Four-Zone Distribution of Coal Seam Stress in Hard-Roof Working Faces and Its Influence on Gas Flow

Abstract

1. Introduction

2. Numerical Simulation of Overlying Strata Collapse and Stress Distribution

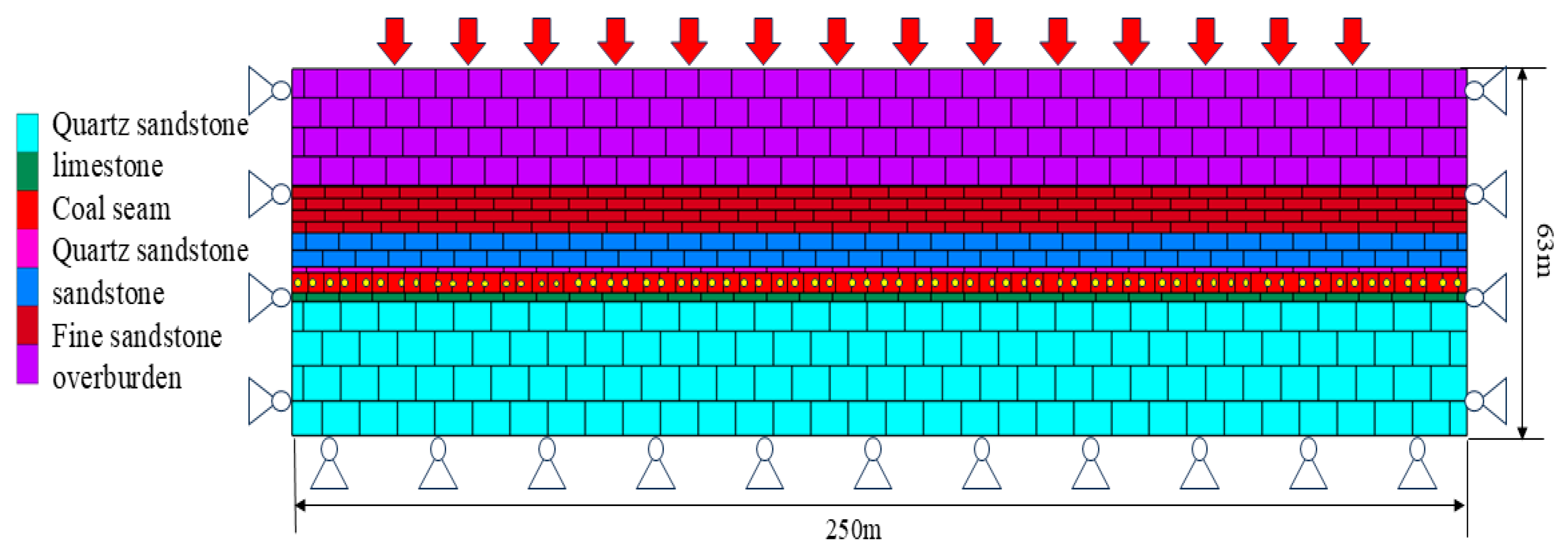

2.1. Numerical Model Establishment

2.2. Analysis of Numerical Simulation Results

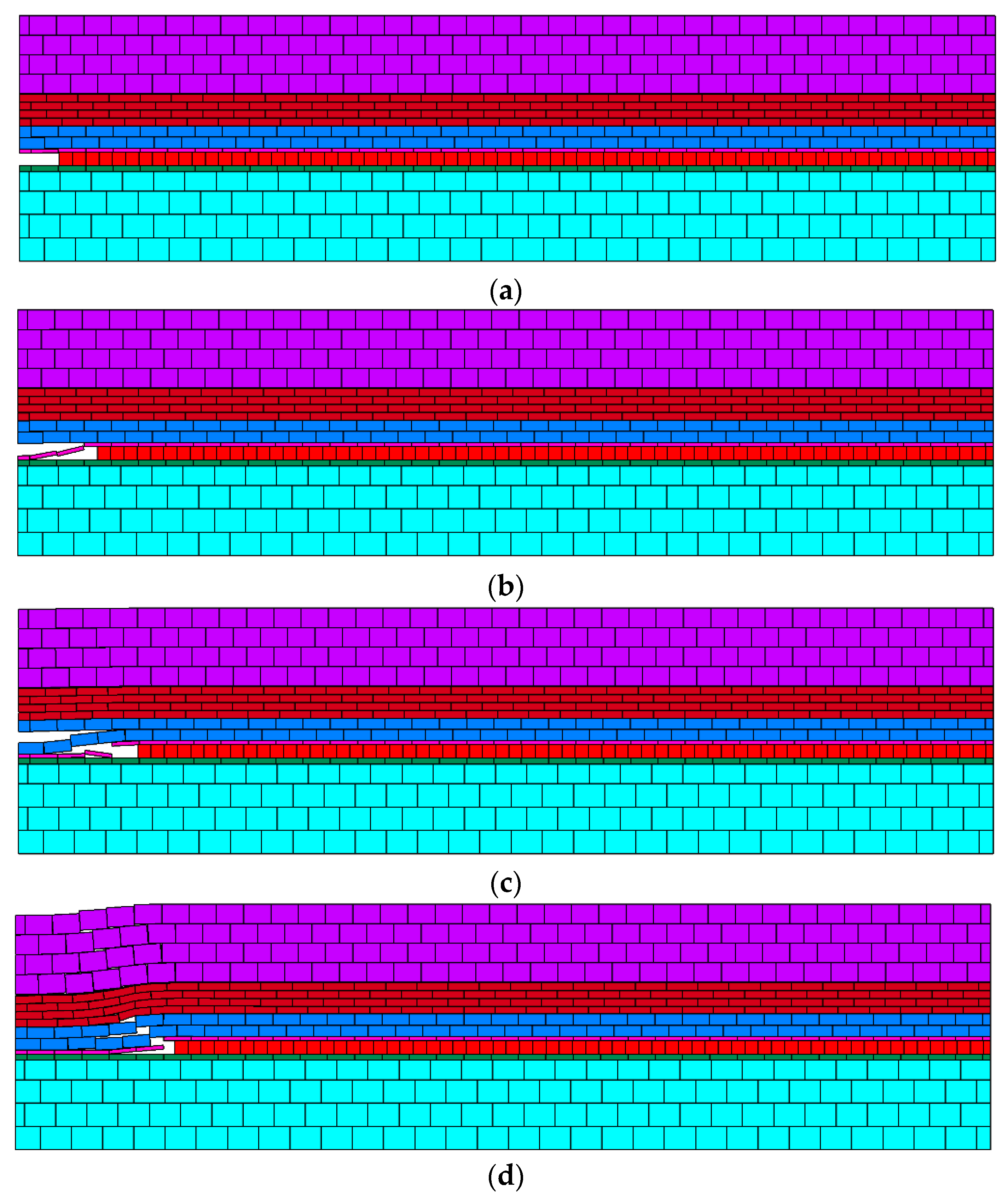

2.2.1. Roof Collapse Characteristics at Different Coal Seam Mining Distances

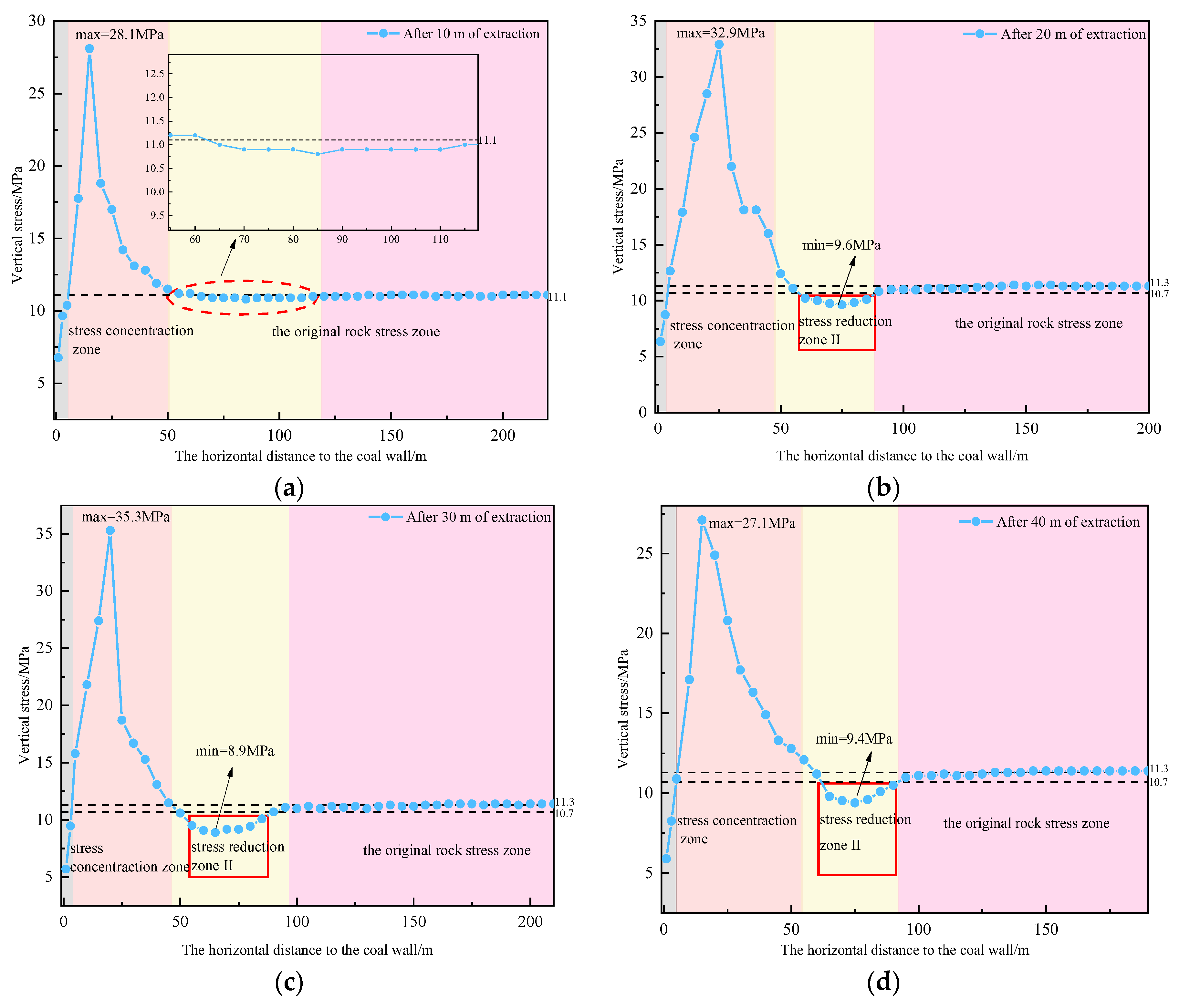

2.2.2. Coal Seam Stress Distribution at Different Mining Distances

3. Numerical Simulation of Stress Effects on Gas Extraction Flow

3.1. Gas–Solid Coupling Model

3.1.1. Stress Field Equation

3.1.2. Seepage Field Equation

3.1.3. Cross Coupling

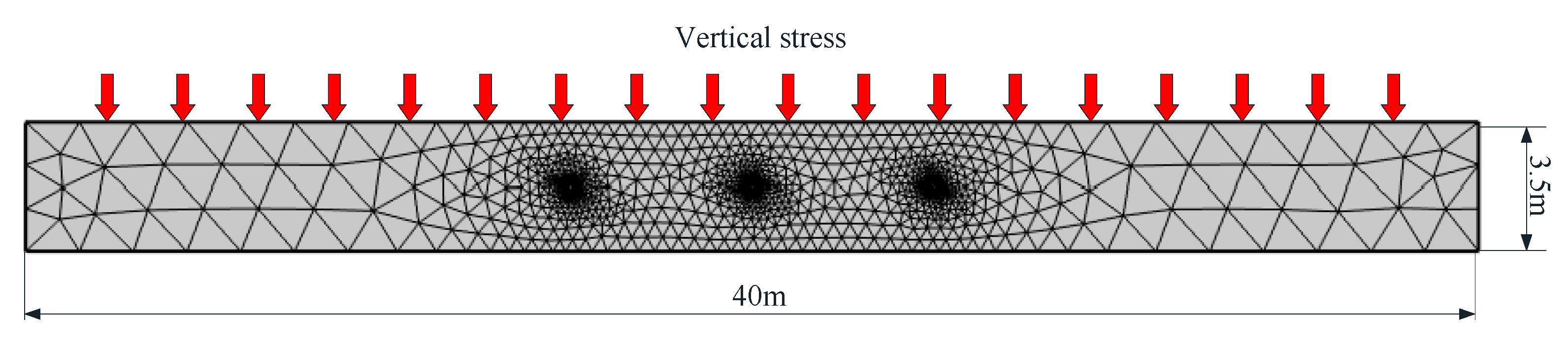

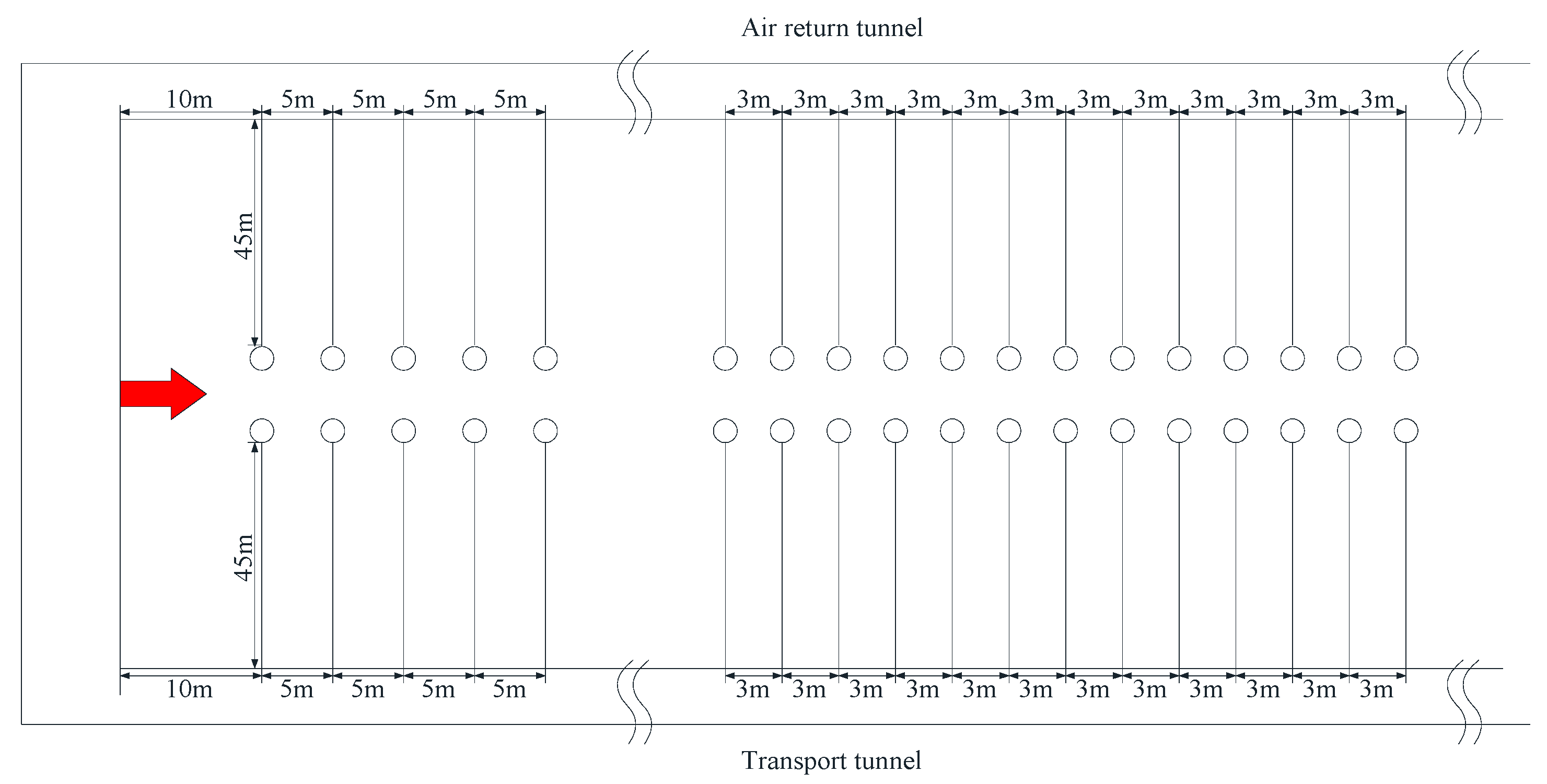

3.2. Numerical Model Establishment

3.3. Analysis of Simulation Results

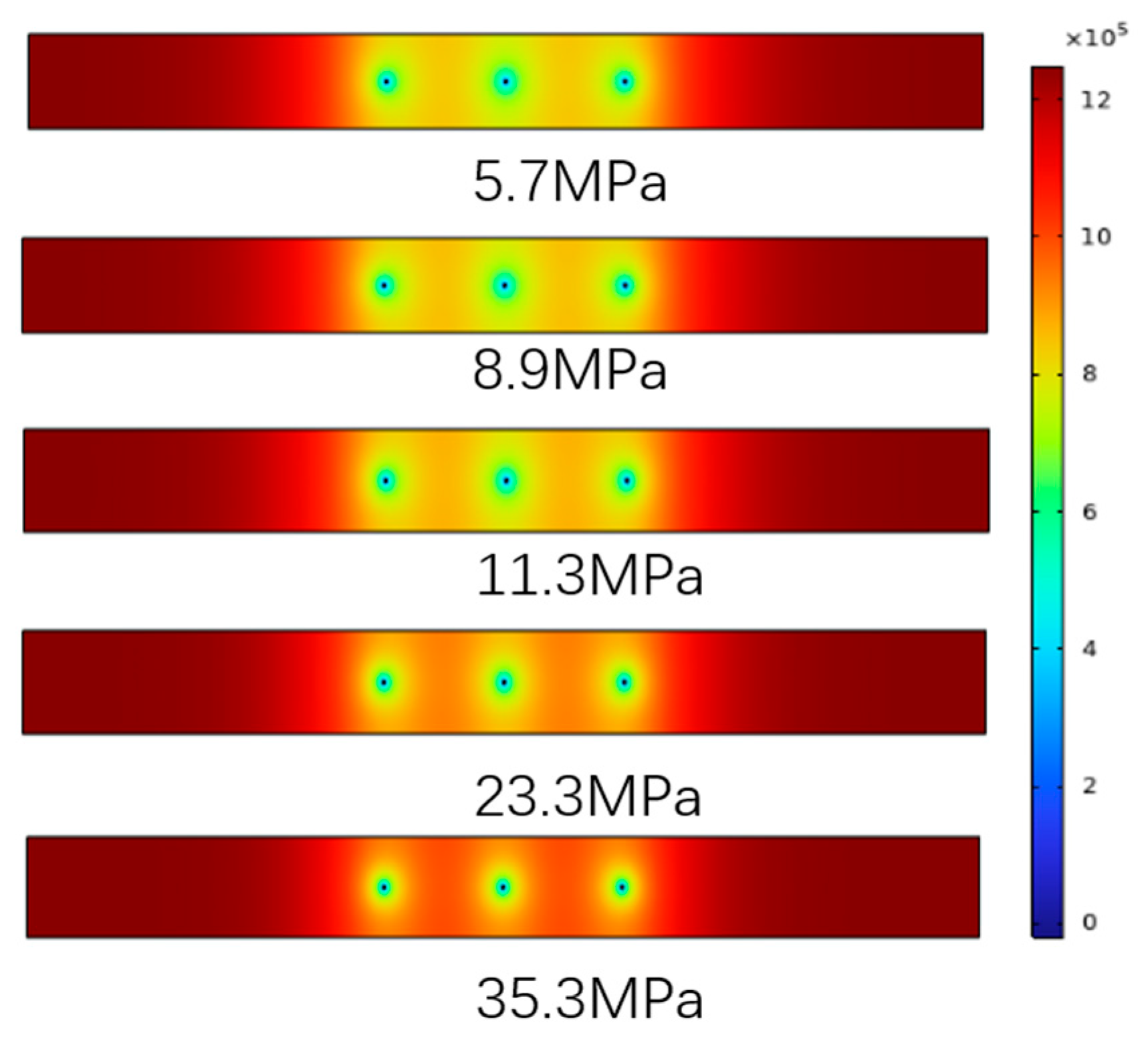

3.3.1. Impact of Stress on Coal Seam Permeability

3.3.2. Impact of Stress on Gas Pressure

4. Field Measurement of Gas Extraction Flow Rate at the Working Face

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kong, S.; Cheng, Y.; Ren, T.; Liu, H. A sequential approach to control gas for the extraction of multi-gassy coal seams from traditional gas well drainage to mining-induced stress relief. Appl. Energy 2014, 131, 67–78. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.Q.; Yang, W.; Liu, T.; Zhai, C. An integrated technology for gas control and green mining in deep mines based on ultra-thin seam mining. Environ. Earth Sci. 2017, 76, 243. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, Y.P.; An, F.H.; Zhou, H.-X.; Kong, S.-L.; Wang, W. Characteristics of gas disaster in the Huaibei coalfield and its control and development technologies. Nat. Hazards 2014, 71, 85–107. [Google Scholar] [CrossRef]

- Dai, X.L.; Gao, R.; Gao, W.C.; Bai, D.; Huang, X. Exploring the Distribution Characteristics of High Static Load in the Island Working Face of Extra-Thick Coal Seams with Hard Roof: Addressing the Challenge of Rock Burst Risk. Appl. Sci. 2024, 14, 1961. [Google Scholar] [CrossRef]

- Jiang, J.Q.; Wang, P.; Zheng, P.; Wu, Q.L. Evolution characteristics of mining-induced fracture and abutment stress under high-position hard thick stratum and its effect on gas migration. J. Min. Saf. Eng. 2017, 34, 624–631. [Google Scholar] [CrossRef]

- Zhang, C.L.; Xu, J.; Peng, S.J.; Li, Q.; Yan, F.; Chen, Y. Dynamic behavior of gas pressure and optimization of borehole length in stress relaxation zone during coalbed methane production. Fuel 2018, 233, 816–824. [Google Scholar] [CrossRef]

- Chen, Y.X.; Chu, T.X.; Chen, X.X.; Jiang, B.; Chen, P.; Cao, J.; He, N. Spatiotemporal evolutions of gas pressures in coal seam during gas extraction under mining disturbance. Sci. Rep. 2024, 14, 30253. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Liu, H.D.; Liu, C.Y.; Liu, S. Study on the Influence of Mining Stress on the Sustainable Utilization of Floor Roadway in Qinan Coal Mine. Sustainability 2024, 16, 2905. [Google Scholar] [CrossRef]

- Pan, Y.; Gu, S.; Li, W.S. Analysis on bending moment property of hard roof influenced by elastic, hardening and softening zone of coal seam. Chin. J. Rock Mech. Eng. 2016, 35 (Suppl. S2), 3846–3857. [Google Scholar] [CrossRef]

- Hui, Q.J. Study on Peak and Valley Characteristics of Front Abutment Pressure of Hard Roof Longwall Working Face. Ph.D. Thesis, Liaoning Technical University, Fuxin, China, 2024. [Google Scholar]

- Yin, G.Z.; He, B.; Li, M.H. Coupling mechanism between flow rate of gas drainage and coal seam abutment stress under mining conditions. J. China Coal Soc. 2015, 40, 736–741. [Google Scholar] [CrossRef]

- Nian, F.T.; Ju, F.; Zheng, C.S.; Wu, H.; Cheng, X. Effects of Coal Permeability Anisotropy on Gas Extraction Performance. Processes 2023, 11, 1408. [Google Scholar] [CrossRef]

- Zhang, C.; Bai, Q.S.; Chen, Y.H. Using stress path-dependent permeability law to evaluate permeability enhancement and coalbed methane flow in protected coal seam: A case study. Geomech. Geophys. Geo-Energy Geo-Resour. 2020, 6, 53. [Google Scholar] [CrossRef]

- Peng, S.J.; Guo, S.C.; Xu, J.; Guo, C.Y.; Zhang, C.L.; Jia, L. Impacts of mining-induced stress concentration on coal-bed methane drainage in boreholes parallel with bedding. Rock Soil Mech. 2019, 40 (Suppl. S1), 99–108. [Google Scholar] [CrossRef]

- Yang, G.; Zhao, H.B. Damage characteristics of gas extraction boreholes under different crustal stresses and their effects on gas extraction. Energy Sci. Eng. 2024, 12, 2591–2615. [Google Scholar] [CrossRef]

- Zhang, C.L.; Chugh, Y.P.; Feng, R.M.; Zhang, Y.; Shen, W.; Wu, J.; Yang, Y. A Numerical Investigation of the Stress Relief Zones Around a Longwall Face in the Lower Seam for Gas Drainage Considerations. Comput. Model. Eng. Sci. 2021, 127, 135–157. [Google Scholar] [CrossRef]

- Hou, P.; Xue, Y.; Gao, F.; Wang, S.; Jiao, X.; Zhu, C. Numerical Evaluation on Stress and Permeability Evolution of Overlying Coal Seams for Gas Drainage and Gas Disaster Elimination in Protective Layer Mining. Min. Metall. Explor. 2022, 39, 1027–1043. [Google Scholar] [CrossRef]

- Liu, Z.D.; Cheng, Y.P.; Liu, Q.Q.; Jiang, J.; Li, W.; Zhang, K. Numerical assessment of CMM drainage in the remote unloaded coal body: Insights of 425 geostress-relief gas migration and coal permeability. J. Nat. Gas Sci. Eng. 2017, 45, 487–501. [Google Scholar] [CrossRef]

- Ding, X.; Zhai, C.; Xu, J.Z.; Yu, X.; Sun, Y. Study on Coal Seepage Characteristics and Secondary Enhanced Gas Extraction Technology under Dual Stress Disturbance. Sustainability 2022, 14, 15118. [Google Scholar] [CrossRef]

- Li, S.Z.; Wang, Z.F. Study on the Coupling Effect of Stress Field and Gas Field in Surrounding Rock of Stope and Gas Migration Law. Energies 2023, 16, 6672. [Google Scholar] [CrossRef]

- Guo, H.; Yuan, L.; Shen, B.; Qu, Q.; Xue, J. Mining-induced strata stress changes, fractures and gas flow dynamics in multi-seam longwall mining. Int. J. Rock Mech. Min. Sci. 2012, 54, 129–139. [Google Scholar] [CrossRef]

- Li, S.; Fan, C.J.; Han, J.; Luo, M.; Yang, Z.; Bi, H. A fully coupled thermal-hydraulic-mechanical model with two-phase flow for coalbed methane extraction. J. Nat. Gas Sci. Eng. 2016, 33, 324–336. [Google Scholar] [CrossRef]

- Chen, Y.X.; Chu, T.X.; Chen, X.X.; Chen, P. Coupling of stress and gas pressure in dual porosity medium during coal seam mining 433. Powder Technol. 2020, 367, 390–398. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Cheng, Y.P.; Wang, H.F.; Zhou, H.X.; Wang, L.; Li, W.; Liu, H.Y. Numerical assessment of the effect of equilibration time on coal permeability evolution characteristics. Fuel 2015, 140, 81–89. [Google Scholar] [CrossRef]

- Li, S.; Zhang, H.H.; Fan, J.C.; Tao, M. Coal seam dual media model and its application to the proper interpolation among the boring-holes in gas extraction. J. Saf. Environ. 2018, 18, 1284–1289. [Google Scholar] [CrossRef]

- Xu, C.; Qin, L.L.; Wang, K.; Sun, H.; Cao, M. Gas seepage laws based on dual porosity and dual permeability: Numerical simulation and coalbed methane extraction practice. Energy Sci. Eng. 2021, 9, 509–519. [Google Scholar] [CrossRef]

- Yin, G.Z.; Li, M.H.; Li, S.Z.; Li, W.P.; Yao, J.W.; Zhang, Q.G. 3D numerical simulation of gas drainage from boreholes based on solid-gas coupling model of 441 coal containing gas. J. China Coal Soc. 2013, 38, 535–541. [Google Scholar] [CrossRef]

- Fan, C.J.; Elsworth, D.; Li, S.; Zhou, L.; Yang, Z.; Song, Y. Thermo-hydro-mechanical-chemical couplings controlling CH4 production and CO2 sequestration in enhanced coalbed methane recovery. Energy 2019, 173, 1054–1077. [Google Scholar] [CrossRef]

- Fan, J.C.; Li, S.; Luo, M.K.; Yang, Z.H.; Zhang, H.H.; Wang, S. Deep CBM extraction numerical simulation based on hydraulic-mechanical-thermal coupled model. J. Saf. Environ. 2016, 41, 3076–3085. [Google Scholar] [CrossRef]

- Yuan, X.Q.; Dong, W.X.; Fan, J.Y.; Liu, P.; Li, Z.Z.; Fourmeau, M.; Chen, J.; Liu, W. Dynamic gas emission during coal seam drilling under the thermo-hydro-mechanical coupling effect: A theoretical model and numerical simulations. Gas Sci. Eng. 2024, 131, 205454. [Google Scholar] [CrossRef]

- Wei, J.P.; Wang, D.K.; Yao, B.H. Influence of Moisture Content on the Seepage Characteristics of Gas-bearing Coal. Disaster Adv. 2013, 6, 282–288. [Google Scholar]

- Talapatra, A.; Karim, M.M. The influence of moisture content on coal deformation and coal permeability during coalbed methane (CBM) production in wet reservoirs. J. Pet. Explor. Prod. Technol. 2020, 10, 1907–1920. [Google Scholar] [CrossRef]

| No. | Lithology | Density (kg/m3) | Bulk (GPa) | Tensile (MPa) | Cohesion (MPa) | Friction (°) |

|---|---|---|---|---|---|---|

| 1 | quartz sandstone | 2559 | 7.36 | 5.56 | 3.87 | 6.90 |

| 2 | limestone | 2516 | 5.38 | 4.12 | 5.32 | 5.80 |

| 3 | coal seam | 1413 | 1.26 | 1.14 | 0.7 | 1.16 |

| 4 | quartz sandstone | 2519 | 5.38 | 4.22 | 5.64 | 4.80 |

| 5 | sandstone | 2528 | 7.45 | 5.85 | 6.58 | 6.80 |

| 6 | fine sandstone | 2421 | 9.06 | 6.88 | 5.68 | 5.80 |

| 7 | overburden | 2236 | 3.16 | 2.05 | 2.23 | 3.18 |

| Parameter | Variable | Value | Unit |

|---|---|---|---|

| Coal elastic modulus | E | 2723 | MPa |

| Elastic modulus of coal matrix | 8459 | MPa | |

| Poisson’s ration | υ | 0.36 | |

| Coal skeleton density | 1470 | kg/m3 | |

| Coal matrix porosity | 0.045 | ||

| Coal fracture porosity | 0.011 | ||

| Gas dynamic viscosity | 1.34 × 10−15 | Pa·s | |

| Initial horizontal permeability | 5.14 × 10−16 | m2 | |

| Langmuir volume constant | 0.0256 | m3/kg | |

| Langmuir pressure constant | 2.07 | MPa | |

| Adsorption time | 0.221 | d | |

| Initial porosity of the coal matrix | 1.25 | MPa | |

| Initial porosity of the coal fracture | 1.25 | MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Feng, X. Four-Zone Distribution of Coal Seam Stress in Hard-Roof Working Faces and Its Influence on Gas Flow. Processes 2025, 13, 3585. https://doi.org/10.3390/pr13113585

Zhang C, Feng X. Four-Zone Distribution of Coal Seam Stress in Hard-Roof Working Faces and Its Influence on Gas Flow. Processes. 2025; 13(11):3585. https://doi.org/10.3390/pr13113585

Chicago/Turabian StyleZhang, Chunhua, and Xiaoyu Feng. 2025. "Four-Zone Distribution of Coal Seam Stress in Hard-Roof Working Faces and Its Influence on Gas Flow" Processes 13, no. 11: 3585. https://doi.org/10.3390/pr13113585

APA StyleZhang, C., & Feng, X. (2025). Four-Zone Distribution of Coal Seam Stress in Hard-Roof Working Faces and Its Influence on Gas Flow. Processes, 13(11), 3585. https://doi.org/10.3390/pr13113585