Optimization of Flushing Fluid Plugging Theory Based on Plugging Experiments and Simulations

Abstract

1. Introduction

2. Research Procedure

- (1)

- Prepare a standard steel core with a 5 mm fracture width and 17 mm fracture length, filled with 20–40-mesh quartz sand. Conduct optimization experiments using different plugging theories and compare the plugging effectiveness of the three theories through invasion depth testing.

- (2)

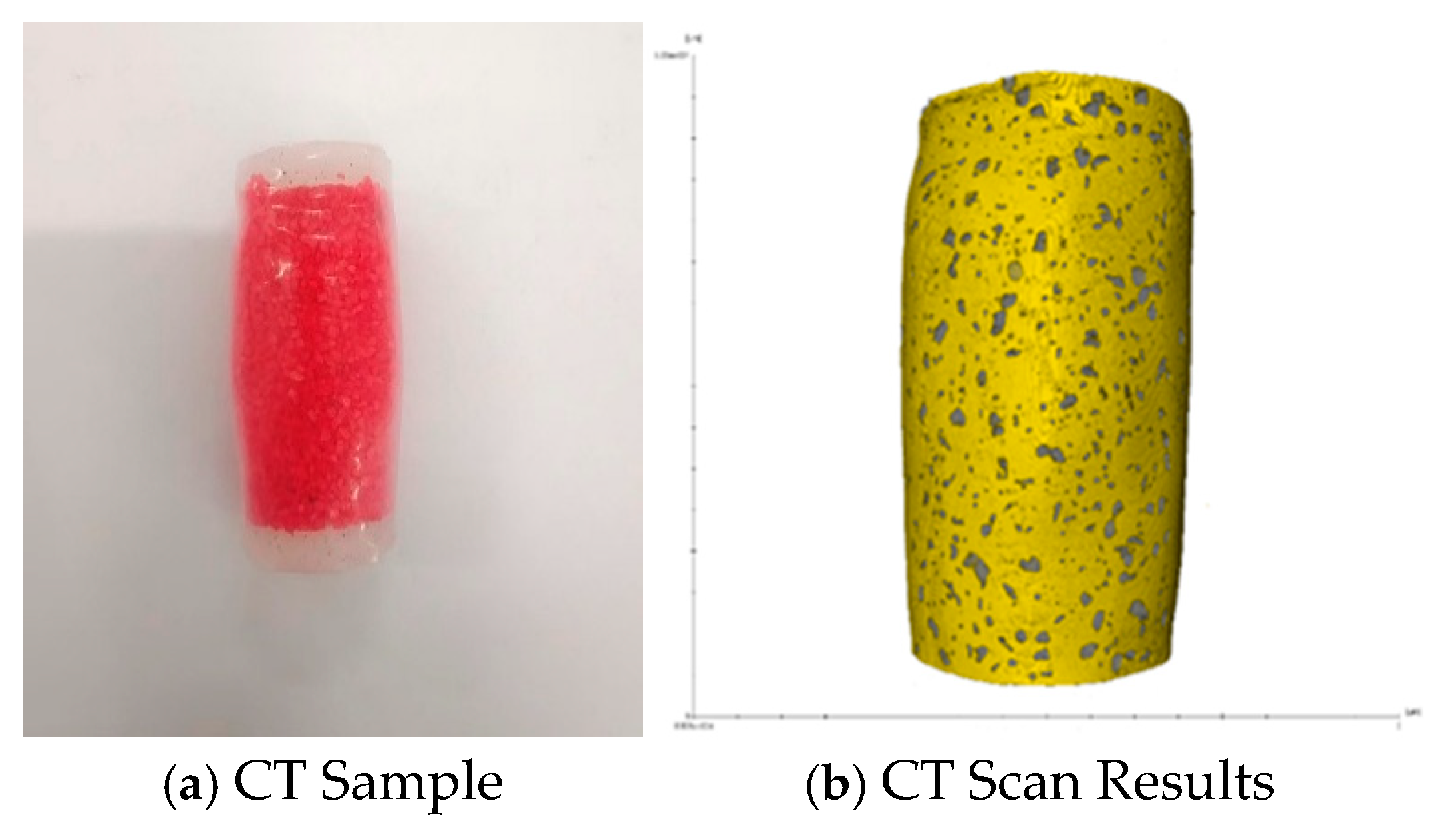

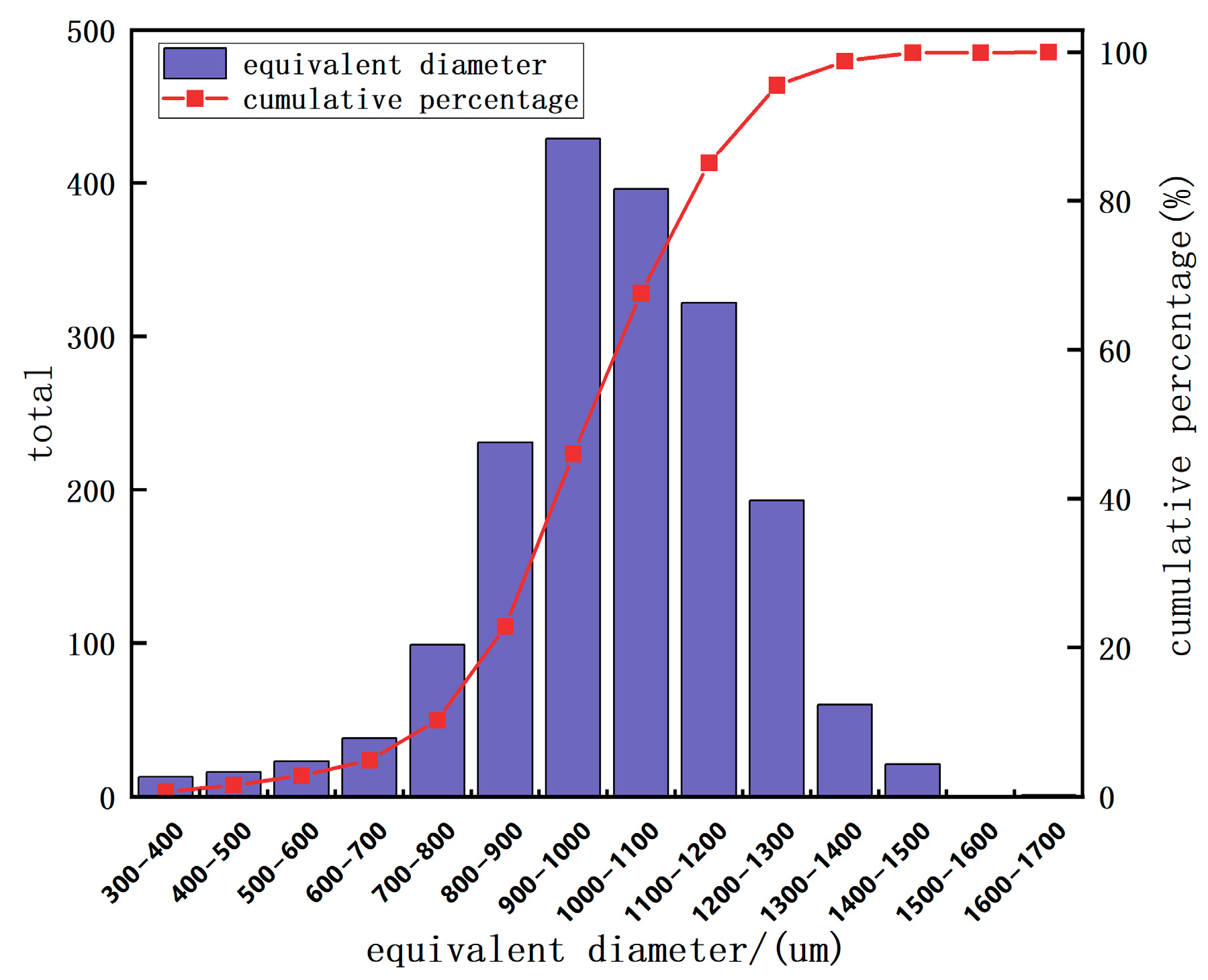

- A standard-sized core is prepared by fixing 20–40-mesh quartz sand with a thermoplastic tube, followed by CT scanning to obtain its pore size distribution characteristics and porosity, providing fundamental parameters for model establishment. Based on the parameters acquired from CT scanning, a foundational numerical simulation model is constructed to simulate the plugging processes of different plugging theories, thereby optimizing and selecting the most effective plugging theory.

- (3)

- The simulation results are validated and analyzed through sand-packed-tube displacement experiments. Permeability tests for the three plugging theories are conducted using sand-packed tubes to quantitatively characterize their plugging effectiveness. This enables the selection of the optimal plugging theory and verification of the simulation results.

2.1. Sample Data

- (1)

- Plugging Experiment Samples

- (2)

- Basic Data for Simulation Samples

2.2. Plugging Experiment

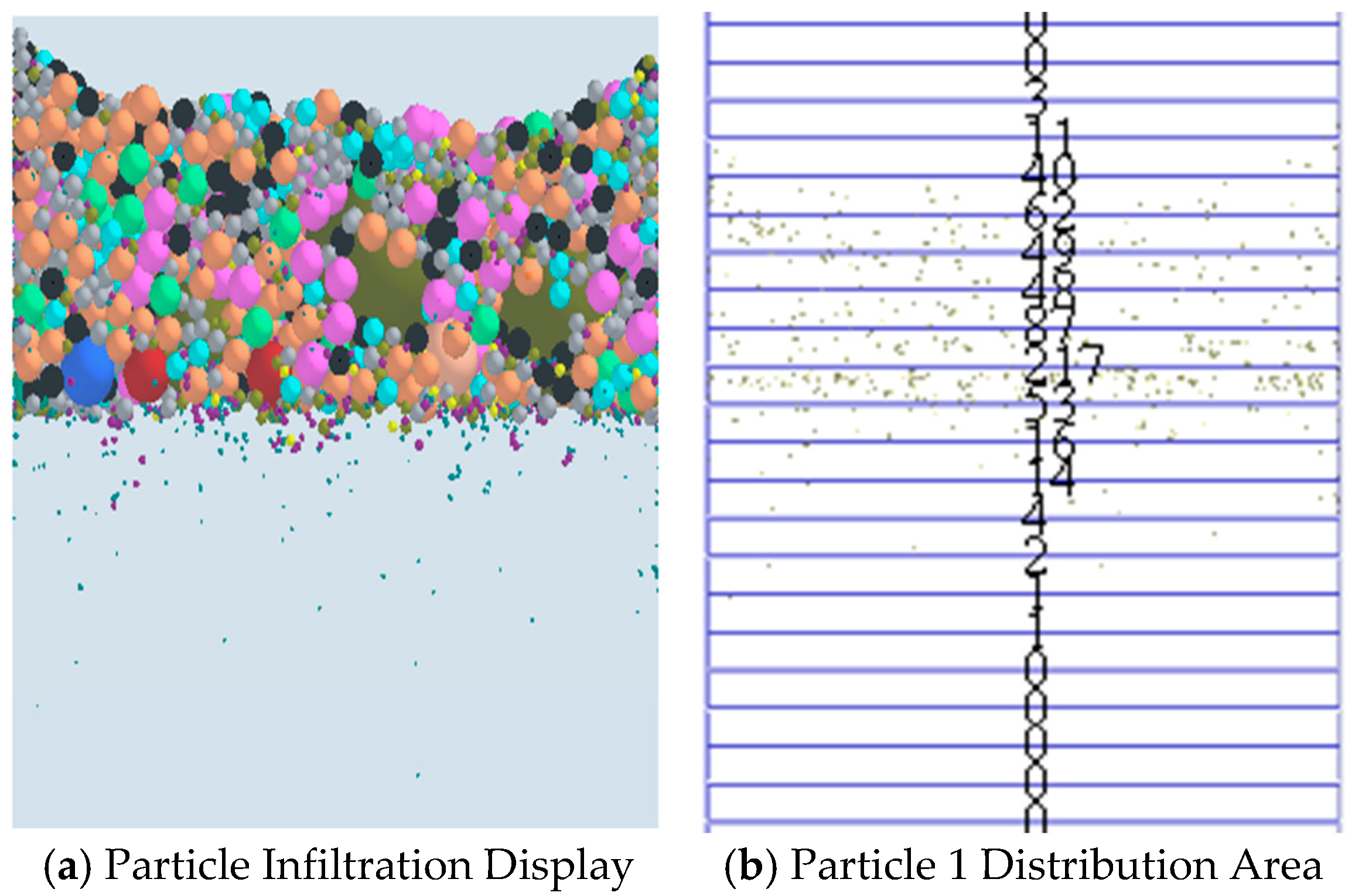

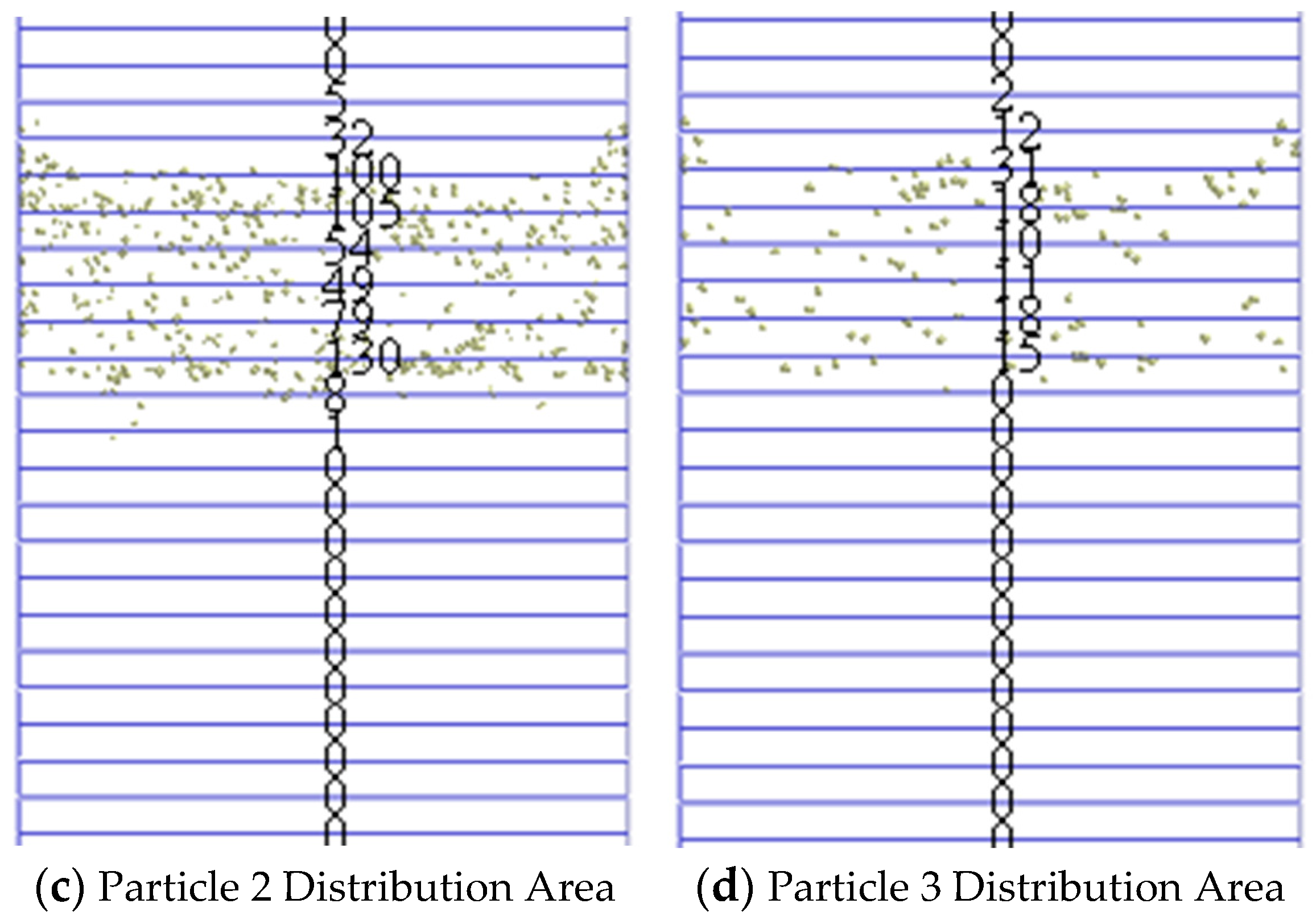

2.3. Plugging Simulation

2.4. Permeability Optimization Experiment

3. Results and Discussion

3.1. Plugging Experiment Results

3.2. Simulation Results

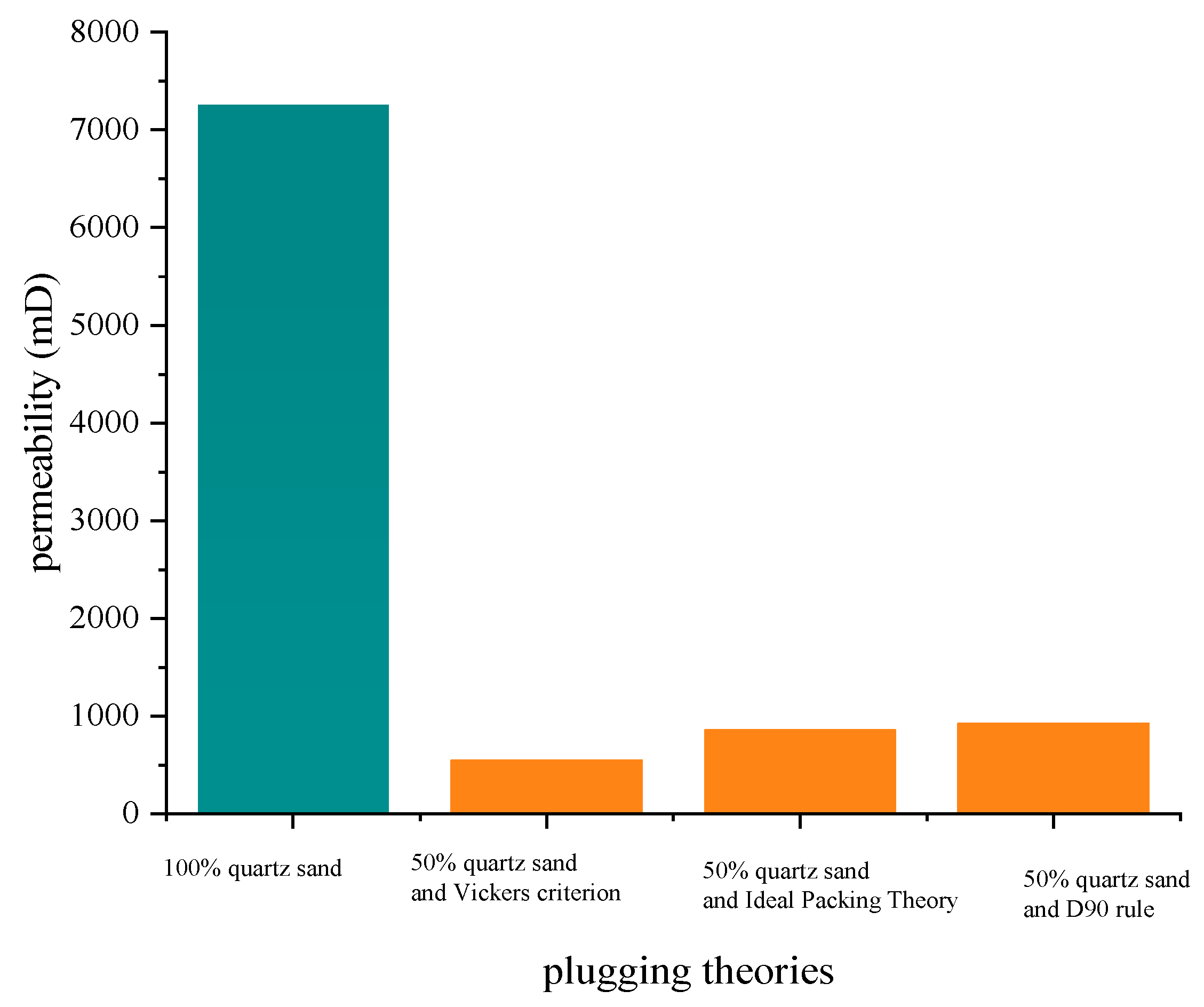

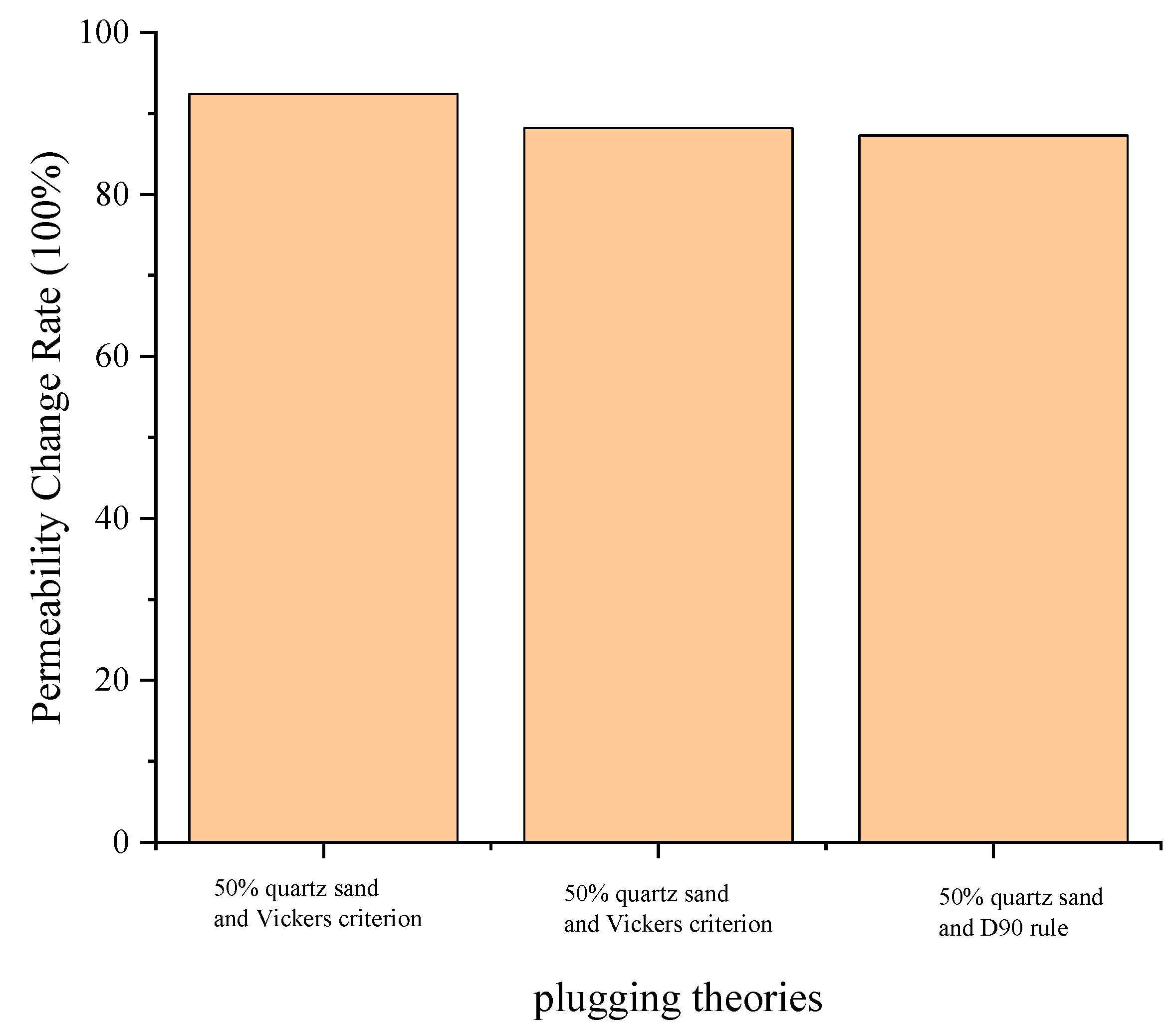

3.3. Permeability Experiment Optimization Results

4. Conclusions

- (1)

- The plugging test results indicate that the Vickers criterion achieves the best sealing performance. The Vickers criterion ensures uniform distribution of plugging particles within the 8–200 mesh range. This relatively uniform particle size distribution design contributes to improved sealing performance. Smaller particles can fill the voids between larger particles, forming a denser sealing layer that effectively prevents fluid invasion and reduces penetration depth. This approach demonstrates significant advantages in controlling particle invasion and establishing effective plugging barriers.

- (2)

- Based on the CFD-DEM model, the particle migration, bridging, and accumulation sealing processes guided by the three theories were simulated and analyzed. The Vickers criterion demonstrated superior plugging performance, enabling rapid formation of effective sealing in shallow regions.

- (3)

- The sand-packed-tube displacement experiment results indicate that the temporary plugging agent based on the Vickers criterion formed a plugging layer with the lowest permeability (reduced to 548 mD), significantly outperforming both the Ideal Packing Theory and the D90 rule. Its uniformly distributed particle size range (8–200 mesh) creates a densely packed structure through particle gradation, effectively preventing fluid invasion. This validates the scientific basis and practical rationality of the Vickers criterion in designing particle size matching for plugging materials.

- (4)

- The superiority of the Vickers criterion in the plugging of shale oil horizontal wells was verified by combining experimental and numerical simulation methods. However, there are still some limitations, mainly including that the difference between the experimental conditions and actual formation environment may lead to result deviations, and the simplification of some parameter assumptions in the numerical simulation may affect the simulation accuracy. Future research needs to employ conditions closer to on-site actual working conditions, refine the experimental design and simulation parameters, and explore more new plugging materials and their interaction mechanisms with formations, as well as their impact on subsequent plugging removal and flowback operations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moghadam, A.; Loizzo, M. Quantitative assessment of well leakage, part I: Cement stress evolution. Geomech. Energy Environ. 2024, 40, 100586. [Google Scholar] [CrossRef]

- Tian, Z.; Shi, L.; Qiao, L. Problems in the wellbore integrity of a shale gas horizontal well and corresponding countermeasures. Nat. Gas Ind. B 2015, 2, 522–529. [Google Scholar] [CrossRef]

- Zhang, B.; Pan, Z.; Cao, L.; Xie, J.; Chu, S.; Jing, Y.; Lu, N.; Sun, T.; Li, C.; Xu, Y. Measurement of wellbore leakage in high-pressure gas well based on the multiple physical signals and history data: Method, technology, and application. Energy Sci. Eng. 2023, 12, 4–21. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Xiong, Y.; Peng, G.; Wang, G.; Lu, J.; Zhong, L.; Wang, J.; Yan, Z.; Wei, R. Study on borehole temperature distribution when the well-kick and the well-leakage occurs simultaneously during geothermal well drilling. Geothermics 2022, 104, 102441. [Google Scholar] [CrossRef]

- Ai, E.; Li, Q.; Liu, Z.; Wang, L.; Ma, C. Research on the Mechanism of Wellbore Strengthening Influence Based on Finite Element Model. Processes 2025, 13, 2185. [Google Scholar] [CrossRef]

- Zang, X.; Qiu, Z.; Zhong, H.; Zhao, X.; Guo, P.; Gao, W.; Lin, Y. Fracture surface morphology characterization and its influence on plugging performance of granular lost circulation materials. Geoenergy Sci. Eng. 2023, 230, 212189. [Google Scholar] [CrossRef]

- Miranda, C.R.; Oliveira, J.L.; Cavalcante, G.M.; d’Almeida, A.R.; Pereira, R.F.; Santos, R.L.; Surmas, R. Materials for Controlling Severe Lost Circulation—Laboratory Evaluation; Society of Petroleum Engineers (SPE): Buenos Aires, Argentina, 2017. [Google Scholar]

- Tian, A.; Fu, G.; Tang, J.; Wang, D. Numerical Simulation of the Transport and Sealing Law of Temporary Plugging Particles in Complex Fractures of Carbonate-Type Thermal Storage. Energies 2024, 17, 3283. [Google Scholar] [CrossRef]

- Wang, D.; Qin, H.; Zheng, C.; Sun, D.; Yu, B. Transport mechanism of temporary plugging agent in complex fractures of hot dry rock: A numerical study. Geothermics 2023, 111, 102714. [Google Scholar] [CrossRef]

- Wang, Y.; Fan, Y.; Wang, X. Study on migration law of multiscale temporary plugging agent in rough fractures of shale oil reservoirs. Front. Phys. 2023, 11, 1228006. [Google Scholar] [CrossRef]

- Xu, J.; Wang, J.; Wang, M.; Hu, G.; Zhou, P.; Miao, H.; Kang, K.; Feng, H. Performance Research and Field Application of the Knot Temporary Plugging Agent. Chem. Technol. Fuels Oils 2022, 58, 544–553. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, X.; Liang, L.; Xiong, J. Experimental Study on the Adaptability of Plugging Drilling Fluids to Wellbore Stability in Hard Brittle Shale Formations. ACS Omega 2022, 7, 48034–48046. [Google Scholar] [CrossRef]

- Pan, Y.; Cui, X.; Wang, H.; Lou, X.; Yang, S.; Oluwabusuyi, F.F. Oluwabusuyi F F. Research Progress of Intelligent Polymer Plugging Materials. Molecules 2023, 28, 2975. [Google Scholar] [CrossRef] [PubMed]

- Chang, L.; Wang, H.; Zhuo, L.; Huang, H.; Zou, L.; Wang, Q.; Li, H.; Yu, J. Analysis of Wellbore Stability considering the Interaction between Fluid and Shale. Geofluids 2023, 2023, 4488607. [Google Scholar] [CrossRef]

- Liu, X.; Zeng, W.; Liang, L.; Lei, M. Wellbore stability analysis for horizontal wells in shale formations. J. Nat. Gas Sci. Eng. 2016, 31, 1–8. [Google Scholar] [CrossRef]

- Yao, L.; Quan, X.; Ma, J.; Wang, G.; Feng, Q.; Jin, H.; Yang, J. Development and Performance Evaluation of a Gel-Based Plugging System for Complex Fractured Formations Using Acrylic Resin Particles. Gels 2025, 11, 162. [Google Scholar] [CrossRef]

- Xu, P.; Yu, J.; Xie, L. Synthesis and Evaluation of Plugging Gel Resistant to 140 degrees C for Lost Circulation Control: Effective Reduction in Leakage Rate in Drilling Process. Polymers 2024, 16, 1658. [Google Scholar] [CrossRef]

- Vickers, S.; Cowie, M.; Jones, T.; Twynam, A.J. A New Methodology that Surpasses Current Bridging Theories to Efficiently Seal a Varied Pore Throat Distribution as Found in Natural Reservoir Formations. Wiert. Naft. Gaz 2006, 23, 501–505. [Google Scholar]

- Chellappah, K.; Aston, M. A new outlook on the ideal packing theory for bridging solids. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 15–17 February 2012. [Google Scholar]

- Alsaba, M.; Al Dushaishi, M.F.; Nygaard, R.; Nes, O.-M.; Saasen, A. Updated criterion to select particle size distribution of lost circulation materials for an effective fracture sealing. J. Pet. Sci. Eng. 2017, 149, 641–648. [Google Scholar] [CrossRef]

- Whitfill, D. Lost circulation material selection, particle size distribution and fracture modeling with fracture simulation software. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition, Jakarta, Indonesia, 25–27 August 2008. [Google Scholar]

- Mei, W.; Shu, S.; Lai, T.; Liu, W.; Hu, G. Pore and throat network model and its application to the optimal selection of temporary plugging particles. In Proceedings of the SPE Formation Damage Control Symposium, Lafayette, LA, USA, 14–15 February 1996. [Google Scholar]

- Feng, W.; Yan, J. Designing Drill-in Fluids by Using Ideal Packing Technique. Pet. Sci. 2007, 4, 44–51. [Google Scholar] [CrossRef]

- Lin, C.; Xu, Q.-C.; Han, L.-X.; Li, G.; He, H.; Zhou, H.-L.; She, J.-P. Fracture sealing performance of granular lost circulation materials at elevated temperature: A theoretical and coupled CFD-DEM simulation study. Pet. Sci. 2024, 21, 567–581. [Google Scholar] [CrossRef]

- Saparbayeva, N.; Balakin, B.V. CFD-DEM model of plugging in flow with cohesive particles. Sci. Rep. 2023, 13, 17188. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, M.V.; De Lai, F.C.; Junqueira, S.L.M. Numerical Evaluation of CFD-DEM Coupling Applied to Lost Circulation Control: Effects of Particle and Flow Inertia. Math. Probl. Eng. 2019, 2019, 6742371. [Google Scholar] [CrossRef]

- Bao, D.; Qiu, Z.; Zhao, X.; Zhong, H.; Chen, J.; Liu, J. Experimental investigation of sealing ability of lost circulation materials using the test apparatus with long fracture slot. J. Pet. Sci. Eng. 2019, 183, 106396. [Google Scholar] [CrossRef]

- Liu, X.; Xiao, Y.; Ding, Y. Research Progress and Prospects of Nano Plugging Agents for Shale Water-Based Drilling Fluids. ACS Omega 2025, 10, 5138–5147. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Lu, Y. Study on Improving Plugging Performance of Polyurethane Plugging Agent by Modified Nano-SiO2. J. Adv. Phys. Chem. 2018, 7, 70–77. [Google Scholar] [CrossRef]

| Plugging Theories | Particle Size (Mesh) | Percentage (%) |

|---|---|---|

| Vickers Criterion | 8–26 | 25 |

| 26–45 | 25 | |

| 45–100 | 25 | |

| 100–200 | 25 | |

| Ideal Packing Theory | 8–10 | 10 |

| 10–16 | 40 | |

| 16–200 | 50 | |

| D90 Rule | 8–10 | 10 |

| 10–200 | 90 |

| Particle Size Range (mm) | 0.075–0.15 | 0.15–0.56 | 0.56–0.7 | 0.7–2.36 |

| Average Particle Size (mm) | 0.05625 | 0.1775 | 0.315 | 0.765 |

| Particle Size Range (mm) | 0.075–1.01347 | 1.01347–1.6917 | 1.6917–2.36 |

| Average Particle Size (mm) | 0.2721175 | 0.6762925 | 1.012925 |

| Particle Size Range (mm) | 0.075–1.6917 | 1.6917–2.36 |

| Average Particle Size (mm) | 0.441675 | 1.012925 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, W.; Zhang, S.; Peng, C.; Zhang, L.; Dou, C.; Zhang, X.; Zhuang, Y. Optimization of Flushing Fluid Plugging Theory Based on Plugging Experiments and Simulations. Processes 2025, 13, 3639. https://doi.org/10.3390/pr13113639

Shi W, Zhang S, Peng C, Zhang L, Dou C, Zhang X, Zhuang Y. Optimization of Flushing Fluid Plugging Theory Based on Plugging Experiments and Simulations. Processes. 2025; 13(11):3639. https://doi.org/10.3390/pr13113639

Chicago/Turabian StyleShi, Wei, Shifeng Zhang, Chao Peng, Lian Zhang, Chenjing Dou, Xiaojian Zhang, and Yan Zhuang. 2025. "Optimization of Flushing Fluid Plugging Theory Based on Plugging Experiments and Simulations" Processes 13, no. 11: 3639. https://doi.org/10.3390/pr13113639

APA StyleShi, W., Zhang, S., Peng, C., Zhang, L., Dou, C., Zhang, X., & Zhuang, Y. (2025). Optimization of Flushing Fluid Plugging Theory Based on Plugging Experiments and Simulations. Processes, 13(11), 3639. https://doi.org/10.3390/pr13113639