Digital Twin Frameworks for Oil and Gas Processing Plants: A Comprehensive Literature Review

Abstract

1. Introduction

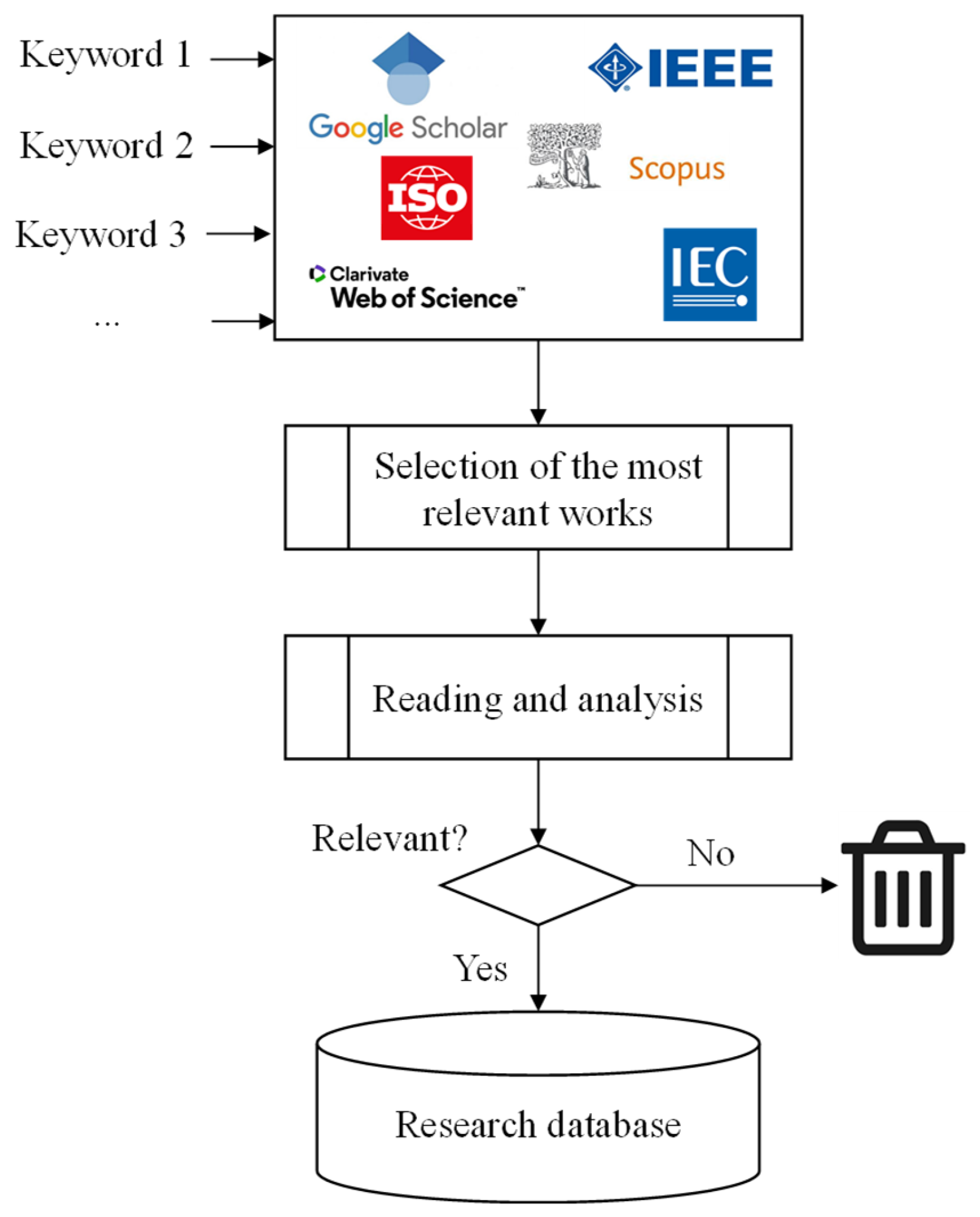

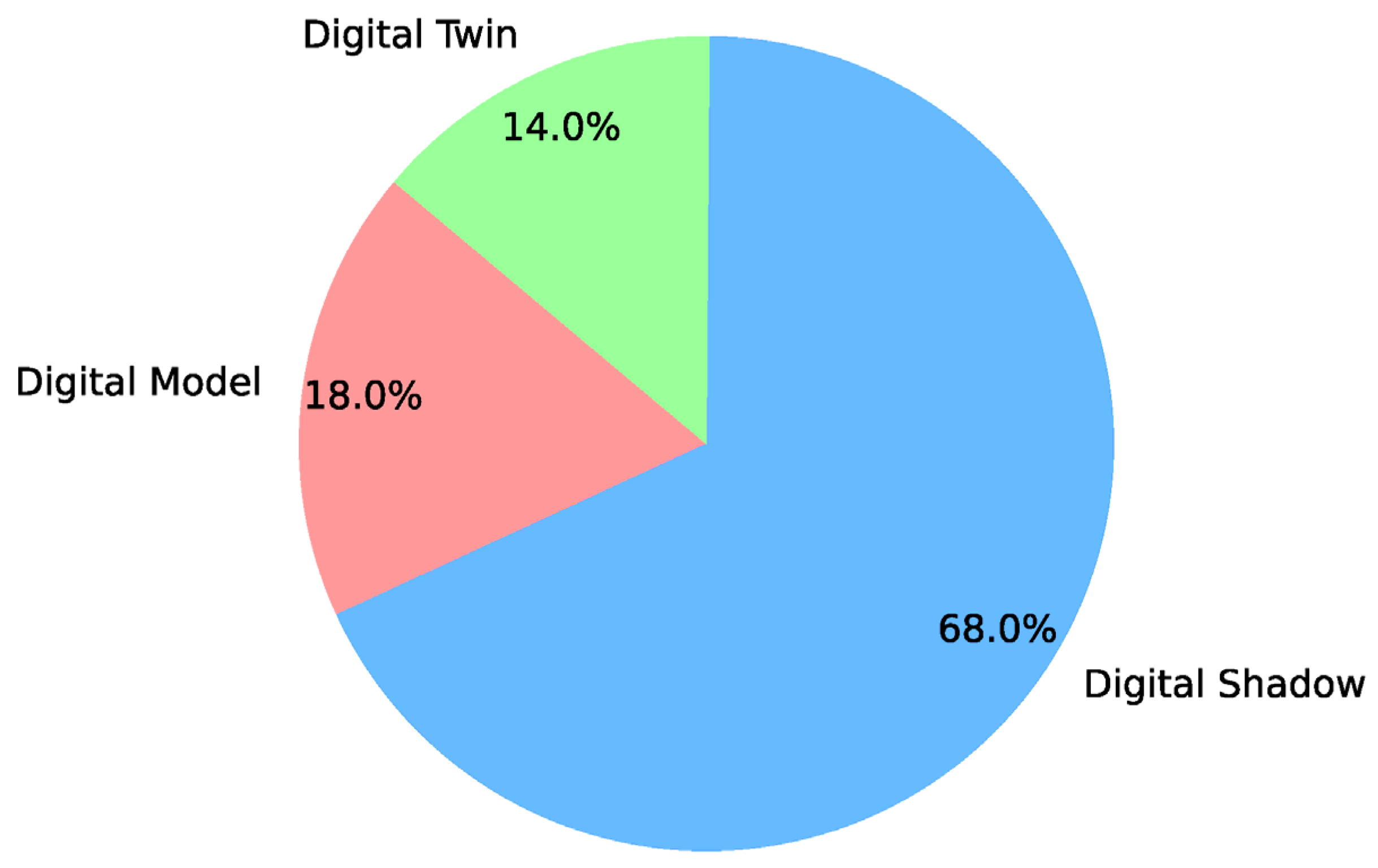

2. Literature Search Method

3. Digital Twins—Concepts and Definitions

- Isolated applications: drilling advisory twins (kick/loss prevention), compressor anti-surge twins, pipeline leak-detection models.

- Enterprise-wide deployments: integrated field-management twins linking well inflow, processing plants, and logistics chains (e.g., Shell and Equinor pilots).

3.1. Theoretical Foundations of Digital Twins

3.1.1. Concept Evolution and Definitions

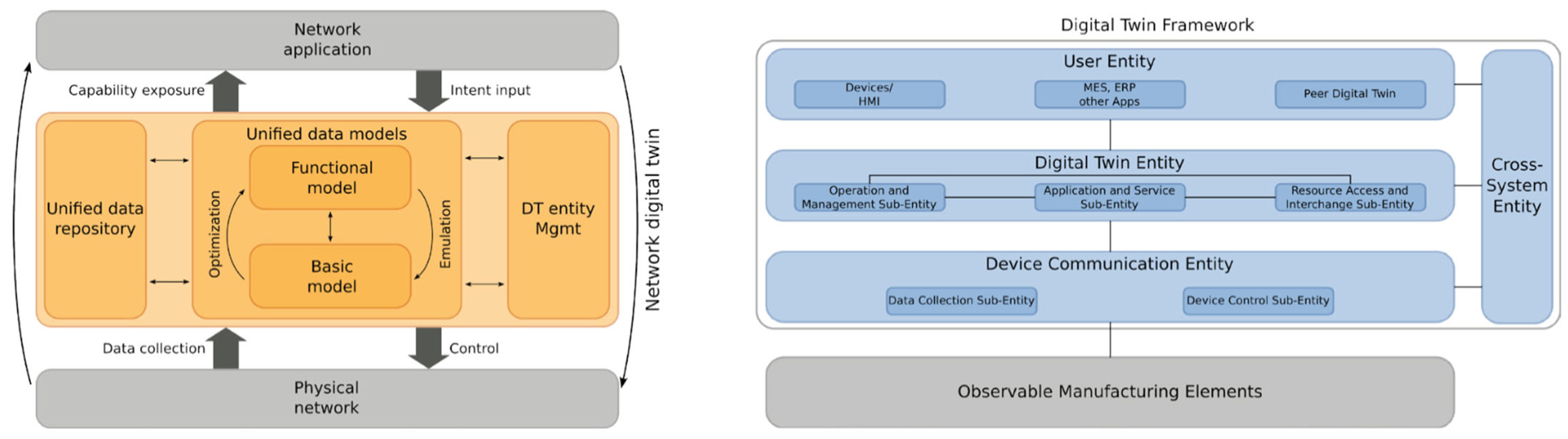

3.1.2. Frameworks and Models

3.2. Digital Twin Modeling and Implementation Techniques

3.2.1. Modeling Tools and Approaches

3.2.2. Data Integration and Computational Infrastructure

3.2.3. Control and Integration

3.3. Applications of Digital Twins in Oil and Gas

3.3.1. Process Plant and Facilities Twins

3.3.2. Economic Impact and ROI Studies

3.3.3. Sustainability Driven DT Applications and Lifecycle Asset Management with Decommissioning Twins

3.3.4. Maintenance, Training, and Other Use Cases

4. High-Accuracy/High-Fidelity Models

4.1. ASPEN-HYSYS (Commercial Dynamic/Steady-State Simulators)

4.2. MATLAB/Simulink (Numerical Prototyping and Control-Oriented Twins)

4.3. Implemented Code (Bespoke Solvers and In-House Frameworks)

4.4. Integrated Platforms (Co-Simulation/Co-Execution)

4.5. Other Platforms: EMSO (Equation-Oriented Modeling Simulator)

4.6. Machine Learning (Surrogates, Observers and Hybrid Twins)

5. Data Structures and Modeling Approaches

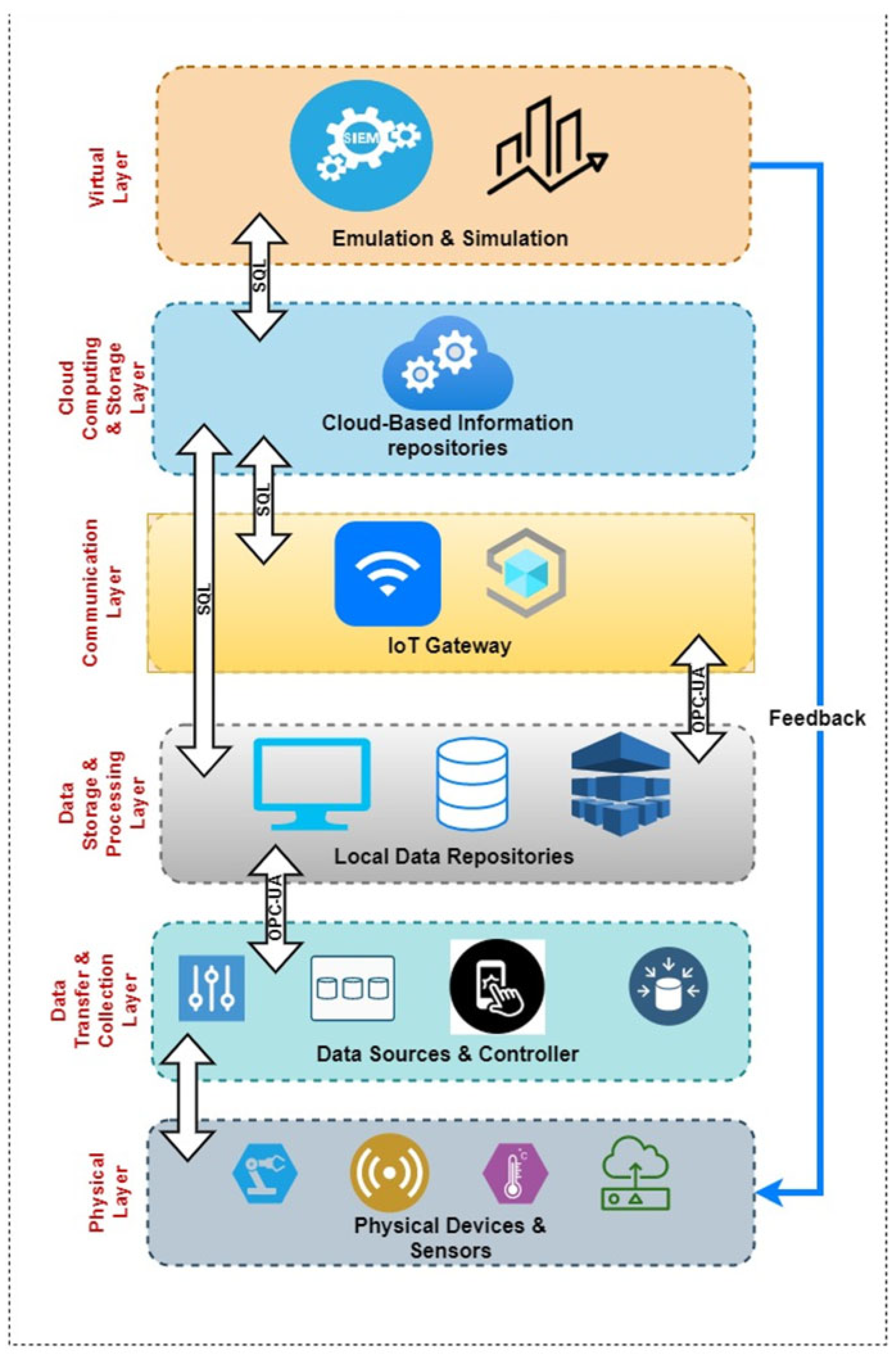

5.1. Real-Time Data Architecture (Edge ↔ Cloud)

5.2. Cyber-Security & Data Governance

5.3. Standards & Interoperability

5.4. General Modeling Approaches

5.5. Complex Nonlinear Systems

5.6. Bond-Graph and Causal Approaches

5.7. Modelica and Equation-Based Object-Oriented Modeling

5.8. Object-Oriented Patterns (Recent Advances)

6. Topside Configuration and Process Plant and a Real Case Study

6.1. Brazilian Pre-Salt Standard FPSO—Specifics on the Process Plant

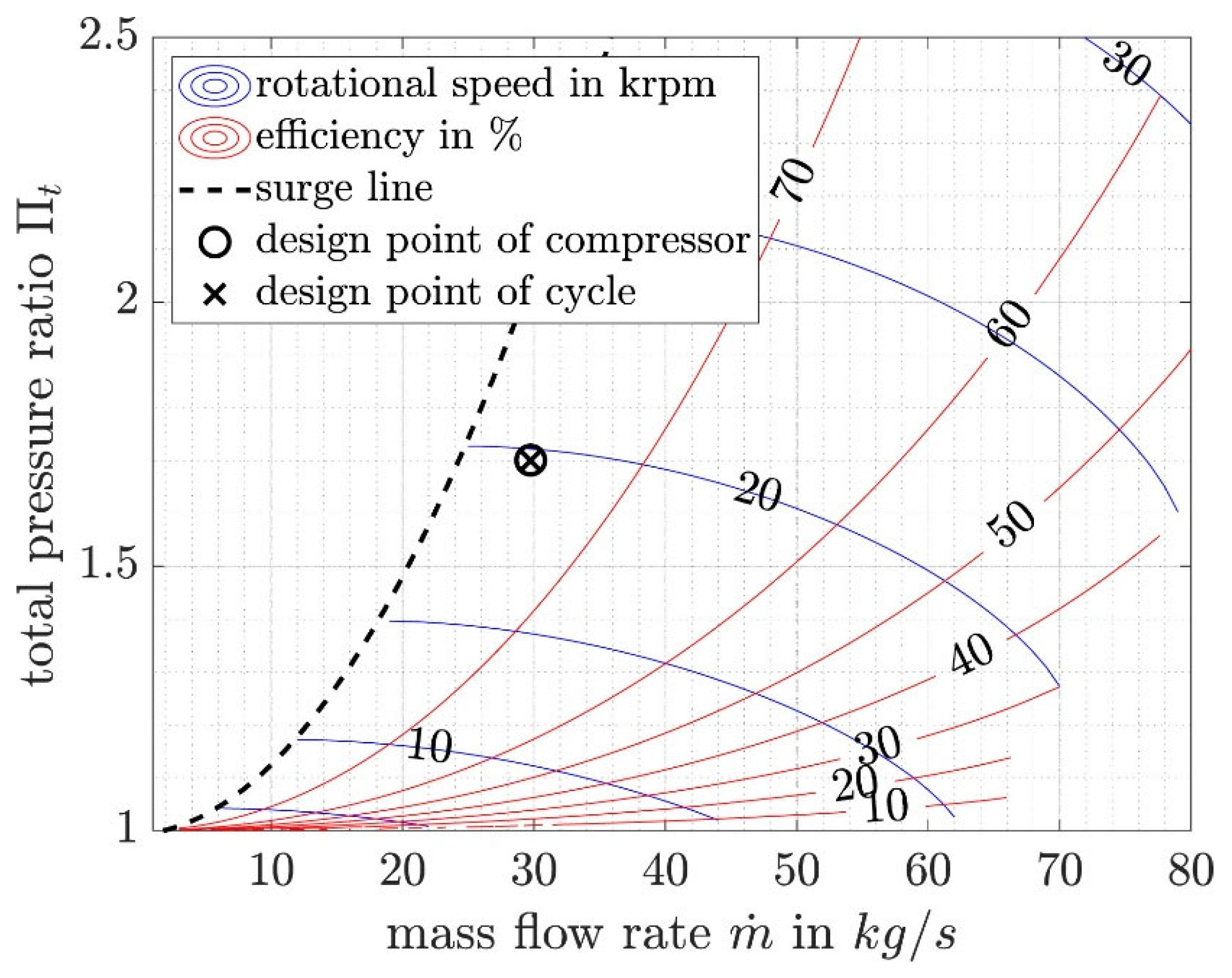

6.2. Compressor Design and Performance Data

6.3. Fluid Properties

6.4. Verification, Validation & Certification (VVC)

7. Summary of Reference Sources

8. Latest Developments and Future Directions

- Automation and Scalability: As seen with Sierla et al. [38] and Santillán Martínez [37], there is a push toward automating the generation of twins for existing facilities. This involves using artificial intelligence to parse engineering documents and sensor logs to build the twin’s model. A related development is the concept of a self-updating or adaptive twin. Walmsley et al. [88] introduced the concept of adaptive digital twins for energy-intensive industries, which can adjust their fidelity or scope according to the current needs (for example, simplifying certain aspects to focus computational power on a critical subsystem during an anomaly). This adaptability helps manage computational load and maintain real-time performance.

- Integration of AI/ML: Modern digital twins increasingly incorporate machine learning for anomaly detection, predictive analytics, and even controlling complex systems. The combination of physics-based models with data-driven models (hybrid twins) leverages the strengths of both: physics models ensure consistency with known laws and provide extrapolation capability, while ML models can capture subtle patterns and uncertainties from historical data. There is also a trend of using DTs to generate synthetic data for training AI, as demonstrated by Aiken et al. [46]. This is particularly useful when real failure data is scarce—a twin can simulate failure scenarios to augment training datasets for predictive maintenance algorithms.

- Edge Computing and 5G: With the advent of 5G networks and better edge computing hardware, deploying parts of the twin closer to the field equipment is becoming practical. This reduces latency for critical control decisions. For instance, a compressor’s twin might run directly on a rugged edge computer at a remote compressor station, ensuring that if a surge condition is detected, the system can respond immediately to prevent damage. Meanwhile, cloud connectivity allows less time-sensitive analysis and fleet-level aggregation (comparing twins of multiple similar assets to identify best practices or deviations).

- Standardization Efforts: Lack of standard data formats and interfaces for digital twins has been a challenge. In response, industry groups and standards bodies are working on interoperability frameworks. The Open Group’s Digital Twin Consortium and organizations such as ISO are discussing standards for DT terminology and architecture. In the oil and gas industry, where multiple vendors’ equipment must interoperate, this is crucial. We see research proposing standardized asset administration shells or utilizing formats such as AutomationML and FMU (Functional Mock-up Unit) for model exchange between different simulation tools. Uhlenkamp’s maturity model [6] also indirectly fosters standard thinking by categorizing what a “Level 5” twin should look like in terms of integration and functionality.

- Cybersecurity and Reliability: As DTs become integrated with operations, ensuring their security is paramount. A compromised digital twin could provide false readings or even send harmful instructions. Recent work has identified cybersecurity as a significant concern for O&G digital twins. Research in this direction includes making twins read-only for specific layers (to prevent external manipulation of the physical asset) and using blockchain for data integrity of sensor streams. Moreover, there is a focus on the reliability of twins—how to ensure the twin does not drift from reality. This involves automated re-calibration routines and anomaly handlers that know when the twin’s predictions are no longer trustworthy (perhaps flagging the need for model re-training or sensor maintenance).

- Human Factors and Collaboration: Another development is using DTs as collaboration platforms. For example, during the COVID-19 pandemic, travel to offshore platforms was restricted, so engineers utilized digital twins in conjunction with remote collaboration software to jointly analyze problems from onshore locations. Mixed reality interfaces (like HoloLens-based systems) are being refined to allow multiple users to interact with a twin simultaneously, each possibly seeing data relevant to their discipline. This sociotechnical aspect of DTs is crucial for adoption, as it makes the technology user-friendly and integrates it into workflows for engineers, operators, and decision-makers.

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Emmert-Streib, F. Defining a Digital Twin: A Data Science-Based Unification. Mach. Learn. Knowl. Extr. 2023, 5, 1036–1054. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Chen, B.-Q.; Videiro, P.M.; Soares, C.G. Opportunities and Challenges to Develop Digital Twins for Subsea Pipelines. J. Mar. Sci. Eng. 2022, 10, 739. [Google Scholar] [CrossRef]

- Sharma, A.; Kosasih, E.; Zhang, J.; Brintrup, A.; Calinescu, A. Digital Twins: State of the art theory and practice, challenges, and open research questions. J. Ind. Inf. Integr. 2022, 30, 100383. [Google Scholar] [CrossRef]

- Leipnitz, M.T.; Petry, R.H.; Rodrigues, F.H.; Silva, H.R.d.S.; Correia, J.B.; Becker, K.; Wickboldt, J.A.; Carbonera, J.L.; Netto, J.C.; Abel, M. Architecting Digital Twins: From Concept to Reality. Procedia Comput. Sci. 2025, 256, 530–537. [Google Scholar] [CrossRef]

- Uhlenkamp, J.-F.; Hauge, J.B.; Broda, E.; Lutjen, M.; Freitag, M.; Thoben, K.-D. Digital Twins: A Maturity Model for Their Classification and Evaluation. IEEE Access 2022, 10, 69605–69635. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Springer: Berlin/Heidelberg, Germany, 2016; pp. 85–113. [Google Scholar] [CrossRef]

- Wagg, D.J.; Worden, K.; Barthorpe, R.J.; Gardner, P. Digital Twins: State-of-the-Art and Future Directions for Modeling and Simulation in Engineering Dynamics Applications. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part B 2020, 6, 030901. [Google Scholar] [CrossRef]

- Woldeyohannes, A.D.; Majid, M.A.A. Simulation model for natural gas transmission pipeline network system. Simul. Model. Pract. Theory 2011, 19, 196–212. [Google Scholar] [CrossRef]

- Scardini, D.P.; Scardua, L.A.; de Almeida, G.M. Digital Twin of a Horizontal Three-phase Separator in an Offshore Oil Extraction and Processing Platform using NARX Neural Networks. In Congresso Brasileiro de Automática-CBA; Sociedade Brasileira de Automática-SBA: São Paulo, Brazil, 2022; Volume 3. [Google Scholar] [CrossRef]

- Bárkányi, Á.; Chovan, T.; Nemeth, S.; Abonyi, J. Modelling for digital twins, potential role of surrogate models. Processes 2021, 9, 476. [Google Scholar] [CrossRef]

- Martin-Villalba, C.; Urquia, A.; Shao, G. Implementations of the Tennessee Eastman Process in Modelica. IFAC-PapersOnLine 2018, 51, 619–624. [Google Scholar] [CrossRef]

- Fritzson, P.; Pop, A.; Abdelhak, K.; Ashgar, A.; Bachmann, B.; Braun, W.; Bouskela, D.; Braun, R.; Buffoni, L.; Casella, F.; et al. The OpenModelica Integrated Environment for Modelling, Simulation and Optimisation. Model. Identif. Control 2020, 41, 241–295. [Google Scholar] [CrossRef]

- Quoilin, S.; Desideri, A.; Wronski, J.; Bell, I.; Lemort, V. ThermoCycle: A Modelica library for the simulation of thermodynamic systems. In Proceedings of the 10th International Modelica Conference, Lund, Sweden, 10–12 March 2014. [Google Scholar] [CrossRef]

- Valdés, R.; Sotelo, C.; Muñoz-Torres, F.; Favela-Contreras, A.; Cruz, E.; Sotelo, D. Dynamic Simulation of an Oil and Gas Plant Using Aspen-HYSYS®: A Real Startup Process. Arab. J. Sci. Eng. 2024, 50, 4599–4611. [Google Scholar] [CrossRef]

- Jonach, T.; Haddadi, B.; Jordan, C.; Harasek, M. Dynamic Simulation of a Gas and Oil Separation Plant with Aspen HYSYS. Energies 2023, 16, 4111. [Google Scholar] [CrossRef]

- Verma, A.K. Process Modelling and Simulation in Chemical, Biochemical and Environmental Engineering; CRC Press: Boca Raton, FL, USA, 2014; ISBN 9781482205923. [Google Scholar] [CrossRef]

- Bidgoli, A.A. Simulation and Optimization of Primary Oil and Gas Processing Plant of FPSO Operating in Pre-Salt Oil Field. Ph.D. Thesis, Universidade de São Paulo, São Paulo, Brazil, 2018. [Google Scholar] [CrossRef]

- Kunz, O.; Wagner, W. The GERG-2008 wide-range EOS for natural gases and mixtures. J. Chem. Eng. Data 2012, 57, 3032–3091. [Google Scholar] [CrossRef]

- Nazari, S.; Bashipour, F. A rigorous model to compute thermodynamic properties of natural gas without full component analysis. Flow Meas. Instrum. 2021, 77, 101879. [Google Scholar] [CrossRef]

- Tukur, N.; Osigwe, E.O. A model for booster station matching of gas turbine and gas compressor power under different ambient conditions. Heliyon 2021, 7, e07222. [Google Scholar] [CrossRef]

- Knebel, F.P.; Trevisan, R.; Nascimento, G.S.D.; Abel, M.; Wickboldt, J.A. A study on cloud and edge computing for the implementation of digital twins in the Oil & Gas industries. Comput. Ind. Eng. 2023, 182, 109363. [Google Scholar] [CrossRef]

- Schroeder, G.; Steinmetz, C.; Pereira, C.E.; Muller, I.; Garcia, N.; Espindola, D.; Rodrigues, R. Visualising the digital twin using web services and augmented reality. In Proceedings of the 2016 IEEE 14th International Conference on Industrial Informatics (INDIN), Poitiers, France, 19–21 July 2016; IEEE: Piscataway, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Alam, K.M.; El Saddik, A. C2PS: A digital twin architecture reference model for the cloud-based cyber-physical systems. IEEE Access 2017, 5, 2050–2062. [Google Scholar] [CrossRef]

- Gesser, R.S.; Sartori, R.; Damo, T.P.; Vettorazzo, C.M.; Becker, L.B.; Lima, D.M.; de Lima, M.L.; Ribeiro, L.D.; Campos, M.C.; Normey-Rico, J.E. Advanced control applied to a gas compression system of an offshore platform. J. Pet. Sci. Eng. 2022, 208, 109428. [Google Scholar] [CrossRef]

- Wang, T.; Feng, K.; Ling, J.; Liao, M.; Yang, C.; Neubeck, R.; Liu, Z. Pipeline condition monitoring towards digital twin system: A case study. J. Manuf. Syst. 2024, 73, 256–274. [Google Scholar] [CrossRef]

- Munari, E.; Morini, M.; Pinelli, M.; Brun, K.; Simons, S.; Kurz, R. Measurement and Prediction of Centrifugal Compressor Axial Forces during Surge, Part II. J. Eng. Gas Turbines Power 2018, 140, 012602. [Google Scholar] [CrossRef]

- Wanasinghe, T.R.; Wroblewski, L.; Petersen, B.; Gosine, R.G.; James, L.A.; De Silva, O.; Mann, G.K.I.; Warrian, P.J. Digital Twin for the Oil and Gas Industry: Overview, Research Trends, Opportunities, and Challenges. IEEE Access 2020, 8, 104175–104197. [Google Scholar] [CrossRef]

- Garcia-Hernandez, A.; Tavares, T.S.; Wilcox, M. Dynamic Pipeline System Simulation of Multi-stage Compressor Trains. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012. [Google Scholar] [CrossRef]

- Soares, R.d.P.; Secchi, A.R. EMSO: A New Environment for Modelling, Simulation and Optimization. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar] [CrossRef]

- Chu, F.; Wang, F.; Wang, X.; Zhang, S. A hybrid ANN-mechanistic model for centrifugal compressor. Neural Comput. Appl. 2014, 24, 1259–1268. [Google Scholar] [CrossRef]

- Meza, E.B.M.; de Souza, D.G.B.; Copetti, A.; Sobral, A.P.B.; Silva, G.V.; Tammela, I.; Cardoso, R. Tools, Technologies and Frameworks for Digital Twins in the O&G Industry. Sensors 2024, 24, 6457. [Google Scholar] [CrossRef]

- Jin, C.; Kim, S.-J.; Kim, M.; Lee, Y.; Guha, A.; Ryu, S.; Xu, W. Real-time dynamic and structural behavior estimation of a steel lazy wave riser through finite-element-based digital twin and hull-motion sensor. Appl. Ocean Res. 2024, 150, 104137. [Google Scholar] [CrossRef]

- Shen, F.; Ren, S.S.; Zhang, X.Y.; Luo, H.W.; Feng, C.M. A Digital Twin-Based Approach for Optimization and Prediction of Oil and Gas Production. Math. Probl. Eng. 2021, 2021, 3062841. [Google Scholar] [CrossRef]

- Layer, M.; Neubert, S.; Tiemann, L.; Stelzer, R. Identification and retrieval of relevant information for instantiating DTs during process-plant construction. Proc. Des. Soc. 2023, 3, 2175–2184. [Google Scholar] [CrossRef]

- Pierobon, L.; Casati, E.; Casella, F.; Haglind, F.; Colonna, P. Design methodology for flexible energy conversion systems accounting for dynamic performance. Energy 2014, 68, 667–679. [Google Scholar] [CrossRef]

- Santillán Martínez, G. Simulation-Based Digital Twins of Industrial Process Plants: A Semi-Automatic Implementation Approach 2019; Aalto University: Espoo, Finland, 2019; ISBN 978-952-60-8537-1. [Google Scholar]

- Sierla, S.; Azangoo, M.; Rainio, K.; Papakonstantinou, N.; Fay, A.; Honkamaa, P.; Vyatkin, V. Roadmap to semi-automatic generation of digital twins for brownfield process plants. J. Ind. Inf. Integr. 2022, 27, 100282. [Google Scholar] [CrossRef]

- de Andrade, A.M.T.; Vaz, C.E.M.; Ribeiro, J.; Lopreato, L.G.R.; Nascimento, R.F.S.D. Offshore Production Units for Pre-Salt Projects. In Proceedings of the Offshore Technology Conference (OTC), Houston, TX, USA, 4–7 May 2015; 2015. [Google Scholar] [CrossRef]

- Pietrasik, M.; Wilbik, A.; Grefen, P. The enabling technologies for digitalization in the chemical process industry. Digit. Chem. Eng. 2024, 12, 100161. [Google Scholar] [CrossRef]

- AMS 100-61; Economics of Digital Twins: Costs, Benefits and Economic Decision Making. National Institute of Standards and Technology (NST): Gaithersburg, MD, USA, 2024. Available online: https://nvlpubs.nist.gov/nistpubs/ams/NIST.AMS.100-61.pdf (accessed on 23 October 2025).

- Amezquita, J.; Hoyos, J. A Flare System Digital Twin for CO2e Emissions Inference. Automation.com. 2024. Available online: https://www.automation.com/en-us/articles/september-2024/flare-system-digital-twin-co2e-emissions-inference (accessed on 23 October 2025).

- Yu, W.; Patros, P.; Young, B.; Klinac, E.; Walmsley, T.G. Energy digital twin technology for industrial energy management: Classification, challenges and future. Renew. Sustain. Energy Rev. 2022, 161, 112407. [Google Scholar] [CrossRef]

- Mortensen, J. End-to-End Project and Asset Lifecycle Management for Oil & Gas. IFS Blog 2024 29 April 2024. Available online: https://blog.ifs.com/end-to-end-project-and-asset-lifecycle-management-for-oil-gas/ (accessed on 23 October 2025).

- Zhang, S.; Liang, X.; Ji, R.; Jiang, W.; Ge, S.S. Advancing Offshore Operations with Digital Twin Technology: A Case Study of FLNG Operations in Offshore Environments. In Proceedings of the 2024 IEEE International Conference on Cybernetics and Intelligent Systems (CIS) and IEEE International Conference on Robotics, Automation and Mechatronics (RAM), Hangzhou, China, 8–11 August 2024; IEEE: Piscataway, NJ, USA, 2024. [Google Scholar] [CrossRef]

- Aiken, W.; Carden, L.; Bhabhrawala, A.; Branco, P.; Jourdan, G.-V.; Berg, A. Strategic Digitalization in Oil and Gas: A Case Study on Mixed Reality and Digital Twins. IEEE Access 2024, 12, 87248–87267. [Google Scholar] [CrossRef]

- Oppelt, M.; Wolf, G.; Urbas, L. Life Cycle Simulation for a Process Plant based on a Two-Dimensional Co-Simulation Approach. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- IEC. IEC 62424 Ed. 2.0 b:2016, Representation of Process Control Engineering—Requests in P&I Diagrams and Data Exchange Between P&ID Tools and PCE-CAE Tools. 2016. Available online: https://webstore.ansi.org/standards/iec/IEC62424Ed2016 (accessed on 23 October 2025).

- Wilkinson, M.D.; Dumontier, M.; Aalbersberg, I.J.; Appleton, G.; Axton, M.; Baak, A.; Blomberg, N.; Boiten, J.W.; da Silva Santos, L.B.; Bourne, P.E.; et al. The FAIR Guiding Principles for scientific data management and stewardship. Sci. Data 2016, 3, 160018. [Google Scholar] [CrossRef] [PubMed]

- American Bureau of Shipping. Guidance Notes on Verification and Validation of Models, Simulations and Digital Twins. 2024. Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/design_and_analysis/348-guidance-notes-on-verification-and-validation-of-models,-simulations,-and-digital-twins-2024/348-vandv-gn-nov24.pdf (accessed on 23 October 2025).

- NASA-STD-7009B; Standard for Models and Simulations. NASA: Moffett Field, CA, USA, 2020. Available online: https://standards.nasa.gov/sites/default/files/standards/NASA/B/1/NASA-STD-7009B-Final-3-5-2024.pdf (accessed on 23 October 2025).

- ISO 23247-1:2023; Digital Twin Framework for Manufacturing, Part 1: Overview. ISO: Geneva, Switzerland, 2023. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:23247:-1:ed-1:v1:en (accessed on 23 October 2025).

- ISO/TS 15926-4:2024; Industrial Automation Systems and Integration—Integration of Life-Cycle Data for Process Plants Including Oil and Gas Production Facilities. ISO: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/81270.html (accessed on 23 October 2025).

- Allahyarzadeh-Bidgoli, A.; Dezan, D.J.; Salviano, L.O.; Junior, S.d.O.; Yanagihara, J.I. FPSO fuel consumption and hydrocarbon liquids recovery optimization over the lifetime of a deep-water oil field. Energy 2019, 181, 927–942. [Google Scholar] [CrossRef]

- Hofer, M.; Ren, H.; Hecker, F.; Buck, M.; Brillert, D.; Starflinger, J. Simulation, analysis and control of a self-propelling heat removal system using supercritical CO2 under varying boundary conditions. Energy 2022, 247, 123500. [Google Scholar] [CrossRef]

- AspenTech. Aspen HYSYS Dynamics, Intuitive Dynamic Modelling Across the Full Lifecycle (Product Note/Guide). 2023. Available online: https://www.aspentech.com/en/products/engineering/aspen-hysys-dynamics (accessed on 23 October 2025).

- Allahyarzadeh-Bidgoli, A.; Dezan, D.J.; Salviano, L.O.; Junior, S.d.O.; Yanagihara, J.I. Lifetime sensitivity analysis of FPSO operating parameters on energy consumption and overall oil production in a pre-salt oil field. Chem. Eng. Commun. 2020, 207, 1483–1507. [Google Scholar] [CrossRef]

- Guo, X.; Wu, B.; Li, X. A Solution for Constructing Semi-Submersible Platform Digital Twins Based on Deep Learning. In Proceedings of the ISOPE International Ocean and Polar Engineering Conference, Rhodes, Greece, 16–21 June 2024; ISOPE: Mountain View, CA, USA, 2024. Available online: https://onepetro.org/ISOPEIOPEC/proceedings-abstract/ISOPE24/ISOPE24/ISOPE-I-24-311/546687 (accessed on 23 October 2025).

- Warke, V.; Kumar, S.; Bongale, A.; Kotecha, K. Sustainable development of smart manufacturing driven by the digital twin framework: A statistical analysis. Sustainability 2021, 13, 10139. [Google Scholar] [CrossRef]

- Wallner, B. Digital twin development and operation of a flexible manufacturing cell using iso 23247. In Procedia CIRP; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar] [CrossRef]

- ISO 15926; Life Cycle Data for Process Plant: An Overview. ISO: Geneva, Switzerland, 2005. Available online: https://hal.science/hal-02017232/document (accessed on 23 October 2025).

- Cameron, I.T.; Hangos, K. Process Modelling and Model Analysis; Elsevier: Amsterdam, The Netherlands, 2001; Available online: https://shop.elsevier.com/books/process-modelling-and-model-analysis/cameron/978-0-12-156931-0 (accessed on 23 October 2025).

- Ljung, L. System Identification: Theory for the User; Prentice Hall: Hoboken, NJ, USA, 1999; Available online: https://www.mit.bme.hu/data/migrate/oktatas/targyak/9132/Ljung_L_System_Identification_Theory_for_User-ed2.pdf (accessed on 23 October 2025).

- Pivetta, M.V.L. A Machine Learning Approach for Petroleum Production Forecasting in a Digital Twin. Ph.D. Thesis, Universidade Federal do Rio Grande do Sul, Porto Alegre, Brazil, 2024. [Google Scholar]

- Karnopp, D.C.; Margolis, D.L.; Rosenberg, R.C. System Dynamics: Modeling, Simulation, and Control of Mechatronic Systems; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar] [CrossRef]

- Kulikov, G.G.; Thompson, H.A. Dynamic Modelling of Gas Turbines; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar] [CrossRef]

- Mohamed, O.R.; Ibrahim, I.A.; Bevrani, H. Progress in Modeling and Control of Gas Turbine Power Generation Plants. Energies 2020, 13, 2358. [Google Scholar] [CrossRef]

- Borutzky, W. Bond Graph Methodology: Development and Analysis of Multidisciplinary Dynamic System Models; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Colonna, P.; van Putten, H. Dynamic Modeling of Steam Power Cycles: Part I, Modeling Paradigm and Validation. Appl. Therm. Eng. 2007, 27, 467–480. [Google Scholar] [CrossRef]

- van Putten, H.; Colonna, P. Dynamic Modeling of Steam Power Cycles: Part II, Simulation of a Small Simple Rankine Cycle System. Appl. Therm. Eng. 2007, 27, 481–498. [Google Scholar] [CrossRef]

- Casella, F.; Leva, A. Modelica open library for power plant simulation: Design and experimental validation. In Proceedings of the 3rd International Modelica Conference, Linköping, Sweden, 3–4 November 2003; Available online: https://modelica.org/events/Conference2003/papers/h08_Leva.pdf (accessed on 23 October 2025).

- Casella, F. Simulation of Large-Scale Models in Modelica: State of the Art and Future Perspectives. In Proceedings of the 11th International Modelica Conference, Versailles, France, 21–23 September 2015. [Google Scholar] [CrossRef]

- Allahyarzadeh-Bidgoli, A.; de Mello, P.E.B.; Dezan, D.J.; Saltara, F.; Salviano, L.O.; Yanagihara, J.I. Thermodynamic analysis and optimization of a multi-stage compression system for CO2 injection unit: NSGA-II and gradient-based methods. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 458. [Google Scholar] [CrossRef]

- Schiavo, F.; Casella, F. Object-oriented modelling and simulation of heat exchangers with finite element methods. Math. Comput. Model. Dyn. Syst. 2007, 13, 211–235. [Google Scholar] [CrossRef]

- Rang, J. Improved traditional Rosenbrock–Wanner methods for stiff ODEs and DAEs. J. Comput. Appl. Math. 2015, 286, 128–144. [Google Scholar] [CrossRef]

- Hauge, E.; Aamo, O.M.; Godhavn, J.-M. Model based pipeline monitoring with leak detection. IFAC Proc. Vol. 2007, 40, 318–323. [Google Scholar] [CrossRef]

- Desideri, A.; Hernandez, A.; Gusev, S.; Broek, M.v.D.; Lemort, V.; Quoilin, S. Steady-state and dynamic validation of a small-scale WHR ORC using the ThermoCycle library. Energy 2016, 103, 701–712. [Google Scholar] [CrossRef]

- Kurzke, J. An enhanced compressor map extension method suited for spool speeds down to 1%. JGPP Soc. J. 2024, 8, 215–226. [Google Scholar] [CrossRef]

- PTC 10-2022; Compressors and Exhausters. ASME: New York, NY, USA, 2022. Available online: https://www.asme.org/codes-standards/find-codes-standards/axial-and-centrifugal-compressors (accessed on 23 October 2025).

- Allahyarzadeh-Bidgoli, A.; Heidaryan, E.; Yanagihara, J.I.; Filho, P.d.A.P. Assessment of correlations and simulation software to calculate phase diagrams of pre-salt fluids. Pet. Sci. Technol. 2021, 39, 410–420. [Google Scholar] [CrossRef]

- Thol, M.; Richter, M.; May, E.F.; Lemmon, E.W.; Span, R. EOS-LNG: A fundamental equation of state for the calculation of thermodynamic properties of liquefied natural gases. J. Phys. Chem. Ref. Data 2019, 48, 033102. [Google Scholar] [CrossRef]

- ISO 12213-2:2006; Natural Gas—Calculation of Compression Factor Part 2: Calculation Using Molar-Composition Analysis. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/44411.html (accessed on 23 October 2025).

- Huber, M.L.; Lemmon, E.W.; Bell, I.H.; McLinden, M.O. The NIST REFPROP database for highly accurate properties of industrially important fluids. Ind. Eng. Chem. Res. 2022, 61, 15449–15472. [Google Scholar] [CrossRef]

- API Standard 617; Axial and Centrifugal Compressors and Expander-Compressors. 9th ed. API: Washington, DC, USA, 2022. Available online: https://www.apiwebstore.org/standards/617 (accessed on 23 October 2025).

- Trauer, J.; Schweigert-Recksiek, S.; Schenk, T.; Baudisch, T.; Mörtl, M.; Zimmermann, M. A digital twin trust framework for industrial application. in Proceedings of the Design Society. Proc. Des. Soc. 2022, 2, 293–302. [Google Scholar] [CrossRef]

- Unal, C.; Williams, B.; Hemez, F.; Atamturktur, S.; McClure, P. Improved best estimate plus uncertainty methodology, including advanced validation concepts, to license evolving nuclear reactors. Nucl. Eng. Des. 2011, 241, 1813–1833. [Google Scholar] [CrossRef]

- Bist, N.; Panchal, S.; Gupta, R.; Soni, A.; Sircar, A. Digital transformation and trends for tapping connectivity in the oil and gas sector. Hybrid Adv. 2024, 6, 100256. [Google Scholar] [CrossRef]

- Walmsley, T.G.; Patros, P.; Yu, W.; Young, B.R.; Burroughs, S.; Apperley, M.; Carson, J.K.; Udugama, I.A.; Aeowjaroenlap, H.; Atkins, M.J.; et al. Adaptive digital twins for energy-intensive industries and their local communities. Digit. Chem. Eng. 2024, 10, 100139. [Google Scholar] [CrossRef]

| Reference | Focus | Key Contribution |

|---|---|---|

| Grieves [7] | Origin of the DT concept in manufacturing | First articulated the DT concept for the product lifecycle (digital model + real-world counterpart) in the manufacturing context. Introduced the idea of a persistent virtual copy of a physical asset. |

| Tao et al. [2] | State-of-the-art review (Industry 4.0) | Reviewed DT applications across industries; highlighted that modeling is the core of DT and identified cyber–physical integration as a pressing challenge. Emphasized the need for a unified DT modeling methods. |

| Wagg et al. [8] | Engineering simulations (dynamics) | Surveyed the use of DTs in engineering dynamics and simulations. Discussed the state-of-the-art in high-fidelity modeling for structural health monitoring and prognostics (PHM). |

| Sharma et al. [4] | DT theory and open questions | Analyzed the state-of-the-art in DT theory vs. practice; defined essential DT components and properties. Outlined challenges and open research questions (e.g., standardization, real- time data integration, model uncertainty). |

| Uhlenkamp et al. [6] | DT maturity model | Proposed a formal maturity model to classify and evaluate digital twins. Defined multiple levels of DT capability across seven categories (data, models, integration, etc.), providing a framework to assess and guide DT development. |

| Emmert-Streib [1] | Unified definition approach | Offered a data-science-based unification of DT definitions. Defined a DT as “a digital representation of a real object essentially indistinguishable from its counterpart”. Highlighted the need for clarity in concept for cross-domain adoption. |

| Reference | Domain/System | Modeling Approach and Contribution |

|---|---|---|

| Woldeyohannes et al., [9] and Wang et al., [26] | Gas pipeline network | Developed a dynamic simulation model for a natural gas transmission pipeline system. Demonstrated accurate prediction of pressure-flow dynamics, laying groundwork for pipeline twins. |

| Chu et al. [31] | Centrifugal compressor | Proposed a hybrid ANN–mechanistic model for compressor performance. Extended the compressor map to low speeds using neural networks, improving fidelity of compressor models used in DTs (especially near surge conditions). |

| Martin-Villalba et al. [12] | Chemical process (TE benchmark) | Implemented the Tennessee Eastman process in Modelica as part of an open library. Showcased object-oriented modeling of a complex process, illustrating how modular models can support industrial process twins. |

| Knebel et al. [22] | Offshore O&G processing plant | Presented a rigorous dynamic simulation of a full FPSO process using Aspen HYSYS. The digital model replicates an actual two-stage separation and gas conditioning process, validated with a real start-up sequence (a step toward a high- fidelity process twin). |

| Bárkányi et al. [11] and Jin et al. [33] | Process systems (general) | Explored surrogate modeling within DTs. Reviewed how reduced-order models and machine learning proxies can accelerate simulations. Concluded that hybrid models (combining first-principles and data-driven surrogates) can maintain accuracy while enabling real-time twin computation. |

| Reference | Application Domain | Use Case and Findings |

|---|---|---|

| Wanasinghe et al. [28] | Industry overview (O&G sector) | Comprehensive literature review of DT in oil&gas. Found that asset integrity monitoring, project planning, and lifecycle management are key DT application areas in O&G, while challenges include cybersecurity, lack of standardization, and unclear scope. Noted that O&G DT adoption is early-stage and mostly pilot projects, indicating significant room for growth. |

| Shen et al. [34] | Production optimization | Implemented a digital twin for oil & gas production processes (from wells to processing). The DT provided a visualization of the production system and enabled optimization of production parameters. Demonstrated improved forecasting of production performance and better decision-making in controlling wells and surface facilities. |

| Chen et al. [3] | Subsea pipeline lifecycle | Outlined opportunities for DT in subsea pipeline design, operation, and life extension. Described the DT as “a paradigm combining multi- physics modeling with data-driven analytics to mirror the life of the pipeline”. Highlighted challenges in sensor data availability underwater, but showed that a well-calibrated twin can predict issues such as corrosion or fatigue before they manifest physically. |

| Santillán Martínez [37] | Brownfield process plant | Proposed a semi-automatic method to generate a process plant’s digital twin from legacy documentation (P&IDs, 3D models). Developed a 7-step workflow to create a steady-state simulation model of a brownfield plant and then extend it to a dynamic twin. This approach was validated on an existing industrial process, reducing manual effort in twin development. |

| Aiken et al. [46] | Training & Mixed Reality | Case study of a DT used with mixed reality for an offshore facility. The digital twin, integrated with MR headsets, provided an interactive training environment for new operators. Notably, the system also generated synthetic data to train deep learning models (for computer vision in inspections), illustrating a novel dual use of the twin (human training and AI model training). The study reported improved training outcomes and a reusable “digitalization architecture” for similar applications. |

| Meza et al. [32] | Tools & frameworks (survey) | Performed an in-depth analysis of tools, technologies, and frameworks used in developing O&G digital twins. Identified common platforms (IoT cloud services, simulation software, data analytics tools) and observed “significant trends indicating growing interest and investment” in DT solutions within O&G. Provided a taxonomy of current solutions and highlighted gaps (e.g., integration between proprietary software and open standards). |

| Platform/Approach | Application Domain | Main Capabilities & Features | Representative References |

|---|---|---|---|

| ASPEN HYSYS (commercial steady/dynamic simulator) | Process plants | Full-plant steady & dynamic simulation of start-up, shutdown, upsets, and energy-integration; validated models for plant-level DTs and operator training; rigorous property packages; heat/mass balance closure; transient replication for control and “what-if” analysis. | [16,54,57] |

| Pipelines | Coupled with pipeline solvers for compositional systems; serves as a boundary condition provider for gathering networks. | [18] | |

| Compressor trains | Vendor-map-based models for anti-surge analysis, recycle strategies, load-sharing, and fuel-minimisation studies. | [18] | |

| MATLAB/Simulink (numerical prototyping, control-oriented) | Pipelines | Reduced-order control models for transient thermal-hydraulics; validated hot-oil restart logic; nonlinear observers for multiphase leak/slug detection. | [27] |

| Implemented code (bespoke solvers, in-house frameworks) | Pipelines | Custom finite-volume solvers for transient compressible flows with leak detection and batch tracking; validated gas-network models. | [9] |

| Compressor trains | Custom code with performance maps, surge criteria, and control logic for deterministic real-time execution in operational DTs. | [29] | |

| Process plants | Vendor model wrapping to ensure determinism, traceability, and IP control in on-premise DTs. | [29] | |

| Integrated platforms (co-simulation/co-execution) | Compressor trains & plants | Orchestrated process-control-mechanical simulation for start-up/trip evaluation; validated surge-avoidance and load-sharing; supports hardware-in-the-loop before commissioning. | [12] |

| Other platforms—EMSO (Equation-Oriented Modeling Simulator) | Compressor trains & process units | Equation-oriented modeling with thermodynamic consistency and fast re-solves; open architecture with custom property packages; DT pipeline integration. | [25] |

| Machine learning (surrogates, observers, hybrid twins) | Compressor trains | Data-driven models for compressor map correction and fault detection; hybrid physics–ML twins. | [31] |

| Pipelines & plants | Surrogate models for optimiser acceleration and soft sensing (hydrate risk, viscosity) with retraining and uncertainty tracking. | [31] |

| Approach/Tool/Standard | Lifecycle Coverage | Data-Model Openness | Interoperability Stack | Time-Synchronization Fidelity | Validation/VVUQ Practices | Deployment Readiness (TRL) | Key Advantages | Key Limitations |

|---|---|---|---|---|---|---|---|---|

| ASPEN HYSYS/Unisim | Design → Operation | Proprietary | OPC UA partial | High (validated dynamic solver) | Verified with plant start-up data | 8–9 | Mature, validated process dynamics; integrated thermodynamics | Limited openness; license-dependent |

| Modelica/OpenModelica | Full lifecycle | Fully open Functional Mock-up Interface/Unit (FMI/FMUs) | FMI 2.0, Automation ML | Moderate–high | Built-in model verification; supports co-simulation V&V | 7 | Modular, reusable, open source | Needs expertise; lacks an industrial validation corpus |

| EMSO (Equation-Oriented) | Design ↔ Optimization | Open equations | Custom data binding | High (deterministic solvers) | Manual code verification | 6–7 | Transparent equations; fast optimization | Low industrial penetration |

| MATLAB/Simulink | Control & operation | Semi-proprietary | OPC UA, FMI connectors | High (real-time control-grade) | Experimental validation common | 8 | Widely used for control prototyping; fast deployment | Limited plant-wide interoperability |

| ISO 23247 | Limited—focused on operation and monitoring stage | High—conceptual and technology-neutral, flexible ontology alignment | Weak native support; needs mapping to OPC UA, ISO 15926, or domain ontologies | Low—not intended for real-time or streaming synchronization | Conceptual; no validation framework for model fidelity | 6–7—pilot-level in manufacturing, rare in O&G |

|

|

| ISO 15926 | Full—design, engineering, construction, operation, maintenance | Very high—open, semantic (OWL/RDF), but complex | Strong semantic base but limited interoperability with dynamic standards (OPC UA, WITSML) | Low-to-Moderate—lifecycle data focus, not real-time | None standardized; relies on external QA/QC processes | 5–6—industrially accepted in design data, not yet real-time |

|

|

| IEC 62424 | Partial—mainly design and basic engineering | Medium—prescriptive XML schema; limited extensibility | Moderate—works within engineering toolchains only | Low—static P&ID exchange only | Not applicable—data exchange standard only | 8–9—widely deployed in design workflows |

|

|

| Machine-learning/Hybrid twins | Operation & predictive maintenance | Dependent on data access | API-based | Medium–High (depends on refresh rate) | Empirical cross-validation | 5–7 | Fast inference, adaptive models | Requires retraining, less physics transparency |

| Topic/Method | Core Purpose | Key Features & Practices | Representative References |

|---|---|---|---|

| 4.1 Real-Time Data Architecture (Edge ↔ Cloud) | Balancing low-latency control and large-scale analytics | Edge-assisted deployments reduce latency and bandwidth; latency-sensitive analytics at the edge, fleet-level optimization in the cloud; private 5G + pub/sub data fabrics enable deterministic updates. | [22] |

| 4.2 Cybersecurity & Data Governance | Securing OT–IT integrated twins and ensuring compliance | Defense-in-depth and zero-trust principles; threat modeling; zone/conduit segregation; integrated monitoring; FAIR metadata and lineage for auditability. | [49] |

| 4.3 Standards & Interoperability | Ensuring cross-platform compatibility and lifecycle traceability | Reference architectures and shared information models; vendor-neutral exchange; federated twins spanning process, control, and enterprise layers. | [52] |

| 4.4 General Modeling Approaches | Defining model type and structure for DTs | First-principles, empirical, and hybrid approaches; structure selection; parameter/state estimation; grey-box identification; robust preprocessing for online–offline consistency. | [63,76] |

| 4.5 Complex Nonlinear Systems | Managing multi-domain, nonlinear plant dynamics | Mixed-fidelity stacks; multi-point linearization for LPV control; model reduction and regularization for real-time performance. | [66,67] |

| 4.6 Bond Graph & Causal Approaches | Energy-based, domain-agnostic modeling | Explicit causality; conservation-law adherence; early algebraic-loop detection; validated causal models for power-process equipment. | [65,68,69,70] |

| 4.7 Modelica & Equation-Based Object-Oriented Modeling | Multi-domain, modular plant-wide modeling | Declarative language; validated libraries (ThermoPower, ThermoCycle); robust initialization; hybrid-system simulation; FMU export for co-simulation. | [13,14,71,72,74,77] |

| 4.8 Object-Oriented Patterns (Recent Advances) | Improving maintainability, robustness, and edge deployment | Linear-implicit formulations for stiff networks; open toolchains (OpenModelica) for debugging and optimization; control-oriented reduced models for turbomachinery. | [13,69,75] |

| Topic/Subsection | Core Purpose | Key Features & Practices | Representative References |

|---|---|---|---|

| 6.1 FPSO specifics | Define scope, resolution, and data binding of the topside digital twin | Covers hydrocarbon and utility systems affecting production, energy use, and safety; first-principles unit models linked to P&ID/CAE with ISO 15926 and IEC 62424 compliance for lifecycle traceability; steady vs. dynamic fidelity selected per use case; bindings to real-time process data, setpoints, calculated properties, and events with typed, versioned tags. | [48,53,57] |

| 6.2 Compressor Constructive Data | Provide physical and performance data for accurate compressor sub-models | Includes geometry, rotor train config, seals, guide vanes, sidestreams, cooling type, design/guarantee points; uses API 617 and ASME PTC 10 standards for verification and map certification; reconciles constructive data with factory and site performance tests; embeds verified maps and surge margins for realistic control studies. | [79,84] |

| 6.3 Fluid Properties | Ensure accurate thermophysical property predictions across operating envelope | Selects EOS based on gas composition and conditions: GERG-2008 for broad coverage, EOS LNG for high-accuracy LNG predictions, AGA8 DC92 for custody transfer; comparative studies determine optimal EOS; integrates EOS package outputs (Z, k, μ, λ, flash) into compressors and separators for thermodynamic consistency. | [19,80,81,82,83] |

| 6.4 Verification, Validation & Certification (V&V) | Establish credibility and maintain certification for safety-critical twins | Uses class-society and agency standards (ABS, NASA-STD-7009 B) for VVUQ; includes model form declaration, code verification, data quality assessment, and predictive uncertainty quantification; adds governance for change control, evidence retention, cryptographic baseline locking; recommends automated regression testing for certification preservation. | [50,51,85] |

| Source Type | Count | Examples/Representative References | Description |

|---|---|---|---|

| Peer-reviewed journal articles, books, and Theses | 59 | [1,2,3,4,5,6,7,8,9,10,11,13,15,16,17,18,19,20,21,22,24,25,26,27,28,31,32,33,34,36,37,38,40,43,46,54,55,57,59,62,63,64,65,66,67,68,69,70,73,74,75,77,78,80,81,83,86,87,88] | Scientific papers providing validated research results on digital twins, modeling, and O&G applications. |

| Conference papers/proceedings | 15 | [12,14,23,29,30,35,39,45,47,58,60,71,72,76,85] | Peer-reviewed conference contributions on digital-twin methods, implementation, and integration frameworks. |

| Industry standards (ISO/IEC/API/ASME/NASA/ABS) | 8 | [48,49,52,53,61,79,82,84] | Authoritative technical standards governing interoperability, lifecycle data, V&V, and compressor design. |

| Technical reports & guidelines (NIST, ABS, NASA) | 3 | [41,50,51] | Government and classification-society guidance documents on verification, validation, and economic assessment. |

| Professional and Industry Sources | 3 | [42,44,56] | Media articles, vendor product notes, and software documentation |

| Thematic Cluster | Focus Description | Source Count | Representative References |

|---|---|---|---|

| Digital-twin frameworks & architectures | Conceptual models, architectures, and definitions for DTs in O&G and manufacturing | 18 | [1,2,3,4,5,6,28,32,38,40,45,46,58,87,88] |

| Modeling & simulation platforms | ASPEN HYSYS, Modelica, MATLAB, EMSO, and hybrid-model methods for FPSO and process plants | 22 | [9,12,13,14,15,16,17,18,27,30,54,55,56,57,63,64,65,66,67,71,72,73,74] |

| Interoperability standards & data models | ISO 15926, ISO 23247, IEC 62424, OPC UA (Open Platform Communications Unified Architecture), AML (Automation Markup Language); lifecycle data integration and information models | 10 | [48,49,50,51,52,53,60,61,62,84] |

| Process-safety and reliability/Hazard and Operability (HAZOP) integration | Digital twins for hazard analysis, monitoring, and verification/validation frameworks | 8 | [50,51,57,76,79,80,85,86] |

| Dynamic simulation & system identification | Methods for system identification, transient modeling, and hybrid dynamic simulation | 12 | [19,20,21,23,25,26,31,67,68,69,70,75] |

| Machine-learning & hybrid twins | Data-driven or hybrid (physics + ML) models for production optimization and diagnostics | 9 | [10,11,31,35,64,65,69,73,77] |

| Economic & sustainability applications | DT use in methane mitigation, energy efficiency, and life-cycle cost optimization | 9 | [41,42,43,44,59,80,81,87,88] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamidishad, N.; Barbosa, R.S.; Allahyarzadeh-Bidgoli, A.; Yanagihara, J.I. Digital Twin Frameworks for Oil and Gas Processing Plants: A Comprehensive Literature Review. Processes 2025, 13, 3488. https://doi.org/10.3390/pr13113488

Hamidishad N, Barbosa RS, Allahyarzadeh-Bidgoli A, Yanagihara JI. Digital Twin Frameworks for Oil and Gas Processing Plants: A Comprehensive Literature Review. Processes. 2025; 13(11):3488. https://doi.org/10.3390/pr13113488

Chicago/Turabian StyleHamidishad, Nayereh, Rafael Silverio Barbosa, Ali Allahyarzadeh-Bidgoli, and Jurandir Itizo Yanagihara. 2025. "Digital Twin Frameworks for Oil and Gas Processing Plants: A Comprehensive Literature Review" Processes 13, no. 11: 3488. https://doi.org/10.3390/pr13113488

APA StyleHamidishad, N., Barbosa, R. S., Allahyarzadeh-Bidgoli, A., & Yanagihara, J. I. (2025). Digital Twin Frameworks for Oil and Gas Processing Plants: A Comprehensive Literature Review. Processes, 13(11), 3488. https://doi.org/10.3390/pr13113488