Exploration of a Novel Technology for Waterless Fracturing in Shale Reservoirs Based on Microwave Heating

Abstract

1. Introduction

2. Principle of Waterless Fracturing Technology for Shale Reservoirs

3. Mathematical Model for Shale Reservoir Fracturing Based on Microwave Heating

3.1. Temperature Field Model of Pore Water in Shale Reservoirs

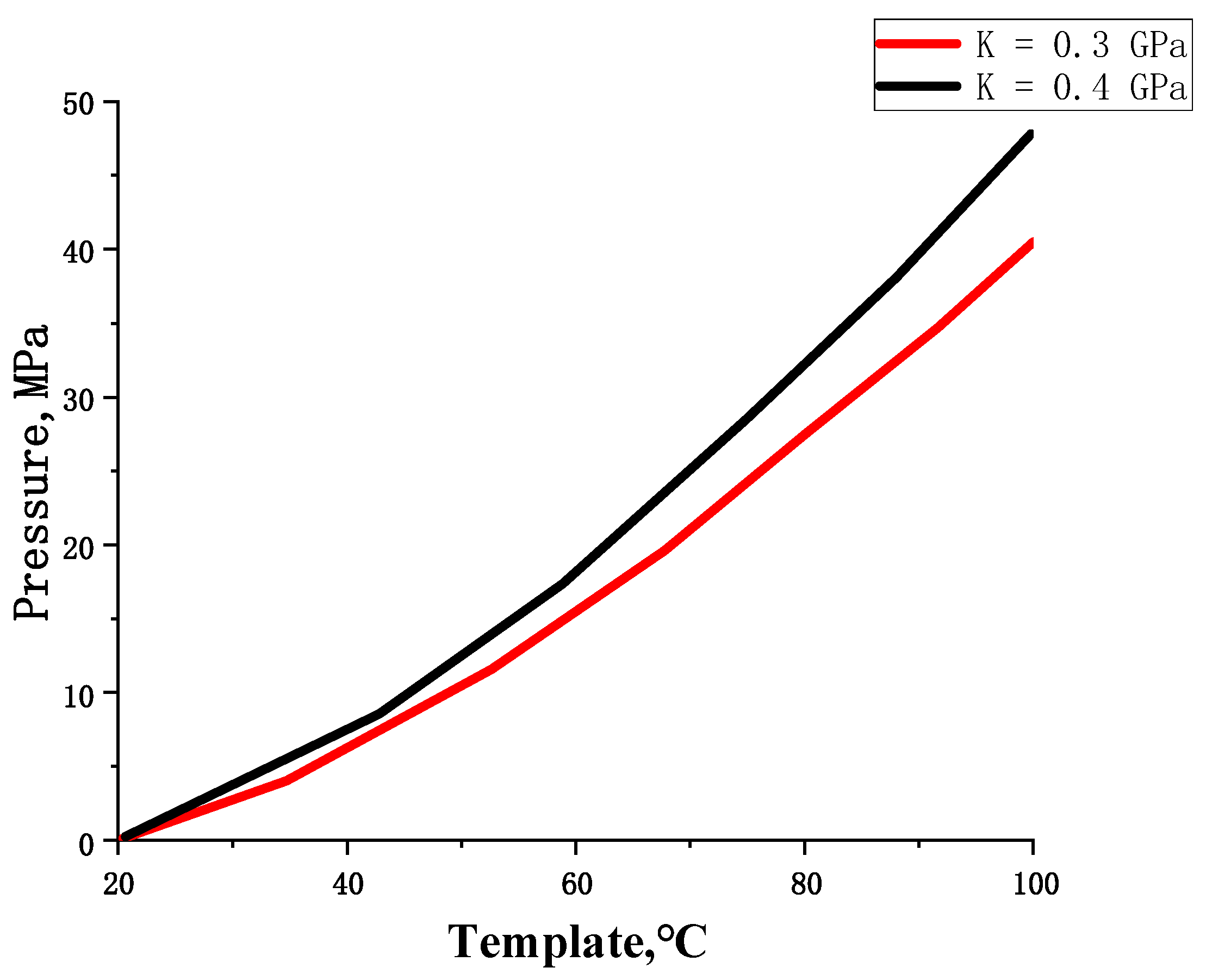

3.2. Pressure Field Model of Pore Water in Shale Reservoirs

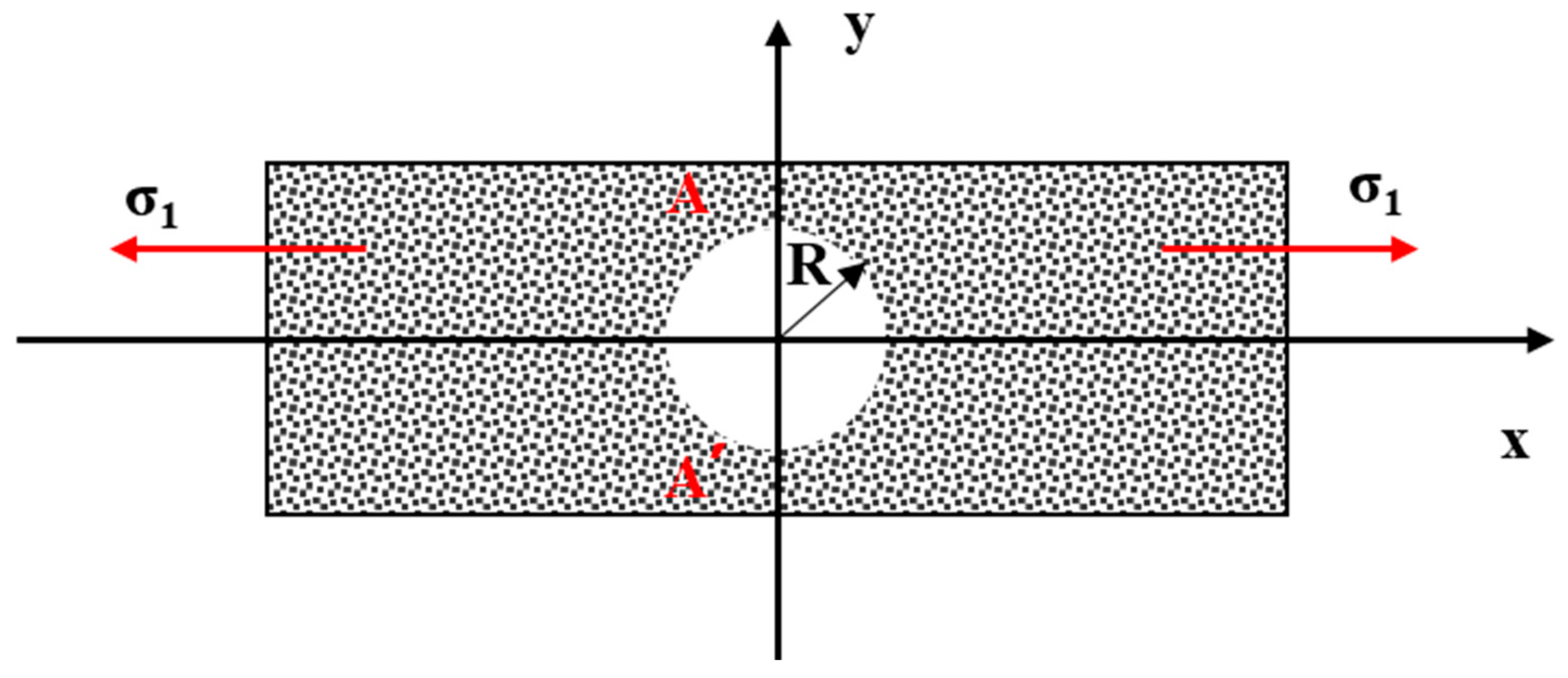

3.3. Tensile Strength Criterion for Fracturing in Shale Reservoirs

4. Laboratory Experiments and Discussion of Results

4.1. Experimental Samples and Sample Preparation

4.2. Experimental Procedures

4.2.1. Measurement of Water Content in Rock Samples

4.2.2. Microwave Irradiation Heating Experiments

4.2.3. Brazilian Tensile Strength Test

4.3. Experimental Results and Discussion

4.3.1. Microwave Heating of Tight Sandstone from the Daqing Oilfield

4.3.2. Microwave Heating of Shale and Clay Slabs

5. Summary and Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feng, Q.; Xu, S.; Xing, X.; Zhang, W.; Wang, S. Advances and challenges in shale oil development: A critical review. Adv. Geo-Energy Res. 2020, 4, 406–418. [Google Scholar] [CrossRef]

- Xu, Y.; Lun, Z.; Pan, Z.; Wang, H.; Zhou, X.; Zhao, C.; Zhang, D. Occurrence space and state of shale oil: A review. J. Pet. Sci. Eng. 2022, 211, 110183. [Google Scholar] [CrossRef]

- Zou, C.; Pan, S.; Jing, Z.; Gao, J.; Yang, Z.; Wu, S.; Zhao, Q. Shale oil and gas revolution and its impact. Acta Pet. Sin. 2020, 41, 1. [Google Scholar] [CrossRef]

- Gao, F.; Shao, Y.; Zhou, K. Analysis of microwave thermal stress fracture characteristics and size effect of sandstone under microwave heating. Energies 2020, 13, 3614. [Google Scholar] [CrossRef]

- Chen, T.; Zheng, X.; Qiu, X.; Feng, X.-T.; Elsworth, D.; Cui, G.; Jia, Z.; Pan, Z. Experimental Study on the Feasibility of Microwave Heating Fracturing for Enhanced Shale Gas Recovery. J. Nat. Gas Sci. Eng. 2021, 94, 104073. [Google Scholar] [CrossRef]

- Li, J.; Li, H.; Yang, C.; Ren, X.; Li, Y. Geological characteristics of deep shale gas and their effects on shale fracability in the Wufeng-Longmaxi Formations of the southern Sichuan Basin, China. Lithosphere 2023, 2023, 4936993. [Google Scholar] [CrossRef]

- Fan, C.; Li, H.; Qin, Q.; He, S.; Zhong, C. Geological conditions and exploration potential of shale gas reservoir in Wufeng and Longmaxi Formation of southeastern Sichuan Basin, China. J. Pet. Sci. Eng. 2020, 191, 107138. [Google Scholar] [CrossRef]

- Chen, T.T.; Dutrizac, J.E.; Haque, K.E.; Wyslouzil, W.; Kashyap, S. The Relative Transparency of Minerals to Microwave Radiation. Can. Metall. Q. 1984, 23, 349–351. Available online: https://www.tandfonline.com/doi/abs/10.1179/cmq.1984.23.3.349 (accessed on 10 March 2025). [CrossRef]

- Bridges, J.; Ridge, P.; Taflove, A. Apparatus and Method for In Situ Heat Processing of Hydrocarbonaceous Formations. 1979. Available online: https://www.osti.gov/biblio/6142394 (accessed on 10 March 2025).

- Kumar, H.; Lester, E.; Kingman, S.; Bourne, R.; Avila, C.; Jones, A.; Robinson, J.; Halleck, P.M.; Mathews, J.P. Inducing fractures and increasing cleat apertures in a bituminous coal under isotropic stress via application of microwave energy. Int. J. Coal Geol. 2011, 88, 75–82. [Google Scholar] [CrossRef]

- Li, Q.; Cheng, B.; Li, X.; Yin, T.; Huang, L. Fracture behaviour of microwave-heated granite under indentation: Experimental and numerical investigation. Eng. Fract. Mech. 2022, 269, 108535. [Google Scholar] [CrossRef]

- Li, H.; Tian, L.; Huang, B.; Lu, J.; Shi, S.; Lu, Y.; Huang, F.; Liu, Y.; Zhu, X. Experimental study on coal damage subjected to microwave heating. Rock Mech. Rock Eng. 2020, 53, 5631–5640. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.; Yin, T. Effect of microwave heating on fracture behavior of granite: An experimental investigation. Eng. Fract. Mech. 2021, 250, 107758. [Google Scholar] [CrossRef]

- Chen, J.H.; Georgi, D.; Liu, H.H.; Zhang, J.; Eppler, G. Assessing Tensile Strength of Unconventional Tight Rocks Using Microwaving. In Proceedings of the Unconventional Resources Technology Conference, San Antonio, TX, USA, 20–22 July 2015; pp. 2273–2284. [Google Scholar] [CrossRef]

- Jaeger, J.C.; Cook, N.G.W.; Zimmerman, R. Fundamentals of Rock Mechanics; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar] [CrossRef]

- Jizba, D.L. Mechanical and Acoustical Properties of Sandstones and Shales. PhD Thesis, Standford University, Stanford, CA, USA, 1991. [Google Scholar]

- Press, D.C. Thermal expansion of fluorspar and iron pyrite. Proc. Indian Acad. Sci.-Sect. A 1949, 30, 284–294. [Google Scholar] [CrossRef]

- Dong, X.; Duan, Z.; Nie, T.; Gao, D. An analytical model for reservoir temperature during electromagnetic heating based on power transmission. Appl. Therm. Eng. 2013, 219, 119441. [Google Scholar] [CrossRef]

- Hepler, L.G.; Chu, H. AOSTRA Handbook on Oil Sands, Bitumen, and Heavy Oil; Petroleum University Press: Dongying, China, 1982. (In Chinese) [Google Scholar]

- Oliveira, M.E.C.; Franca, A.S. Microwave heating of foodstuffs. J. Food Eng. 2002, 53, 347–359. [Google Scholar] [CrossRef]

- Cooper, J.R.; Dooley, R.B. Revised release on the IAPWS industrial formulation 1997 for the thermodynamic properties of water and steam. Int. Assoc. Prop. Water Steam 2007, 1, 48. Available online: https://www.iapws.org/relguide/IF97-Rev.pdf (accessed on 10 March 2025).

- Holmgren, M. Thermodynamic Properties of Water and Steam; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar] [CrossRef]

- Lin, W. Mechanical Properties of Mesaverde Sandstone and Shale at High Pressures; Lawrence Livermore Laboratory, University of California: Livermore, CA, USA, 1983; Available online: https://www.osti.gov/biblio/6063243 (accessed on 15 March 2025).

- Liu, H.H.; Rutqvist, J.; Berryman, J.G. On the relationship between stress and elastic strain for porous and fractured rock. Int. J. Rock Mech. Min. Sci. 2009, 46, 289–296. [Google Scholar] [CrossRef]

- Carr, H.Y.; Purcell, E.M. Effects of Diffusion on Free Precession in Nuclear Magnetic Resonance Experiments. Phys. Rev. 1954, 94, 630–638. [Google Scholar] [CrossRef]

- ASTM D3967-16; Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens. ASTM International: West Conshohocken, PA, USA, 2016.

- Zhang, T.; Gu, T.; Jiang, J.; Zhang, J.; Zhou, X. An ordinary state-based peridynamic model for granular fracture in polycrystalline materials with arbitrary orientations in cubic crystals. Eng. Fract. Mech. 2024, 301, 110023. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Gu, T.T.; Wang, X.; Zhang, T.; Zhang, Z.-P. Mechanical and volumetric fracturing behaviors of layered composite sandstones with a contrast in grain size under true triaxial stresses. Rock Mech. Rock Eng. 2024, 57, 4089–4105. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Zhou, X.P. Forecasting catastrophic rupture in brittle rocks using precursory AE time series. J. Geophys. Res. Solid Earth 2020, 125, e2019JB019276. [Google Scholar] [CrossRef]

| Rock Type | Thermal Expansion Coeff., (K−1) |

|---|---|

| Berea Sandstone (Dry) | 1.5 × 10−6 |

| Boom Clay (wet) | 3.3 × 10−6 |

| Calcite | 13.1 × 10−6 |

| Water | 6.6 × 10−5 |

| Pyrite | 9.7 × 10−6 (40 °C) |

| Rock/Mineral | Dielectric Const. (εr′) | Dielectric Loss (εr″) |

|---|---|---|

| 20 Ω salt water (1.1 GHz) | 79 | 5.6 |

| 1 Ω salt water (1.1 GHz) | 77 | 21 |

| 0.1 Ω salt water (1.1 GHz) | 59 | 167 |

| Dolomite (1 GHz) | 7.41 | 1.80 × 10−3 |

| Calcite (1 GHz) | 8.94 | 4.20 × 10−4 |

| Quartz (1 GHz) | 3.89 | 5.33 × 10−4 |

| Pyrite (2.45 GHz) | 83 | 17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; Liu, T.; Cao, G.; Liu, Y.; Qi, M. Exploration of a Novel Technology for Waterless Fracturing in Shale Reservoirs Based on Microwave Heating. Processes 2025, 13, 3576. https://doi.org/10.3390/pr13113576

Ma L, Liu T, Cao G, Liu Y, Qi M. Exploration of a Novel Technology for Waterless Fracturing in Shale Reservoirs Based on Microwave Heating. Processes. 2025; 13(11):3576. https://doi.org/10.3390/pr13113576

Chicago/Turabian StyleMa, Lei, Tao Liu, Guangsheng Cao, Ying Liu, and Mingyu Qi. 2025. "Exploration of a Novel Technology for Waterless Fracturing in Shale Reservoirs Based on Microwave Heating" Processes 13, no. 11: 3576. https://doi.org/10.3390/pr13113576

APA StyleMa, L., Liu, T., Cao, G., Liu, Y., & Qi, M. (2025). Exploration of a Novel Technology for Waterless Fracturing in Shale Reservoirs Based on Microwave Heating. Processes, 13(11), 3576. https://doi.org/10.3390/pr13113576