Preparation and Properties of Nano-Lignin-Reinforced Poly(butylene adipate-co-terephthalate) Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of LNP

2.3. Preparation of PBAT/LNP Composite

2.4. Measurement of Composite Properties

2.4.1. Mechanical Properties

2.4.2. Thermal Properties

2.4.3. Water Contact Angle

2.4.4. Water Vapor Transmission

2.4.5. Oxygen Permeability

2.4.6. UV-Blocking Performance

2.4.7. Degradation Test

2.4.8. Antibacterial Property

2.5. Calculation and Statistical Analysis

2.6. Measurements

3. Results and Discussion

3.1. Characterization

3.1.1. Characterization of LNP

3.1.2. Characterization of PBAT/LNP Composite

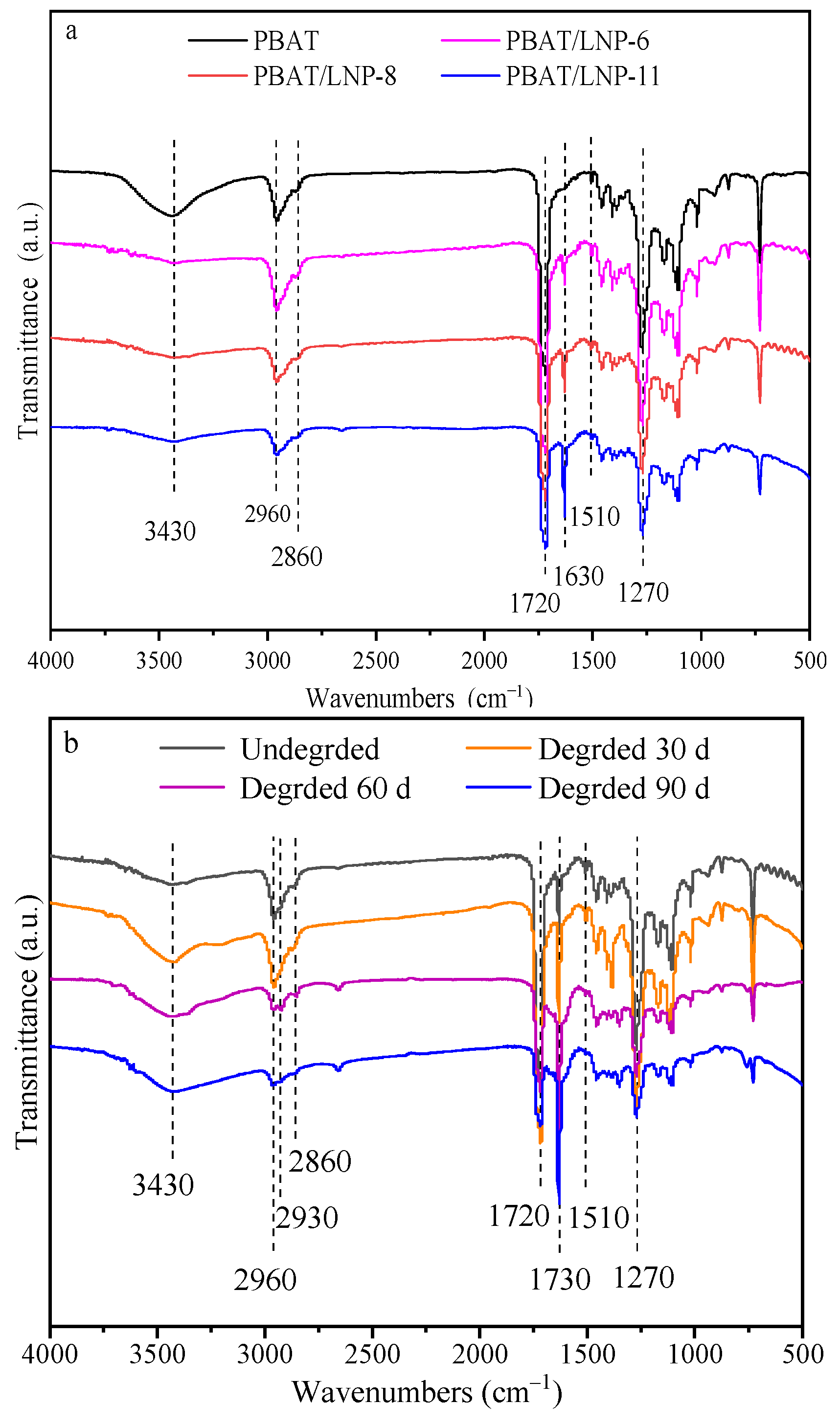

FTIR

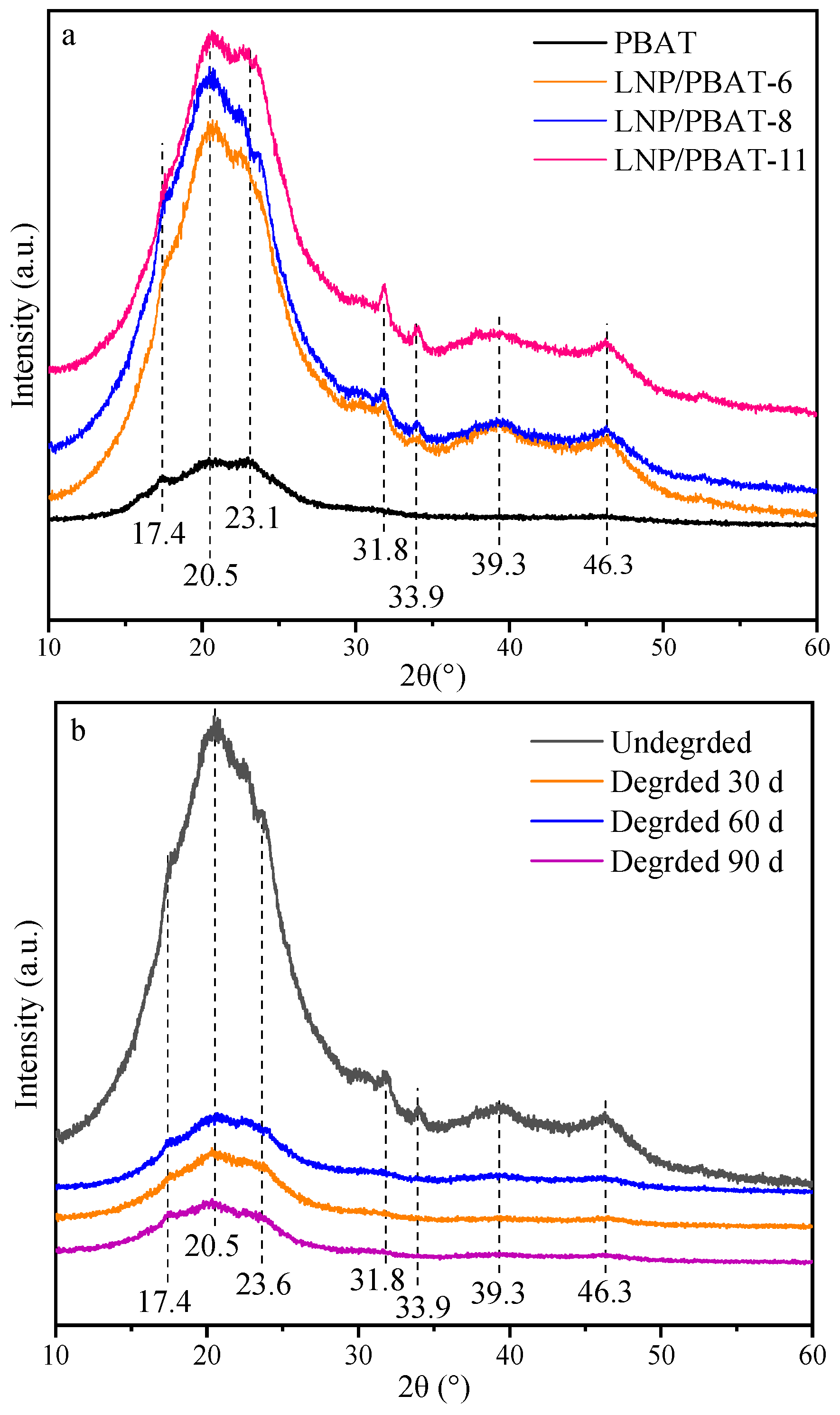

XRD

SEM

3.2. Properties of Composites

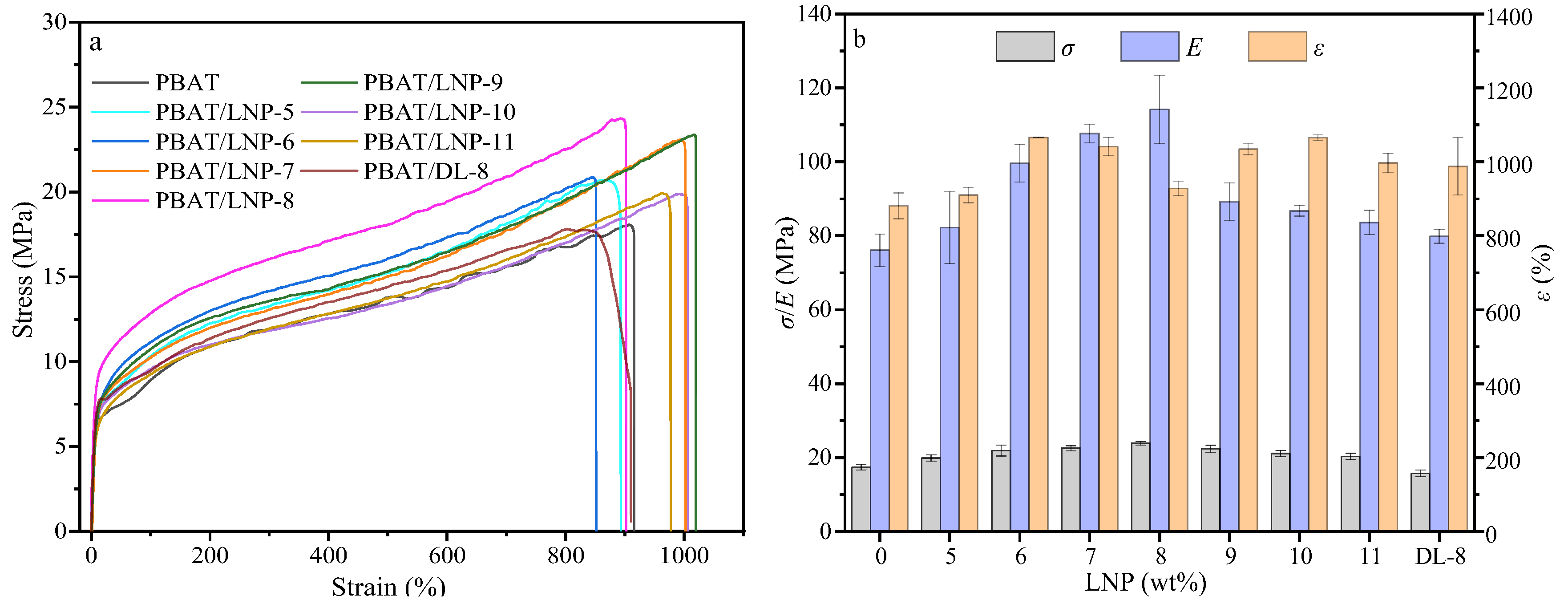

3.2.1. Mechanical Properties

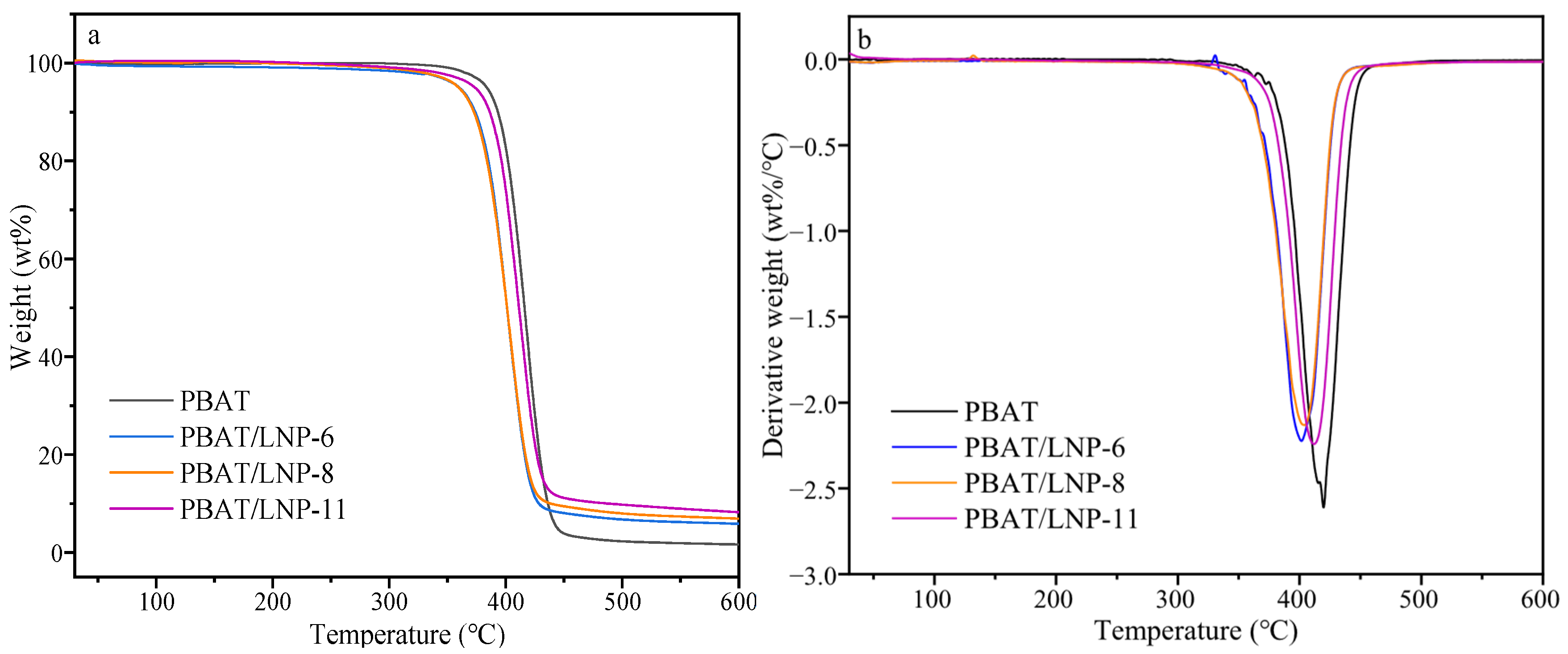

3.2.2. Thermal Properties

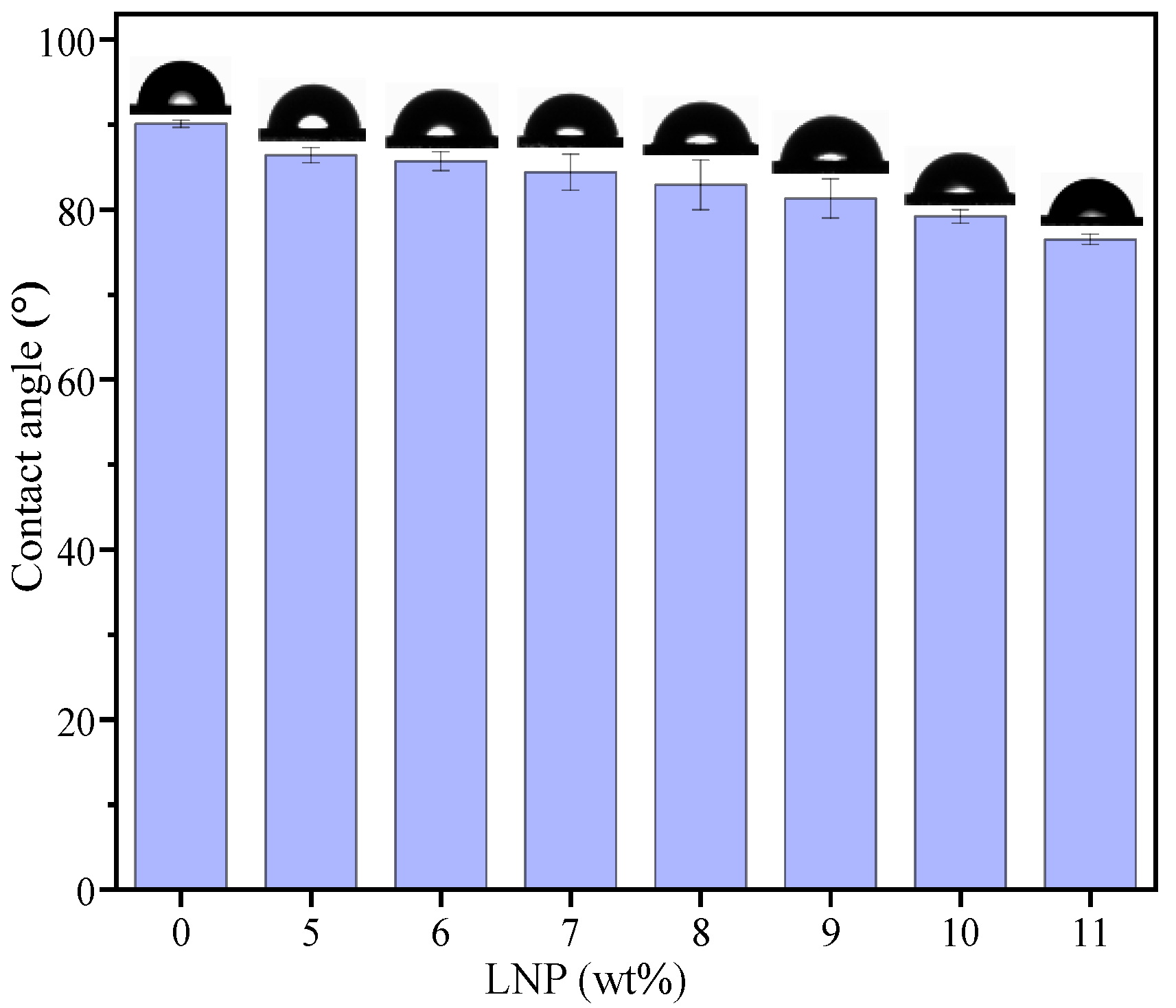

3.2.3. WCA

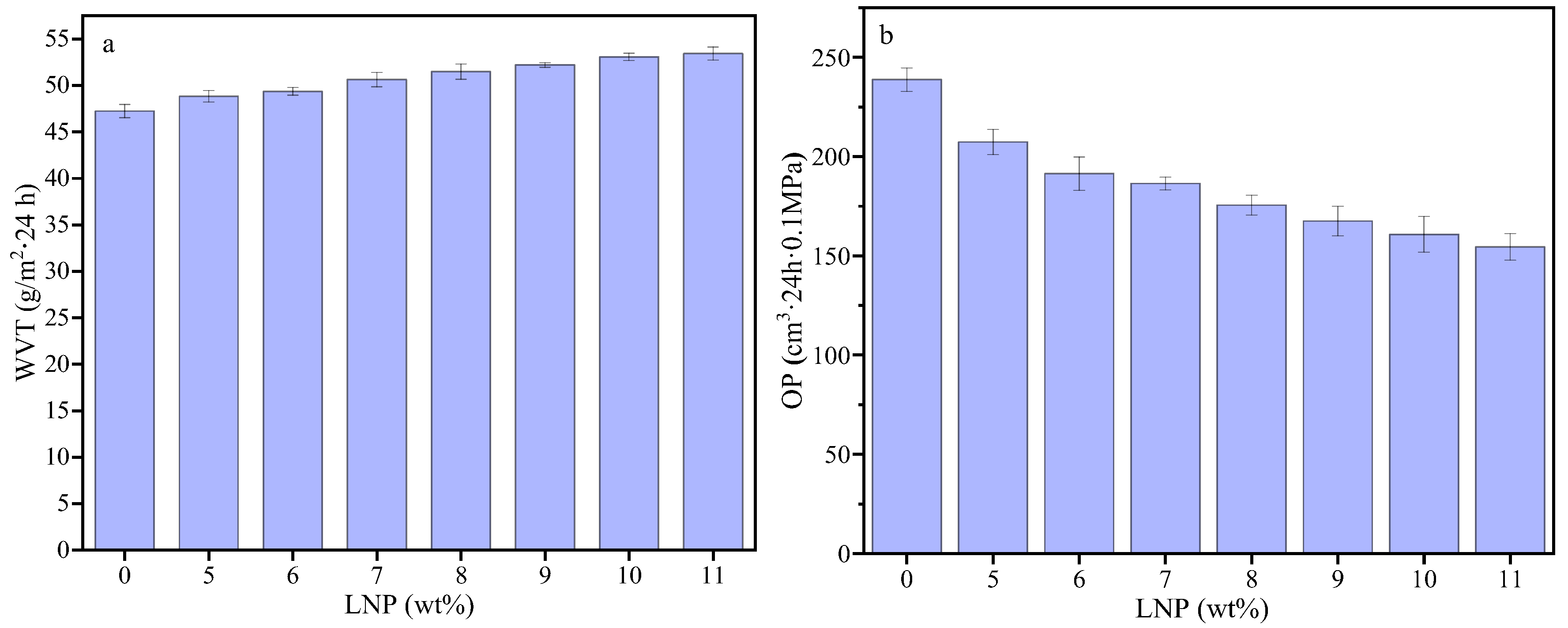

3.2.4. Gas Barrier Properties

3.2.5. UV-Blocking Performance

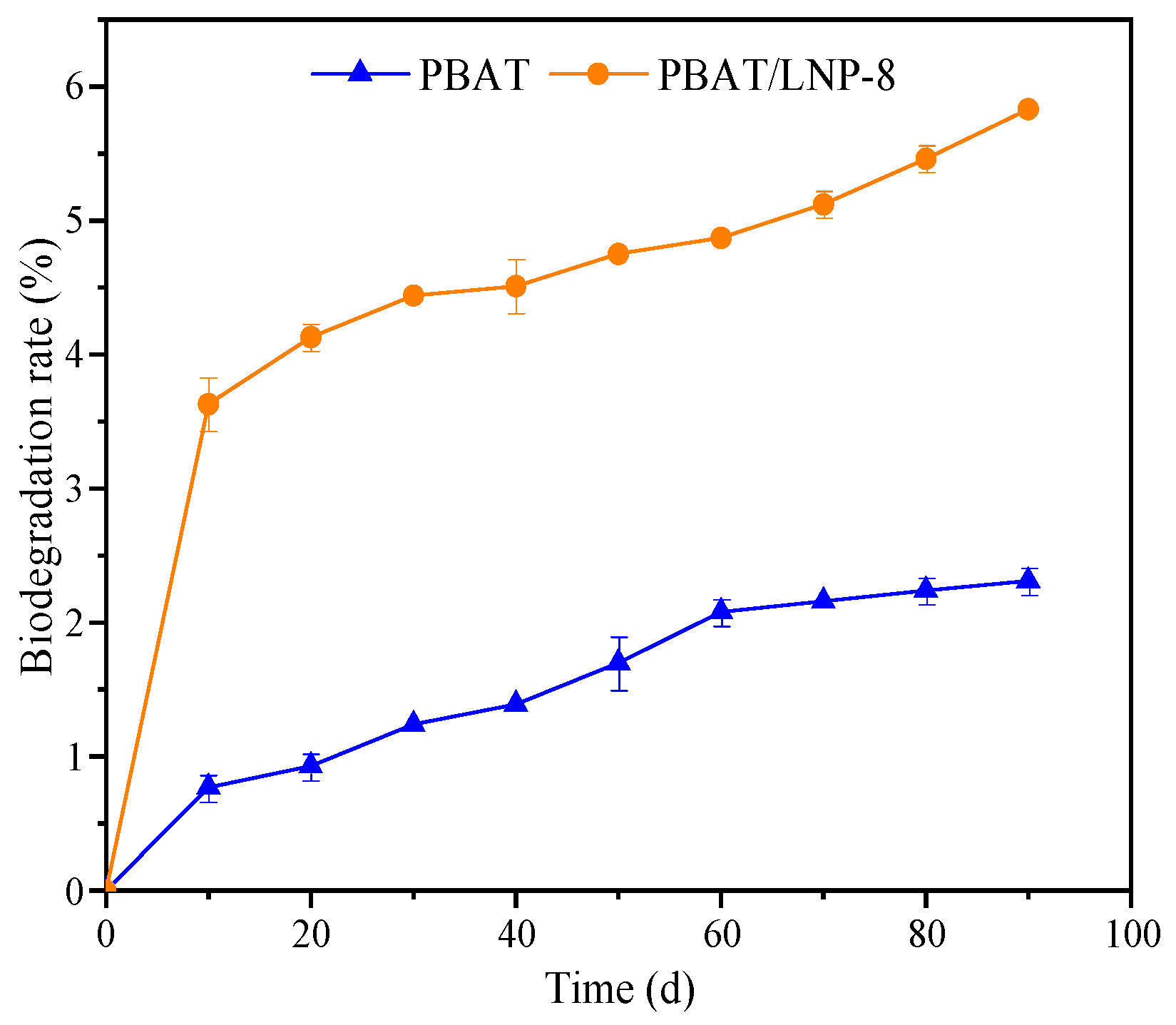

3.2.6. Biodegradation Property

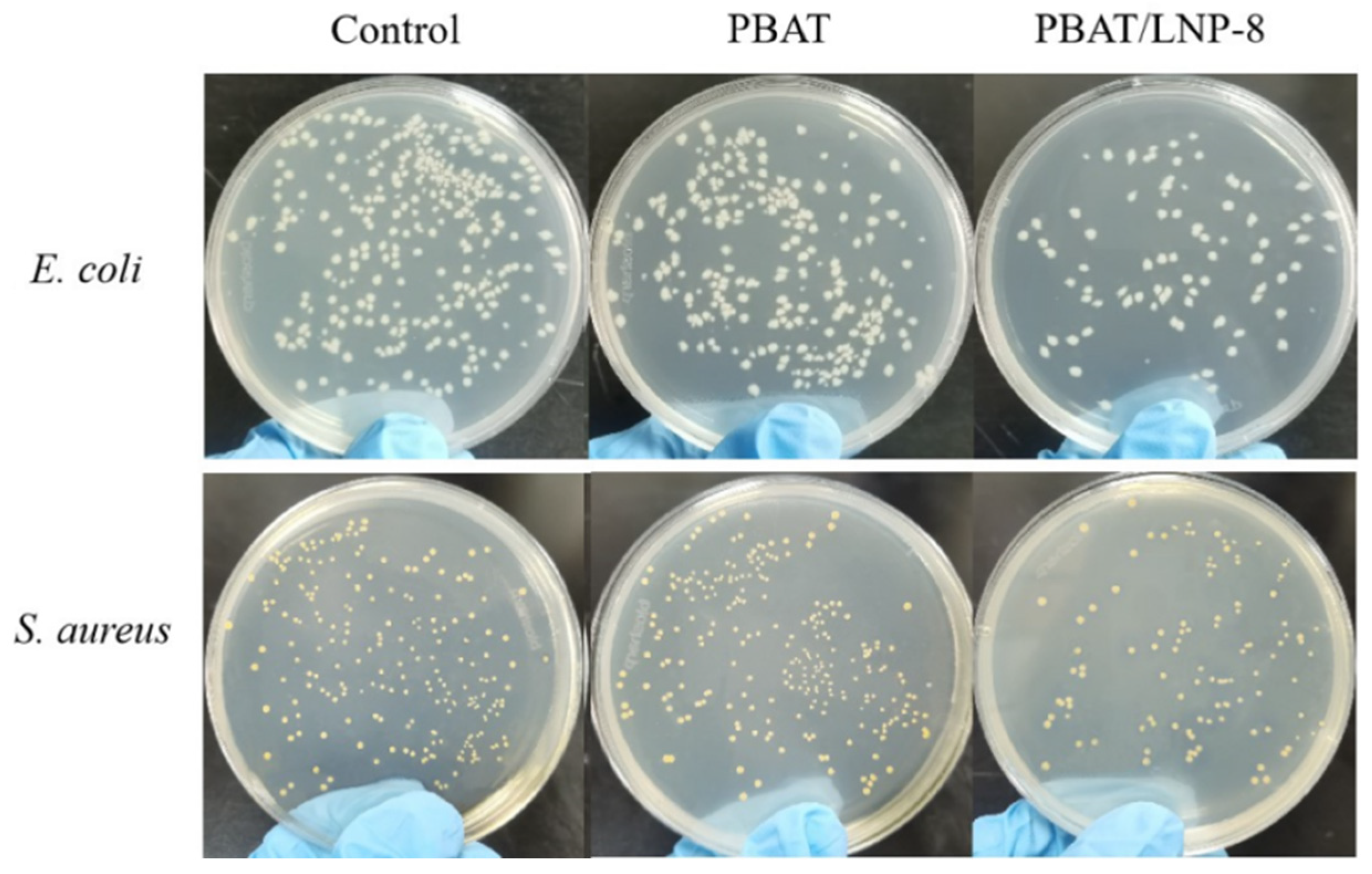

3.2.7. Antibacterial Property

3.2.8. Comparison of the Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xiao, L.; Yao, Z.; He, Y.; Han, Z.; Zhang, X.; Li, C.; Xu, P.; Yang, W.; Ma, P. Antioxidant and antibacterial PBAT/lignin-ZnO nanocomposite films for active food packaging. Ind. Crop. Prod. 2022, 187, 115515. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Cividanes, L.S.; Gouveia, R.F.; Lona, L.M.F. An overview on properties and applications of poly(butylene adipate-co-terephthalate)-PBAT based composites. Polym. Eng. Sci. 2019, 59, E7–E15. [Google Scholar] [CrossRef]

- Cheng, Z.; Ning, M.; Mao, K.; Nong, X.; Li, J.; Xiao, N.; Zhang, X.; Ding, Q.; Wang, H.; Liu, M. Bamboo powder lignocellulose/polybutylene adipate terephthalate biodegradable bioplastic composite film for food packaging materials. Int. J. Biol. Macromol. 2025, 316, 144781. [Google Scholar] [CrossRef]

- Bilal, M.; Qamar, S.A.; Qamar, M.; Yadav, V.; Taherzadeh, M.J.; Lam, S.S.; Iqbal, H.M.N. Bioprospecting lignin biomass into environmentally friendly polymers-applied perspective to reconcile sustainable circular bioeconomy. Biomass Convers. Biorefin. 2022, 14, 4457–4483. [Google Scholar] [CrossRef]

- Chen, Y.; Feng, T.; Long, Y.; Pan, C.; Fan, G.; Bai, J.; Song, G. Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials. e-Polymers 2023, 23, 20230145. [Google Scholar] [CrossRef]

- Fan, G.; Peng, Q.; Chen, Y.; Long, Y.; Bai, J.; Song, G.; Cheng, Q. Preparation of biodegradable composite films based on carboxymethylated holocellulose from wheat straw. Int. J. Biol. Macromol. 2023, 242, 124868. [Google Scholar] [CrossRef] [PubMed]

- Peng, Q.; Chen, Y.; Fan, G.; Song, G.; Cheng, Q. Acetylation of wheat straw holocellulose for a biodegradable film. Cellulose 2023, 30, 8997–9012. [Google Scholar] [CrossRef]

- Chen, M.; Li, Y.; Liu, H.; Zhang, D.; Shi, Q.S.; Zhong, X.Q.; Guo, Y.; Xie, X.B. High value valorization of lignin as environmental benign antimicrobial. Mater. Today Bio 2022, 118, 100520. [Google Scholar] [CrossRef] [PubMed]

- Xiong, S.J.; Zhou, S.J.; Wang, H.H.; Wang, H.M.; Shen, X.J.; Yu, S.; Li, H.; Zheng, L.; Wen, J.L.; Yuan, T.Q.; et al. A strong, tough and cost-effective biodegradable PBAT/lignin composite film via intrinsic multiple noncovalent interactions. Green Chem. 2023, 25, 3175–3186. [Google Scholar] [CrossRef]

- Mo, J.; Wang, H.; Yan, M.; Huang, J.; Li, R.; Sun, D.; Lei, J.; Qiu, X.; Liu, W. Construction of interfacial dynamic bonds for high performance lignin/polymer biocompositess. Front. Chem. Sci. Eng. 2023, 17, 1372–1388. [Google Scholar] [CrossRef]

- Li, W.; Huang, J.; Liu, W.; Qiu, X.; Lou, H.; Zheng, L. Lignin modified PBAT composites with enhanced strength based on interfacial dynamic bonds. J. Appl. Polym. Sci. 2022, 139, e52476. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, S.; Liu, Z.; Lei, Y.; Jiang, S.; Zhang, K.; Yan, W.; Qin, J.; He, M.; Qin, S.; et al. Enhanced mechanical and biodegradable properties of PBAT/lignin composites via silane grafting and reactive extrusion. Compos. Part B-Eng. 2021, 220, 108980. [Google Scholar] [CrossRef]

- Olonisakin, K.; Wen, A.; He, S.; Lin, H.; Tao, W.; Chen, S.; Lin, W.; Li, R.; Zhang, X.; Yang, W. The development of biodegradable PBAT-lignin-tannic acid composite film: Properties, biodegradability, and potential barrier application in food packaging. Food Bioprocess. Technol. 2023, 16, 1525–1540. [Google Scholar] [CrossRef]

- Zhu, B.; Xu, Y.; Xu, H. Preparation and application of lignin nanoparticles: A review. Nano Futures 2022, 6, 032004. [Google Scholar] [CrossRef]

- Ainali, N.M.; Tarani, E.; Zamboulis, A.; Črešnar, K.P.; Zemljič, L.F.; Chrissafis, K.; Lambropoulou, D.A.; Bikiaris, D.N. Thermal stability and decomposition mechanism of PLA nanocomposites with kraft lignin and tannin. Polymers 2021, 13, 2818. [Google Scholar] [CrossRef] [PubMed]

- Makri, S.P.; Xanthopoulou, E.; Klonos, P.A.; Grigoropoulos, A.; Kyritsis, A.; Tsachouridis, K.; Bikiaris, D.N. Effect of micro-and nano-lignin on the thermal, mechanical, and antioxidant properties of biobased PLA-lignin composite films. Polymers 2022, 14, 5274. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Guo, Q.; Zhu, R.; Liu, Y.; Xu, F.; Zhang, X. Facile fabrication of transparent lignin sphere/PVA nanocomposite films with excellent UV-shielding and high strength performance. Int. J. Biol. Macromol. 2021, 189, 635–640. [Google Scholar] [CrossRef]

- Wang, Z.; Li, C.; Liu, X.; Jia, W.; Huang, L.; Wu, L.; Fatehi, P.; Shi, H. Fabrication and Performance of PBAT Composite Films Reinforced with High-Molecular-Weight Lignin Nanoparticles for Sustainable Packaging. ACS Sustain. Chem. Eng. 2025, 13, 13740–13752. [Google Scholar] [CrossRef]

- Botta, L.; Titone, V.; Teresi, R.; Scarlata, M.C.; Lo Re, G.; La Mantia, F.P.; Lopresti, F. Biocomposite PBAT/lignin blown films with enhanced photo-stability. Int. J. Biol. Macromol. 2022, 217, 161–170. [Google Scholar] [CrossRef]

- Yu, B.; Fan, G.; Zhao, S.; Lu, Y.; He, Q.; Cheng, Q.; Song, G. Simultaneous isolation of cellulose and lignin from wheat straw and catalytic conversion to valuable chemical products. Appl. Biol. Chem. 2021, 64, 15. [Google Scholar] [CrossRef]

- Long, H.; Hu, L.; Yang, F.; Cai, Q.; Zhong, Z.; Zhang, S.; Guan, L.; Xiao, D.; Zheng, W.; Zhou, W.; et al. Enhancing the performance of polylactic acid composites through self-assembly lignin nanospheres for fused deposition modeling. Compos. Part B Eng. 2022, 239, 109968. [Google Scholar] [CrossRef]

- Li, H.; Li, F.; Wang, L.; Sheng, J.; Xin, Z.; Zhao, L.; Xiao, H.; Zheng, Y.; Hu, Q. Effect of nano-packing on preservation quality of Chinese jujube (Ziziphus jujuba Mill. var. inermis (Bunge) Rehd. Food Chem. 2009, 114, 547–552. [Google Scholar] [CrossRef]

- ISO 527-4-2021; Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composite. ISO: Geneva, Switzerland, 2021.

- ASTM E-96-95; Standard Test Methods for Water Vapor Transmission of Materials. ASTM: West Conshohocken, PA, USA, 1995.

- Pinheiro, I.F.; Ferreira, F.V.; Souza, D.H.S.; Gouveia, R.F.; Lona, L.M.F.; Morales, A.R.; Mei, L.H.I. Mechanical.; rheological and degradation properties of PBAT nanocomposites reinforced by functionalized cellulose nanocrystals. Eur. Polym. J. 2017, 97, 356–365. [Google Scholar] [CrossRef]

- Quan, X.; Ma, J.; Sun, L.; Huang, G.; Sui, S.; Li, H.; Shao, Q.; Yan, S.; Wang, Y.; Wang, X. Enhanced functional properties of chitosan films incorporated with proanthocyanidins/cinnamaldehyde/γ-cyclodextrin microcapsules for citrus fruit preservation. J. Food Process. Preserv. 2025, 2025, 7504108. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, S.; Xia, X.; Tan, M.; Lv, Y.; Cheng, Y.; Tao, Y.; Lu, J.; Du, J.; Wang, H. High-performance carboxymethyl cellulose-based hydrogel film for food packaging and preservation system. Int. J. Biol. Macromol. 2022, 223, 1126–1137. [Google Scholar] [CrossRef] [PubMed]

- Lin, X.; Chen, L.; Li, H.; Lv, Y.; Liu, Y.; Lu, X.; Liu, M. Mild depolymerization of the sinocalamus oldhami alkali lignin to phenolic monomer with base and activated carbon supported nickel-tungsten carbide catalyst composite system. Bioresour. Technol. 2021, 333, 125136. [Google Scholar] [CrossRef]

- Yu, H.; Wang, B.; Wang, Y.; Xu, E.; Wang, R.; Wu, S.; Wu, W.; Ji, B.; Feng, X.; Xu, H.; et al. Lignin nanoparticles with high phenolic content as efficient antioxidant and sun-blocker for food and cosmetics. ACS Sustain. Chem. Eng. 2023, 11, 4082–4092. [Google Scholar] [CrossRef]

- Liu, C.; Li, Y.; Hou, Y. A simple environment-friendly process for preparing high-concentration alkali lignin nanospheres. Eur. Polym. J. 2019, 112, 15–23. [Google Scholar] [CrossRef]

- Zhang, J.; Tian, Z.; Ji, X.; Zhang, F. Fabrication mechanisms of lignin nanoparticles and their ultraviolet protection ability in PVA composite film. Polymers 2022, 14, 4196. [Google Scholar] [CrossRef]

- Cai, Y.; Lv, J.; Feng, J. Spectral characterization of four kinds of biodegradable plastics: Poly (lactic acid), poly (butylenes adipate-co-terephthalate), poly (hydroxybutyrate-co-hydroxyvalerate) and poly (butylenes succinate) with FTIR and raman spectroscopy. J. Polym. Environ. 2013, 21, 108–114. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K. Biodegradable nanocomposites of poly(butylene adipate-co-terephthalate) (PBAT) and organically modified layered silicates. J. Polym. Environ. 2012, 20, 195–207. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A.I.R. study on cellulose with the varied moisture contents: Insight into the supramolecular structure. Materials 2013, 13, 4573. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Hou, Y.; Wu, W.; Li, H.; Ren, S.; Li, J. Polycyclic aromatics observed in enzymatic lignin by spectral characterization and ruthenium ion-catalyzed oxidation. J. Agric. Food Chem. 2021, 69, 12148–12155. [Google Scholar] [CrossRef] [PubMed]

- Barros, J.J.P.; Oliveira, R.R.; Luna, C.B.; Wellen, R.M.; Moura, E.A.B. Effectiveness of modified lignin on poly(butylene adipate-co-terephthalate)/poly(lactic acid) mulch film performance. J. Appl. Polym. Sci. 2023, 140, 54684. [Google Scholar] [CrossRef]

- Gu, X.; Hou, J.; Ai, S. Effect of silane modified nano-SiO2 on the mechanical properties and compatibility of PBAT/lignin composite films. J. Appl. Polym. Sci. 2021, 139, 52051. [Google Scholar] [CrossRef]

- Ferreira, R.R.; Souza, A.G.; Barbosa, R.F.S.; Marciano, J.S.; Marques, F.A.S.; Mitra, S.K.; Rosa, D.S. The synergistic effect of nanocellulose and nanocapsules into poly(butylene adipate-co-butylene terephthalate) films for active packaging. Polymer 2020, 35, 100996. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Galeski, A.; Pawlak, A. PBAT green composites: Effects of kraft lignin particles on the morphological, thermal, crystalline, macro and micromechanical properties. Polymer 2020, 203, 122748. [Google Scholar] [CrossRef]

- Giteru, S.G.; Ali, A.; Oey, I. Understanding the relationship between rheological characteristics of pulsed electric fields treated chitosan-zein-poly(vinyl alcohol)-polyethylene glycol composite dispersions and the structure-function of their resulting thin-films. Food Hydrocoll. 2021, 113, 106452. [Google Scholar] [CrossRef]

- Zou, Z.; Ismail, B.; Zhang, X.; Yang, Z.; Liu, D.; Guo, M. Improving barrier and antibacterial properties of chitosan composite films by incorporating lignin nanoparticles and acylated soy protein isolate nanogel. Food Hydrocoll. 2023, 134, 108091. [Google Scholar] [CrossRef]

- Ge, X.; Chang, M.; Jiang, W.; Zhang, B.; Xing, R.; Bulin, C. Investigation on two modification strategies for the reinforcement of biodegradable lignin/poly(lactic acid) blends. J. Appl. Polym. Sci. 2020, 137, 49354. [Google Scholar] [CrossRef]

- Wang, H.M.; Wang, B.; Yuan, T.Q.; Zheng, L.; Shi, Q.; Wang, S.F.; Sun, R.C. Tunable, UV-shielding and biodegradable composites based on well-characterized lignins and poly(butylene adipate-co-terephthalate). Green Chem. 2020, 22, 8623–8632. [Google Scholar] [CrossRef]

- Xiong, S.J.; Zhou, S.J.; Wang, H.H.; Wang, H.M.; Yu, S.; Zheng, L.; Yuan, T.Q. Fractionation of technical lignin and its application on the lignin/poly-(butylene adipate-co-terephthalate) bio-composites. Int. J. Biol. Macromol. 2022, 209, 1065–1074. [Google Scholar] [CrossRef]

- Li, Y.; Li, F.; Yang, Y.; Ge, B.; Meng, F. Research and application progress of lignin-based composite membrane. J. Polym. Eng. 2021, 41, 245–258. [Google Scholar] [CrossRef]

- Siracusa, V. Food packaging permeability behaviour: A report. Int. J. Polym. Sci. 2012, 2012, 302029. [Google Scholar] [CrossRef]

- Kim, J.; Bang, J.; Park, S.; Jung, M.; Jung, S.; Yun, H.; Kim, J.H.; Choi, I.G.; Kwak, H.W. Enhanced barrier properties of biodegradable PBAT/acetylated lignin films. Sustain. Mater. Technol. 2023, 7, e00686. [Google Scholar] [CrossRef]

- Xing, Q.; Buono, P.; Ruch, D.; Dubois, P.; Wu, L.; Wang, W.J. Biodegradable UV-blocking films through core–shell lignin–melanin nanoparticles in poly(butylene adipate-co-terephthalate). ACS Sustain. Chem. Eng. 2019, 7, 4147–4157. [Google Scholar] [CrossRef]

- Yang, W.; Fortunati, E.; Gao, D.; Balestra, G.M.; Giovanale, G.; He, X.; Torre, L.; Kenny, J.M.; Puglia, D. Valorization of acid isolated high yield lignin nanoparticles as innovative antioxidant/antimicrobial organic materials. ACS Sustain. Chem. Eng. 2018, 6, 3502–3514. [Google Scholar] [CrossRef]

- He, Y.; Li, H.; Fei, X.; Peng, L. Carboxymethyl cellulose/cellulose nanocrystals immobilized silver nanoparticles as an effective coating to improve barrier and antibacterial properties of paper for food packaging applications. Carbohydr. Polym. 2021, 252, 117156. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Feng, T.; Liu, J.; Pan, C.; Wang, Y.; Wu, Z.; Fan, G. Preparation and Properties of Nano-Lignin-Reinforced Poly(butylene adipate-co-terephthalate) Composites. Processes 2025, 13, 3507. https://doi.org/10.3390/pr13113507

Li Y, Feng T, Liu J, Pan C, Wang Y, Wu Z, Fan G. Preparation and Properties of Nano-Lignin-Reinforced Poly(butylene adipate-co-terephthalate) Composites. Processes. 2025; 13(11):3507. https://doi.org/10.3390/pr13113507

Chicago/Turabian StyleLi, Yongshuang, Ting Feng, Jifei Liu, Cheng Pan, Yi Wang, Zhenzhen Wu, and Guozhi Fan. 2025. "Preparation and Properties of Nano-Lignin-Reinforced Poly(butylene adipate-co-terephthalate) Composites" Processes 13, no. 11: 3507. https://doi.org/10.3390/pr13113507

APA StyleLi, Y., Feng, T., Liu, J., Pan, C., Wang, Y., Wu, Z., & Fan, G. (2025). Preparation and Properties of Nano-Lignin-Reinforced Poly(butylene adipate-co-terephthalate) Composites. Processes, 13(11), 3507. https://doi.org/10.3390/pr13113507