of central tendency, variability, and potential outliers in numerical data. The box plot is based on five components: minimum value, first quartile (Q1), median (Q2), third quartile (Q3), maximum value, and outliers. Box plots of raw material, cullet, and glass are presented in

Figure 3.

Figure 3 shows that the median values of raw material and glass are slightly higher than the mean. The raw material flow rate varies between 318.03 and 497.50 tons/day, while the cullet varies from 50.70 to 126.37 tons/day. The glass production varies between 323.06 and 488.02 tons/day. The wide variations are mainly due to the daily fluctuations in glass production orders and the changeable availability of cullet in the process. Box plots of the electric boosting, combustion heat input, and specific energy consumption are presented in

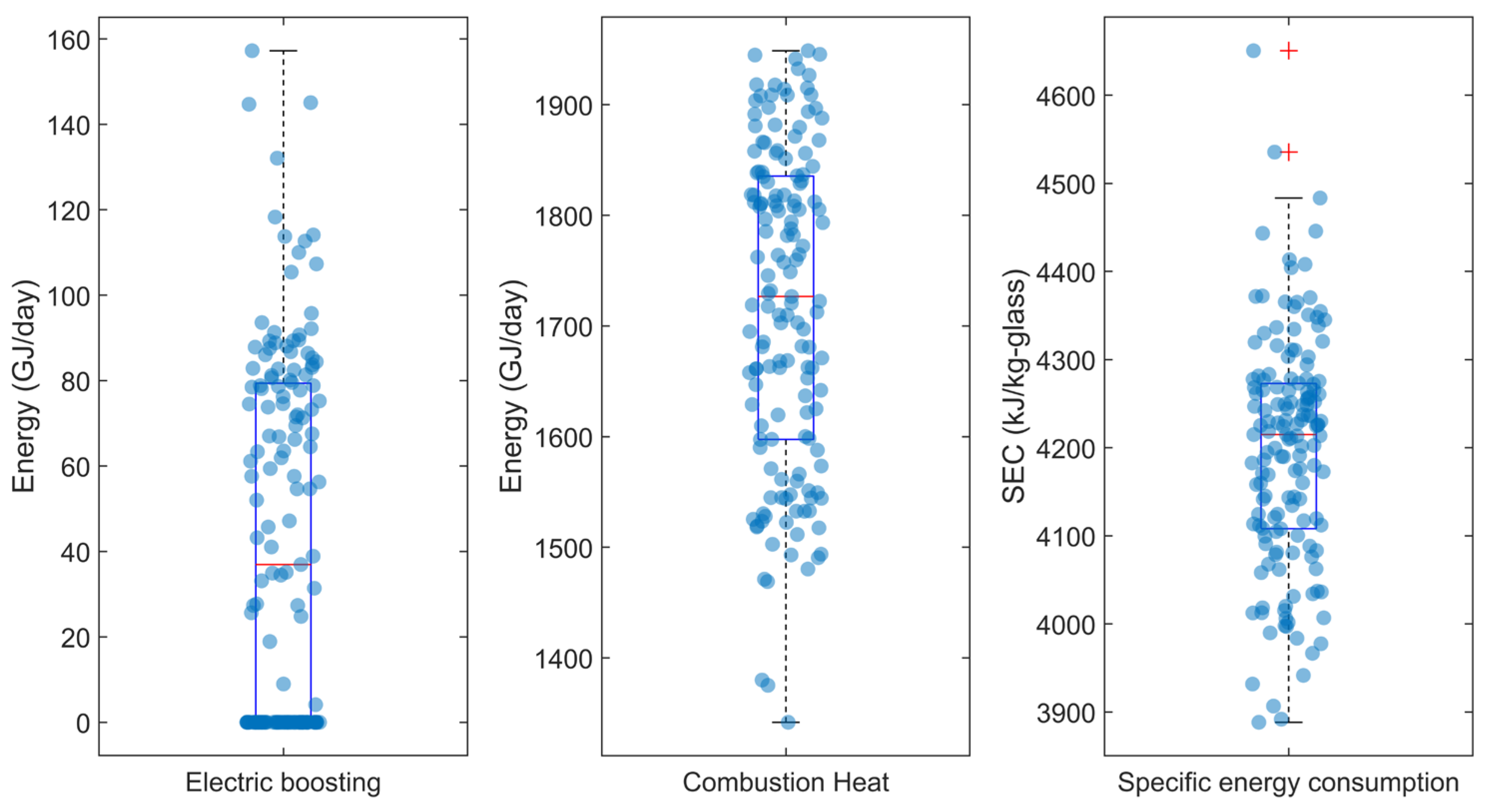

Figure 4.

Figure 4 reveals that the distribution of electric boosting, combustion heat, and specific energy consumption values shows significant variation. The electric boosting ranges from 0 to 157.25 GJ/day. The combustion heat value varies between 1341.79 and 1948.81 GJ/day. Most of the energy used in the glass furnace is supplied by combustion heat (which is primarily derived from natural gas).

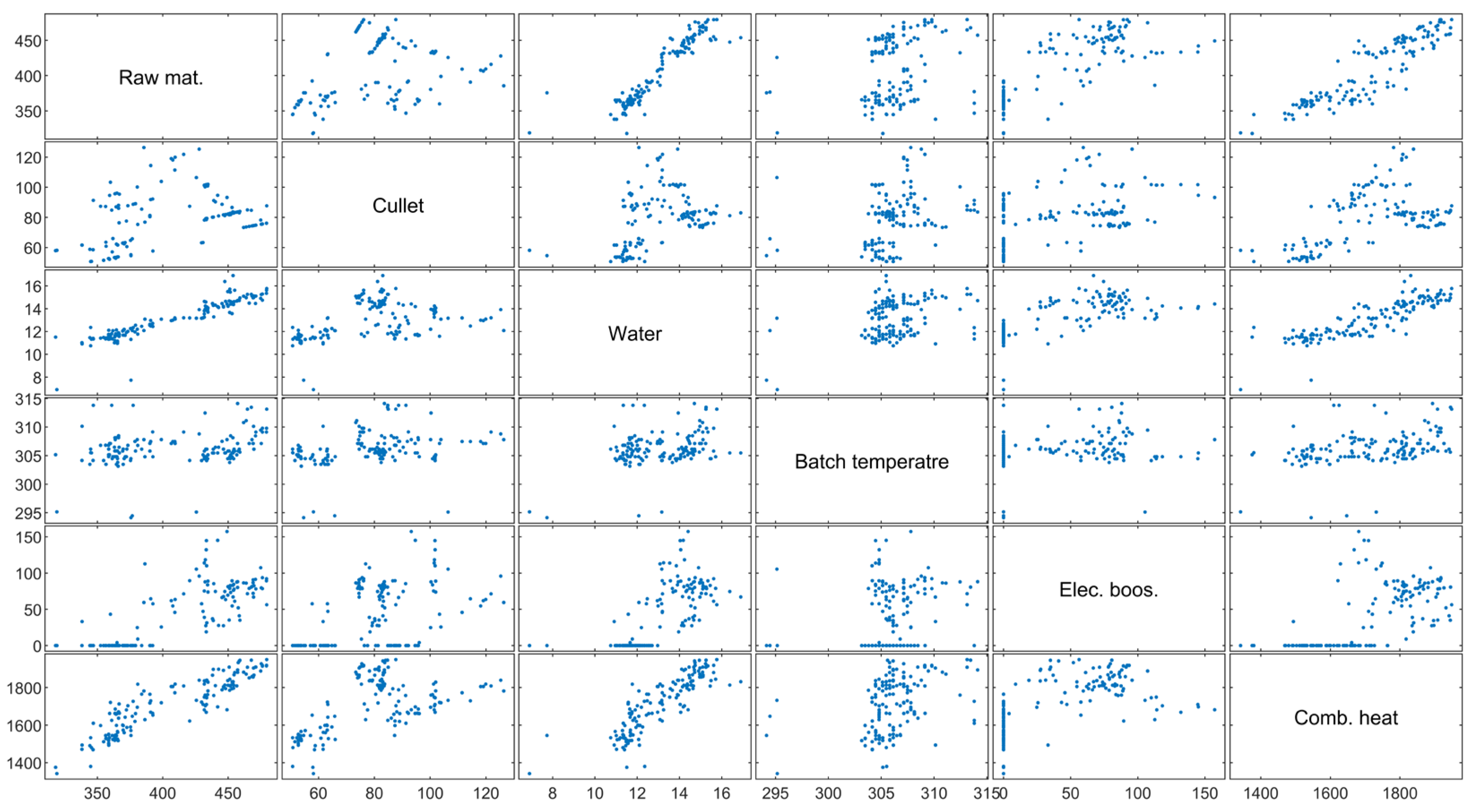

A scatter plot is a graphical tool used to represent the relationship between two quantitative variables. The X-axis corresponds to the independent variable, and the Y-axis corresponds to the dependent variable. Each data point presents an individual observation. Scatter plots are generally used for determining dataset distribution and identifying correlations (positive, negative, or unrelated) between variables. The scatter plot matrix for the variables of raw material, cullet, water, batch temperature, electric boosting, and combustion heat is presented in

Figure 5.

Figure 5 indicates that as the amounts of raw materials, cullet, and water increase, the required combustion heat input also increases. This increase is due to the higher glass production resulting from the increased batch input into the furnace, which in turn raises the overall energy demand. The specific energy consumption of the glass furnace for 151 days is presented in

Figure 6.

When

Figure 6 is examined, it is observed that specific energy consumption exhibits significant fluctuations on certain days, with some days showing notably higher values. The changes are caused by variables such as raw material, cullet, glass production, and electric boosting, which vary from day to day. These variables vary significantly depending on the daily glass production plan, furnace capacity, and factory strategy. For example, higher cullet utilization generally reduces energy demand, while increased raw material input can lead to higher combustion heat. In situations where production volume is high, cullet utilization is increased, and electrical support is used effectively, the specific energy consumption decreases.

Another significant reason for sudden changes in specific energy consumption is the disruption of stability during changes in daily production volume. Transitional periods between low and high production loads can lead to temporary increases in specific energy consumption. In this case, the glass furnace operates outside of optimal operating conditions, resulting in a decrease in furnace energy performance. These production fluctuations generally subside as the furnace adapts to the new production conditions. This adaptation involves adjusting parameters such as the internal temperature of the furnace, raw material feed rates, and electric boosting levels. However, once the production process stabilizes and the system reaches a steady-state condition, specific energy consumption returns to a normal level. This highlights the importance of maintaining production volumes as stable as possible and limiting sudden production fluctuations to improve the energy performance of glass furnaces. As a result, this dynamic structure of glass furnaces highlights the importance of monitoring and optimizing relevant parameters to improve the energy performance of glass furnaces.

3.3. Optimization Problem

This optimization problem aims to minimize the specific energy consumption of the glass furnace under certain operational constraints, using the regression model and dataset. In this way, the energy performance of the furnace can be increased by changing variables such as raw materials, cullet, and electric boosting. Also, it is possible to avoid unnecessary natural gas consumption. This approach allows for predictive decision-making in operations, contributing to both economic and environmental sustainability. Considering the operational characteristics and limitations of industrial glass furnaces, this optimization problem can be formulated as given in Equation (22) as follows:

The objective function of the optimization problem is the specific energy consumption. The optimization problem has four equality constraints and two inequality constraints. The decision variables include the flow rates of glass, raw materials, cullet, and water, and electric boosting. Each variable is subject to upper and lower bounds, which are incorporated into the formulation as inequality constraints.

This optimization formulation is a nonlinear nonconvex optimization problem with equality–inequality constraints. To solve this complex problem, the interior-point method was applied; the interior-point method is efficient for equality–inequality constrained optimization problems. These computations were performed on a high-performance computer to ensure timely and accurate results.

3.4. Training, Validation, and Test Data

The raw and reconciled data were divided into training, validation, and test datasets. A total of 85% of the data was allocated for cross-validation (comprising both training and validation sets), while the remaining 15% was reserved as test data to evaluate the generalization performance of the linear regression model. The split of the training, validation, and test datasets is summarized in

Table 3.

3.5. Linear Regression and Optimization Using Raw Data

3.5.1. Predictor and Response Variables

The raw dataset included variables such as flow rates of raw material, cullet, water, and raw material temperatures, electric boosting, and combustion heat. The predictors and response variables obtained from the raw dataset are summarized in

Table 4.

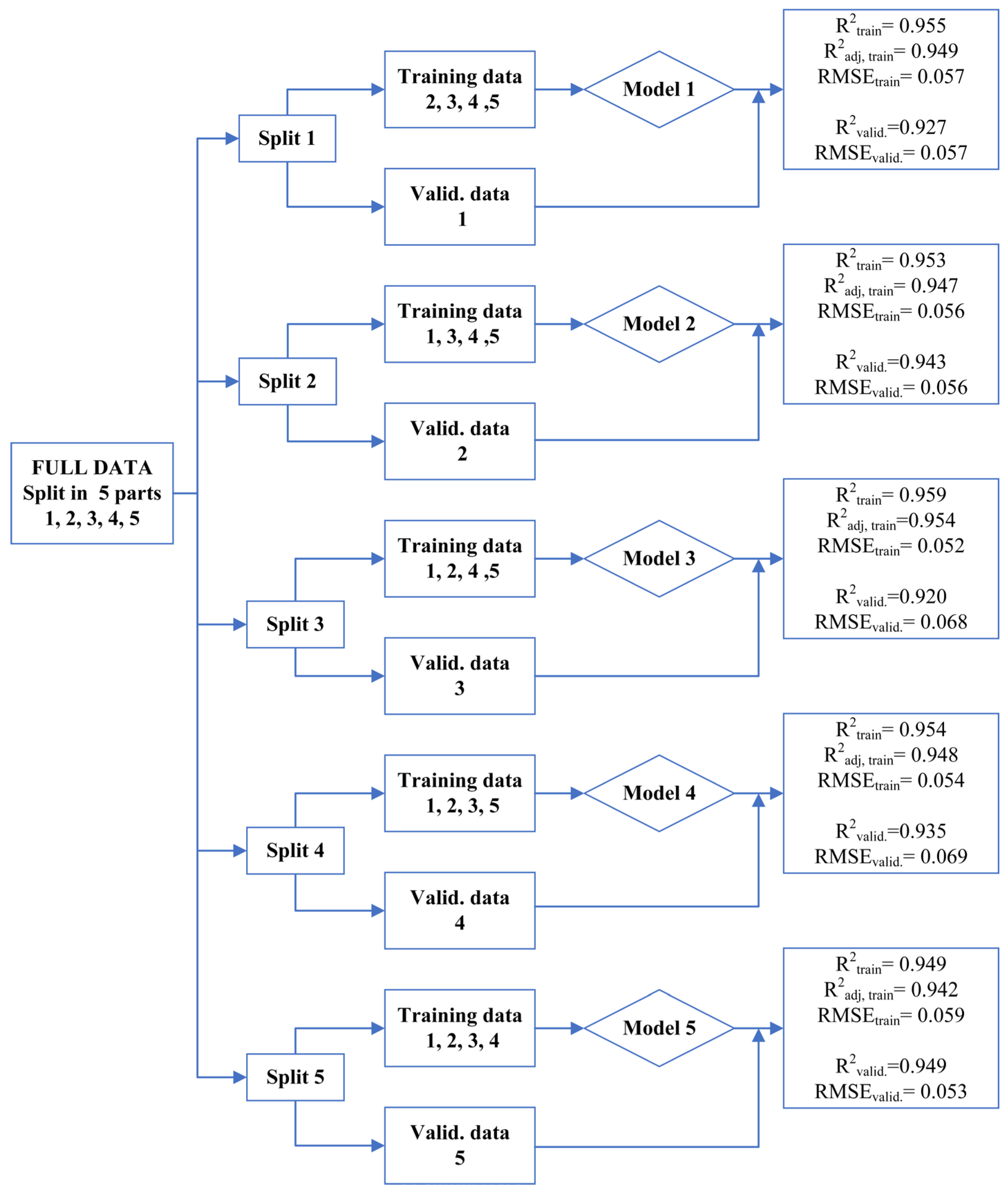

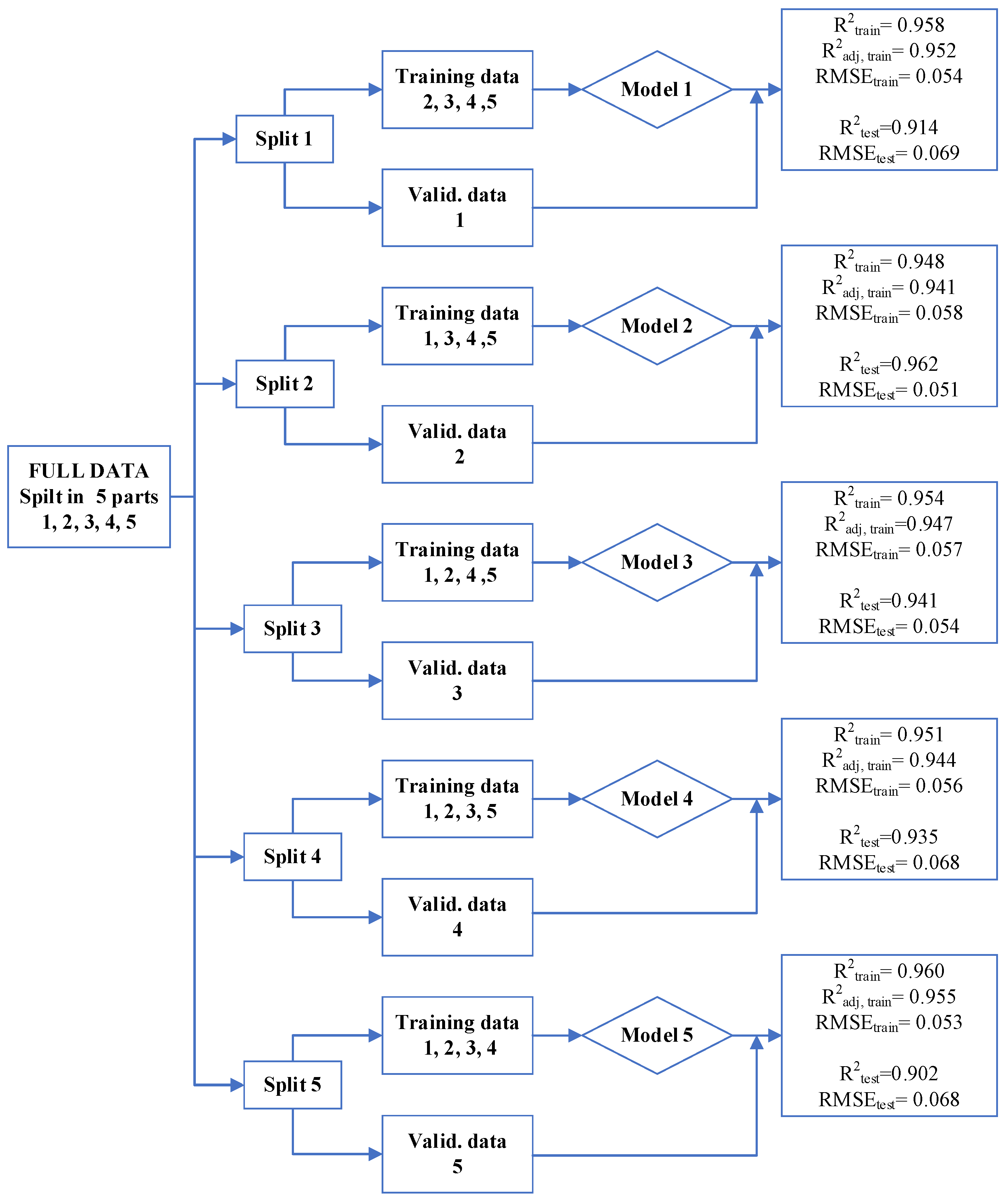

3.5.2. Cross-Validation Results Using Raw Data

The purpose of the cross-validation technique is to determine whether a model performs consistently on different subsets of the dataset. This approach helps when evaluating the reliability of the data, detecting inconsistencies within the dataset, and mitigating the risk of the overfitting problem. To perform cross-validation, the cross-validation data were divided into five folds. A separate regression model was trained for each fold, and performance metrics including the coefficient of determination (

R2) and root mean square error (RMSE) were calculated for each model, for training and validation. The results of the cross-validation analysis are presented in

Figure 7.

The mean R2 value obtained from the five-fold cross-validation was 0.954 with a standard deviation of 0.0039. These results show that the model demonstrated high and consistent performance on different sub-datasets. In addition, the low standard deviation enhances the generalizability of the model and suggests that it is unlikely to suffer from overfitting.

3.5.3. Stepwise Linear Regression Results

The linear regression model was created by using the min–max normalized raw training dataset. In total, 128 days of the normalized raw training data were used in the construction of this regression model. The results of stepwise linear regression with the normalized raw training dataset are presented in

Table 5.

As shown in

Table 5, the R-squared value was 0.953, the

p-value was

. The regression model coefficients, along with their

t-statistics and

p-values, are provided in

Table 6.

The equation corresponding to the stepwise regression model (using training normalized raw data,

n presents that the variable is normalized), as detailed in

Table 6, is given in Equation (23).

The final model equation in real physical units, obtained by denormalizing Equation (23) using the formula

, is shown in Equation (24).

Table 6 reveals that all of the

p-values in the model are less than 0.05. The regression model developed from the training raw dataset was evaluated by comparing the predicted values with the observed values. The results of this comparison are illustrated in

Figure 8.

3.5.4. Testing of the Linear Regression Model Using the Test Part of the Raw Dataset

The linear regression model developed using the training data was evaluated on the test dataset. The main objective of this testing phase was to assess how accurately the model’s predictions aligned with the actual (unseen) data. This step also provides insights into the model’s generalizability and its potential applicability in real-world scenarios. The results of the model when applied to the test data are presented in

Table 7.

The R-squared value of the raw test dataset (0.949) is very close to that of the raw training dataset (0.953), which indicates that the model does not suffer from overfitting and maintains a high level of predictive accuracy on unseen data. In order to evaluate the prediction performance of the regression model on the test data, the actual values (observations), estimated values (model estimations), and relative errors of combustion heat were calculated and are presented in

Table 8.

Table 8 reports that the relative error in predicting the combustion heat required by the glass furnace ranged from a minimum of 0.106% to a maximum of 2.604%, with the most errors around 1.328% (mean absolute error). The relative error between the actual and predicted combustion heat value may have been caused by a sudden change in daily glass production. If the daily glass production requirement of the furnace had been a little more stable, the value of the relative error that the model would have made may perhaps have been even lower. In addition, accurately knowing the daily combustion heat requirement before production begins allows precise estimation of the amount of natural gas needed from the network and its cost.

These results demonstrate that the regression model has robust predictive capability. The small difference between training and test R2 values confirms that the model captures the underlying process dynamics effectively and can be applied confidently for energy performance optimization in glass furnaces.

3.5.5. The Solution of the Optimization Problem with Raw Data

The optimization problem was solved using the interior-point method. The minimum specific energy consumption and the corresponding optimal values of the decision variables are presented in

Table 9.

Table 9 indicates that the optimization problem yields the best minimum specific energy consumption when solved using the interior-point method. It is observed that as the amount of produced molten glass increases, the specific energy consumption of the glass furnace also increases. Also, the lower humidity in the raw material is provided to increase energy consumption.

3.6. Linear Regression and Constrained Optimization Using Reconciled Data

In this section, the reconciled dataset is normalized. A linear regression model is then created using the normalized reconciled data. This linear regression model, created with the training normalized reconciled data, is then denormalized using the denormalization method. This regression model is then optimized for the specific energy consumption of this furnace using certain constraints and optimization methods.

3.6.1. Predictor and Response Variables

The reconciled dataset includes variables such as flow rates of raw material, cullet, water, and raw material temperatures, and electric boosting. The response variable is combustion heat. These predictors and response variables, which are obtained from reconciled data, are summarized in

Table 10.

3.6.2. Cross-Validation Results Using Training Reconciled Data

The cross-validation data (reconciled dataset) were divided into five sets. The results of the cross-validation analysis are presented in

Figure 9.

The mean R2 value obtained from the five-fold cross-validation is 0.9542 with a standard deviation of 0.0050. The closeness of these R2 values provides important information about the generalizability of the model. These results show that the model demonstrates high and consistent performance on different sub-datasets.

3.6.3. Stepwise Linear Regression Results

The linear regression model was created using min–max training normalized reconciled data. In total, 128 days of normalized reconciled data were used in the construction of this regression model. The reason for using normalized data as regression data was to both increase the regression model and obtain more accurate and reliable results. The results of stepwise linear regression with normalized reconciled data are presented in

Table 11.

As shown in

Table 11, the R-squared value is 0.953, the

p-value value is 2.1·10

−85. The regression model coefficients, along with their

t-statistics and

p-values, are provided in

Table 12.

The equation corresponding to the stepwise regression model (using normalized reconciled data), as detailed in

Table 12, is given in Equation (25).

The final model equation in real physical units, obtained by denormalizing Equation (25) using the formula

, is shown in Equation (26).

Table 12 shows that all of the

p-values in the model are less than 0.05, indicating that these variables are statistically significant. In general, the high adjusted R-squared value (94.9%) and significant F-statistic of the model indicate that the independent variables explain the dependent variable quite well. This situation confirms that the selected variables and model structure successfully capture the effects on the process. As a result, the obtained model quantitatively reveals the effects of glass furnace process parameters and provides important information for glass furnaces.

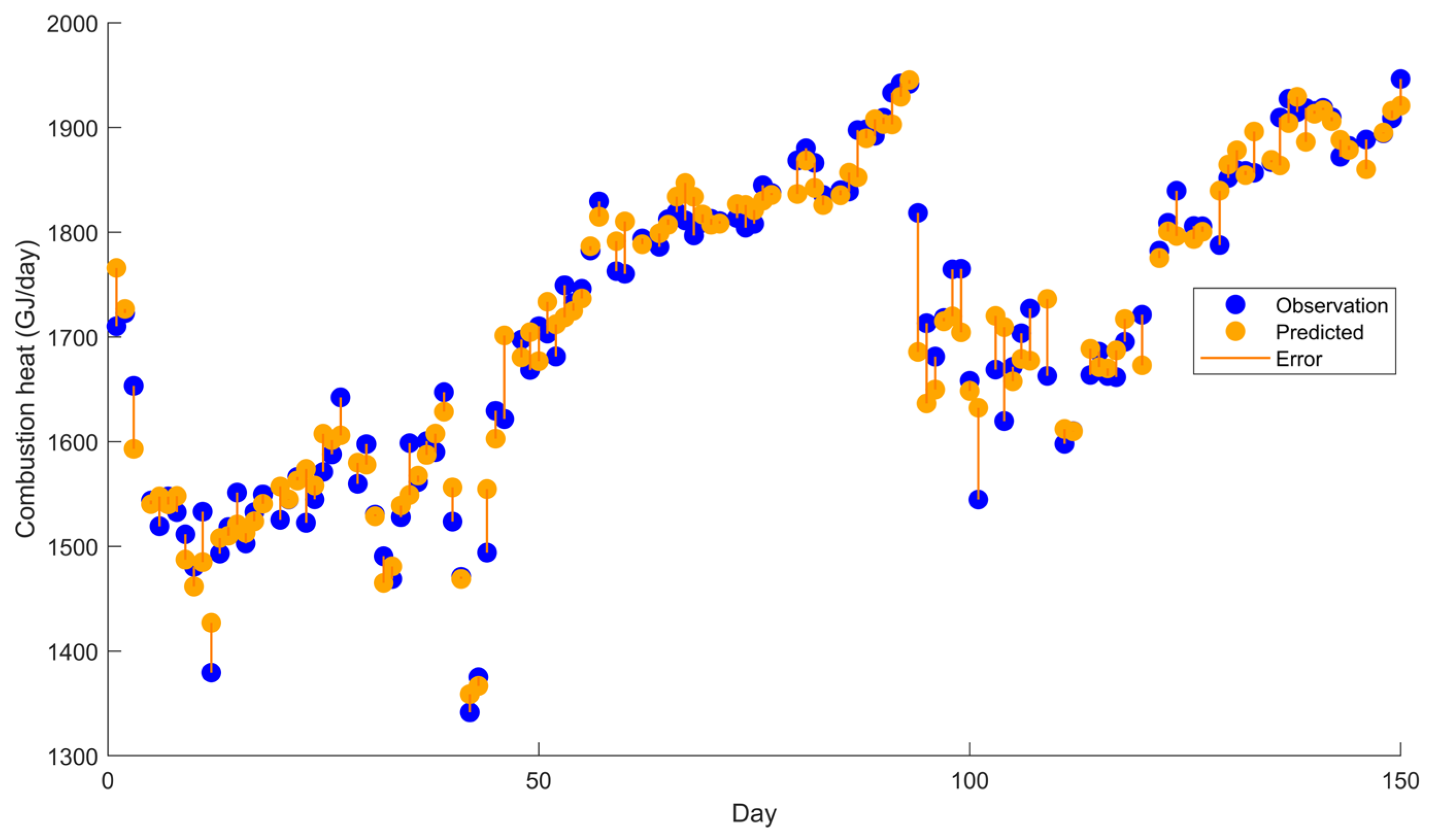

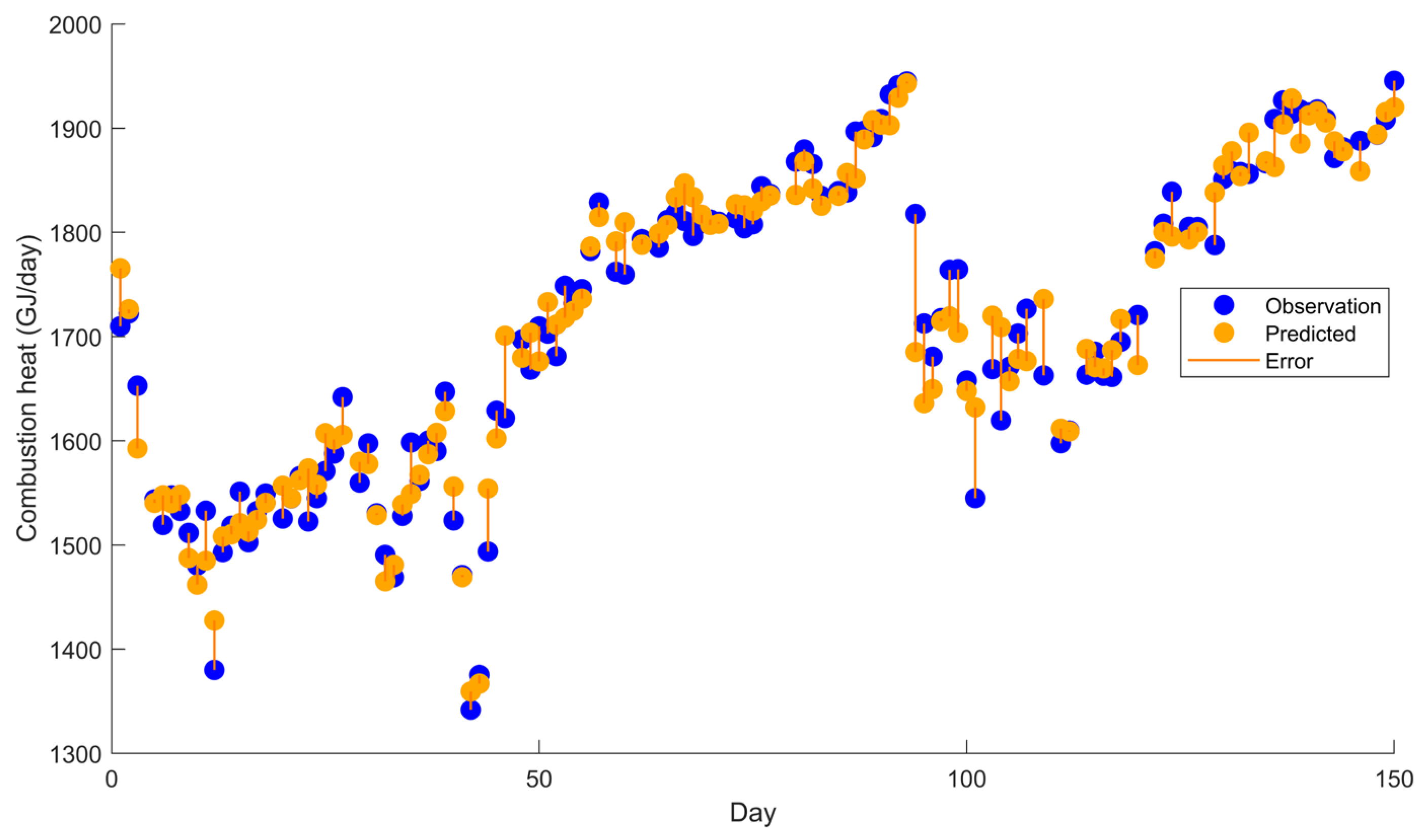

The model developed using the reconciled dataset was evaluated by comparing the predicted values with the actual values. In this analysis, the predictive performance of the model is assessed by comparing the observed values, the corresponding predicted values, and the associated prediction errors. The results of this comparison are illustrated in

Figure 10.

The linear regression model gives results very close to the actual values. Furthermore, the prediction errors are relatively small, indicating a strong model fit. These results suggest that the model has high predictive capability and can be reliably used in further energy optimization studies. The accuracy of the model also indicates that the selected predictor variables are highly relevant to combustion heat behavior in glass furnaces.

3.6.4. Testing of Linear Regression Model Using the Test Part of the Reconciled Dataset

The linear regression model developed using the training data was evaluated on the test dataset. The linear regression model was developed using training data and tested on the test dataset. The test results are presented in

Table 13.

The R

2 value of the test dataset (0.9496) is quite close to the R-squared value of the training dataset (0.955), indicating that the model avoids overfitting and provides high levels of prediction accuracy. The relative errors for the prediction performance of the model on the test part of the reconciled dataset, based on actual and predicted values, were obtained and are summarized in

Table 14.

According to

Table 14, the relative error in estimating the required combustion heat for a glass furnace ranged from 0.077% to 2.994%, with nearly all errors around 1.322% (mean absolute error). These errors could be due to the sudden fluctuations in glass production. More stable glass production may lead to low relative error. As can be seen from the results, the regression model demonstrates robust prediction capability, as evidenced by the

R2 value.

3.6.5. The Solution of the Optimization Problem with Reconciled Data

The optimization problem was solved using the interior-point method. The minimum specific energy consumption and the corresponding optimal values of the decision variables are presented in

Table 15.

As detailed in

Table 15, the optimal solution was obtained under nonlinear inequality constraints using the interior-point method. The specific energy consumption value (3660.088

) reported here corresponds to the lowest achievable energy consumption while satisfying all process constraints. When

Table 15 is examined, it can be observed that as the amount of produced molten glass increases, the specific energy consumption of the glass furnace also increases. This outcome reflects the increasing energy demand required to maintain thermal efficiency during high-capacity operation. Moreover, it should be noted that the value of electric boosting is close to its upper operational limit, which suggests that maximizing electric assistance plays a critical role in optimizing energy performance under constrained conditions. Additionally, the minimum SEC obtained is consistent with the values reported in the literature and is considered a reasonable and realistic result for industrial-scale glass furnaces. Furthermore, based on the developed model, when the electric boosting power is kept constant, the relationship between raw material and cullet flow rates becomes an important factor in determining combustion heat demand.

3.7. Comparison of Regression Model and Optimization Results Using Raw Data and Reconciled Data

The metrics of the linear regression models and optimization results obtained with raw data and reconciled data are given in

Table 16.

Comparing the regression and optimization results (

Table 16) obtained using raw and reconciled data reveals that the regression model built with reconciled data yields more reliable results. Lower

p-values, RMSE, AICc, and BIC metrics were obtained with the reconciled data. In the optimization results, the lowest specific energy consumption was 3659.30 kJ/kg glass with the raw data, while it was 3660.088 kJ/kg glass with the reconciled data. If a specific energy consumption analysis had been conducted using only the raw data, we would have found a lower specific energy consumption value than expected, which would have been misleading. However, using reconciled data prevented this misleading error, and a more reliable specific energy consumption result was obtained. In summary, using reconciled data instead of raw data both increased the reliability of the linear regression model and helped achieve more reliable optimization results. As a result, better results for optimizing furnace performance were obtained by creating a linear regression model and using reconciled data.

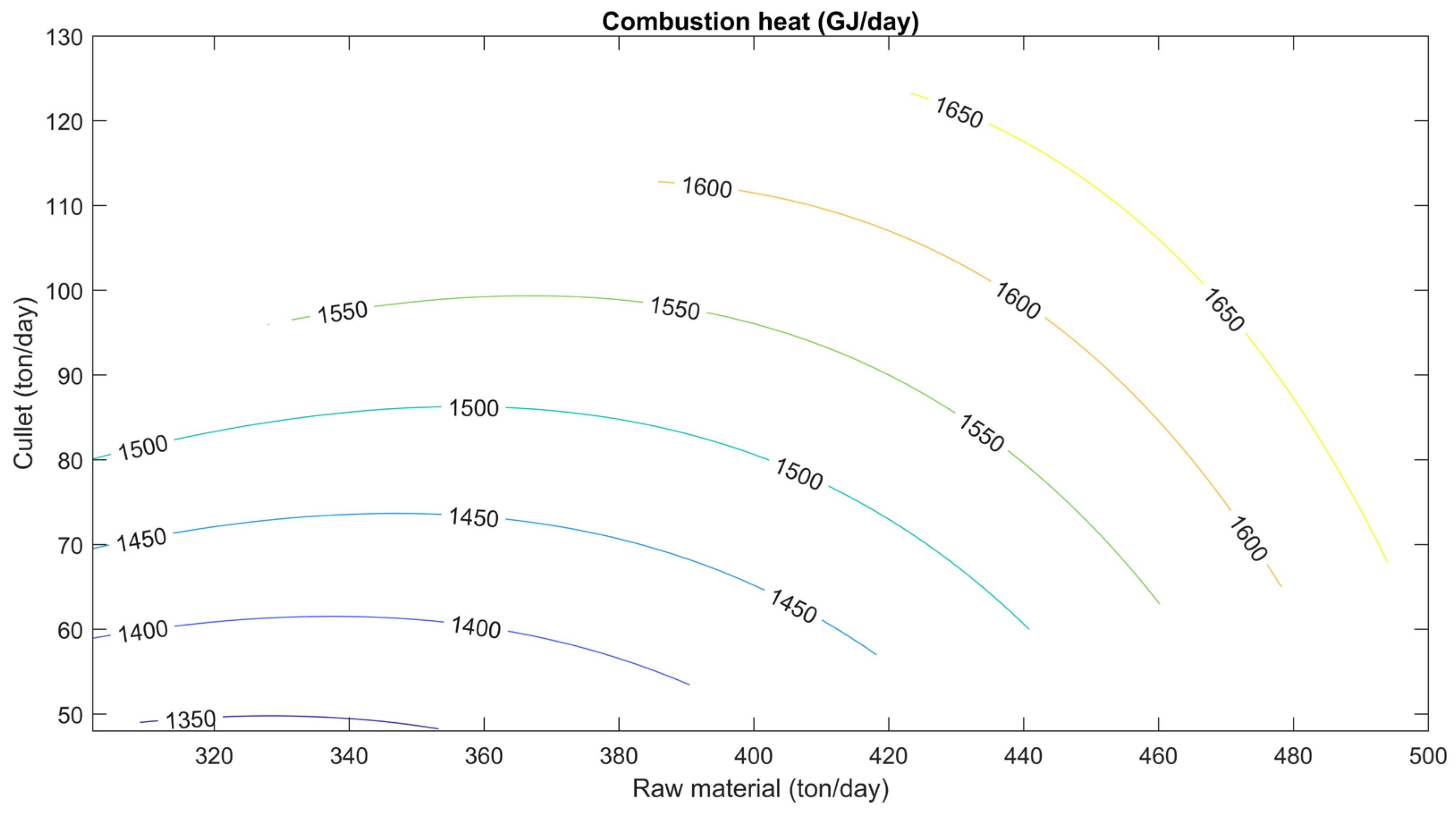

3.8. Graphical Analysis of Specific Energy Consumption Dependency on Raw Material and Cullet (with Reconciled Data)

In this section, the effects of raw material and cullet consumption on the specific energy consumption of a glass furnace are investigated, assuming certain optimal points that minimize specific energy consumption in the optimization problem. These constants were met under the following conditions: a humidity (water/raw material ratio) of 0.03, a raw material temperature of 305 K, electric boosting of 157 GJ, and a maximum glass production capacity of 500 tons. The combustion heat requirement of the glass furnace under these conditions is given in

Figure 11.

As can be seen from

Figure 11, when the amounts of raw materials and cullet increase, the combustion heat required by the glass furnace also rises. This is expected, as processing larger quantities of material demands greater thermal input to maintain melting efficiency and quality.

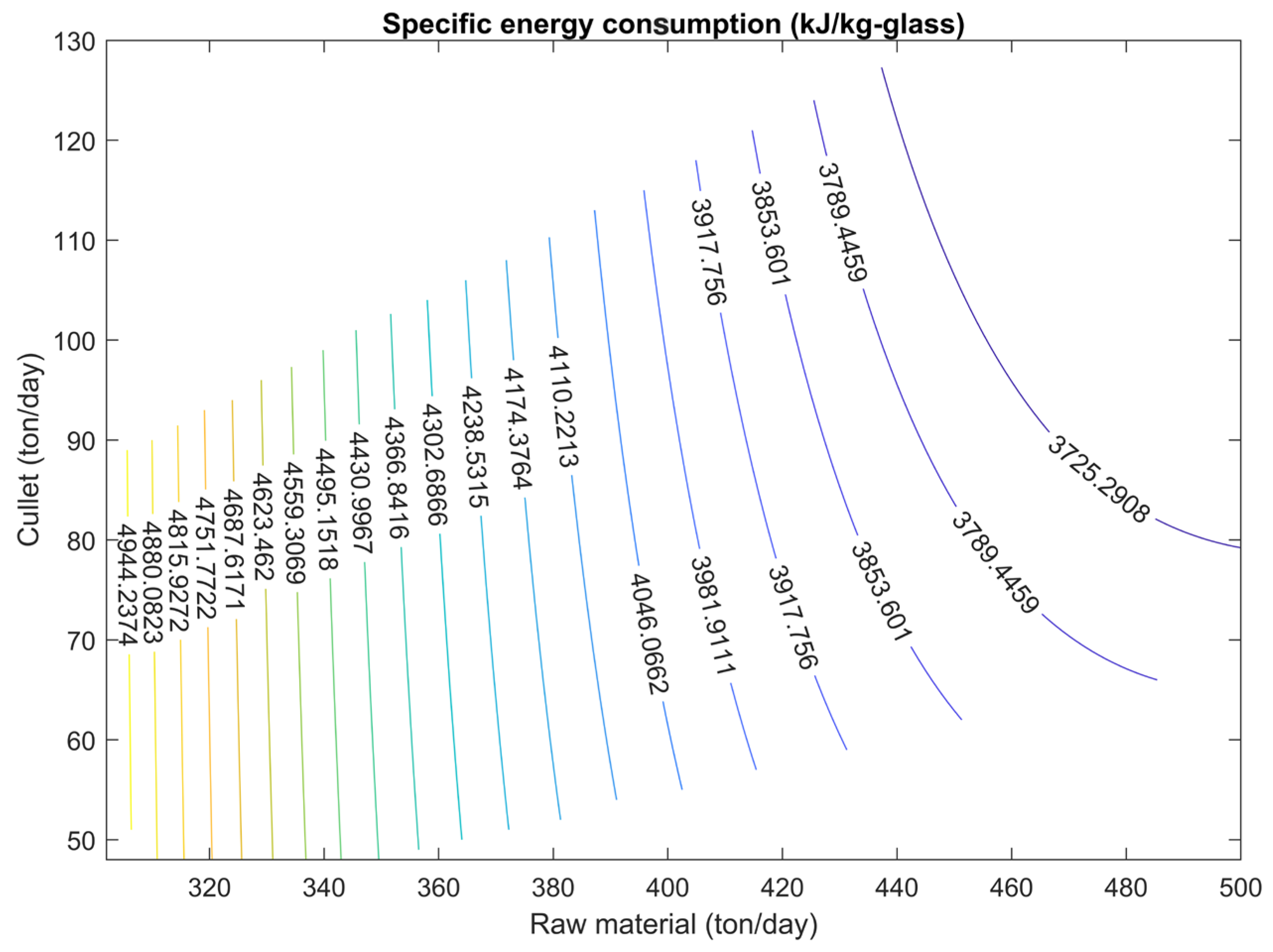

The estimated specific energy consumption as a function of raw material and cullet inputs under this condition is illustrated in

Figure 12 (contour plot with level curves). These visualizations help to better understand how material input combinations influence energy performance and to identify operating points that yield lower specific energy consumption values.

Figure 12 illustrates that as the flow rates of raw materials and cullet rise, the specific energy of the glass furnace decreases. An important observation is that despite the increase in daily glass production associated with these higher input rates, the specific energy consumption of the glass furnace decreases, indicating improved energy efficiency at larger production scales. These findings highlight the model’s capability not only to optimize energy use but also to provide reliable, precise predictions of the furnace’s energy demand (combustion heat) with minimal error margins, based on varying daily production requirements. Such insights are critical for operational planning and cost reduction in glass manufacturing. The effect of electric boosting on specific energy consumption is given by

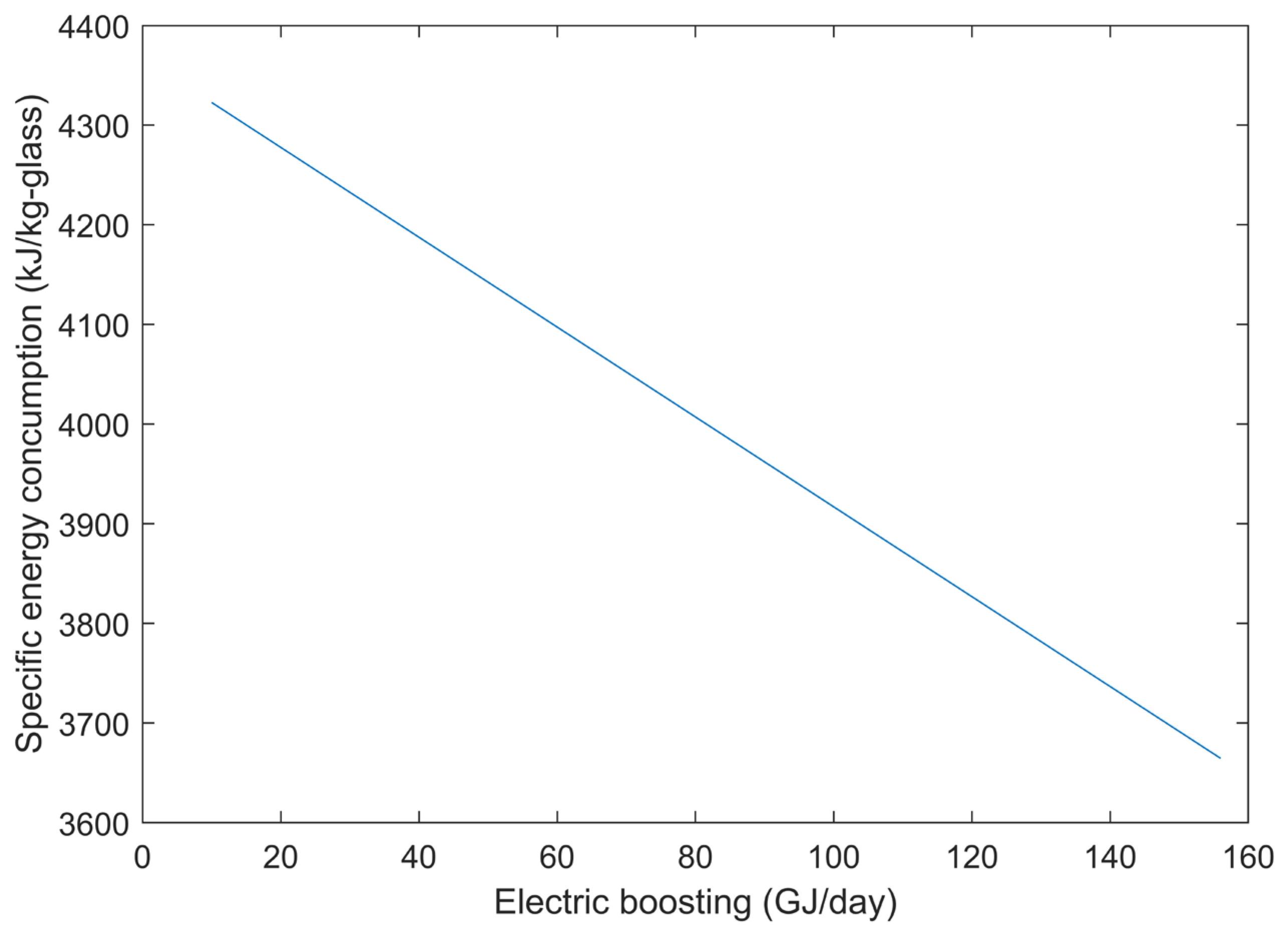

Figure 13.

Figure 13 illustrates that the specific energy consumption of the glass melting furnace is strongly affected by changes in electric boosting. According to

Figure 13, an increase in electric boosting adversely affects the specific energy consumption. However, the adverse linear trend indicates that achieving higher electric boosting rates can contribute to a more efficient melting process. This is because heat transfer from electric boosting to the glass bath is more effective than that from fuel combustion over the glass bath. Consequently, the energy requirement per unit mass of glass decreases steadily as the electric boosting increases.

This finding highlights the positive impact of electric boosting on the overall energy performance of the furnace. When the findings and results are examined, this study demonstrates that the energy performance of glass furnaces can be significantly improved through the integration of data reconciliation, statistical modeling, and advanced optimization methods. Furthermore, even a slight improvement in energy performance, particularly in energy-intensive glass furnaces, results in significant fuel savings. The stepwise linear regression model employed in this study explains a significant portion of the variation in combustion heat demand. Furthermore, this regression model provides high prediction accuracy with both the training and test data sets. The use of reconciled process data and cross-validation also increases model reliability and prevents overfitting. Furthermore, it is demonstrated that specific energy consumption can be effectively reduced using various optimization algorithms under certain operational constraints. Among the optimization methods tested, the interior-point algorithm provided the most efficient solution with the lowest specific energy consumption.

The most striking of these results is that specific energy consumption decreases significantly as cullet flow rate, glass production, and the amount of electric boosting increase. It is also worth discussing the suggestion that if global glass factories built fewer furnaces and produced glass at full capacity instead of operating at half capacity, the specific energy consumption of these glass furnaces would decrease significantly (

Figure 12), because the furnaces are designed for full capacity but are operated at half capacity. Currently, significant efforts are being made to improve the energy performance of glass furnaces. In addition to this effort, it is understood that operating glass furnaces at near full capacity can significantly improve their energy performance. When planning for the future, it is crucial to operate existing furnaces at full capacity rather than overbuilding. This will reduce specific energy consumption and avoid the cost of installing additional furnaces.

3.9. Limitations

The primary objective of this study is to predict and subsequently optimize the energy performance of a glass furnace based on various input variables. However, there are certain physical limitations inherent to this process. These limitations include the following:

The data obtained from the glass furnaces are aggregated daily rather than being instantaneous. In future, collecting minute- or hour-based data is expected to enable more detailed and accurate analyses.

The raw material typically remains inside the furnace for approximately 24 h; however, due to internal circulation, individual material batches do not exit the furnace simultaneously. Therefore, calculations are performed using the average residence time.

Due to the extremely high temperatures within the furnace, data cannot be gathered uniformly from all regions. To address the missing measurements, data reconciliation methods are employed to estimate these unmeasured variables.

4. Conclusions

In this study, to optimize the specific energy consumption of a glass furnace, the effects of critical variables such as raw material, cullet, water, raw material temperature, and electrical energy were investigated quantitatively. The findings show that increasing the raw material and cullet flow rate and using electric boosting significantly increased the energy performance of the furnace. Furthermore, the regression model obtained by using reconciled data via data reconciliation rather than raw data was proven to provide more reliable and consistent results in the optimization process.

The main contributions and key findings of this research study are as follows. When comparing two different linear regression models, the model created with the reconciled data () was found to be much more reliable. Afterwards, the most reliable optimization results were obtained with reconciled data. The minimum specific energy consumption was found to be 3660.088 using the interior-point method, under optimized process conditions. When the glass furnace operates at partial capacity instead of full capacity, the furnace uses more energy. Overall, the specific energy consumption of glass furnaces may be effectively decreased through optimizing production parameters, increasing electric boosting usage and the cullet ratio, and nearly full capacity operation. The findings of this study offer important implications for both the glass furnace studied and other industrial processes involving similar energy intensity. The demonstration that specific energy consumption can be reduced through accurate modeling and optimization techniques provides a critical framework for industrial efficiency and sustainability.

Future studies could involve real-time or high-frequency data collection to analyze transient behavior more accurately. Furthermore, hybrid modeling approaches that combine process-based models and statistical data-driven models to take advantage of their complementary strengths could be employed to better capture the furnace’s dynamic performance. Finally, integrating the optimization framework with techno-economic and environmental analysis considering parameters such as energy cost and CO2 emissions would enable a more sustainable assessment of glass furnace operations.