Comprehensive Investigation for CO2 Flooding Methodology in a Reservoir with High Water Content

Abstract

1. Introduction

2. Adaptability Analysis of CO2 Flooding Based on the Fuzzy Hierarchical Comprehensive Evaluation Method

3. Laboratory-Scale Core Experiment Research

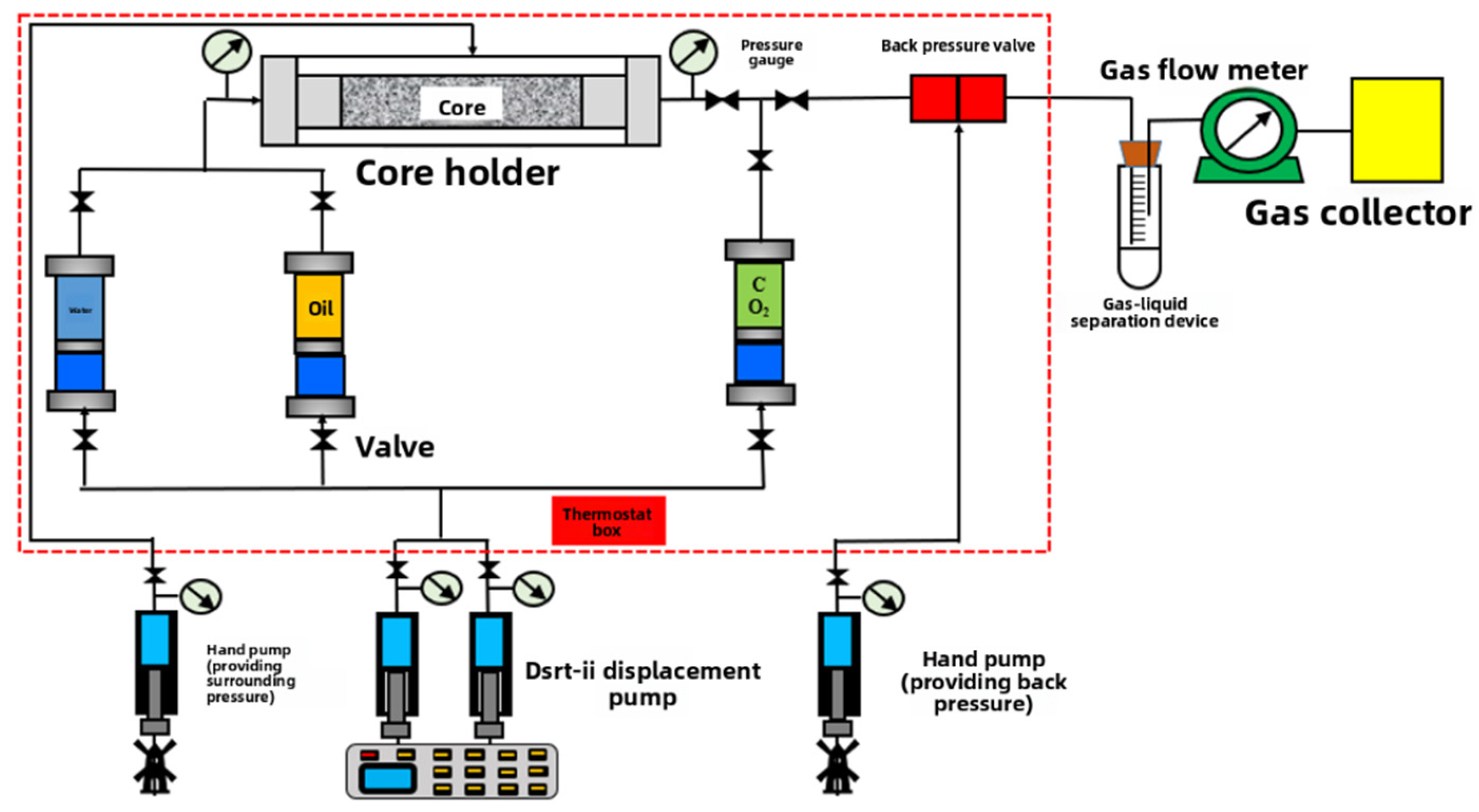

3.1. Experimental Equipment and Methods

- (1)

- Cores: All cores are natural cores collected from the oilfield. They all have a diameter of 2.5 cm and length of about 5–6 cm.

- (2)

- Gas: CO2, with a purity of 99.99%.

- (3)

- Formation water: Water-type CaCl2; the total salinity is 23,546 mg/L. The crude oil viscosity at 90 °C is 4.18 mPa·s.

- (4)

- Surfactants: 0.1% Sodium dodecylbenzenesulfonate (SDBS) at mass concentration, 0.1% Tween 80, and a mixture of the two (SDBS to Tween 80 is 2.5:1).

- (5)

- Fracturing fluid: Collected from the oilfield.

3.2. Experimental Procedures

3.2.1. Experimental Procedure for Core Flooding

3.2.2. Experimental Procedure for Huff-n-Puff

3.3. Experimental Results and Analysis

3.3.1. Comparison Between Different Displacement Media and Influencing Factors

- (1)

- Comparison between Different Displacement Media

- (2)

- Factors Affecting CO2 Flooding

3.3.2. Comparison Between Different Huff-n-Puff Media and Influencing Factors

- (1)

- Comparison between Different Huff-n-Puff Media

- (2)

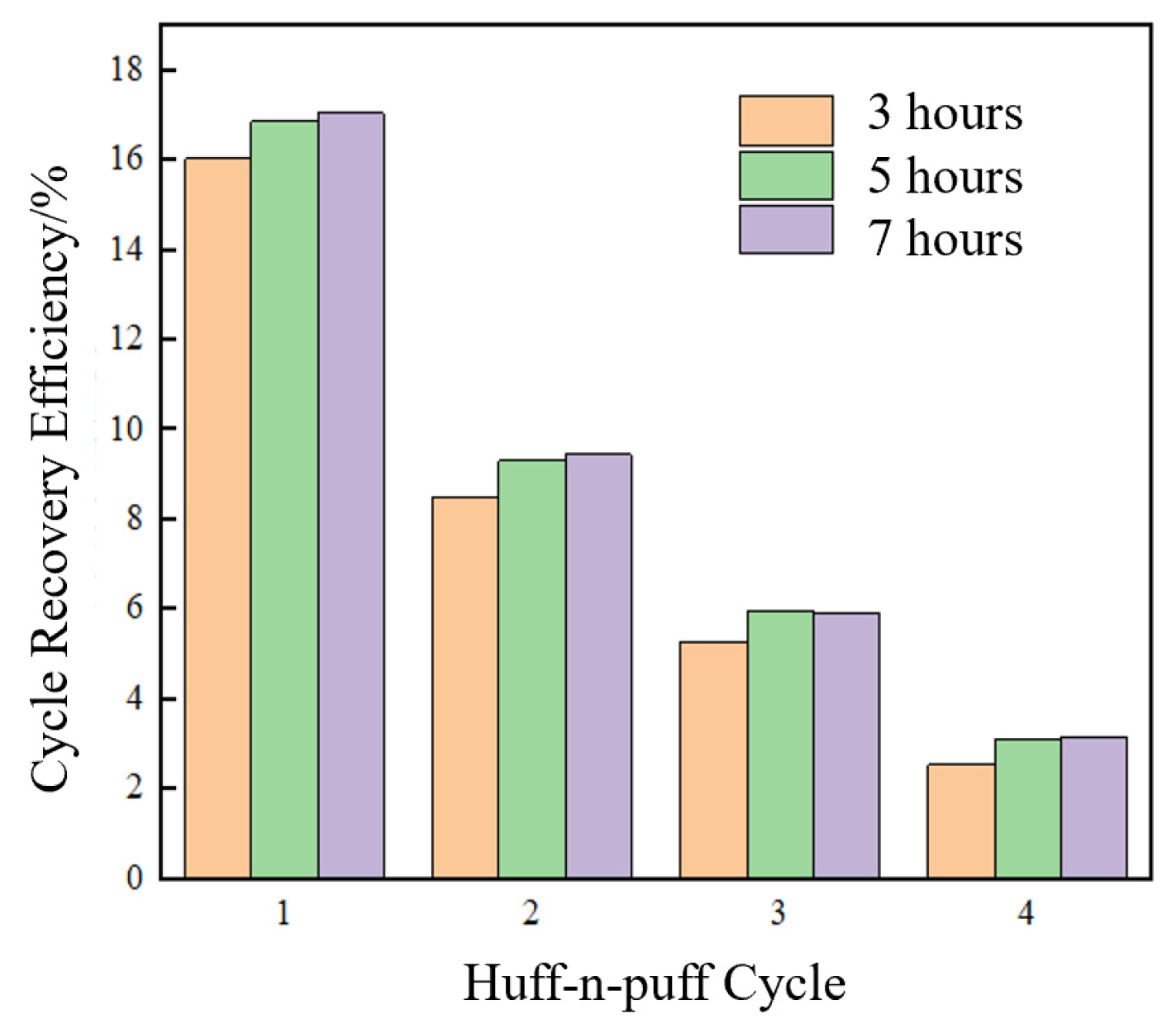

- Factors Affecting CO2 Flooding

4. Reservoir Numerical Simulation and Analysis

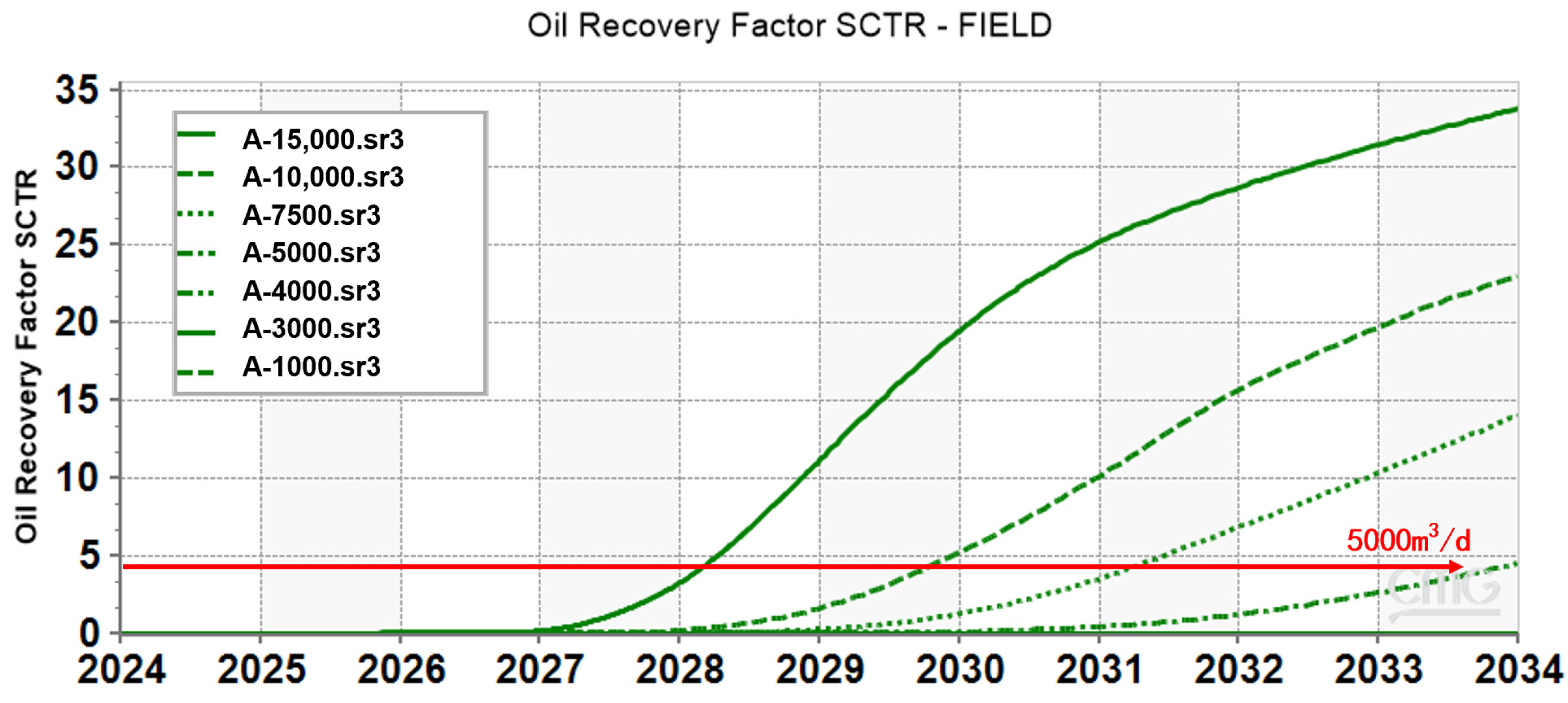

4.1. Numerical Simulation for CO2 Flooding

4.2. Oil Change Rate of CO2 Analysis

5. Conclusions

- (1)

- A Fuzzy Hierarchical Comprehensive Evaluation method is firstly applied for the adaptation analysis of CO2 flooding, and the results are compared with the published data for other similar reservoirs. The fuzzy comprehensive evaluation index Z is 0.8711 for target reservoir C, showing the good adaptation of CO2 flooding, and thus more confidence is obtained in determining the development method.

- (2)

- Core flooding experiments demonstrate that CO2 exhibits the highest oil displacement efficiency, outperforming surfactants and formation water. At an injection rate of 0.2 mL/min, the core recovery slightly exceeds that at 0.1 mL/min. An increased water saturation elevates oil displacement resistance, so the recovery rate of CO2 significantly decreases.

- (3)

- Under identical CO2 flooding conditions, surfactant-assisted CO2 huff-n-puff demonstrated the highest recovery rate, 0.85% higher than the recovery rate of only CO2 huff-n-puff. Considering the cost of the surfactant, CO2 is the optimized medium for huff-n-puff. The experimental study also shows that the recovery factor increases when the soaking time increases, while the increment rate drops, and 5 h in lab conditions is the optimized soaking time. Similarly, the cumulative recovery rate increases with huff-n-puff cycles, while the cyclic recovery rate decreased with increased flooding cycles.

- (4)

- Based on the geological models of Well A and B, a CO2 flooding simulation was conducted. Layer merging significantly enhances computational efficiency, while maintaining calculation accuracy. For reservoir C, CO2 miscible flooding using a five-spot well pattern can effectively enhance the oil recovery rate if an optimal injection rate can be achieved. However, constrained by the formation fracture pressure, the CO2 flooding injection rate for Well A should not exceed 7500 m3/d, resulting in a 10-year recovery rate of 27.39% and an oil replacement rate of 0.2 t/t, with an oil change rate of 0.2 t/t. For Well Block B, the CO2 injection rate should be less than 3000 m3/d, corresponding to a recovery rate of only 0.48% after 10 years and an oil change rate of 0.07 t/t.

- (5)

- The C reservoir’s tight sandstone formation exhibits a very low initial oil saturation, which is 30–50%. Although various methods have demonstrated the effectiveness of CO2 flooding compared to other methods, the oil recovery rate remains low. Considering the cost in drilling new wells and expanding gas injection facilities, the future development of the C reservoir is highly challenging.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Xing, H.; Liu, J.; Liu, X. A review on hydraulic fracturing of unconventional reservoir. Petroleum 2015, 1, 8–15. [Google Scholar] [CrossRef]

- Pan, B.; Fang, C.; Guo, Y.; Zhang, L.; Lei, J.; Fan, Y. Logging Evaluation and Production Capacity Prediction of Sulige Tight Sandstone Reservoirs Based on Rock Physics Conversion Models. Chin. J. Geophys. 2018, 61, 5115–5124. [Google Scholar]

- Han, Y.; Xie, J. Review of the Mechanism of Water Lock Damage in Tight Sandstone Reservoirs. Petrochem. Technol. 2018, 25, 222. [Google Scholar]

- Zhang, S.; Abdallah, K.B.; Li, L.; Hamdi, E.; Liu, J. Multiphase flow controlled by synergistic injection-production pressure: Enabling CO2 geo-sequestration with additional gas recovery from vertically heterogeneous depleted shale reservoirs. Fuel 2025, 398, 135591. [Google Scholar] [CrossRef]

- Gao, H.; Sun, W.; Pang, Z.; Zhang, R.; Ma, E. Study on the Saturation of Mobile Fluids in Low-Permeability Tight Gas Reservoirs: A Case Study of the Box 8 Reservoir in the Sulige Su 48 Block. Adv. Geophys. 2014, 29, 324–330. [Google Scholar]

- Chengzao, J.I.A. On the breakthroughs and significance of unconventional oil and gas in classical petroleum and natural gas geology theory. Pet. Explor. Dev. 2017, 44, 1–10. [Google Scholar]

- Al Adasani, A.; Bai, B. Analysis of EOR projects and updated screening criteria. J. Pet. Sci. Eng. 2011, 79, 10–24. [Google Scholar] [CrossRef]

- He, Y.; Zhao, S.; Ji, B.; Liao, H.; Zhou, Y. Selection and Potential Evaluation of Sandstone Reservoirs for CO2 EOR. Oil Gas Geol. Recovery Rate 2020, 27, 140–145. [Google Scholar]

- Wang, G.; Zheng, X.; Zhang, Y.; Lü, W.; Wang, F.; Yin, L. Screening method for low-permeability reservoirs suitable for carbon dioxide flooding. Pet. Explor. Dev. 2015, 42, 390–396. [Google Scholar] [CrossRef]

- Wang, Y. Mechanism Study on CO2 EOR in Tight Sandstone Reservoirs. Ph.D. Thesis, Northwest University, Xi’an, China, 2019. [Google Scholar]

- Lan, J.; Tang, F.; Xie, D.; Liang, X.; Mao, J.; Wang, G. Experimental Study on CO2 EOR in Tight Reservoirs. Contemp. Chem. Ind. 2023, 52, 997–1001. [Google Scholar]

- Shu, X. The Effect of Interfacial Tension on the Relative Permeability Curve of CO2 EOR in Low-Permeability Reservoirs. J. Pet. Nat. Gas 2013, 35, 122–123. [Google Scholar]

- Sun, C.; Wang, W.; Chen, G.; Ma, C. Experimental Study on the Interfacial Tension of Oil/Water and Oil/Gas Interfaces in CO2-Injected Oil and Gas Reservoir Fluid Systems. J. China Univ. Pet. Nat. Sci. Ed. 2006, 30, 109–112. [Google Scholar]

- Wang, H.; Wang, R.; Lu, Z.; Lyu, C.; Luo, M.; Zhao, C. High-temperature and high-pressure CO2/crude oil interfacial tension and its effect on oil displacement efficiency. Sci. Technol. Eng. 2017, 17, 38–42. [Google Scholar]

- Alfarge, D.; Wei, M.; Bai, B. Factors Affecting CO2-EOR in Shale-Oil Reservoirs: Numerical Simulation Study and Pilot Tests. Energy Fuels 2017, 31, 8462–8480. [Google Scholar] [CrossRef]

- Zhang, L. Feasibility analysis of carbon dioxide enhanced oil recovery technology in low permeability Fuyou oil reservoirs. Inn. Mong. Petrochem. Ind. 2014, 40, 108–109. [Google Scholar]

- Guo, M.; Huang, C.; Dong, X.; Zhou, Y.; Tang, R. Study on the Mechanism of CO2 Enhanced Oil Recovery in Tight Sandstone Reservoirs of Yanchang Oilfield. Pet. Nat. Gas Chem. 2018, 47, 75–79, 88. [Google Scholar]

- Gu, Y. Carbon Dioxide Flooding Technology for Ultra-Low Permeability Reservoirs to Greatly Enhance oil Recovery. IOP Conf. Ser. Earth Environ. Sci. 2021, 859, 012066. [Google Scholar] [CrossRef]

- Wang, C.; Cui, M.; Wang, K.; Wei, Y.; Wang, K.; Gao, H. Full-Scale Experimental Study on the Effect of CO2 Flooding on Storage-Seepage Capacity of Tight Sandstone Reservoirs. ACS Omega 2023, 8, 11897–11907. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Li, M.; Liu, Y.; Zhou, H. Visualization Experiment on the Micro-Mechanism of CO2 Injection and Extraction. Block Oil Gas Fields 2017, 24, 230–232. [Google Scholar]

- Zuloaga, P.; Yu, W.; Miao, J.; Sepehrnoori, K. Performance evaluation of CO2 Huff-n-Puff and continuous CO2 injection in tight oil reservoirs. Energy 2017, 134, 181–192. [Google Scholar] [CrossRef]

- Ma, Q.; Yang, S.; Lv, D.; Wang, M.; Chen, J.; Kou, G.; Yang, L. Experimental investigation on the influence factors and oil production distribution in different pore sizes during CO2 huff-n-puff in an ultra-high-pressure tight oil reservoir. J. Pet. Sci. Eng. 2019, 178, 1155–1163. [Google Scholar] [CrossRef]

- Song, Y.; Song, Z.; Zeng, H.; Tai, C.; Chang, X. N2 and CO2 Huff-n-Puff for Enhanced Tight Oil Recovery: An Experimental Study Using Nuclear Magnetic Resonance. Energy Fuels 2022, 36, 1515–1521. [Google Scholar] [CrossRef]

- Afari, S.; Ling, K.; Sennaoui, B.; Maxey, D.; Oguntade, T.; Porlles, J. Optimization of CO2 huff-n-puff EOR in the Bakken Formation using numerical simulation and response surface methodology. J. Pet. Sci. Eng. 2022, 215, 110552. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, X.; Xu, J. Application of Fuzzy Integrated Evaluation Method in Well Selection for Intra-layer CO2 Enhanced Oil Recovery. Digit. Des. 2016, 5, 56–58. [Google Scholar]

- He, Y.; Zhao, S.; Ji, B.; Liao, H.; Zhou, Y. Reservoir Screening and Potential Evaluation for CO2 EOR in Sandstone Reservoirs. Oil Gas Geol. Recovery Rate 2020, 27, 140–145. [Google Scholar]

- Yu, M.; Li, X.; Tie, L.; Xu, J.; Liu, W. Establishment and Application of a CO2 Fracturing Screening System for Low-Permeability Reservoirs Based on an Improved Fuzzy Comprehensive Evaluation Method. Math. Pract. Underst. 2017, 47, 114–119. [Google Scholar]

| Block | Viscosity/mPa·s | Density/(g·cm−3) | Oil Saturation/% | Temperature /°C | Permeability/ (10−3 μm2) | Porosity/% | Depth /m |

|---|---|---|---|---|---|---|---|

| 1# | 3.5 | 871 | 40 | 88 | 20 | 8 | 1676 |

| 2# | 3.5 | 873 | 72 | 18 | 16 | 18 | 336 |

| 3# | 3.2 | 876 | 83 | 39 | 1.2 | 6 | 579 |

| C | 4.18 | 832.7 | 50 | 90 | 0.26 | 10.13 | 2673 |

| Block | Viscosity/mPa·s | Density/(g·cm−3) | Oil Saturation/% | Temperature /°C | Permeability/ (10−3 μm2) | Porosity/% | Depth /m |

|---|---|---|---|---|---|---|---|

| 1# | 0.9836 | 1 | 1 | 1 | 1 | 0.9846 | 1 |

| 2# | 0.9836 | 1 | 1 | 0.9972 | 1 | 1 | 0.6183 |

| 3# | 0.9990 | 1 | 1 | 1 | 0.0907 | 0.8 | 0.9987 |

| C | 0.8918 | 1 | 1 | 1 | 0.0602 | 1 | 1 |

| Core Number | Porosity/% | Gas Permeability/mD | Length/cm | Diameter/cm | Displacement Medium | Pressure /MPa | Constant Speed/ (min·mL−1) | Back Pressure /MPa | Water Saturation /% |

|---|---|---|---|---|---|---|---|---|---|

| N1 | 9.09 | 0.69 | 5.759 | 2.505 | water | 35 | 32.12 | ||

| N2 | 9.49 | 0.75 | 5.371 | 2.506 | Surfactant | 35 | 30.81 | ||

| N3 | 9.79 | 0.64 | 5.667 | 2.509 | CO2 | 0.2 | 25 | 29.02 | |

| N4 | 9.53 | 0.63 | 5.683 | 2.508 | CO2 | 0.1 | 25 | 27.44 | |

| N5 | 12.35 | 0.66 | 5.813 | 2.503 | CO2 | 0.2 | 25 | 52.26 |

| Core. Number | Porosity/% | Gas Permeability/mD | Length/cm | Diameter/cm | Displacement Medium | Injection Pressure/MPa | Back Pressure/MPa | Soaking Time/h | Cycles |

|---|---|---|---|---|---|---|---|---|---|

| N6 | 7.4 | 0.34 | 5.815 | 2.503 | Fracturing Fluid | 25 | 15 | 5 | 4 |

| N7 | 9.5 | 0.57 | 5.919 | 2.502 | Surfactant | 25 | 15 | 5 | 4 |

| N8 | 6.3 | 0.30 | 5.960 | 2.523 | CO2 | 25 | 15 | 5 | 4 |

| N9 | 14.74 | 0.92 | 5.848 | 2.497 | CO2 + Surfactant | 25 | 15 | 5 | 4 |

| N10 | 9 | 0.54 | 5.763 | 2.526 | CO2 | 25 | 15 | 7 | 4 |

| N11 | 11.6 | 1.05 | 5.926 | 2.501 | CO2 | 25 | 15 | 3 | 4 |

| Core Number | Displacement Medium | First Round/% | Second Round/% | Third Round/% | Fourth Round/% | Cumulative Recovery Rate/% |

|---|---|---|---|---|---|---|

| N6 | Fracturing fluid | 12.99 | 6.50 | 3.13 | 0.96 | 23.59 |

| N7 | Surfactant | 13.68 | 6.84 | 3.96 | 1.80 | 26.28 |

| N8 | CO2 | 16.87 | 9.32 | 5.99 | 3.11 | 35.29 |

| N9 | Surfactant + CO2 | 16.26 | 9.80 | 6.70 | 3.38 | 36.14 |

| Well Block A | Well Block B | ||||

|---|---|---|---|---|---|

| Gas Injection Rate (m3/d) | Recovery Rate (%) | Injection Pressure (MPa) | Gas Injection Rate (m3/d) | Recovery Rate (%) | Injection Pressure (MPa) |

| 5000 | 14.92 | 36.8 | 3000 | 0.48 | 32.2 |

| 7500 | 27.39 | 44.0 | 4000 | 1.87 | 36.1 |

| 10,000 | 37.25 | 50.7 | 5000 | 4.57 | 39.8 |

| Oilfield Type | Porosity (%) | Permeability (mD) | CO2 Oil Change Rate (t/t) |

|---|---|---|---|

| Changqing Oilfield | 6–12 | 0.1–10 | 0.3–0.5 |

| Daqing Oilfield | 8–10 | 1–5 | 0.2–0.4 |

| Xinjiang Oilfield | 7–12 | 0.1–10 | 0.25–0.45 |

| C Reservoir | 6–12 | 0.1–10 | 0.01–0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Wang, B.; Wu, Q.; Miao, J.; Kang, H.; Wang, X. Comprehensive Investigation for CO2 Flooding Methodology in a Reservoir with High Water Content. Processes 2025, 13, 3657. https://doi.org/10.3390/pr13113657

Chen S, Wang B, Wu Q, Miao J, Kang H, Wang X. Comprehensive Investigation for CO2 Flooding Methodology in a Reservoir with High Water Content. Processes. 2025; 13(11):3657. https://doi.org/10.3390/pr13113657

Chicago/Turabian StyleChen, Shaoyong, Bo Wang, Qiong Wu, Jing Miao, Haijun Kang, and Xiuyu Wang. 2025. "Comprehensive Investigation for CO2 Flooding Methodology in a Reservoir with High Water Content" Processes 13, no. 11: 3657. https://doi.org/10.3390/pr13113657

APA StyleChen, S., Wang, B., Wu, Q., Miao, J., Kang, H., & Wang, X. (2025). Comprehensive Investigation for CO2 Flooding Methodology in a Reservoir with High Water Content. Processes, 13(11), 3657. https://doi.org/10.3390/pr13113657