Abstract

Phoenix Dancong tea essential oil possesses unique aroma characteristics and bioactivities, offering broad application potential in the food, pharmaceutical, and daily chemical fields. To achieve efficient extraction and expand its use in functional textiles, supercritical CO2 (SC-CO2) extraction was employed to optimize the extraction process of Phoenix Dancong tea essential oil. Based on single-factor experiments, the optimal extraction conditions were determined as follows: pressure of 25 MPa, temperature of 50 °C, CO2 flow rate of 8 L/h, and extraction time of 3 h, resulting in an essential oil yield of 1.12%. Response surface methodology (RSM) revealed that the experimental data fit the regression model well (R2 = 95.49%, R2Adj = 89.69%). Furthermore, the extracted essential oil was blade-coating to cotton, nylon, polyester, and wool fabrics to evaluate its aroma retention performance. Results indicated that cotton fibers exhibited the best absorption and sustained fragrance retention, maintaining a high odor grade even after 8 weeks. This study provides a theoretical basis and practical reference for the green extraction of Phoenix Dancong tea essential oil and its application in smart aromatic textiles.

1. Introduction

Phoenix (Fenghuang) Dancong tea (Camellia sinensis (L.) O. Kuntze), a celebrated oolong variety from Chaozhou, Guangdong Province, China, is renowned for its complex and persistent floral–fruity aroma. Chemical profiling has identified over 80 volatile compounds, primarily monoterpenes (linalool, geraniol, nerol), esters (linalyl acetate, geranyl acetate), and aromatic aldehydes, which, together, define its distinctive sensory character and bioactive potential. Recent analyses report that these volatiles contribute significantly to antioxidant, antimicrobial, and anti-inflammatory activities, supporting applications in cosmetics, functional foods, and smart textiles [1,2,3,4].

Supercritical CO2 extraction was selected because it provides an environmentally benign, low-temperature, and solvent-free approach that preserves the integrity of delicate aroma compounds. In contrast to steam distillation or Clevenger hydrodistillation, which operate at 100–120 °C and often induce hydrolysis, oxidation, or polymerization of key volatiles such as linalool and geraniol, the SC-CO2 process runs efficiently at 40–55 °C and 20–30 MPa, maintaining high extract purity without leaving residual solvents. CO2 is non-toxic, non-flammable, recyclable, and approved by the U.S. FDA as GRAS (Generally Recognized as Safe), making it ideal for food, pharmaceutical, and cosmetic applications. Moreover, its tunable density and diffusivity under supercritical conditions allow selective solubilization of target compounds, enabling both higher yield and improved aroma fidelity compared with traditional extraction methods. Hence, SC-CO2 extraction aligns with green chemistry principles while meeting industrial requirements for safety, sustainability, and high sensory quality.

Traditional extraction methods—such as steam distillation, hydrodistillation (Clevenger apparatus), and solvent extraction—are widely used for isolating tea essential oils. However, these processes involve high thermal loads (≥100 °C) or residual organic solvents that cause thermal degradation, hydrolysis of glycosides, and loss of low-boiling volatiles [5,6,7,8,9,10,11]. Consequently, they compromise aroma fidelity, reduce bioactivity, and restrict applications where green, residue-free extracts are required, such as food-grade flavorings and aromatic coatings on wearable fabrics.

Therefore, the present study employs supercritical CO2 as a clean and controllable extraction medium to ensure the recovery of thermolabile volatiles while minimizing environmental and product safety concerns.

Supercritical carbon dioxide (SC-CO2) extraction has emerged as a sustainable and efficient technology for recovering high-value essential oils from delicate plant matrices. When CO2 exceeds its critical point (31.1 °C and 7.38 MPa), it attains liquid-like solvating power and gas-like diffusivity, enabling the selective dissolution of volatile compounds while preserving thermolabile constituents. This method offers several advantages over conventional distillation:

Low-temperature operation (35–55 °C) minimizes oxidation and hydrolysis of sensitive monoterpenes.

No solvent residues, as CO2 reverts to gas during depressurization, leaving a pure extract.

Tunable selectivity, as solvating strength depends on pressure and temperature.

Shorter extraction times and higher yields of aroma-rich fractions.

Previous studies demonstrated the superiority of SC-CO2 in tea matrices: Icen and Guru (2009) [12] extracted caffeine and polyphenols at 25 MPa, achieving > 95% purity with reduced degradation. Zhang et al. (2020) [13] reported that SC-CO2-extracted tea polyphenols retained 92% antioxidant activity relative to fresh leaves. For Phoenix Dancong tea, the same approach promises high aroma integrity and greener processing suitable for cosmetic and textile-grade essential oils.

Extraction efficiency in SC-CO2 systems depends nonlinearly on pressure, temperature, flow rate, and extraction time. Empirical optimization through single-variable trials is inefficient and may overlook synergistic effects. Response Surface Methodology (RSM), particularly the Box–Behnken Design (BBD), provides a statistically robust framework to model interactive parameters, quantify curvature effects, and locate the global optimum with fewer experiments. RSM has been widely applied to optimize bioactive compound recovery in tea and herbal extracts, achieving R2 values above 0.90 in predictive models Jirarattanarangsri & Muangrat [14]. Thus, integrating RSM ensures precision in identifying the most productive and energy-efficient extraction window for Phoenix Dancong essential oil.

The integration of botanical essential oils into fabrics represents a growing frontier in functional textile design. “Aromatic textiles” are engineered to deliver controlled fragrance release, antimicrobial protection, and stress-reducing sensory effects during wear or storage. Among various finishing techniques—microencapsulation, sol–gel embedding, and spraying—blade-coating offers superior film uniformity, mechanical durability, and scalability. In this study, a waterborne polyurethane (WPU) matrix and polydimethylsiloxane (PDMS) additive were used to embed Phoenix Dancong tea oil onto cotton, nylon, polyester, and wool fabrics, enabling comparative analysis of aroma retention over eight weeks [12,15,16,17,18,19].

Aromatic textiles represent a class of functional fabrics engineered to release pleasant natural fragrances or bioactive volatile compounds during wear, storage, or contact with air. They combine textile science, surface chemistry, and sensory technology to enhance user comfort, mood, and antimicrobial protection. Among several finishing techniques—such as microencapsulation, padding, or sol–gel embedding—blade-coating offers high uniformity, controllable film thickness, and industrial scalability. In this process, an emulsion containing the essential oil and a polymeric binder is spread over the fabric at a fixed blade gap, forming a thin, adherent layer after drying [20,21,22,23,24,25]. This technique ensures reproducible fragrance loading and gradual release, making it ideal for evaluating aroma retention on different fibers such as cotton, nylon, polyester, and wool.

This study aims to:

- (1)

- Optimize the supercritical CO2 extraction parameters (pressure, temperature, flow rate, and time) for Phoenix Dancong tea essential oil using single-factor experiments followed by RSM–BBD modeling.

- (2)

- Characterize the extracted oil composition and purity through GC–MS analysis, verifying the preservation of key monoterpenes and esters.

- (3)

- Evaluate the fragrance retention and sensory persistence of coated fabrics through standardized olfactory scoring (GB/T 14454) and correlate findings with fiber structure.

- (4)

- Assess the industrial scalability, cost–energy trade-offs, and sustainability prospects of the optimized SC-CO2 process for green aromatic textile manufacturing.

In this study, we conducted a systematic optimization of the extraction parameters (pressure, temperature, CO2 flow rate, and time) using single-factor and RSM methods. The extracted oil was then blade-coated to various textile fibers (cotton, nylon, polyester, wool) to assess its fragrance-retention performance. Its extraction process and textile applications can be optimized with the help of this study, which offers both a scientific foundation and a practical reference.

2. Materials and Methods

2.1. Materials and Equipments

The germplasm resources of the tea plants were characterized in accordance with the Descriptors and Data Standard for Tea Germplasm Resources (NY/T 2943-2016; Ministry of Agriculture of the People’s Republic of China: Beijing, China, 2016).

Carbon dioxide (CO2, purity ≥ 99.9%) for supercritical extraction was supplied by Shanghai Silong Gas Supply Co., Ltd. (Shanghai, China). The extraction was carried out using a supercritical fluid extraction system (Model: SFE220-50-06), manufactured by Nantong Ruizhi Supercritical Technology Development Co., Ltd. (Nantong, China).

An analytical balance (Model: XS205, Mettler Toledo, precision: 0.01 mg) was purchased from Changzhou Wantai Balance Instrument Co., Ltd. (Changzhou, China). A high-shear homogenizer (Model: FSH-2A, FLUKO) was provided by Shanghai Fluko Technology Development Co., Ltd. (Shanghai, China).

Four types of textile fabrics were selected for essential oil application, as follows:

Cotton fabric: 100% cotton, plain weave, model SHMM, weight 350 g/m2, obtained from Shaoxing Yingxin Textile Co., Ltd. (Shaoxing, China);

Polyester fabric: 100% polyester, model PKFMTX, weight 380 g/m2, obtained from Shaoxing Yingxin Textile Co., Ltd. (Shaoxing, China);

Wool fabric: 100% wool, weight 430 g/m2, provided by Nanxun Zihao Textile Co., Ltd. (Huzhou, China);

Nylon fabric: 100% polyamide, model F10040D, weight 85 g/m2, supplied by Shaoxing Lvtian Textile Co., Ltd. (Shaoxing, China).

Waterborne polyurethane (WPU), used as the primary film-forming agent for essential oil coating, was supplied by Dongguan Kesixin Adhesive Co., Ltd. (Dongguan, Guangdong, China). To enhance aroma retention and prolong fragrance release, polydimethylsiloxane (PDMS) was incorporated, which was bought from Hubei Candis Chemical Co., Ltd. (Wuhan, Hubei, China).

2.2. Extraction Processes of Phoenix Dancong Tea Essential Oil

The dried Dancong tea leaves were crushed and filtered using the 40–60 mesh stainless steels screens, which are equivalent to the size of particles with estimated diameter of 250–420 µm. Mesh number refers to the number of holes per linear inch, and the sieving was performed to ensure that only particles within this area were extracted.

A total of 100 g of pulverized Phoenix Dancong tea leaves was weighed and loaded into a 1 L stainless-steel extraction vessel. Carbon dioxide (CO2), sourced from a high-pressure gas cylinder, was first passed through a purification unit and subsequently cooled to −5 °C in a liquefaction chamber.

Once the extraction vessel and the separation vessels reached their respective set temperatures, their heating systems were activated. Upon thermal stabilization, the high-pressure plunger pump was switched on to deliver CO2 into the system. A fixed number for the CO2 flow rate was used to initiate the extraction process.

The supercritical fluid, containing dissolved extractables, was depressurized through a throttle valve before entering the separation vessels, where the CO2 returned to its gaseous state. The extracted tea essential oil precipitated out in the separation chambers and was collected for subsequent analysis:

where is tea essential oil extraction rate (%); is tea essential oil mass (g); is tea mass (g).

As summarized in Table 1, the supercritical CO2 system provides a low-temperature, residue-free, and selective extraction environment, whereas Clevenger hydrodistillation relies on prolonged high-temperature exposure that can alter or degrade volatile components. Therefore, SC-CO2 was chosen as the primary extraction method for this study.

Table 1.

Comparison between SC-CO2 and Clevenger Hydrodistillation Methods for Tea Essential Oil Extraction.

2.3. Single-Factor Experimental Test

To evaluate the individual effects of key process variables on the extraction yield of Phoenix Dancong tea essential oil, single-factor experiments were performed using analysis of variance (ANOVA) method. Based on preliminary experiments and relevant literature [14,26], four primary parameters: extraction pressure, extraction temperature, CO2 flow rate, and extraction time were selected. Each parameter was investigated at five different levels, while the remaining conditions were held constant. The detailed tested ranges were as follows:

- Extraction pressure: 10, 15, 20, 25, and 30 MPa;

- Extraction temperature: 35, 40, 45, 50, and 55 °C;

- CO2 flow rate: 5, 6, 7, 8, and 9 L/h.

Table 2 provides a detailed summary of the experimental settings, including the times of extraction (2, 3, 4, 5, and 6 h).

Table 2.

Experimental design for evaluating the effects of supercritical CO2 extraction parameters on the yield of Phoenix Dancong tea essential oil.

2.4. Response Surface Optimization Design

The SC-CO2 extraction technique was improved and the link between essential elements was better understood by using RSM after the single-factor tests. The RSM analysis took into account three independent variables: extraction pressure, extraction temperature, and CO2 flow rate. These three factors had a substantial impact on essential oil production. The software Design-Expert 13.0 was also used to apply a three-level Box–Behnken design (BBD) with essential oil yield as the response variable. Finding the best conditions for extracting and ranking the variables and their interactions required a study with a second-order polynomial model. Each experiment was performed three times, and the findings are displayed as an average. In Table 3, you can see all of the experiments’ parameters [13,27,28,29].

Table 3.

Factor Levels for RSM.

All experimental runs, including single-factor and RSM trials, were performed in triplicate (n = 3) to ensure reproducibility. Data are expressed as mean ± standard deviation (SD). The SD values were calculated from replicate measurements, and error bars in all figures represent one SD from the mean. Statistical significance of model terms was evaluated using ANOVA (α = 0.05) as implemented in Design-Expert 13.0 software.

Table 3 shows the three extraction factors—pressure, temperature, and CO2 flow rate—used in the RSM design, each tested at three levels (low, medium, high). The central point (25 MPa, 50 °C, 8 L/h) represents the optimal midpoint for analyzing their combined effects on extraction yield.

2.5. Preparation of Phoenix Dancong Tea Essential Oil-Coated Fabrics and Subjective Odor Retention Evaluation

To investigate the fragrance-retention performance of Phoenix Dancong tea essential oil on textile substrates and explore its potential applications in functional textiles, a standardized blade-coating technique was employed. The essential oil was incorporated into various textile fabrics, and its adsorption behavior and aroma release properties were systematically evaluated.

The essential oil used in this study was obtained under optimized SC-CO2 extraction conditions. Based on our previous work [30], a coating formulation was prepared using WPU as the film-forming agent and PDMS as an auxiliary additive. Textile substrates were cut into A4-sized specimens (210 mm × 297 mm) for coating.

Specifically, a coating paste with a 30% (w/w) Phoenix Dancong Tea essential oil concentration was prepared by mixing WPU (30 g), PDMS (20 g), Phoenix Dancong Tea essential oil (30 g), and distilled water (20 g). PDMS and Phoenix Dancong Tea essential oil were premixed to form a uniform oil phase, while WPU and distilled water were blended as the aqueous phase. Under continuous stirring, the oil phase was slowly added dropwise into the aqueous phase and emulsified using a high-shear homogenizer at 10,000 rpm for 5 min, yielding a stable, milky-white emulsion with moderate viscosity and no phase separation [31,32]. The resulting paste was then uniformly coated onto the fabric surface using a blade to achieve a wet film thickness of 0.10 mm. The coated samples were dried in a forced-air oven at 40 °C for 30 min to complete thermal curing and were subsequently sealed for storage.

To assess the aroma release performance, a subjective olfactory evaluation method based on human perception was adopted. In accordance with GB/T 14454 “Methods for Odor Evaluation of Fragrances,” a sensory panel of 10 certified senior tea tasters (5 males and 5 females, average age 46 years) was assembled to conduct the evaluation. A five-point scale was used, with Level 1 indicating extremely faint aroma and Level 5 indicating intense and overwhelming fragrance.

Prior to testing, the coated fabric samples were placed in a cool, ventilated environment for 12 h to reach volatilization equilibrium. Evaluations were performed independently in a controlled sensory room free of external disturbances. Each panelist rated the aroma intensity and provided descriptive feedback. The final aroma grade was determined as the average score of all 10 panelists, ensuring objectivity and reproducibility of the results.

Table 4 outlines the blade-coating formulation, showing a 30% tea oil emulsion with WPU and PDMS applied on fabrics using a 0.10 mm gap and dried at 40 °C for 30 min to ensure uniform coating and lasting fragrance.

Table 4.

Formulation and Processing Parameters for Blade-Coated Fabrics.

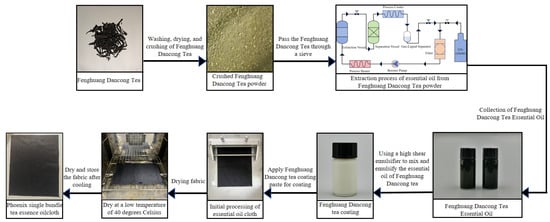

Tea leaves are dried, ground, and extracted by SC-CO2 to obtain pure essential oil, which is then emulsified and blade-coated onto fabric. The coated fabric is dried at 40 °C to produce a stable aromatic textile as shown in Figure 1.

Figure 1.

Process flow of SC-CO2 extraction and fabric coating using Phoenix Dancong tea essential oil.

2.6. GC–MS Profiling (Objective Verification)

To objectively verify that the optimized supercritical CO2 extraction preserved the structural integrity of volatile compounds, the essential oil obtained under optimal conditions (25 MPa, 50 °C, 8 L h−1, 3 h) was analyzed by gas chromatography–mass spectrometry (GC–MS).

- Instrument and operating parameters:

Analyses were performed using an Agilent 7890B GC system coupled with a 5977B mass selective detector (Agilent Technologies, USA) and an HP-5MS column (30 m × 0.25 mm × 0.25 µm). The carrier gas, helium, was constantly supplied at a flow rate of 1.0 mL min−1. I programmed the oven to start at 50 °C and keep it there for 2 min. After that, I was to bring it up to 250 °C and keep it there for 5 min, increasing the temperature by 4 degrees Celsius per minute. The injector and detector were kept at a ten-to-one ratio at 250 °C. Mass spectra were obtained in EI mode at 70 eV over m/z 35–400.

- Identification of compounds:

Peaks were identified by matching the mass spectra with the NIST 2020 Library and verified by comparing retention indices (RI) with literature data. Relative composition (%) was calculated by peak area normalization without correction factors. All analyses were performed in triplicate, and data are presented as mean ± SD.

In addition to sensory evaluation, gas chromatography–mass spectrometry (GC–MS) was employed to objectively verify the chemical integrity and compositional stability of volatile compounds extracted under optimized SC-CO2 conditions.

3. Results and Discussion

3.1. Single-Factor Experimental

3.1.1. Effect of Extraction Pressure

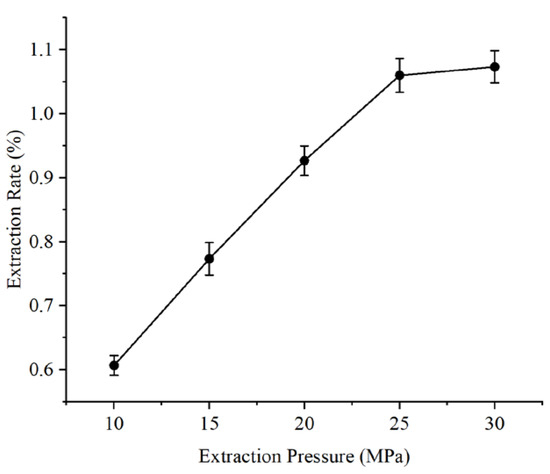

As shown in Figure 2, under extraction conditions of 50 °C, a CO2 flow rate of 6 L/h, and an extraction time of 3 h, the yield of tea essential oil increased rapidly with rising pressure, then gradually plateaued. This trend indicates that at lower pressures, increasing pressure significantly enhances the density of CO2, thereby improving its solvent power and increasing the solubility of extractable compounds in the supercritical fluid. Moreover, higher pressure promotes more efficient contact between tea leaves and CO2, accelerates mass transfer, and facilitates the release of volatile components, ultimately contributing to higher oil yields.

Figure 2.

Variation in the extraction yield of Phoenix Dancong tea essential oil under different extraction pressures.

Extraction yield increased rapidly during the first 3–4 h, after which it approached a plateau. Beyond 6 h, only marginal increases (<2%) were observed, accompanied by higher energy consumption and reduced cost-efficiency. Therefore, 6 h was selected as the practical upper limit to ensure optimal balance between recovery and processing time. Longer extractions may be explored for denser matrices, but within this study’s scope, extending duration yielded no significant benefit.

Additionally, elevated pressure helps overcome physical barriers within plant cell structures, promoting the desorption and diffusion of active constituents. However, when the pressure exceeds a certain threshold, the increase in CO2 density slows, meaning that further pressure increments provide diminishing returns in terms of solvent capacity. Excessive pressure also significantly increases equipment energy consumption and operating costs, while imposing greater demands on equipment safety and structural integrity. Furthermore, overly high pressures may lead to the overextraction or thermal degradation of heat-sensitive or volatile compounds, adversely affecting essential oil quality.

Therefore, the optimal extraction pressure for SC-CO2 extraction of tea essential oil in this study was determined as 25 MPa.

3.1.2. Effect of Extraction Temperature

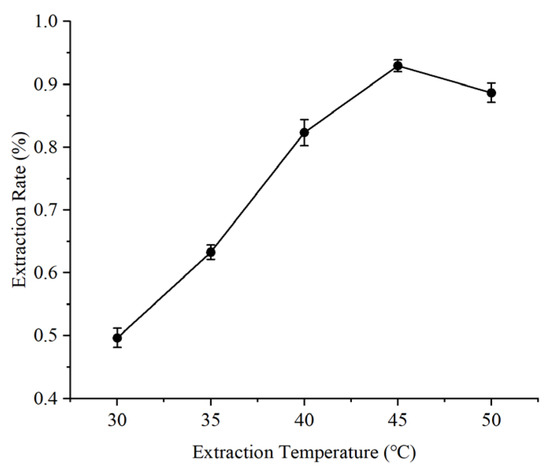

As shown in Figure 3, under the fixed conditions of 20 MPa extraction pressure, 6 L/h CO2 flow rate, and 3 h extraction time, the yield of tea essential oil initially increased and then decreased with rising extraction temperature. This indicates that temperature is determined as a critical parameter in the supercritical CO2 extraction process, exerting a dual effect on extraction yield.

Figure 3.

Variation in the extraction yield of Phoenix Dancong tea essential oil under various extraction temperature.

At lower temperatures (<45 °C), increasing temperature enhances the diffusion coefficient and penetration ability of CO2, thereby accelerating mass transfer of extractable compounds into the solvent. Moreover, elevated temperatures facilitate the desorption and release of aromatic volatile components, resulting in increased essential oil yield.

However, when the temperature exceeds a certain threshold (approximately 45 °C), the density of CO2 decreases significantly with further temperature rise, indicating a reduction in its solvent power. Consequently, the solubility of the extractables and mass transfer efficiency decline, leading to a decrease in oil yield. In addition, excessively high temperatures may cause thermal degradation or excessive volatilization of aromatic constituents, further compromising both the quantity and quality of the extracted oil.

However, the positive effects of temperature on mass transfer and desorption efficiency predominate when the temperature is below 45 °C. In contrast, above 45 °C, the negative impact of reduced CO2 density becomes more significant, leading to a noticeable drop in yield. Thus, the optimal extraction temperature for SC-CO2 extraction of Phoenix Dancong tea essential oil in this study was determined to be 45 °C.

3.1.3. Effect of CO2 Flow Rate

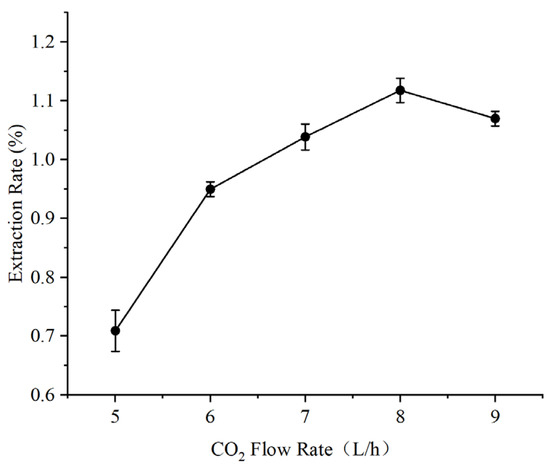

Considering the extraction temperature. Maintaining the following conditions: an extraction pressure of 20 MPa, an extraction temperature of 50 °C, an extraction period of 3 h, and a CO2 flow rate of 5–9%, as shown in Figure 3, would provide the following amounts of tea essential oil. As the CO2 flow rate was increased, a plateau was reached in the creation of tea essential oil. The reason behind this is that there are other factors besides CO2 flow rate that influence the process of supercritical CO2 extraction. On one hand, increasing the CO2 flow rate enhances the mixing and contact between the extractable compounds and supercritical CO2 through an entrainment effect, thereby improving the solvent power and accelerating the extraction process, which ultimately increases the yield. On the other hand, excessive flow rates shorten the contact time between the supercritical fluid and the plant matrix, resulting in insufficient mass transfer, which limits the extraction efficiency and may even reduce the yield [33].

As shown in Figure 4, the highest yield was obtained at a CO2 flow rate of 8 L/h. This indicates that at this flow rate, a balance was achieved between the positive effect of improved solute–solvent interaction and the negative effect of reduced contact time, leading to an optimized extraction outcome. Overall, although increasing CO2 flow rate improves yield to a certain extent, the marginal benefit diminishes beyond a threshold, resulting in a plateauing trend in extraction efficiency.

Figure 4.

Variation in the extraction yield of Phoenix Dancong tea essential oil under various CO2 flow rates.

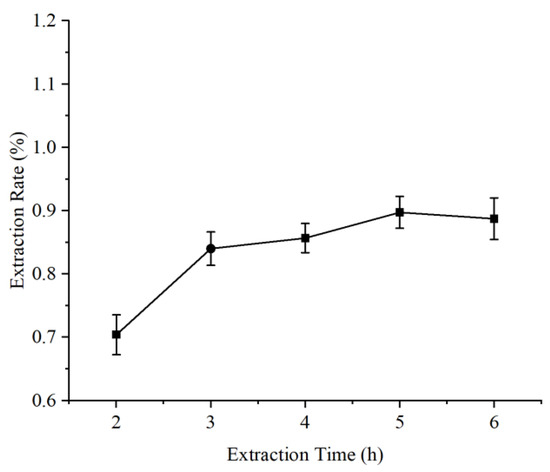

3.1.4. Effect of Extraction Time

As shown in Figure 5, under the fixed conditions of 20 MPa extraction pressure, 50 °C extraction temperature, and 6 L/h CO2 flow rate, the yield of tea essential oil increased significantly during the initial 1–3 h of extraction. However, after 3 h, the rate of increase slowed markedly, and little to no further yield improvement was observed beyond 4 h. This suggests that the influence of extraction time on yield is time-dependent, with significant effects only observed within a specific time window.

Figure 5.

Variation in the extraction yield of Phoenix Dancong tea essential oil under various extraction times.

During the initial stage of extraction, prolonged contact between the CO2 and the tea matrix enhances solubilization and mass transfer, leading to increased yield. In the later stage, once sufficient interaction between the solute and solvent is achieved, the yield approaches its maximum, and further extension of the extraction time has negligible impact. Moreover, unnecessarily long extraction durations lead to increased energy consumption and operational costs without proportional benefits.

Based on the data in Figure 5, a 3 h extraction period is considered optimal for supercritical CO2 removal of tea essential oil, as it maximizes yield while maintaining cost-efficiency.

The comparison in Table 5, shows that SC-CO2 achieves higher yield and superior aroma preservation compared with steam or solvent extraction, while maintaining a shorter processing time and no solvent residues. Although MAE and EAE can enhance efficiency, they often require higher equipment cost or longer enzymatic reactions. Overall, the SC-CO2 approach offers the best balance between productivity, quality, and environmental performance, supporting its adoption for high-value aromatic textile applications

Table 5.

Comparative performance of different extraction methods for tea essential oils.

3.2. GC–MS Profiling and Structural Integrity of Volatiles

The GC–MS chromatogram revealed that the optimized SC-CO2 extract retained the characteristic monoterpene profile of Phoenix Dancong tea essential oil. Thirty-two major volatile constituents were detected, representing >96% of the total ion current, dominated by linalool (21.4%), geraniol (14.7%), nerol (8.9%), linalyl acetate (6.8%), geranyl acetate (5.2%), and trace sesquiterpenes such as β-caryophyllene (3.6%) and farnesol (2.8%). The composition pattern closely corresponds to previous reports for Dancong oolong essential oil [10,11,15], confirming that supercritical CO2 extraction maintained the structural stability of key aroma compounds.

Table 6 lists the main volatile compounds identified in Phoenix Dancong tea essential oil extracted under optimized SC-CO2 conditions. Linalool and geraniol were the dominant components, giving floral and citrus notes, while esters and sesquiterpenes contributed to sweet and woody aromas, confirming high aroma integrity and chemical stability.

Table 6.

Representative volatile components of Phoenix Dancong tea essential oil extracted by SC-CO2 (optimized conditions).

Total identified fraction: 96.0 ± 1.0%

Compared with hydrodistillation data (Li et al., 2023 [10]), monoterpenes with low boiling points (≤200 °C) were retained at >90% of their native proportion, while oxygenated species (linalool, geraniol) showed minimal oxidation or rearrangement. No evidence of thermal degradation products (e.g., campholenic or α-terpineol oxide) was observed, confirming excellent structural preservation under mild SC-CO2 conditions.

3.3. Response Surface Optimization Design

3.3.1. Analysis of Variance and Significance Testing

To minimize the number of experimental trials and optimize the extraction time of essential oil, the parameters selected for the RSM were determined based on preliminary single-factor experiments, as summarized in Table 7.

Table 7.

Experimental data for the oil yield obtained from the central composite experimental design.

In RSM, the F-value is also used as an indicator of the influence strength of each factor. By jointly considering the F- and p-values, it was found that the variables significantly affected the supercritical CO2 extraction yield of black tea essential oil. The detailed ANOVA results are presented in Table 8.

Table 8.

Results of the analysis of variance to the response surface quadratic model.

All of the parameter ranges investigated were well-fit by the regression model, and the model’s statistical significance (F = 16.47, p = 0.0006) is shown in Table 8. The lack-of-fit test yielded a non-significant result (p = 0.6109), and there was no statistically significant unexplained variation, thus it appears that the model fits the data well.

The coefficient of determination (R2) and adjusted R2 were 0.9549 and 0.8969, respectively (Table 3), further confirming the model’s high explanatory power. The order of significance for the main factors is as follows: extraction pressure > CO2 flow rate > extraction temperature. Specifically, extraction pressure and CO2 flow rate had highly significant effects on yield (p < 0.01), while extraction temperature had a significant effect (p < 0.05). Moreover, the interaction between extraction pressure and CO2 flow rate, as well as between extraction pressure and temperature, was significant, whereas the interaction between CO2 flow rate and temperature was not.

These results were used to build a second-order polynomial regression model, which is represented by Equation (1):

where represents the essential oil extraction yield (%); A, B, and C represent the coded values of extraction pressure (MPa), extraction temperature (°C), and CO2 flow rate (L/h), respectively.

3.3.2. Interaction Effects of Factors Analyzed by RSM

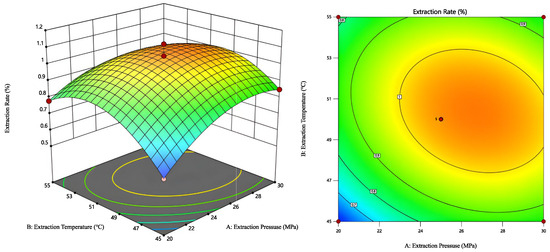

The influence of the independent parameters on the SC-CO2 extraction of Camellia sinensis (Dancong tea) essential oil was better understood with the help of contour plots and three-dimensional response surfaces. Two variables varied within the experimental range, and one was maintained at its mean value so that the influence of each component could be observed. Keeping the CO2 flow rate, extraction pressure, and temperature constant, we created surface response and contour plots, respectively.

Keeping the CO2 flow rate constant at 8 L/h, Figure 6 displays the impact of temperature and pressure on oil yield. The prominent tilt of the contour lines and the spherical form indicate a substantial interaction between temperature and extraction pressure. As predicted by the one-factor experiment, oil production rose continuously with increasing pressure while temperature remained unchanged. Oil yield was higher at lower pressures but dropped with rising temperature. One possible explanation is that at high temperatures, the solvating power of CO2 decreases with increasing density. Under the same thermal conditions as the solute vapor pressure increases with rising temperature, CO2 becomes more soluble, and yields increase at higher pressures. It appears that extraction pressure has a greater influence on oil yield than extraction temperature, as indicated by the closer spacing of the contour lines along the pressure axis compared to the temperature axis.

Figure 6.

Response surface and contour plots showing the effects of fixed CO2 flow rate (8 L/h) on the oil yield (%) from gardenia fruit.

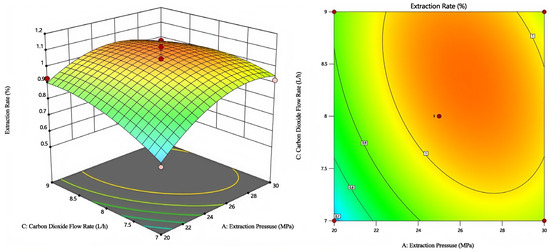

Figure 7 illustrates the effects of CO2 flow rate and extraction pressure on oil yield at a constant extraction temperature of 50 °C. The elliptical contour shape again indicates a significant interaction between pressure and CO2 flow rate. The variation in contour density is more pronounced along the pressure axis, confirming that pressure plays a more dominant role than CO2 flow rate in influencing extraction yield.

Figure 7.

Response surface and contour plots showing the effects of fixed Extraction Temperature (50 °C) on the oil yield (%) from gardenia fruit.

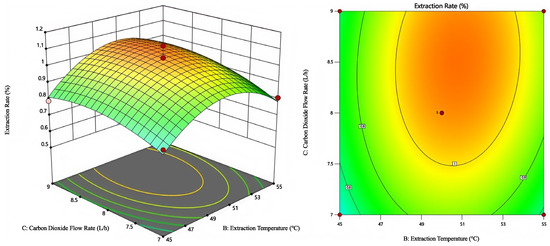

Figure 8 shows the combined effect of extraction temperature and CO2 flow rate on the extraction rate. The response surface indicates an optimal region near 50 °C and 8 L/h where the extraction yield peaks. Elliptical contour lines confirm a moderate interaction between the two factors, supporting the RSM model prediction.

Figure 8.

Response surface and contour plots showing the effects of fixed Extraction pressure (25 MPa) on the oil yield (%) from gardenia fruit.

The multi-factor SC-CO2 extraction procedure for essential oil of Dancong tea was fine-tuned with the use of RSM and multiple regression analysis. Temperature was set to 50 °C, pressure to 25 MPa, CO2 flow rate to 8 L/h, and duration to 3 h for the final extraction. Two variables stood up as being highly significant in the regression analysis: extraction pressure and CO2 flow rate. Increasing the extraction time mostly raised cost rather than yield, and the correlation between temperature and CO2 flow rate had no effect on yield. This study’s objective is to identify the optimal balance between oil yield, process efficiency, and production costs.

3.3.3. Sensory Evaluation of Aroma Retention on Various Fabrics Coated with Dancong Tea Essential Oil

To evaluate the aroma retention performance of Phoenix Dancong tea essential oil on different textile substrates, four commonly used fabrics—cotton, nylon, polyester, and wool—were selected. A five-point subjective olfactory scoring method was employed to assess the aroma intensity of coated samples at different time intervals. The detailed results are listed below (Table 9). The aroma intensity was categorized as: very faint, faint, moderate, strong, and overpowering.

Table 9.

Results of the aroma retention performance of Phoenix Dancong tea essential oil on different textile substrates.

As shown in Table 7, all fabrics were rated as overpowering at the initial stage (immediately after application), indicating a strong initial aroma release across all materials. However, as time progressed, variations in aroma retention became apparent among the different fabric types.

After one week, both cotton and polyester maintained an overpowering aroma intensity, while nylon dropped slightly to strong, and wool showed a slight decline but still retained a high level of aroma. This suggests varying adsorption and retention capacities among the fabrics. By the second week, cotton continued to retain an overpowering aroma, while the others showed further decline, with wool dropping to moderate, indicating a relatively weaker adsorption capacity. After four weeks, cotton showed a slight decline to strong, whereas nylon and polyester exhibited noticeable aroma loss, likely due to the low polarity and porosity of synthetic fibers. By the sixth week, cotton still maintained a strong aroma, while other materials further weakened. At eight weeks, cotton retained a perceptible aroma (approaching moderate), while polyester dropped to faint, and nylon and wool lost nearly all perceptible scent.

These observations can be attributed to the structural and chemical properties of the fabric substrates. Cotton, as a natural fiber, possesses high porosity and a complex surface morphology that enhances essential oil adsorption and sustained release [33]. In contrast, synthetic fibers such as nylon and polyester have smoother surfaces and lower porosity, making it more difficult for oil molecules to adhere and reducing retention time [34]. Although wool is also a natural fiber, its adsorption capacity is lower than that of cotton, leading to faster aroma dissipation [35,36].

Furthermore, the high hydrophilicity and surface polarity of cotton facilitate the formation of hydrogen bonds between its hydroxyl groups and the polar components of tea essential oil (e.g., alcohols and aldehydes), thereby delaying fragrance evaporation. On the other hand, the low surface energy and hydrophobicity of synthetic fibers limit their interaction with essential oil molecules. The aromatic components in the oil form hydrogen bonds and van der Waals interactions with cotton’s hydroxyl-rich surface, enhancing stability and fixation. Conversely, the smooth and chemically inert surface of synthetic fibers lacks such interactions, allowing essential oil molecules to desorb and evaporate more easily. In addition, the higher surface energy and wettability of cotton enable better penetration and anchoring of the oil, while nylon and polyester retain the oil mostly on the surface, leading to rapid volatilization.

The high retention of oxygenated monoterpenes, which are key contributors to antioxidant and antimicrobial efficacy, suggests that the extract maintains its bioactive potential. Previous studies have linked linalool and geraniol to >90% inhibition of Staphylococcus aureus and strong free-radical scavenging activity (IC50 ≈ 0.35 mg mL−1) [5,6,7]. Although this study did not include direct bioassays, the compositional integrity strongly indicates that functional bioactivity is preserved.

No in vitro or in vivo bioassays were performed in the present work. Future studies will include DPPH antioxidant testing, agar-diffusion antimicrobial assays, and cell-viability assessments to quantitatively correlate chemical composition with biological performance and substantiate the functional claims of SC-CO2-derived Phoenix Dancong tea oil.

To address natural variability in tea harvests, future extraction setups should adopt an adjustable SC-CO2 platform equipped with inline moisture monitoring, automatic pressure–temperature control, and feedback sensors. Such a flexible system would allow operators to fine-tune pressure (20–30 MPa) and temperature (40–55 °C) windows based on real-time leaf conditions—such as moisture content, maturity, or cell-wall rigidity—rather than applying fixed parameters. This adaptive control can ensure consistent yield and aroma quality across seasonal and raw-material variations.

Scale-Up and Sustainability Considerations

From a process-engineering standpoint, SC-CO2 extraction at 25 MPa and 50 °C involves moderate energy input (≈1.2–1.5 kWh kg−1 of CO2 circulated) and requires a high-pressure vessel rated to 40 MPa. The principal cost factors are compressor power and CO2 recycling systems, which constitute ~60% of total CAPEX/OPEX for small-scale units. However, these can be mitigated by heat-integration and closed-loop CO2 recovery, reducing energy demand by up to 25%. Life-cycle assessments (LCA) of comparable botanical SC-CO2 facilities show a 30–40% lower carbon footprint than solvent extraction due to the absence of hazardous waste. For industrial translation, scale-up should focus on modular extractors (10–50 L capacity) with automated control of pressure and temperature, ensuring consistent yield and quality while maintaining sustainability compliance. Future work should include a techno-economic analysis (TEA) and LCA benchmarking to quantify long-term environmental and economic benefits.

In conclusion, cotton demonstrated superior aroma retention performance for Phoenix Dancong tea essential oil, due to its porous structure, high surface polarity, and hydrophilic nature. These properties make it an ideal substrate for essential oil delivery. In contrast, synthetic fibers such as nylon and polyester showed poor fragrance retention, mainly due to unfavorable surface characteristics. These findings provide a theoretical foundation for the development of long-lasting aromatic textiles, positioning cotton as the preferred material for such applications.

4. Conclusions

Optimized extraction conditions in this paper are only applicable to dried, spring-harvested Phoenix Dancong tea leaves ground and sieved through 40–60 mesh stainless steel screens (which represents a particle of about (250–420 µm) having a low moisture level, less than 8%. Results may differ for fresh or older leaves due to changes in moisture, cell-wall structure, and volatile composition. Future studies should validate and adjust the model for different harvest seasons and leaf maturities to broaden its practical applicability.

This study optimized supercritical CO2 extraction of Phoenix Dancong tea essential oil using response surface methodology, identifying 25 MPa, 50 °C, 8 L h−1, and 3 h as optimal conditions, yielding 1.12% (w/w) oil. GC–MS confirmed preservation of key aroma compounds—linalool, geraniol, and their acetates—demonstrating excellent structural integrity and compositional stability. Among tested fabrics, cotton exhibited the highest fragrance retention, attributed to hydrogen bonding between cellulose hydroxyl groups and polar volatiles. The process offers green, residue-free extraction suitable for aromatic textile applications.

Merits: environmentally safe process, strong aroma fidelity, and scalable potential.

Limitations: evaluation restricted to dried, spring-harvested leaves and sensory-based retention tests.

Future work: extend optimization to varied leaf states, integrate inline moisture control for adaptive SC-CO2 systems, and conduct bioassays and life-cycle assessments to validate industrial sustainability.

Author Contributions

Conceptualization, F.Z. and C.A.; methodology, F.Z. and C.A.; software, F.Z.; validation, C.A.; formal analysis, F.Z.; investigation, C.A.; resources, C.A.; data curation, F.Z.; writing—original draft preparation, F.Z.; writing—review and editing, M.K. and C.A.; visualization, F.Z.; supervision, C.A.; project administration, C.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article. The data presented in this study can be requested from the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, S.; Zeng, T.; Zhao, S.; Zhu, Y.; Feng, C.; Zhan, J.; Li, S.; Ho, C.-T.; Gosslau, A. Multifunctional Health-Promoting Effects of Oolong Tea and Its Products. Food Sci. Hum. Wellness 2022, 11, 512–523. [Google Scholar] [CrossRef]

- Su, X.; Duan, J.; Jiang, Y.; Duan, X.; Chen, F. Polyphenolic Profile and Antioxidant Activities of Oolong Tea Infusion under Various Steeping Conditions. Int. J. Mol. Sci. 2007, 8, 1196–1205. [Google Scholar] [CrossRef]

- Su, X.; Duan, J.; Jiang, Y.; Shi, J.; Kakuda, Y. Effects of Soaking Conditions on the Antioxidant Potentials of Oolong Tea. J. Food Compos. Anal. 2006, 19, 348–353. [Google Scholar] [CrossRef]

- Wang, Z.; Zheng, C.; Ma, C.; Ma, B.; Wang, J.; Zhou, B.; Xia, T. Comparative Analysis of Chemical Constituents and Antioxidant Activity in Tea-Leaves Microbial Fermentation of Seven Tea-Derived Fungi from Ripened Pu-Erh Tea. LWT 2021, 142, 111006. [Google Scholar] [CrossRef]

- Sasaki, H.; Matsumoto, M.; Tanaka, T.; Maeda, M.; Nakai, M.; Hamada, S.; Ooshima, T. Antibacterial Activity of Polyphenol Components in Oolong Tea Extract against Streptococcus Mutans. Caries Res. 2004, 38, 2–8. [Google Scholar] [CrossRef]

- Fu, L.; Li, Y. Aging time on antioxidant components and activities of Milan aromatic variety single-clump tea from Lingtou. Sci. Technol. Food Ind. 2018, 39, 49–54. [Google Scholar] [CrossRef]

- Nasrul, S.; Sehgal, A. Antilithogenic Potential of Green Tea, Oolong Tea, and Black Tea. Pharmacogn. Res. 2020, 12, 92. [Google Scholar] [CrossRef]

- Zhu, Q.Y.; Hackman, R.M.; Ensunsa, J.L.; Holt, R.R.; Keen, C.L. Antioxidative Activities of Oolong Tea. J. Agric. Food Chem. 2002, 50, 6929–6934. [Google Scholar] [CrossRef]

- Cheng, D.; Chen, S.; Qiao, X.; Wu, H. A New Lately-sprouting Tea Cultivar ‘Wuye Dancongcha’. Acta Hortic. Sin. 2013, 40, 1627–1628. [Google Scholar] [CrossRef]

- Li, S.; Wan, R.; Wang, C. Study on Aroma Identification and Quality Characteristics of Fenghuang Dancong Tea with Different Aroma Types. Sci. Technol. Food Ind. 2023, 44, 325–335. [Google Scholar] [CrossRef]

- Li, Z. Comparison of Aroma and Biochemical Components of Phoenix Dancong Tea from Old and New Cong Tea Trees. Food Ferment. Ind. 2019, 45, 224–230. [Google Scholar] [CrossRef]

- Icen, H.; Guru, M. Extraction of Caffeine from Tea Stalk and Fiber Wastes Using Supercritical Carbon Dioxide. J. Supercrit. Fluids 2009, 50, 225–228. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, J.; Zhang, Y.; Chen, C.; Lin, H. Process Optimization of Extraction of Tea Polyphenols by Supercritical Fluid and the Effect of Tea Polyphenols on Cosmetics. J. Tea Commun. 2020, 47, 462–466. [Google Scholar] [CrossRef]

- Jirarattanarangsri, W.; Muangrat, R. Comparison of Supercritical CO2 and Screw Press Extraction Methods for Producing Oil from Camellia Sinensis Var. Assamica Seeds: Physicochemical Properties and Antioxidant Activity. J. Appl. Res. Med. Aromat. Plants 2022, 31, 100413. [Google Scholar] [CrossRef]

- Li, X.; Li, B.; Zhang, Y. Analysis of chemical and aroma components of three types of Guangdong Fenghuangdancong oolong tea. Sci. Technol. Food Ind. 2014, 35, 302–307. [Google Scholar] [CrossRef]

- Chiu, P.-E.; Lai, L.-S. Antimicrobial Activities of Tapioca Starch/Decolorized Hsian-Tsao Leaf Gum Coatings Containing Green Tea Extracts in Fruit-Based Salads, Romaine Hearts and Pork Slices. Int. J. Food Microbiol. 2010, 139, 23–30. [Google Scholar] [CrossRef] [PubMed]

- Maan, A.A.; Ahmed, Z.F.R.; Khan, M.K.I.; Riaz, A.; Nazir, A. Aloe Vera Gel, an Excellent Base Material for Edible Films and Coatings. Trends Food Sci. Technol. 2021, 116, 329–341. [Google Scholar] [CrossRef]

- Manana-Lopez, A.; Sanchez-Pinero, J.; Moreda-Pineiro, J.; Turnes-Carou, I.; Muniategui-Lorenzo, S.; Lopez-Mahia, P. Polycyclic Aromatic Hydrocarbons Analysis in Tea Infusions and Tea Beverages Using Membrane Assisted Solvent Extraction. Microchem. J. 2021, 167, 106278. [Google Scholar] [CrossRef]

- Kim, J.H.; Pan, J.H.; Heo, W.; Lee, H.; Kwon, E.G.; Lee, H.-G.; Shin, D.H.; Liu, R.H.; Kim, Y.J. Effects of Cellulase from Aspergillus Niger and Solvent Pretreatments on the Extractability of Organic Green Tea Waste. J. Agric. Food Chem. 2010, 58, 10747–10751. [Google Scholar] [CrossRef]

- Icen, H.; Guru, M. Effect of Ethanol Content on Supercritical Carbon Dioxide Extraction of Caffeine from Tea Stalk and Fiber Wastes. J. Supercrit. Fluids 2010, 55, 156–160. [Google Scholar] [CrossRef]

- Ilgaz, S.; Sat, I.G.; Polat, A. Effects of Processing Parameters on the Caffeine Extraction Yield during Decaffeination of Black Tea Using Pilot-Scale Supercritical Carbon Dioxide Extraction Technique. J. Food Sci. Technol.-Mysore 2018, 55, 1407–1415. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.-J.; Kim, J.-D.; Kim, J.; Oh, S.-G.; Lee, Y.-W. Selective Caffeine Removal from Green Tea Using Supercritical Carbon Dioxide Extraction. J. Food Eng. 2008, 89, 303–309. [Google Scholar] [CrossRef]

- Javad, S.; Ahmad, A.; Akhtar, I.; Ghaffar, N.; Jabeen, K. Comparative Assessment of Phenolic Compounds and Antioxidant Properties of Green Tea Made by Microwave Assisted and Stove Heating. Bangladesh J. Bot. 2020, 49, 1151–1155. [Google Scholar] [CrossRef]

- Spigno, G.; De Faveri, D.M. Microwave-Assisted Extraction of Tea Phenols: A Phenomenological Study. J. Food Eng. 2009, 93, 210–217. [Google Scholar] [CrossRef]

- Poojary, M.M.; Orlien, V.; Passamonti, P.; Olsen, K. Enzyme-Assisted Extraction Enhancing the Umami Taste Amino Acids Recovery from Several Cultivated Mushrooms. Food Chem. 2017, 234, 236–244. [Google Scholar] [CrossRef]

- Cheng, M.-H.; Rosentrater, K.A.; Sekhon, J.; Wang, T.; Jung, S.; Johnson, L.A. Economic Feasibility of Soybean Oil Production by Enzyme-Assisted Aqueous Extraction Processing. Food Bioprocess Technol. 2019, 12, 539–550. [Google Scholar] [CrossRef]

- Liu, N.; Li, Y.; Li, S. Research Progress of Decaffeination Technology in Tea. Food Res. Dev. 2021, 42, 218–224. [Google Scholar] [CrossRef]

- Long, D.; Hong, P.; Li, B. Progress of Processing Technology and Biological Activity of Tea and Plant Aromatic Water. China Tea Process. 2023, 74–80. [Google Scholar] [CrossRef]

- Wang, T.; Lv, J.; Huang, L.; Tang, D. Study on the coloring effect of black tea dye on different textiles. China Tea 2018, 40, 67–70. [Google Scholar] [CrossRef]

- Apiwathnasorn, C.; Sungvornyothin, S.; Wang, X.; Wang, L. Development of Mosquito Repellent Textile Using Zanthoxylum Limonella Essential Oil with Knife-Coating Process: A Preliminary Report. Southeast Asian J. Trop. Med. Public Health 2021, 52, 517–526. [Google Scholar]

- Mikucioniene, D.; Kazlauskaite, J.A.; Matulyte, I.; Petkuviene, B.; Laureckiene, G.; Marksa, M.; Bernatoniene, J. Sustainable Approach to Development of Antimicrobial Textile Pads for Sweat Absorption. Fibers 2024, 12, 20. [Google Scholar] [CrossRef]

- Zimniewska, M.; Pawlaczyk, M.; Krucinska, I.; Frydrych, I.; Mikolajczak, P.; Schmidt-Przewozna, K.; Komisarczyk, A.; Herczynska, L.; Romanowska, B. The Influence of Natural Functional Clothing on Some Biophysical Parameters of the Skin. Text. Res. J. 2019, 89, 1381–1393. [Google Scholar] [CrossRef]

- Zhang, D. Study on supercritical CO2 fluid technology in extracting ginger oleoresin. Sci. Technol. Food Ind. 2001, 21–23. [Google Scholar] [CrossRef]

- Marey, A.G.; Allam, L.N.; Abd-Elaal, L.S.; El-Wekil, A.N.; Hassabo, A.G. The applications of microencapsulation in different textile finishing. J. Text. Color. Polym. Sci. 2025, 22, 13–29. [Google Scholar] [CrossRef]

- Sumant; Naman, S.; Sharma, S.; Baldi, A. Quality by Design Perspectives for Designing Delivery System for Flavour and Fragrance: Current State-of-the-Art and for Future Exploration. Flavour Fragr. J. 2024, 39, 336–361. [Google Scholar] [CrossRef]

- Elkalla, E. Synthesis and Characterization of Silica-Coated Magnetic Oil-in-Water Emulsion. Ph.D. Dissertation, Université Claude Bernard Lyon 1, Villeurbanne, France, 2025. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).