Analysis of Particle Distribution and Aggregation Characteristics in a Hydrocyclone with a Complex Curved Inlet Structure

Abstract

1. Introduction

2. Mathematical Model

2.1. Model Description

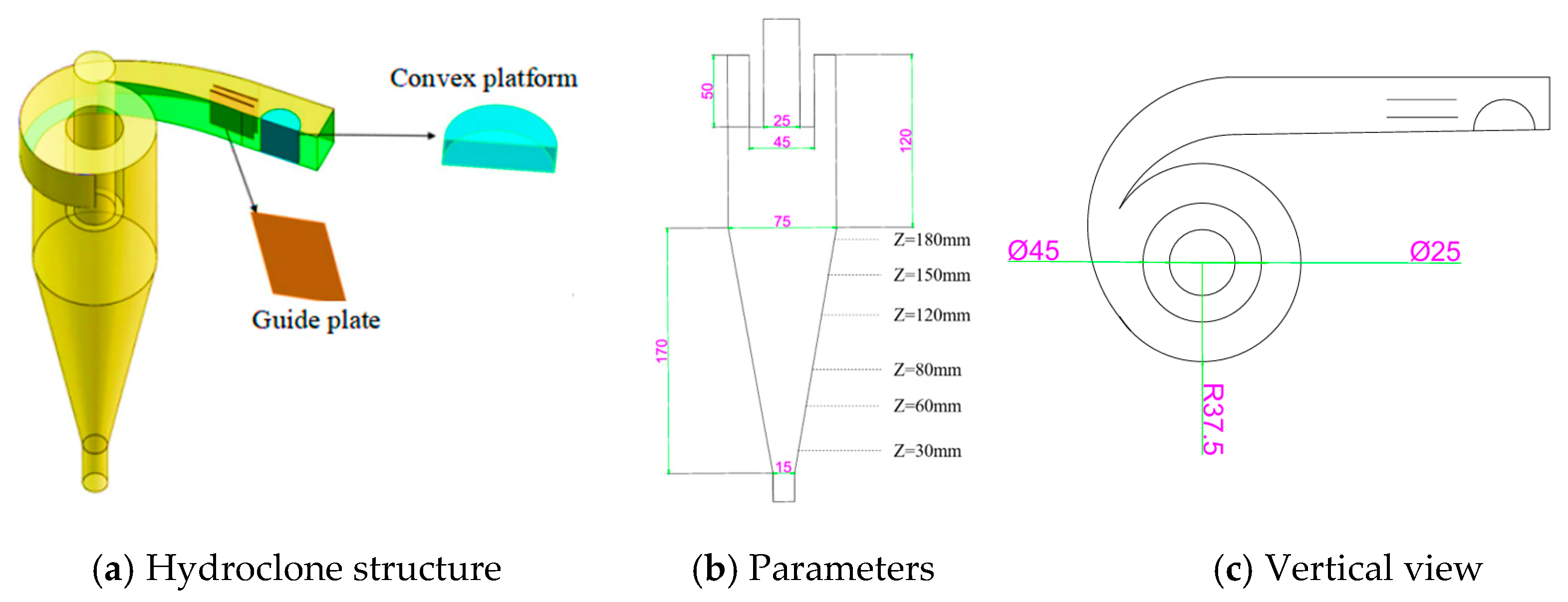

2.2. Geometric Model

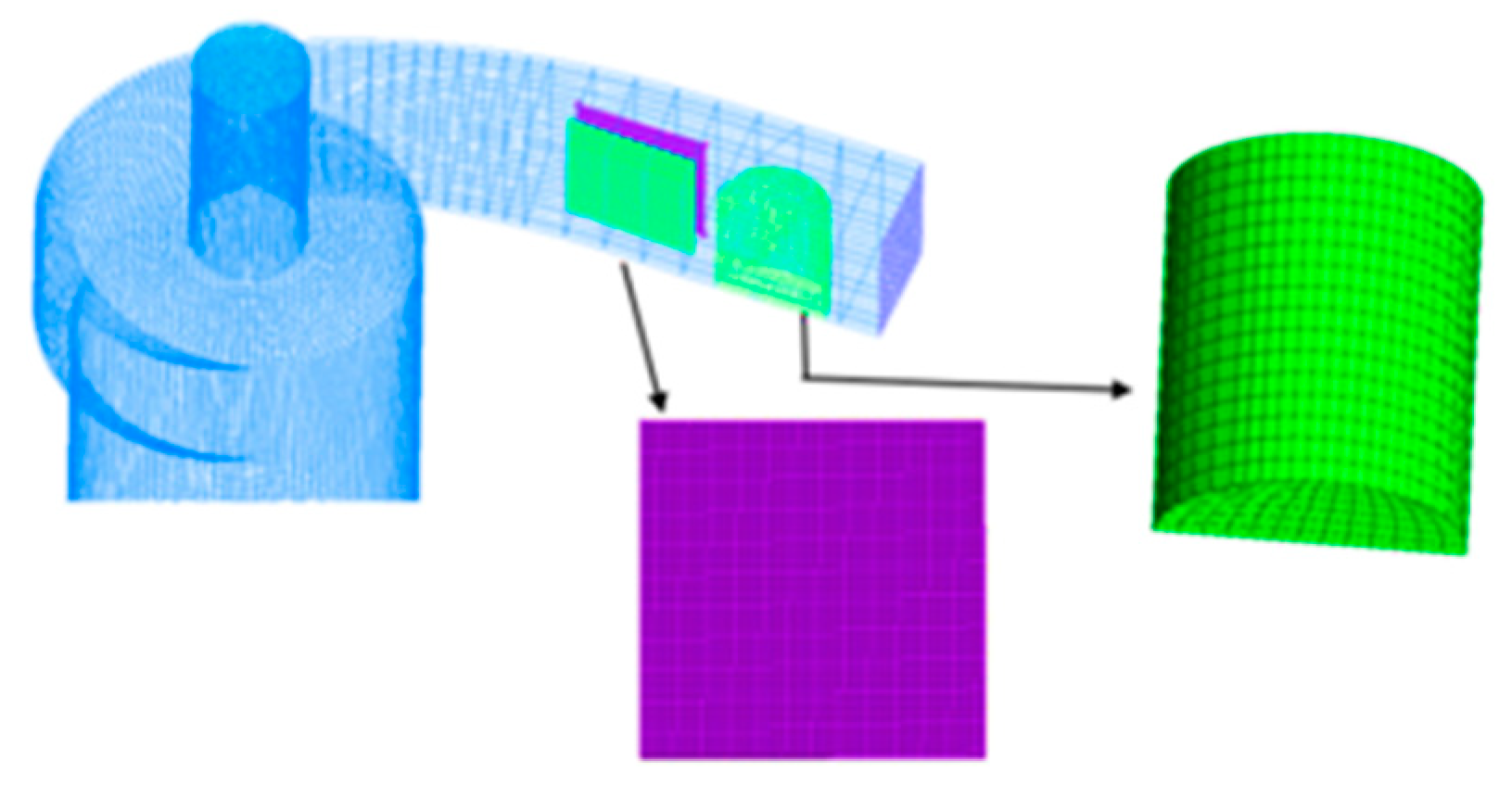

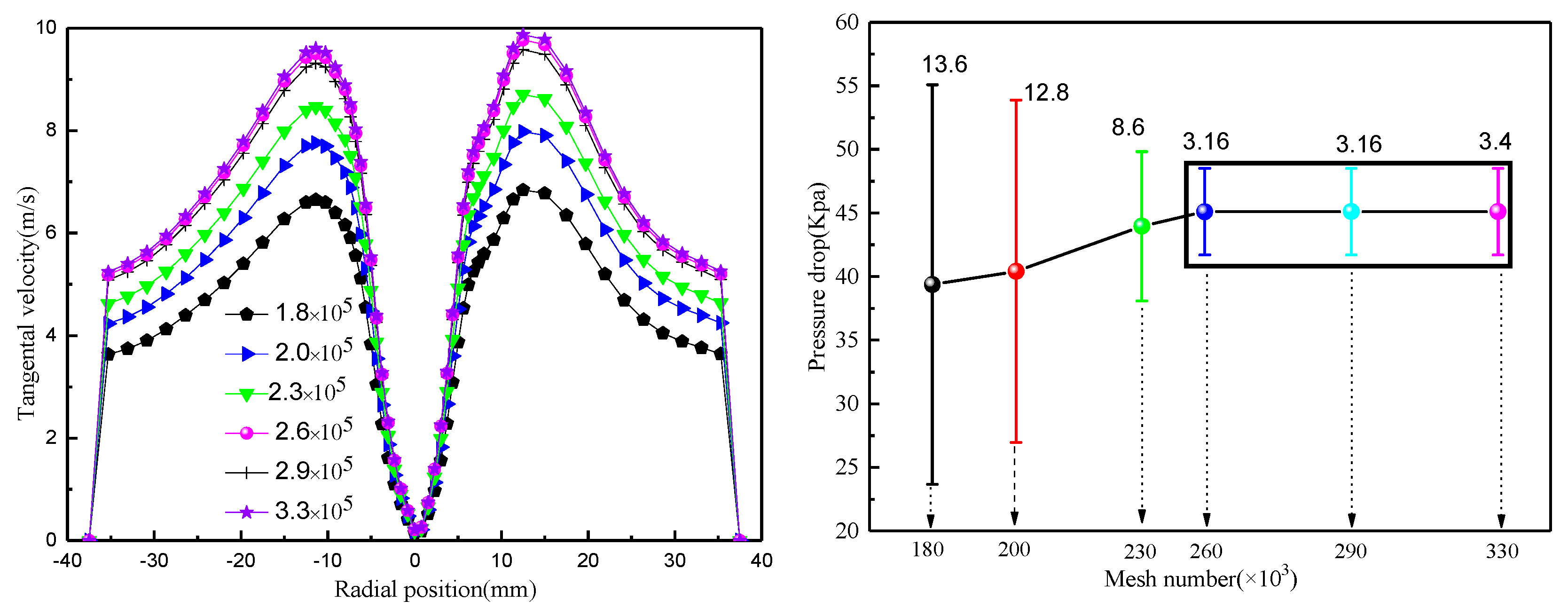

2.3. Boundary Condition Setup and Mesh Division

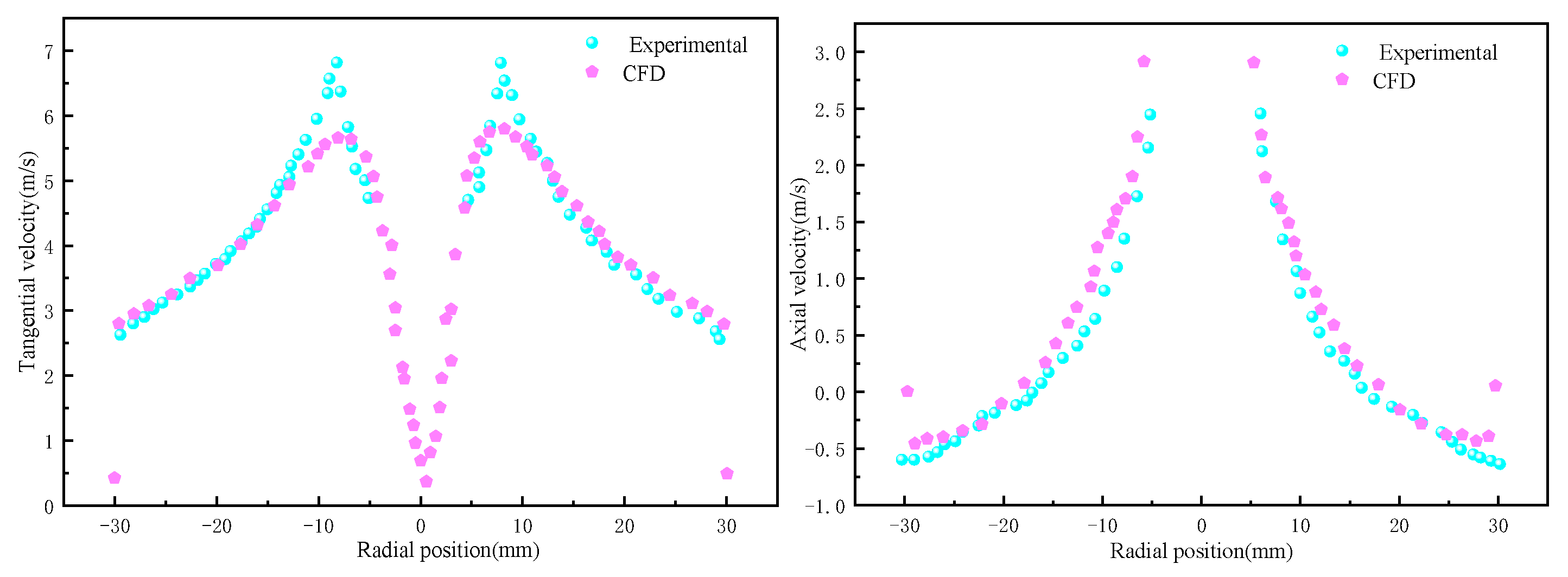

2.4. Model Validation

3. Results and Discussion

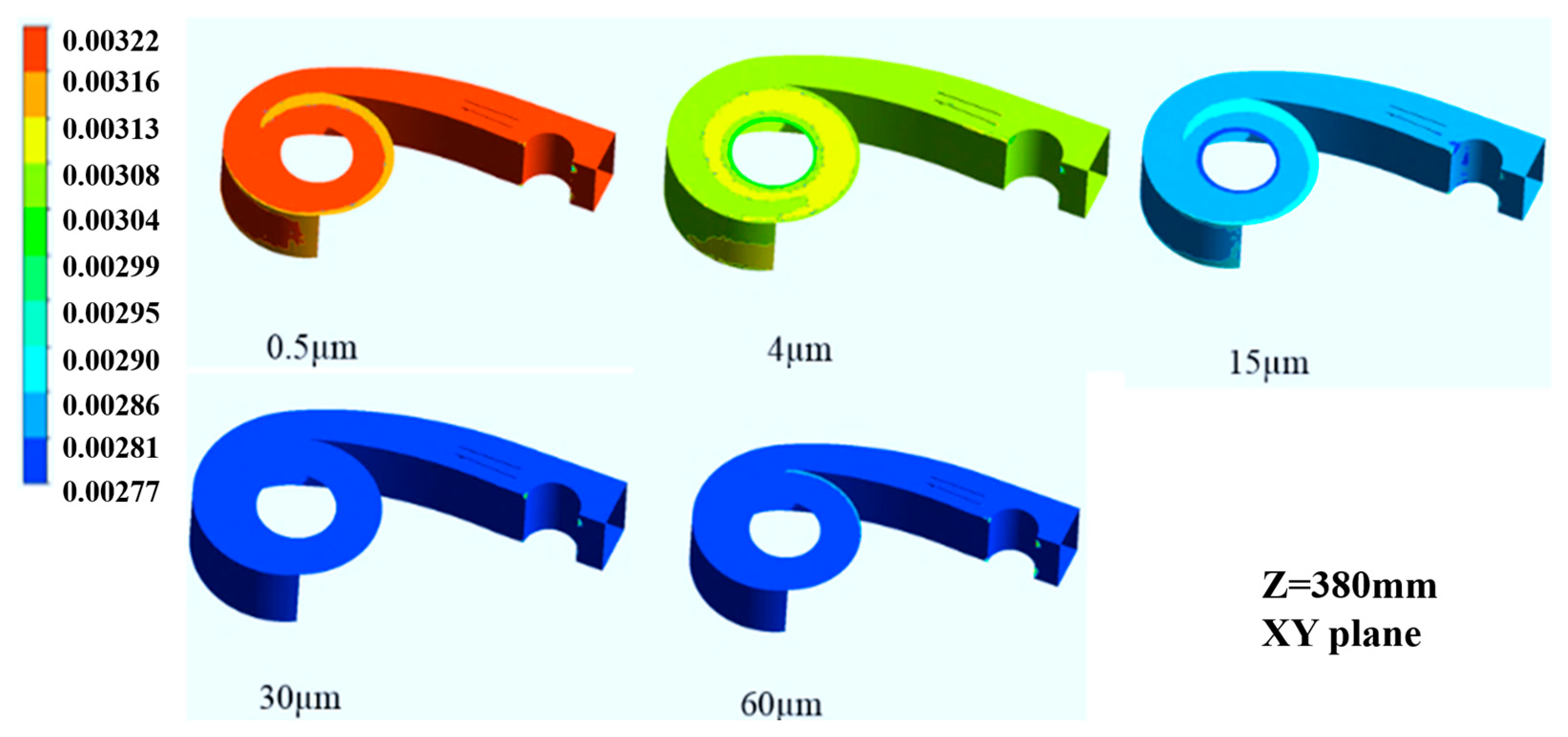

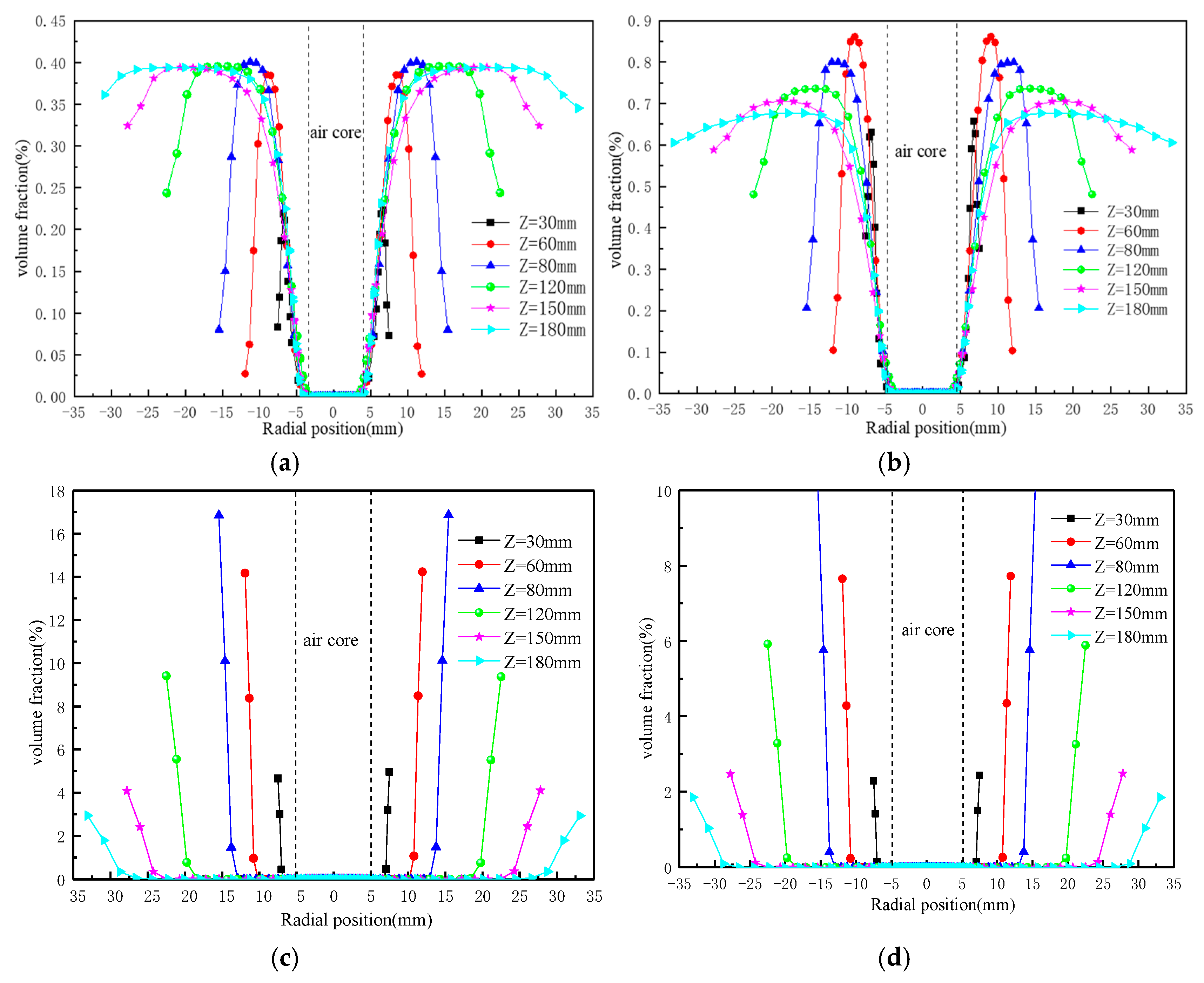

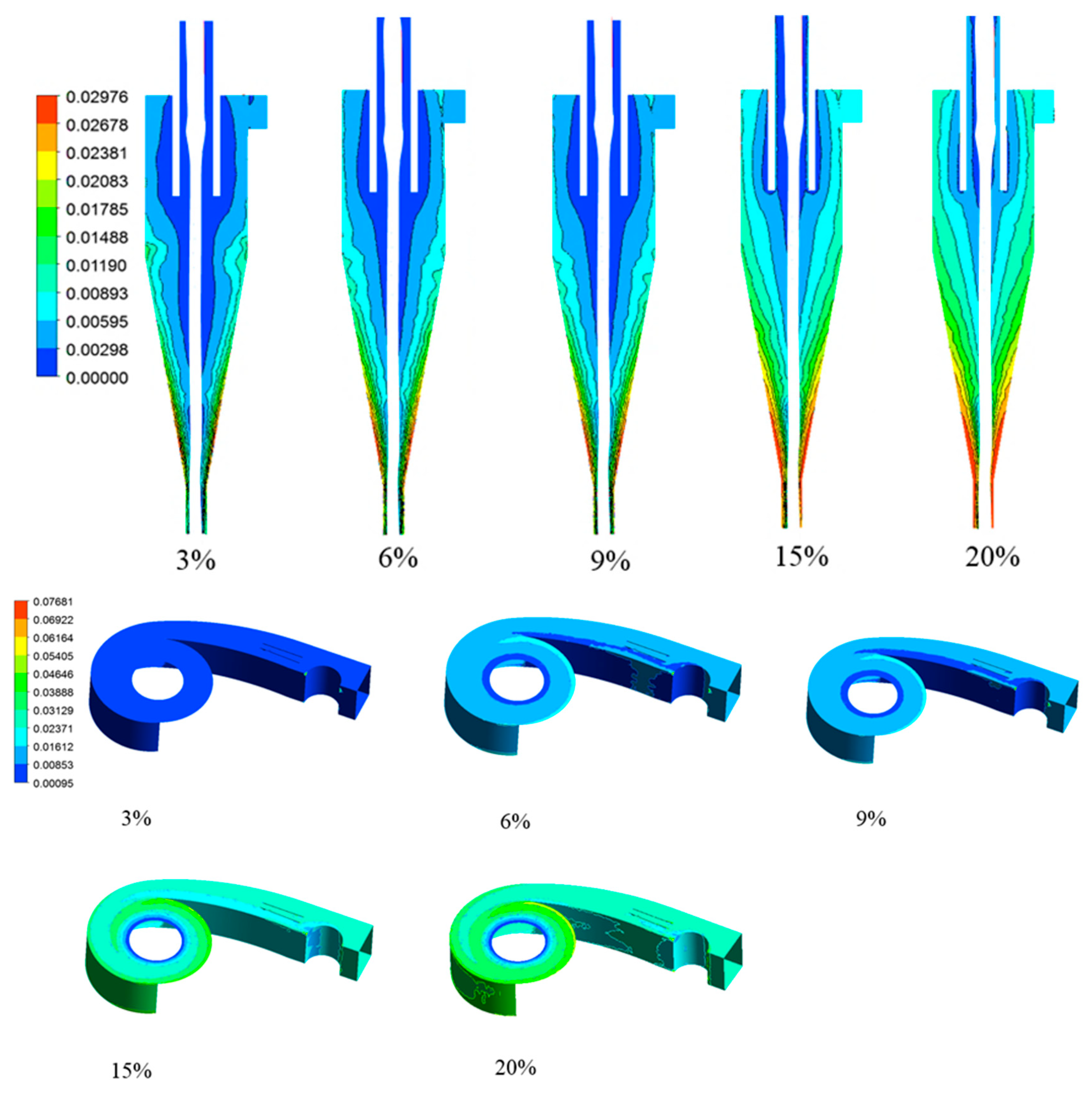

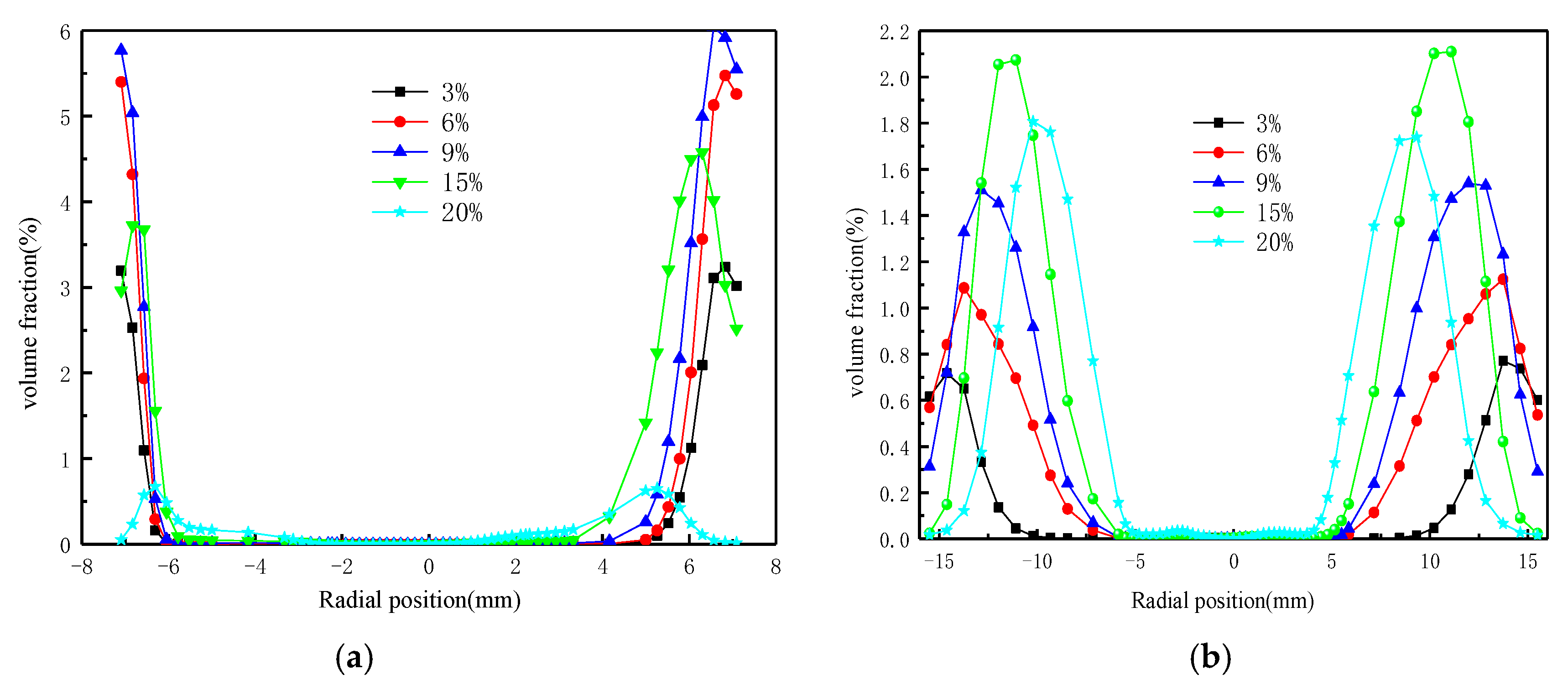

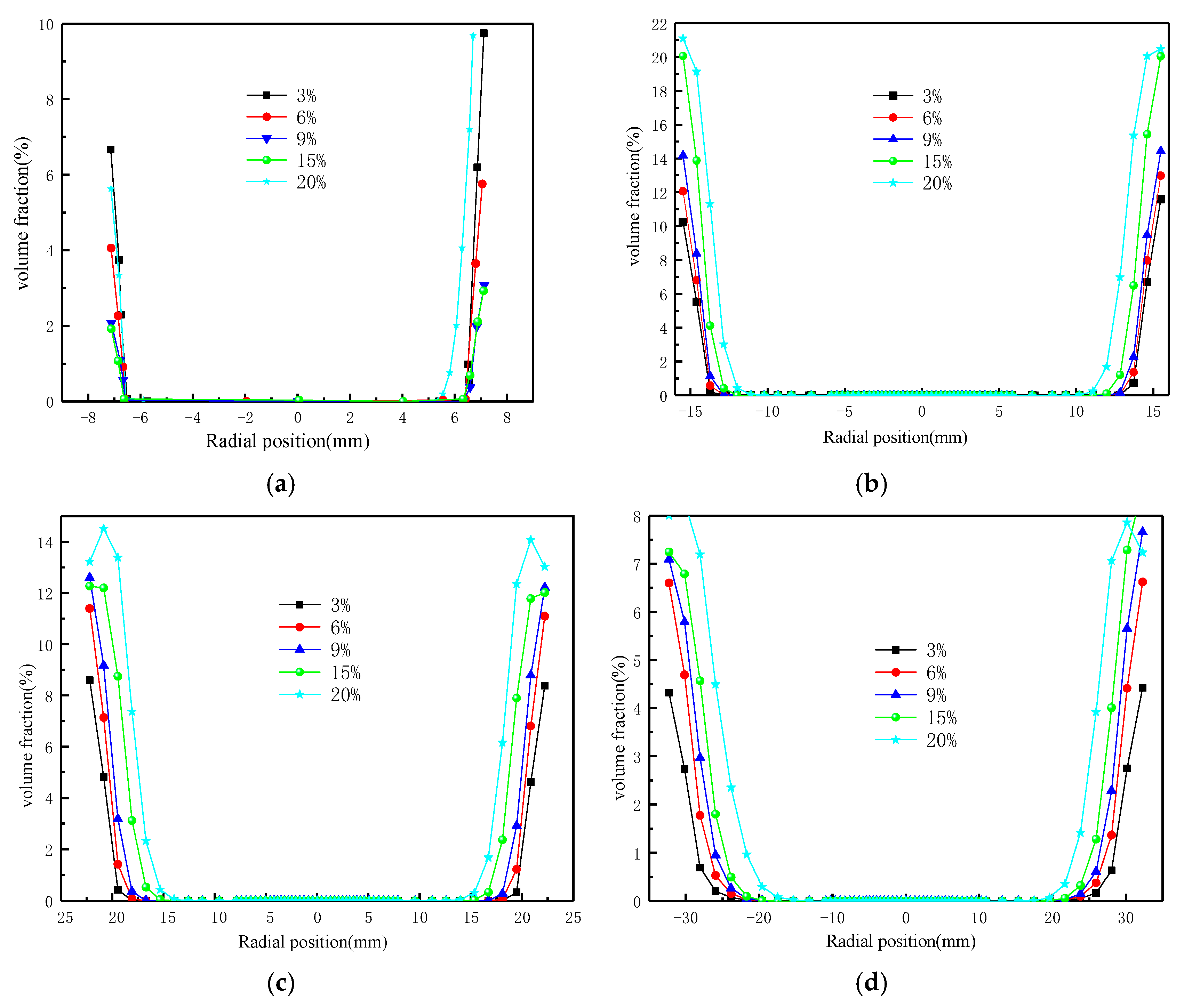

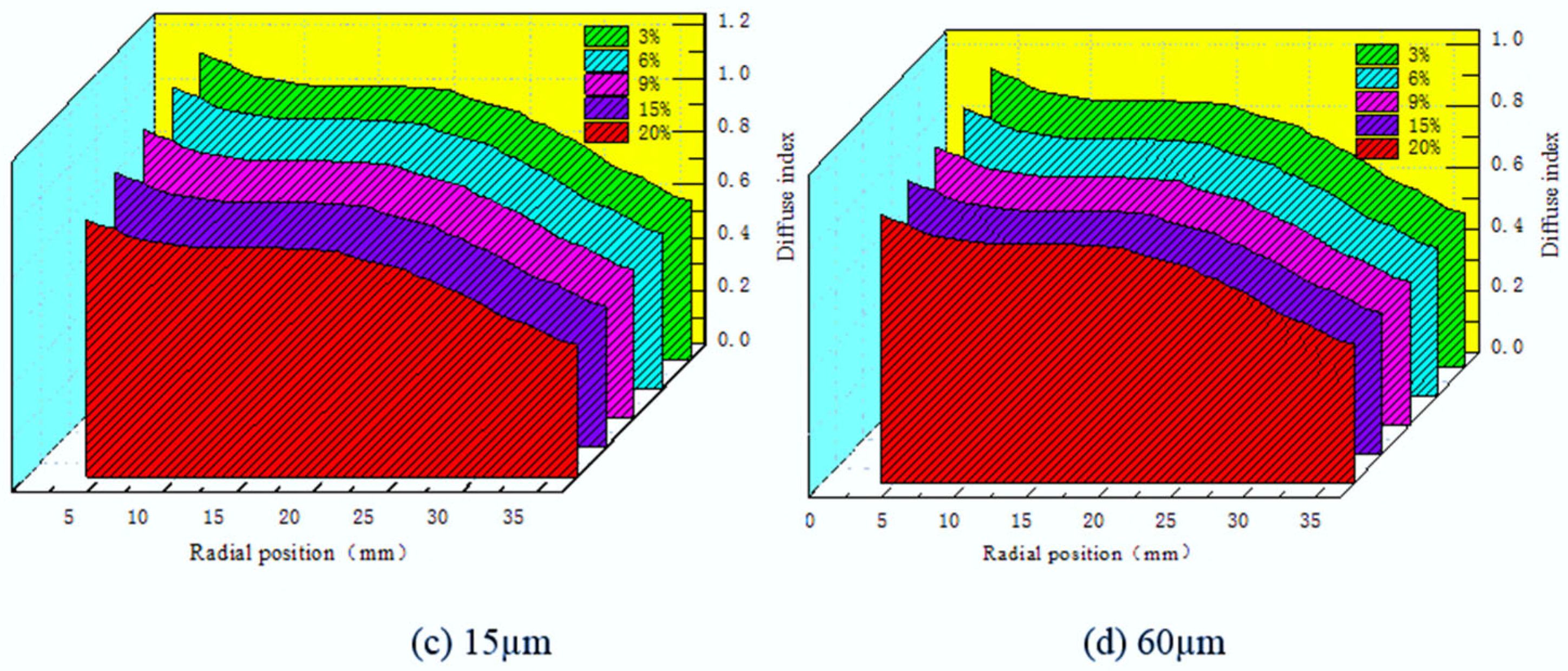

3.1. The Effect of Particle Size on Particle Aggregation Characteristics

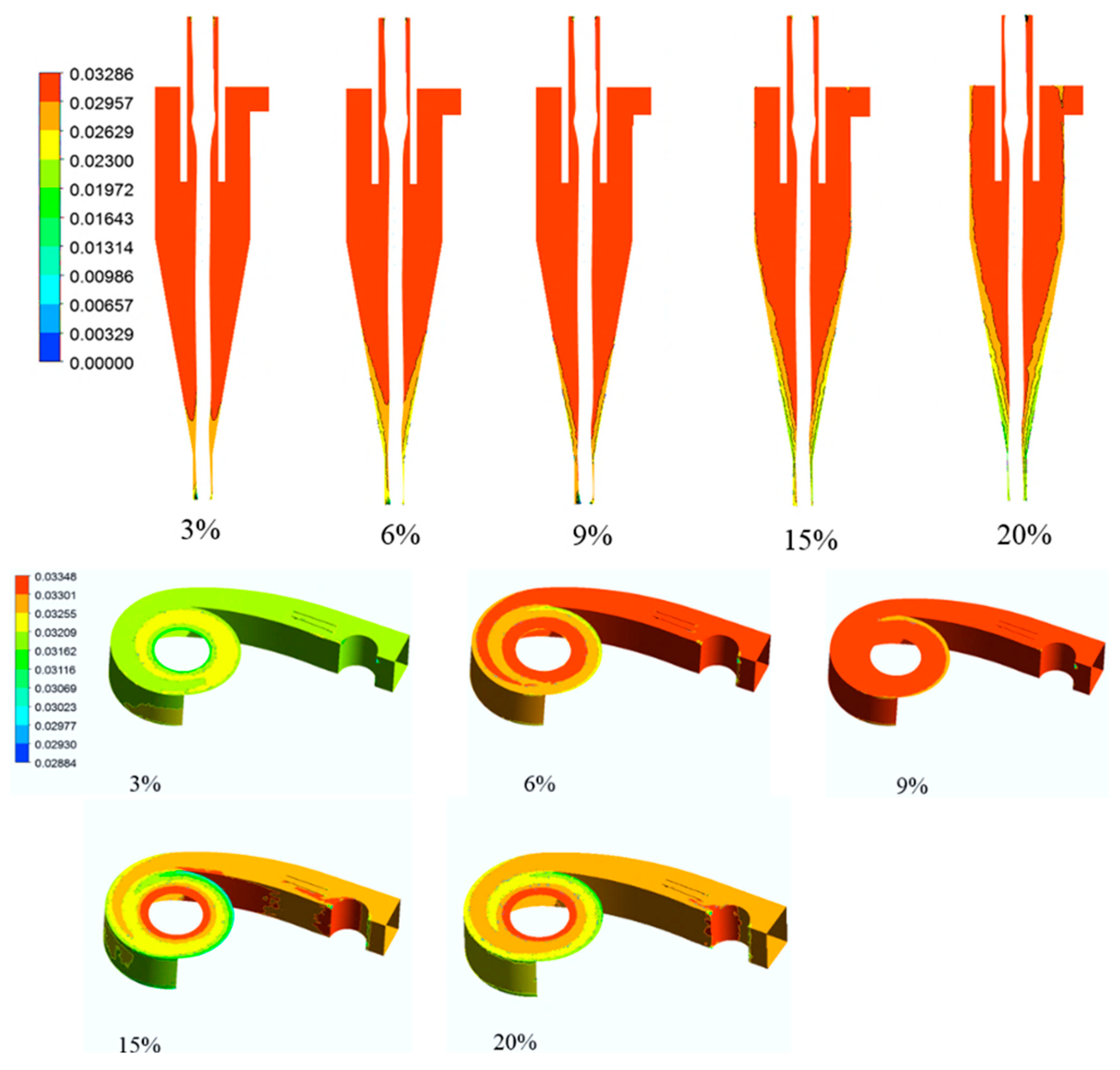

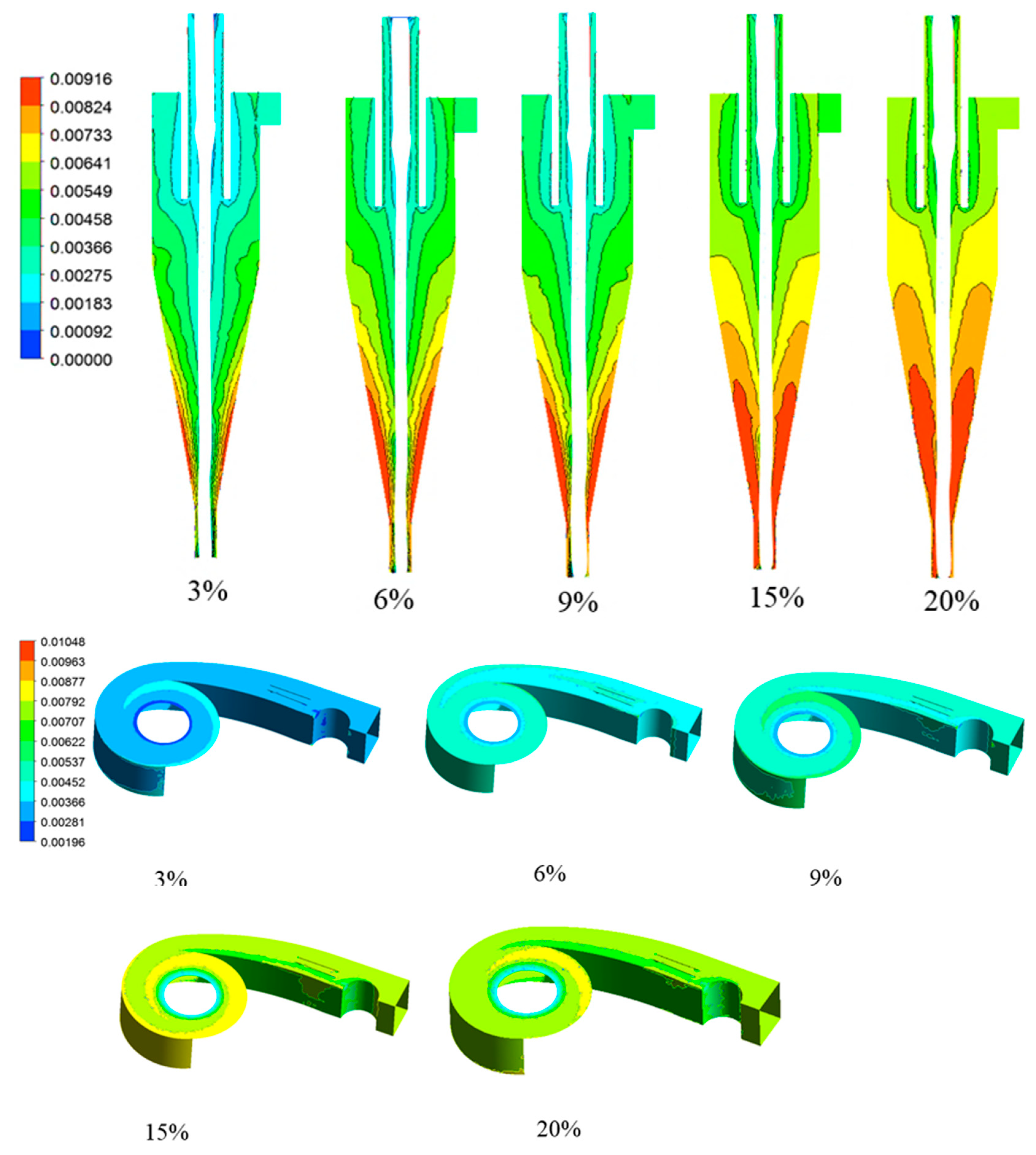

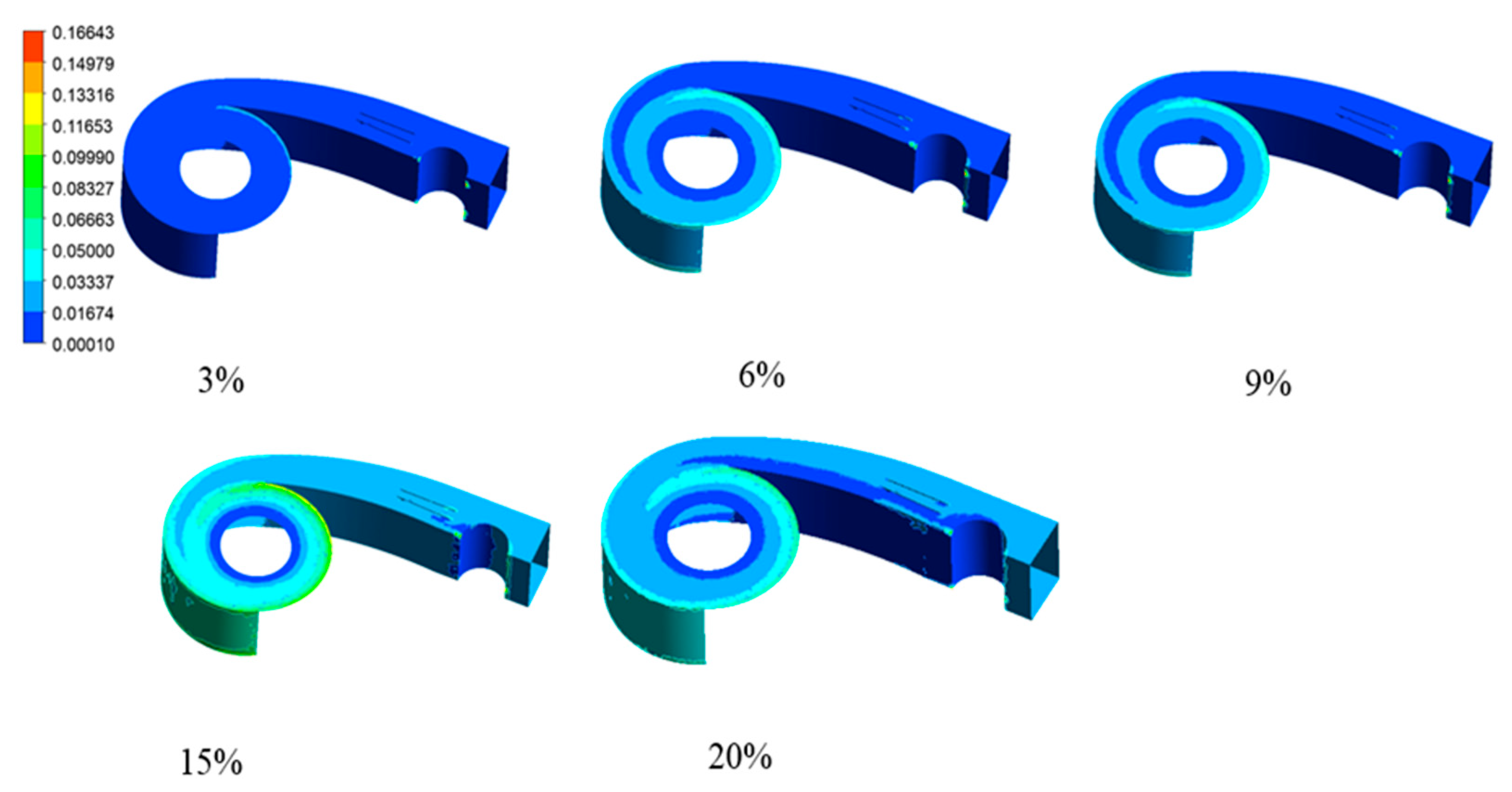

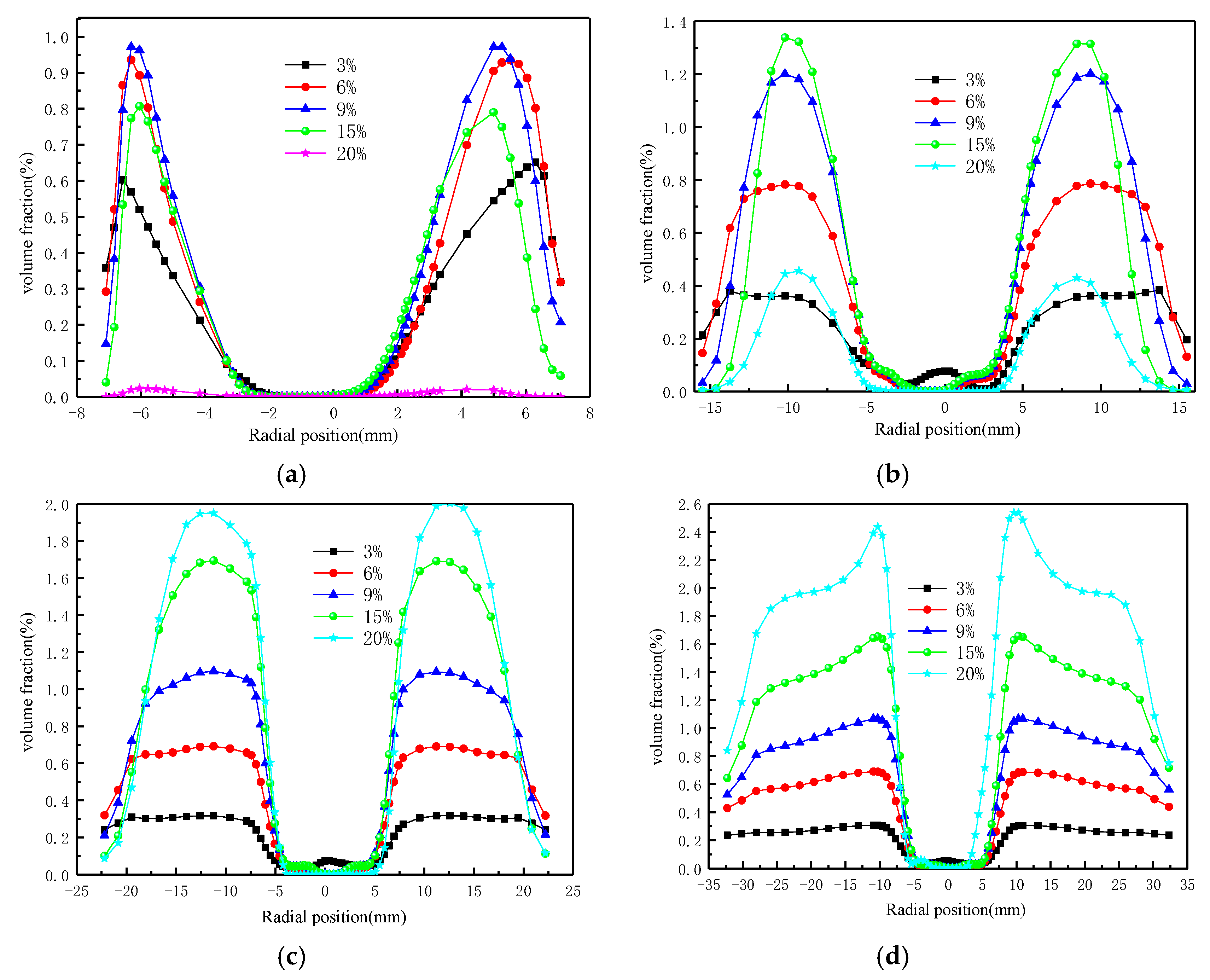

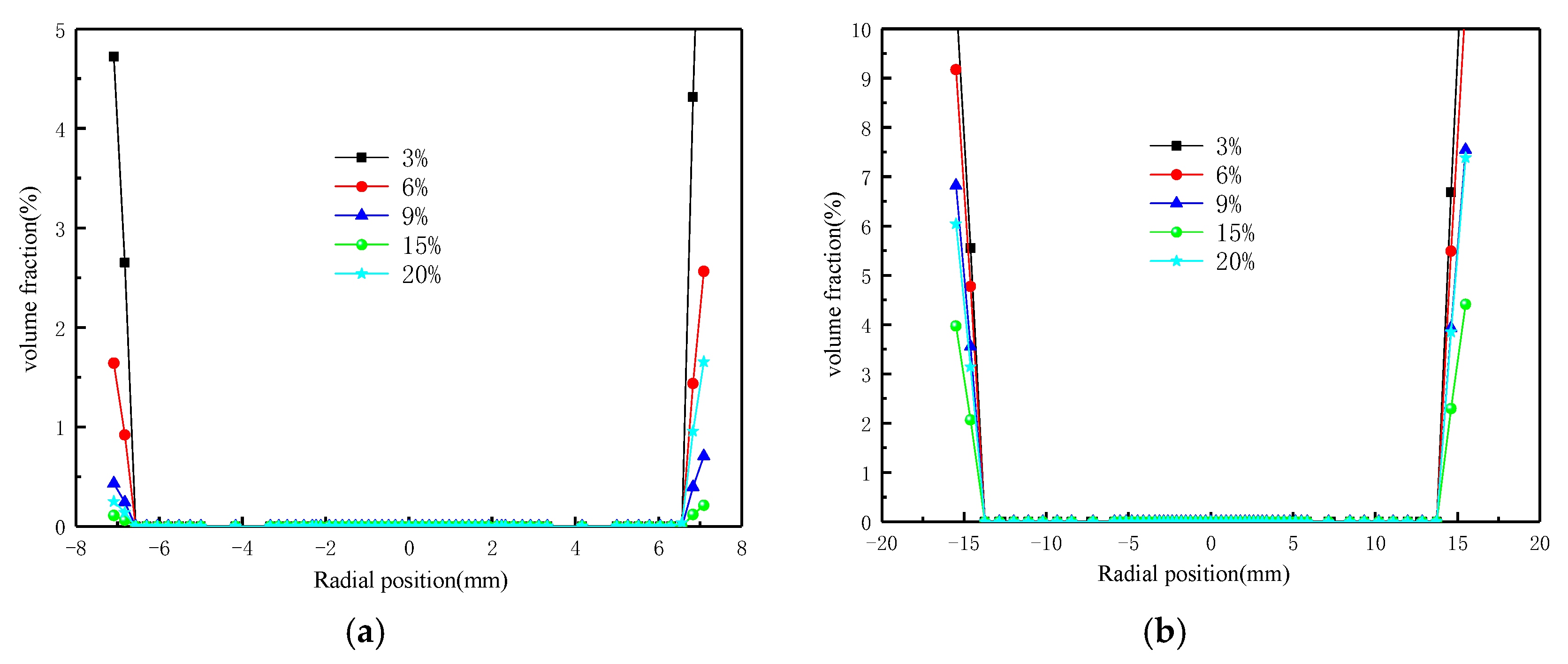

3.2. The Effect of Concentration on Particle Aggregation Characteristics

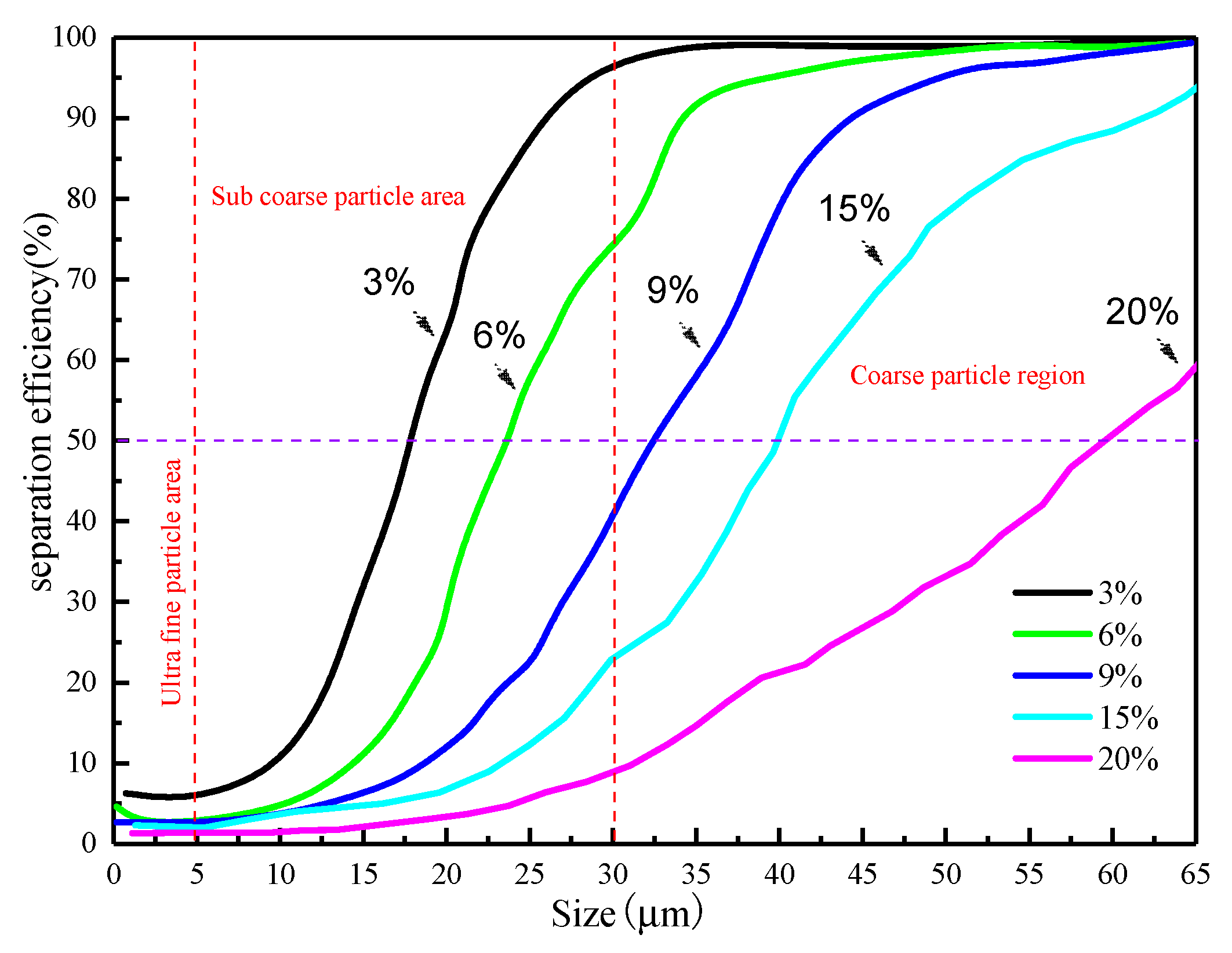

3.3. The Effect of Concentration on Separation Efficiency

4. Experimental Test

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amani, A.; Shamloo, A.; Vatani, P.; Ebrahimi, S. Particles Focusing and Separation by a Novel Inertial Microfluidic Device: Divergent Serpentine Microchannel. Ind. Eng. Chem. Res. 2022, 61, 14324–14333. [Google Scholar] [CrossRef]

- Bridgwater, L.B.; Ihrke, C.A.; Diftler, M.A.; Abdallah, M.E.; Radford, N.A.; Rogers, J.M.; Yayathi, S.; Askew, R.S.; Linn, D.M. The robonaut 2 hand—Designed to do work with tools. In Proceedings of the IEEE International Conference on Robotics and Automation, St. Paul, MN, USA, 14–18 May 2012; pp. 3425–3430. [Google Scholar]

- Chu, L.-Y.; Yu, W.; Wang, G.-J.; Zhou, X.-T.; Chen, W.-M.; Dai, G.-Q. Enhancement of hydrocyclone separation performance by eliminating the air core. Chem. Eng. Process. Process. Intensif. 2004, 43, 1441–1448. [Google Scholar] [CrossRef]

- Dueck, J.; Farghaly, M.; Neesse, T. The theoretical partition curve of the hydrocyclone. Miner. Eng. 2014, 62, 25–30. [Google Scholar] [CrossRef]

- Flores-Luna, R.I.; Dorador-González, J.M.; Espinosa-Bautista, A. Prosthesis Analysis Based on TRIZ. Key Eng. Mater. 2013, 572, 135–138. [Google Scholar] [CrossRef]

- Frausto, J.; Ballantyne, G.; Runge, K.; Powell, M.; Wightman, E.; Evans, C.; Gonzalez, P.; Gomez, S. The effect of screen versus cyclone classification on the mineral liberation properties of a polymetallic ore. Miner. Eng. 2021, 169, 106930. [Google Scholar] [CrossRef]

- Gonçalves, S.M.; Ullmann, G.; Morimoto, M.G.; Barrozo, M.A.d.S.; Vieira, L.G.M. Effect of rheology and solids concentration on hydrocyclones performance: A study involving the design variables of an optimized hydrocyclone. J. Pet. Sci. Eng. 2022, 210, 110019. [Google Scholar] [CrossRef]

- Hands, D.; Robot, S. Developments in dextrous hands for advanced robotic applications. In Proceedings of the Sixth Biannual World Automation Congress, Seville, Spain, 28 June–1 July 2004. [Google Scholar]

- Huang, A.-N.; Maeda, N.; Shibata, D.; Fukasawa, T.; Yoshida, H.; Kuo, H.-P.; Fukui, K. Influence of a laminarizer at the inlet on the classification performance of a cyclone separator. Sep. Purif. Technol. 2017, 174, 408–416. [Google Scholar] [CrossRef]

- Zhao, Q.; Hou, D.; Cui, B.; Wei, D.; Song, T.; Feng, Y. Development of an integrated multichannel inlet for improved particle classification in hydrocyclones. Adv. Powder Technol. 2021, 32, 4546–4561. [Google Scholar] [CrossRef]

- Liu, P.; Chu, L.; Wang, J.; Yu, Y. Enhancement of Hydrocyclone Classification Efficiency for Fine Particles by Introducing a Volute Chamber with a Pre-Sedimentation Function. Chem. Eng. Technol. 2008, 31, 474–478. [Google Scholar] [CrossRef]

- Zhao, B.; Shen, H.; Kang, Y. Development of a symmetrical spiral inlet to improve cyclone separator performance. Powder Technol. 2004, 145, 47–50. [Google Scholar] [CrossRef]

- Insperger, T.; Stepan, G. Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int. J. Numer. Methods Eng. 2004, 61, 117–141. [Google Scholar] [CrossRef]

- Jacobsen, S.; Wood, J.; Knutti, D.; Biggers, K. The UTAH/M.I.T. Dextrous Hand: Work in Progress. Int. J. Robot. Res. 1984, 3, 21–50. [Google Scholar] [CrossRef]

- Ji, L.; He, L.; Chu, K.; Kuang, S. How Particles with Sizes Close to Cut Size Affect the Multiphase Flows and Performance of Hydrocyclones. Ind. Eng. Chem. Res. 2021, 60, 18477–18489. [Google Scholar] [CrossRef]

- Kashiwaya, K.; Noumachi, T.; Hiroyoshi, N.; Ito, M.; Tsunekawa, M. Effect of particle shape on hydrocyclone classification. Powder Technol. 2012, 226, 147–156. [Google Scholar] [CrossRef]

- Kochan, A. Shadow delivers first hand. Ind. Robot. 2005, 32, 15–16. [Google Scholar] [CrossRef]

- Kumar, M.; Reddy, R.; Banerjee, R.; Mangadoddy, N. Effect of particle concentration on turbulent modulation inside hydrocyclone using coupled MPPIC-VOF method. Sep. Purif. Technol. 2021, 266, 118206. [Google Scholar] [CrossRef]

- Kyriakidis, Y.N.; Silva, D.O.; Barrozo, M.A.S.; Vieira, L.G.M. Effect of variables related to the separation performance of a hydrocyclone with unprecedented geometric relationships. Powder Technol. 2018, 338, 645–653. [Google Scholar] [CrossRef]

- Li, X.F.; Li, D.P.; Zhang, G.X.; Lu, Z.Y. Study on real-time control of humanoid robot using emgs. China Mech. Eng. 2006, 17, 488–492. [Google Scholar]

- Li, Z.; Tong, Z.; Zhang, H.; Chu, K.; Li, R.; Miao, H.; Zhao, J.; Yu, A. CFD-DEM simulation of the supercritical water-solid flow in cyclone. Powder Technol. 2023, 418, 118261. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, L.; Sun, Y.; Gao, S.; Jiang, M.; Jiang, M.; Rosso, D. Separation performance of hydrocyclones with medium rearrangement internals. J. Environ. Chem. Eng. 2021, 9, 105642. [Google Scholar] [CrossRef]

- Mustafa, A.K.Q. Hydrocyclone flow characteristics and measurements. Flow Meas. Instrum. 2020, 73, 101741. [Google Scholar] [CrossRef]

- Der, O.; Bertola, V. An experimental investigation of oil-water flow in a serpentine channel. Int. J. Multiph. Flow 2020, 129, 103327. [Google Scholar] [CrossRef]

- Olga, V.; Bongers, R.M.; Van, D. Functionality of i-limb and i-limb pulse hands—Case report. J. Rehabil. Res. Dev. 2013, 50, 1123–1128. [Google Scholar]

- Otto, A.; Rauh, S.; Ihlenfeldt, S.; Radons, G. Stability of milling with non-uniform pitch and variable helix Tools. Int. J. Adv. Manuf. Technol. 2017, 89, 2613–2625. [Google Scholar] [CrossRef]

- Padhi, M.; Mangadoddy, N.; Sreenivas, T.; Vakamalla, T.R.; Mainza, A.N. Study on multi-component particle behaviour in a hydrocyclone classifier using experimental and computational fluid dynamics technique. Sep. Purif. Technol. 2019, 229, 115698. [Google Scholar] [CrossRef]

- Pietro, B.; Marco, M. Selective dissolution process featuring a classification device for the removal of fines in crystallization—Experiments. Ind. Eng. Chem. Res. 2021, 60, 15752–15765. [Google Scholar]

- Rama, Y.M.; Udaya, K.B. Parametric CFD studies on hydrocyclone. Powder Technol. 2012, 230, 36–47. [Google Scholar] [CrossRef]

- Sun, R.; Hou, F.; Ding, Y.; Geng, K.; Yang, Q. Design and performance evaluation of soil washing on heavy metal contaminated soil by hydrocyclone. Chin. J. Environ. Eng. 2018, 12, 1208–1217. [Google Scholar]

- Vakamalla, T.R.; Mangadoddy, N. The dynamic behaviour of a large-scale 250-mm hydrocyclone—A CFD study. Asia Pac. J. Chem. Eng. 2019, 14, e2287. [Google Scholar] [CrossRef]

- Wang, G. Developing of a new dexterous three fingered hand. Chin. J. Mech. Eng. 1997, 33, 71–75. [Google Scholar]

- Ye, J.; Xu, Y.; Song, X.; Yu, J. Numerical modelling and multi-objective optimization of the novel hydrocyclone for ultra-fine particles classification. Chem. Eng. Sci. 2019, 207, 1072–1084. [Google Scholar] [CrossRef]

- Hsieh, K.T. Phenomenological Model of the Hydrocyclone. Master’s Thesis, The University of Utah, Salt Lake City, UT, USA, 1988. [Google Scholar]

- Delgadillo, J. Modeling of 75-and 250-mm Hydrocyclones and Exploration of Novel Designs Using Computational Fluid Dynamics. Ph.D. Thesis, University of Utah, Salt Lake City, UT, USA, 2006. [Google Scholar]

| Size/μm | Interval/% | Positive Cumulative Content/% |

|---|---|---|

| 0~6 | 7.57 | 7.57 |

| 6~24 | 26.85 | 34.42 |

| 24~52 | 44.1 | 78.52 |

| 52~76 | 17.62 | 96.14 |

| >76 | 3.86 | 100 |

| Feed Concentration | Size | −20 μm of Overflow | −20 μm of Underflow | Quality Efficiency | Quantity Efficiency |

|---|---|---|---|---|---|

| /% | /μm | /% | /% | /% | /% |

| 8 | 56.3 | 60.23 | 9.18 | 65.83 | 83.61 |

| 12 | 58.2 | 57.19 | 8.16 | 61.26 | 84.99 |

| 16 | 61.3 | 55.36 | 7.13 | 56.81 | 87.92 |

| 20 | 64.5 | 53.89 | 6.09 | 53.93 | 89.32 |

| 25 | 66.5 | 51.39 | 5.22 | 43.28 | 91.28 |

| Type | Underflow Content of −20 μm/% | Pressure Drop/Kpa | Quality Efficiency/% | Quantity Efficiency/% |

|---|---|---|---|---|

| Base | 16.31% | 46.51 | 60.31 | 82.63 |

| Complex inlet | 9.62 | 45.32 | 65.22 | 83.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Meng, F.; Wang, S.; Liang, Z.; Wei, L.; Ge, Y.; Fu, Y.; Li, F. Analysis of Particle Distribution and Aggregation Characteristics in a Hydrocyclone with a Complex Curved Inlet Structure. Processes 2025, 13, 3540. https://doi.org/10.3390/pr13113540

Yang H, Meng F, Wang S, Liang Z, Wei L, Ge Y, Fu Y, Li F. Analysis of Particle Distribution and Aggregation Characteristics in a Hydrocyclone with a Complex Curved Inlet Structure. Processes. 2025; 13(11):3540. https://doi.org/10.3390/pr13113540

Chicago/Turabian StyleYang, Huaibin, Fanping Meng, Shuilin Wang, Zhitao Liang, Lizhao Wei, Yu Ge, Yuting Fu, and Feng Li. 2025. "Analysis of Particle Distribution and Aggregation Characteristics in a Hydrocyclone with a Complex Curved Inlet Structure" Processes 13, no. 11: 3540. https://doi.org/10.3390/pr13113540

APA StyleYang, H., Meng, F., Wang, S., Liang, Z., Wei, L., Ge, Y., Fu, Y., & Li, F. (2025). Analysis of Particle Distribution and Aggregation Characteristics in a Hydrocyclone with a Complex Curved Inlet Structure. Processes, 13(11), 3540. https://doi.org/10.3390/pr13113540