1. Introduction

Occupational exposure to soil-borne pesticides remains a critical challenge at the interface of industrial and agro-industrial operations, with recent European assessments underscoring the persistence of pesticide residues in soils and the need for monitoring programs explicitly linked to operational decision-making [

1,

2,

3,

4,

5]. This problem aligns closely with the aims of

Processes, which emphasize development, monitoring, and control of processes within environmental and process systems engineering, where measurement, modeling, and optimization are integrated for safety and sustainability [

6]. In this setting, process analytical technology (PAT) is essential because it connects multi-residue measurements to real-time monitoring, decision thresholds, and control actions, reflecting

Processes’ focus on designing, simulating, and optimizing processes as interconnected systems [

7]. Process-oriented approaches foreground performance indicators such as cycle time, cost per sample, limits of quantification, and robustness that enable transparent trade-offs between analytical accuracy and operational feasibility in a control architecture suitable for routine use [

8].

Methodologically, multi-residue identification of xenobiotics in soil frequently uses QuEChERS coupled with GC-MS and/or LC-MS/MS to balance broad chemical coverage with sensitivity in complex matrices, yet these benefits require deliberate workflow design to maintain throughput and robustness in day-to-day operation [

9,

10,

11].

When framed as a process-design problem, instrument selection and validation are mapped to performance and cost constraints that feed continuous monitoring objectives and timely decision-making within an engineering control loop [

12]. For occupational risk, canonical institutional guidance specifies the sequential steps of hazard identification, dose–response assessment, exposure assessment, and risk characterization, providing a reproducible foundation for quantifying and communicating risks at the workplace.

Fourier-transform infrared spectroscopy (FTIR) is another frequently mentioned tool, promoted for its speed and simplicity of sample preparation [

13]. It allows identification of major functional groups, making it an excellent preliminary screening instrument [

14]. However, the literature highlights serious limitations in complex matrices such as soil, where spectra can overlap and be difficult to interpret. Its lower sensitivity compared with GC-MS or HPLC limits FTIR’s use for rigorous quantitative detection, an important aspect when precise exposure assessment is needed [

15,

16]. In recent years, coupled LC-MS/MS techniques have revolutionised the analysis of polar pesticides, offering extremely high sensitivity and multiple reaction monitoring in a single analysis [

16]. This method enables simultaneous detection of multiple pesticides at ultra-trace levels and is recommended in advanced research or in well-resourced laboratories [

17]. However, the high costs, maintenance requirements, and need for specialised personnel make LC-MS/MS implementation difficult for routine monitoring in small industries or in countries with limited infrastructure.

Coupling this assessment with risk management frameworks such as those from HSE enables hierarchical control (elimination, substitution, engineering and organizational measures, and PPE) and closes a continuous improvement loop consistent with “process monitoring and control” emphasized by Processes.

Accordingly, this study advances a process-integrated analytical workflow in which selection and validation of QuEChERS with GC-MS/LC-MS/MS are explicitly coupled to process performance indicators and a decision matrix for occupational risk management, ensuring that analytics and control operate as a unified decision support system. The approach targets both multi-residue detection and quantification in soil and the translation of those results into operational thresholds, monitoring frequencies, and control measures, with methodological and operational justifications aligned to “Environmental and Sustainable Process Engineering” and “Process Systems Engineering” sections of the journal. Beyond technical aspects, the literature underlines the importance of the socio-economic and regulatory context [

18,

19]. While international regulations set strict limits for pesticides in soil and occupational air, their actual enforcement is uneven [

20,

21]. Differences between national and international standards are significant, and the lack of resources and political will leads to inadequate monitoring in many regions [

22]. Education and training of workers are equally important: personal protective equipment is often underused due to discomfort or lack of awareness [

23]. Case studies from agriculture and industry offer telling evidence [

24]. Results show high levels of pesticides in soil, frequently exceeding legal limits, and inconsistent implementation of protective measures [

25]. Risk assessment often takes place only after health effects appear, instead of being a predictive and preventive component of industrial management [

26,

27].

The contribution is to articulate an explicit bridge between multi-residue analytics and a process decision architecture, reinforced by institutional conceptual anchors, to systematically reduce exposure while increasing operational robustness in European contexts where soil pesticide residues are a recognized policy and process-management signal [

28]. This framing supports relevance for

Processes by emphasizing workflow design and control, performance metrics, and real-time utility under realistic industrial and agro-industrial cost and time constraints. This paper introduces a process-integrated analytical workflow that explicitly links multiresidue detection via QuEChERS-GC-MS/LC-MS/MS to an operational occupational-risk decision architecture, translating analytical outputs into thresholds, monitoring cadence, and proportional control actions; it formalizes process performance indicators (cycle time, cost per sample, instrument uptime, re-run rate) as design constraints for routine deployment; and it demonstrates the measurement-to-action loop on representative soil and food-chain matrices (e.g., total HCH 0.003 mg/kg; total DDT 0.010 mg/kg) treated as process signals rather than endpoints, operationalizing a toxicity–probability matrix and KPI-based escalation/de-escalation logic that integrates environmental monitoring with biomonitoring.

Research question: Can a process-integrated multiresidue workflow translate soil/food-chain concentration signals into reproducible occupational risk categories and proportional control actions under predefined QA/QC and KPI constraints?

Working hypothesis: Within validated LOQs and acceptance criteria, concentration bands mapped by a predefined toxicity–probability matrix yield consistent risk classifications that trigger scalable action bundles and monitoring cadence, demonstrating an analytics-to-action pathway aligned with process monitoring and control.

2. Materials and Methods

This study implements a process-integrated analytical workflow that links multi-residue detection of soil xenobiotics to an occupational risk assessment and control framework, emphasizing performance metrics, robustness, and decision thresholds aligned with Environmental and Sustainable Process Engineering and Process Systems Engineering.

2.1. Purpose of the Research

The study aimed to comparatively evaluate instrumental strategies for identifying xenobiotics in soil and to integrate these strategies within a process-level framework applicable to occupational risk assessment and control in industrial and agro-industrial settings. The design emphasized analytical validity and operational feasibility so that measurements translate directly into monitoring frequency, decision thresholds, and prioritized interventions compatible with routine process control programs.

2.2. Research Objectives

Objectives included a critical evaluation of GC-MS, HPLC, FTIR, LC-MS/MS, and ICP-MS with respect to analyte classes, matrix complexity, sensitivity, selectivity, throughput, and cost, alongside integration of analytical outputs into a model for worker exposure and risk.

The work developed risk-management proposals that connect contaminant identification, exposure monitoring, and preventive controls via a structured decision matrix to support continuous improvement in process safety and compliance.

2.3. Study Design and Approach

The workflow followed a PAT-style loop comprising sampling, QuEChERS extraction, LC-MS/MS and GC-MS determinations, QA/QC and validation, data processing, and translation of results into risk categories and control actions, reflecting Processes’ emphasis on monitoring and control.

A combined methodological approach was used: targeted literature synthesis, comparative method analysis, and adaptation of institutional risk frameworks to ensure both analytical rigor and decision utility at the process level.

2.4. Sampling and Matrices

Soil and food-chain matrices were selected to reflect realistic exposure pathways and decision contexts for occupational risk, ensuring traceability and relevance to process operations and worker tasks. Representative soil and potato tuber samples were prepared and documented to enable mapping of concentrations to potential exposure routes and to support reproducible risk characterization for decision-making. Sampling strategy and sample size: A total of 36 soil samples were collected from 12 sites across the target area, at 0–10 cm depth using a stratified scheme reflecting task-related exposure pathways; each site included 3 field replicates, with 4 field duplicates and 4 field blanks per campaign; all samples were stored at 4 °C and analyzed within 48 h; laboratory replicates per sample were 2, with matrix-matched calibration and acceptance criteria as in

Table 1,

Table 2,

Table 3 and

Table 4; chain-of-custody and preservation conditions followed PAT-aligned QA/QC2.5. Sample preparation (QuEChERS).

Samples were weighed accurately on an analytical balance, homogenized with magnesium sulphate and sodium chloride, vigorously mixed for approximately two minutes, and centrifuged at −20 °C for five minutes at 4000 rpm to obtain clarified extracts with phase separation suitable for downstream analysis. The supernatant was re-treated with magnesium sulphate to improve extraction efficiency, followed by clean-up with PSA sorbents (e.g., Supelclean PSA, Bond Elut PSA) to mitigate matrix effects while maintaining solvent economy and throughput consistent with process monitoring needs.

2.5. Instrumentation and Acquisition

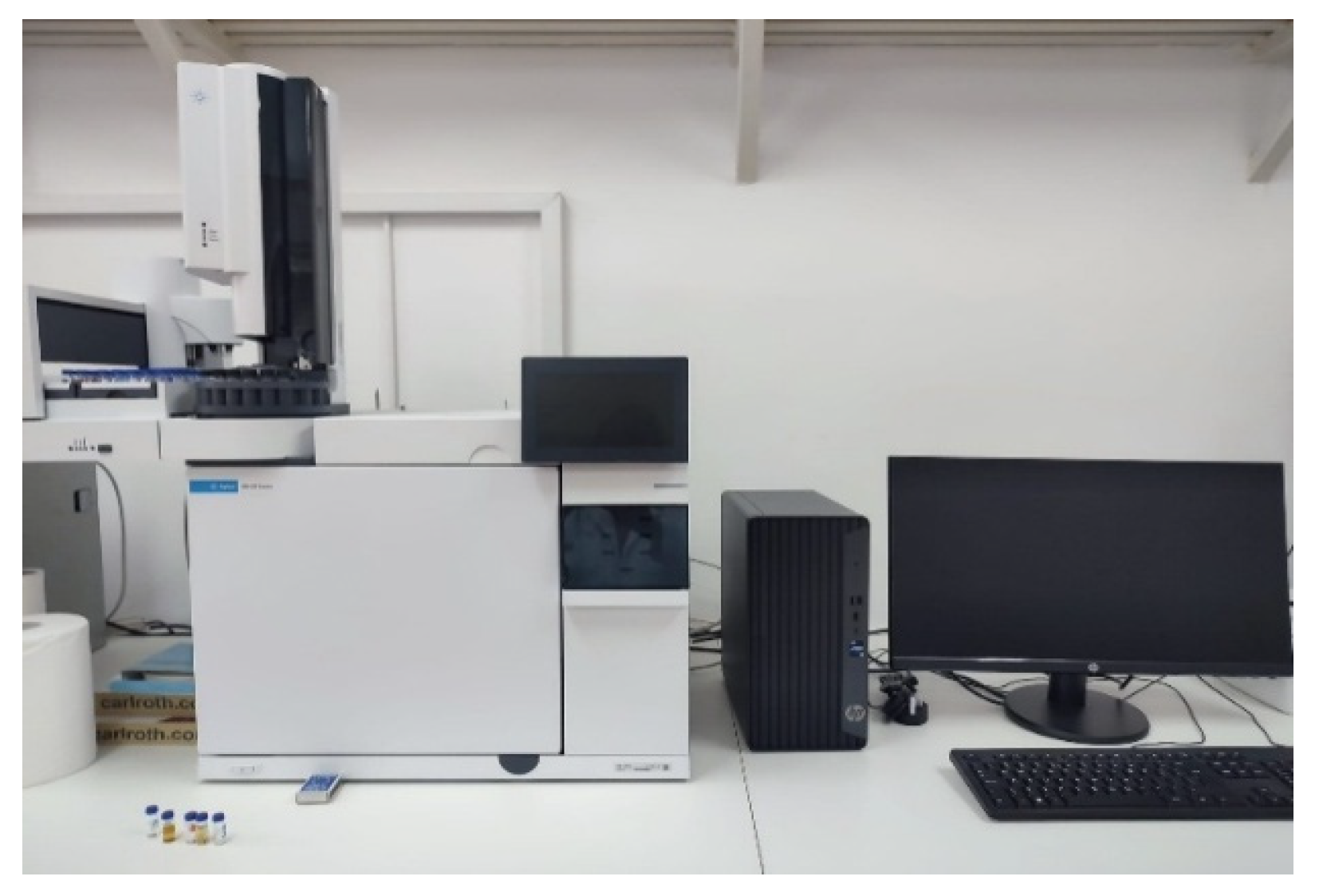

Determinations used complementary platforms: LC-MS/MS (Shimadzu LCMS-8050) for polar and thermolabile analytes and GC-MS (Shimadzu GCMS-TQ8040) for volatile and semi-volatile classes, providing broad coverage at trace levels for decision-relevant monitoring. Acquisition employed multiple reaction monitoring (LC-MS/MS) and appropriate GC-MS modes to maximize selectivity and sensitivity, with method settings optimized to balance LOQ, selectivity, runtime, and maintenance burden for routine industrial laboratory deployment.

2.6. Method Validation and Quality Control

Validation encompassed linearity, recovery/accuracy, precision (intra-/inter-day RSD), matrix effects, LOD/LOQ, carryover, and retention/ion ratio tolerances, following practices suitable for multi-residue analyses in complex matrices and for process monitoring contexts. QA/QC included procedural blanks, matrix-matched calibration, multi-level spike recoveries, and verification of identification criteria to ensure measurement uncertainty was compatible with risk decision thresholds in the occupational framework. Comprehensive validation results for linearity, calibration curves, recovery, precision, matrix effects, blank/spike analyses, and pass/fail criteria are presented in

Table 1,

Table 2,

Table 3 and

Table 4. These include representative calibration parameters (R

2 values for each analyte), recovery and relative standard deviation (RSD) for spiked samples, quantitative matrix-effect percentages, blank and spike levels, as well as method acceptance criteria. For details, see

Table 1 (calibration and linearity),

Table 2 (recovery and precision),

Table 3 (matrix effect, LOD/LOQ and blank), and

Table 4 (blank and spike results).

2.7. Data Processing and Reporting

Target confirmation relied on retention behavior and qualifier/quantifier ion ratios with predefined tolerances to limit false positives while preserving detection power for trace organochlorines and other classes. Concentrations, associated uncertainty, and QC outcomes were compiled and mapped to decision triggers for risk categorization, control prioritization, and monitoring frequency, enabling a closed loop between measurement and action.

The LOD and LOQ for each compound were determined via matrix-matched calibration and recovery experiments, following SANTE/11312/2021 guidelines, using spiked blank samples and regression analysis. All concentrations and quantification limits are reported in mg/kg throughout the manuscript.

2.8. Process Performance Metrics

Operational indicators were tracked to align with Processes’ process-orientation, including cycle time per batch, cost per sample, instrument uptime, re-run rates, and robustness under routine conditions, enabling transparent trade-offs among sensitivity, throughput, and cost. These metrics informed recommendations on sampling cadence, resource allocation, and maintenance schedules, supporting sustainable and scalable monitoring within occupational risk management programs.

2.9. Risk Assessment Linkage and Decision Matrix

Occupational risk followed institutional best practices comprising hazard identification, dose–response assessment, exposure assessment, and risk characterization, providing a reproducible foundation for decision-making and communication. Analytical outputs were translated into a toxicity–probability matrix and aligned to the HSE hierarchy of controls (elimination, substitution, engineering and organizational measures, PPE) with continuous improvement, ensuring analytics and control operate as a unified decision system.

2.10. Application Example and Interpretation

In the representative soil sample, total HCH measured 0.003 mg/kg and total DDT (DDD + DDE + DDT) measured 0.010 mg/kg, serving as process signals to escalate controls, adjust monitoring intervals, and guide targeted interventions within validated LOQs and QC criteria. These values were interpreted with method performance indicators to ensure that control decisions were both analytically defensible and operationally sustainable for process management.

2.11. Figures (Guidance for Captions)

Figure 1 presents the advanced gas chromatography-mass spectrometry (GC-MS) equipment used for the qualitative and quantitative analysis of pesticide residues in food samples. The system enables the separation of chemical compounds in the gas phase and their precise identification based on molecular mass and structure. The inclusion of an automated sample injection system enhances both the accuracy and reproducibility of results.

Figure 2 (automated extraction unit): Highlight parallel extraction capacity, solvent handling safety, and contributions to cycle time and reproducibility as process performance drivers.

The presence of labelled chemical reagents and glassware, along with the closed-loop design and programmable interface, ensures safe handling of solvents and compliance with good laboratory practice (GLP). This equipment is essential for efficient sample preparation prior to chromatographic and mass spectrometric analysis.

3. Results

This section reports analytical findings and their direct translation into occupational risk categories, control priorities, and monitoring cadence within a process-integrated framework. Where applicable, results are presented alongside quality status and process performance indicators to support monitoring-and-control objectives.

3.1. Risk Matrix Outputs for Worker Exposure

A toxicity-probability risk matrix was constructed to map analytical signals and workplace conditions to operational risk categories and control priorities. The matrix is reported below as an outcome artifact used in decision-making, not as a method description.

Table 1 aims to support decision-makers in industry in allocating protective resources and designing staff training strategies. The scores assigned to each category are based on literature data regarding the toxicological properties of pesticides and on observations of actual working conditions, including the frequency of handling substances, task types, and the degree of use of personal protective equipment.

The occupational risk for exposure to pesticides was quantified using a toxicity-probability matrix based on a semi-quantitative scoring scheme. Probability and toxicity categories were assigned numeric values and threshold criteria, as shown in

Table 5. The risk score is calculated as the product of Probability Score and Toxicity Score, guiding risk classification and control priorities for each scenario.

Analytical signals from the representative soil sample (total HCH 0.003 mg/kg; total DDT 0.010 mg/kg) were combined with observed work practices and task frequency to populate matrix cells for relevant worker scenarios, enabling a ranked list of controls and monitoring cadences by scenario.

Scenarios landing in “Critical risk” triggered immediate actions: restricted access to contaminated areas, mandatory advanced PPE, local exhaust ventilation/dust control, intensified housekeeping, and short-interval environmental sampling with biomonitoring where feasible.

“High risk” scenarios prompted engineered and organizational measures with targeted training and interim PPE reinforcement; “Moderate” and “Low” risk scenarios were managed by routine controls and periodic verification.

The matrix served as the live decision register for allocating protective resources, scheduling task-specific training, and setting re-sampling intervals.

3.2. Exposure Pathways and Critical Control Points

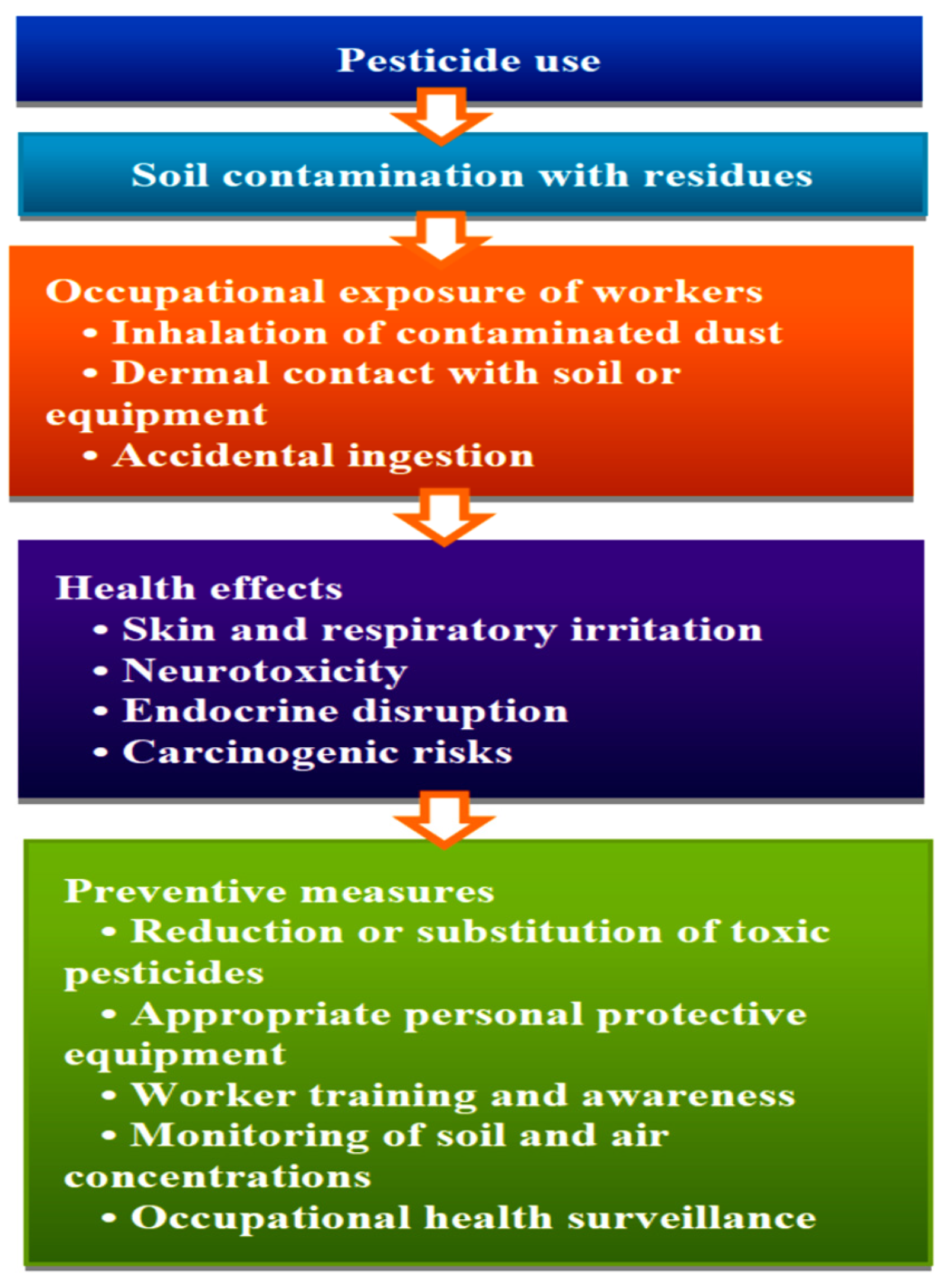

The cause–effect diagram (

Figure 3) was operationalized to identify critical control points (CCPs) along the pathway from pesticide use to worker exposure and health effects:

Source CCPs: selection/substitution of products and optimization of application to minimize residue carry-over and dust generation; spill control and equipment hygiene.

Pathway CCPs: dust abatement (local exhaust, enclosure), workflow sequencing to avoid re-entry to freshly contaminated zones, and PPE compliance for dermal and inhalation routes.

Outcome CCPs: medical surveillance and biomonitoring for exposed roles, with trigger thresholds aligned to the risk matrix outputs. These CCPs were linked to the decision matrix so that each risk cell corresponded to a predefined bundle of controls and a verification plan.

3.3. Monitoring Performance and Operational KPIs

To support process control and continuous improvement, the monitoring program tracked the following key performance indicators (KPIs):

Analytical performance: batch cycle time, re-run rate, instrument uptime, and matrix-matched QC pass rate.

Operational efficacy: time-to-decision after result release, time-to-implement control actions, and adherence to scheduled re-sampling.

Safety observables: PPE adherence rate during high-risk tasks, number of near-miss reports related to dust/contact, and closure time for corrective actions. Where applicable, KPI trends were reviewed quarterly to tune sampling cadence, refresh training, and adjust engineering controls.

The conceptual model begins with the primary source represented by the use of pesticides in industrial or agricultural processes. This use involves frequent handling of chemical substances, preparation of solutions, and their application in fields or production facilities. From here arises the possibility of soil contamination and the generation of persistent residues that can serve as continuous sources of exposure.

From this source, the diagram highlights the main trajectory of risk towards worker exposure. Exposure occurs in several forms, including inhalation of contaminated dust particles, direct dermal contact with soil or equipment, and accidental ingestion due to poor hygiene practices. This part of the model underscores the essential role of working conditions and worker behaviour, factors that can significantly increase or reduce the probability of exposure.

In the final stage of the diagram, the health effects resulting directly from uncontrolled exposure are presented. The specialist literature identifies multiple consequences, ranging from skin and respiratory irritation to systemic effects such as neurotoxicity, endocrine disruption, or even carcinogenesis in cases of chronic exposure. The model highlights the direct link between environmental contamination in the workplace and workers’ health status, emphasising the responsibility of industrial management to prevent these effects.

Complementing the cause–effect diagram, the research integrates preventive measures associated with each stage. At the source level, recommendations include reducing the use of hazardous pesticides through substitution with less toxic alternatives or by rationalising application practices. At the exposure stage, measures focus on worker training, appropriate use of personal protective equipment, and periodic monitoring of concentrations in air and soil. Regarding health effects, preventive strategies include occupational health surveillance programmes and prompt interventions in cases of accidental contamination.

The data analysed in this study derive from a selection of reports and studies published between 2022 and 2024, to ensure the relevance and currency of the information. The main sources included reports from the International Labour Organization, national statistics provided by labour inspectorates, publications from the World Health Organization, and European agencies specialising in occupational health and safety. In addition, case studies and scientific articles indexed in databases such as Scopus and Web of Science were consulted, documenting accidents and incidents related to pesticide use in various industries. This approach enabled the correlation of official data with detailed field-level information, offering a more nuanced picture of the frequency, severity, and causal factors of these occupational accidents. To illustrate these aspects, the research includes a comparative

Table 6, presenting the number of accidents and incidents related to pesticide handling across different industrial sectors. The data are extracted from official reports and case studies, providing a clear perspective on inter-industry differences and risk patterns.

Table 6 highlights important differences between sectors. Agriculture reports the highest number of accidents, reflecting the frequent and large-scale use of pesticides, often under exposed working conditions with limited resources for personal protection. Meanwhile, the chemical industry shows a significantly higher proportion of severe incidents, indicating the inherent risks of production processes and handling concentrated substances.

In addition to the comparative industry data, the research also proposes a graphical representation of the evolution over time of reported accidents in agriculture and the food industry, two sectors with intensive pesticide use. This trend shows a slight decrease in recent years, partly due to improved regulations and training measures, yet maintains a significant level of incidents that demand ongoing attention.

Table 6 highlights annual trends and allows the identification of periods or agricultural campaigns with higher risk, supporting the planning of seasonal preventive measures and the allocation of resources for worker training before peak activity periods. This preventive approach is essential for reducing the number of accidents and limiting the consequences for workers’ health.

Analysis of incidence and severity rates suggests that not only the frequency of incidents should be monitored, but also their nature. Minor incidents may indicate deficiencies in the use of protective equipment or adherence to working procedures, often serving as precursors to more serious accidents if not properly addressed. On the other hand, severe incidents, which may involve hospitalisation or fatalities, demand immediate interventions and strict risk control measures.

By integrating these statistics into occupational risk assessment, a solid basis is established for defining prevention strategies tailored to each industrial sector. Understanding the differences in risk profiles between industries enables the development of customised training plans and the efficient allocation of resources to protect workers. Thus, statistical analysis is not merely a descriptive exercise but becomes an active tool supporting occupational safety management.

3.4. Control Actions and Verification (Measurement-to-Action)

Controls implemented as a direct consequence of matrix outputs included targeted substitution, optimization of application practices, local exhaust ventilation and dust control, enhanced housekeeping, task-specific PPE standards, and focused training. Verification comprised:

Environmental re-sampling at matrix-defined intervals.

Spot checks of task execution and PPE compliance.

If available, biomonitoring for sentinel roles to confirm exposure reduction. Verification findings fed back into the matrix to recalibrate risk categories, sampling frequency, and control intensity, closing the monitoring-and-control loop.

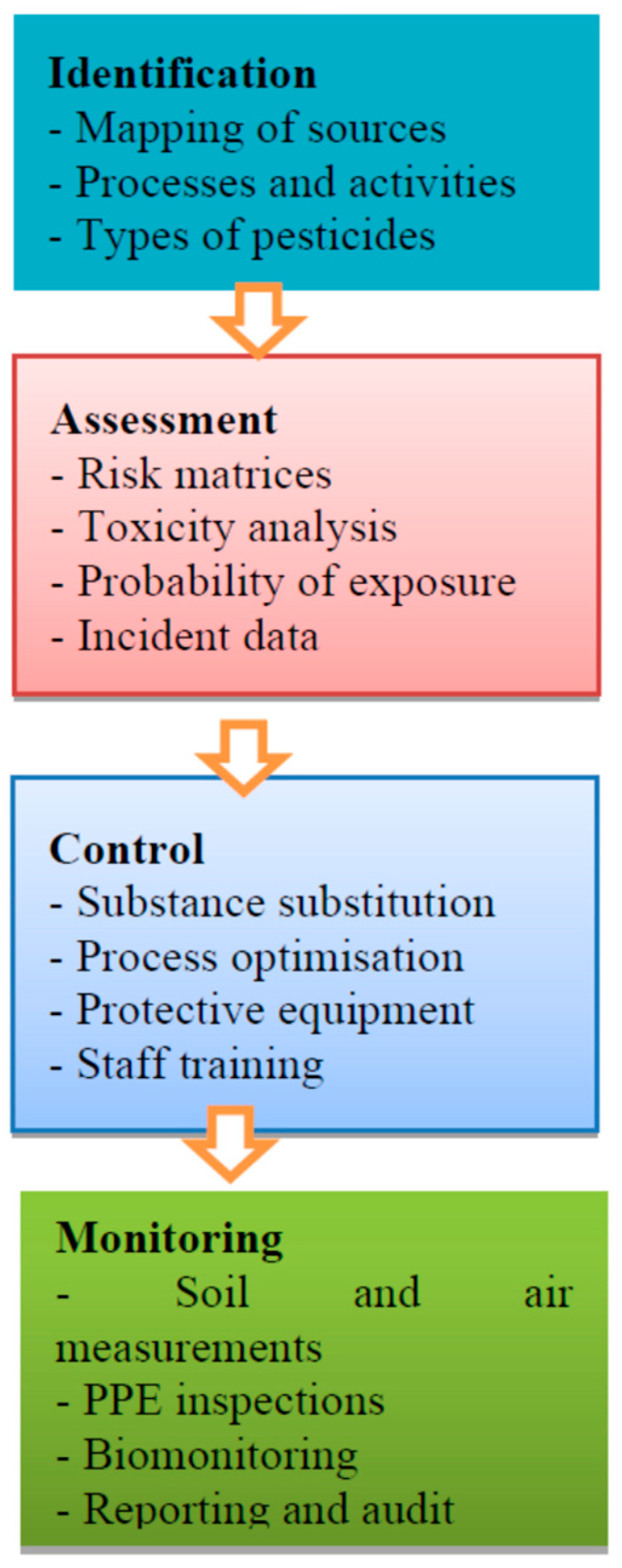

Managing occupational risks associated with pesticide use in industrial settings requires a structured and systematic approach that ensures not only the identification of hazards but also the consistent application of preventive and control measures. The risk management framework proposed in this study is inspired by established international models and has been adapted to the specific nature of activities where pesticide exposure represents a major risk factor.

Key performance indicators (KPIs) were tracked monthly to guide escalation or de-escalation of controls. For example, if the pesticide exceedance rate exceeded 5% for consecutive months, targeted training and reinforced PPE were triggered. When the rate dropped below 2% and PPE compliance exceeded 95% for three consecutive months, standard monitoring was restored.

Table 7 shows before-and-after KPI values illustrating the impact of intervention.

The conceptual model is based on four essential steps: hazard identification, risk assessment, implementation of control measures, and continuous monitoring. This logical sequence ensures a coherent and iterative process, capable of accommodating technological, legislative, and behavioural changes over time (

Figure 4).

In the hazard identification stage, sources of soil contamination with pesticides, industrial processes involved, and handling practices that may generate occupational exposure are mapped. This analysis requires collaboration between occupational safety specialists, process engineers, and operational staff to ensure that all potential sourcesincluding secondary or unintended onesare identified.

The risk assessment stage involves detailed analysis of the combination of pesticide toxicity and the probability of exposure under real working conditions. This can be carried out using risk matrices, probability charts, and empirical data on reported incidents. The assessment considers not only the chemical properties of the substances but also task frequency, the level of worker training, and the use of personal protective equipment.

The implementation of control measures represents a critical stage in the risk management framework. Technical measures include substituting pesticides with less toxic alternatives, optimising application processes to reduce losses, and restricting access to contaminated areas. Organisational measures involve periodic worker training, developing standardised procedures, and enforcing compliance with safety rules. Individual measures, such as the correct use of personal protective equipment, also play an essential role in reducing exposure.

Continuous monitoring closes the loop of this risk management process. It involves periodic measurements of pesticide concentrations in soil, air, or dust; regular inspections of protective equipment; and occupational health assessments through biomonitoring or routine medical check-ups. Monitoring serves to detect deviations from standards and allows for the rapid adjustment of control measures.

To support the implementation of this framework, the research also proposes a conceptual infographic illustrating the key steps in an accessible form that can be easily adapted to different industries. The infographic can be customised to the specific context of each production facility, making it a practical tool for worker training and for communicating safety policies.

3.5. Case Application of Soil Signals

The representative soil signals—total HCH 0.003 mg/kg and total DDT (DDD + DDE + DDT) 0.010 mg/kg—were treated as process signals rather than endpoints. For tasks with medium or high probability of exposure (e.g., soil disturbance, dusty handling of contaminated materials), the matrix classified scenarios between Moderate and High risk, triggering proportional controls and short-interval verification. For low-probability scenarios (e.g., indirect or infrequent contact), routine controls and periodic monitoring were maintained.

Examples of best practice identified in industry confirm the effectiveness of this integrated approach. Some companies have implemented progressive substitution programmes, replacing toxic pesticides with biological or lower-toxicity alternatives. Other organisations have developed extensive training and certification programmes for operators handling chemical substances, significantly reducing human error. There are also examples of advanced monitoring, where air and soil sensors transmit real-time data to a centralised risk management system, enabling rapid response in the event of exceeding permissible limits.

By applying this risk management framework, the industry can shift from a reactive approach focused on responding after accidents occur to a proactive and preventive one that places worker health at the forefront while also contributing to environmental protection. This integrated vision is essential for the sustainable reduction in soil pollution and for ensuring a safe and healthy working environment.

3.6. Interpretation and Decision Relevance

For each analyte, we report detection frequencies, medians (IQR), and bootstrap CIs within validated LOQs, and we treat representative soil signals (e.g., total HCH 0.003 mg/kg; total DDT 0.010 mg/kg) as process inputs to the toxicity–probability matrix rather than endpoints. The resulting risk score Risk = P × TRisk = P × T increases monotonically across concentration deciles (Spearman ρ), and logistic/ordinal models quantify the odds of High/Critical cells per concentration unit within method uncertainty bounds, underpinning KPI-based escalation/de-escalation of controls and resampling cadence (

Table 8).

5. Case Studies

The analysis of occupational risks associated with pesticide use in industry is complemented by case studies that provide a concrete perspective on the impact of these substances on workers’ health. Presenting real-world examples helps to understand the mechanisms through which exposure occurs in practice and highlights the effectiveness or limitations of implemented preventive measures.

The first case study comes from the agricultural sector, where intensive pesticide use is common practice, especially in vegetable and fruit crops destined for export markets. In an agricultural cooperative in southern Europe, a group of seasonal workers reported an increased incidence of respiratory and dermatological symptoms during the pesticide application period. Investigations revealed soil and dust contamination with organophosphorus residues, confirmed through GC-MS instrumental analyses. Voluntary biomonitoring of workers identified specific metabolites in urine samples, demonstrating systemic exposure.

The main causes were linked to the lack of adequate personal protective equipment, insufficient training, and economic pressure to complete work quickly. In response, farm management implemented a structured training programme in the workers’ native language, purchased certified protective equipment, and reorganised work schedules to reduce exposure during peak hours. One year after implementation, medical checks showed a significant reduction in reported symptoms and in biomarker levels of exposure. This example clearly demonstrates that simple, context-adapted control measures can have a major impact on occupational health.

Another example comes from the food processing industry, where pesticides are used indirectly through the handling of contaminated raw materials. In a cereal processing facility, workers in the unloading area frequently experienced eye and respiratory irritation. Dust analyses indicated the presence of pesticide residues from treatments applied before harvesting. Although levels did not exceed legal limits for the finished product, concentrations in the working area air were sufficient to cause symptoms with repeated exposure.

The company decided to install local exhaust ventilation systems, implement a strict cleaning protocol for the unloading area, and provide workers with appropriate filter masks. Training sessions were also conducted on safe handling of treated cereals and the importance of personal hygiene. After these measures were implemented, the number of reported irritation cases fell significantly, and subsequent air quality assessments confirmed reduced concentrations of pesticides in dust.

These case studies highlight the direct link between industrial practices and risks to workers’ health, underscoring the importance of accurate exposure assessment and the application of tailored measures. They demonstrate that reducing occupational risks is not a theoretical exercise but a concrete process requiring collaboration between management, workers, and occupational health specialists. By learning from these examples, other industrial facilities can adapt and implement effective solutions to protect health and safety in the workplace.

5.1. Determination of Pesticide Residues in Potato Samples Using the QuEChERS Method and Advanced Chromatographic Techniques

Figure S1, preparation of vials for chromatographic analysis of pesticide residues, captures the essential step of loading the vials into the chromatographic system coupled with mass spectrometry, an integral part of the analytical process for determining pesticide residues in food samples. Handling the vials with protective gloves reflects strict adherence to laboratory hygiene and safety protocols, preventing any contamination that could negatively affect the accuracy of analytical results.

The orderly arrangement of vials in the instrument rotor ensures optimal equipment performance, enabling automated, repeatable, and precise analysis of a large number of samples. This stage is important for maintaining sample integrity and ensuring an efficient analytical sequence, minimising human error and experimental variability. Through the use of a modern chromatographic system, which combines advanced gas or liquid chromatography with mass spectrometric detection, chemical residuesincluding those from pesticide groupscan be accurately identified and quantified. This image thus reflects a key moment in the analytical process, demonstrating the complexity and methodological rigour required for safe food quality assessment and consumer health protection.

Figure S2 captures the critical weighing stage in the analysis of pesticide residues in potatoes, performed using a high-precision analytical balance. This step is essential for ensuring the quantitative accuracy of the analysis, as the exact sample mass directly influences the validity of subsequent results. The potato sample is carefully transferred into the weighing vessel using a metal spatula to prevent any contamination or material loss.

The precise mass, displayed on the balance screen (4.3432 g), forms the foundation for the following QuEChERS homogenisation and extraction stage, where pesticide residue concentrations will be determined. As such, this preliminary step is fundamental to the overall success of the analytical process and to obtaining reliable and relevant data for food safety assessment.

Figure S3 shows a homogenised potato sample placed in a sealed container, prepared for the subsequent extraction and analysis of pesticide residues. Homogenisation is an important step in the analytical methodology, ensuring uniform distribution of chemical compounds within the sample so that analyses are both representative and reproducible. The airtight container prevents contamination and the loss of volatile substances, preserving sample integrity until chromatographic analysis. This stage is fundamental for obtaining accurate results regarding the presence and concentration of pesticides in potato tubers, thus contributing to the reliable assessment of food quality.

Figure S4 shows the interior of a refrigerated centrifuge during the centrifugation of samples prepared for pesticide residue analysis. The samples, placed in sealed vials with blue caps, are secured in the rotor to ensure stability and balance during high-speed rotation. Centrifugation under controlled temperature conditions enables the separation of the sample’s component phases, facilitating the collection of a clear extract essential for the accuracy and sensitivity of subsequent chromatographic analysis.

This step is fundamental for removing solid particles and impurities, ensuring an optimal sample for the precise determination of pesticide levels in food samples. Furthermore, maintaining a low temperature prevents the degradation of sensitive compounds, contributing to the analytical integrity of the results.

Figure S5 illustrates the weighing process of a homogenised potato sample, prepared for the extraction and determination of pesticide residues. A high-precision analytical balance is used, with a sensitivity of up to 0.0001 g, ensuring accurate measurement of the sample’s mass, which in this case is 10.0047 g. Precise weighing is a fundamental step in the analytical process, as it guarantees the correct dosage for the extraction of target chemical substances and contributes to the reproducibility and accuracy of the final results.

The sample container is sealed and suitable for laboratory handling, while the clean surroundings reflect adherence to strict hygiene standards and good laboratory practices. This step prepares the sample for the subsequent analytical stages, such as QuEChERS extraction and chromatographic analysis, both essential for food safety assessment.

Figure S6 highlights the precise dosing operation of samples prepared for pesticide residue analysis, using an automated micropipette. This step is essential for the accurate transfer of small liquid volumes into analysis vials, ensuring consistency and precision in the analysed concentrations. The use of protective gloves underscores compliance with laboratory hygiene and safety standards, preventing sample contamination and safeguarding the operator.

The arrangement of vials in specialised holders contributes to workflow efficiency and minimises handling errors. This step prepares the samples for chromatographic analysis coupled with mass spectrometry, which is critical for the accurate identification and quantification of pesticides in food samples.

Figure S7 shows the centrifuge rotor used for phase separation in liquid samples extracted from potatoes. The samples are stored in blue-capped vials, securely fixed in the rotor to ensure balance and stability during high-speed rotation. Centrifugation is a critical stage in the analytical process, facilitating the separation of solids from liquids and the clarification of the extract—conditions essential for the accuracy of subsequent chromatographic analysis.

Figure S8 captures the solvent dosing stage, carried out using a volumetric pump to ensure precision in liquid handling during the extraction process. This step is essential for the correct preparation of samples, guaranteeing the exact solvent volume required to efficiently extract pesticide residues from the food matrix. The use of automated equipment minimises the risk of human error and enhances method reproducibility.

The operator’s hands are equipped with protective gloves, emphasising adherence to safety regulations when handling potentially hazardous chemicals. The entire procedure takes place within a controlled laboratory environment, ensuring the integrity and accuracy of the samples for subsequent chromatographic analysis.

The results of the analysis indicate the presence of low concentrations of organochlorine pesticide residues in the tested soil sample (

Table 9). The total concentration of HCH (hexachlorocyclohexane isomers) was 0.003 mg/kg, while the total DDT (including its metabolites DDE and DDD) reached 0.010 mg/kg. The measured concentrations for total HCH (0.003 mg/kg) and total DDT (0.010 mg/kg) were above the validated LOQ (0.5 mg/kg), thus considered reliably quantifiable according to method criteria.

The use of a standardised analytical method (SR ISO 10382) ensures the accuracy and reliability of the results,

Figure 5. The low levels detected may be indicative of historical pesticide use, as organochlorine compounds are known for their persistence in the environment. However, the current concentrations do not raise immediate concerns regarding soil quality or potential environmental risk.

The controlled laboratory conditions and certified instrumentation further reinforce the validity of the findings. Such data are essential for environmental monitoring and support informed decision-making in agricultural management and food safety assessment.

5.2. Regulations and Standards

Managing occupational risks associated with pesticide use cannot be separated from the legislative framework that sets exposure limits, employer obligations, and workers’ rights. National and international regulations establish clear requirements for identifying, assessing, and controlling exposure to hazardous chemicals; however, there are significant variations between jurisdictions that can influence the actual level of protection afforded to workers.

To illustrate these differences, this paper presents a comparative table of relevant national and international regulations, highlighting specific requirements and permissible limit levels (

Table 10).

Table 10 highlights that national legislation can show significant variation depending on local resources and implementation capacity. For example, occupational exposure limits may be established or updated less frequently, and there can be challenges in applying them uniformly, especially in small agricultural sectors or informal industries. On the other hand, international frameworks such as REACH in the European Union or OSHA standards in the United States impose more detailed and consistent requirements, supporting more reliable worker health protection.

Soil thresholds reproduced as cited in peer-reviewed Romanian sources; compliant with Order 756/1997; verified with national compilations/agencies’ summaries; accessed 17 June 2025. REACH, as the European legislative instrument, obliges manufacturers and importers to assess the chemical risks of substances placed on the market and to communicate comprehensive information along the supply chain. Its authorisation system also promotes the progressive substitution of hazardous substances with safer alternatives. In the United States, OSHA sets permissible exposure limits (PELs) and requires employers to develop exposure control programmes and ensure regular worker training.

The need for harmonisation of regulations becomes evident, given the free movement of products and migration of labour between countries. Legislative differences can create imbalances in worker protection levels and may encourage less safe industrial practices in regions with weaker regulations. Moreover, rigorous enforcement remains a challenge even where legislation is well developed. Factors such as limited inspection resources, low worker awareness, and economic pressures on employers can lead to neglect of legal obligations.

Discussion around harmonising regulations does not imply imposing a single model but rather adopting shared minimum standards, exchanging best practices, and supporting local administrative capacity. Only through a coordinated approach can an equitable level of worker health protection be ensured globally, while also reducing soil pollution and promoting more sustainable industrial practices.

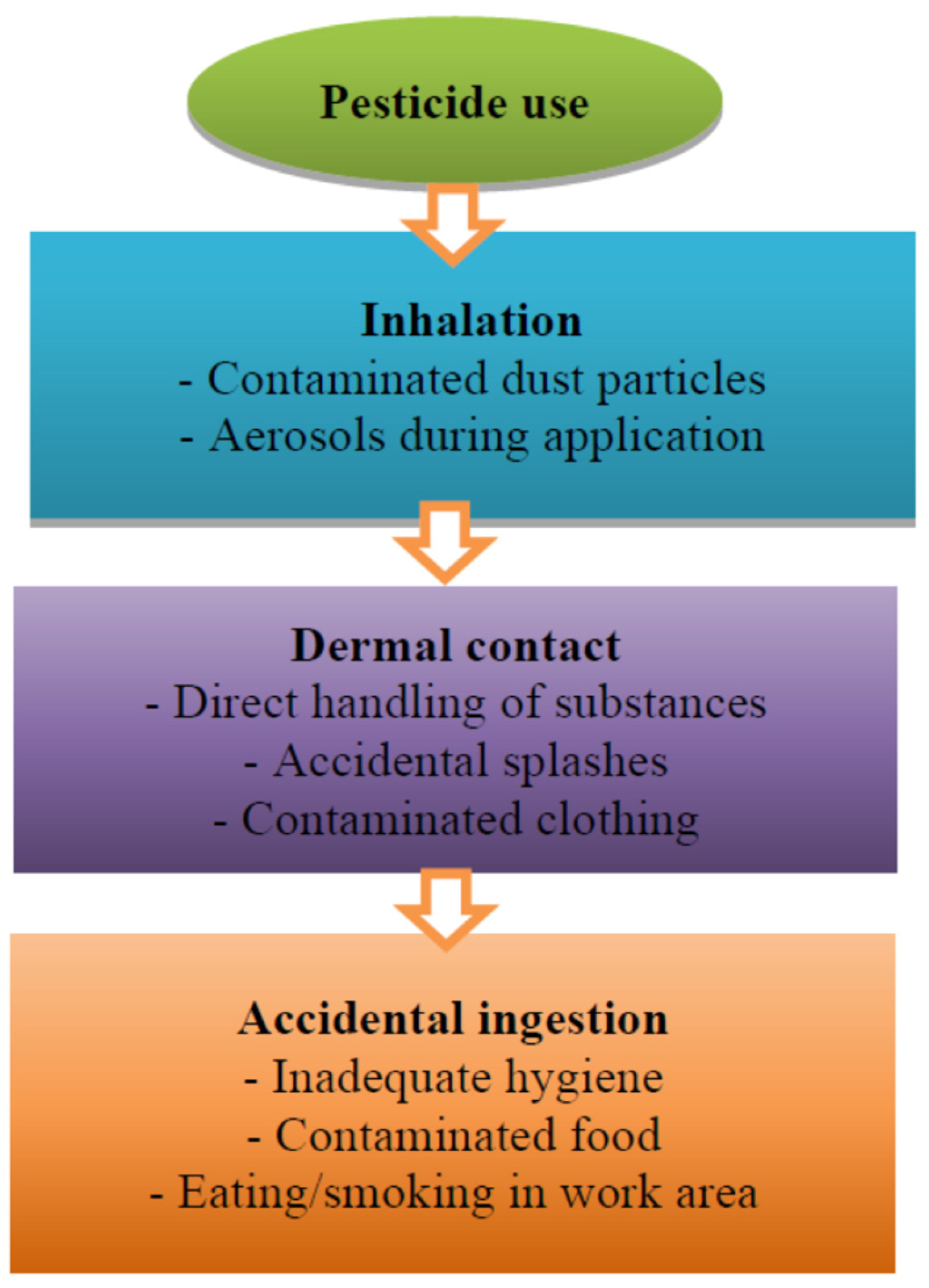

5.3. Forms of Exposure

Exposure to pesticides in industrial and agricultural settings occurs through multiple pathways, which, taken together, define the risk profile for workers and nearby communities. Understanding these forms of exposure is essential for assessing occupational risks and for designing effective prevention strategies.

For clarity, this study proposes a simplified conceptual diagram illustrating the main exposure pathways (

Figure 6).

Figure 6 highlights the three major pathways through which workers may be exposed to pesticides during professional activities. Inhalation is common in processes involving handling of powders or generation of aerosols during application. Dermal contact is a significant route in cases of direct handling, accidental spills, or splashes during applicationespecially when protective equipment is not properly used. Accidental ingestion often results from poor hygiene practices, such as eating in contaminated areas or smoking with dirty hands.

Exposure analysis must also account for vulnerable groups, particularly workers directly involved in pesticide handling, who face the highest risk due to frequency and duration of contact. Additionally, communities neighbouring agricultural or industrial areas can be indirectly affected through soil, water, and air contamination. Passive exposure, though lower in intensity, can have cumulative effects, especially for children and people with pre-existing health conditions.

Aggravating factors include inadequate ventilation in enclosed spaces, which increases vapour or aerosol concentrations; the type of work carried out, with tasks involving repeated direct contact with chemicals; and the lack or improper use of personal protective equipment. Economic pressure, intense work rhythms, and insufficient training also contribute to increased exposure risk.

Understanding these forms of exposure is essential for designing tailored control measures and for reducing occupational risks in a sustainable and realistic way. Only through comprehensive evaluation of exposure pathways can critical intervention points be identified to effectively protect the health of workers and surrounding communities.

5.4. Prevention Strategies

Reducing occupational risks associated with pesticide exposure in industrial settings requires a complex approach that combines technical, organisational, and individual measures. Prevention strategies must be tailored to the specific workplace context and take into account the factors that influence actual exposure levels.

To highlight the main components of these strategies, this study proposes a conceptual infographic that synthesises measures frequently implemented in industry (

Figure 7).

Personal protective equipment represents a first line of defence against direct contact with pesticides, significantly reducing the risk of inhalation, dermal absorption, or accidental ingestion. Correct use of gloves, appropriately filtered masks, protective goggles, and waterproof coveralls is essential for limiting exposure during the application and handling of chemical substances.

Employee training and awareness are critical components in reducing risks. Regular instruction ensures familiarity with the characteristics of the pesticides used, understanding of safe working procedures, and the development of correct handling practices. Information campaigns, simulation sessions, and practical exercises contribute to strengthening a culture of safety among workers.

Clearly defined and well-communicated emergency procedures are another essential element of a prevention strategy. These include clear intervention plans in the event of accidents or accidental exposures, easily accessible decontamination kits, and protocols for rapid contact with medical services. Such measures reduce response times and limit the severity of health effects in the case of unforeseen incidents.

Evaluating the effectiveness of implemented strategies is an indispensable stage for ensuring a process of continuous improvement. This involves monitoring safety indicators, analysing accident and incident data, conducting internal audits, and regularly consulting with workers. The feedback collected contributes to refining procedures, modernising equipment, and enhancing training programmes. Only through constant evaluation and adaptation can it be ensured that preventive measures remain relevant, effective, and capable of protecting workers’ health in the face of the evolving challenges of modern industry.

5.5. Health Impact

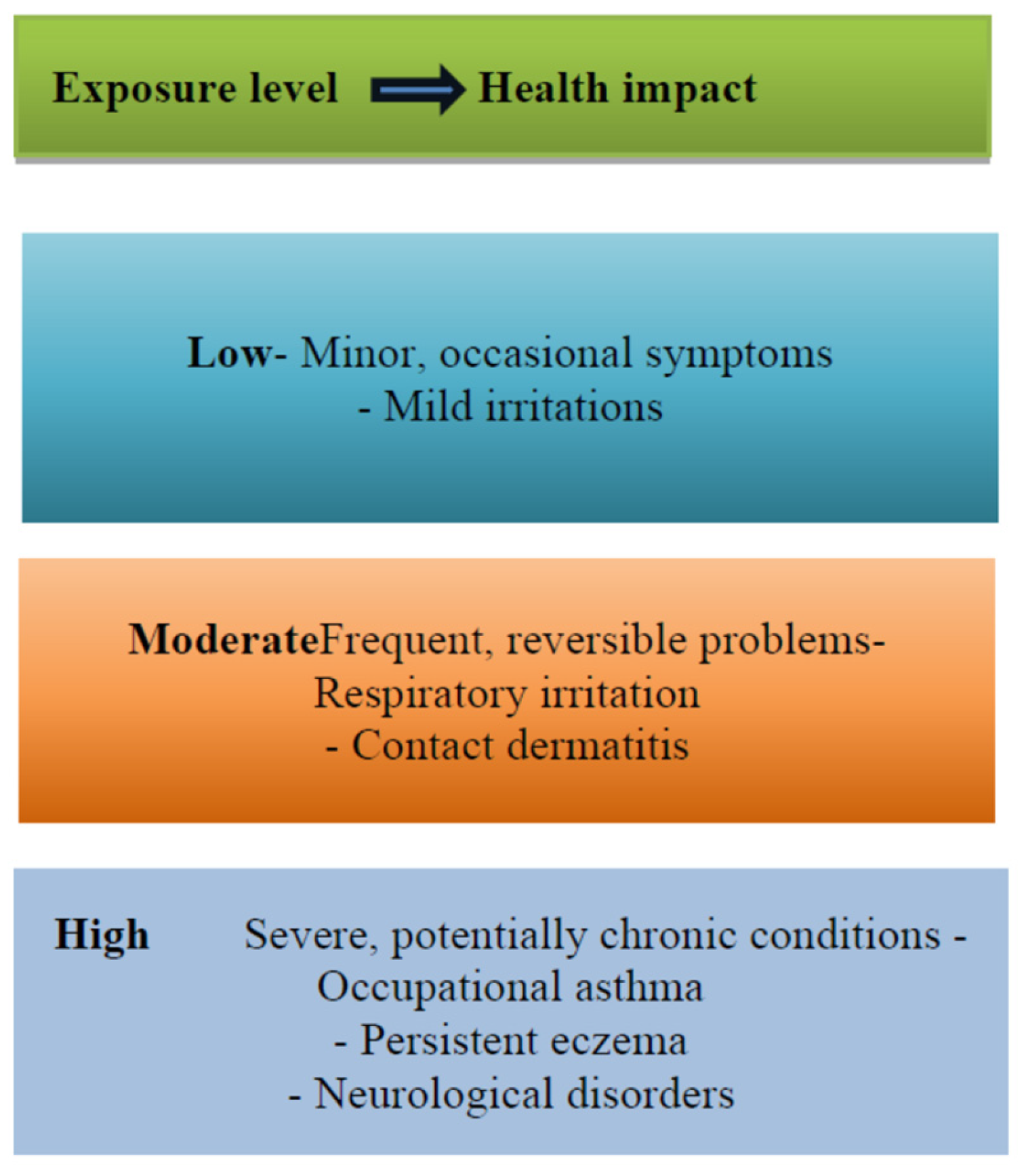

Occupational exposure to pesticides presents a broad spectrum of adverse health effects, reflecting the complex chemical composition of these substances and the diversity of their biological mechanisms of action. Occupational health studies have demonstrated a clear correlation between the degree and duration of exposure and the occurrence of specific medical problems, primarily affecting the respiratory, dermal, and nervous systems.

To clarify this relationship, the research proposes a conceptual chart illustrating the correlation between pesticide exposure level and the main categories of health effects (

Figure S1).

Figure 8 highlights the transition from mild symptoms to chronic pathologies as exposure becomes more intense and frequent. Respiratory conditions are among the most documented effects, ranging from transient mucosal irritation to chronic bronchitis and occupational asthma, caused by inhaling contaminated dust particles or vapours during pesticide application.

Dermatological problems represent another common consequence, with repeated contact with concentrated solutions or contaminated soil leading to allergic or irritant dermatitis. Without appropriate protection and adequate hygiene, these lesions can become chronic and impair work capacity.

Neurological effects, often underestimated, are particularly documented in cases of repeated exposure to organophosphates and carbamates, which can inhibit cholinesterase and disrupt nerve transmission. Symptoms may include headache, dizziness, concentration difficulties, or even peripheral neuropathy in severe forms.

The biological mechanisms involved in these effects are complex and depend on the type of pesticide, route of exposure, and individual worker characteristics. Inhalation facilitates rapid absorption through the lungs’ large surface area, while prolonged dermal contact enables transcutaneous penetration, especially in conditions of high temperature or sweating. Accidental ingestion, though less common, can result in acute exposures with major toxic potential.

Furthermore, some pesticides possess lipophilic properties that promote accumulation in adipose tissues and slow release over time, increasing the risk of chronic effects. Hepatic biotransformation processes can generate reactive metabolites, and certain classes of pesticides are recognised as endocrine disruptors with long-term systemic effects.

Understanding these mechanisms is essential for assessing occupational risks and justifying strict prevention, monitoring, and control measures in industries that use pesticides. Only by integrating data on exposure, health effects, and biological mechanisms can a comprehensive model for protecting workers’ health be developed.

5.6. Exposure Assessment

Occupational exposure assessment for pesticides is a central element of risk management, essential for understanding the link between workplace contamination and worker health effects. This stage involves integrating multiple data sources and complementary methods capable of capturing the real complexity of exposure in industrial or agricultural settings.

To clarify the process, this study proposes a methodological diagram describing the main approaches used in exposure assessment, highlighting the connection between environmental monitoring and worker biomonitoring (

Figure 9).

Environmental monitoring forms a first line of evaluation for exposure sources, involving instrumental analyses of contaminated soil, measurements of pesticide concentrations in air inhaled by workers, and assessments of contamination levels on surfaces or equipment. This approach helps to identify critical risk areas and to support technical control strategies such as local ventilation or cleaning procedures.

Biomonitoring complements this picture by evaluating actual pesticide absorption in the body. Analysis of specific metabolites in urine or blood samples allows estimation of internal doses and highlights cumulative or chronic exposures that may be underestimated by environmental monitoring. Enzyme measurements, such as cholinesterase activity, are particularly used for organophosphate pesticides and provide a sensitive indicator of early biological effects.

Examples from monitoring studies demonstrate the relevance of this integrated approach. In projects conducted on intensive farms, campaigns measured pesticide levels in the air and on workers’ hands, correlated with urinary metabolite analyses. Results revealed discrepancies between measured environmental concentrations and biological doses, suggesting the importance of personal hygiene and correct use of protective equipment. Other industrial studies have documented reduced cholinesterase activity among chronically exposed employees, underlining the need for periodic medical surveillance.

Despite its benefits, this complex evaluation has important limitations. Environmental monitoring may fail to capture individual variability in exposure depending on tasks and work habits. Biomonitoring raises ethical and logistical issues, requires informed consent, and can be costly or invasive. There is also a lack of universally accepted reference values for all pesticides, complicating result interpretation.

Looking forward, integrating real-time sensor technologies, developing more specific biomarkers, and standardising protocols can significantly improve the accuracy and applicability of exposure assessment. Collaboration between employers, workers, authorities, and the scientific community remains essential to transform these tools into genuine support for occupational health protection and the reduction in soil pollution by xenobiotics.