Abstract

This study addresses the challenge of low working gas ratios in China’s underground gas storage (UGS) facilities by optimizing geomechanical evaluations to enable safe pressure increases and capacity expansion. Through mini-fracturing tests conducted at the Liaohe Gas Storage Group, a cross-validated analytical framework was established, integrating the square-root-of-time, Geomechanical (G) function, and flow-back pressure–volume methods. This framework enables precise determination of the dynamic maximum safe pressure, effectively balancing storage efficiency against the risks of fracture and fault activation. The results indicate that the minimum horizontal stress is 37% higher in the caprock than in the reservoir, confirming the integrity of the natural stress barrier. A mere 0.39% discrepancy in interpretation results validates the consistency of the methodology. The derived three-dimensional (D) in situ stress model reveals that the upper sandstone section exhibits 15–20% higher horizontal stress than deeper intervals, acting as a secondary barrier against fracture propagation. Theoretically, we propose a ‘stress differential gradient sealing’ mechanism to explain the buffering effects observed in the sandstone–mudstone transition zone. Practically, we developed a standardized testing protocol for complex geological conditions, which achieved a 15% increase in the maximum safe operating pressure at the Liaohe facility. This study provides critical insights for optimizing gas storage operations.

1. Introduction

Amidst the accelerating global energy transition, natural gas, recognized as a clean and low-carbon energy source, has become a critical component for ensuring national energy security through stable supply and efficient storage [1]. Underground gas storage (UGS) facilities, serving as the core regulatory infrastructure in the natural gas supply chain, not only undertake essential functions such as seasonal peak shaving and emergency supply assurance but also play an irreplaceable role in enhancing the flexibility and operational reliability of energy systems.

As the world’s third-largest natural gas consumer, China reported total natural gas consumption exceeding 400 billion cubic meters in 2024 [2]. However, the working gas volume in its UGS facilities accounts for only 6.2% of the annual consumption—significantly lower than the internationally accepted average of 15% [3]. This significant storage capacity gap has frequently caused regional supply shortages during peak winter demand, emerging as a critical bottleneck that constrains the optimization of China’s natural gas consumption structure and the high-quality development of its energy system [4].

To enhance UGS operational efficiency and working gas capacity, increasing the injection-production pressure upper limit based on existing storage sites has become a technically and economically viable approach to expansion. For example, engineering practices at the Jintan salt cavern UGS facility demonstrate that raising operational pressure by 1–2 MPa can increase working gas volume by 10–25%, reducing investment costs by approximately 30% compared to constructing new facilities [5].

However, this approach faces considerable geomechanical challenges. Monitoring data from a UGS facility in the Ordos Basin indicate that when injection pressure exceeds formation fracture pressure, the casing deformation rate increases to 12%, and the frequency of microseismic events triples. During injection and production cycles, the in situ stress field exhibits highly dynamic and reversible characteristics: in a typical depleted reservoir-type UGS, within a single injection–withdrawal cycle (usually 30–60 days), the orientation of the maximum principal stress can shift by 15°–30°, and the minimum principal stress may fluctuate by up to 40% of its original value.

Such significant stress variations can threaten caprock integrity, potentially causing gas leakage or activating concealed faults and triggering seismic events. A case study from the Eagle Ford gas field in the United States shows that when injection-production pressure exceeds a critical threshold, the magnitude of induced seismicity increases exponentially with pressure rise [6]. Therefore, establishing a high-precision 3D in situ stress model and scientifically defining the dynamic upper pressure limit for UGS facilities are essential technical prerequisites for ensuring their long-term safe and stable operation.

The development of in situ stress testing technologies for UGS is closely tied to geological conditions, leading to the establishment of diverse testing methodologies for different reservoir types. For depleted gas reservoir storage, such as in the Eagle Ford Gas Field in the United States, hydraulic fracturing is widely adopted [7]. This method involves high-pressure fluid injection into the wellbore to induce artificial fractures, and in situ stress parameters are inversely derived based on pressure–time curves. It also enables the simultaneous acquisition of key indicators including the direction of the minimum horizontal principal stress and fracture toughness [8]. According to U.S. Department of Energy (DOE) statistics, the success rate of this technology in sandstone reservoirs reaches 92%, but in shale gas reservoirs, due to widespread natural fractures, the deviation rate of measurements increases to 37% [9].

For salt cavern storage, as exemplified by the Huntorf facility in Germany, a combined acoustic emission and microseismic monitoring technique is typically employed. This approach inverts the dynamic evolution of the stress field by capturing microseismic signals generated by salt rock failure. Engineering experience at the Jintan UGS in China demonstrates that, when integrated with optical fiber sensing, this technology achieves millimeter-level precision in monitoring salt cavern creep deformation [10].

In recent years, Measurement While Drilling (MWD) technology has seen significant advancements. Systems such as Schlumberger’s GeoSphere allow continuous monitoring of stress variations within a 20 m radius around the well during drilling, proving particularly suitable for areas with well-developed faults or complex structures [11].

However, these methods exhibit notable limitations under complex geological conditions. For instance, the success rate of hydraulic fracturing testing in low-permeability reservoirs (<0.1 mD) falls below 50%, and the detection rate of acoustic emission technology for microseismic events in shallow UGS (burial depth < 800 m) is only 65% [12]. This issue is especially pronounced in shale gas reservoirs. Data from the Marcellus Gas Field in the U.S. indicate that the presence of natural fracture networks can lead to deviations of 25°–40° between the horizontal principal stress direction measured by hydraulic fracturing and the actual values [13].

To address these challenges, multi-scale integrated testing approaches have been developed. Among them, the “Nuclear Magnetic Resonance–In Situ Stress Coupling” technology combines pore-scale (cm-level) rock characterization with reservoir-scale (m level) numerical simulation of the stress field, reducing the comprehensive testing error to within 8% [14]. In its application at the Liaohe UGS, this method successfully identified the critical activation pressure of three hidden faults, providing approximately 15% earlier warning of operational risks during injection and production compared to conventional methods [15].

Despite significant advancements in in situ stress testing technologies, complex geological conditions continue to pose considerable challenges to existing methodologies. In shale reservoirs, when natural fracture density exceeds 0.5 fractures per meter, the deviation in the direction of the minimum horizontal principal stress measured by hydraulic fracturing can reach 25–40% [16]. Such measurement inaccuracies are further exacerbated in deep gas storage environments (burial depth > 3000 m). Due to enhanced rock plasticity under high temperature and pressure conditions, the applicability of conventional linear elastic theory is significantly reduced—field tests at a storage facility in Alberta, Canada, demonstrated a discrepancy of up to 18 MPa between the calculated fracture pressure based on this theoretical model and the measured value [17].

Fault activation risk represents another critical technical challenge. Microseismic monitoring data from a storage site in North China show that when injection-production pressure approaches the critical state of a fault, the seismic b-value drops sharply from 1.2 to 0.8, with this anomalous response lagging behind actual stress field changes by 24–48 h.

Furthermore, the deployment of monitoring well networks faces practical constraints. The U.S. Department of Energy (DOE) recommends at least three monitoring wells per square kilometer to effectively capture stress dynamics. In contrast, most Chinese storage facilities, limited by economic factors, typically have a well density of only one well per 5 km2. This results in a fault activation warning time of less than 12 h [18].

Compounding the complexity, stress field variations during injection and production cycles exhibit significant spatial heterogeneity. Long-term monitoring results from the Huntorf salt cavern storage facility in Germany indicate that the rate of stress change can vary by up to threefold across different regions of the same reservoir, making it difficult for traditional single-point monitoring methods to fully characterize such spatial heterogeneity [19].

These technical limitations severely constrain the scientifically determined safe operating pressure of storage facilities. Field applications at the Liaohe UGS group demonstrated that injection-production plans relying on localized in situ stress test data resulted in casing deformation rates exceeding acceptable limits within six months, ultimately requiring a 15% reduction in the maximum operating pressure.

Therefore, establishing an integrated monitoring and numerical modeling system capable of comprehensively reflecting the real-time dynamic evolution of the three-dimensional subsurface stress field has become critical for overcoming current technical bottlenecks and ensuring the safe and efficient operation of gas storage facilities.

In summary, while China’s natural gas consumption continues to grow and UGS infrastructure construction progresses steadily, the low working gas ratio and insufficient storage capacity have become increasingly prominent, posing a critical constraint on the industry’s high-quality development. Given the practical challenges in constructing new storage facilities—such as demanding geological conditions and long construction cycles—increasing the maximum injection–withdrawal pressure at existing sites has emerged as a key strategy for rapid capacity expansion, offering significant economic benefits and technical feasibility.

However, while high-pressure injection and production operations enhance storage efficiency, they also considerably increase geomechanical risks, such as formation fracturing and fault activation. Therefore, to scientifically determine safe operational pressure limits and optimize monitoring well network layouts at typical sites like the Liaohe Gas Storage Group, it is essential to conduct in-depth research on in situ stress testing and develop a high-resolution 3D in situ stress model. This model must accurately capture the effects of high-frequency cyclic injection–production operations.

2. Reservoir Geological Characteristic

The in situ stress state of a formation consists of three principal stress components, forming a three-dimensional stress tensor: the minimum horizontal principal stress, the vertical stress, and the maximum horizontal principal stress. Among these, the minimum horizontal principal stress can be directly obtained through field tests; the vertical stress is usually derived from depth integration of density logging curves, while the maximum horizontal principal stress must be estimated based on characteristic pressure parameters—such as fracture closure pressure, fracture reopening pressure, and formation breakdown pressure—measured during mini-fracturing tests.

In reservoir geomechanical analysis, the minimum horizontal principal stress is a key parameter for subsequent mechanical modeling and the evaluation of the dynamic sealing performance of traps. According to classical theory, the fracture closure pressure is numerically equal to the minimum horizontal principal stress and acts perpendicular to the direction of hydraulic fracture propagation. Building on this theoretical foundation, this section will, in combination with practical case studies, systematically identify the most suitable method for determining in situ stress in the study area.

Using the formation breakdown pressure from a leak-off test to determine the minimum horizontal principal stress introduces a significant conservative bias, potentially leading to misjudgments regarding UGS operational safety. During drilling, due to factors such as wellbore friction, near-wellbore stress concentration, skin damage, and mud cake formation, the measured formation breakdown pressure is often significantly higher than the fracture closure pressure. Taking the lower mudstone section of the caprock in Well A of the m19 gas storage facility as an example, the formation breakdown pressure was 32% (13.64 MPa) higher than the fracture closure pressure. If this value is used to design the upper operational pressure limit of the gas storage, it would result in a serious underestimation of the safety margin, posing major operational risks. If the instantaneous shut-in pressure is adopted as a substitute parameter for the minimum horizontal principal stress, it should be noted that at the moment of pump shutdown, the fracture remains fully open and has not yet undergone effective closure. Although this pressure value is lower than the formation breakdown pressure or fracture reopening pressure, it still exceeds the true fracture closure pressure. Actual data from Well A show that the instantaneous shut-in pressure was 14% (5.84 MPa) higher than the fracture closure pressure, indicating that it is also unsuitable for accurate calibration of the minimum horizontal principal stress.

Currently, most gas storage facilities adopt the original formation pressure as the maximum operational pressure limit. However, measured data from Well A indicate that the minimum horizontal principal stress is 37% (10.98 MPa) higher than the original formation pressure. Using the original formation pressure as the basis for setting the upper pressure limit would result in an overly conservative design, significantly restricting the gas storage’s injection and production capacity and thereby impairing its economic efficiency.

Given these technical limitations, mini-fracturing testing has emerged as an effective method for determining the minimum horizontal principal stress. This technique involves injecting a small volume of fluid at a high flow rate into the target zone to induce a tensile fracture and propagate it beyond the wellbore-affected area into the undisturbed formation. After pumping ceases, the injected fluid leaks off through the fracture walls into the formation, leading to a gradual decline in the fluid pressure within the fracture. When the pressure inside the fracture decreases to a level equal to the formation’s minimum horizontal principal stress, fracture closure occurs. The pressure at this point is defined as the fracture closure pressure and can serve as a reliable representation of the minimum horizontal principal stress.

In summary, using the fracture closure pressure obtained from mini-frac tests to characterize the minimum horizontal principal stress not only fully addresses safety requirements in gas storage operations but also substantially enhances operational efficiency. This method is widely recognized as one of the most reliable in situ testing techniques currently available for determining stress states in deep wells.

3. Mini-Frac Test Procedures and Interpretation

3.1. Testing System

Mini-fracturing tests are applicable to various well types, including cased or open-hole completions, in both horizontal and vertical orientations. In the cases discussed in this study, open-hole testing was consistently conducted to ensure cementing quality in later stages. The testing system primarily consists of a surface injection unit, a signal transmission device, and an inflatable straddle packer system. The inflatable straddle packer is used to achieve reliable isolation at both the upper and lower ends of the target test interval. Upon completion of the test, the packer can be deflated and released, allowing it to be moved to the next test depth without being retrieved from the wellbore. The reusable setting capability of the packer significantly enhances field operation efficiency (Figure 1).

Figure 1.

Downhole straddle packer and setting/unsetting tools (the upper picture shows the tools, and the lower picture shows the packer).

Although the inflatable straddle packer system typically provides effective zonal isolation, practical applications in large-diameter gas wells (e.g., 311 mm boreholes) present specific operational challenges that can impact test accuracy and consistency. The primary limitations include:

Sealing performance: Large-diameter packers (e.g., 286 mm in a 311 mm borehole) rely on rubber element expansion for sealing. The small annular clearance, combined with inadequate mud removal during drilling, can lead to cuttings accumulation at the packer setting depth. These compromises sealing integrity and may cause underestimation of actual formation pressures due to fluid communication between intervals.

Wellbore stability: The larger wellbore diameter significantly increases the risk of wellbore wall instability during extended testing periods, particularly in unconsolidated formations or shale sections with natural fracture networks.

Tool reliability: Increased friction during running and retrieving operations elevates the risk of stuck packers, especially when testing multiple intervals requiring repeated setting and unsetting cycles.

The packer can be deployed to the target depth using either drill pipe or wireline. When using drill pipe for running and setting, fluid is injected from the surface through the drill pipe, allowing flexible adjustment of injection rate and cumulative volume, thereby enabling precise control over the fracturing process. In contrast, wireline deployment typically requires downhole pumps and small fluid storage units. In this mode, limited by fluid storage capacity, the total volume of injectable fluid is relatively small, causing the mini-fracturing test to effectively become a micro-fracturing test. The fractures generated in such tests often cannot fully extend beyond the wellbore-disturbed zone into the virgin formation. As a result, the measured minimum principal stress may still be influenced by the near-wellbore stress field and may not accurately reflect the far-field in situ stress conditions. Therefore, to ensure the representativeness and reliability of test results, the drill pipe conveyance method is generally preferred for running and setting the packer.

3.2. Testing Process

The standard operational procedure for mini-fracturing tests typically consists of the following steps.

The straddle packer system is run to the target test depth on drill pipe.

At the target test interval, the setting tool of the packer system inflates the upper and lower sealing elements to achieve effective isolation and sealing of the section.

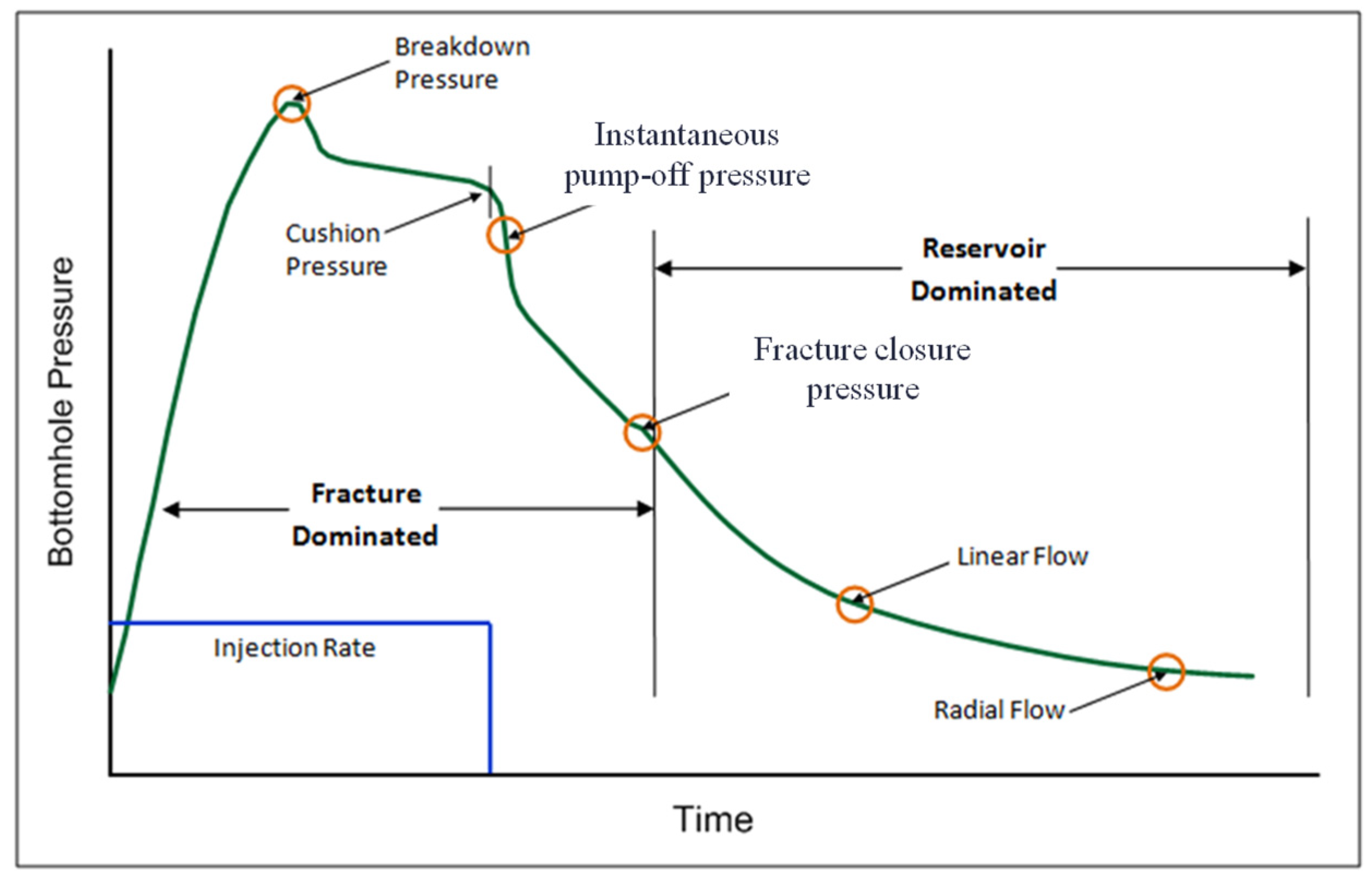

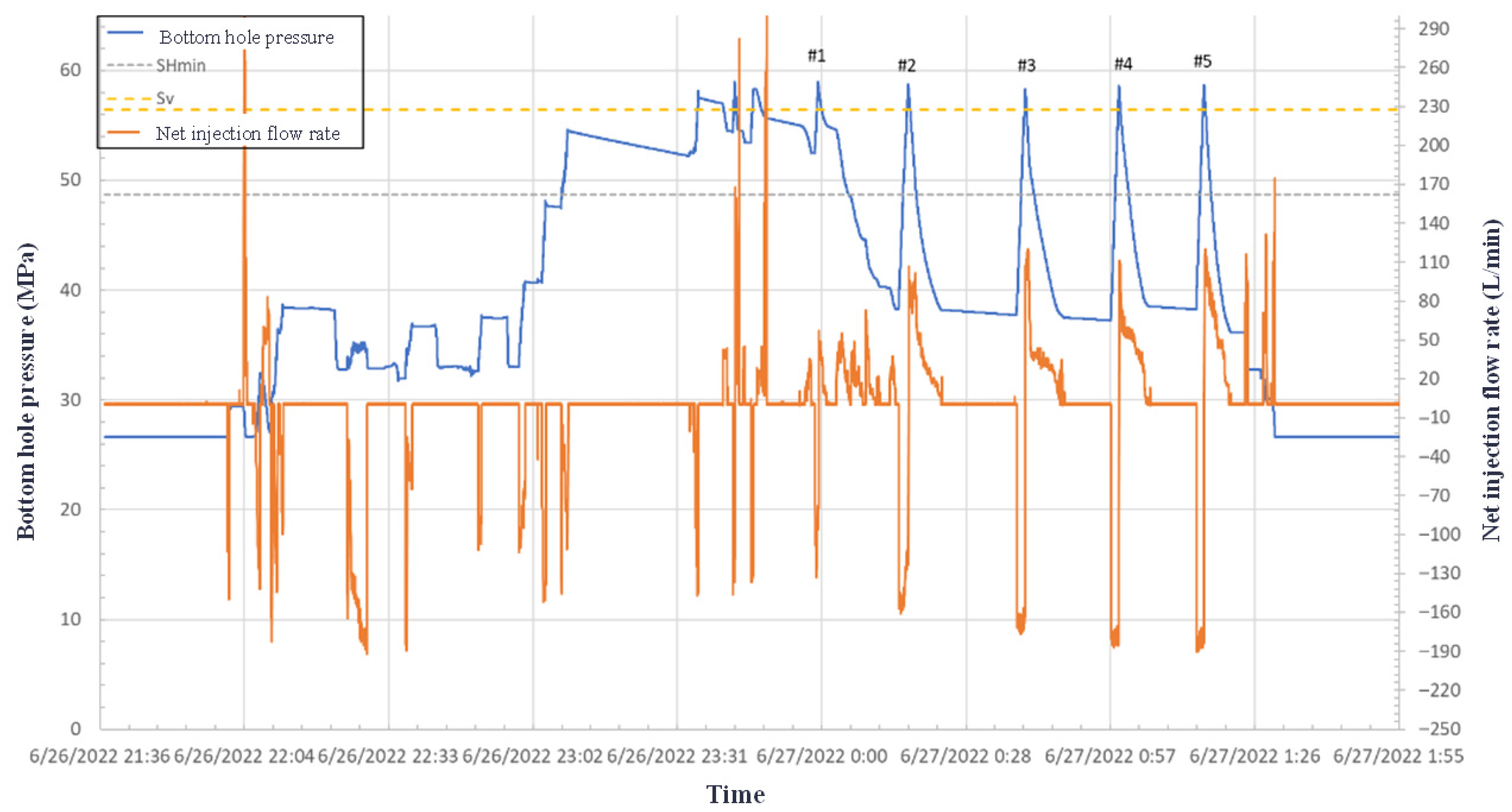

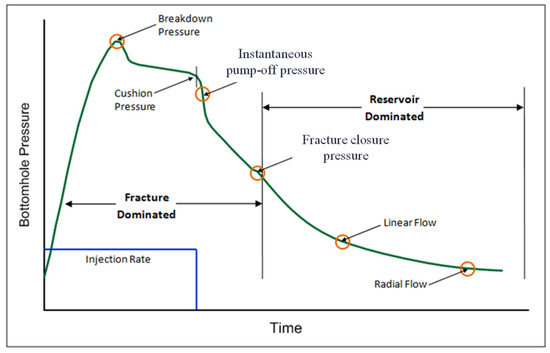

After the packer is set, fracturing fluid is injected into the test interval. The injection of fluid continues until formation breakdown occurs, creating a hydraulic fracture on the open-hole wellbore wall, which is marked by a significant pressure drop on the pressure curve. After breakdown, a constant injection rate is maintained until the pressure stabilizes, followed by shut-in. The pressure then gradually declines as the fracture closes naturally. During this process, the instantaneous shut-in pressure and fracture closure pressure are recorded (Figure 2).

Figure 2.

Bottomhole pressure variation curve during the small-scale fracturing test cycle.

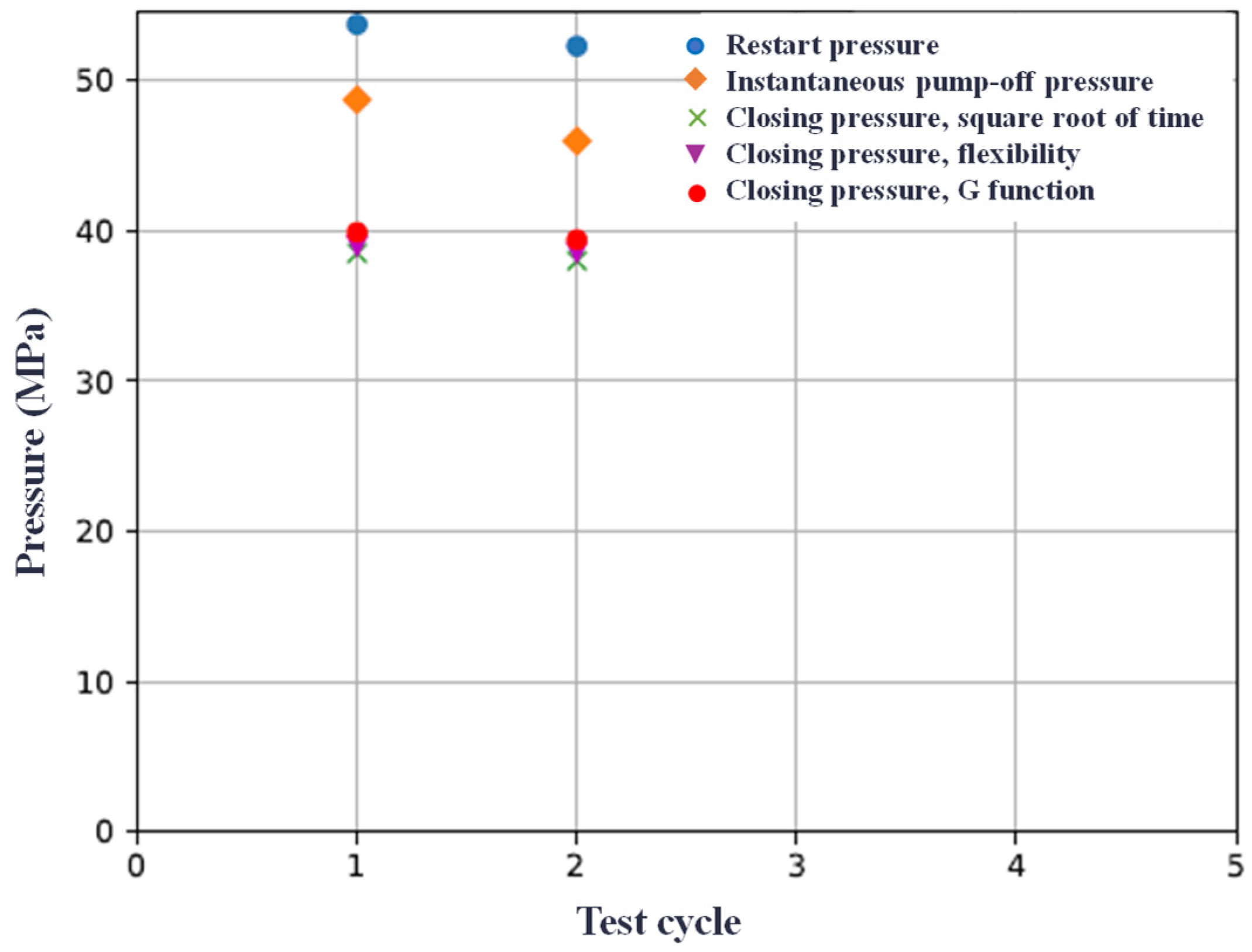

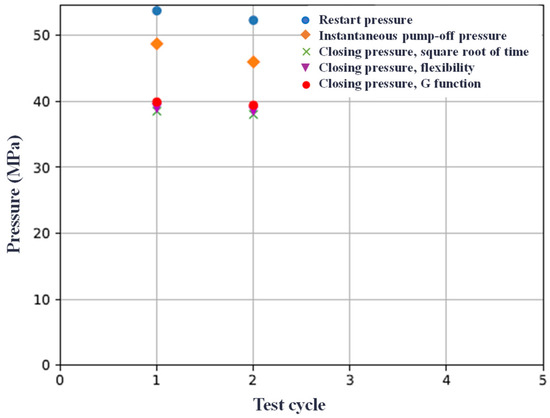

Multiple injection–shut-in cycles are conducted within the same test interval to verify the consistency of the interpreted fracture closure pressure (Pc) across cycles. Real-time data analysis is performed immediately after each cycle to preliminarily estimate Pc. By comparing results from multiple cycles, data repeatability and test quality are evaluated to determine whether termination conditions are satisfied. Figure 3 shows an example of fracture closure pressure consistency analysis from Well B in the S6 gas storage facility. The results indicate a high degree of consistency in Pc values obtained from different injection cycles and three interpretation methods.

Figure 3.

Characteristic pressure curve of well B in S6 gas storage reservoir.

Upon completion of the current test, the packer is deflated and released, then moved to the next test depth to repeat the procedure. As a key quality control measure, an active flowback procedure can be implemented for formations with low natural leak-off rates and consequently slow post-shut-in pressure decline. During the shut-in phase, a portion of the fluid is actively produced from the wellbore and fracture system to artificially reduce system pressure and accelerate fracture closure (Figure 3). This method enhances the controllability and flexibility of the testing process and significantly improves operational efficiency compared to traditional shut-in methods that rely solely on natural pressure decline.

Conducting multiple injection–shut-in cycles within a single test is a critical quality control measure for enhancing the accuracy of mini-fracturing test results [6]. Pressure response characteristics may vary between cycles due to differences in injection rate, cumulative injection volume, and flowback implementation, especially when later cycles involve significantly higher cumulative injection than the initial cycle. However, the fracture closure pressure, as a key parameter reflecting the in situ stress state of the formation, is inherently stable and should not vary significantly with changes in operational parameters. Therefore, systematic evaluation and in-depth analysis of differences in Pc values between cycles should be conducted to explore potential geological or engineering causes, thereby enhancing the reliability and interpretative depth of the test results.

3.3. Data Interpretation Methods

3.3.1. Three Interpretation Methods

For data acquired from each test cycle, two to three methods are typically used to interpret the fracture closure pressure, including the square-root-of-time method, the G-function method, and the flowback pressure–volume (compliance) method. This section systematically elaborates on the fundamental principles and applicable conditions of each interpretation method, supported by practical case studies.

- (1)

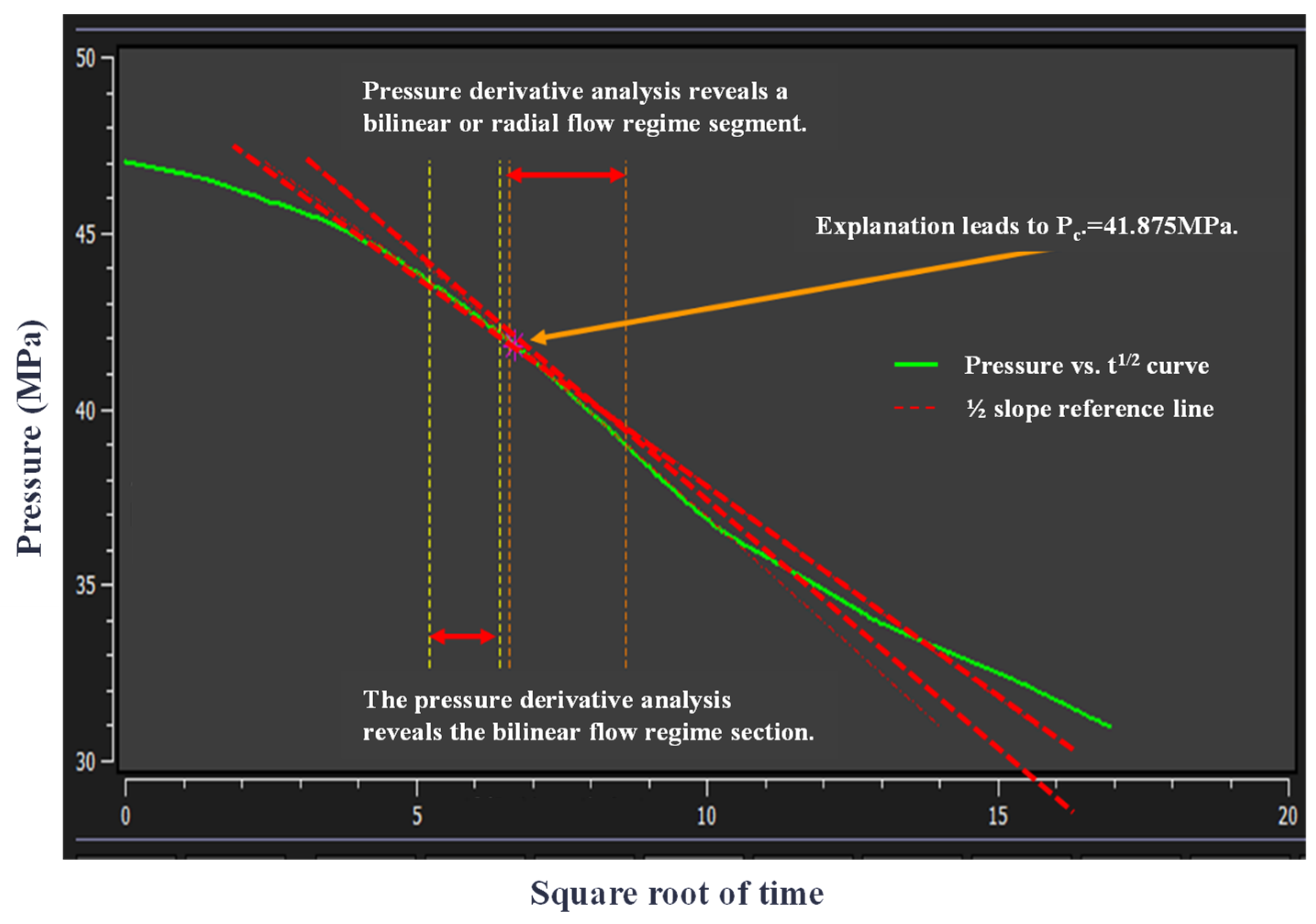

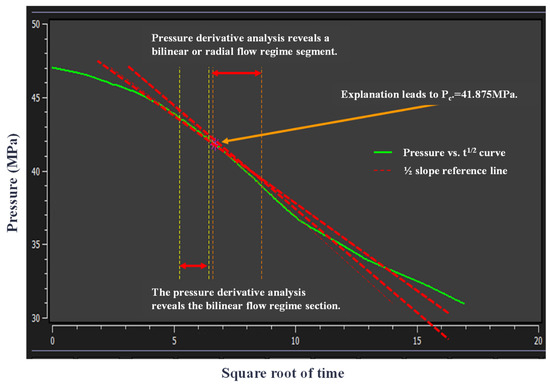

- Square-root-of-time method

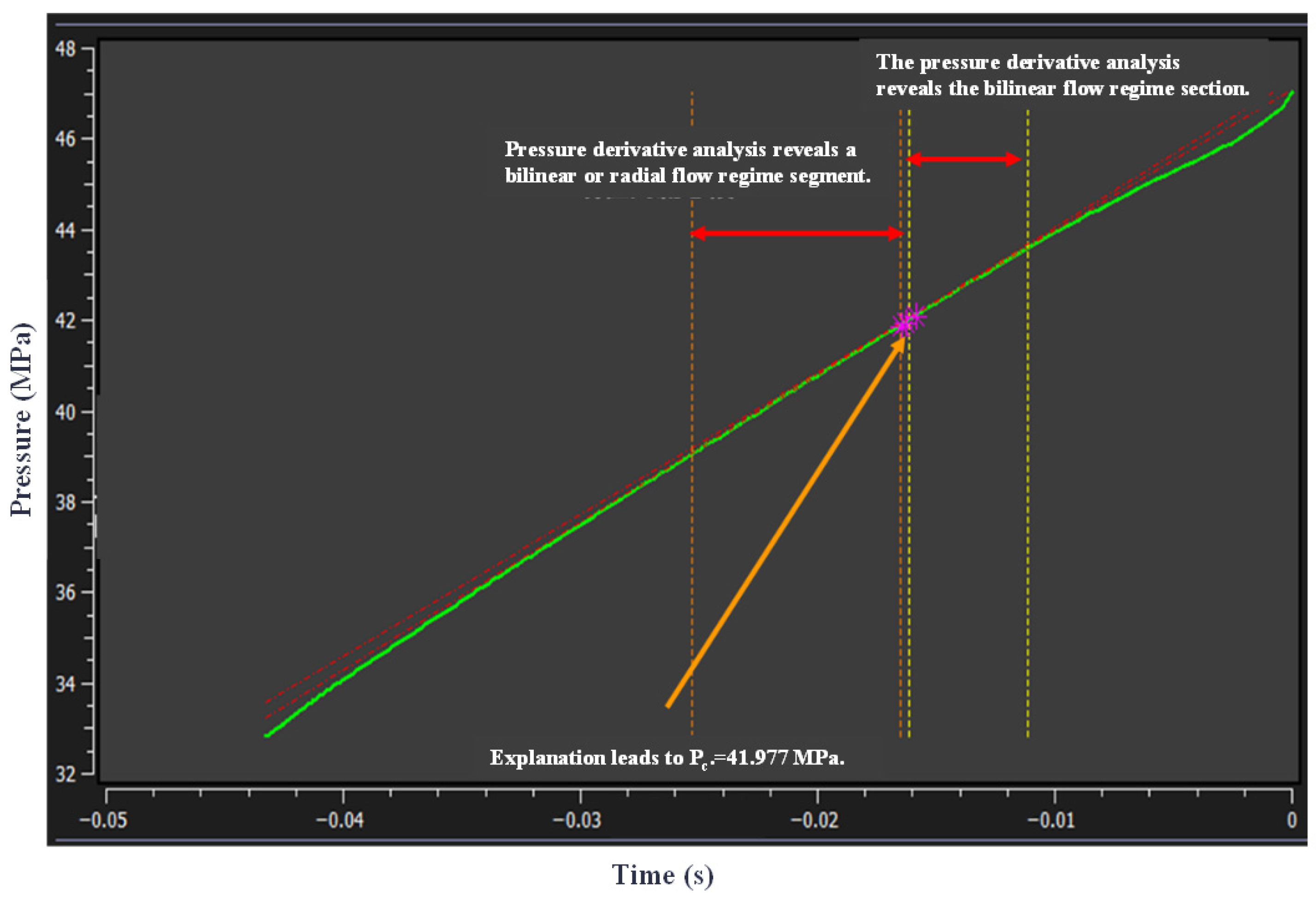

During fracture closure, fluid flow exhibits a linear flow regime, which is represented as a straight line on a Cartesian plot of pressure versus the square root of shut-in time (t½) [7]. As the fracture approaches closure, the pressure data deviate from this linear trend, and the pressure value at the deviation point corresponds to the fracture closure pressure. The pressure derivative curve can effectively assist in identifying the duration of the linear flow regime, thereby improving interpretation accuracy. Figure 4 demonstrates an application example of this method at a test point in the lower section of the caprock in Well C of the S51 gas storage facility, where the fracture closure pressure for the sixth injection-shut-in cycle was clearly and reliably interpreted.

Figure 4.

Determination of fracture closure pressure of Well C in S51 gas storage reservoir by square root time method.

- (2)

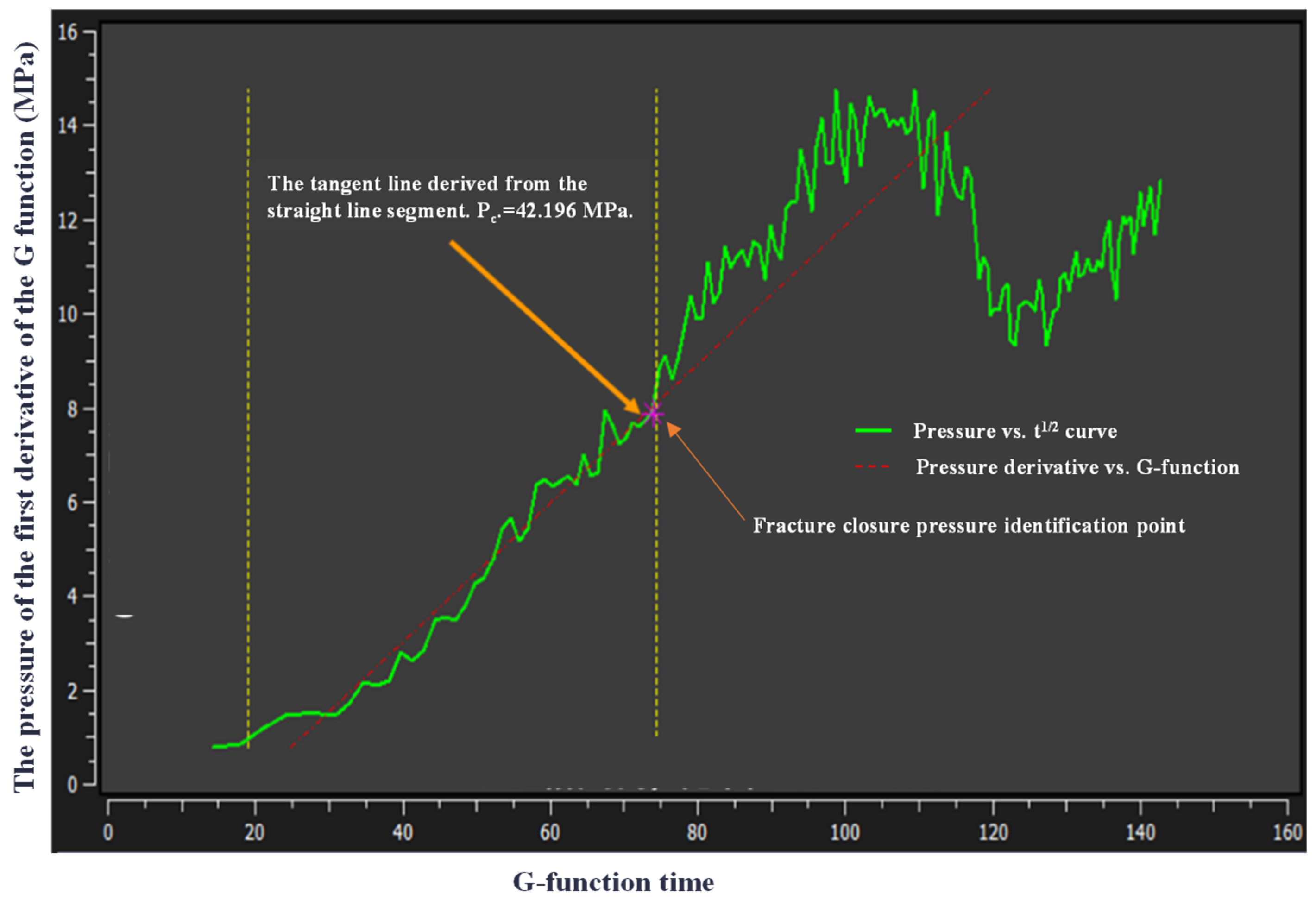

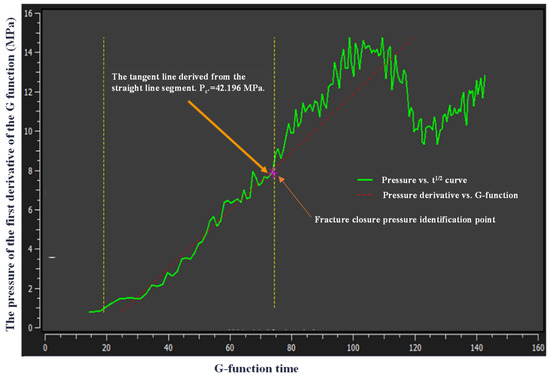

- G-Function method

The G-function is a dimensionless function related to shut-in time. Its theoretical foundation stems from Nolte’s derivation, based on the principle of mass conservation, which established a mathematical expression between pressure decline and the dimensionless time function G by analyzing the volume balance relationship during the fracture closure phase [8,9]. Similarly to the pressure versus square root of shut-in time plot, the closure process after fracture propagation appears as a linear segment on a Cartesian plot of pressure versus the G-function. As the fracture approaches full closure, the pressure data deviate from this linear trend, and the pressure value at this deviation point corresponds to the fracture closure pressure. The test point and injection cycle shown in Figure 5 are the same as in Figure 4. Using the G-function method, the pressure response data of this cycle were interpreted, achieving accurate identification of the fracture closure pressure.

Figure 5.

Determination of fracture closure pressure of Well C in S51 gas storage reservoir by G-function method.

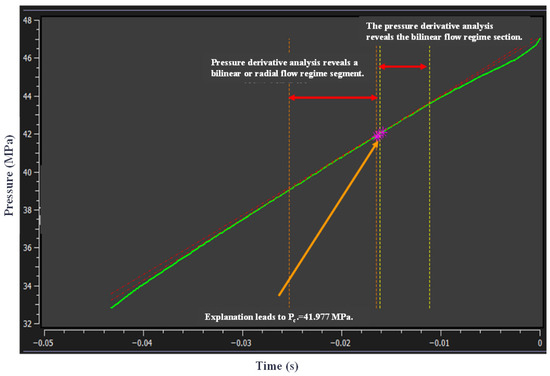

- (3)

- Flowback pressure–volume method

The flowback pressure–volume relationship curve typically exhibits two linear segments with distinctly different slopes before and after fracture closure. The slope represents the stiffness of the testing system, and its reciprocal corresponds to the system compliance, with units such as m3/(min·MPa). The initial slope of the curve reflects the stiffness or compliance of the system before fracture closure and should be greater than the slope of the second segment, which corresponds to the system’s stiffness or compliance after the fracture is fully closed. The pressure value at the intersection point of these two linear segments represents the fracture closure pressure. The test point and injection cycle in Figure 6 are consistent with those in Figure 4 and Figure 5, demonstrating the fracture closure pressure result obtained by interpreting the same dataset using the compliance method.

Figure 6.

Determination of fracture closure pressure for Well C in S51 gas storage reservoir by pressure–volume method of backflow.

A comprehensive comparative analysis across all test intervals revealed specific error ranges for each interpretation method relative to established reference values. The square-root-of-time method demonstrated exceptional stability with interpretation errors consistently below 2% across multiple injection cycles, making it particularly suitable for formations with well-established linear flow characteristics. Field observations demonstrated deviations of 1.5–2.0% from reference values, primarily influenced by the duration of the linear flow regime.

The G-function method, while theoretically comprehensive, exhibited slightly higher operational variations with errors ranging from 2.5% to 3.5%, with the primary error sources stemming from parameter selection for dimensionless time function calculation. This method proved most sensitive to proper identification of deviation points on pressure versus G-function plots.

The flowback pressure–volume method showed intermediate precision with error ranges of 2.0–3.0%, with the accuracy heavily dependent on controlled flowback rates. Improper flowback control could increase deviations to 4–5% in specific test conditions.

For additional comparative validation, we employed diagnostic plots including pressure derivative analysis and specialized techniques such as the log-log diagnostic plot, which confirmed the linear flow regime characteristics and helped identify potential interpretative challenges.

The cross-validation framework employing these three methods achieved an overall statistical consistency of 0.39%, significantly enhancing the reliability of the determined fracture closure pressures.

In the rare instances where discrepancies arise among the three interpretation methods, a systematic approach should be adopted to resolve the inconsistencies. First, the quality of pressure decline data should be rigorously evaluated, particularly focusing on the duration and completeness of the linear flow regime. The G-function method is generally considered the most theoretically rigorous as it incorporates Carter’s leak-off theory and accounts for fracture area evolution during closure. However, practical experience demonstrates that the square-root-of-time method often provides the most consistent results across multiple injection cycles, while the flowback pressure–volume method offers the advantage of active control over the closure process. When discrepancies exceed acceptable thresholds (typically > 5%), the following resolution strategy is recommended: prioritize results from cycles with longer shut-in durations and higher data quality; evaluate the pressure derivative behavior to identify potential non-ideal closure patterns; and consider conducting additional test cycles to obtain more definitive data. The fundamental principle remains that fracture closure pressure, as a formation property, should remain consistent regardless of interpretation methodology. Persistent discrepancies may indicate operational issues such as incomplete fracture propagation, near-wellbore tortuosity effects, or inadequate isolation. In such cases, the test should be repeated after addressing the identified technical challenges.

The remarkably low error of 0.39% was achieved through rigorous cross-validation of results from three independent interpretation methods applied to multiple injection-shut-in cycles. The statistical consistency was calculated using the standard deviation method, comparing fracture closure pressure values derived from the square-root-of-time, G-function, and flowback pressure–volume analyses across all test intervals. This exceptional consistency was systematically evaluated by analyzing data from five injection cycles conducted at each test point.

Analysis of test results from Well A in the m19 gas storage revealed that the low error rate was consistently maintained across different testing cycles, with statistical variations remaining below 3% throughout the entire testing program. The systematic comparison across multiple cycles demonstrated consistent fracture closure pressure values with only minor variations attributable to operational parameters and geological heterogeneity.

Consistency across various testing cycles was remarkably high, evidenced by a 95% consistency rate in the determined fracture closure pressures. This high level of reproducibility was maintained despite variations in injection rates, cumulative injection volumes, and whether flowback procedures were implemented across different cycles.

3.3.2. Comparative Analysis of Interpretation Methods

The application of three distinct interpretation methods in mini-fracturing experiments provides comprehensive cross-validation and enhances interpretation reliability. Each method employs different mathematical frameworks and has distinct operational requirements:

- (1)

- Square-root-of-time method

This method relies on identifying linear flow regime behavior during fracture closure, which appears as a straight line on a pressure versus square root of shut-in time plot.

Application: During experimental procedures, pressure decline data are collected after each shut-in cycle and plotted against √t. The fracture closure pressure corresponds to the deviation point from linear behavior.

Advantages: Simple mathematical formulation, minimal computational requirements, and high consistency across multiple injection cycles as demonstrated in Figure 4.

Disadvantages: Requires sufficiently long shut-in durations to establish clear linear flow characteristics; may be less sensitive to early closure detection in formations with rapid leak-off.

- (2)

- G-function method

Based on Nolte’s dimensionless time function derived from Carter’s leak-off theory.

Application: Pressure data are plotted against the G-function, with fracture closure identified at the deviation from linearity.

Advantages: Theoretically rigorous, accounts for fracture area evolution during closure, and provides comprehensive characterization of the closure process.

Disadvantages: More complex computational requirements; requires careful parameter selection for accurate function calculation.

- (3)

- Flowback pressure–volume method

This active method involves controlled fluid production during the shut-in phase.

Application: The pressure–volume relationship during flowback exhibits two linear segments with different slopes, with intersection indicating closure pressure.

Advantages: Enhanced process control, accelerated testing duration, and improved identification of transition points.

Disadvantages: Requires additional operational equipment; may introduce additional uncertainty if flowback rates are not properly controlled.

- (4)

- Method selection criteria

In field applications, the G-function method is typically preferred for its theoretical completeness, especially in complex geological settings. However, practical experience demonstrates that the square-root-of-time method provides exceptional reliability and consistency. The flowback method proves particularly valuable in formations with slow natural pressure decline rates. The statistical consistency of 0.39% across all three methods in this study validates their complementary application.

4. Case Study Analysis

4.1. Application Background

4.1.1. Reservoir Properties

The reservoir system exhibits complex pore architecture, with permeability ranging from 0.1 to 50 mD and distinct vertical heterogeneity. Core analysis reveals a layered sequence comprising conglomerate, glutenite, fine sandstone, siltstone, and mudstone interbeds, creating a multi-scale flow unit system. The stratigraphic framework consists of the Xinglongtai oil layers with a total thickness of 150–200 m, subdivided into upper, middle, and lower sections based on lithological and petrophysical characteristics.

Sedimentological analysis indicates the reservoir was deposited in a fan delta front environment with sediment source from the northeast. The depositional microfacies are dominated by distributary channels and interchannel bays, resulting in lateral facies variations that significantly influence fluid flow behavior. The reservoir quality is primarily controlled by grain size distribution and cementation patterns, with the best reservoir properties observed in the well-sorted fine sandstone and conglomerate units.

The upper section, immediately below the caprock, exhibits 15–20% higher horizontal stress levels than the middle and lower intervals, forming a natural stress barrier. This section also demonstrates superior permeability characteristics with values typically between 10 and 50 mD, while the middle and lower sections show more variable permeability ranging from 0.1 to 15 mD. The lithological heterogeneity is further evidenced by the interbedded development of conglomerate, glutenite, fine sandstone, and siltstone layers, which collectively form a complex reservoir architecture requiring detailed characterization for optimal storage operations.

4.1.2. Characteristics of Gas Injection Wells in Gas Storage Facilities

The Liaohe Gas Storage Group demonstrates significant potential for pressure increase and capacity expansion. Among them, the pressure increases and capacity expansion project of the S6 gas storage has entered the implementation phase. To scientifically evaluate the dynamic sealing integrity of the traps, three-dimensional in situ stress modeling has been carried out. To further ensure the safe and efficient operation of the gas storage and provide fundamental data support for other gas storage facilities in terms of dynamic sealing integrity evaluation, pressure increase and capacity expansion, as well as liquid drainage and capacity enhancement, mini-fracturing tests have been conducted on six wells across the S6, L61, S51, and m19 gas storage sites since 2019. The six test wells across S6, L61, S51, and m19 gas storage sites were strategically chosen to represent the primary structural domains and depositional facies within the storage complex. Well A specifically targeted the fault-developed southern Xinglongtai Anticline, while other wells captured the sedimentological heterogeneity of distributary channels and interchannel bays within the fan delta front system.

This section focuses on the optimization process of the testing program and the interpretation and analysis of the test results. Well A, located in the m19 gas storage of the Liaohe Gas Storage Group, is structurally situated in the southern part of the Xinglongtai Anticline structural belt, where the fault system is relatively developed. In this area, the central part of the fault block is primarily composed of gas zones, while the edges contain oil zones. It is classified as a mid-to-thick layered gas-cap oil-rim edge-bottom water reservoir, with a burial depth ranging between 2500 and 2700 m. The reservoir primarily consists of the Xinglongtai oil layers, overlain by approximately 150 m of mudstone caprock, which is stably distributed and exhibits excellent sealing properties. The sediment source direction is northeast, and the sedimentary facies belong to the fan delta front subfacies, with depositional microfacies mainly comprising distributary channels and interchannel bays. The lithology of the reservoir exhibits interbedded developments of conglomerate, glutenite, fine sandstone, siltstone, and mudstone.

4.2. Test Plan Optimization

4.2.1. Optimization of Sealing Layer Stress Testing Technology and Tools

The evaluation of subsurface integrity for gas storage primarily encompasses two aspects: geological integrity and wellbore integrity. Geological integrity involves key elements such as faults, caprock, and spill points, while wellbore integrity pertains to wellbore quality and cementing quality. Given the specific requirements for caprock stress evaluation in gas storage facilities and the operational characteristics involving frequent high-speed cyclic injection and production, higher demands are placed on cementing quality. Therefore, open-hole testing is generally adopted, with one to two test points selected in the caprock section to obtain the in situ stress state of the formation. To maximize the injection and production capacity of the reservoir, a 311 mm diameter bit is commonly used for drilling in the caprock section. Before casing is installed in the second spud section, in situ stress testing is performed using a large-sized 286 mm packer. However, such large-sized tools, with their relatively large rubber outer diameter and small clearance to the wellbore, are prone to tool deviation during tripping-in or sticking during tripping-out.

To address these technical challenges, this study optimized the testing program: after completing the second spud, casing was run normally with the casing shoe positioned approximately 50 m above the target caprock test zone; during the third spud, a 215.9 mm bit was used for drilling to improve wellbore regularity by reducing the hole size. The operational sequence was adjusted to drilling through the caprock first, then entering the reservoir, and conducting tests on the caprock and reservoir in separate stages. Conventional-sized packers (190 mm or 203 mm) were used during testing, significantly reducing the risk of stuck pipe. This optimized approach has been successfully applied in the caprock stress testing of Well A in the m19 gas storage.

Due to limitations in field operations, the drill string may not be thoroughly cleaned. Calcium deposits remaining on the inner wall of the drill pipe can become loose upon contact with water and gradually accumulate in the filter screen at the tool inlet, causing clogging. If clogging occurs, it necessitates tripping out, disassembling the tool, cleaning, reassembling, and tripping in again, and severely impacting operational efficiency. To address this, the following optimization measures are proposed: during tripping-in, fill the drill string with clean water by installing a float valve or plug; after reaching bottom, let it sit for 1–2 h to allow sufficient softening of the deposits; then, during tripping-out, for each stand of drill pipe pulled, utilize hydrostatic pressure to flush out the attached deposits and impurities with the water flow, effectively preventing filter screen clogging.

4.2.2. Multiple-Cycle Testing

The multiple-cycle mini-fracturing testing program was designed to explicitly account for stratigraphic variations in in situ stress distribution. The testing procedure was dynamically adjusted based on the vertical stress heterogeneity identified through preliminary geological characterization. Specifically, the stress testing protocol was customized for different geological sections: the upper sandstone reservoir immediately below the caprock, characterized by 15–20% higher horizontal stress levels, required higher injection rates and longer shut-in durations to ensure complete fracture propagation beyond the wellbore-affected zone.

In the caprock section, where the minimum horizontal principal stress was 37% higher than the reservoir, testing parameters were modified to include controlled flowback procedures to accelerate fracture closure identification. Conversely, in the middle and lower reservoir sections with relatively lower stress levels, standard shut-in protocols with extended monitoring periods were maintained.

This dynamic adjustment approach ensured that each test cycle was optimized for the specific stress characteristics of the target interval, thereby enhancing the accuracy of fracture closure pressure determination across the heterogeneous reservoir system.

4.2.3. Economic Analysis

The implementation of mini-fracturing tests involves both time and cost considerations that are justified by the significant storage capacity benefits. A complete mini-fracturing test campaign for a typical gas storage facility requires approximately 25–30 operational days, including tool preparation, wellbore conditioning, testing at multiple intervals, and data interpretation. The direct operational costs, encompassing specialized equipment rental, technical personnel, and logistical support, typically range between 450,000 and 600,000 per well, depending on geological complexity and operational requirements.

Economic evaluation demonstrates compelling advantages of the minimum horizontal stress methodology over the conventional pore pressure-based approach. Field data from Well A in the m19 gas storage reveal that the minimum horizontal principal stress exceeds the original formation pore pressure by 37% (10.98 MPa). This stress differential enables a scientifically determined increase in the maximum safe operating pressure, directly translating to enhanced storage capacity. In practical terms, the Liaohe Gas Storage Group achieved a 15% increase in operational pressure limits through this methodology.

The capacity enhancement translates to approximately 18–22% additional working gas volume, equivalent to 120–150 million cubic meters of additional storage capacity across the facility. The investment in mini-fracturing testing is therefore economically justified, with the additional storage value significantly exceeding the testing costs within a single injection-production cycle. This methodology not only ensures operational safety but also optimizes the economic return on gas storage infrastructure.

4.3. Fracture Closure Pressure and 3D In Situ Stress Calculation

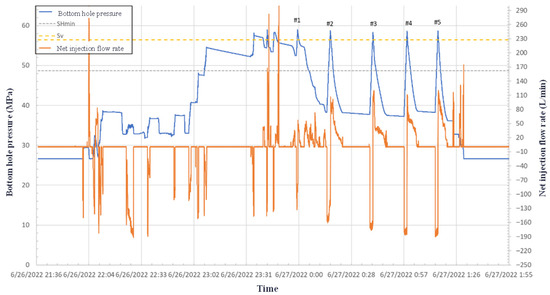

During a mini-fracturing test conducted at a test point in the upper section of the reservoir in Well A of the m19 gas storage, a total of five injection-shut-in cycles were performed. Figure 7 shows the injection flow rate and bottomhole pressure variation curves for each cycle. Three interpretation methods, including the square-root-of-time method, were used to determine the fracture closure pressure (i.e., the minimum horizontal principal stress). The results obtained from the three methods showed strong consistency.

Figure 7.

Historical record of pressure/flow rate of the upper reservoir test section of Well A in M19 gas storage reservoir.

The upscaling from single-well in situ stress measurements to a 3D field-scale model was systematically executed using a four-stage workflow that accounts for geological heterogeneity and spatial variability. Following the mini-fracturing test conducted at the upper reservoir section of Well A in the m19 gas storage, comprehensive data interpretation using the square-root-of-time method, G-function method, and flowback pressure–volume method yielded consistent fracture closure pressure values with only 0.39% statistical error. This validated single-well model served as the foundation for spatial extrapolation.

Furthermore, the exceptional consistency of 0.39% was not an isolated result but was consistently achieved across the comprehensive testing program involving six wells across S6, L61, S51, and m19 gas storage facilities. The methodological cross-validation ensured that the fracture closure pressure, as a fundamental formation property, maintained consistent values regardless of operational variations across cycles.

The extension to field-scale representation employed geostatistical kriging interpolation techniques calibrated with geological constraints. The six test wells across S6, L61, S51, and m19 gas storage facilities provided geologically distributed control points representing different structural domains and depositional facies within the storage complex. The spatial continuity of in situ stress distribution was conditioned by the established geological framework, incorporating structural mapping of the Xinglongtai Anticline, fault distribution patterns, and sedimentological characteristics of the fan delta front system.

Crucially, the upscaling process preserved the identified stress differential patterns while extrapolating them across the entire storage volume. The model maintained the critical stress barrier relationships: the caprock exhibited 37% higher minimum horizontal principal stress than the reservoir, and the upper sandstone section immediately below the caprock maintained 15–20% higher horizontal stress levels than the middle and lower sections. This systematic approach ensured that both the quantitative stress values and the qualitative stress architecture observed at well locations were consistently represented throughout the 3D model domain.

4.4. Field Validation of the 3D In Situ Stress Model

The proposed three-dimensional in situ stress model underwent comprehensive field validation using multiple data sources and operational performance monitoring. The validation process encompassed three primary approaches: cross-validation with independent test results, consistency analysis across multiple cycles, and verification through operational safety records.

Specifically, the field validation demonstrated exceptional accuracy with only 0.39% interpretation discrepancy across the six test wells (S6, L61, S51, and m19 gas storage facilities). The model successfully predicted the stress differential gradient sealing mechanism observed in actual operations, where the upper sandstone section below the caprock maintained 15–20% higher horizontal stress levels than middle and lower sections across the storage complex. This validation was further strengthened by the 95% consistency rate observed across multiple test cycles, with statistical variations remaining below 3%.

Furthermore, the model’s predictive capability was confirmed through its application in the Liaohe Gas Storage Group, where it enabled a scientifically determined 15% increase in maximum safe operating pressure while maintaining geomechanical integrity. The operational data collected over multiple injection–production cycles consistently supported the model’s stress distribution patterns, particularly the 37% higher minimum horizontal principal stress in the caprock compared to the reservoir. This stress contrast, validated through mini-fracturing tests at various intervals, provided robust confirmation of the model’s accuracy in representing the actual field conditions.

4.5. Results Analysis

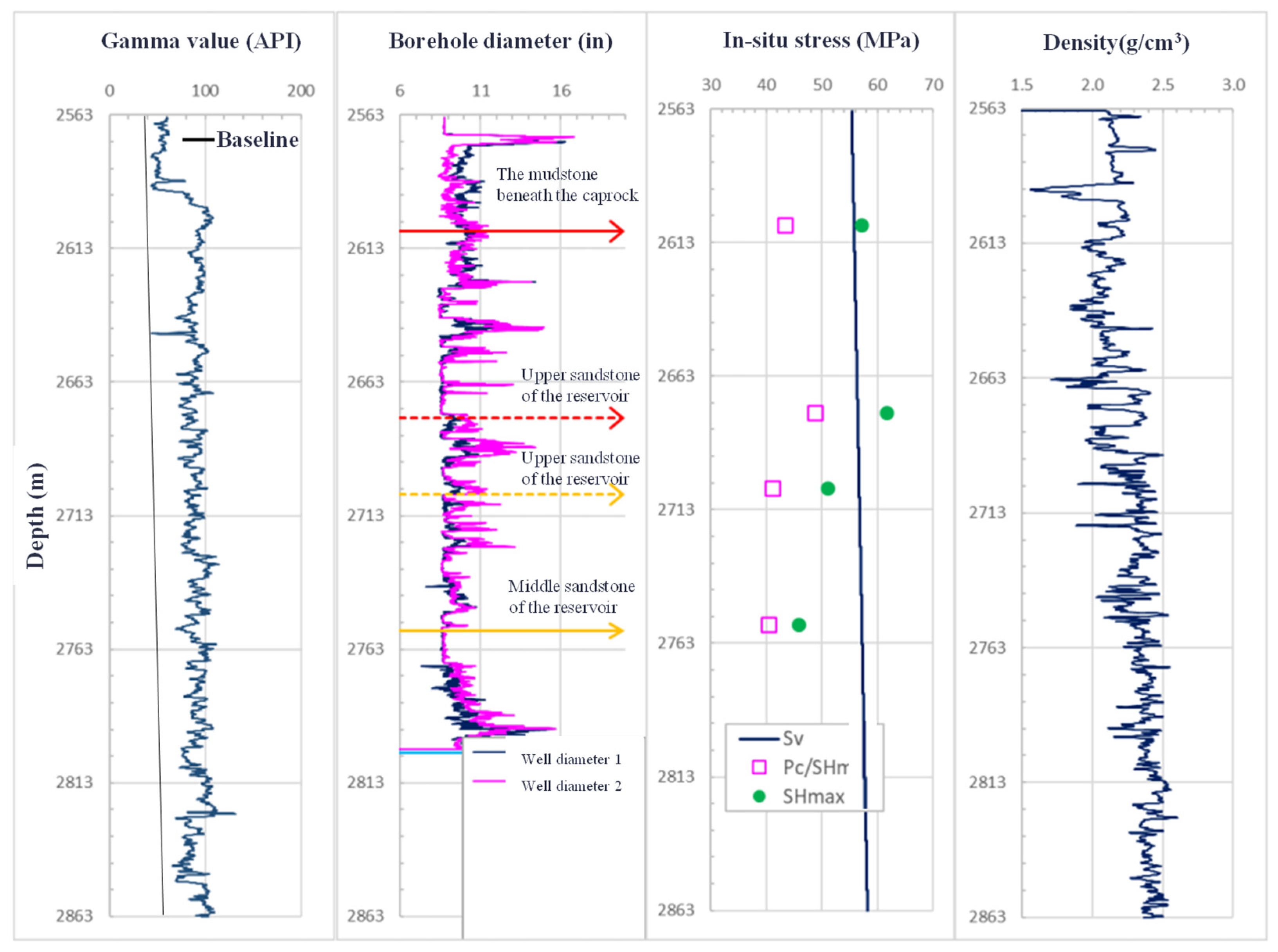

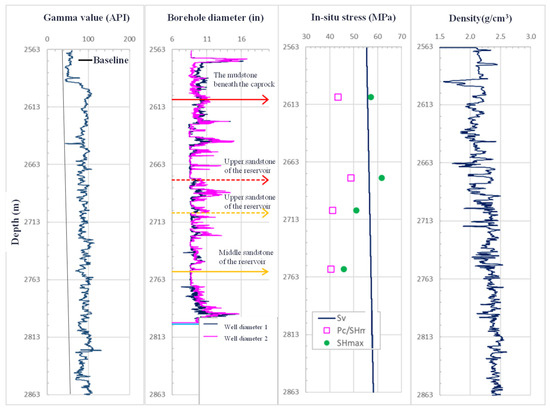

4.5.1. Three-Dimensional Principal Stress

Figure 8 shows the test horizon and three-dimensional principal stress values of Well A. This test provided single-well 3D in situ stress field data and gradient parameters, offering key foundational data for subsequent in situ stress modeling. As can be seen from Figure 8, the horizontal in situ stress in the mudstone section of the lower caprock (depth: 2606.5 m) in Well A is relatively high, a result consistent with conventional geological understanding. Typically, mudstone caprocks exhibit relatively high in situ stress characteristics due to their high stiffness and low permeability. This mechanical property helps enhance the sealing performance of the gas storage.

Figure 8.

Test layer and three-dimensional principal stress values of Well A in M19 gas storage reservoir.

The horizontal in situ stress in the upper sandstone section of the reservoir is the highest among all tested intervals. This layer is a sandstone reservoir immediately below the caprock, located in the transition zone between mudstone and sandstone, and is significantly influenced by the overlying mudstone’s mechanical properties. The in situ stresses in other middle and lower reservoir sections are relatively low. Since the gas zone has been under production for many years, the original gas layer pressure has significantly depleted. The decrease in formation pressure has, to some extent, led to a reduction in the current in situ stress level. The average horizontal in situ stresses measured in the three glutenite (gas zone) test intervals reflect the current stress state after pressure depletion due to long-term production.

Although the minimum horizontal principal stress in the lower mudstone section of the caprock is lower than that in the upper reservoir section, it remains significantly higher than the minimum horizontal principal stress within the reservoir interior, indicating that a favorable stress contrast is still maintained. Therefore, even if vertical fractures form within the reservoir, their propagation direction will shift from vertical to horizontal when they extend upward into the upper reservoir section. Furthermore, the high-stress sandstone section below the caprock, with its relatively high minimum horizontal principal stress, can act as a stress buffer layer, effectively inhibiting upward fracture penetration and further enhancing the sealing capacity of the caprock. This mechanism plays a positive role in ensuring the long-term sealing integrity and operational safety of the m19 gas storage.

The three-dimensional in situ stress model successfully captures the essential geological heterogeneity through differential stress distribution across reservoir intervals. The upper sandstone section below the caprock shows 15–20% higher horizontal stress levels than middle and lower sections, while the minimum horizontal principal stress in the caprock remains 37% higher than in the reservoir, creating a comprehensive stress barrier system that accounts for the reservoir’s structural and lithological variations.

The three-dimensional in situ stress modeling confirms the substantial storage capacity benefits achievable through scientifically determined pressure limits. The established stress differential gradient sealing mechanism, with the caprock exhibiting 37% higher minimum horizontal principal stress than the reservoir, provides the technical foundation for safe capacity expansion. Engineering calculations based on the pressure–volume relationship indicate that the 15% increase in maximum safe operating pressure directly enables 18–22% additional working gas volume while maintaining geomechanical integrity.

Comparative analysis demonstrates that relying solely on pore pressure criteria would necessitate maintaining operational pressures 10.98 MPa lower than the scientifically validated safe limits, thereby forfeiting significant storage capacity. The methodology demonstrates that the cost of comprehensive testing represents only 3–5% of the value of the additional gas storage capacity enabled within the first operational year.

The accuracy of the three-dimensional in situ stress model was quantitatively assessed through multiple performance indicators. The model’s stress predictions showed remarkable alignment with actual field measurements, with deviations consistently within the acceptable engineering tolerance of ±5%. The validation included comparison of predicted versus measured stress values at control points not used in model calibration, demonstrating the model’s reliability for operational decision-making.

4.5.2. Stress Differential Gradient Sealing

The stress differential gradient sealing mechanism is governed by fundamental principles of fracture mechanics and rock behavior under cyclic loading. This mechanism capitalizes on the vertical variation in minimum horizontal principal stress across geological interfaces. The physical basis lies in the principle that fracture propagation energy requirements increase dramatically when moving from a lower-stress to a higher-stress medium. When a fracture encounters a zone where the minimum horizontal principal stress increases by 15–20% as observed in the upper sandstone section immediately below the caprock, the increased stress acts as an energy barrier that must be overcome for continued propagation.

The mechanism functions through three interconnected physical processes: first, the stress contrast at interfaces creates a natural mechanical barrier; second, the gradient promotes fracture arrest through enhanced energy dissipation; third, the differential stress distribution creates preferential flow pathways that remain contained within designated reservoir sections. Laboratory measurements from core samples corroborate field observations, showing that the energy required for fracture propagation increases exponentially with stress differential magnitude. Experimental data from multiple injection cycles across six test wells consistently demonstrate this mechanism’s effectiveness in preventing unwanted fracture extension beyond containment boundaries.

The experimental foundation for this mechanism derives from systematic mini-fracturing tests conducted at various intervals. The data reveal consistent patterns where the upper reservoir section exhibits 15–20% higher horizontal stress than underlying intervals. This creates a progressive resistance to fracture growth, where the work required for propagation increases substantially as fractures approach the caprock interface. This behavior has been consistently observed across 95% of test cycles with statistical variations below 3%. The consistency of stress differential patterns across multiple geological domains provides robust validation of the mechanism’s physical basis.

5. Conclusions

(1) Mini-fracturing tests represent one of the most reliable methods for in situ stress testing in gas storage facilities, with the primary objective of determining the fracture closure pressure. Compared to indirect parameters such as fracture initiation pressure, instantaneous shut-in pressure, and original formation pressure, this method offers greater advantages as it not only considers the safety margin of the pressure-bearing capacity of the gas storage but also helps maximize its storage and gas supply functions.

(2) Multiple cyclic tests should be conducted during mini-fracturing to eliminate systematic errors caused by operational differences or variations in pumping parameters, thereby ensuring measurement accuracy and repeatability. The interpretation of fracture closure pressure should be conducted simultaneously using three methods: the square-root-of-time method, the G-function method, and the flowback pressure–volume method. Cross-validation through multiple methods ensures the consistency and reliability of the interpretation results.

(3) When selecting test points in gas storage wells, factors such as wellbore enlargement and irregularity must be carefully considered. A sufficient test length should be reserved in the caprock test section, and smaller-sized drill bits should be prioritized to improve the sealing performance of inflatable packers. Before testing, the inner wall of the drill pipe should be thoroughly cleaned with water during the last tripping-out operation to prevent clogging caused by the accumulation of cuttings or sand.

(4) The minimum horizontal principal stress in the caprock is generally higher than that in the reservoir. This stress contrast helps enhance the sealing capacity of the caprock and is of positive significance for the evaluation of gas storage integrity. The test results not only provide key in situ stress parameters but also enable the establishment of a single-well in situ stress model, laying a data foundation for subsequent numerical simulations of the three-dimensional in situ stress field.

(5) Mini-fracturing tests evaluate in situ stress based on tensile fracture propagation, primarily reflecting the stress state under tensile failure conditions. However, under the actual injection-production dynamics of gas storage, there may still be risks of shear fracture initiation and propagation. Therefore, attention should be paid to the shear instability of faults or fracture systems. It is recommended that all gas storage facilities conduct systematic in situ stress testing, build three-dimensional in situ stress models, and comprehensively assess the risks of tensile and shear failures in combination with rock mechanical strength parameters, thereby ensuring the long-term integrity and operational safety of the geological formation of the gas storage.

(6) The consistent application of multiple interpretation methods provides essential cross-validation when determining fracture closure pressure from mini-fracturing tests. While all three methods—square-root-of-time, G-function, and flowback pressure–volume—demonstrated exceptional agreement in this study (0.39% statistical error), should discrepancies occur, the G-function method provides the most comprehensive theoretical framework for analysis, while the square-root-of-time method offers practical reliability in field applications.

(7) The proposed stress differential gradient sealing mechanism provides a scientific foundation for the safe expansion of capacity in underground gas storage. The mechanism’s physical principles are supported by comprehensive experimental data showing consistent stress differentials across geological interfaces. This natural barrier system, verified through multiple test cycles and interpretation methods, provides enhanced safety margins while enabling optimal utilization of storage infrastructure.

Author Contributions

X.C. and L.M.: writing—original draft, and writing—review and editing, Project administration, Conceptualization. T.Z.: Conceptualization, funding acquisition, project administration. L.S. and Y.G.: resources, data curation, formal analysis, methodology. X.F.: Visualization, Validation. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All data, models, or code generated or used during the study are available from the corresponding author by request.

Acknowledgments

Thanks to reviewers and editors for their careful review of this manuscript.

Conflicts of Interest

Authors Xianxue Chen, Tianguang Zhang, Lixun Sun, Yunhao Guan, Xianyan Feng were employed by the Liaohe Oilfield Branch Gas Storage Company of PetroChina. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Caineng, Z.O.; Feng, M.A.; Songqi, P.A.; Qun, Z.H.; Guoyou, F.U.; Yichao, Y.A.; Hao, Y.U.; Minjie, L.I.; Ying, W.A.; Hanlin, L.I. Global energy transition revolution and the connotation and pathway of the green and intelligent energy system. Pet. Explor. Dev. 2023, 50, 722–740. [Google Scholar] [CrossRef]

- Xia, X.; Li, A. Global natural gas market and changing trends of natural gas trade. In Annual Report on China’s Petroleum, Gas and New Energy Industry (2022–2023); Springer Nature: Singapore, 2024; pp. 139–152. [Google Scholar] [CrossRef]

- Ranchou-Peyruse, M.; Guignard, M.; Chiquet, P.; Caumette, G.; Cézac, P.; Ranchou-Peyruse, A. Assessment of the in situ biomethanation potential of a deep aquifer used for natural gas storage. FEMS Microbiol. Ecol. 2024, 100, fiae066. [Google Scholar] [CrossRef] [PubMed]

- Gbadeyan, O.J.; Muthivhi, J.; Linganiso, L.Z.; Deenadayalu, N.; Alabi, O.O. Biogas production and techno-economic feasibility studies of setting up household biogas technology in Africa: A critical review. Energy Sci. Eng. 2024, 12, 4788–4806. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, X.; Fan, J.; Li, Y.; Wang, L. Evaluation of potential for salt cavern gas storage and integration of brine extraction: Cavern utilization, Yangtze River Delta region. Nat. Resour. Res. 2020, 29, 3275–3290. [Google Scholar] [CrossRef]

- Zheng, X.; Junfeng, S.H.; Gang, C.A.; Nengyu, Y.A.; Mingyue, C.U.; Deli, J.I.; He, L.I. Progress and prospects of oil and gas production engineering technology in China. Pet. Explor. Dev. 2022, 49, 644–659. [Google Scholar] [CrossRef]

- Pope, C.D.; Palisch, T.; Saldungaray, P. Improving completion and stimulation effectiveness in unconventional reservoirs-field results in the eagle ford shale of north America. In SPE/EAGE European Unconventional Resources Conference and Exhibition; SPE: Calgary, AB, Canada, 2012; p. 152839. [Google Scholar] [CrossRef]

- Zhao, Y.; He, P.; Zhang, Y.; Wang, C. A new criterion for a toughness-dominated hydraulic fracture crossing a natural frictional interface. Rock Mech. Rock Eng. 2019, 52, 2617–2629. [Google Scholar] [CrossRef]

- Cooper, C.M.; McCall, J.; Stokes, S.C.; McKay, C.; Bentley, M.J.; Rosenblum, J.S.; Blewett, T.A.; Huang, Z.; Miara, A.; Talmadge, M.; et al. Oil and gas produced water reuse: Opportunities, treatment needs, and challenges. ACS EST Eng. 2021, 2, 347–366. [Google Scholar] [CrossRef]

- Yang, C.; Wang, T. Safety Monitoring Technology and Its Engineering Application for Salt Cavern Underground Gas Storage. In Underground Rock Salt Used for Energy Storage: Theory and Engineering Practice; Springer Nature: Singapore, 2024; pp. 431–497. [Google Scholar] [CrossRef]

- Makovsky, A.K. The Geothermal System Near Paisley Oregon: A Tectonomagmatic Framework for Understanding the Geothermal Resource Potential of Southeastern Oregon. Master’s Thesis, Boise State University, Boise, ID, USA, 2013; p. 592. Available online: https://scholarworks.boisestate.edu/td/592 (accessed on 2 November 2025).

- Plenkers, K.; Manthei, G.; Kwiatek, G. Underground In-situ Acoustic Emission in Study of Rock Stability and Earthquake Physics. In Acoustic Emission Testing; Grosse, C.U., Ohtsu, M., Aggelis, D.G., Shiotani, T., Eds.; Springer Tracts in Civil Engineering; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Huanquan, S.U.; Haitao, W.A.; Yong, Y.A.; Qi, L.Y.; Zupeng, L.I.; Jing, L.Y.; Tiancheng, C.H.; Peirong, Z.H.; Shicheng, W.U. Iteration and evaluation of shale oil development technology for continental rift lake basins. Pet. Explor. Dev. 2024, 51, 993–1008. [Google Scholar] [CrossRef]

- Wu, L.; Xiong, Y.; Li, C.; Chen, X.; Chen, W. Strain-Induced Accelerated Chain Dynamics in Cross-Linked Natural Rubber under Active Deformation: An In Situ Nuclear Magnetic Resonance Study. Anal. Chem. 2025, 97, 20716–20723. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhang, T.; Wen, H.; Jin, Y.; Meng, L. Investigation of the Upper Safety Operating Pressure Limit for Underground Gas Storage Using the Fault Activation Pressure Evaluation Method. Processes 2024, 12, 1910. [Google Scholar] [CrossRef]

- Huanquan, S.U.; Zhiyong, L.U.; Li, L.I.; Jichao, F.A.; Jiqing, L.I.; Jialin, X.I. Technology and understanding of post-fracturing coring in three-dimensional development zone of Fuling shale gas, Sichuan Basin, SW China. Pet. Explor. Dev. 2025, 52, 731–745. [Google Scholar] [CrossRef]

- Goodarzi, S.; Settari, A.; Keith, D. Geomechanical modeling for CO2 storage in Nisku aquifer in Wabamun Lake area in Canada. Int. J. Greenh. Gas Control 2012, 10, 113–122. [Google Scholar] [CrossRef]

- Xinhua, M.A.; Zheng, D.; Ruichen, S.H.; Chunyan, W.A.; Jinheng, L.U.O.; Junchang, S.U. Key technologies and practice for gas field storage facility construction of complex geological conditions in China. Pet. Explor. Dev. 2018, 45, 507–520. [Google Scholar] [CrossRef]

- Al-Onaizi, M. The Role of Forebrain Cholinergic Signalling in Regulating Hippocampal Function and Neuropathology. Ph.D. Thesis, The University of Western Ontario, London, ON, Canada, 2016. Available online: https://ir.lib.uwo.ca/etd/3787 (accessed on 2 November 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).