Effect of Ignition Timing on Combustion and Emissions in a Downsized Rotary Engine Fueled with Methanol

Abstract

1. Introduction

2. Establishment and Verification of Mathematical Mode

2.1. Geometric Model and Boundary Condition Setting

2.2. Mathematical Models and Meshing

2.3. Scheme Design

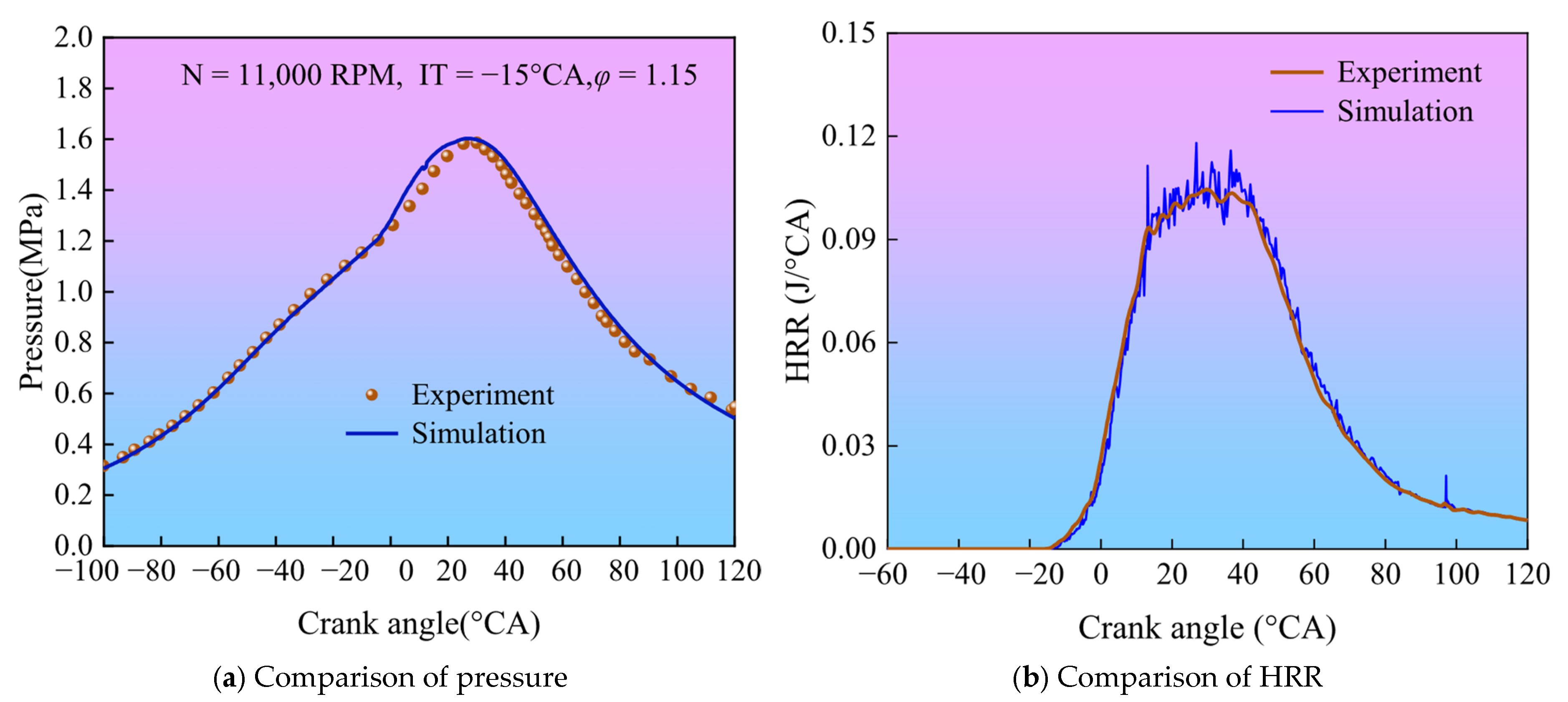

2.4. Model Validation and Calibration

3. Results and Discussion

3.1. Impact of IT on Flame Propagation

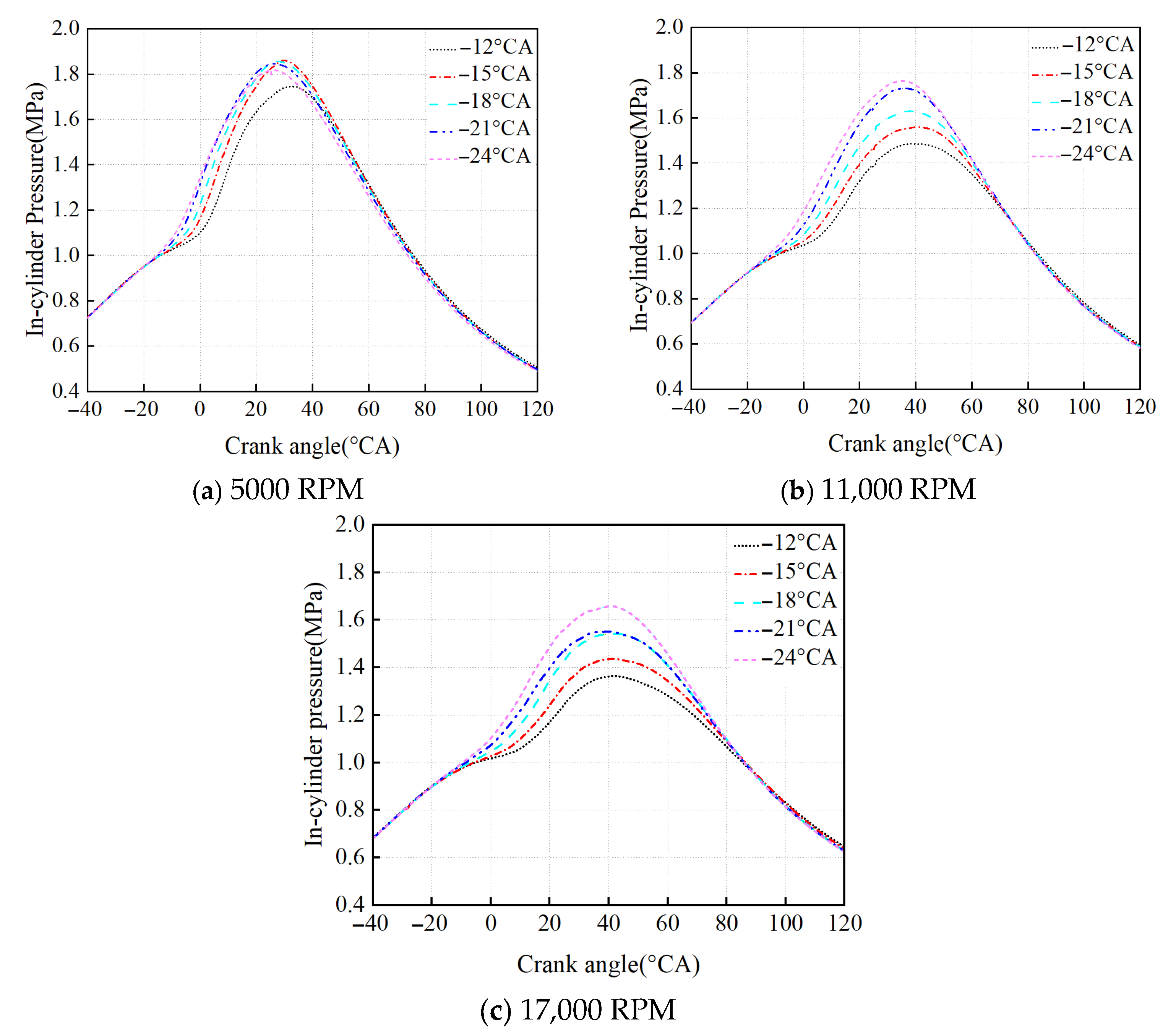

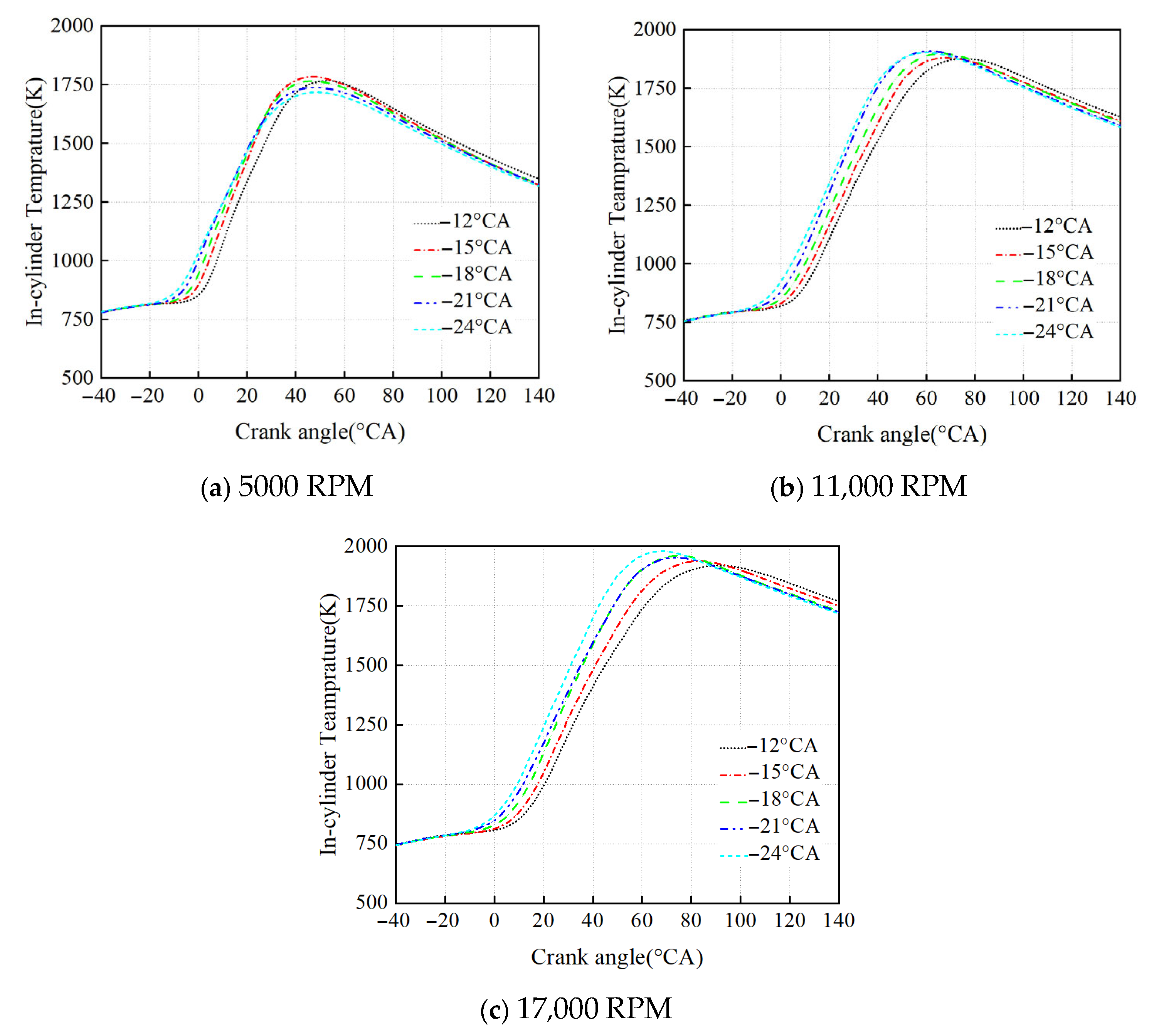

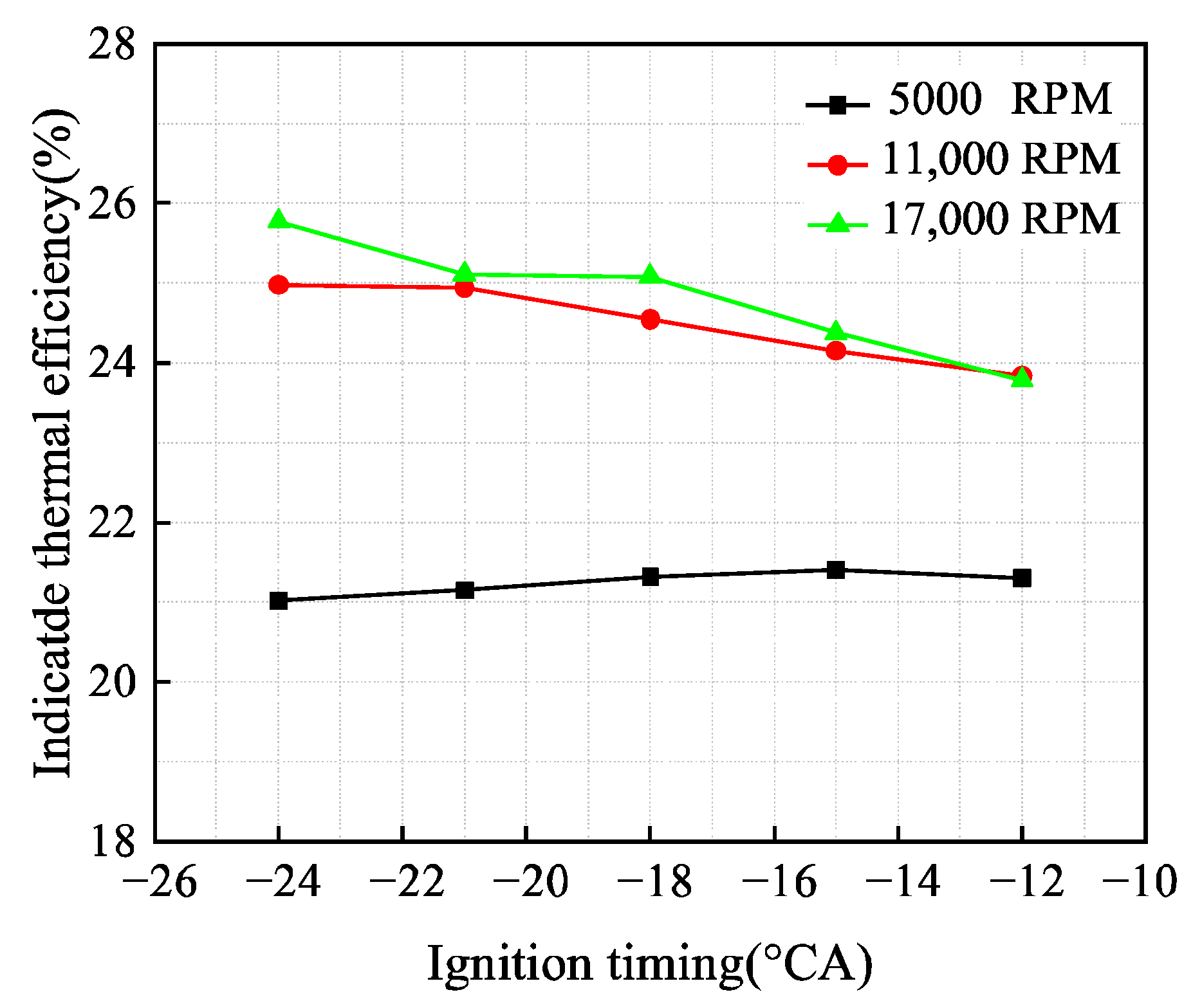

3.2. Impact of IT on Combustion Characteristics

3.3. Impact of IT on Emissions

4. Conclusions

- (1)

- Propagation of the flame front in the leading side of the chamber is facilitated, but that in the trailing side is inhibited. Higher engine speeds prolong the duration of combustion. For a constant engine speed, a earlier IT elevates the flame propagation speed and the spread range of the flame front is larger.

- (2)

- The flame development period is extended with enhancing engine speed at the same IT. Delaying the IT shortens the flame formation stage. However, the IT exhibits a greater effect on the flame propagation period at low speeds, especially after −21 °CA, and the flame development period is shortened by 13% between −21 °CA and −15 °CA.

- (3)

- The max pressure increases slightly when delaying the IT from −24 °CA to −15 °CA but drops sharply at −12 °CA for 5000 RPM. Nevertheless, for 11,000 RPM and 17,000 RPM, the max pressure is enhanced remarkably with advancing the IT. At the same IT, the max pressure is dropped as the engine speed is elevated.

- (4)

- The ITE first rises and then drops as the IT is postponed at 5000 RPM and exhibits the best performance at −15 °CA, where the it reaches 21.40%. However, at 11,000 RPM and 17,000 RPM, the ITE decreases with the delay of the IT, and the maximum values can reach 24.98% and 25.78% at −24 °CA. Compared to the IT of −15 °CA, the ITE obtained at −24 °CA increased by 2% and 1.1%, respectively.

- (5)

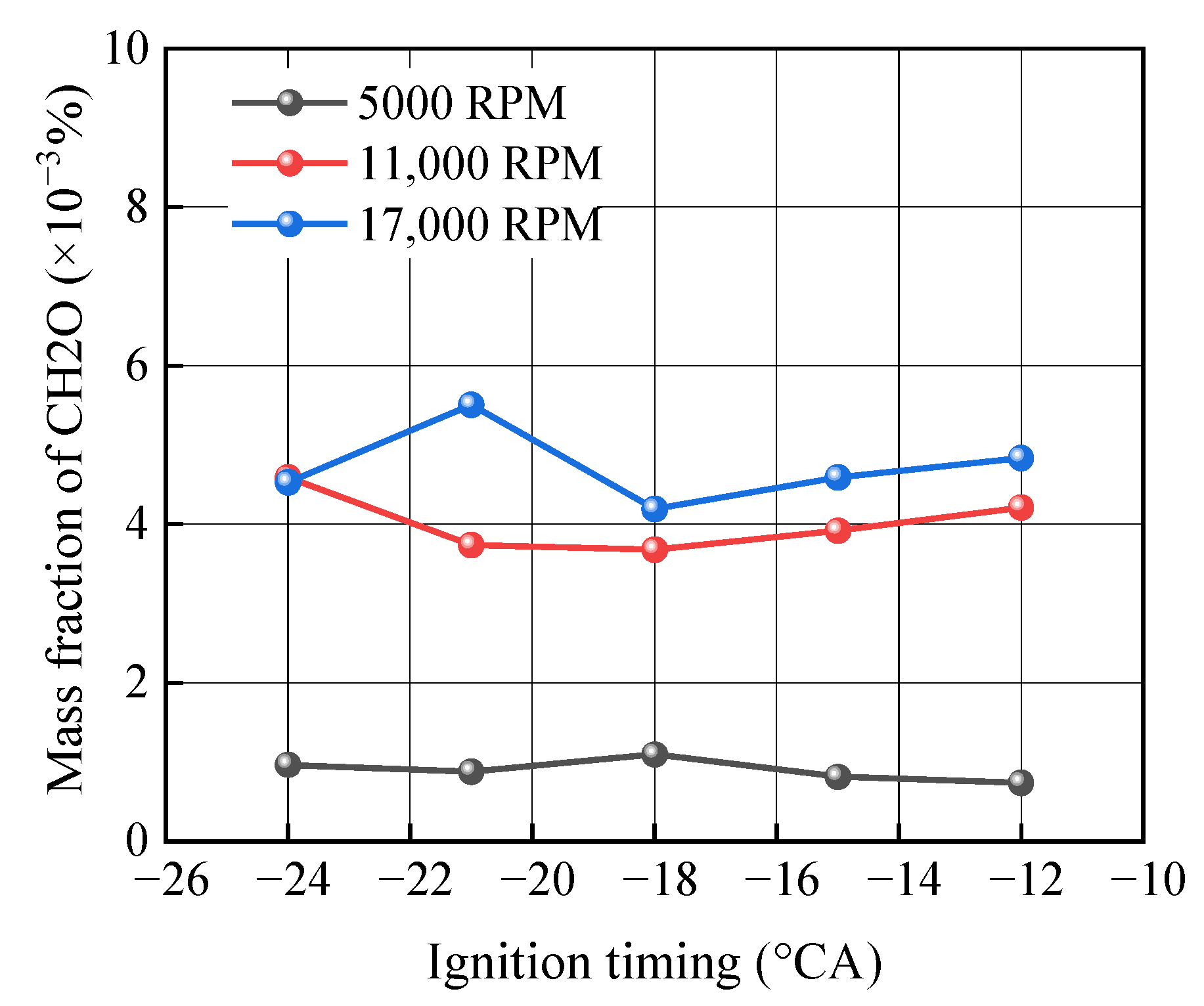

- The optimized IT primarily demonstrates a significant effect on pollutant emissions under low-speed conditions (5000 RPM), while it exhibits limited impact at high engine speeds. At 5000 RPM, strategic IT adjustment achieves maximum reductions of 2% in CO emissions and 33% in formaldehyde emissions. With increasing engine speed, greater combustion losses occur, leading to dramatically elevated pollutant emissions under high-speed conditions. Compared to low-speed operation, the high-speed condition at 17,000 RPM exhibits maximum increases of 267% in CO emissions and a 25-fold increase in formaldehyde emissions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, J.; Meng, H.; Ji, C.; Wang, S. Comparatively investigating the leading and trailing spark plug on the hydrogen rotary engine. Fuel 2022, 308, 122005. [Google Scholar] [CrossRef]

- Fan, B.; Zeng, Y.; Zhang, Y.; Pan, J.; Yang, W.; Wang, Y. Research on the hydrogen injection strategy of a direct injection natural gas/hydrogen rotary engine considering apex seal leakage. Int. J. Hydrogen Energy 2021, 46, 9234–9251. [Google Scholar] [CrossRef]

- Cihan, Ö.; Doğan, H.E.; Kutlar, O.A.; Demirci, A.; Javadzadehkalkhoran, M. Evaluation of heat release and combustion analysis in spark ignition Wankel and reciprocating engine. Fuel 2020, 261, 116479. [Google Scholar] [CrossRef]

- Fan, B.; Zeng, Y.; Pan, J.; Fang, J.; Salami, H.A.; Wang, Y. Evaluation and analysis of injection strategy in a peripheral ported rotary engine fueled with natural gas/hydrogen blends under the action of apex seal leakage. Fuel 2022, 310, 122315. [Google Scholar] [CrossRef]

- Morris, N.; Hart, G.; Wong, Y.J.; Simpson, M.; Howell-Smith, S. Laser surface texturing of Wankel engine apex seals. Surf. Topogr. Metrol. Prop. 2020, 8, 034001. [Google Scholar] [CrossRef]

- Yang, J.; Ji, C.; Wang, S.; Zhang, Z.; Wang, D.; Ma, Z. Numerical investigation of the effects of hydrogen enrichment on combustion and emissions formation processes in a gasoline rotary engine. Energy Convers. Manag. 2017, 151, 136–146. [Google Scholar] [CrossRef]

- Cihan, Ö.; Akın, O. Effect of leading and trailing spark plugs on combustion, fuel consumption and exhaust emission in a Wankel engine. Arab. J. Sci. Eng. 2021, 46, 7471–7482. [Google Scholar] [CrossRef]

- Muroki, T.; Moriyoshi, Y.; Takagi, M.; Suzuki, K.; Imai, M. Research and Development of a Direct Injection Stratified Charge Rotary Engine with a Pilot Flame Ignition System; SAE Technical Paper 2001-01-1844; SAE International: Warrendale, PA, USA, 2001. [Google Scholar] [CrossRef]

- Rose, S.W.; Yang, D.C.H. Wide and multiple apex seals for the rotary engine: (Abbr.: Multi-apex-seals for the rotary engine). Mech. Mach. Theory 2014, 74, 202–215. [Google Scholar] [CrossRef]

- Amrouche, F.; Varnhagen, S.; Erickson, A.P.; Park, W.J. An experimental study of a hydrogen-enriched ethanol fueled Wankel rotary engine at ultra lean and full load conditions. Energy Convers. Manag. 2016, 123, 178–184. [Google Scholar] [CrossRef]

- Fan, B.; Zhang, Y.; Pan, Y.P.O. Experimental and numerical study on the formation mechanism of flow field in a side-ported rotary engine considering apex seal leakage. J. Energy Resour. Technol. 2020, 143, 22303. [Google Scholar] [CrossRef]

- Fan, B.; Pan, J.; Liu, Y.; Chen, W.; Lu, Y.; Otchere, P. Numerical investigation of mixture formation and combustion in a hydrogen direct injection plus natural gas port injection (HDI + NGPI) rotary engine. Int. J. Hydrogen Energy 2018, 43, 4632–4644. [Google Scholar] [CrossRef]

- Warren, S.; Yang, D.C.H. Design of rotary engines from the apex seal profile (Abbr.: Rotary engine design by apex seal). Mech. Mach. Theory 2013, 64, 200–209. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, J.; Zhou, Y. Effect of DLC coating on the friction power loss between apex seal and housing in small Wankel rotary engine. Tribol. Int. 2019, 134, 365–371. [Google Scholar] [CrossRef]

- Shi, C.; Ji, C.; Ge, Y.; Wang, S.; Bao, J.; Yang, J. Numerical study on ignition amelioration of a hydrogen-enriched Wankel engine under lean-burn condition. Appl. Energy 2019, 255, 113800. [Google Scholar] [CrossRef]

- Muroki, T.; Moriyoshi, Y. Combustion characteristics of spark-ignition and pilot flame ignition systems in a model Wankel stratified charge engine. Proc. Inst. Mech. Eng. 2000, 214, 949–955. [Google Scholar] [CrossRef]

- Loktionov, E.Y.; Pasechnikov, N.A. First tests of laser ignition in Wankel engine. J. Phys. Conf. Ser. 2021, 1787, 12031. [Google Scholar] [CrossRef]

- Dimpelfeld, P.M.; MacK, J.R. Design and Testing of a Natural Gas Fueled 5.8 Liter Rotary Engine; SAE Technical Paper 920307; SAE International: Warrendale, PA, USA, 1992. [Google Scholar] [CrossRef]

- Kamo, P.; Yamada, T.Y.; Hamada, Y. Starting Low Compression Ratio Rotary Wankel Diesel Engine; SAE Technical Paper 870449; SAE International: Warrendale, PA, USA, 1987. [Google Scholar] [CrossRef]

- Pan, J.; Cheng, B.; Tao, J.; Fan, B.; Liu, Y.; Otchere, P. Experimental investigation on the effect of blending ethanol on combustion characteristic and idle performance in a gasoline rotary engine. J. Therm. Sci. 2021, 30, 1187–1198. [Google Scholar] [CrossRef]

- Su, T.; Ji, C.; Wang, S.; Cong, X.; Shi, L. Enhancing idle performance of an n-butanol rotary engine by hydrogen enrichment. Int. J. Hydrogen Energy 2018, 43, 6434–6442. [Google Scholar] [CrossRef]

- Jeffry, L.; Ong, M.Y.; Nomanbhay, S.; Mofijur, M.; Mubashir, M.; Show, P.L. Greenhouse gases utilization: A review. Fuel 2021, 301, 121017. [Google Scholar] [CrossRef]

- Celik, M.B.; Ozdalyan, B.; Alkan, F. The use of pure methanol as fuel at high compression ratio in a single cylinder gasoline engine. Fuel 2011, 90, 1591–1598. [Google Scholar] [CrossRef]

- Liu, J.; Ma, H.; Liang, W.; Yang, J.; Sun, P.; Wang, X.; Wang, Y.; Wang, P. Experimental investigation on combustion characteristics and influencing factors of PODE/methanol dual-fuel engine. Energy 2022, 260, 125131. [Google Scholar] [CrossRef]

- Verhelst, S.; Turner, J.W.G.; Sileghem, L.; Vancoillie, J. Methanol as a fuel for internal combustion engines. Prog. Energy Combust. Sci. 2019, 70, 43–88. [Google Scholar] [CrossRef]

- Zhen, X.; Wang, Y. An overview of methanol as an internal combustion engine fuel. Renew. Sustain. Energy Rev. 2015, 52, 477–493. [Google Scholar] [CrossRef]

- El-Amam, S.H.; Desoky, A.A. A study on the combustion of alternative fuels in spark-ignition engines. Int. J. Hydrogen Energy 1985, 10, 497–504. [Google Scholar] [CrossRef]

- Wouters, C.; Burkardt, P.; Fischer, M. Effects of stroke on spark-ignition combustion with gasoline and methanol. Int. J. Engine Res. 2022, 23, 804–815. [Google Scholar] [CrossRef]

- Wouters, C.; Lehrheuer, B.; Heuser, B.; Pischinger, S. Gasoline blends with methanol, ethanol and butanol. MTZ Worldw. 2020, 81, 16–21. [Google Scholar] [CrossRef]

- Vancoillie, J.; Demuynck, J.; Sileghem, L.; Verhelst, S. Comparison of the renewable transportation fuels, hydrogen and methanol formed from hydrogen, with gasoline–Engine efficiency study. Int. J. Hydrogen Energy 2012, 37, 9914–9924. [Google Scholar] [CrossRef]

- An, H.; Yang, W.M.; Li, J. Numerical modeling on a diesel engine fueled by biodiesel–methanol blends. Energy Convers. Manag. 2015, 93, 100–108. [Google Scholar] [CrossRef]

- Ni, P.; Wang, Z.; Wang, X.; Hou, L. Regulated and unregulated emissions from a non-road small gasoline engine fueled with gasoline and methanol-gasoline blends. Energy Sources Part A Recovery Util. Environ. Eff. 2014, 36, 1499–1506. [Google Scholar] [CrossRef]

- Wu, B.; Wang, L.; Shen, X.; Yan, R.; Dong, P. Comparison of lean burn characteristics of an SI engine fueled with methanol and gasoline under idle condition. Appl. Therm. Eng. 2016, 95, 264–270. [Google Scholar] [CrossRef]

- Tian, Z.; Wang, Y.; Zhen, X.; Liu, Z. The effect of methanol production and application in internal combustion engines on emissions in the context of carbon neutrality: A review. Fuel 2022, 320, 123902. [Google Scholar] [CrossRef]

- Black, F.M. Overview of the Technical Implications of Methanol and Ethanol as Highway Motor-Vehicle Fuels; SAE Technical Paper 912413; SAE International: Warrendale, PA, USA, 1991; pp. 1161–1190. [Google Scholar] [CrossRef]

- Gao, J.; Tian, G.; Ma, C.; Huang, L.; Xing, S. Explorations of the impacts on a hydrogen fuelled opposed rotary piston engine performance by IT under part load conditions. Int. J. Hydrogen Energy 2021, 46, 11994–12008. [Google Scholar] [CrossRef]

- Gong, C.; Li, Z.; Chen, Y.; Liu, J.; Liu, F.; Han, Y. Influence of ignition timing on combustion and emissions of a spark-ignition methanol engine with added hydrogen under lean-burn conditions. Fuel 2019, 235, 227–238. [Google Scholar] [CrossRef]

- Ji, C.; Liang, C.; Gao, B.; Wei, B.; Liu, X.; Zhu, Y. The cold start performance of a spark-ignited dimethyl ether engine. Energy 2013, 50, 187–193. [Google Scholar] [CrossRef]

- Su, T.; Ji, C.; Wang, S.; Shi, L.; Yang, J.; Cong, X. Effect of spark timing on performance of a hydrogen-gasoline rotary engine. Energy Convers. Manag. 2017, 148, 120–127. [Google Scholar] [CrossRef]

- Yang, J.; Ji, C.; Wang, S.; Meng, H. An experimental study on ignition timing of hydrogen Wankel rotary engine. Int. J. Hydrogen Energy 2022, 47, 17468–17478. [Google Scholar] [CrossRef]

- Jiao, H.; Zou, R.; Wang, N.; Luo, B.; Pan, W.; Liu, J. Optimization design of the ignition system for Wankel rotary engine considering ignition environment, flow, and combustion. Appl. Therm. Eng. 2022, 201, 117713. [Google Scholar] [CrossRef]

- Wang, S.; Sun, Y.; Yang, J.; Wang, H. Effect of excess air ratio and ignition timing on the combustion and emission characteristics of the ammonia-hydrogen Wankel rotary engine. Energy 2024, 302, 131779. [Google Scholar] [CrossRef]

- Chang, K.; Ji, C.; Wang, S.; Yang, J.; Wang, H.; Meng, H.; Liu, D. Numerical investigation of the synchronous and asynchronous changes of ignition timing in a double spark plugs direct injection rotary engine. Energy 2023, 268, 126688. [Google Scholar] [CrossRef]

- Zou, R.; Li, F.; Liu, J.; Yang, W.; Lei, L.; Zhang, L. Effect of ignition timing on combustion characteristics and emissions of an X-type rotary engine with the high efficiency hybrid cycle. Fuel 2025, 380, 133250. [Google Scholar] [CrossRef]

- Fan, B.; Li, W.; Zeng, Y.; Fan, M.; Yang, H.; Pan, J.; Zhang, Y.; Jiang, C. The coupling effect of turbulent jet ignition and injection strategy on the combustion performance of a pure methanol rotary engine. Appl. Therm. Eng. 2025, 258, 124544. [Google Scholar] [CrossRef]

- Ji, C.; Shi, C.; Wang, S.; Yang, J.; Su, T.; Wang, D. Effect of dual-spark plug arrangements on ignition and combustion processes of a gasoline rotary engine with hydrogen direct-injection enrichment. Energy Convers. Manag. 2019, 181, 372–381. [Google Scholar] [CrossRef]

- Otchere, P.; Pan, J.; Fan, B.; Chen, W.; Lu, Y.; Li, J. Mixture formation and combustion process of a biodiesel fueled direct injection rotary engine (DIRE) considering injection timing, spark timing and equivalence ratio–CFD study. Energy Convers. Manag. 2020, 217, 112948. [Google Scholar] [CrossRef]

- Fan, B.; Pan, J.; Tang, A.; Pan, Z.; Zhu, Y.; Xue, H. Experimental and numerical investigation of the fluid flow in a side-ported rotary engine. Energy Convers. Manag. 2015, 95, 385–397. [Google Scholar] [CrossRef]

- Spreitzer, J.; Zahradnik, F.; Geringer, B. Implementation of a Rotary Engine (Wankel Engine) in a CFD Simulation Tool with Special Emphasis on Combustion and Flow Phenomena; SAE Technical Paper 2015-01-0382; SAE International: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Li, J.; Zhao, Z.; Kazakov, A.; Chaos, M.; Dryer, F. A comprehensive kinetic mechanism for CO, CH2O, and CH3OH combustion. Int. J. Chem. Kinet. 2010, 39, 109–136. [Google Scholar] [CrossRef]

- Pomraning, E.; Richards, K.; Senecal, P. Modeling Turbulent Combustion Using a RANS Model, Detailed Chemistry, and Adaptive Mesh Refinement; SAE Technical Paper 2014-01-1116; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Yang, J.; Wang, H.; Ji, C.; Chang, K.; Wang, S. Investigation of intake closing timing on the flow field and combustion process in a small-scaled Wankel rotary engine under various engine speeds designed for the UAV application. Energy 2023, 273, 127147. [Google Scholar] [CrossRef]

- Ji, C.; Wang, S. Effect of hydrogen addition on combustion and emissions performance of a spark ignition gasoline engine at lean conditions. Int. J. Hydrogen Energy 2009, 34, 7823–7834. [Google Scholar] [CrossRef]

- Deshaies, B.; Joulin, G. On the initiation of a spherical flame kernel. Combust. Sci. Technol. 1984, 37, 99–116. [Google Scholar] [CrossRef]

- Lim, G.; Lee, S.; Park, C.; Choi, Y.; Kim, C. Effect of ignition timing retard strategy on NOx reduction in hydrogen-compressed natural gas blend engine with increased compression ratio. Int. J. Hydrogen Energy 2014, 39, 2399–2408. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Rated speed/RPM | 17,000 |

| Displacement/mm | 4970 |

| Compression ratio | 8.5 |

| Generating radius/mm | 21 |

| Eccentricity/mm | 3 |

| Cylinder thickness/mm | 14.5 |

| Fuel | Methanol |

| Number of rotors | 1 |

| Boundary Region | Boundary Type | Temperature (K) | Pressure (Bar) |

|---|---|---|---|

| Inlet | Inflow | 320 | 0.61 |

| Outlet | Outflow | 800 | 1.01 |

| Intake port | Fixed wall | 330 | – |

| Exhaust port | Fixed wall | 550 | – |

| Rotor wall | Moving wall | 520 | – |

| Cylinder sides | Fixed wall | 550 | – |

| Cylinder top | Fixed wall | 550 | – |

| Cylinder bottom | Fixed wall | 550 | – |

| Plug wall | Fixed wall | 550 | – |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, L.; Hou, T.; Liu, Y.; Yao, S.; Zou, R. Effect of Ignition Timing on Combustion and Emissions in a Downsized Rotary Engine Fueled with Methanol. Processes 2025, 13, 3565. https://doi.org/10.3390/pr13113565

Zhang Y, Li L, Hou T, Liu Y, Yao S, Zou R. Effect of Ignition Timing on Combustion and Emissions in a Downsized Rotary Engine Fueled with Methanol. Processes. 2025; 13(11):3565. https://doi.org/10.3390/pr13113565

Chicago/Turabian StyleZhang, Yi, Liangyu Li, Ting Hou, Yanzhe Liu, Shiliang Yao, and Run Zou. 2025. "Effect of Ignition Timing on Combustion and Emissions in a Downsized Rotary Engine Fueled with Methanol" Processes 13, no. 11: 3565. https://doi.org/10.3390/pr13113565

APA StyleZhang, Y., Li, L., Hou, T., Liu, Y., Yao, S., & Zou, R. (2025). Effect of Ignition Timing on Combustion and Emissions in a Downsized Rotary Engine Fueled with Methanol. Processes, 13(11), 3565. https://doi.org/10.3390/pr13113565