Several Issues and Suggestions Regarding the Future Intrinsically Safe Chemical Industrial Park: Insights from Severe Hazardous Chemical Accident Analysis and Industrial Park Field Investigations

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Collection

2.2. Methodology

2.2.1. Step 1: Comprehensive Survey of Severe Chemical Incidents

2.2.2. Step 2: Analysis of Severe Chemical Accidents

2.2.3. Step 3: Investigation of Chemical Process Safety Elements and Accidents

2.2.4. Step 4: Discourse on Pertinent Challenges and Prescriptive Measures for the Prospective Inherently Safe Chemical Industry Park

3. Results and Discussion

3.1. Comprehensive Survey of Severe Chemical Incidents

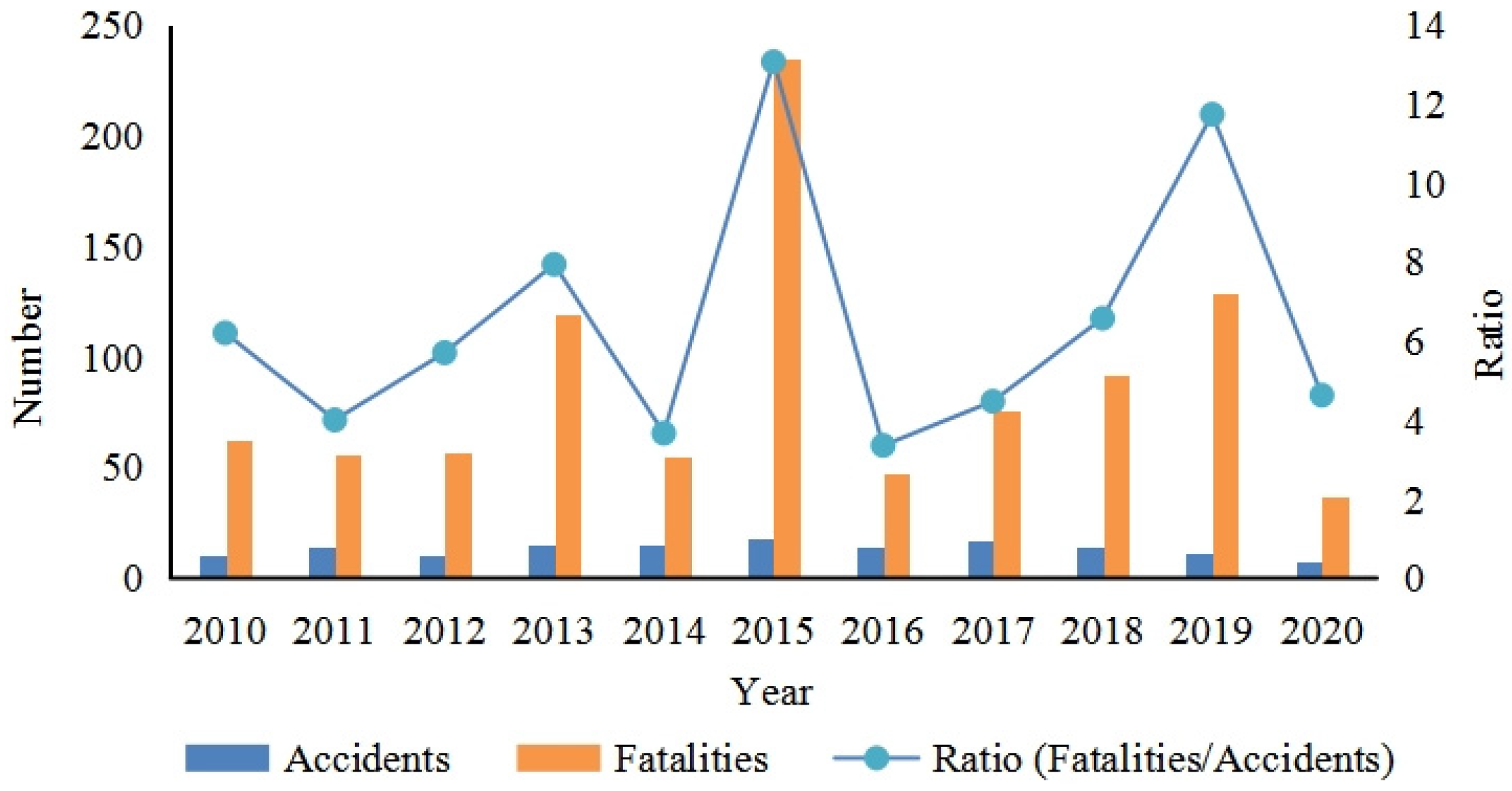

3.1.1. Severe Chemical Accidents Trend Analysis

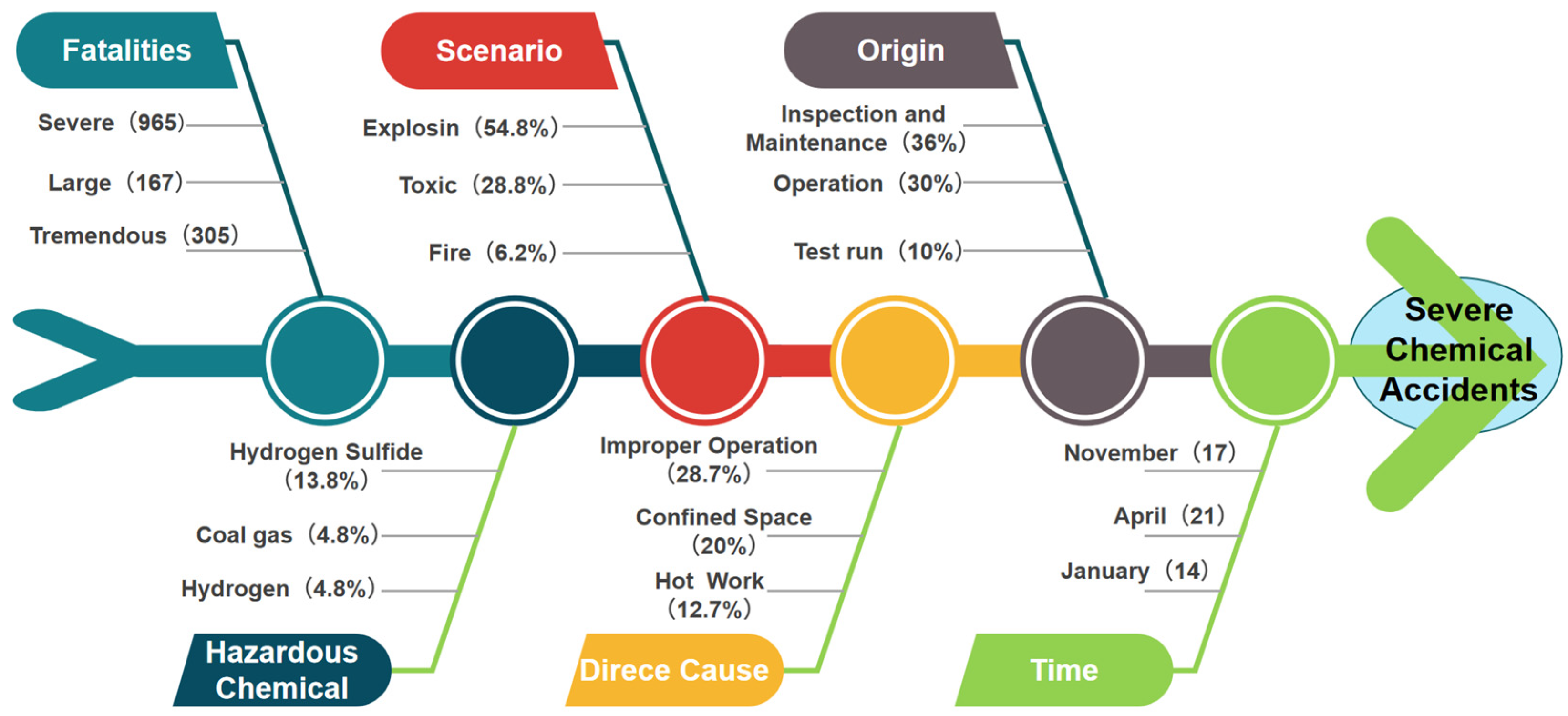

3.1.2. Severe Accident Level Analysis

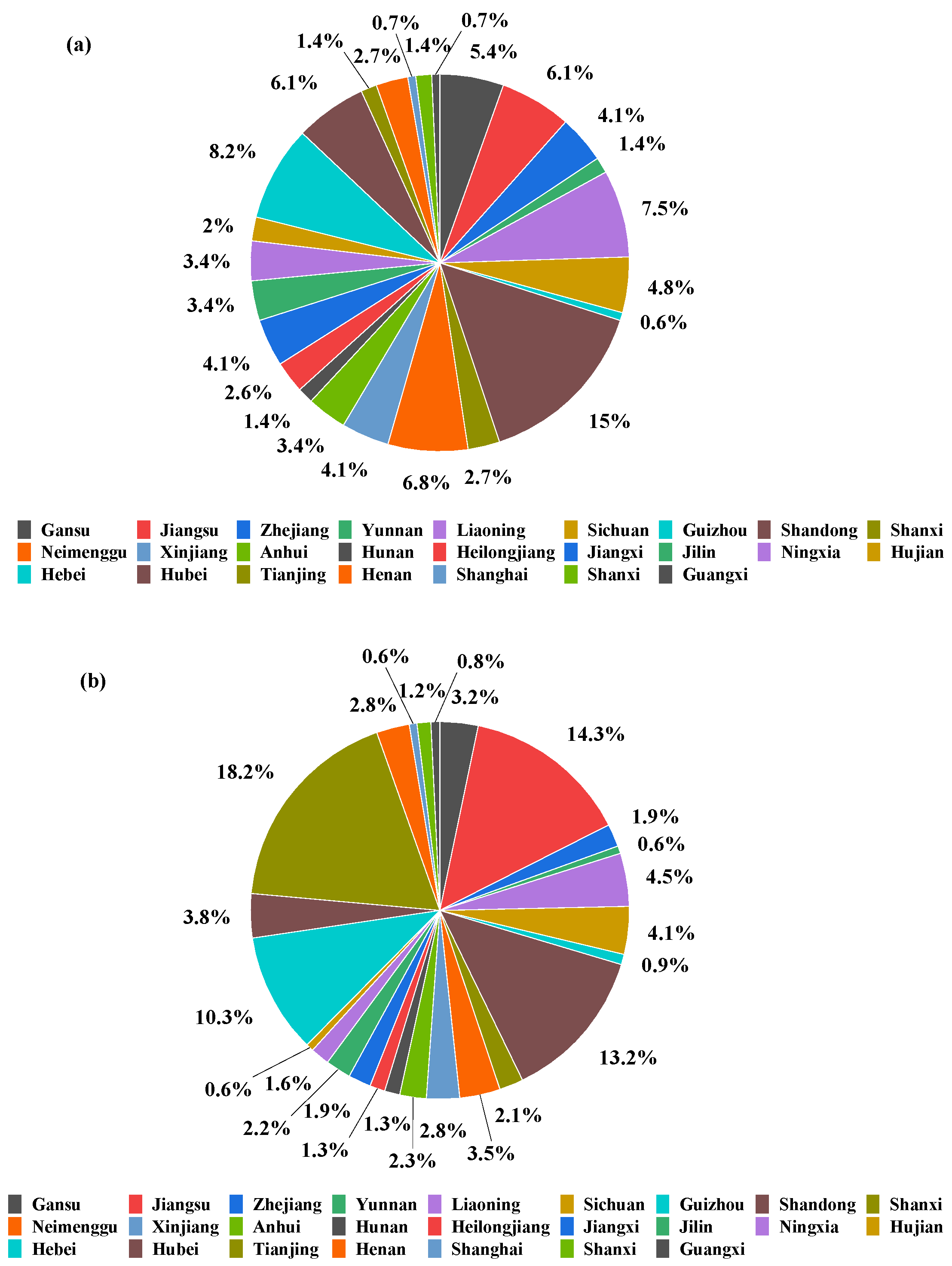

3.1.3. Accident Analysis by Province

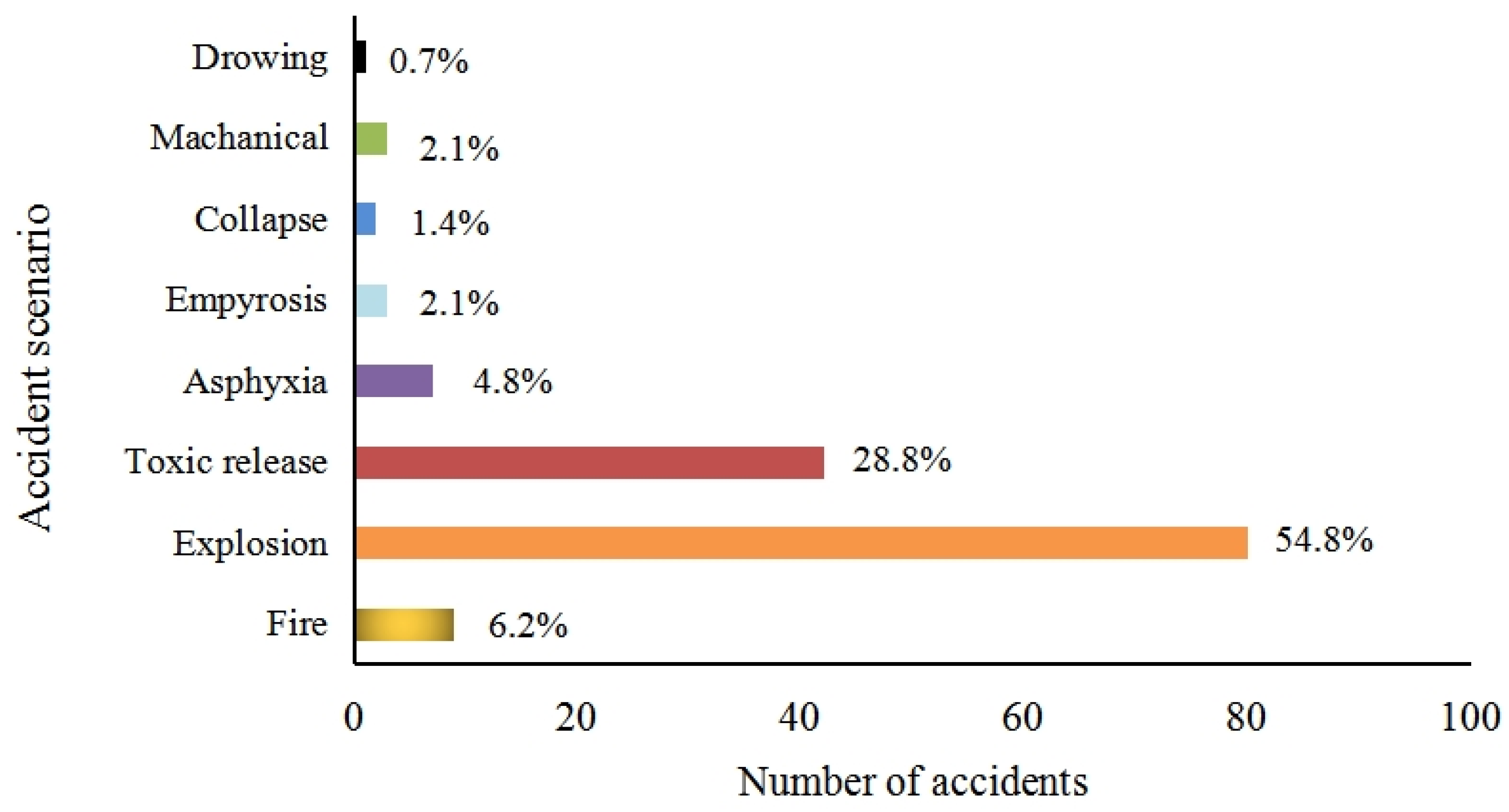

3.1.4. Analysis of Accident Scenarios

3.1.5. Analysis of Accident Origin

3.1.6. Hazardous Chemical Analysis

3.1.7. Direct Cause of the Severe Chemical Accidents

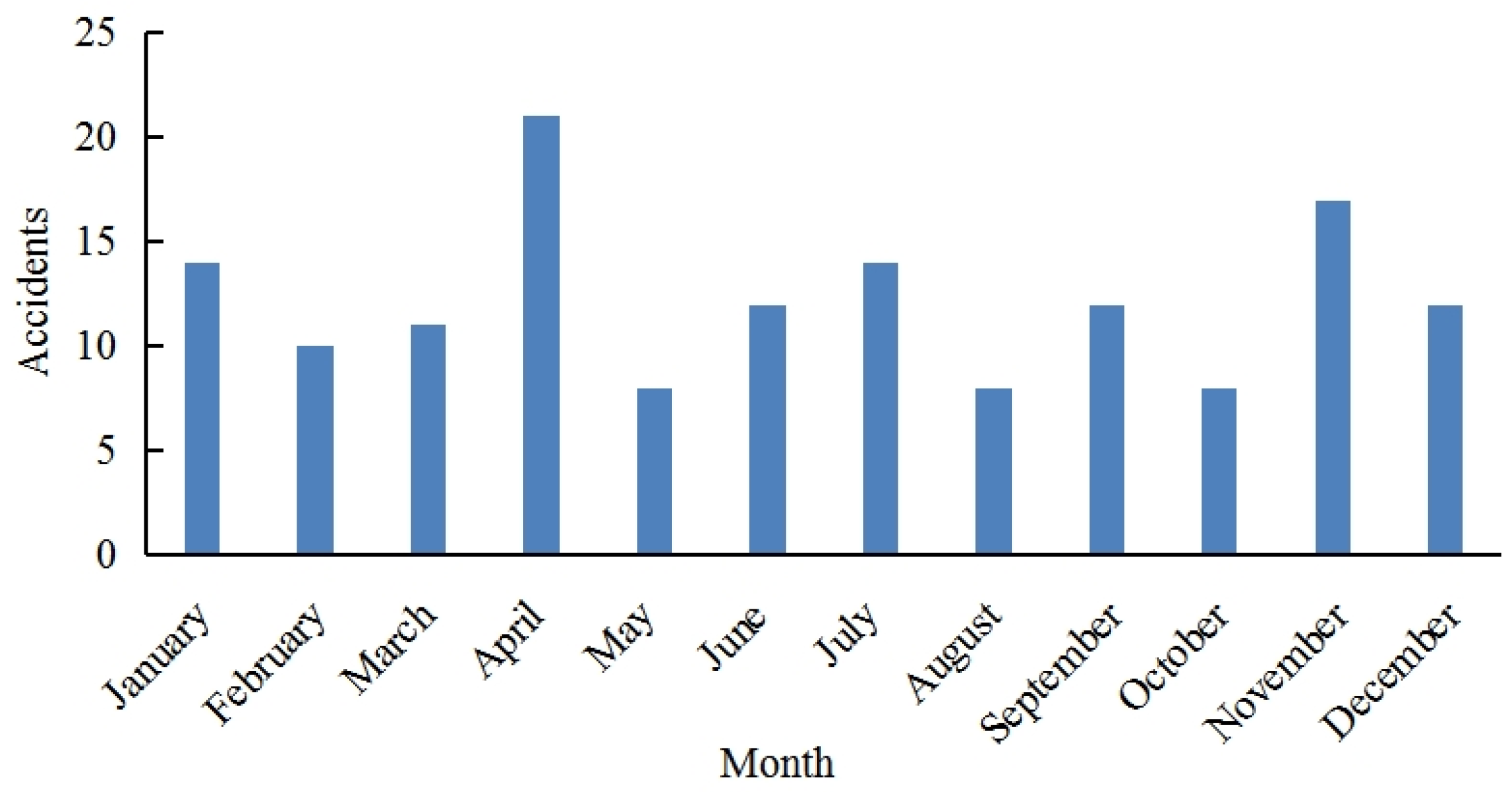

3.1.8. Time Distribution of Accidents

3.2. Relationship Between Severe Accidents and Elements of Chemical Process Safety

- Process Hazard Analysis. Chemical facilities handling hazardous materials or implementing high-risk processes inherently involve hazardous factors such as high temperature, high pressure, toxicity, and leakage. Process hazard analysis refers to the identification and assessment of potential hazards in production processes using scientific and effective analytical methods; a comprehensive risk assessment is essential for mitigating these hazards. Common analytical methods include the checklist method, what-if analysis, hazard and operability (HAZOP) studies, and failure mode and effects analysis (FMEA). Analysis of 150 severe accidents reveals that 57.3% of indirect causes were attributed to inadequate risk identification. For example, during the crude oil tank explosion at the Liaoyang Petrochemical Branch of China National Petroleum Corporation, workers used iron tools and standard lighting equipment during tank cleaning operations, failing to recognize the ignition risk of combustible gases. Therefore, mastering process hazard analysis techniques and identifying effective protective measures are critical for reducing the frequency and severity of accidents.

- Training. Training is a core element of process safety management, with specific requirements established by numerous countries and regulatory authorities. For instance, the Occupational Safety and Health Law mandates that enterprises and production units provide safety education and training to employees. The former State Administration of Work Safety issued regulations on enterprise safety training, requiring the establishment of safety training systems in compliance with relevant laws and administrative regulations. Many accident investigation reports cite insufficient personnel training or poor training quality as indirect causes of accidents. Among the 150 severe accidents analyzed in this study, 85.5% involved training-related issues. A typical case is the “1.6” gas poisoning accident at Xinjiang Dahuangshan Hongji Coke Co., Ltd. The investigation report identified the inexperience of frontline managers and employees (mostly new recruits from colleges and vocational schools) and their lack of on-site operational practice as indirect causes. Thus, improving the effectiveness and quality of chemical safety training is an urgent priority for chemical enterprises.

- Mechanical Integrity. Mechanical integrity covers the entire lifecycle of equipment, including installation, operation, maintenance, repair, inspection, and disposal. When selecting equipment, enterprises must choose products with high reliability, excellent performance, and low maintenance needs that comply with legal and regulatory requirements. Meanwhile, routine maintenance of equipment should be strengthened. A major explosion occurred in the air separation unit of Yima Co., Ltd. (Sanmenxia, China) on 19 July 2019, resulting in 15 fatalities (caused by glass fragments and heavy objects impacted by the explosion shockwave). The root cause was the failure to promptly address a leak, which allowed oxygen-enriched gas to infiltrate perlite, leading to low-temperature embrittlement of the cold box support frame and panels. Under overpressure conditions, a violent “sandstorm-like” sand ejection event occurred, ultimately causing the cold box to collapse.

- Change Management. Improper modifications may introduce new hazards and even trigger accidents. A typical example is the 2013 hydrogen sulfide poisoning incident in Gansu, which resulted from unapproved modifications to key processes, equipment, and facilities. The newly added drying equipment lacked comprehensive verification; without a formal design and due to unauthorized technical modifications, inherent risks and hazardous factors of the process could not be fully identified, and no contingency plan was developed for potential failures of the induced draft fan shutdown. When modifying process technologies, equipment, procedures, or organizational structures, strict adherence to a management system is essential. The core objective of change management is to ensure that all modifications undergo thorough evaluation before implementation—with associated risks identified, analyzed, and controlled—to maintain process integrity during the transition. Enterprises must establish a scientific and streamlined change management system, with particular focus on risk analysis of modifications. During the implementation phase, pre-modification safety inspections, training for affected personnel, and updates to diagrams and documents are also indispensable.

- Accident and Incident Management. Every incident or accident arises from one or more root causes. Identifying these causes and promptly improving corporate management not only prevents recurrence of similar accidents but also mitigates the risk of other potential incidents. Thus, incident management is essentially a proactive accident prevention strategy. The Regulations on the Reporting and Investigation of Production Safety Accidents require accident investigations to adhere to the principles of scientific rigor, legal compliance, fact-based analysis, and practical effectiveness. Throughout the investigation process, detailed inspection and comprehensive analysis of the production process and accident site are necessary—these efforts also contribute to the optimization of operating procedures and safety management. Therefore, enterprises should conduct in-depth investigation and analysis of minor incidents with the same rigor as severe accidents.

- Compliance Review. Compliance review plays a critical role in identifying deficiencies in an enterprise’s process safety management system through continuous monitoring and evaluation during risk management. Distinct from routine safety inspections, this element is an integral part of the overall safety management framework. The primary goal of compliance review is to ensure the effective implementation and continuous improvement of other system elements, thereby achieving the overarching objective of preventing major accidents. By conducting rigorous compliance reviews, organizations can verify the effectiveness of safety measures and implement data-driven improvements to their process safety management systems.

3.3. Several Issues Regarding the Future Inherently Safe Chemical Industry Park

3.3.1. Systemic Risk Management Continues to Face Significant Challenges

- The overall risk assessment of the park lacks precision and scientific rigor. Although regular comprehensive risk assessments are conducted as mandated for accreditation of chemical industrial parks, there is an objective tendency to merely aggregate the risks of all enterprises without adequately accounting for the interplay among product categories, production processes, mutual material safeguards, emergency response capabilities, and other factors. The analysis of domino effects, project admission and exit criteria, supporting functional facilities, and integrated management of safety production and emergency response lacks detail and a systematic approach, failing to provide precise decision support for the park’s overall planning and project attraction strategies.

- The quality and effectiveness of major hazard source control need enhancement. Taking the Taixing Economic and Technological Development Zone as an example, there are 47 enterprises constituting 193 major hazard sources, including 86 first- and second-level major hazard sources, accounting for 44.6%. Over the past three years, the total number of major hazard sources in the park has increased by 39, with 38 added in 2023 alone. Based on this trend, the number of major hazard sources in the park may exceed 250 by the end of 2030. The rapid growth of major hazard sources exacerbates the difficulty of risk management.

- Industrial linkage is insufficiently tight. A few chemical industrial park enterprises have weak internal circulation, which increases road transportation, loading and unloading, and storage links for hazardous chemicals, raising the absolute value of risk points and thereby increasing the overall safety risk of the park to some extent. There is a lack of unified coordination and consultation mechanisms between enterprises and industries, and the theoretical design values of product correlation have not been implemented in actual production, making it difficult to control overall industrial risks.

3.3.2. Weaknesses in Basic Infrastructure Construction

- The quality and efficiency of closed management within the industrial park need further improvement. In recent years, closed management has become a rigid benchmark for park management. However, research indicates that the scope of closed management areas is extensive, with insufficient ground patrol forces and limited coverage of electronic parking violation capture points. Some enterprises within the park have a weak awareness of risk prevention and proactivity, leading to disorderly vehicle parking in their proprietary areas. The operation and maintenance team for closed management, as well as their training, need to be enhanced, as there is a lack of uniformity in policy enforcement and inconsistent service quality. There is also a delay in feedback regarding equipment malfunctions and errors, which hinders the smooth operation of checkpoints, affecting work efficiency and quality. A mature management system for temporary vehicle entry has not yet been established, leaving room for management gaps.

- The management of hazardous chemicals in dedicated parking lots within the park needs further improvement. Dedicated parking lots are an essential requirement for the high-quality development of chemical industrial parks. Taking the park in the author’s region as an example, there are approximately 700 hazardous chemical vehicles entering and exiting daily, with peaks reaching over 1000 vehicles. Thirty-two percent of these vehicles require parking, yet the park currently has only two dedicated parking lots with 102 parking spaces, including only 17 spaces for heavy vehicles, which is insufficient. The overall management of the parking lots also has weaknesses, with an inadequate liaison and scheduling mechanism with related enterprises. Due to insufficient internal scheduling by enterprises, heavy vehicles may accumulate in the dedicated parking lots, creating short-term congregation risks. Moreover, the hazardous chemicals loaded on heavy vehicles vary, and the superposition of various risk factors could lead to extremely serious consequences and great rescue difficulties in the event of an accident.

- The layout of utility corridors and pipelines needs to be optimized. The internal utility corridors of a chemical park are the lifelines of the park. In the park in the author’s region, for example, there are approximately 58 km of utility corridors (with about 42 km of public utility corridors) and 256 pipelines, mainly transporting 29 types of hazardous chemicals such as liquid chlorine, hydrogen, propane, ethylene, propylene, epoxy ethylene, ethanol, butanol, and nitrogen. Some pipelines built by enterprises are arranged in a crisscross pattern, with power lines, signal lines, and other weak wires mounted indiscriminately, slow renewal of old pipelines, and utility corridors operating at full capacity, increasing the risk factor.

- Non-production functions within the park are redundant and complex. The majority of chemical enterprises have established non-production facilities, such as office buildings and canteens. In the author’s park, for instance, there are 24 chemical companies with 162 employee dormitories, 105 with office buildings, 65 with staff canteens (44 of which utilize open gas flames), and 70 with storage areas. The park can accommodate a peak of 13,000 vehicles, with traffic on the three main access roads reaching 6000 vehicles during peak times. The concentration of people, goods, and vehicles increases the regional risk factor and hinders the safe development of the park.

3.3.3. Insufficient Robustness in Information Technology Support

- The operational quality and efficiency of the smart park platform need further improvement. As the development of smart parks progresses, most have implemented intelligent management platforms. However, it has been observed that these platforms require further functional optimization. The video AI analysis systems are not yet refined, leading to numerous false alarms and ineffective early warning systems.

- The application of enterprise “double prevention” platforms needs to be further strengthened. Some enterprises have not organized all employees to conduct a comprehensive and full-process analysis and identification of risks and dangerous factors in all aspects of production processes and safety management. The identification of risks is incomplete. Upon comprehensive analysis of the risks self-checked by enterprises, it is common to find perfunctory self-checks. Enterprises have not conducted comprehensive inspections from the aspects of systems, management, national standards, and inspection guidelines.

- The operational quality and efficiency of automated control and safety instrumentation systems are suboptimal. Firstly, there is a disparity in the level of automation control. Some enterprises have not achieved a high degree of full-process automation control, and there are still gaps between the control measures for key regulated hazardous chemicals and national policy documents, especially with the latest regulations. Some enterprises are slow to respond and are unable to immediately undertake equipment and facility updates and modifications. Secondly, the management of automated alarm systems is not comprehensive. Although some enterprises have established a “five-in-one” platform, there are issues with untimely alarm handling and incomplete resolution of false alarms.

3.3.4. The Emergency Response System Requires Further Optimization and Improvement

- The emergency command system is not fully developed. The emergency response to incidents in the hazardous chemicals field is sometimes limited by professional capabilities and other factors, affecting its scientific nature. In some places, there is no unified platform for information sharing and integrated communication during on-site emergency response, leading to unsmooth emergency command and dispatch, and a lack of agility in response, thus affecting the efficiency of handling.

3.3.5. Refining Management Capabilities to Meet Higher Standards

- The risk base of hot work operations is high, with significant safety risks. Inspection and maintenance are often accompanied by hot work. In the author’s park, for instance, at the peak of inspection and maintenance, there are about 50 hot operations a day. Accidents and incidents occasionally occur due to hot work operations.

- There are deficiencies in the management of inspection and maintenance operations. According to many accident investigation reports, contractors’ inspection and maintenance plans are not standardized, technical briefings are not comprehensive, and violations occur from time to time.

3.3.6. Improvement in Many Other Detailed Aspects

- The regulatory capacity for hazardous chemical enterprises at ports is weak. Many parks have port terminals that support the park. Taking the author’s park as an example, there are three hazardous chemical storage enterprises at the port, with a total of 109 storage tanks and a capacity of 364,350 cubic meters, involving nine level-one major hazard sources and one level-four major hazard source. Only two regulatory personnel are responsible for safety supervision in the port area, and neither has a background in chemical engineering, which is insufficient to meet safety supervision needs.

- Chemical training bases have not fully played their expected role. As a supporting facility for the park, a few chemical training bases are limited by economic and other factors; the construction of chemical training bases is relatively slow, and in some regions, the teaching faculty is relatively weak.

3.4. Future Intrinsically Safe Chemical Park Model

3.5. Countermeasures and Suggestions

3.5.1. Systemic Risk Management

3.5.2. Basic Infrastructure Construction

3.5.3. Intelligence

3.5.4. Emergency Response

3.5.5. Refining Management

3.5.6. Other Detailed Aspects

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cao, G.Z.; Yang, L.; Liu, L.X.; Ma, Z.W.; Wang, J.N.; Bi, J. Environmental incidents in China: Lessons from 2006 to 2015. Sci. Total Environ. 2018, 633, 1165–1172. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Wu, C.; Reniers, G.; Huang, L.; Kang, L.G.; Zhang, L.B. The future of hazardous chemical safety in China: Opportunities, problems, challenges and tasks. Sci. Total Environ. 2018, 643, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Jacobsson, A.; Ek, Å.; Akselsson, R. Method for evaluating learning from incidents using the idea of “level of learning”. J. Loss Prev. Process Ind. 2011, 24, 333–343. [Google Scholar] [CrossRef]

- Yoon, C.; Kwak, H.; Jung, S. A Study on ESG Evaluation Indicators Through Chemical Accident Data Analysis and Double Materiality Assessment. Processes. 2025, 13, 323. [Google Scholar] [CrossRef]

- Shorten, C.V.; Galloway, J.; Krebs, J.G.; Fleming, R.S. A 12-year history of hazardous materials incidents in Chester County, Pennsylvania. J. Hazard. Mater. 2022, 89, 29–40. [Google Scholar] [CrossRef]

- Cozzani, V.; Gubinelli, G.; Antonioni, G.; Spadoni, G.; Zanelli, S. The assessment of risk caused by domino effect in quantitative area risk analysis. J. Hazard. Mater. 2005, 127, 14–30. [Google Scholar] [CrossRef]

- Oggero, A.; Darbra, R.M.; Munoz, M.; Planas, E.; Casal, J. A survey of accidents occurring during the transport of hazardous substances by road and rail. J. Hazard. Mater. 2006, 133, 1–7. [Google Scholar] [CrossRef]

- Nivolianitou, Z.; Konstandinidou, M.; Michalis, C. Statistical analysis of major accidents in petrochemical industry notified to the major accident reporting system (MARS). J. Hazard. Mater. 2006, 137, 1–7. [Google Scholar] [CrossRef]

- Georgiadou, P.S.; Papazoglou, I.A.; Kiranoudis, C.T.; Markatos, N.C. Multi-objective evolutionary emergency response optimization for major accidents. J. Hazard. Mater. 2010, 178, 792–803. [Google Scholar] [CrossRef]

- Yang, J.; Li, F.Y.; Zhou, J.B.; Zhang, L.; Huang, L.; Bi, J. A survey on hazardous materials accidents during road transport in China from 2000 to 2008. J. Hazard. Mater. 2010, 184, 647–653. [Google Scholar] [CrossRef]

- Duan, W.L.; Chen, G.H.; Ye, Q.; Chen, Q.G. The situation of hazardous chemical accidents in China between 2000 and 2006. J. Hazard. Mater. 2011, 186, 1489–1494. [Google Scholar] [CrossRef] [PubMed]

- Kourniotis, S.P.; Kiranoudis, C.T.; Markatos, N.C. Statistical analysis of domino chemical accidents. J. Hazard. Mater. 2000, 71, 239–252. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.M.; Zhong, M.H.; Xing, J.J. Industrial accidents: Challenges for China’s economic and social development. Saf. Sci. 2005, 43, 503–522. [Google Scholar] [CrossRef]

- Jung, S.; Woo, J.; Kang, C. Analysis of severe industrial accidents caused by hazardous chemicals in South Korea from January 2008 to June 2018. Saf. Sci. 2020, 124, 104580. [Google Scholar] [CrossRef]

- Wang, B.; Li, D.L.; Wu, C. Characteristics of hazardous chemical accidents during hot season in China from 1989 to 2019: A statistical investigation. Saf. Sci. 2020, 129, 104788. [Google Scholar] [CrossRef]

- Gao, X.M.; Abdul Raman, A.A.; Hizaddin, H.F.; Bello, M.M.; Buthiyappan, A. Review on the inherently safer design for chemical processes: Past, present and future. J. Clean. Prod. 2021, 305, 127154. [Google Scholar] [CrossRef]

- Di Martino, Y.; Duque, S.E.; Reniers, G.; Cozzani, V. Making the chemical and process industries more sustainable: Innovative decision-making framework to incorporate technological and non-technological inherently safer design (ISD) opportunities. J. Clean. Prod. 2021, 296, 126421. [Google Scholar] [CrossRef]

- Zhao, J.L.; Li, Z.J.; Xu, Y.; Chen, Y. Dynamic risk assessment framework for chemical industrial park storage facilities: Integration of enhanced TOPSIS and Bayesian networks. Process Saf. Environ. Prot. 2025, 201, 107535. [Google Scholar] [CrossRef]

- Chen, C.; Reniers, G. Chemical industry in China: The current status, safety problems, and pathways for future sustainable development. Saf. Sci. 2020, 128, 104741. [Google Scholar] [CrossRef]

- Hou, J.; Gai, W.; Cheng, W.; Deng, Y. Hazardous chemical leakage accidents and emergency evacuation response from 2009 to 2018 in China: A review. Saf. Sci. 2021, 135, 105101. [Google Scholar] [CrossRef]

- Yemelin, P.V.; Kudryavtsev, S.S.; Yemelina, N.K. Improving the industrial safety management system at enterprises with chemically hazardous sites. J. Saf. Sci. Resil. 2024, 5, 432–448. [Google Scholar] [CrossRef]

- Jung, S.; Kim, H.; Kang, C. Efficiency Analysis of the Integrated Application of Hazard Operability (HAZOP) and Job Safety Analysis (JSA) Compared to HAZOP Alone for Preventing Fire and Explosions in Chemical Plants. Processes 2025, 13, 88. [Google Scholar] [CrossRef]

- Yuan, S.; Yang, M.; Reniers, G.; Chen, C.; Wu, J. Safety barriers in the chemical process industries: A state-of-the-art review on their classification, assessment, and management. Saf. Sci. 2022, 148, 105647. [Google Scholar] [CrossRef]

- Zhou, J.L.; Liu, L.M.; Su, Y.N.; Liang, R.J.; Feng, J.Z.; Wang, X. Statistical investigation on the characteristics of hazardous chemical accidents in special work in China from 2008 to 2021. Process Saf. Prog. 2023, 43, 195–208. [Google Scholar] [CrossRef]

- Su, C.; Deng, J.; Li, X.Y.; Cheng, F.M.; Huang, W.H.; Wang, C.P.; He, W.B.; Wang, X.P. Research on the game strategy of mutual safety risk prevention and control of industrial park enterprises under blockchain technology. Syst. 2024, 12, 351. [Google Scholar] [CrossRef]

- Kim, L.S.; Yoon, C.; Lee, D.; Shin, G.; Jung, S. A study on the sustainability of petrochemical industrial complexes through accident data analysis. Processes 2024, 12, 2637. [Google Scholar] [CrossRef]

- Fyffe, L.; Krahn, S.; Clarke, J.; Kosson, D.; Hutton, J. Apreliminary analysis of Key Issues in chemical industry accident reports. Saf. Sci. 2016, 82, 368–373. [Google Scholar] [CrossRef]

- Moura, R.; Beer, M.; Patelli, E.; Lewis, J.; Knoll, F. Learning from major accidents to improve system design. Saf. Sci. 2016, 84, 37–45. [Google Scholar] [CrossRef]

- Dakkoune, A.; Vernières-Hassimi, L.; Leveneur, S.; Lefebvre, D. Risk analysis of French chemical industry. Saf. Sci. 2018, 105, 77–85. [Google Scholar] [CrossRef]

- Wang, B.; Wu, C.; Kang, L.G.; Reniersc, G.; Huang, L. Work safety in China’s Thirteenth Five-Year plan period (2016–2020): Current status, new challenges and future tasks. Saf. Sci. 2018, 104, 164–178. [Google Scholar] [CrossRef]

- Tao, G.; Yang, P.; Zhang, L. Smart chemical industry parks in China: Current status, challenges, and pathways for future sustainable development. J. Loss Prev. Process Ind. 2023, 83, 105105–105124. [Google Scholar] [CrossRef]

- Kletz, T.A. Accident reports may not tell us everything we need to know. J. Loss Prev. Process Ind. 2009, 22, 753–756. [Google Scholar] [CrossRef]

- Hemmatian, B.; Abdolhamidzadeh, B.; Darbra, R.M.; Casal, J. The significance of domino effect in chemical accidents. J. Loss Prev. Process Ind. 2014, 29, 30–38. [Google Scholar] [CrossRef]

- Al-shanini, A.; Ahmad, A.; Khan, F. Accident modelling and analysis in process industries. J. Loss Prev. Process Ind. 2014, 32, 319–334. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, Q.S.; Yan, W.G.; Sun, J.H. An evacuation model coupling with toxic effect for chemical industrial park. J. Loss Prev. Process Ind. 2015, 33, 258–265. [Google Scholar] [CrossRef]

- Kwon, H.; Lee, C.; Seo, D.; Moon, I. Korean experience of process safety management (PSM) regulation for chemical industry. J. Loss Prev. Process Ind. 2016, 42, 2–5. [Google Scholar] [CrossRef]

- Chen, C.; Reniers, G.; Zhang, L.B. An innovative methodology for quickly modeling the spatial-temporal evolution of domino accidents triggered by fire. J. Loss Prev. Process Ind. 2018, 54, 312–324. [Google Scholar] [CrossRef]

- Gai, W.M.; Deng, Y.F. Survey-based analysis on the diffusion of evacuation advisory warnings during regional evacuations for accidents that release toxic vapors: A case Study. J. Loss Prev. Process Ind. 2019, 57, 174–185. [Google Scholar] [CrossRef]

- Dou, Z.; Mebarki, A.; Cheng, Y.; Zheng, X.P.; Jiang, J.C.; Wang, Y.; Li, Y.; Li, J.H. Review on the emergency evacuation in chemicals-concentrated areas. J. Loss Prev. Process Ind. 2019, 60, 35–45. [Google Scholar] [CrossRef]

- Chen, C.; Reniers, G.; Khakzad, N. Integrating safety and security resources to protect chemical industrial parks from man-made domino effects: A dynamic graph approach. Reliab. Eng. Syst. Saf. 2019, 191, 106470. [Google Scholar] [CrossRef]

- Kidam, K.; Hussin, N.E.; Hassan, O.; Ahmad, A.; Johari, A.; Hurme, M. Accident prevention approach throughout process design life cycle. Process Saf. Environ. Prot. 2014, 92, 412–422. [Google Scholar] [CrossRef]

- Goh, Y.M.; Tan, S.; Lai, K.C. Learning from the Bhopal disaster to improve process safety management in Singapore. Process Saf. Environ. Prot. 2015, 97, 102–108. [Google Scholar] [CrossRef]

- Yang, Y.F.; Chen, G.H.; Chen, P. The probability prediction method of domino effect triggered by lightning in chemical tank farm. Saf. Environ. Prot. 2018, 116, 106–114. [Google Scholar] [CrossRef]

- Jahangiri, M.; Hoboubi, N.; Rostamabadi, A.; Keshavarzi, S.; Hossein, A.A. Human Error Analysis in a Permit to Work System: A Case Study in a Chemical Plant. Saf. Health Work. 2016, 7, 6–11. [Google Scholar] [CrossRef] [PubMed]

- Amyotte, P.A.; Berger, S.; Edwards, D.W.; Gupta, J.P.; Hendershot, D.C.; Khan, F.I.; Mannan, M.S.; Willey, R.J. Why major accidents are still occurring. Curr. Opin. Chem. Eng. 2016, 14, 1–8. [Google Scholar] [CrossRef]

- Laidoune, A.; Gharbi, M.E.H.R. Analysis Testing of Sociocultural Factors Influence on Human Reliability within Sociotechnical Systems: The Algerian Oil Companies. Saf. Health Work. 2016, 7, 194–200. [Google Scholar] [CrossRef]

- Duan, W.; He, B. Emergency Response System for Pollution Accidents in Chemical Industrial Parks. Int. J. Environ. Res. Public Health 2015, 12, 7868–7885. [Google Scholar] [CrossRef]

- AlRukaibi, F.; Alrukaibi, D.; Alkheder, S.; Alojaiman, S.; Sayed, T. Optimal route risk-based algorithm for hazardous material transport in Kuwait. J. Loss Prev. Process Ind. 2018, 52, 40–53. [Google Scholar] [CrossRef]

- Huang, Y.H.; Chen, G.H.; Zhao, Y.M.; Xu, Q.M. An advanced dynamic risk assessment method for chemical industry park cyber-physical system based on improved graphsage. Process Saf. Environ. Prot. 2025, 204, 107990. [Google Scholar] [CrossRef]

- Peterson, L.; Gosea, I.V.; Benner, P.; Sundmacher, K. Digital twins in process engineering: An overview on computational and numerical methods. Comput. Chem. Eng. 2025, 193, 108917. [Google Scholar] [CrossRef]

- Mhiri, M.; Mkacher, H.; Al-Khatib, M.; Kharbeche, M.; AlNouss, A.; Haouari, M. Enhancing liquefied natural gas supply chain robustness through digital twin-driven machine learning models: A special case of cryogenic heat exchanger. Gas Sci. Eng. 2025, 143, 205714. [Google Scholar] [CrossRef]

- GB 6944-2025; Classification and Code of Dangerous Goods. National Standards of People’s Republic of China: Beijing, China, 2025.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Zhao, C.; Zhang, L. Several Issues and Suggestions Regarding the Future Intrinsically Safe Chemical Industrial Park: Insights from Severe Hazardous Chemical Accident Analysis and Industrial Park Field Investigations. Processes 2025, 13, 3630. https://doi.org/10.3390/pr13113630

Li S, Zhao C, Zhang L. Several Issues and Suggestions Regarding the Future Intrinsically Safe Chemical Industrial Park: Insights from Severe Hazardous Chemical Accident Analysis and Industrial Park Field Investigations. Processes. 2025; 13(11):3630. https://doi.org/10.3390/pr13113630

Chicago/Turabian StyleLi, Sen, Chen Zhao, and Lijing Zhang. 2025. "Several Issues and Suggestions Regarding the Future Intrinsically Safe Chemical Industrial Park: Insights from Severe Hazardous Chemical Accident Analysis and Industrial Park Field Investigations" Processes 13, no. 11: 3630. https://doi.org/10.3390/pr13113630

APA StyleLi, S., Zhao, C., & Zhang, L. (2025). Several Issues and Suggestions Regarding the Future Intrinsically Safe Chemical Industrial Park: Insights from Severe Hazardous Chemical Accident Analysis and Industrial Park Field Investigations. Processes, 13(11), 3630. https://doi.org/10.3390/pr13113630