Inducing Interconnected Fractures in Granite via Pulsed Power Plasma Using Nanoparticles: A Waterless Stimulation Approach for Enhanced Geothermal Systems

Abstract

1. Introduction

2. Nanoparticle-Enhanced Pulsed Power Plasma Stimulation

3. Experimental Setup and Measurements

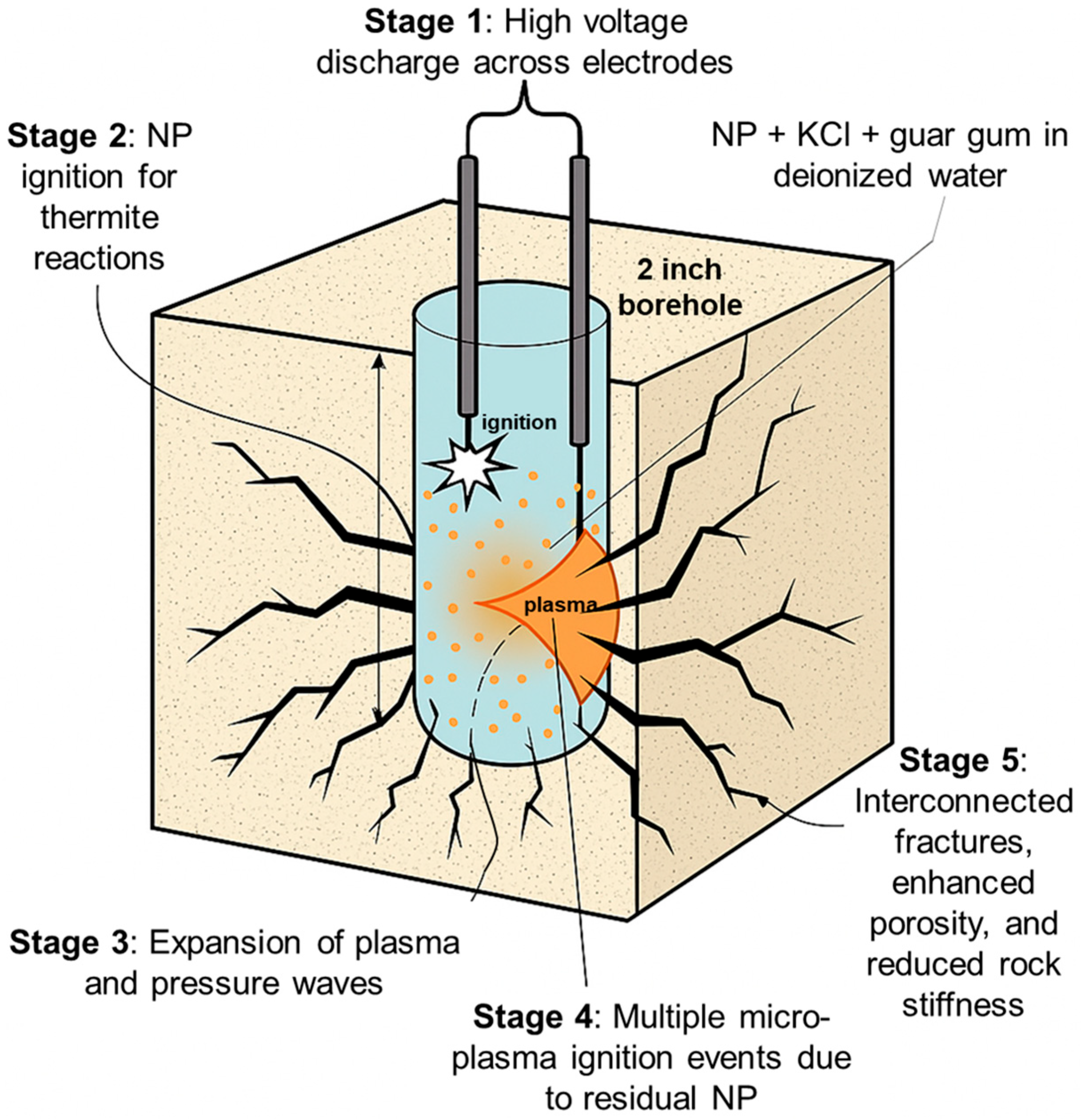

3.1. Mechanistic Framework of NP-3PS

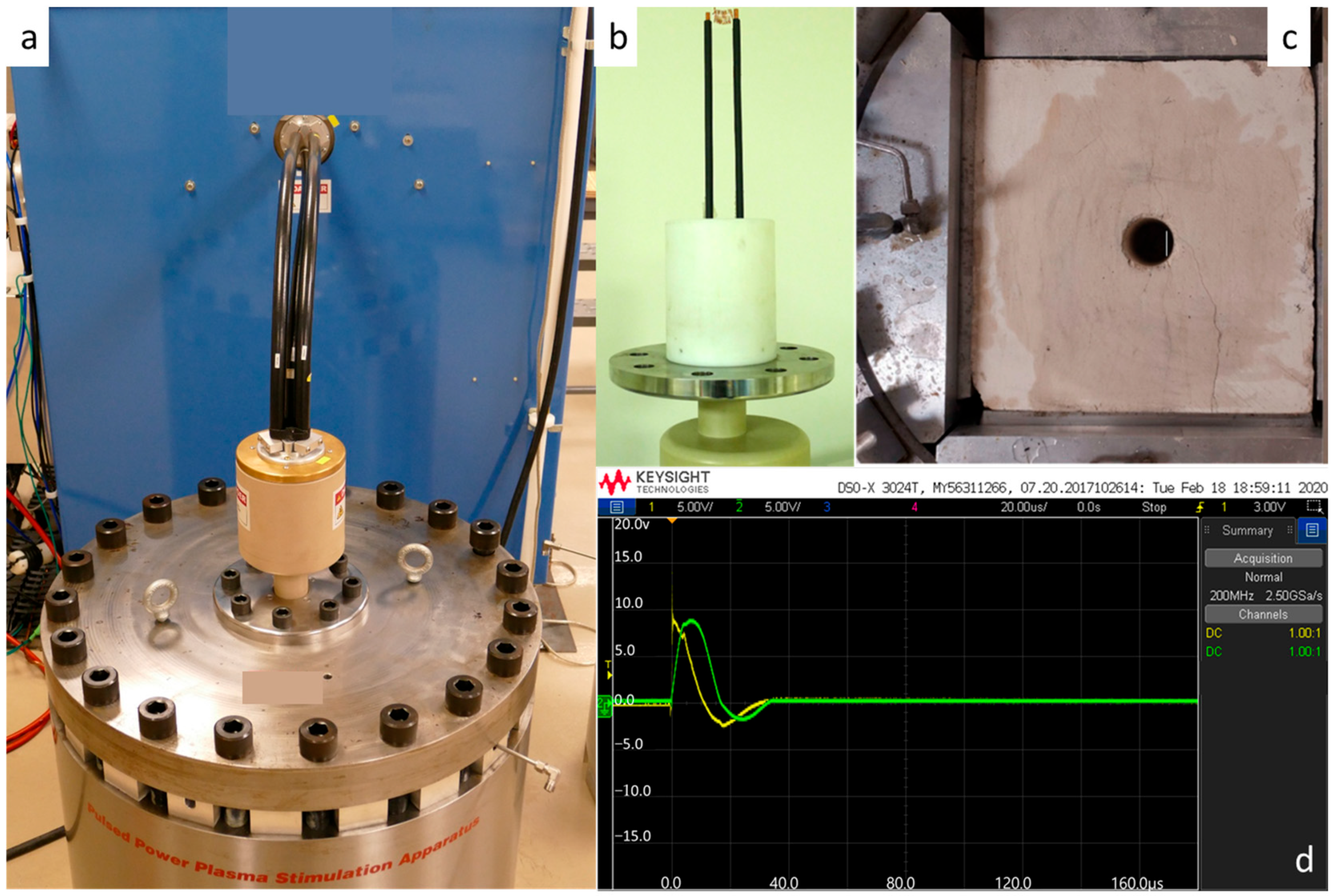

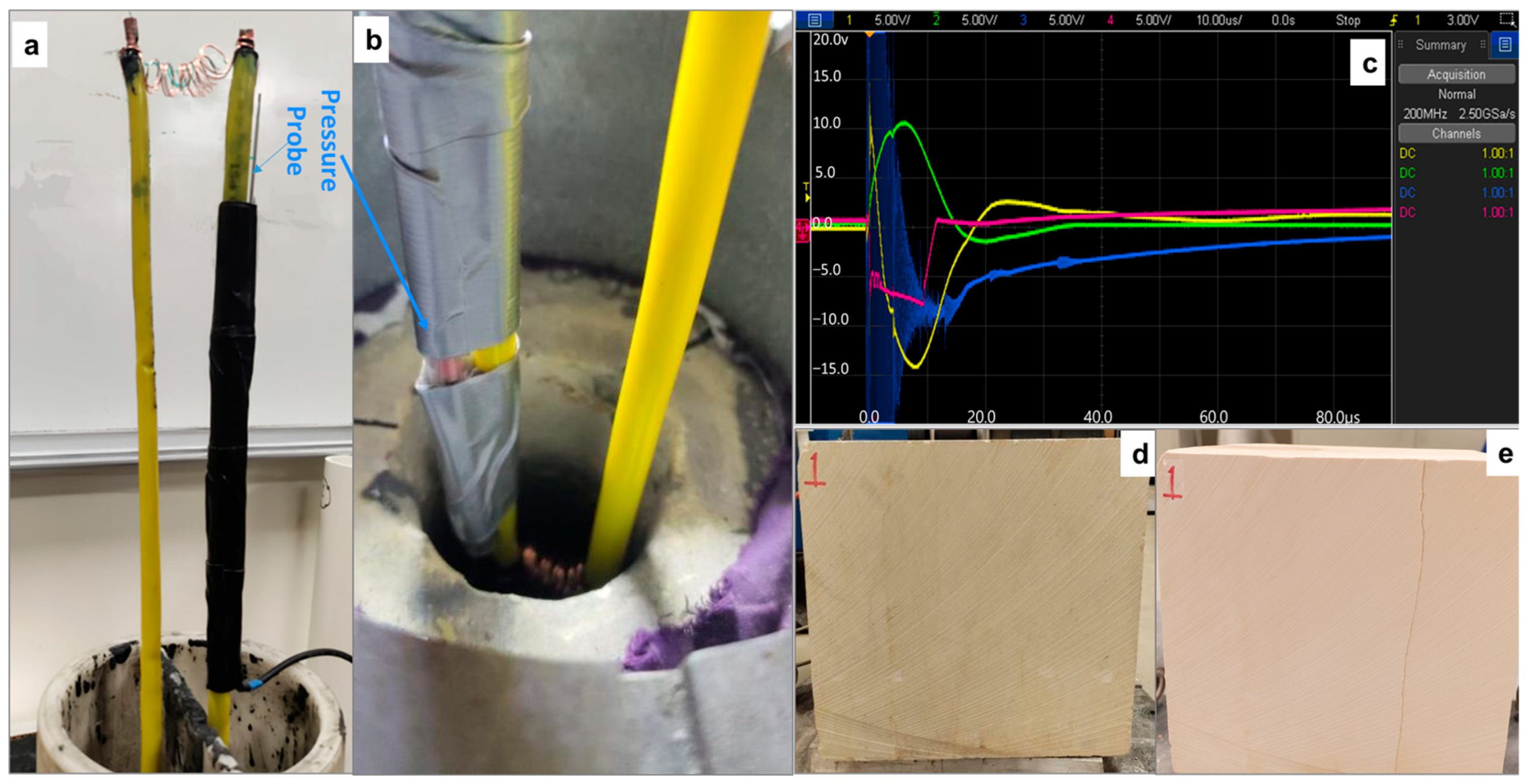

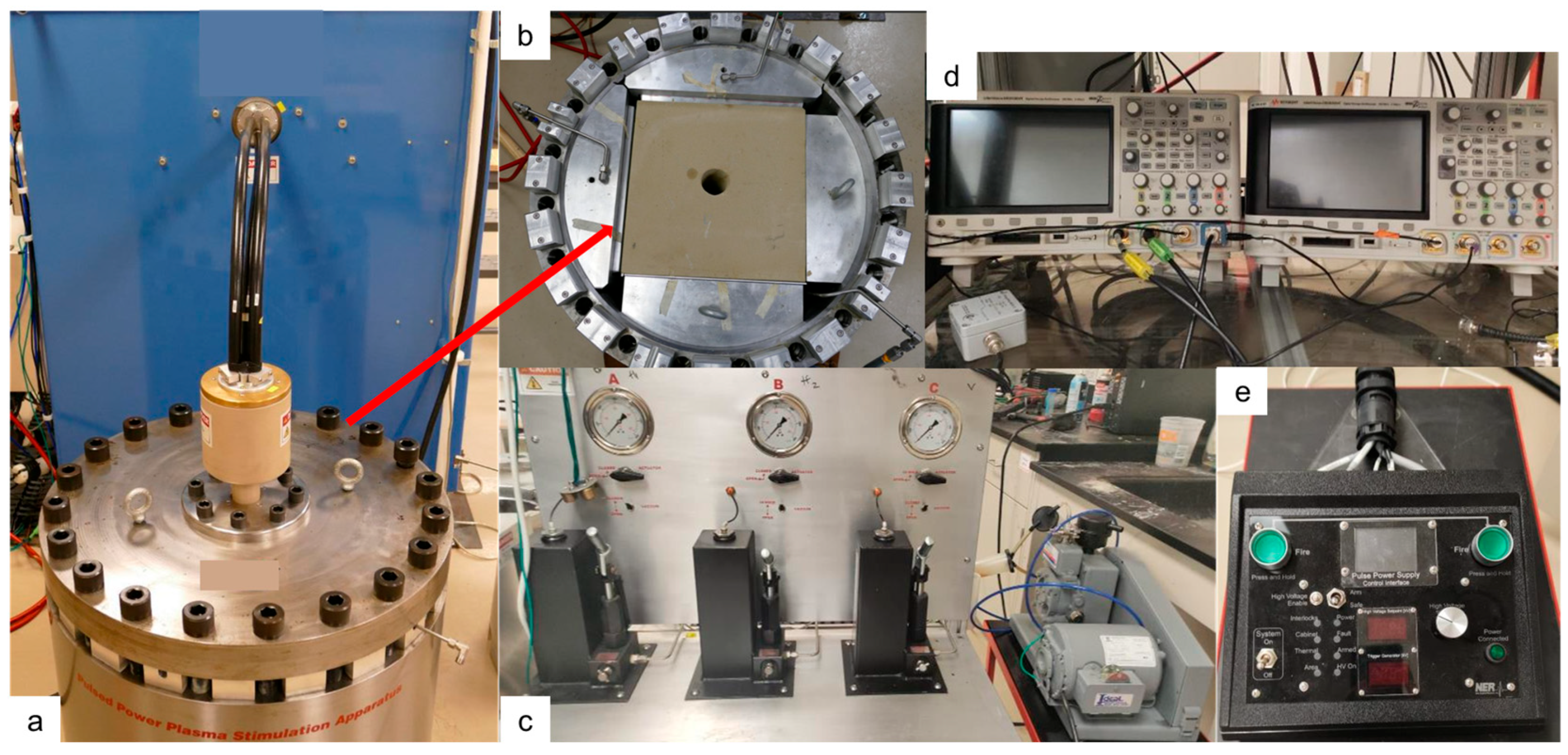

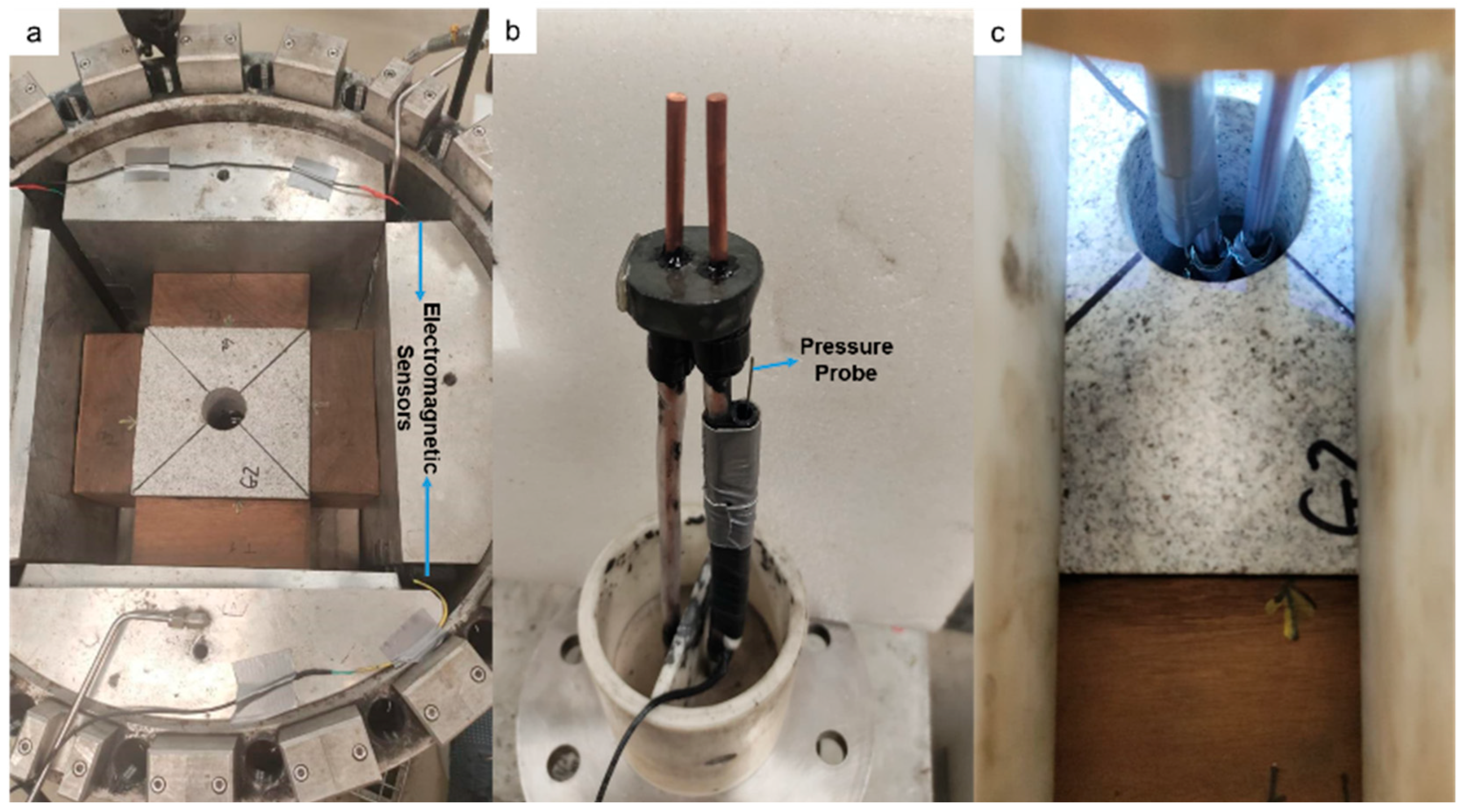

3.2. System Configuration

3.3. Specimen Preparation and Stimulation Conditions

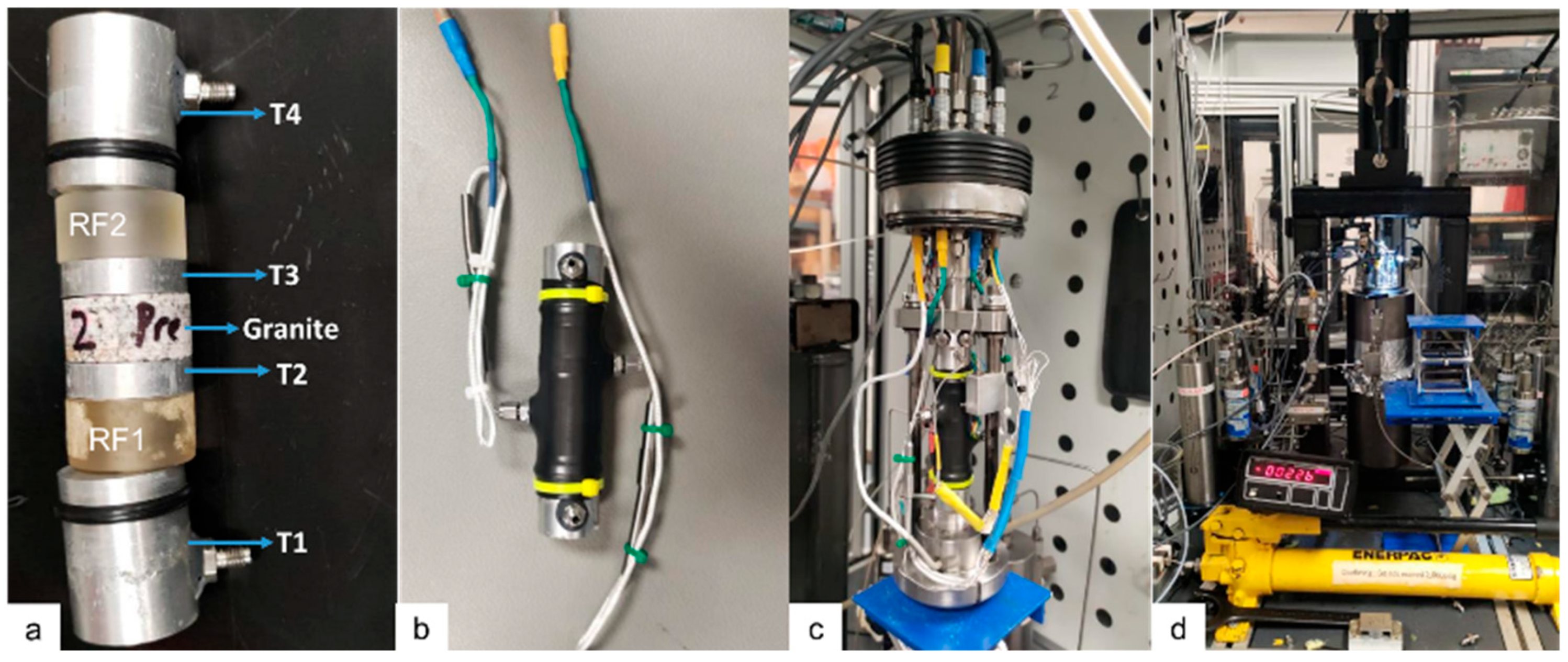

3.4. Measurement Techniques

- T1: Top of RF1 (heat source),

- T2: RF1–granite interface,

- T3: Granite–RF2 interface,

- T4: Bottom of RF2 (heat sink).

- is the effective thermal conductivity

- is the referenced thermal conductivity of RF1 and RF2

- are the lengths of the granite, RF1, and RF2, respectively

- are the cross-sectional areas of the granite, RF1, and RF2, respectively

- = T2 − T3

- = T1 − T2

- = T3 − T4

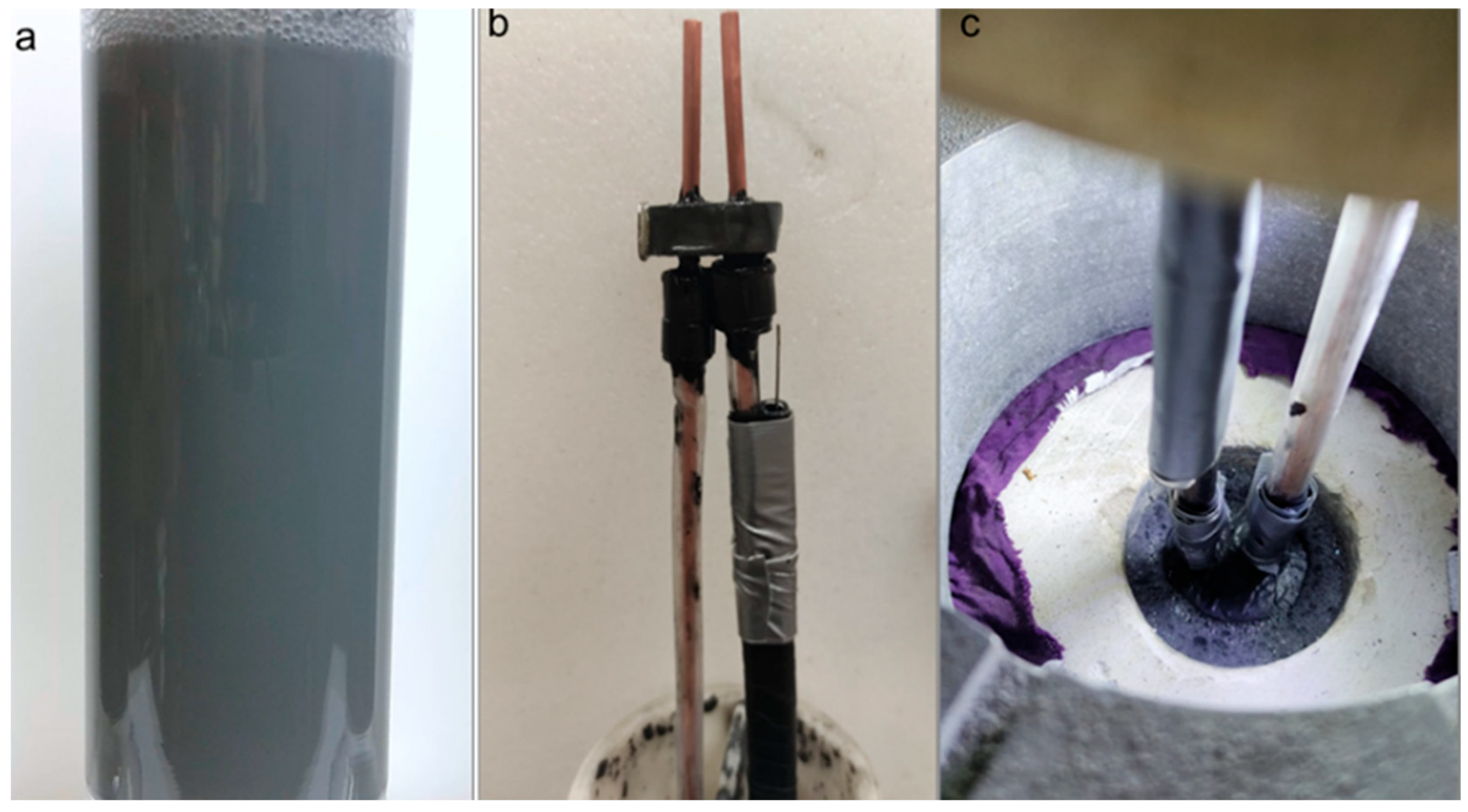

4. Nanoparticle Fluid Optimization

- Al NP of 60–80 nm, 99.7% purity (SkySpring Nanomaterials, Inc., Texas, USA) were selected as the active energetic component due to their high specific surface area (approximately 20–30 m2/g) [43] and chemical stability in brine. Preliminary suspension and ignition tests confirmed that this size range provided an optimal balance between rapid thermite activation and oxidative resistance in the brine. Smaller particles (<50 nm) exhibited strong agglomeration tendencies, resulting in premature oxidation and reduced reactivity, whereas larger particles (>100 nm) showed poor dispersion and diminished plasma energy yield.

- KCl served as the ionic base of the NP fluid, providing both high conductivity and physicochemical stability under high-temperature, high-salinity geothermal conditions. Although clay stabilization is not a primary concern in crystalline geothermal reservoirs (unlike in conventional operations where KCl prevents clay swelling and permeability loss [44,45]), its inclusion here maintains ionic strength, ensures stable electrochemical pathways, and promotes consistent plasma channel formation and sustained thermite reactions between NPs. This KCl (Nutricost Manufacturing, LLC., Utah, USA) conductive environment enhances electron mobility across the discharge gap, accelerating plasma initiation and strengthening electro-mechanical energy coupling during NP-3PS events.

- A polymeric stabilizer, guar gum (ACH Food Companies, Inc., California, USA), was added at 0.18 wt% to increase viscosity and improve NP suspension over extended periods. This concentration, consistent with conventional HF formulations [46], provided adequate stability for more than ten days without significantly affecting flowability or discharge behavior. Although viscosity variation was not systematically analyzed in this study, the selected guar concentration maintained homogeneous particle dispersion throughout all laboratory trials and was therefore adopted as the baseline for subsequent experiments.

4.1. NP-3PS in 4 wt% KCl and 0.18 wt% Guar Gum Base Fluid

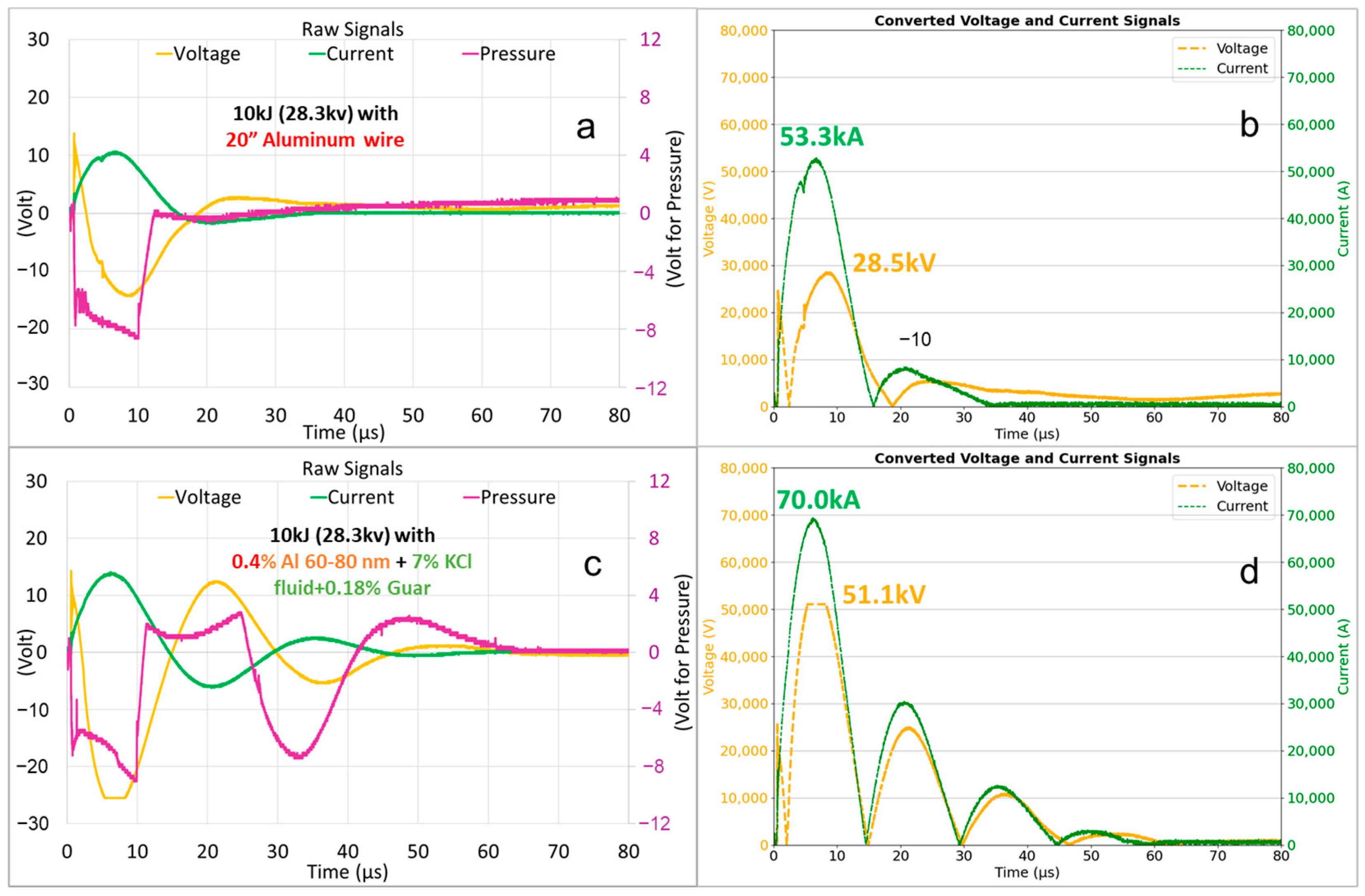

4.2. NP-3PS in 7 wt% KCl and 0.18 wt% Guar Gum Base Fluid

4.3. NP-3PS in 10 wt% KCl and 0.18 wt% Guar Gum Base Fluid

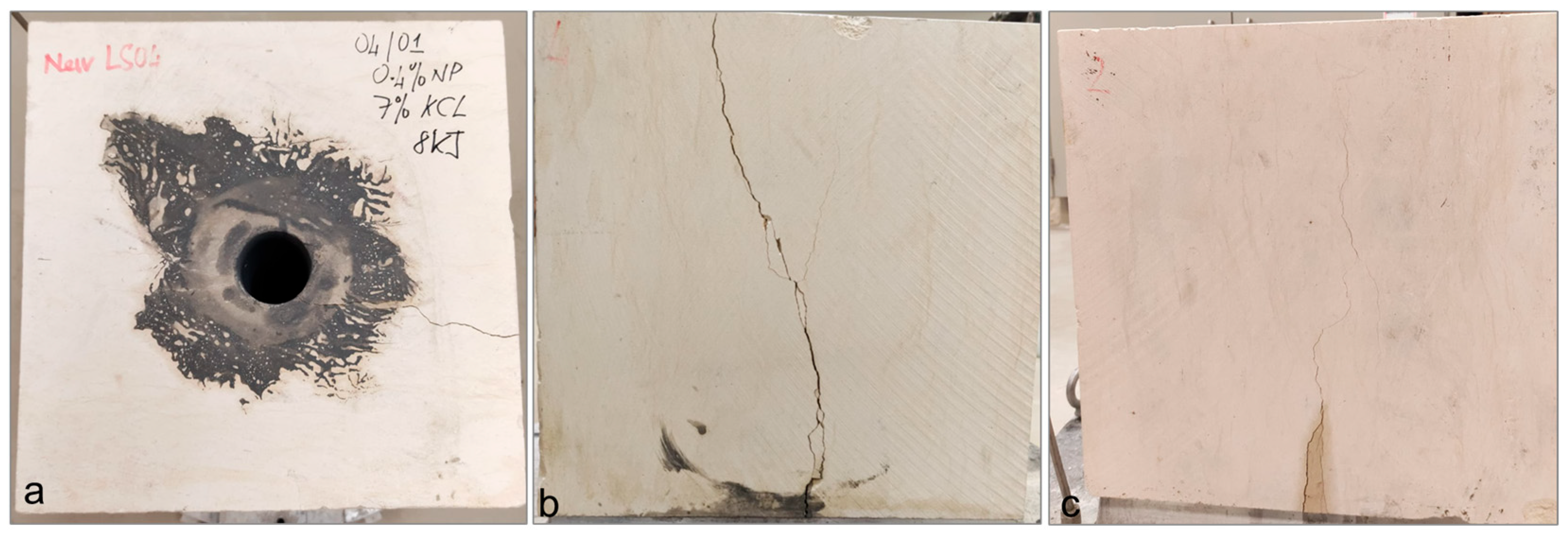

5. Granite Stimulation Results

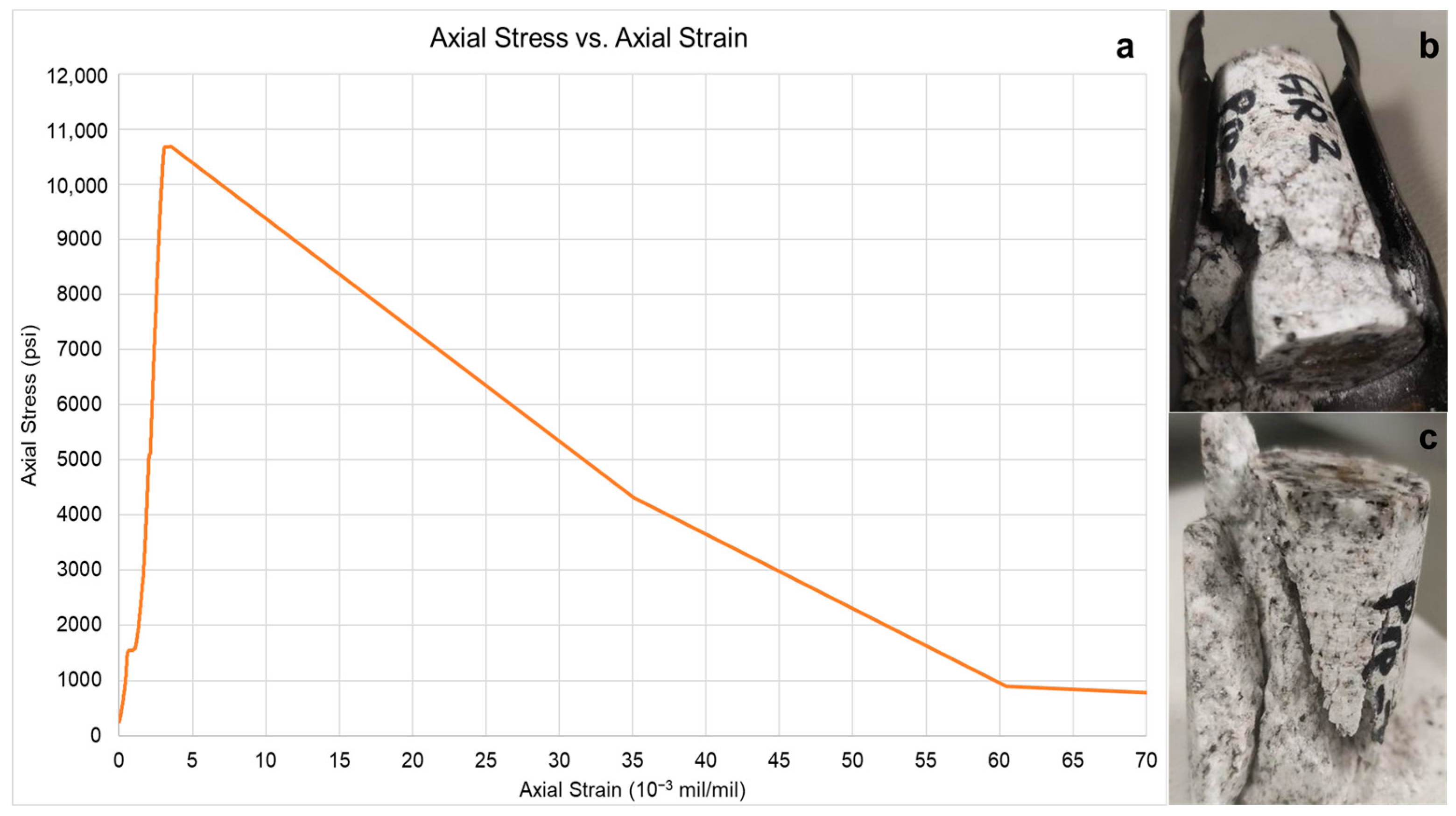

5.1. Baseline Mechanical Characterization of Granite

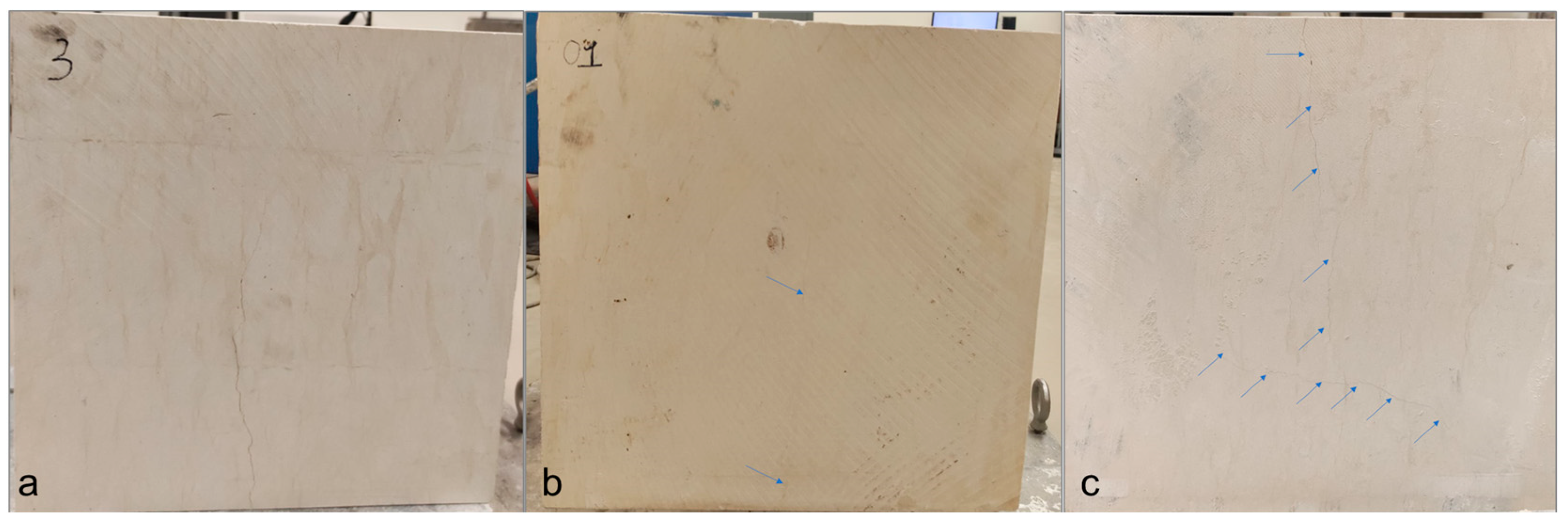

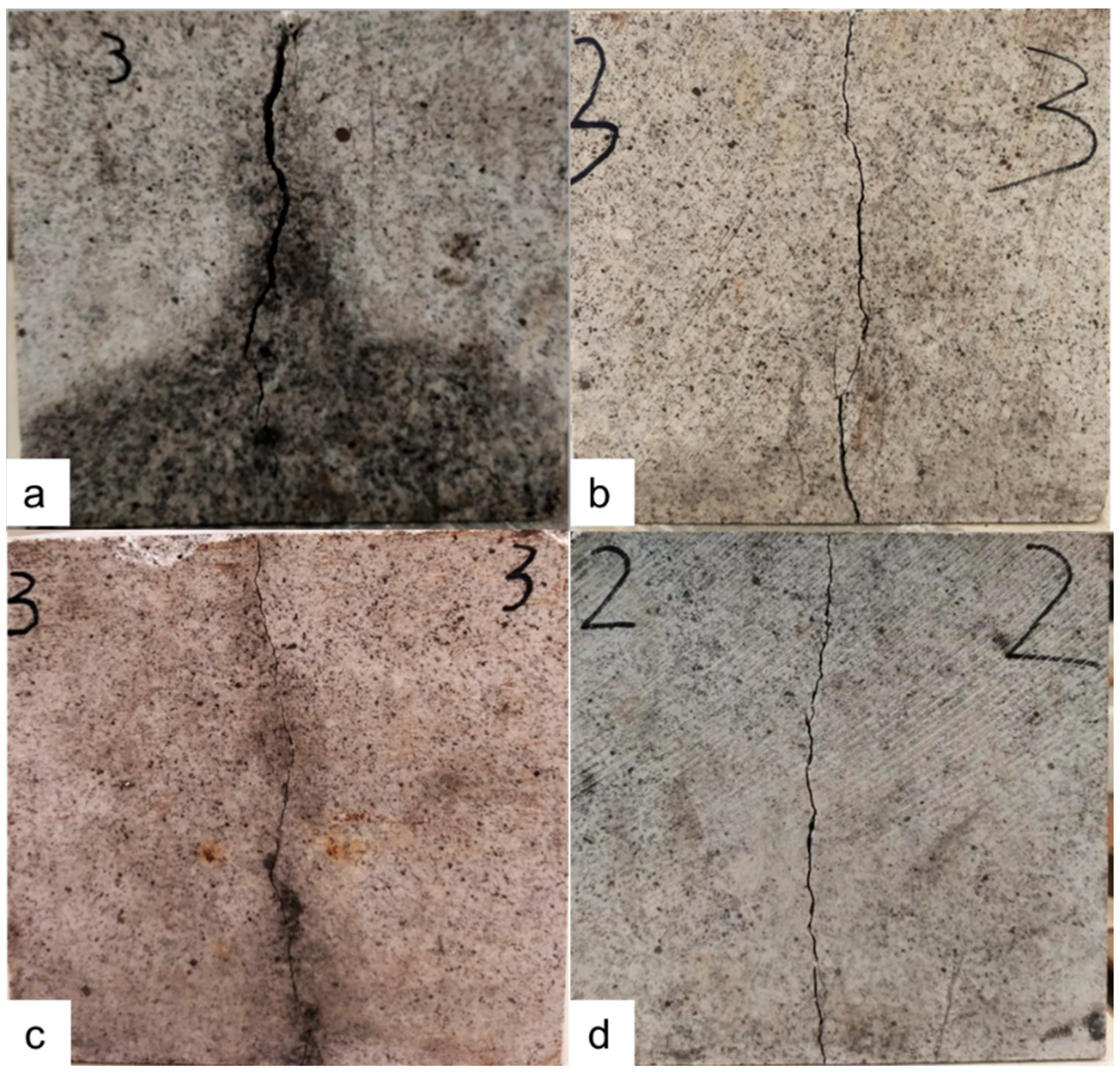

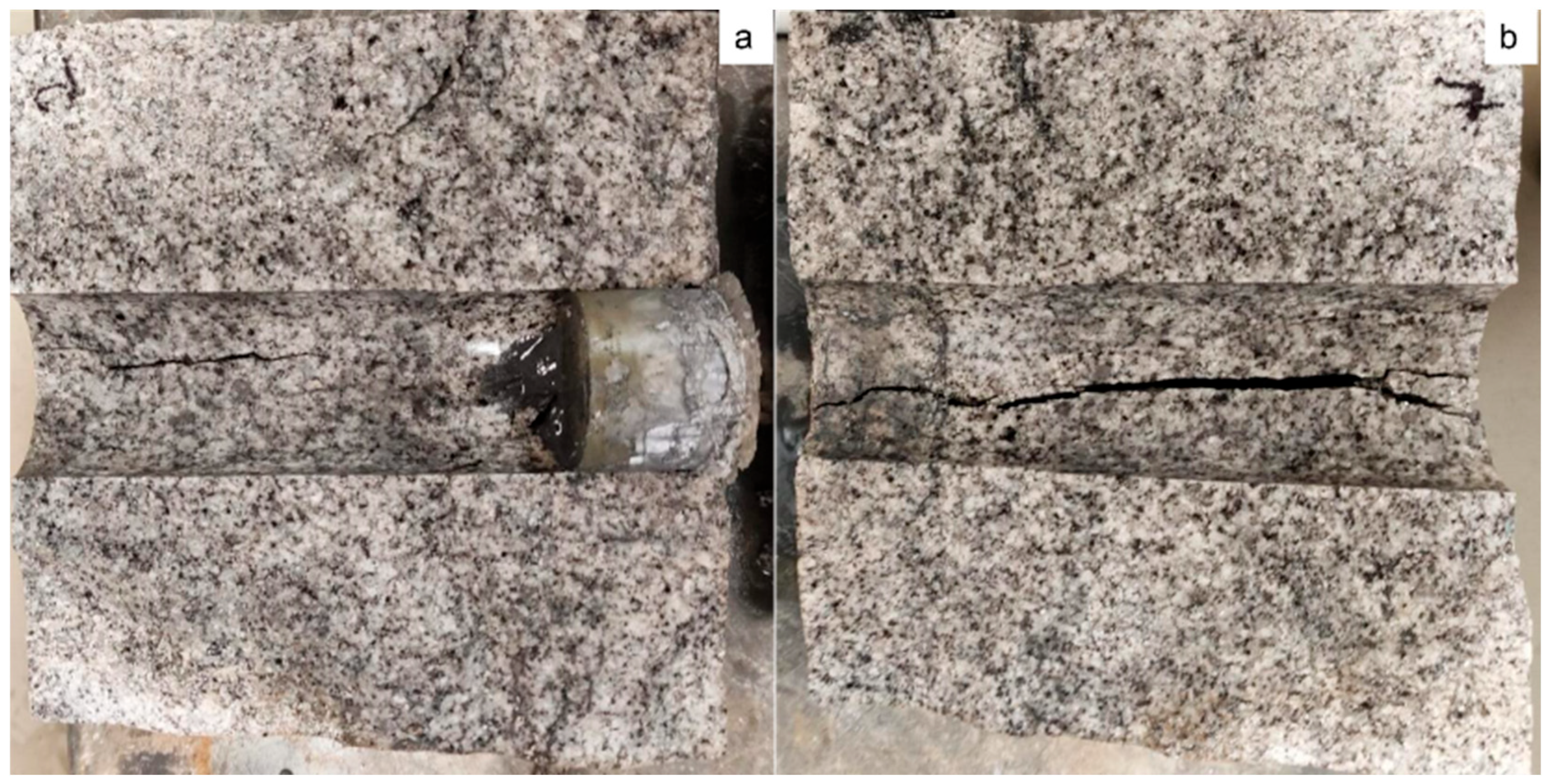

5.2. Macroscopic Fracture Morphologies

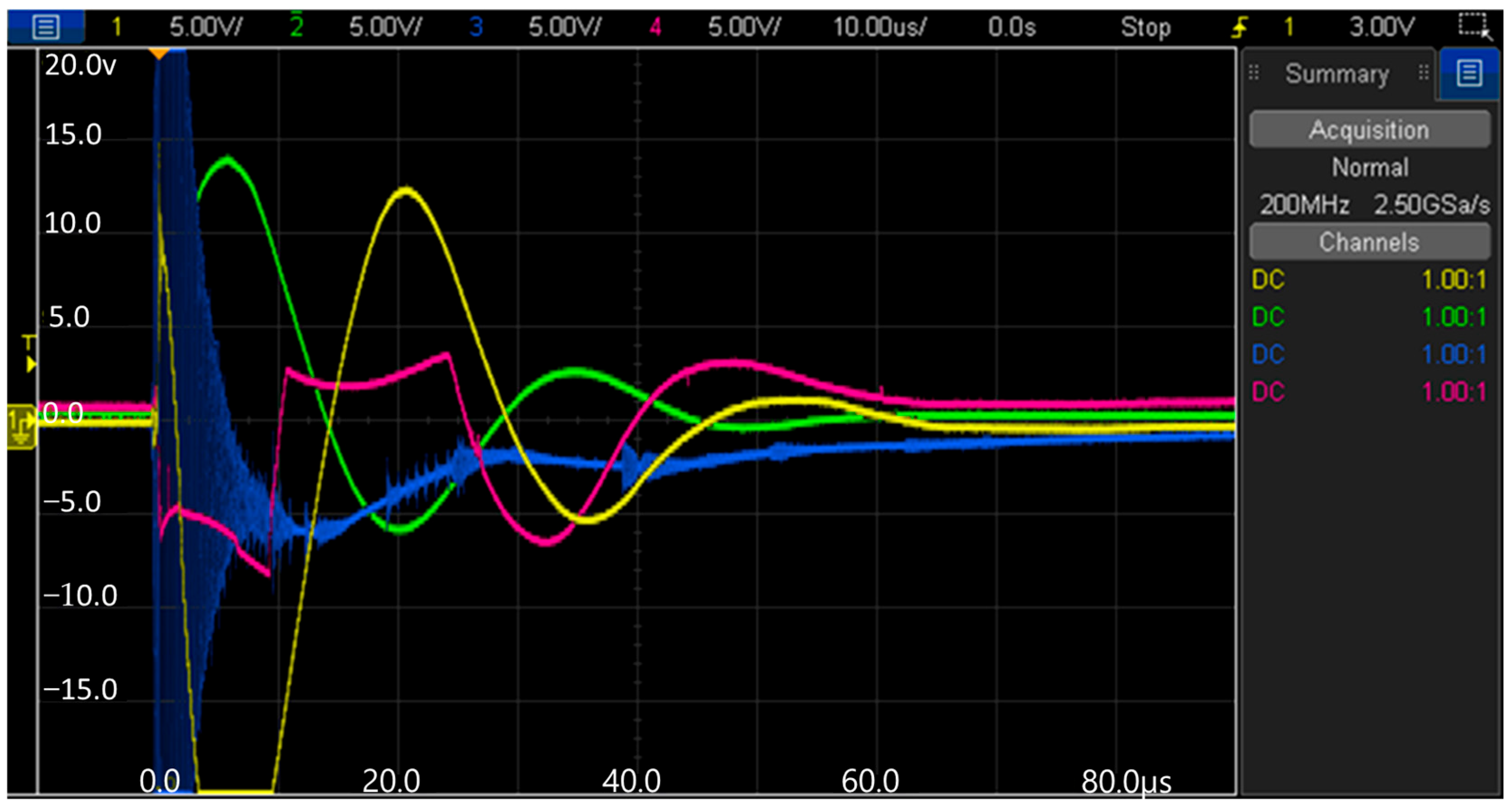

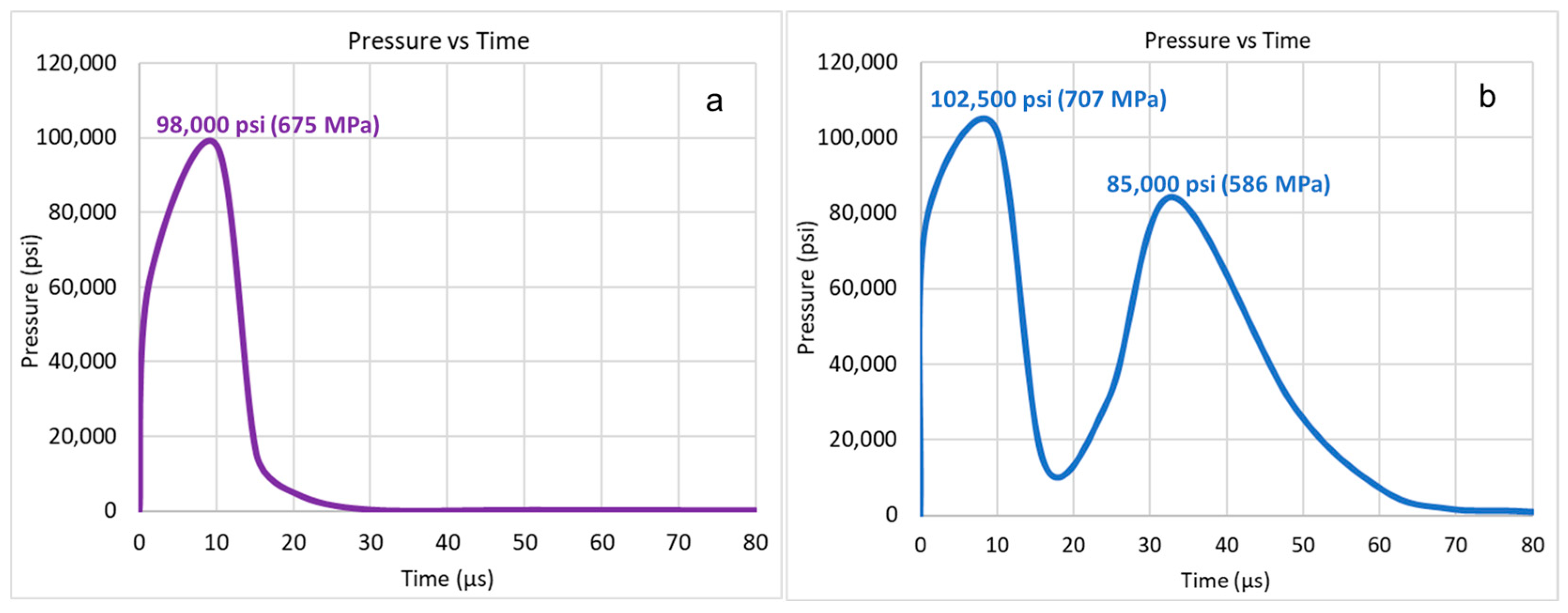

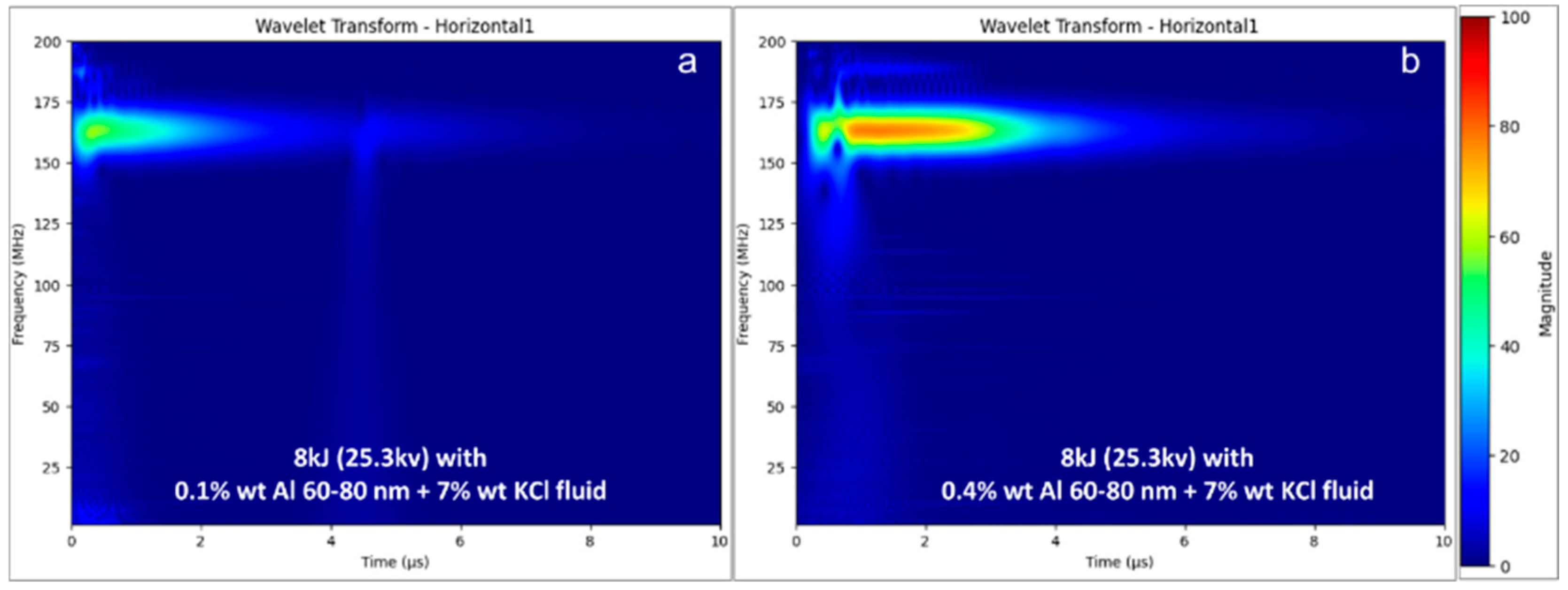

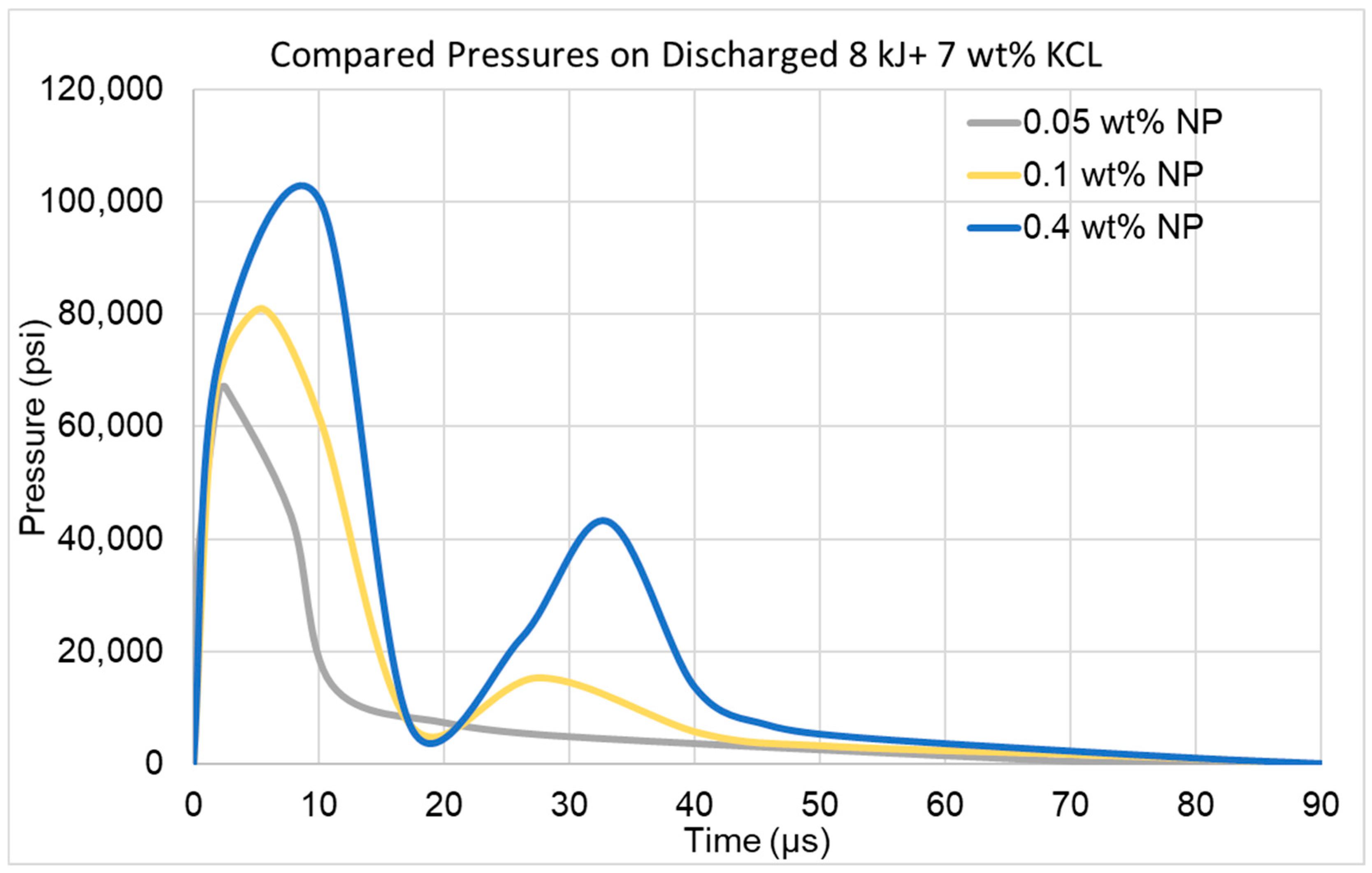

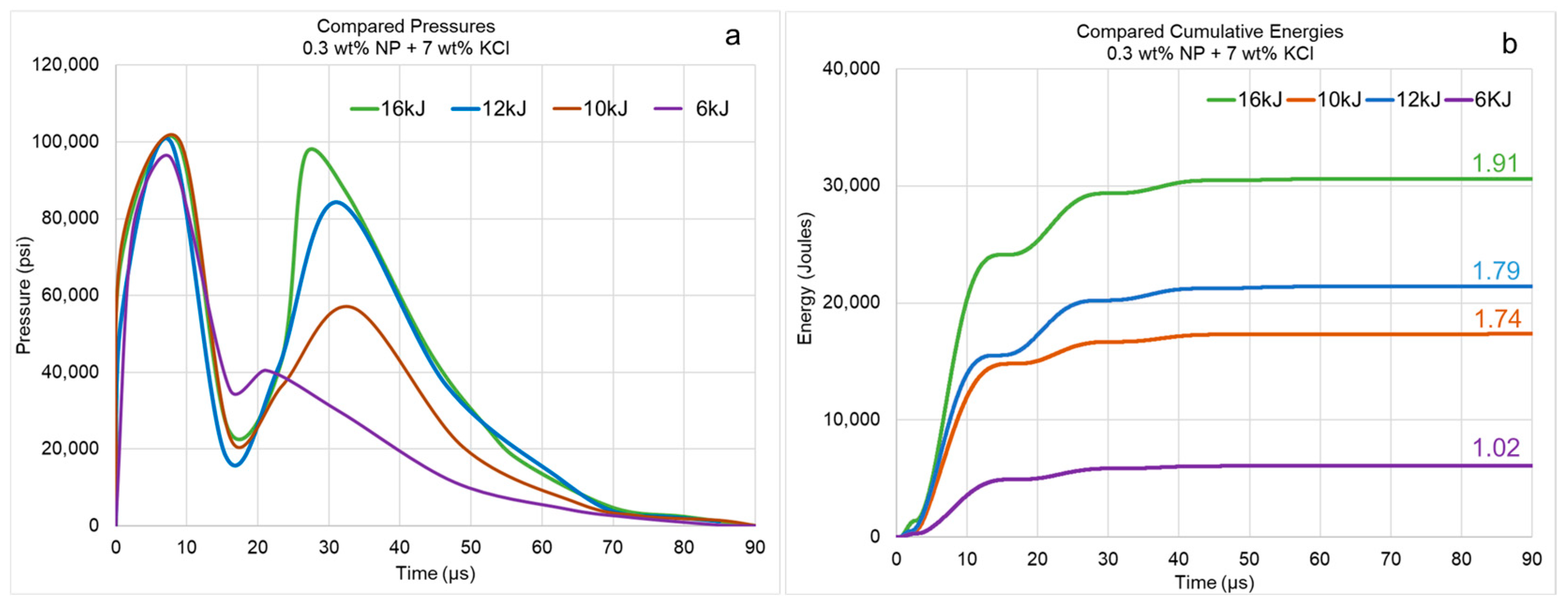

5.3. Dynamic Pressure Responses and Stimulation Efficiency

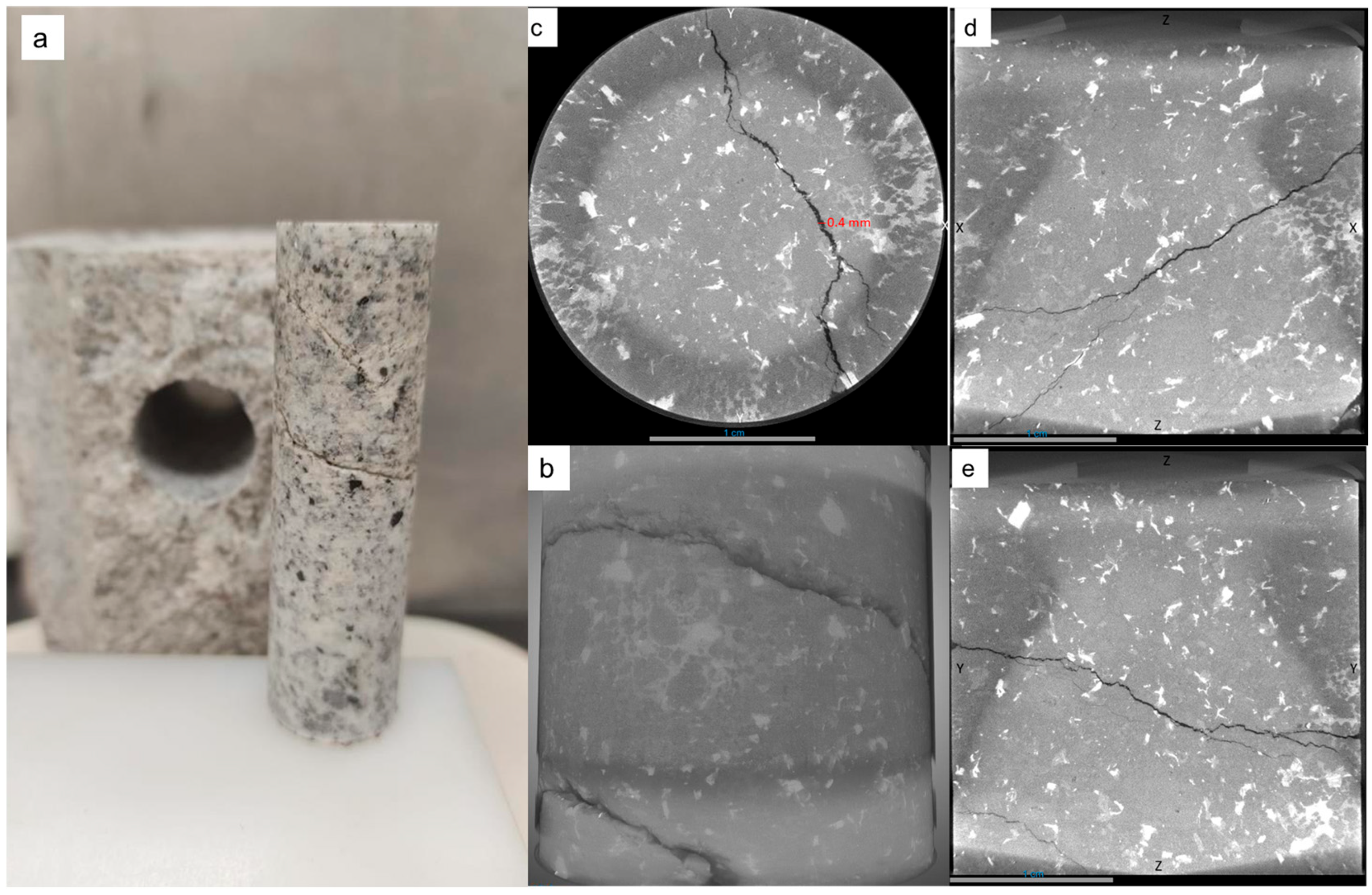

5.4. Subsurface Fracture Characterization via Micro-CT

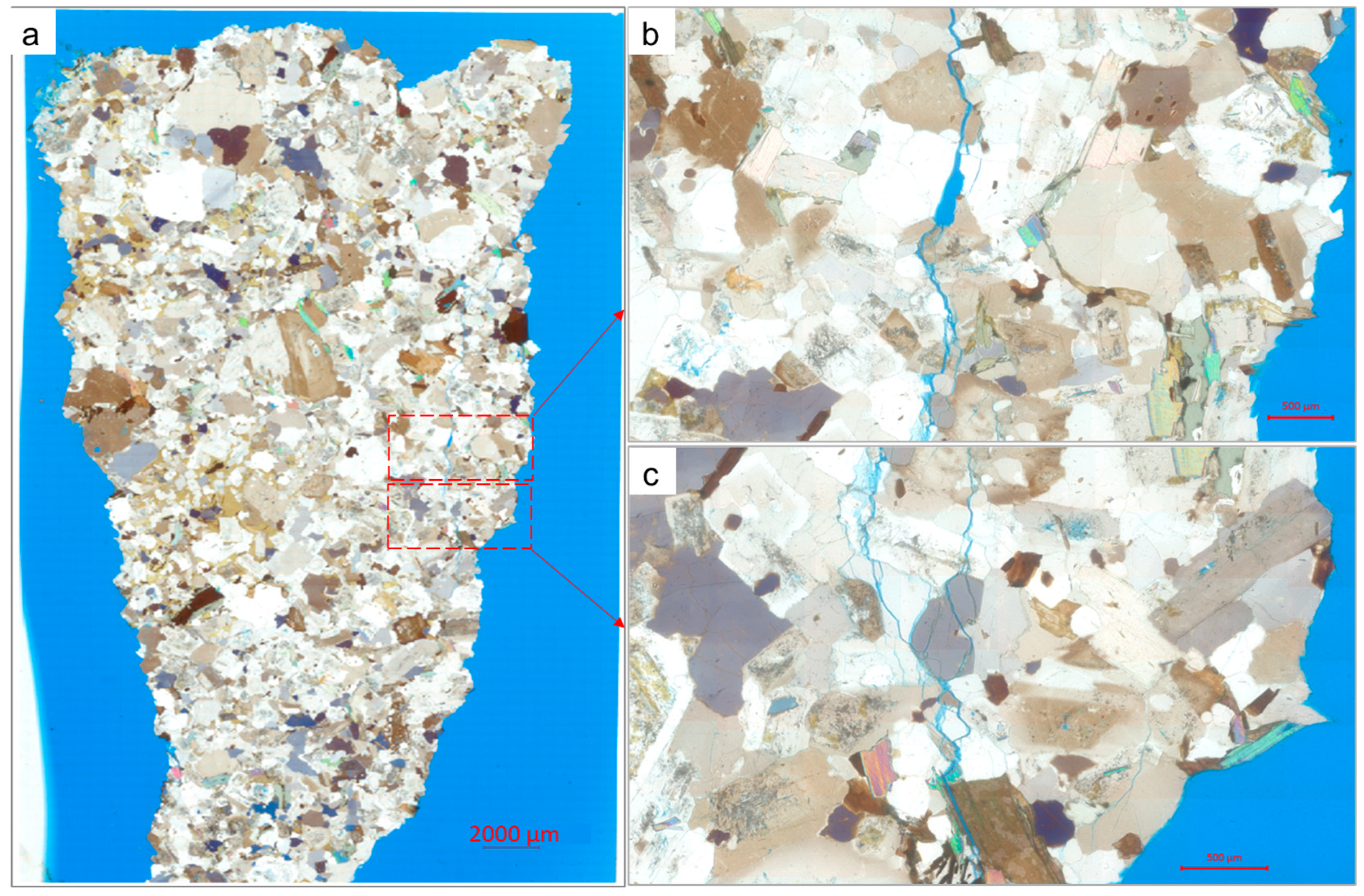

5.5. Grain-Scale Microstructural Insights from Thin-Section Petrography

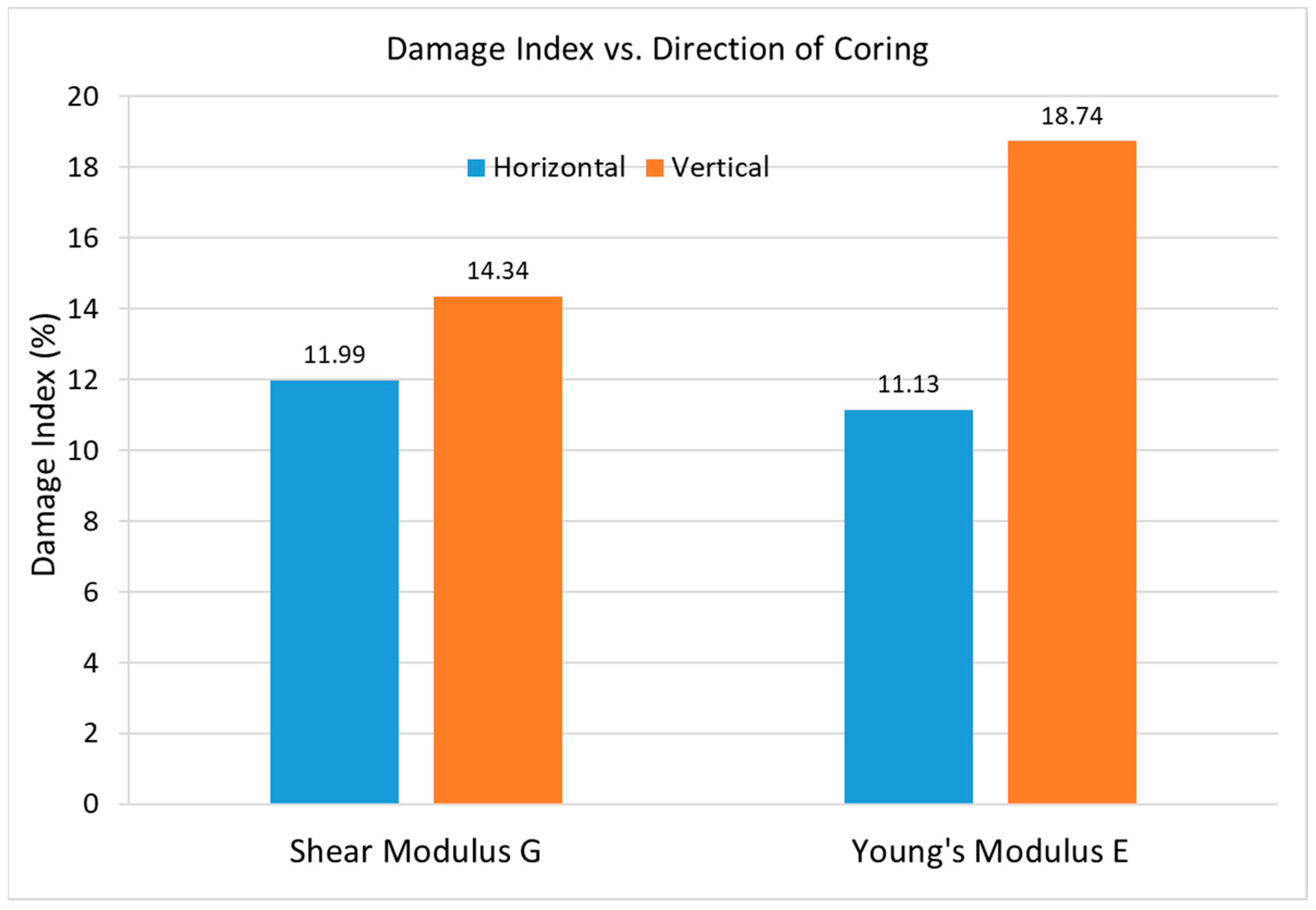

5.6. Acoustic and Petrophysical Property Degradation

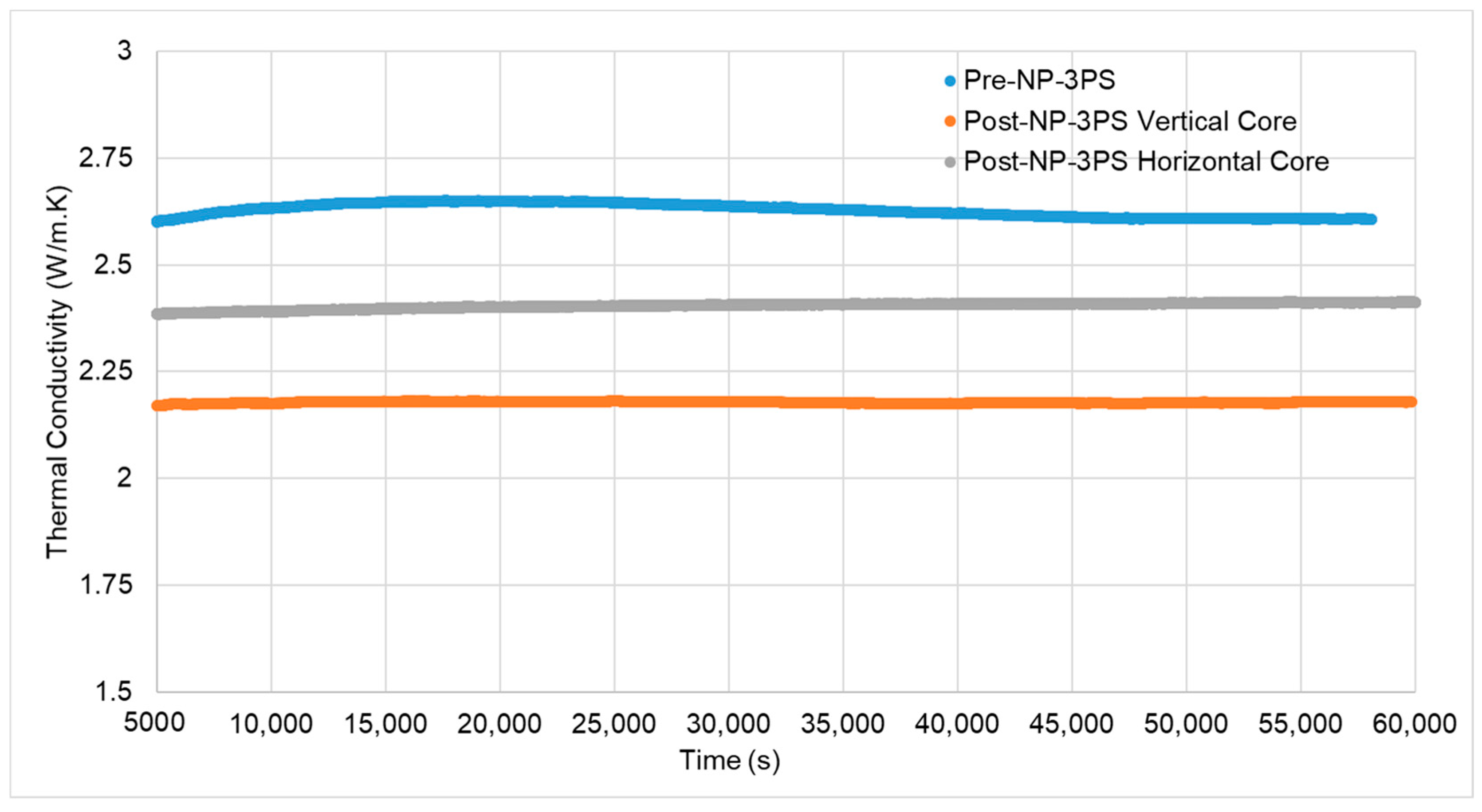

5.7. Thermal Conductivity Modifications

5.8. Quantitative Energy Efficiency Comparison with Field-Scale EGS and Potential Scalibility

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| 3PS | Pulsed Power Plasma Stimulation |

| Al | Aluminum |

| CT | Computed Tomography |

| E | Young’s Modulus |

| EGS | Enhanced Geothermal System |

| EHF | Electrohydraulic Fracturing |

| EM | Electromagnetic |

| EUR | Estimated Ultimate Recovery |

| G | Shear Modulus |

| HF | Hydraulic Fracturing |

| hp | Horse Power |

| K | Bulk Modulus |

| KCl | Potassium Chloride |

| NP | Nanoparticles or Nanoparticle |

| NP-3PS | Nanoparticle-enhanced pulsed power plasma stimulation |

| PAED | Pulsed Arc Electrohydraulic Discharge |

| PCED | Pulsed Corona Electrohydraulic Discharge |

| RF | Reference |

| Vp | Compressional Wave Velocity |

| Vs | Shear Wave Velocity |

| ν | Poisson’s Ratio |

| wt% | Weight Percent |

References

- Maugeri, L. Squeezing more oil from the ground. Sci. Am. 2009, 301, 56–63. Available online: https://www.jstor.org/stable/26001556 (accessed on 13 September 2025). [CrossRef] [PubMed]

- Boak, J.; Kleinberg, R. Shale Gas, Tight Oil, Shale Oil and Hydraulic Fracturing. In Future Energy: Improved, Sustainable and Clean Options for Our Planet, 3rd ed.; Letcher, T.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 67–95. [Google Scholar] [CrossRef]

- Moska, R.; Labus, K.; Kasza, P. Hydraulic fracturing in enhanced geothermal systems—Field, tectonic and rock mechanics conditions—A review. Energies 2021, 14, 5725. [Google Scholar] [CrossRef]

- Xie, Z.; Han, D.; Li, J.; Li, K. A State-of-the-Art Review of Hydraulic Fracturing in Geothermal Systems. Sustainability 2024, 16, 11087. [Google Scholar] [CrossRef]

- England, K.; Li, P.; Xing, P.; Moore, J.; McLennan, J. 2024 Enhanced Geothermal System Hydraulic Fracturing Campaign at Utah FORGE. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2025. [Google Scholar] [CrossRef]

- Li, H.; Liu, B.; He, Q.; Gao, Y.; Ma, D.; Yang, H.; Cheng, J.; Ye, J.; Liu, G. Improving Hard Rock Materials Cuttability by Hydraulic Fracturing at Mining Working Face. Appl. Sci. 2024, 14, 11908. [Google Scholar] [CrossRef]

- USGS. Water Use in Hydraulic Fracturing. 2023. Available online: https://www.usgs.gov/ (accessed on 13 September 2025).

- Ellsworth, W.L. Injection-induced earthquakes. Science 2013, 341, 1225942. [Google Scholar] [CrossRef] [PubMed]

- National Research Council. Induced Seismicity Potential in Energy Technologies; National Academies Press: Washington, DC, USA, 2013; Available online: https://nap.nationalacademies.org/catalog/13355/induced-seismicity-potential-in-energy-technologies (accessed on 13 September 2025).

- Verdon, J.P.; Kettlety, T.; Kendall, J.M. Geomechanical Interpretation of Induced Seismicity at the Preston New Road PNR-2 Well, Lancashire, England; Oil and Gas Authority: London, UK, 2020; Available online: https://www.nstauthority.co.uk/media/6967/olgoga-pnr-2final.pdf (accessed on 13 September 2025).

- Baptie, B.; Reay, D. Potential Risks of Induced Seismicity from High Volume Hydraulic Fracturing of Shales in Northern Ireland. 2021. Available online: https://nora.nerc.ac.uk/id/eprint/531954/1/OR21003.pdf (accessed on 13 September 2025).

- Hui, G.; Chen, Z.; Wang, P.; Gu, F.; Kong, X.; Zhang, W. Mitigating risks from hydraulic fracturing-induced seismicity in unconventional reservoirs: Case study. Sci. Rep. 2022, 12, 12537. [Google Scholar] [CrossRef]

- Burnham, A.; Han, J.; Clark, C.E.; Wang, M.; Dunn, J.B.; Palou-Rivera, I. Life-cycle greenhouse gas emissions of shale gas, natural gas, coal, and petroleum. Environ. Sci. Technol. 2012, 46, 619–627. [Google Scholar] [CrossRef]

- Wells, N.J. Analysis of Emissions Profiles of Hydraulic Fracturing Engine Technologies. Master’s Thesis, West Virginia University, Morgantown, WV, USA, 2022. Available online: https://researchrepository.wvu.edu/cgi/viewcontent.cgi?article=12355&context=etd (accessed on 13 September 2025).

- La Borderie, C.; Reess, T.; Chen, W.; Maurel, O.; Rey-Berbeder, F.; De Ferron, A. Electrohydraulic Fracturing of Rocks; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Melton, N.M.; Cross, T.S. Fracturing oil shale with electricity. J. Pet. Technol. 1968, 20, 37–41. [Google Scholar] [CrossRef]

- Touya, G.; Reess, T.; Pecastaing, L.; Gibert, A.; Domens, P. Development of subsonic electrical discharges in water and measurements of the associated pressure waves. J. Phys. D Appl. Phys. 2006, 39, 5236. [Google Scholar] [CrossRef]

- Soliman, M.Y.; Rezaei, A.; Khalaf, M.; Gordon, P.; Cipolla, C. Pulse power plasma stimulation: A technique for waterless fracturing, enhancing the near wellbore permeability, and increasing the EUR of unconventional reservoirs. Gas Sci. Eng. 2024, 122, 205201. [Google Scholar] [CrossRef]

- Maddirala, R.; Shukla, R.; Pramanik, R.; Mishra, D.A.; Sharma, A.; Jain, R.; Kakati, H. Impact of Pulse Plasma-Based Shockwave Technology on Sandstone Porosity and Pore Connectivity Using Ultrasonic Compressional Wave Velocity and Microtomography. Energy Fuels 2024, 38, 20433–20448. [Google Scholar] [CrossRef]

- Xiao, Y.; House, W.; Unal, E.; Soliman, M.Y. Pulsed Power Plasma Stimulation Technique-Experimental Study on Single Pulse Test for Fractures Initiation. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018. [Google Scholar] [CrossRef]

- Chen, W.; Maurel, O.; Reess, T.; De Ferron, A.S.; La Borderie, C.; Pijaudier-Cabot, G.; Rey-Bethbeder, F.; Jacques, A. Experimental study on an alternative oil stimulation technique for tight gas reservoirs based on dynamic shock waves generated by pulsed arc electrohydraulic discharges. J. Pet. Sci. Eng. 2012, 88, 67–74. [Google Scholar] [CrossRef]

- Chen, W.; Maurel, O.; La Borderie, C.; Reess, T.; De Ferron, A.; Matallah, M.; Pijaudier-Cabot, G.; Jacques, A.; Rey-Bethbeder, F. Experimental and numerical study of shock wave propagation in water generated by pulsed arc electrohydraulic discharges. Heat Mass Transf. 2014, 50, 673–684. [Google Scholar] [CrossRef]

- He, J.; Zhang, R.; Zhang, J.; Liu, M.; Izuchukwu, O.N. Experimental evaluation of near wellbore stimulation–using electrical explosion shockwave on tight sand reservoir. Oil Gas Sci. Technol. Rev. d’IFP Energ. Nouv. 2018, 73, 60. [Google Scholar] [CrossRef]

- Han, R.; Zhou, H.; Liu, Q.; Wu, J.; Jing, Y.; Chao, Y.; Zhang, Y.; Qiu, A. Generation of electrohydraulic shock waves by plasma-ignited energetic materials: I. Fundamental mechanisms and processes. IEEE Trans. Plasma Sci. 2015, 43, 3999–4008. [Google Scholar] [CrossRef]

- Xiao, Y. Pulsed Power Plasma Stimulation-Experimental and Numerical Study on Single-Pulse Test. Ph.D. Thesis, Texas Tech University, Lubbock, TX, USA, May 2017. Available online: https://hdl.handle.net/2346/82042 (accessed on 13 September 2025).

- Nguyen, S.T.; El-Tayeb, M.E.-S.; Adel Gabry, M.; Soliman, M.Y. Pulsed Power Plasma Stimulation: A Comprehensive Review and Field Insights. Energies 2025, 18, 3334. [Google Scholar] [CrossRef]

- Campin, D. An Assessment of the Application of Propellant Enhancement to Conventional Wells. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Virtual, 17–19 November 2020. [Google Scholar] [CrossRef]

- Tester, J.; Anderson, B. Impact of Enhanced Geothermal Systems (EGS) on the United States in the 21st Century. In The Future of Geothermal Energy, Massachusetts Institute of Technology; Idaho National Laboratory: Idaho Falls, ID, USA, 2006; Available online: https://energy.mit.edu/wp-content/uploads/2006/11/MITEI-The-Future-of-Geothermal-Energy.pdf (accessed on 13 September 2025).

- Lei, Z.; Zhang, Y.; Cui, Q.; Shi, Y. The injection-production performance of an enhanced geothermal system considering fracture network complexity and thermo-hydro-mechanical coupling in numerical simulations. Sci. Rep. 2023, 13, 14558. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Liu, X.F.; Wang, D.B.; Zheng, B.; Chen, T.H.; Wang, Q.; Bai, H.; Yao, E.D.; Zhou, F.J. A review of reservoir damage during hydraulic fracturing of deep and ultra-deep reservoirs. Pet. Sci. 2024, 21, 384–409. [Google Scholar] [CrossRef]

- Li, Z.; Zhi, X.; Wu, Z.; Qian, G.; Jiang, R.; Wang, B.; Huang, R.; Yu, X. Role of different energy storage methods in decarbonizing urban distributed energy systems: A case study of thermal and electricity storage. J. Energy Storage 2023, 73, 108931. [Google Scholar] [CrossRef]

- Shao, L.; Zhang, J.; Chen, X.; Xu, D.; Gu, H.; Mu, Q.; Yu, F.; Liu, S.; Shi, X.; Sun, J.; et al. Artificial intelligence-driven distributed acoustic sensing technology and engineering application. PhotoniX 2025, 6, 4. [Google Scholar] [CrossRef]

- Friedlingstein, P.; O’Sullivan, M.; Jones, M.W.; Andrew, R.M.; Hauck, J.; Landschützer, P.; Le Quéré, C.; Li, H.; Luijkx, I.T.; Olsen, A.; et al. Global carbon budget 2024. Earth Syst. Sci. Data 2025, 17, 965–1039. [Google Scholar] [CrossRef]

- Jia, Y.; Tsang, C.F.; Hammar, A.; Niemi, A. Hydraulic stimulation strategies in enhanced geothermal systems (EGS): A review. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 211. [Google Scholar] [CrossRef]

- Zhou, W.; Lanza, F.; Grigoratos, I.; Schultz, R.; Cousse, J.; Trutnevyte, E.; Muntendam-Bos, A.; Wiemer, S. Managing induced seismicity risks from enhanced geothermal systems: A good practice guideline. Rev. Geophys. 2024, 62, e2024RG000849. [Google Scholar] [CrossRef]

- Bazargan, M.; Soliman, M.Y.; Habibpour, M.; Rezaei, A. Plasma Torch Perforation to Route Hydraulic Fracturing Operation in Unconventional Reservoirs. In Proceedings of the 48th US Rock Mechanics/Geomechanics Symposium, Minneapolis, MN, USA, 1–4 June 2014; Available online: https://onepetro.org/ARMAUSRMS/proceedings/ARMA14/ARMA14/ARMA-2014-6991/122411 (accessed on 13 September 2025).

- Soliman, M.Y. Fracturing Treatment of Subterranean Formations Using Shock Waves. U.S. Patent 10,309,202, 4 June 2019. [Google Scholar]

- Rezaei, A.; Siddiqui, F.; Callen, N.; Gordon, P.; House, W.; Soliman, M.Y. Pulsed Power Plasma to Enhance Near Wellbore Permeability and Improve Well Performance. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2020. [Google Scholar] [CrossRef]

- Khalaf, M.; Soliman, M.; Farouq-Ali, S.M.; Cipolla, C.; Dusterhoft, R. Experimental study on pulsed plasma stimulation and matching with simulation work. Appl. Sci. 2024, 14, 4752. [Google Scholar] [CrossRef]

- Ostadhassan, M.; Zeng, Z.; Zamiran, S. Geomechanical Modeling of an Anisotropic Formation-Bakken Case Study. In Proceedings of the 46th U.S. Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, 24–27 June 2012; Available online: https://onepetro.org/ARMAUSRMS/proceedings/ARMA12/ARMA12/ARMA-2012-221/122300 (accessed on 13 September 2025).

- Ma, Z.; Xiu, N.; Fu, H.; Hou, B.; Chen, D.; Hou, C. Study on calculation of transversely isotropic dynamic rock mechanical parameters and conversion model between dynamic parameters and static parameters. Unconv. Resour. 2023, 3, 297–304. [Google Scholar] [CrossRef]

- Feng, Z.; Xiao, X. Thermal conductivity measurement of flexible composite phase-change materials based on the steady-state method. Micromachines 2022, 13, 1582. [Google Scholar] [CrossRef]

- Aboueldahab, A. Investigation of the Effect of Nano-Particles Activated Carbon on Heating Heavy Oil Reservoirs. Master’s Thesis, Texas Tech University, Lubbock, TX, USA, December 2016. Available online: https://ttu-ir.tdl.org/items/44f9e7e8-ea49-4603-843b-673dbbf8e254 (accessed on 13 September 2025).

- Gdanski, R. High-pH Clay Instability Rating. In Proceedings of the International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 20–21 February 2002. [Google Scholar] [CrossRef]

- Abrams, M.E.; Grieser, B.; Benoit, D.N. Everything You Wanted to Know About Clay Damage but Were Afraid to Ask. In Proceedings of the 2016 AADE Fluids Technical Conference and Exhibition, Houston, TX, USA, 12–13 April 2016; Available online: https://www.aade.org/application/files/7815/7131/8490/AADE-16-FTCE-35_-_Abrams.pdf (accessed on 13 September 2025).

- Barati, R.; Liang, J.T. A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J. Appl. Polym. Sci. 2014, 131, 40735. [Google Scholar] [CrossRef]

- Moore, J.; Simmons, S.; McLennan, J.; Jones, C.; Skowron, G.; Wannamaker, P.; Nash, G.; Hardwick, C.; Hurlbut, W.; Allis, R.; et al. Utah FORGE: Phase 2C Topical Report; Geothermal Data Repository; Energy and Geoscience Institute at the University of Utah: Salt Lake City, UT, USA, 11 December 2019; No. EE0007080. [Google Scholar] [CrossRef]

- Moore, J.; Wannamaker, P.; McLennen, J.; Pankow, K.; Skowron, G.; Nash, G.; Jones, C.; Barker, B.; Podgorney, R.; Simmons, S. Utah FORGE: 2023 Phase 3B Year 1 Annual Report; Geothermal Data Repository; Energy and Geoscience Institute at the University of Utah: Salt Lake City, UT, USA, 9 August 2023; No. EE0007080; Available online: https://gdr.openei.org/submissions/1523. (accessed on 13 September 2025).

- Smith, M.C.; Ponder, G.M. Hot-Dry-Rock Geothermal-Energy Development Program; Annual Report, Fiscal Year 1981; Los Alamos National Laboratory: Los Alamos, NM, USA, 1982. [Google Scholar] [CrossRef][Green Version]

- Tenzer, H. Development of hot dry rock technology. Geo-Heat Cent. Q. Bull. 2001, 22, 14–22. Available online: https://pangea.stanford.edu/ERE/pdf/IGAstandard/ISS/2003Germany/III/2_1.ten.pdf (accessed on 13 September 2025).

- Gürtürk, M. Predicting the optimal timing for system upgrades in binary geothermal power Plants: A thermodynamic and exergetic approach. Energy Convers. Manag. 2025, 343, 120225. [Google Scholar] [CrossRef]

- Zarrouk, S.J.; Moon, H. Efficiency of geothermal power plants: A worldwide review. Geothermics 2014, 51, 142–153. [Google Scholar] [CrossRef]

| Sample | Pre-NP-3PS | Pre-NP-3PS | Post-NP-3PS | Post-NP-3PS | Unit |

|---|---|---|---|---|---|

| Vertical Core | Horizontal Core | Vertical Core | Horizontal Core | ||

| Length | 5.11 × 10−2 | 5.11 × 10−2 | 5.92 × 10−2 | 5.29 × 10−2 | m |

| Diameter | 2.51 × 10−2 | 2.51 × 10−2 | 2.51 × 10−2 | 2.52 × 10−2 | m |

| Volume | 2.53 × 10−5 | 2.53 × 10−5 | 2.92 × 10−5 | 2.64 × 10−5 | m3 |

| Weight | 6.64 × 10−2 | 6.64 × 10−2 | 7.56 × 10−2 | 6.85 × 10−2 | kg |

| Density | 2625.5 | 2625.5 | 2589.7 | 2591.8 | kg/m3 |

| Δt P-wave | 1.16 × 10−5 | 1.15 × 10−5 | 1.53 × 10−5 | 1.24 × 10−5 | s |

| Δt S-wave | 1.92 × 10−5 | 1.92 × 10−5 | 2.38 × 10−5 | 2.10 × 10−5 | s |

| Vp | 4.39 × 103 | 4.44 × 103 | 3.86 × 103 | 4.28 × 103 | m/s |

| Vs | 2.67 × 103 | 2.67 × 103 | 2.49 × 103 | 2.52 × 103 | m/s |

| ν | 0.21 | 0.22 | 0.14 | 0.24 | unitless |

| K | 2.58 × 1010 | 2.68 × 1010 | 2.05 × 1010 | 2.45 × 1010 | Pa |

| G | 1.87 × 1010 | 1.86 × 1010 | 1.60 × 1010 | 1.64 × 1010 | Pa |

| E | 4.51 × 1010 | 4.57 × 1010 | 3.67 × 1010 | 4.06 × 1010 | Pa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, S.T.; Y. Soliman, M.; Adel Gabry, M.; El-Tayeb, M.E.-S.; Myers, M.; Chen, Y.; Unomah, G.; Hathon, L. Inducing Interconnected Fractures in Granite via Pulsed Power Plasma Using Nanoparticles: A Waterless Stimulation Approach for Enhanced Geothermal Systems. Processes 2025, 13, 3721. https://doi.org/10.3390/pr13113721

Nguyen ST, Y. Soliman M, Adel Gabry M, El-Tayeb ME-S, Myers M, Chen Y, Unomah G, Hathon L. Inducing Interconnected Fractures in Granite via Pulsed Power Plasma Using Nanoparticles: A Waterless Stimulation Approach for Enhanced Geothermal Systems. Processes. 2025; 13(11):3721. https://doi.org/10.3390/pr13113721

Chicago/Turabian StyleNguyen, Son T., Mohamed Y. Soliman, Mohamed Adel Gabry, Mohamed E.-S. El-Tayeb, Michael Myers, Yanming Chen, Gabriel Unomah, and Lori Hathon. 2025. "Inducing Interconnected Fractures in Granite via Pulsed Power Plasma Using Nanoparticles: A Waterless Stimulation Approach for Enhanced Geothermal Systems" Processes 13, no. 11: 3721. https://doi.org/10.3390/pr13113721

APA StyleNguyen, S. T., Y. Soliman, M., Adel Gabry, M., El-Tayeb, M. E.-S., Myers, M., Chen, Y., Unomah, G., & Hathon, L. (2025). Inducing Interconnected Fractures in Granite via Pulsed Power Plasma Using Nanoparticles: A Waterless Stimulation Approach for Enhanced Geothermal Systems. Processes, 13(11), 3721. https://doi.org/10.3390/pr13113721