An Experimental Study on the Influence of CO2 Real-Time Contact on the Mechanical Properties of Shale

Abstract

1. Introduction

2. Experimental Methodology

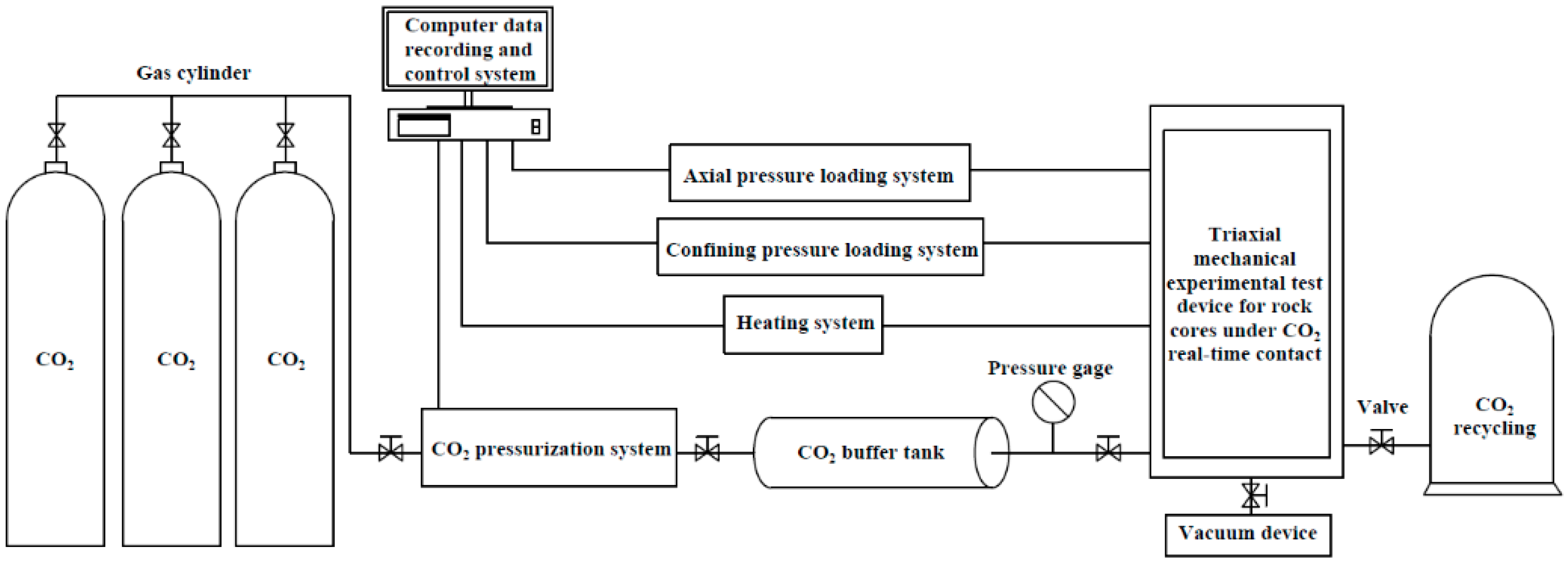

2.1. Experimental Apparatus

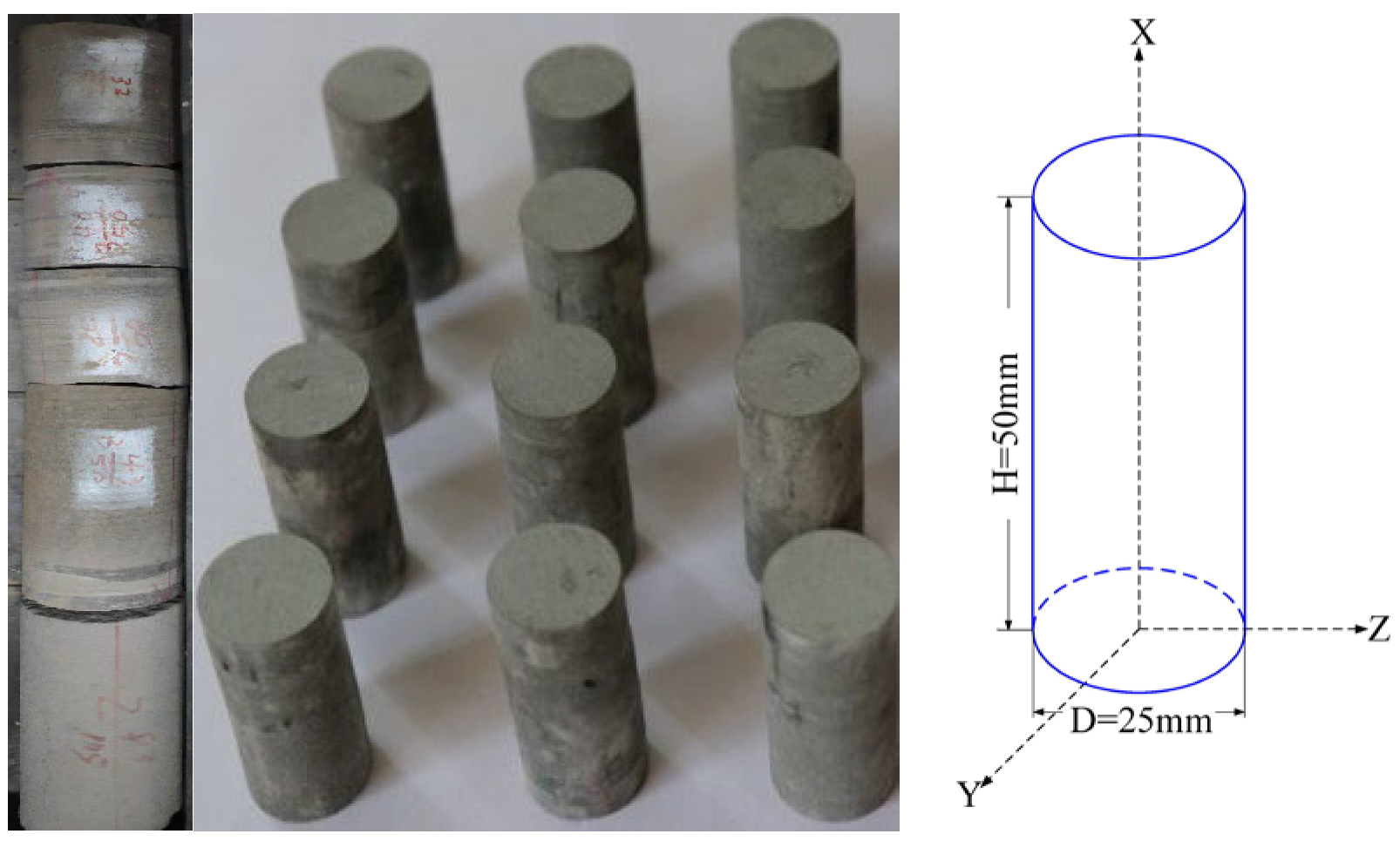

2.2. Sample Preparation

2.3. Experimental Procedure

2.3.1. Basic Process

2.3.2. Experimental Program

2.3.3. Calculation of the Rock Mechanical Parameters

3. Results and Discussion

3.1. Rock Mechanics Parameter Results

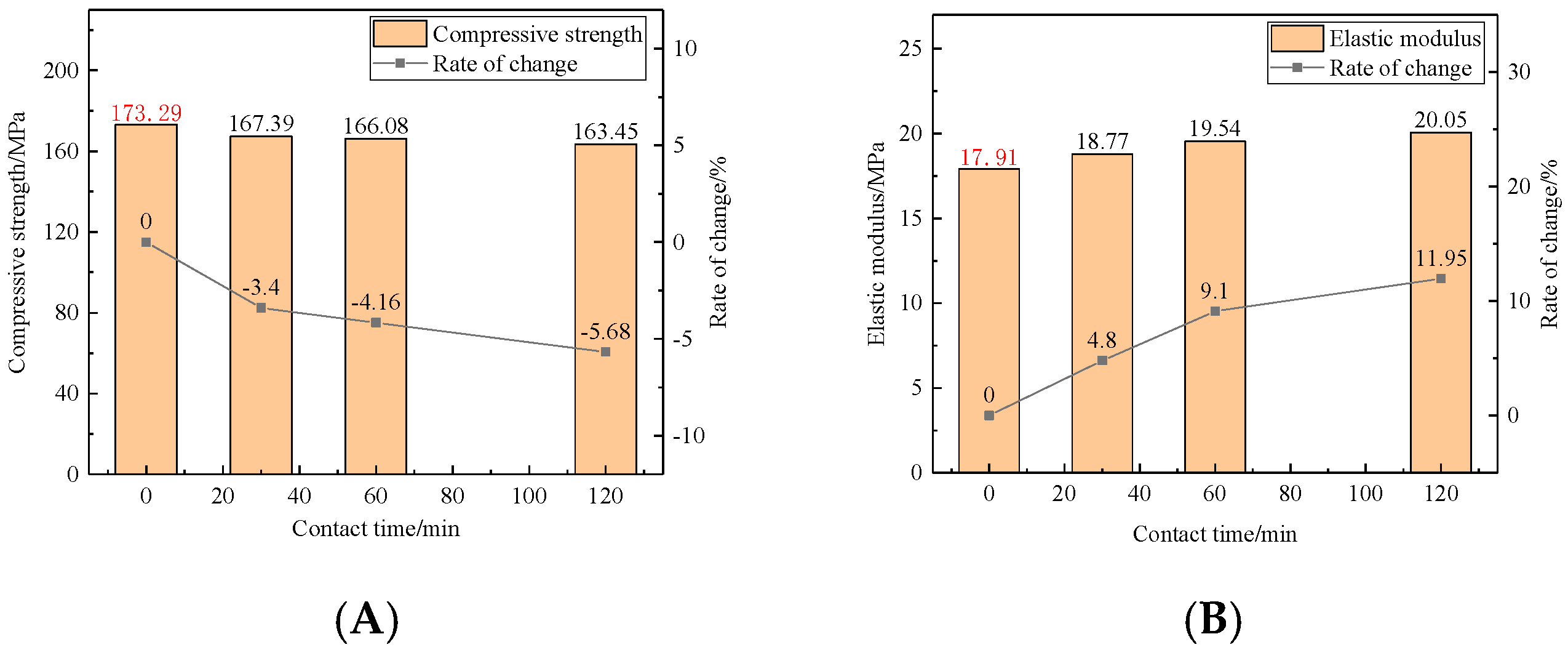

3.1.1. Effect of CO2 Real-Time Contact Time

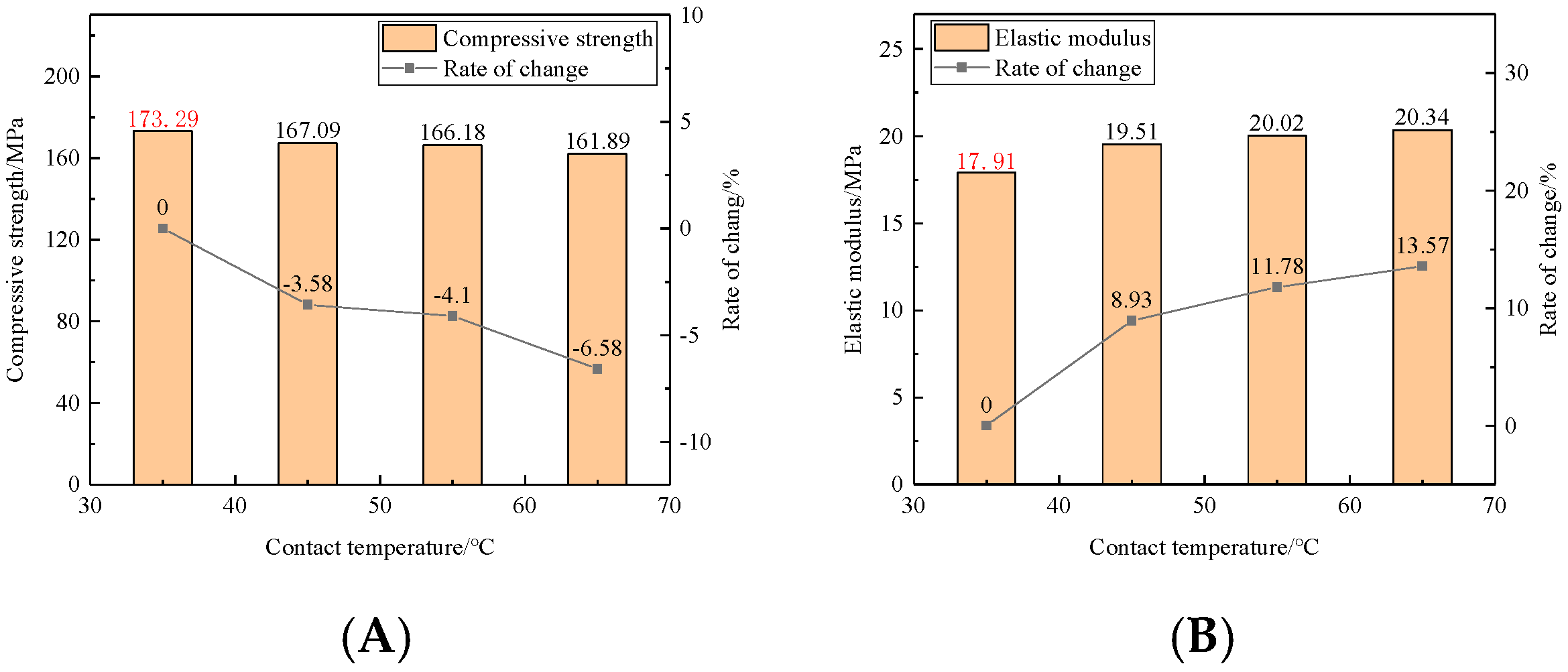

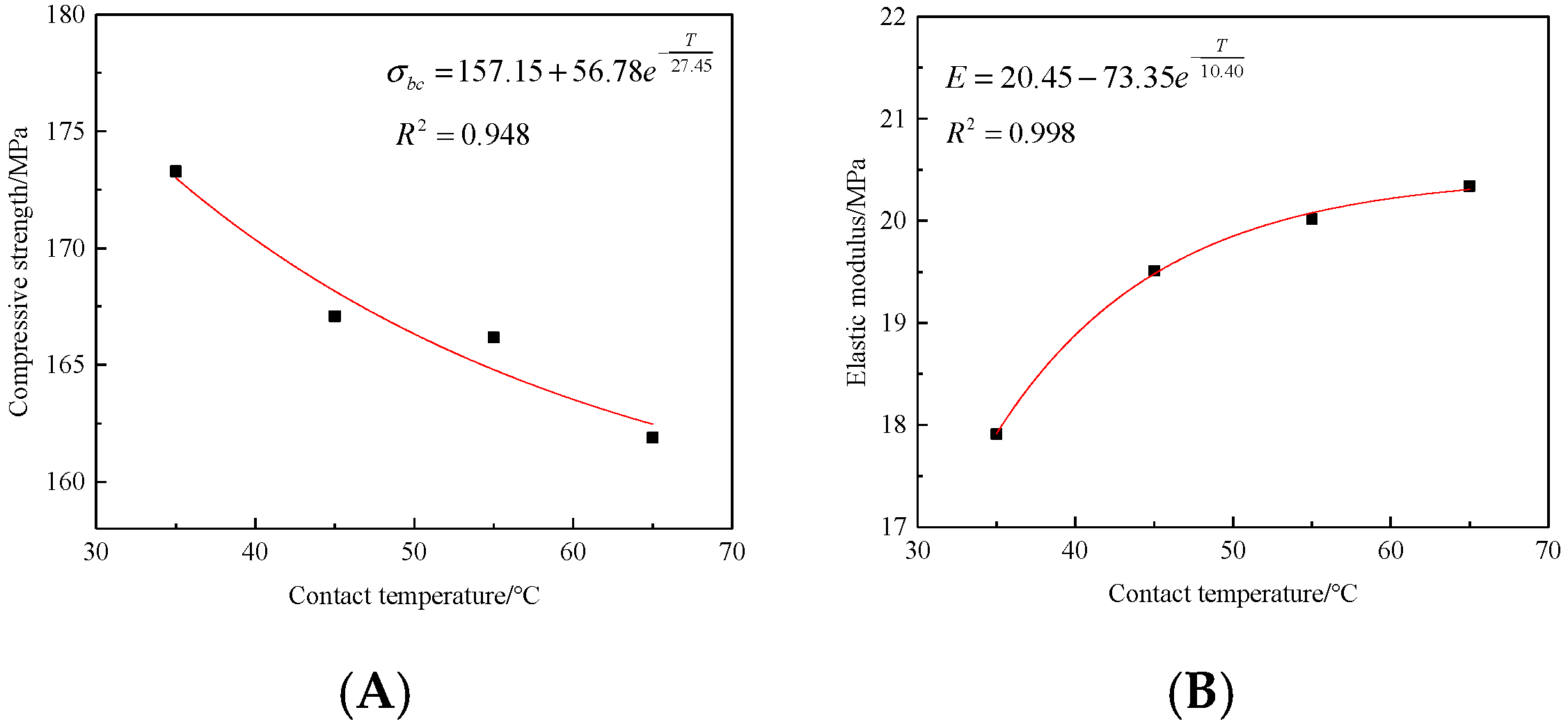

3.1.2. Effect of CO2 Real-Time Contact Temperature

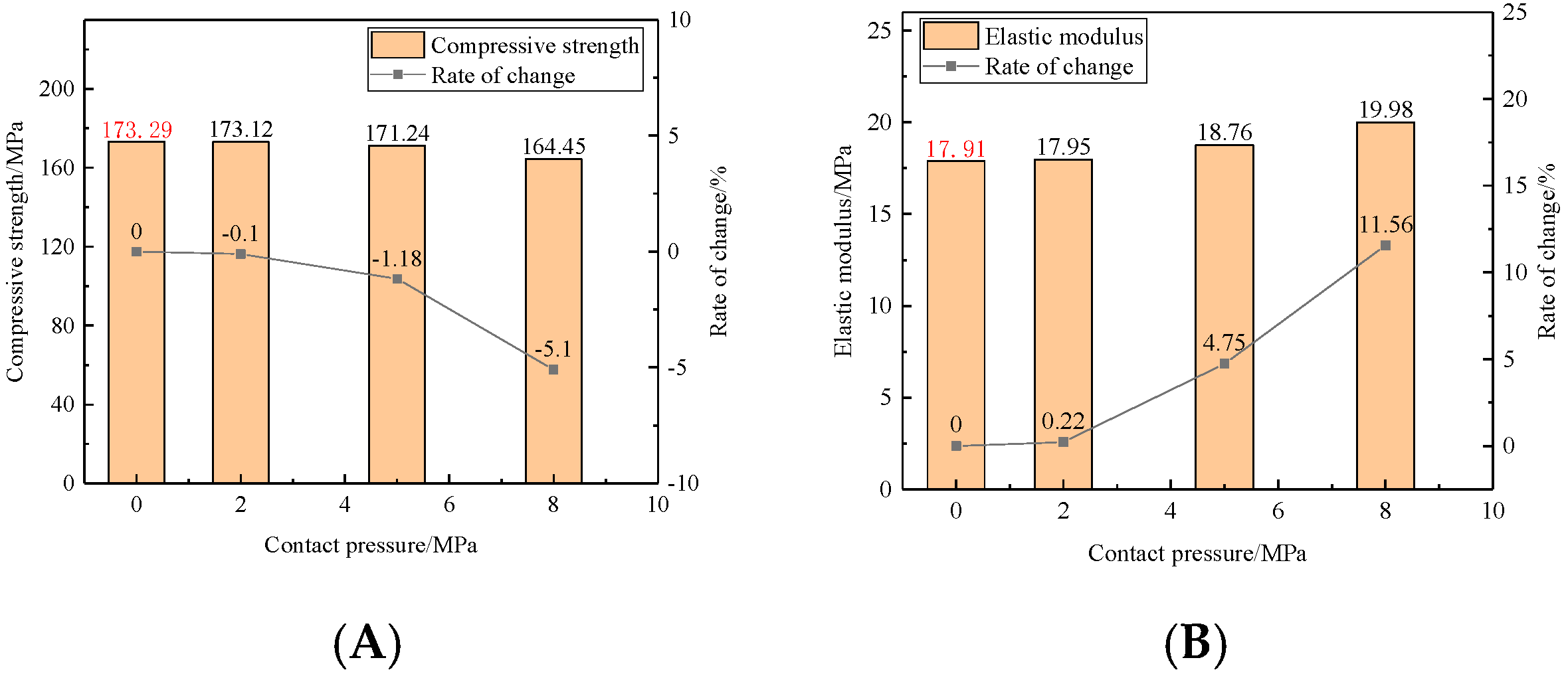

3.1.3. Effect of CO2 Real-Time Contact Pressure

3.1.4. Discussion

3.2. Rock Mechanics Parameter Fitting

3.2.1. Effect of CO2 Real-Time Contact Time

3.2.2. Effect of CO2 Real-Time Contact Temperature

3.2.3. Effect of CO2 Real-Time Contact Pressure

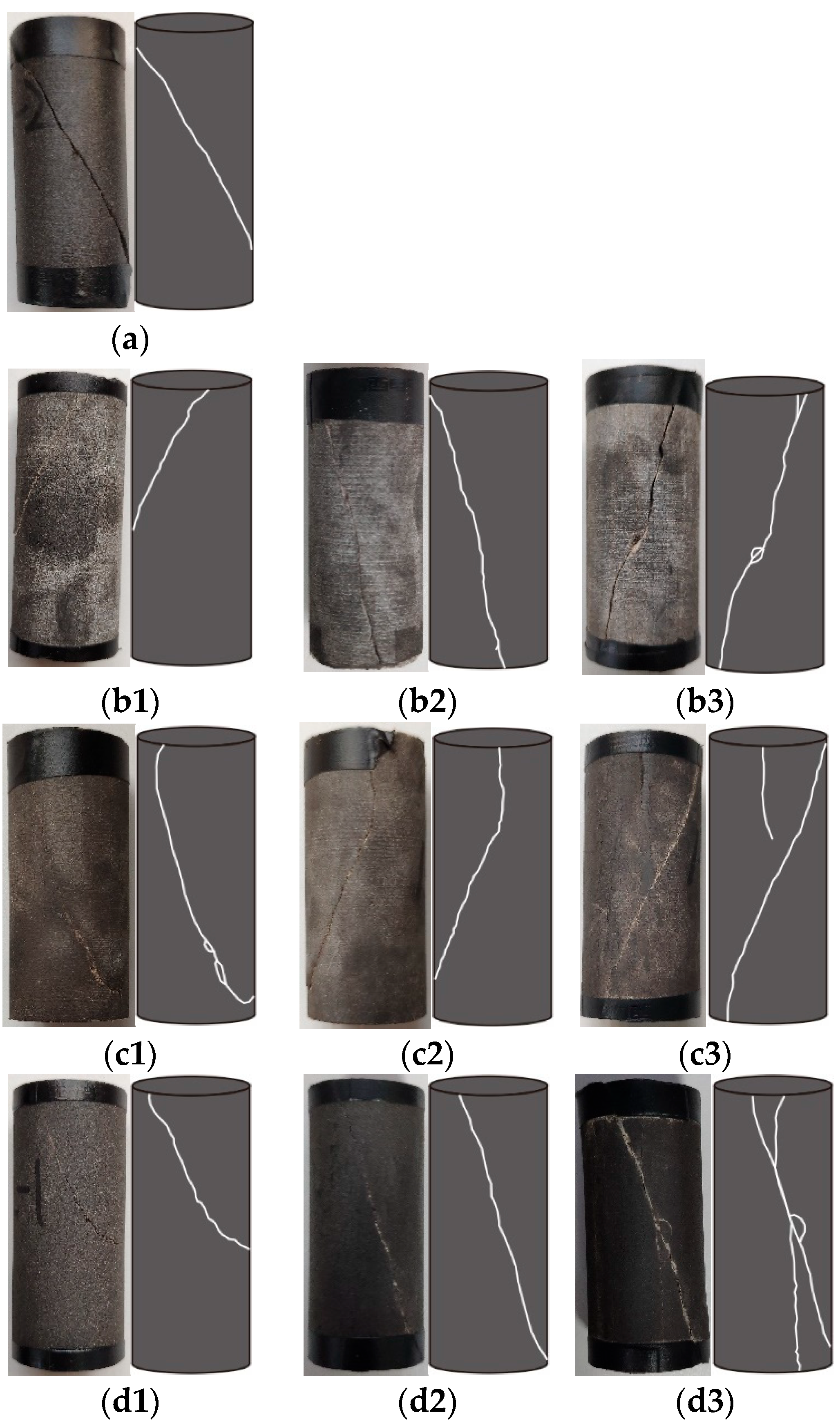

3.3. Rock Damage Form Results

3.3.1. Comparison of Failure Mode

3.3.2. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chang, Y.; Huang, R.; Ries, R.J.; Masanet, E. Life-cycle comparison of greenhouse gas emissions and water consumption for coal and shale gas fired power generation in China. Energy 2015, 86, 335–343. [Google Scholar] [CrossRef]

- Jin, Z.; Bai, Z.; Gao, B.; Ming, L. Has China ushered in the shale oil and gas revolution? Oil Gas Geol. 2019, 40, 451–458. [Google Scholar] [CrossRef]

- Pan, Y.; Hui, D.; Luo, P.; Zhang, Y.; Sun, L.; Wang, K. Experimental investigation of the geochemical interactions between supercritical CO2 and shale: Implications for CO2 storage in gas-bearing shale formations. Energy Fuels 2018, 32, 1963–1978. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Weingarten, M.; Ge, S. Induced seismicity: The potential hazard from shale gas development and CO2 geologic storage. Geosci. J. 2016, 20, 137–148. [Google Scholar] [CrossRef]

- Zhou, J.; Hu, N.; Xian, X.; Zhou, L.; Tang, J.; Kang, Y.; Wang, H. Supercritical CO2 fracking for enhanced shale gas recovery and CO2 sequestration: Results, status and future challenges. Adv. Geo-Energy Res. 2019, 3, 207–224. [Google Scholar] [CrossRef]

- Scanlon, B.R.; Reedy, R.C.; Nicot, J.P. Comparison of water use for hydraulic fracturing for unconventional oil and gas versus conventional oil. Environ. Sci. Technol. 2014, 48, 12386–12393. [Google Scholar] [CrossRef] [PubMed]

- Zou, C.; Zhu, R.; Wu, S.; Yang, Z.; Tao, S.; Yuan, X. Types, characteristics, genesis and prospects of conventional and unconventional hydrocarbon accumulations: Taking tight oil and tight gas in china as an instance. Shiyou Xuebao/Acta Pet. Sin. 2012, 33, 173–187. [Google Scholar] [CrossRef]

- Wang, J.; Wang, K.; Shan, X.; Taylor, K.G.; Ma, L. Potential for CO2 storage in shale basins in China. Int. J. Greenh. Gas Control 2024, 132, l04060. [Google Scholar] [CrossRef]

- Zhang, J.; Guan, Y.; Li, T.; Yin, G. Solubility Variation and Prediction Model of CO2 in Water-Bearing Crude Oil. ACS Omega 2022, 7, 44420–44427. [Google Scholar] [CrossRef]

- Hu, Y. Mechanism and Experimental Research of Supercritical Carbon Dioxide Fracturing Shale. Ph.D. Thesis, Wuhan University, Wuhan, China, 2019. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CDFD&dbname=CDFD&filename=1018033279.nh (accessed on 10 September 2024).

- Karacan, C.Z. Heterogeneous sorption and swelling in a confined and stressed coal during CO2 injection. Energy Fuels 2003, 17, 1595–1608. [Google Scholar] [CrossRef]

- Nikita, G.; Amit, V. Supercritical Carbon Dioxide Utilization for Hydraulic Fracturing of Shale Reservoir, and Geo-Storage: A Review. Energy Fuels 2023, 37, 14604–14621. [Google Scholar] [CrossRef]

- Zhou, J.; Xie, S.; Jiang, Y.; Xian, X.; Liu, Q.; Lu, Z.; Lyu, Q. Influence of supercritical CO2 exposure on CH4 and CO2 adsorption behaviors of shale: Implications for CO2 sequestration. Energy Fuels 2018, 32, 6073–6089. [Google Scholar] [CrossRef]

- Zhao, X.; Xiao, J.; Hou, J.; Wu, J.; Lyu, X.; Zhang, J.; Liu, Y. Economic and scale prediction of CO2 capture, utilization and storage technologies in China. Pet. Explor. Dev. 2023, 50, 657–668. [Google Scholar] [CrossRef]

- Liu, S.Q.; Huang, F.; Du, R.; Chen, S.; Guan, Y.; Liu, H.; Wang, T. Progress and typical case analysis of demonstration projects of the geological sequestration and utilization of CO2. Coal Geol. Explor. 2023, 51, 158–174. [Google Scholar] [CrossRef]

- Wang, W.; Tang, R.; Jiang, S.; Wang, H.; Yang, H.; Wang, W. The engineering practice of CO2 capture, utilization and storage (CCUS) in coal chemical industry of Yanchang Petroleum. Unconventional Oil Gas 2021, 8, 1–7. [Google Scholar] [CrossRef]

- Wang, F.; Kobina, F. The Influence of Geological Factors and Transmission Fluids on the Exploitation of Reservoir Geothermal Resources: Factor Discussion and Mechanism Analysis. Reserv. Sci. 2025, 1, 3–18. [Google Scholar] [CrossRef]

- Wu, J.; Ansari, U. From CO2 Sequestration to Hydrogen Storage: Further Utilization of Depleted Gas Reservoirs. Reserv. Sci. 2025, 1, 19–35. [Google Scholar] [CrossRef]

- Yin, H. Experimental Study on the Interaction Mechanism Between Supercritical CO2 and Shale. Doctoral Dissertation, Chongqing University, Chongqing, China, 2018. Available online: https://d.wanfangdata.com.cn/thesis/ChJUaGVzaXNOZXdTMjAyMDEwMjgSCUQwMTQ5NTg2MxoIeTI2cW1kaTE%3D. (accessed on 18 April 2025).

- Yin, H.; Zhou, J.; Jiang, Y.; Xian, X.; Liu, Q. Physical and structural changes in shale associated with supercritical CO2 exposure. Fuel 2016, 184, 289–303. [Google Scholar] [CrossRef]

- Yin, H.; Zhou, J.; Xian, X.; Jiang, Y.; Lu, Z.; Tan, J.; Liu, G. Experimental study of the effects of sub- and super-critical CO2 saturation on the mechanical characteristics of organic-rich shales. Energy 2017, 132, 84–95. [Google Scholar] [CrossRef]

- Bai, B.; Ni, H.-J.; Shi, X.; Guo, X.; Ding, L. The experimental investigation of effect of supercritical CO2 immersion on mechanical properties and pore structure of shale. Energy 2021, 228, 120663. [Google Scholar] [CrossRef]

- Ding, L.; Ni, H.; Li, M.; Li, W.; Song, W.; Guo, X. Wellbore collapse pressure analysis under supercritical carbon dioxide drilling condition. J. Pet. Sci. Eng. 2018, 161, 458–467. [Google Scholar] [CrossRef]

- Guo, X.; Ni, H.; Li, M.; Zhang, L.; Wang, Y.; Ding, L. Experimental Study on the Influence of Supercritical Carbon Dioxide Soaking Pressure on the Mechanical Properties of Shale. Indian Geotech. J. 2018, 48, 384–391. [Google Scholar] [CrossRef]

- Ni, H.; Guo, X.; Ding, L.; Bai, B.; Sun, X.; Yang, Q. Experiment on mechanical properties of shale soaked with supercritical carbon dioxide. J. China Univ. Pet. (Ed. Nat. Sci.) 2019, 43, 77–84. [Google Scholar] [CrossRef]

- Shaanxi Yanchang Petroleum (Group) Company Limited. A Triaxial Mechanical Experimental Testing Device for Rock Cores Under CO2 Real-Time Contact. CN217717315U, 1 November 2022. Available online: https://kns.cnki.net/kcms2/article/abstract?v=kuqSYziLCIHjKI6KRHymh1o4B3FH6IJ_WZ2vid9RRhCBUfSbOC-EfVpGJYy8pYJ8btHD51VK0hlKjYi2CQ_mX_KlpLeTxLAU5CNdZ3nafM989vtIfhozEV_rkNKsSmdbEx62fPW1d_o=&uniplatform=NZKPT&language=CHS (accessed on 1 June 2025).

- Ao, X.; Lu, Y.; Tang, J.; Chen, Y.; Li, H. Investigation on the physics structure and chemical properties of the shale treated by supercritical CO2. J. CO2 Util. 2017, 20, 274–281. [Google Scholar] [CrossRef]

- Ao, X.; Lu, Y.; Tang, J.; Huang, F.; Liao, Y.; Jia, Y. Deformation properties of shale by sorbing carbon dioxide. J. China Coal Soc. 2015, 40, 2893–2899. [Google Scholar] [CrossRef]

- Jiang, Y.; Luo, Y.; Lu, Y.; Qin, C.; Liu, H. Effects of supercritical CO2 treatment time, pressure, and temperature on microstructure of shale. Energy 2016, 97, 173–181. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, G.; Jiang, Y.; Xian, X.; Liu, Q.; Zhang, D.; Tan, J. Supercritical carbon dioxide fracturing in shale and the coupled effects on the permeability of fractured shale: An experimental study. J. Nat. Gas Sci. Eng. 2016, 36, 369–377. [Google Scholar] [CrossRef]

- Diao, H. Rock mechanical properties and brittleness evaluation of shale reservoir. Acta Petrol. Sin. 2013, 29, 3300–3306. [Google Scholar]

- Lu, Y.; Ao, X.; Tang, J.; Jia, Y.; Zhang, X.; Chen, Y. Swelling of shale in supercritical carbon dioxide. J. Nat. Gas Sci. Eng. 2016, 30, 268–275. [Google Scholar] [CrossRef]

- Qi, R.; Ning, Z.; Wang, Q.; Huang, L.; Wu, X.; Cheng, Z.; Zhang, W. Measurements and modeling of high-pressure adsorption of CH4 and CO2 on shales. Fuel 2019, 242, 728–743. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, J.; Sun, X.; Tian, S.; Tang, J.; Shen, F.; Wu, J. The influences of composition and pore structure on the adsorption behavior of CH4 and CO2 on shale. Front. Earth Sci. 2021, 15, 283–300. [Google Scholar] [CrossRef]

- Lu, Y.; Chen, X.; Tang, J.; Li, H.; Zhou, L.; Han, S.; Ge, Z.; Xia, B.; Shen, H.; Zhang, J. Relationship between pore structure and mechanical properties of shale on supercritical carbon dioxide saturation. Energy 2019, 172, 270–285. [Google Scholar] [CrossRef]

- Tang, B.; Tang, J.; Lu, Y.; Shen, H.; Lu, Z.; Chen, X.; Tian, R.; Zhu, Z. Chemical structure changes of marine shale caused by supercritical carbon dioxide. Energy Explor. Exploit. 2021, 39, 243–255. [Google Scholar] [CrossRef]

- Du, X.; Gu, M.; Hou, Z.; Liu, Z.; Wu, T. Experimental study on kinetics of adsorption of CO2 and CH4 in gas-bearing shale reservoirs. Energy Fuels 2019, 33, 12587–12600. [Google Scholar] [CrossRef]

- Addassi, M.; Hoteit, H.; Oelkers Eric, H. The impact of secondary silicate mineral precipitation kinetics on CO2 mineral storage. Int. J. Greenh. Gas Control 2024, 131, 1104020. [Google Scholar] [CrossRef]

- Zhou, J.; Tian, S.; Zhou, L.; Xian, X.; Zhang, C.; Yang, K.; Dong, Z.; Lu, Z. Effect of sub-/super-critical CO2 and brine exposure on the mechanical and acoustic emission characteristics of shale. J. Nat. Gas Sci. Eng. 2021, 90, 103921. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, K.; Tian, S.; Zhou, L.; Xian, X.; Jiang, Y.; Liu, M.; Cai, J. CO2-water-shale interaction induced shale microstructural alteration. Fuel 2019, 263, 116642. [Google Scholar] [CrossRef]

- Jia, C.; Chen, J.; Guo, Y.; Yang, C.; Xu, J.; Wang, L. Research on mechanical behaviors and failure modes of layer shale. Rock Soil Mech. 2013, 34 (Suppl. S2), 57–61. [Google Scholar] [CrossRef]

- Fatah, A.; Mahmud, H.K.B.; Bennour, Z.; Hossain, M.M.; Gholami, R. Effect of supercritical CO2 treatment on physical properties and functional groups of shales. Fuel 2021, 303, 121310. [Google Scholar] [CrossRef]

- Feng, G.; Kang, Y.; Sun, Z.-D.; Wang, X.-C.; Hu, Y.-Q. Effects of supercritical CO2 adsorption on the mechanical characteristics and failure mechanisms of shale. Energy 2019, 173, 870–882. [Google Scholar] [CrossRef]

| Number | Time (min) | Temperature (°C) | Pressure (MPa) | CO2 Phase |

|---|---|---|---|---|

| a | 0 | 35 | 0 | / |

| b1 | 30 | 35 | 7.5 | supercritical |

| b2 | 60 | 35 | 7.5 | supercritical |

| b3 | 120 | 35 | 7.5 | supercritical |

| c1 | 60 | 45 | 7.5 | supercritical |

| c2 | 60 | 55 | 7.5 | supercritical |

| c3 | 60 | 65 | 7.5 | supercritical |

| d1 | 60 | 35 | 2 | vapor |

| d2 | 60 | 35 | 5 | vapor |

| d3 | 60 | 35 | 8 | supercritical |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Sun, X.; Tang, J.-R.; Shen, F.; Ge, Z.-L.; Xiao, C.-Y.; Cheng, Q.; Mu, J.-F.; Tian, K.; Luo, P. An Experimental Study on the Influence of CO2 Real-Time Contact on the Mechanical Properties of Shale. Processes 2025, 13, 3664. https://doi.org/10.3390/pr13113664

Guo X, Sun X, Tang J-R, Shen F, Ge Z-L, Xiao C-Y, Cheng Q, Mu J-F, Tian K, Luo P. An Experimental Study on the Influence of CO2 Real-Time Contact on the Mechanical Properties of Shale. Processes. 2025; 13(11):3664. https://doi.org/10.3390/pr13113664

Chicago/Turabian StyleGuo, Xing, Xiao Sun, Ji-Ren Tang, Feng Shen, Zhao-Long Ge, Cai-Yun Xiao, Qi Cheng, Jing-Fu Mu, Kun Tian, and Pan Luo. 2025. "An Experimental Study on the Influence of CO2 Real-Time Contact on the Mechanical Properties of Shale" Processes 13, no. 11: 3664. https://doi.org/10.3390/pr13113664

APA StyleGuo, X., Sun, X., Tang, J.-R., Shen, F., Ge, Z.-L., Xiao, C.-Y., Cheng, Q., Mu, J.-F., Tian, K., & Luo, P. (2025). An Experimental Study on the Influence of CO2 Real-Time Contact on the Mechanical Properties of Shale. Processes, 13(11), 3664. https://doi.org/10.3390/pr13113664