Abstract

Digital Twin (DT) technology has rapidly matured from pilot projects to integral components of advanced asset management and process optimization in the oil and gas (O&G) industry. This review provides a structured synthesis of the current state of digital twin frameworks, with a focus on offshore and topside gas-processing systems, such as those found on Floating Production Storage and Offloading (FPSO). Emphasis is placed on high-fidelity process simulations and scalable architectures integrating real-time data with advanced analytics. Drawing on over 85 peer-reviewed sources and industrial frameworks, the paper outlines modular DT architectures, encompassing steady-state and dynamic process simulations (e.g., Aspen HYSYS), reduced-order and hybrid machine learning models, co-simulation environments, and advanced equation-of-state packages (e.g., GERG-2008). Special attention is given to compressor map integration, Equations of State (EOS) selection, ISO/IEC standard compliance, and digital thread continuity. Additionally, the review explores economic and sustainability-driven DT implementations, including flare and methane mitigation, ISO 50001-aligned energy optimization, and lifecycle/decommissioning strategies. It concludes with a technical and economic assessment of DT maturity for gas compression facilities, identifying research gaps in standardization, long-term validation, and cybersecurity integration. The insights provided are intended to support decision-makers, engineers, and researchers in deploying scalable, auditable, and high-impact DT solutions across the O&G value chain.

1. Introduction

DT technology has emerged as a transformative tool within Industry 4.0, offering the potential to replicate, simulate, and optimize complex physical systems through high-fidelity virtual models. In the O&G industry, the application of DTs is particularly promising for enhancing operational efficiency, safety, and sustainability across the upstream, midstream, and downstream sectors. However, the full-scale deployment of DTs in offshore environments, especially on Floating Production Storage and Offloading (FPSO) platforms, remains in its early stages, primarily limited by the complexity of the systems, integration challenges, and the need for real-time data synchronization. Thus, a comprehensive literature synthesis is needed to identify best practices and research gaps, which this review provides.

This review aims to examine the development and application of DT frameworks for typical oil and gas processing plants, focusing on modular and scalable architectures that can effectively address the complex operational conditions prevalent in modern production environments. Particular attention is given to systems designed for high-pressure gas treatment, multiphase separation, and contaminant handling, which are common challenges across both onshore and offshore facilities. Standardized processing configurations are highlighted as applicable reference models in the literature, offering a consistent basis for validating DT methodologies and facilitating the integration of real-time monitoring, predictive analytics, and optimization tools into industrial operations.

The scope of this review encompasses several core components that are fundamental to the development of digital twins for oil and gas processing systems. It begins with a comprehensive bibliographic analysis that contextualizes digital twin concepts, modeling approaches, and their evolving applications within the oil and gas industry. The reviewed literature encompasses methodologies for dynamic modeling of gas compression systems, with a particular emphasis on thermodynamic models based on advanced equations of state (e.g., GERG-2008) and the application of interpolation techniques to represent compressor performance.

Additionally, the review explores economic and sustainability-driven DT implementations, including flare and methane mitigation, ISO 50001-aligned energy optimization, and lifecycle/decommissioning strategies. It concludes with a technical and economic assessment of DT maturity for gas compression facilities, identifying research gaps in standardization, long-term validation, and cybersecurity integration. The insights provided are intended to support decision-makers, engineers, and researchers in deploying scalable, auditable, and high-impact DT solutions across the O&G value chain.

To guide this review, the following research questions (RQs) were formulated:

RQ1: What are the dominant frameworks and standards supporting the implementation of digital twins for FPSO topside processing?

RQ2: How do different modeling and simulation approaches compare in terms of fidelity, interoperability, and readiness for offshore applications?

RQ3: What are the main gaps and research opportunities in developing validated, lifecycle-integrated digital twins for offshore O&G facilities?

This paper begins by outlining the literature search method (Section 2) and presenting key digital twin concepts and frameworks (Section 3), followed by a review of modeling techniques, applications in the oil and gas sector, and high-fidelity simulation tools (Section 4). Enabling data architectures, interoperability standards, and security aspects are then examined (Section 5). A representative case study of a pre-salt FPSO process plant is presented (Section 6), and recent developments and future research directions are discussed (Section 7). By integrating insights from both physics-based modeling and data-driven analytics, the review underscores the potential of scalable digital twin architectures to enable predictive simulations, real-time monitoring, and AI-enhanced control across oil and gas processing facilities.

2. Literature Search Method

The literature search followed a structured and reproducible protocol.

Searches were conducted in Scopus, Web of Science, IEEE Xplore, and Google Scholar between January 2013 and May 2025.

The following Boolean string was used:

(“digital twin” OR “digital shadow” OR “virtual plant”) AND (“oil and gas” OR “FPSO” OR “offshore process” OR “topside”).

Inclusion criteria: peer-reviewed journal papers, conference papers, and standards explicitly addressing digital twin frameworks, modeling, or data integration in oil and gas.

Exclusion criteria: sources not related to process systems or without methodological detail. The screening process identified 215 records, of which 159 remained after relevance filtering and 88 were finally included.

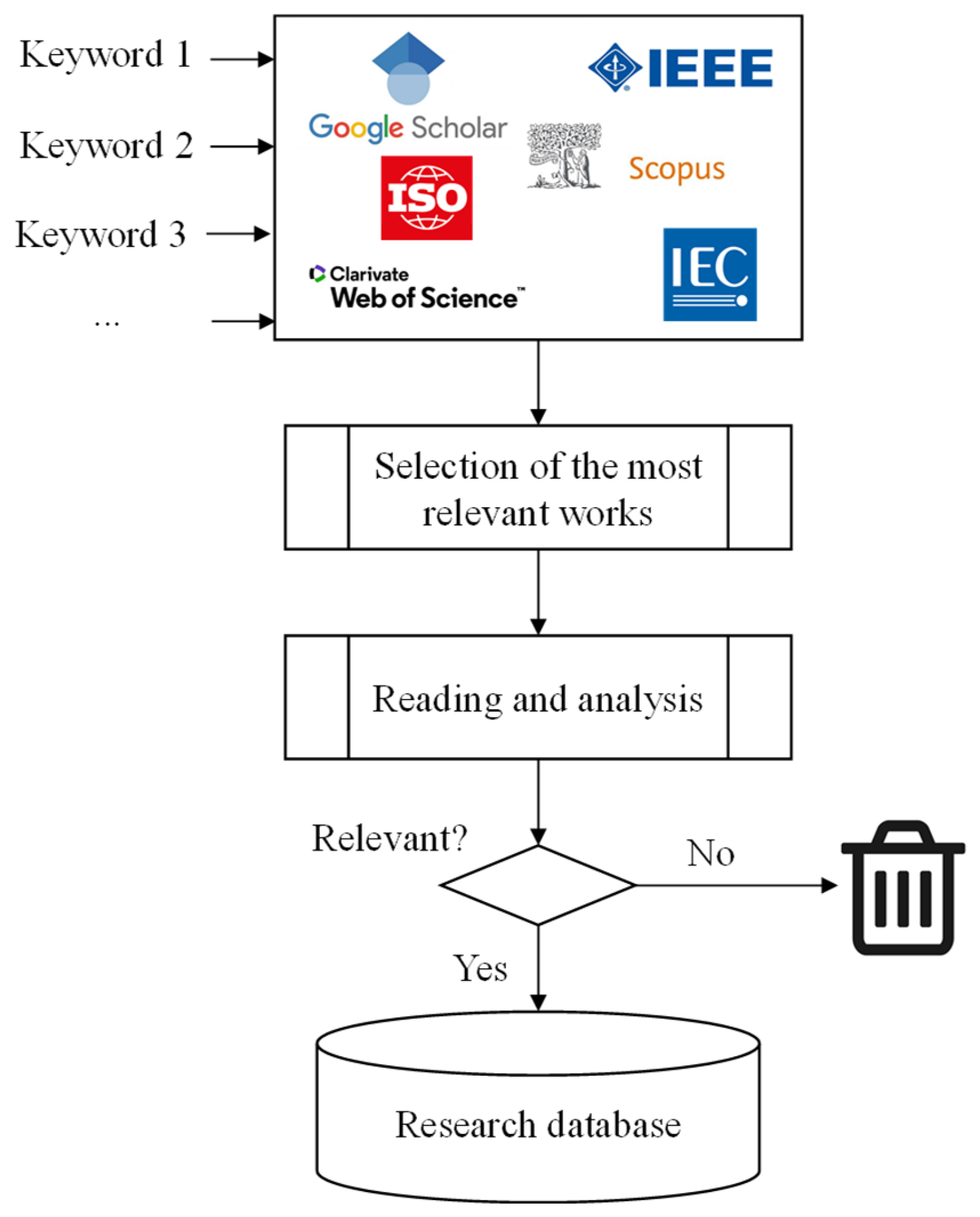

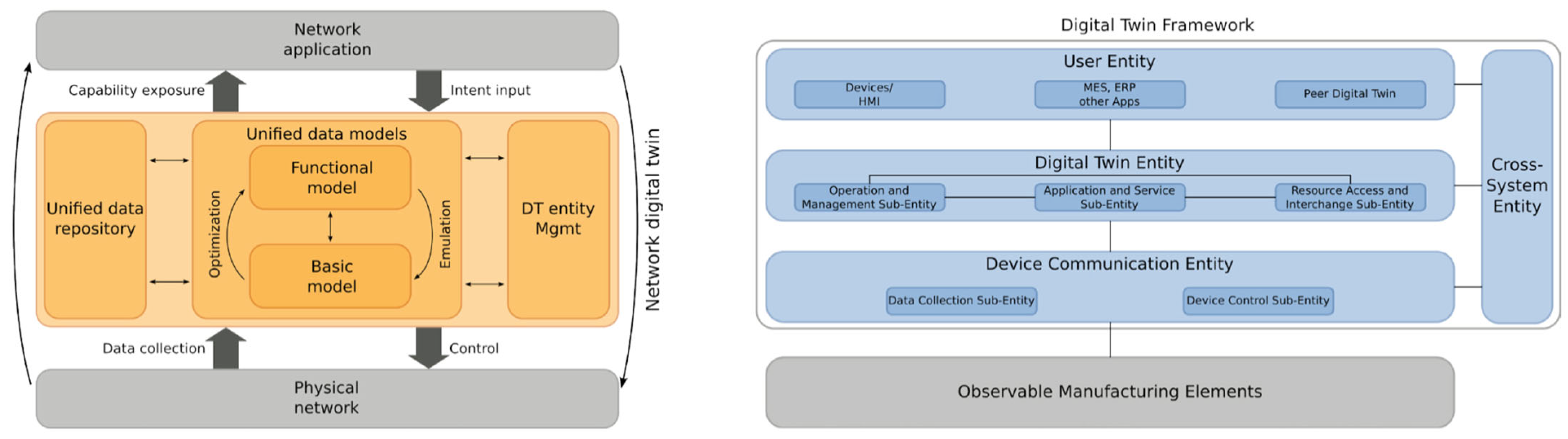

As illustrated in Figure 1, the process begins with the selection of relevant keywords, which are then utilized in various specialized search engines for scientific articles. The most pertinent works are selected for review, while those not directly relevant are discarded. Works of direct interest to this article are retained for review. The initial search explored the broad concept of digital twins, then gradually focused on literature specific to FPSO process plant applications.

Figure 1.

Flowchart summarizing the bibliographic search process used in the research.

Figure 1 illustrates this process, from keyword selection to final inclusion of relevant sources.

The use of established scientific databases such as Scopus, Web of Science, Google Scholar, and IEEE is crucial for conducting a comprehensive and reliable literature review. These platforms provide access to a vast collection of peer-reviewed articles, conference papers, and patents. Utilizing these databases ensures that the review is based on high-quality, verifiable research and helps identify key trends, seminal papers, and influential authors in the field of digital twins. This systematic approach enhances the credibility and rigor of the study.

The integration of standards from organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) is vital for a thorough review of digital twins. These standards provide a common framework for system design, data exchange, and safety protocols, which is particularly critical for applications in high-risk environments such as offshore oil platforms. Adhering to these standards ensures that DTs are built on a foundation of reliability and security, establishing a safe and dependable computational framework that aligns with the operational requirements of real-world systems.

3. Digital Twins—Concepts and Definitions

DT technology refers to the creation of a virtual digital counterpart of a physical asset or process, enabling real-time monitoring, simulation, and optimization. The concept has garnered significant attention as an enabler of the Industry 4.0 (the fourth industrial revolution, characterized by cyber-physical systems, IoT (Internet of Things) integration, advanced analytics, and autonomous decision-making) paradigm, promising improvements in productivity, efficiency, and safety across various industries.

Authors from academia, standards bodies, and industry converge on a core definition of a digital twin: a continuously updated digital representation of a physical asset that supports monitoring, analysis and decision support. Academic definitions emphasize model fidelity and traceable validation, while standards bodies focus on lifecycle data consistency and semantics. Industrial frameworks, on the other hand, prioritize deployment, scalability, and operational robustness.

In the oil and gas (O&G) sector, DTs are viewed as a means to enhance operations while minimizing costs, risks, and downtime. However, adoption in O&G remains nascent—implementations have so far been limited to isolated, specific applications rather than enterprise-wide deployment, which in turn limits the attainable benefits.

- Isolated applications: drilling advisory twins (kick/loss prevention), compressor anti-surge twins, pipeline leak-detection models.

- Enterprise-wide deployments: integrated field-management twins linking well inflow, processing plants, and logistics chains (e.g., Shell and Equinor pilots).

For offshore FPSO topsides, these perspectives must be reconciled: the technical stack should preserve scientific rigor while meeting operational constraints and vendor ecosystems.

To unlock the full potential of DTs, a comprehensive understanding of their theoretical foundations, technical implementations, and use cases in the O&G industry is necessary. This bibliographic review provides an overview of the evolution of the DT concept, the state-of-the-art in modeling and implementation techniques, and specific applications in the oil and gas industry (from upstream drilling to downstream processing). Recent developments and future challenges are also discussed. Key literature sources, including recent academic papers and industry case studies, are surveyed and categorized thematically.

3.1. Theoretical Foundations of Digital Twins

The term “digital twin” broadly refers to a high-fidelity digital representation of a real-world entity that remains in sync with its physical counterpart. Emmert-Streib [1] offers a concise definition: “A digital twin is a digital representation of a real-world object that is essentially indistinguishable from its real-world counterpart”. In practice, this means the digital model mirrors the state and behavior of the physical asset with such accuracy that it can be treated as a virtual twin. Key to this concept is the seamless integration of the cyber and physical spaces, enabling continuous two-way data exchange. Indeed, early work by [2] emphasized that DTs are characterized by a tight cyber–physical fusion, i.e., seamless integration of physical and digital components, and identified the core of DT technology to be the modeling of the physical system. A DT is more than just a static model; it is connected to live data from its physical counterpart, allowing it to update and evolve in real-time. Chen et al. [3] describe the digital twin paradigm as “combining multi-physics modeling with data-driven analytics” to mirror the entire life of an asset. In other words, high-fidelity physics-based simulations are enhanced with real-time sensor data and analytics, ensuring the twin reflects the current condition of the physical system throughout its lifecycle. Maturity frameworks (e.g., model → digital shadow → closed-loop twin) describe progressive capabilities. In practice, most offshore implementations operate at or near the ‘digital shadow’ stage, where monitoring and analytics are employed without automated feedback. Advancing to closed-loop operation requires robust time-synchronization, certified V&V, and cyber-secure actuation chains—gaps that are particularly acute in topside FPSO deployments.

3.1.1. Concept Evolution and Definitions

The digital-twin concept originated in aerospace and manufacturing and has evolved into three distinct strands: provenance-focused (traceable digital thread), model-focused (high-fidelity simulation), and operations-focused (real-time analytics & control). For the oil & gas domain, a pragmatic hybrid view, combining provenance, validated models, and operational analytics, offers the most promising route to enterprise-grade twins. A challenge noted in recent literature is the lack of a single unified definition—different industries and authors emphasize varying aspects (simulation fidelity, data connectivity, intelligence, etc.). Emmert-Streib [1] warns that this lack of clarity in definition could become an obstacle to cross-disciplinary adoption. Nevertheless, common elements in most definitions include (1) a physical entity, (2) a digital model of that entity, and (3) a data connection that keeps the two synchronized. Sharma et al. [4] break down the essential components of a DT as the physical asset, the virtual model, and the enabling connection that allows the twin to continuously update and interact with its physical “twin” (often via IoT sensors and networks). In effect, a DT can be seen as an instance of a cyber-physical system (CPS) where the digital side is an advanced, living simulation of the physical side. DTs “mirror physical assets in the digital world, enriching them with additional capabilities such as decision-making or lifecycle management”. Unlike traditional offline simulations, a DT operates in tandem with the real asset, thus enabling real-time decision support, condition monitoring, and even autonomous control actions.

3.1.2. Frameworks and Models

As DT concepts matured, researchers proposed frameworks to classify and evaluate DT implementations [5]. For example, Uhlenkamp et al. [6] developed a maturity model to categorize digital twins by capability levels. Their model assesses DT solutions across seven dimensions—context, data, computing capabilities, model fidelity, integration, control, and human–machine interface—with 31 characteristics, allowing organizations to evaluate the level of advancement of a given digital twin system. These characteristics include aspects such as model resolution, calibration frequency, latency tolerance, scalability, interoperability level, etc.

Such frameworks underscore that DTs can vary widely in sophistication, ranging from basic twins with one-way data monitoring to advanced twins equipped with predictive analytics, closed-loop control, and optimization features. Tao et al. [2] noted that despite rapid progress, “DT remains a rapidly evolving concept” and pointed out that a unified modeling methodology for digital twins was (and still is) critically needed to standardize development.

In process industries, earlier forms of digital twins existed in practice as high-fidelity simulators used for operator training and control system testing. These were essentially precursors to modern DTs—“widely applied as operator training simulators”—providing an excellent foundation for today’s digital twin applications in large, continuous plants.

Table 1 presents a summary of foundational literature on DT concepts, definitions, and frameworks. Each work contributed to the theoretical foundations of digital twins, from initial concepts to maturity models.

Table 1.

Representative literature on Digital Twin concepts, definitions, and frameworks.

3.2. Digital Twin Modeling and Implementation Techniques

Implementing a digital twin requires integrating advanced modeling techniques with real-time data infrastructure. Unlike traditional simulations or models, which run offline, a Digital Twin is continuously updated with live data, making it an operational tool rather than a one-off analysis model. The fidelity and accuracy of the digital model are paramount—the virtual twin must realistically emulate the physical asset’s behavior under various conditions. This has driven research into high-accuracy modeling of industrial equipment, processes, and systems. In many cases, DT development builds on the rich legacy of engineering modeling and simulation in the oil and gas industry. For example, dynamic simulation models have been meticulously developed for pipeline networks and complex equipment. These include advanced systems similar to multi-stage compressors. Today, these models serve as the physics-based core of digital twins, enabling more accurate simulations and analyses. Their evolution reflects decades of research and innovation in the field. Woldeyohannes et al. [9] developed a simulation model for natural gas transmission pipeline networks that can predict flow and pressure dynamics—such first-principles models are indispensable for pipeline digital twins. Similarly, high-fidelity compressor models, including hybrid approaches that combine physics with data-driven components, have been developed. For example, Chu et al. [10] utilized a neural network coupled with mechanistic models to extend compressor maps to a broader operating range.

A practical example of hybrid data-driven modeling in oil and gas is the development of an NARX-based digital twin for a horizontal three-phase separator in the Campos Basin, Brazil. The model was trained using real operational data and successfully reproduced the dynamic behavior of the liquid level with high accuracy. The reported mean absolute percentage error (MAPE) was below 1%, highlighting the effectiveness of hybrid approaches in representing complex multiphase separation processes. This case study demonstrates that combining data-driven elements with physics-based constraints can deliver robust digital twins for critical control applications such as anti-surge and anti-slug controllers [10].

These examples show that mechanistic models form the foundation of DTs. They capture the essential physics that govern oilfield equipment and processes, including fluid flow, heat transfer, and mechanical behavior.

At the same time, because real-time operation is a requirement, there is growing interest in model reduction and surrogate modeling within DTs. Highly detailed models can be computationally expensive. To address this, researchers such as Bárkányi et al. [11] have explored the potential role of surrogate models, simplified meta-models (e.g., response surface, reduced-order, or machine learning models), that approximate complex system behavior and significantly speed up simulations. These surrogate models can be periodically calibrated with high-fidelity simulation or live data, striking a balance between accuracy and speed. The use of hybrid models (combining first-principles and data-driven approaches) is an emerging theme in DT implementation. For instance, a centrifugal compressor’s digital twin might use fundamental equations for mass/energy balance coupled with an empirical ANN (Artificial Neural Network) to account for effects that are hard to model from first principles alone. Implementation techniques vary (first-principles, grey-box, ML, hybrid), but they should be selected according to the twin’s purpose (design verification vs. real-time control vs. fleet analytics). In topside FPSO cases, multi-fidelity architectures (high-fidelity core + reduced-order runtime surrogates) commonly provide the best compromise between accuracy and real-time performance.

3.2.1. Modeling Tools and Approaches

A variety of modeling paradigms and software tools are employed in building digital twins for the O&G industry. Object-oriented equation-based modeling languages, such as Modelica, have become popular for representing large process systems in a modular manner. Martin-Villalba et al. [12] demonstrated the implementation of the Tennessee Eastman process (a benchmark chemical plant) in Modelica [13,14], showcasing how complex process dynamics can be captured in a reusable model library. Such component-oriented models are very amenable to digital twin development, since each equipment unit (vessel, pump, compressor, etc.) can be a component in the twin, connected in the same topology as the real plant. Commercial process simulators (e.g., Aspen HYSYS, Honeywell Unisim) are also widely used to create high-fidelity steady-state and dynamic models of oil & gas processes. Valdés et al. [15,16] present a rigorous dynamic simulation of an entire offshore oil & gas processing plant using Aspen HYSYS, covering multiple processing stages (gas conditioning, separation, etc.) and a real start-up sequence [17]. This work illustrates that today’s tools can create an accurate digital replica of an FPSO topsides process—essentially a digital twin that can be used to test and optimize operations before implementing changes in the real plant. In an earlier study, Bidgoli [18] simulated and optimized a pre-salt FPSO’s primary oil and gas processing plant, demonstrating the feasibility of modeling complex offshore production facilities as a step toward digital twinning. Taken together, the toolset splits into (i) commercial process engines (HYSYS/Unisim) optimized for validated plant-level fidelity, (ii) control/prototyping environments (MATLAB/Simulink) for automation and HIL, and (iii) open/academic ecosystems (Modelica/EMSO/gPROMS) that emphasize transparency and co-simulation. Effective FPSO twins typically orchestrate a hybrid toolchain (co-simulation or FMU-based federation) to reconcile fidelity, openness and deployment constraints.

Accurate thermodynamic and fluid models are another crucial aspect of DT modeling. Oil and gas processes often involve complex hydrocarbon mixtures under varying pressures and temperatures. Specialized EOS and property models are incorporated into twins to predict fluid behavior accurately. For example, the GERG-2008 wide-range EOS for natural gases (Kunz & Wagner, [19]) extends the range of accuracy for properties of natural gas mixtures (accounting for CO2, N2, etc.), which enhances fidelity when simulating processing facilities with varying gas compositions. Likewise, Nazari & Bashipour [20] developed rigorous models for computing natural gas thermodynamic properties across a wide range of conditions, ensuring that a twin can accurately mirror the physical process even as conditions fluctuate. Such high-accuracy models of fluid properties, along with detailed equipment characteristics (compressor maps, pump curves, heat exchanger correlations), contribute to what is often called high-fidelity digital twins—virtual models that behave almost indistinguishably from the real system over the full operating envelope [21].

3.2.2. Data Integration and Computational Infrastructure

A defining feature of digital twins is their linkage with real-time data. Implementing this requires robust data acquisition systems (sensors, IoT devices), communication networks, and data management architectures. Modern DT deployments utilize industrial IoT platforms to stream field data (such as pressures, temperatures, flow rates, and vibrations) from the physical asset to the digital model. The twin then uses this data for continual calibration and state update. Knebel et al. [22] discuss architectures for cloud and edge computing that support digital twins in O&G operations. In a critical infrastructure such as oil and gas, certain computations may be performed at the edge (on-site, near the asset) for low latency—for example, a drilling rig’s digital twin might run on an edge device to give immediate feedback to operators—while heavy historical data processing or machine learning training might occur in the cloud. Their study noted that a digital twin platform must be capable of monitoring objects in real-time, predicting their state, integrity, and safety conditions, and providing user feedback. This implies not only a high-fidelity model, but also analytical layers (e.g., anomaly detection algorithms, predictive models for equipment failure) and visualization interfaces.

Indeed, many digital twin implementations incorporate a visualization or mixed reality component to facilitate user interaction with the twin. This could be as simple as a dashboard showing live parameters and predictions, or as advanced as an immersive 3D environment. For instance, Schroeder et al. [23] demonstrated the use of web services and augmented reality to visualize a digital twin of industrial equipment, thereby enhancing intuitive understanding of the system state. In the O&G industry, where operations are often remote or hazardous, such visualization can significantly aid in remote operations and training.

From a systems architecture perspective, researchers have formulated reference architectures for DTs that ensure scalability and interoperability. For example, the C2PS (Cloud-based Cyber-Physical Systems) architecture by Alam and El Saddik [24] provides a blueprint with separate layers for data, models, and services in a cloud-based DT environment. Data standards such as AutomationML have been proposed for structuring twin data models and facilitating data exchange between the physical and virtual components. Overall, implementing a digital twin requires bridging multiple domains: sensor and IoT engineering (for data capture), software and network engineering (for communication and cloud/edge computing), and modeling and simulation (for the virtual asset). The success of a DT project hinges on integrating these pieces into a cohesive system.

3.2.3. Control and Integration

Some advanced digital twins are not just passive mirrors but active controllers. They can evaluate what-if scenarios and send optimized setpoints or control actions to the physical asset. This veers into the area of model-predictive control (MPC) and real-time optimization. For example, Gesser et al. [25] applied advanced control strategies to a gas compression system model of an offshore platform, tying the high-fidelity simulation to control logic. In principle, a digital twin with decision-making capability can automatically adjust the physical process for optimal performance—sometimes described as a “closed-loop digital twin.” However, implementing this in critical O&G operations requires rigorous validation and cybersecurity considerations (to ensure the twin’s commands are safe and protected from interference).

Table 2 consolidates the high-fidelity modeling resources surveyed in Section 3 and maps them to three asset classes—process plants, pipelines, and compressor trains—to make coverage and maturity directly comparable. For ASPEN-HYSYS, the table flags strong evidence for whole-plant steady/dynamic replication of start-up, upset and energy-integration behavior in offshore topsides (process plants: high capability), while noting its more limited role for transient pipeline hydraulics and its usefulness as boundary-condition provider (pipelines: basic capability) [16]. For MATLAB/Simulink, the table highlights its value for control-oriented reduced models and co-simulation with process simulators, with validated examples in hot-oil restart, observer design, and anti-surge prototyping (pipelines: intermediate capability; compressors: intermediate capability) (Wang et al., [26]; Munari et al., [27]). Under Implemented code, we emphasize bespoke finite-volume solvers for compressible-flow transients and network dynamics—including leak detection and batch/interface tracking—and validated multi-station gas-network models (pipelines: high capability; compressors: basic capability) (Woldeyohannes et al. [28]; Garcia-Hernandez & Garibay, [29]). Integrated platforms (co-simulation/co-execution) are marked as high-leverage for compressor–plant integration and hardware-in-the-loop testing (compressors/plant: high capability) (Martin-Villalba et al. [12]). EMSO is listed where equation-oriented transparency and fast resolution matter for optimization and thermodynamic consistency (compressors/plant: intermediate capability) (Soares & Secchi, [30]; Gesser et al., [30]). Finally, machine-learning surrogates are shown as accelerators for soft-sensing and map correction inside hybrid twins (physics + ML), provided the training domain is refreshed and uncertainty tracked (pipelines/plant/comp.: high capability) (Chu et al., [31]; Meza et al., [32]). Read row-wise, Table 2 reveals where evidence is strongest (e.g., plant-level dynamics in HYSYS; network transients in bespoke codes) and where gaps remain (e.g., unified transient treatment across plant–pipeline–compression without co-simulation).

Table 2.

Selected works on digital twin modeling and implementation techniques.

3.3. Applications of Digital Twins in Oil and Gas

Digital twin technology has been applied (or piloted) in various segments of the oil and gas value chain, including upstream (exploration and drilling), midstream (pipelines and transport), and downstream (processing plants and refineries). While the use of digital twins (DTs) in the oil and gas industry is still developing, significant progress has been made in several sectors beyond processing plants, such as drilling operations, well management, and subsea systems and pipelines. For example, in drilling, DTs act as real-time simulators to enhance safety and efficiency by providing early warnings for issues such as bit wear or lost circulation, as highlighted by Knebel et al. [22]. In subsea environments and pipelines, DTs are crucial for predictive integrity management, helping to anticipate corrosion or leaks and optimize maintenance schedules, as discussed by Chen et al. [3]. Additionally, Shen et al. [34] have shown how DTs can be used for production optimization in the oil and gas domain. These applications demonstrate the potential of DTs to improve operational safety and efficiency across the entire value chain.

The following subsections discuss notable use cases and research efforts, demonstrating how DTs are applied to processing plants and associated assets.

3.3.1. Process Plant and Facilities Twins

One of the most active areas is the use of digital twins for process plants, such as oil and gas production facilities, gas processing plants, and petrochemical units. These environments are complex and instrumented, making them suitable for developing comprehensive twins that can monitor the plant’s performance, predict issues, and optimize operations [35,36]. Santillán Martínez et al. [37] describe a methodology for semi-automatically creating simulation-based digital twins of industrial process plants (especially brownfield, existing facilities). Their approach uses existing plant data—P&IDs, 3D models, and control system information—to generate a base first-principles model, and then applies a series of steps (a 7-step workflow) to refine this model into a working digital twin. Such efforts are crucial because most O&G facilities are brownfield (already operational), and constructing twins for them requires handling legacy data and retrofit modeling. Sierla et al. [38] similarly propose a roadmap for semi-automated generation of DTs for brownfield process plants, aiming to “reduce the engineering effort” needed to digitalize existing assets.

The FPSO unit is a prime example of a complex asset that benefits from a digital twin. An FPSO’s topside process (separating oil, gas, water, and treating produced fluids) involves many interacting subsystems. A digital twin of an FPSO process can continuously monitor conditions (such as pressures and temperatures in separators and compressors) and predict performance issues or downtime [39]. Bidgoli’s [18] thesis on a pre-salt FPSO processing plant demonstrated the use of simulation and optimization for such a facility, which effectively serves as an offline digital twin used to find optimal operating conditions. More recently, industrial solutions (like Honeywell’s “Digital Twin of the Oil Field” or Kongsberg’s Kognitwin for offshore platforms) have been deployed [40]. These twins help with production optimization, debottlenecking, and operator training. For instance, by simulating different choke settings or compressor configurations on the twin, engineers can optimize oil output and gas lift in a safe virtual environment before implementing changes on the actual FPSO.

Process plant twins are also heavily used for operator training and scenario testing. As noted earlier, operator training simulators have long existed; the modern twist is that these simulators can receive live plant data and thereby become continually updated twins. This enables training on scenarios that align with the current state of the plant. It also enables what-if analyses, such as testing how the plant would respond to a compressor trip or a change in feed composition. In an interesting example, Honeywell’s “Shadow Plant” mimics process operations in parallel, providing operators with a risk-free test bed.

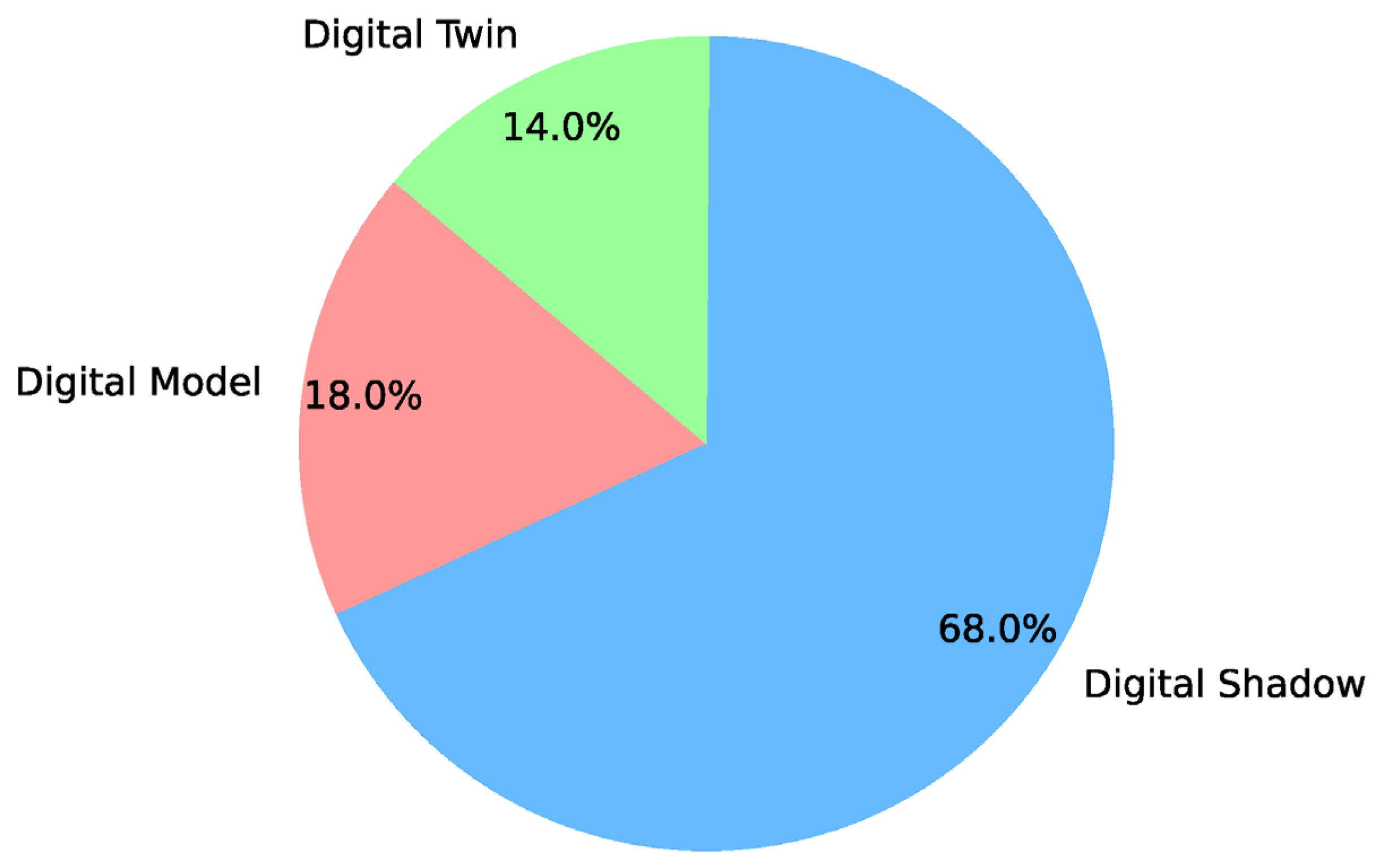

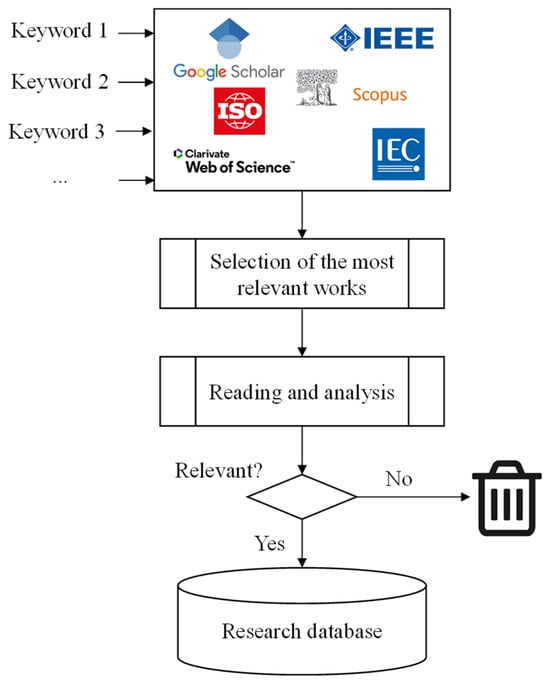

Another use case in downstream operations is the maintenance of refineries and petrochemical plants. Digital twins of equipment, such as reactors, distillation columns, and heat exchangers, are used to monitor fouling and catalyst deactivation. By comparing sensor data to the twin’s predictions, engineers can detect deviations that indicate maintenance needs. The twin can help forecast the remaining useful life of components and schedule turnarounds more optimally. Figure 2 shows a useful typology pie chart to clarify maturity language in a plant-twin section (model → shadow → twin).

Figure 2.

Proportion of Digital Model/Digital Shadow/Digital Twin (Meza et al., [32]).

3.3.2. Economic Impact and ROI Studies

Digital twin initiatives have progressed from anecdotal pilots to board-level investment cases. Contemporary studies adopt a total expenditure (TOTEX) lens that aggregates capital outlays for sensors, edge gateways and private 5G backhaul with recurring expenses such as cloud runtime, license renewal, model drift remediation and cybersecurity patching, feeding these cashflows into standard NPV and IRR calculations for comparability with conventional upgrades [41]. To handle uncertainty, staged deployment and real option thinking are increasingly advocated; modeling shows that deferring high-fidelity enhancements until operational variance subsides can improve expected value relative to one-shot deployments [41].

Quantitative evidence now spans offshore processing and terminal operations. For FPSO-class assets, shifting first-level analytics to ruggedized edge nodes reduced round-trip latency relative to cloud-only regimes and enabled measurable flare-gas savings and downtime avoidance, strengthening the payback case for compressor-train twins [22]. In gas terminal settings, Monte Carlo economics applied to digital twin retrofits yielded positive probability-weighted NPVs when reliability-centered maintenance and operational flexibility benefits were included. Across these studies, the principal negative drivers are latency-induced downtime risk and recurring costs required to sustain model fidelity throughout the asset’s life [22,41].

Commercial models are co-evolving to align incentives. Operators report a shift toward subscriptions in which platform fees scale with asset throughput and toward outcome-linked agreements, in which vendor remuneration is tied to verified improvements in uptime or energy performance. Both structures explicitly recognize the ongoing costs of model maintenance and data stewardship [41]. Two gaps frequently noted are the underrepresentation of carbon-credit revenues in cash flows for flare-mitigation twins and the lack of standardized accounting for fidelity-maintenance costs in brownfields [41].

3.3.3. Sustainability Driven DT Applications and Lifecycle Asset Management with Decommissioning Twins

Digital twins are becoming increasingly integral to ESG (Environmental, Social, and Governance) strategies in the oil and gas industry. The most active area is methane and flare mitigation, where hybrid approaches combine plant data with physics-informed surrogates to provide near-real-time source attribution and operational guidance; case pilots report double-digit flare reductions when choke and header management are coordinated by the twin [42]. Energy-efficiency applications are also maturing: in LNG (Liquefied Natural Gas) processing, integrating a plant-wide twin with ISO 50001 routines enabled coordinated steam-network and refrigeration optimization with statistically significant reductions in specific energy consumption while preserving throughput [43]. These operational KPIs can be streamed to corporate dashboards and audit packages, shortening reporting cycles when accompanied by controlled data lineage [42,43].

Lifecycle-aware twins extend beyond operations by bridging the design, construction, operation, and end-of-life phases. Practice reports emphasize linking engineering and operational data to preserve design intent as an enduring digital thread that supports brownfield modifications and late-life integrity work [44]. For floating LNG and similar assets, lifecycle twins assist in scenario analysis and planning, reducing schedule and cost overruns when used to prioritize inspection, maintenance, and plug-and-abandon sequencing. Assurance practices described for operational twins, traceable models, managed updates and auditable data carry forward directly into late-life and decommissioning contexts [45].

3.3.4. Maintenance, Training, and Other Use Cases

Beyond their core operational uses, digital twins in the O&G industry have been explored for maintenance planning, workforce training, and strategic decision support. Aiken et al. [46] present a case study on the application of mixed reality and digital twins in an oil & gas company. In their implementation, a digital twin was combined with augmented/mixed reality to create a training simulator that new operators could use in the field. The twin provided a realistic, data-driven simulation of the plant, while the mixed-reality interface allowed trainees to interact with virtual equipment overlays on the real plant environment. Notably, Aiken et al. [46] also used the same DT environment to generate synthetic data for training AI models—e.g., computer vision algorithms to recognize equipment or detect anomalies were trained using the twin’s virtual scenarios. This dual use of a DT (human training and AI training) exemplifies the innovative new applications emerging in the industry.

Another growing use case is in asset lifecycle management and project planning. A recent survey (Wanasinghe et al. [28]) identified project planning and life cycle management as key application areas of DTs in O&G. During the construction of a new facility, a digital twin can integrate the 3D design model with construction schedules to create a 4D model (3D + time) that tracks progress and predicts schedule risks. After commissioning, that same model can evolve into the operations twin. This continuity (often called the “digital thread”) ensures that information flows seamlessly from design to operation, reducing data loss and rework. It is anticipated that using DTs for start-up simulations could shorten commissioning times, as some operators have begun to explore this approach.

Life-cycle simulation positions the process-plant digital twin as a continuously reused, continuously validated asset that spans design, automation, commissioning, operation, and revamp. In this paradigm, models created for process design and control engineering are not discarded at handover; instead, they are orchestrated via two-dimensional co-simulation—coupling along a discipline axis (process, control/automation, mechanical/electrical) and along a life-cycle axis (conceptual/design → virtual commissioning → operation/optimization). The result is a federated, time-synchronized simulation that preserves engineering intent, enables early testing of control logic and interlocks, and later supports operator training, performance monitoring, and what-if advisory under real plant constraints. Oppelt et al. [47] demonstrate this 2-D co-simulation approach for process plants, showing how heterogeneous tools can be integrated to maintain model continuity and credibility across phases while reducing integration rework and shortening commissioning and optimization cycles [47].

In maintenance, DTs support predictive maintenance strategies. Rather than relying on fixed inspection intervals, companies can use the twin’s predictions on equipment degradation to perform maintenance exactly when needed (condition-based maintenance). For rotating equipment such as turbines and pumps, a twin augmented with vibration analysis can detect early warning signs of failure (a rise in vibration at specific frequencies, for example) and schedule a repair before a breakdown occurs. Many vendors now offer DT-based asset performance management solutions that integrate with existing monitoring systems.

From a broader perspective, DTs are also being linked with sustainability and emissions monitoring. For instance, a refinery digital twin can track fuel consumption, flaring events, and equipment efficiency, providing real-time insights into greenhouse gas (GHG) emissions. This helps operators optimize the process to reduce emissions and also accurately report environmental metrics.

Lastly, an intriguing development is using digital twins at the enterprise level, not just individual assets. For example, an oil company might have a digital twin of an entire oil field or pipeline network, enabling system-of-systems optimization. This could include market and economic models to turn the DT into a decision support system for investment and logistics. While such holistic twins are complex, they align with the concept of the “Digital Oil Field,” where subsurface models (reservoir simulations), surface facility models, and economic models are all connected.

Table 3 synthesizes the integration stack and governance layer that enable digital-twin operation in safety-critical oil & gas environments. It aligns three columns—(i) real-time data architecture (edge ↔ cloud), (ii) cyber-security & data governance, (iii) standards & interoperability/VVUQ—with the specific capabilities each brings to a deployable twin and the references that substantiate them. In the edge–cloud column, the table cites empirical evidence that edge-assisted partitions reduce latency/bandwidth and support surge/anti-slug control on offshore assets (Knebel et al., [22]). The security column maps well-known defense-in-depth patterns—such as IEC 62443 [48] zones & conduits, centralized monitoring, and zero-trust adjuncts—to twin components, including historians, brokers, and edge gateways, along with FAIR-aligned metadata and lineage for auditability (IEC 62443-3-2/-3-3 [48]; Wilkinson et al., [49]). The standards/interoperability/VVUQ column ties ISO 23247-1:2023 [50] (digital-twin framework) and IEC 62424 (P&ID↔CAE exchange) to model credibility guidance (ABS, [50]; NASA-STD-7009B [51]), emphasizing change control, evidence retention, and uncertainty handling; where lifecycle integration is required, ISO 15926 is shown as the reference information model (ISO 23247-1:2023 [52]; IEC 62424:2016 [48]; ISO 15926-4/-6 [53]). Together, the table provides a checklist view: how to wire data deterministically, how to secure the path from sensor to advisory, and how to maintain traceable, certifiable fidelity as the twin evolves.

Table 3.

Indicates key applications of digital twins in the oil and gas industry.

It is important to note that the ISO 15926 and ISO 23247 standards define fundamental structures for lifecycle interoperability in digital twin environments. However, their direct applicability to the oil and gas (O&G) domain, particularly FPSO topside systems, faces several limitations.

Firstly, ISO 15926′s ontology is highly generic and often lacks direct mappings to offshore-specific asset hierarchies such as turret systems, risers, or subsea control modules. Secondly, ISO 23247 focuses on manufacturing-oriented reference models, which do not fully address the harsh operational conditions, safety requirements, and asset integrity constraints of offshore production.

Moreover, implementation in O&G projects typically requires extensive customization and vendor-specific extensions, leading to fragmented adoption and limited interoperability between legacy systems. Finally, the integration of these standards with proprietary digital platforms (e.g., AVEVA, Honeywell, Siemens) often introduces challenges related to data ownership and semantic consistency.

Despite these limitations, the standards provide a valuable foundation for cross-disciplinary interoperability when adapted to domain-specific ontologies and verified against real FPSO operations.

These examples span upstream, midstream, and downstream, demonstrating the versatility of DT technology in improving operational performance, safety, and decision-making throughout the oil and gas industry.

4. High-Accuracy/High-Fidelity Models

This section reviews high-accuracy modeling platforms and positions them in relation to operational needs. Critical evaluation focuses on three trade-offs: (a) fidelity vs. run-time, (b) openness vs. vendor support, and (c) lifecycle coverage vs. specialized capability. The subsequent subsections present how each platform sits within these trade-offs and their suitability for FPSO topside roles. Each tool offers unique strengths in simulating process plants, pipeline networks, or compressor systems, as summarized below.

4.1. ASPEN-HYSYS (Commercial Dynamic/Steady-State Simulators)

Process plants. Full-plant steady and dynamic models in ASPEN-HYSYS have been used to reproduce start-up/shutdown, upsets, and energy-integration behavior in offshore topsides, providing a validated nucleus for plant-level digital twins and operator-training simulators [54]. High-fidelity property packages and equipment blocks enable rigorous heat/mass balance closure and transient replication, which are necessary for advisory control and what-if analysis [16].

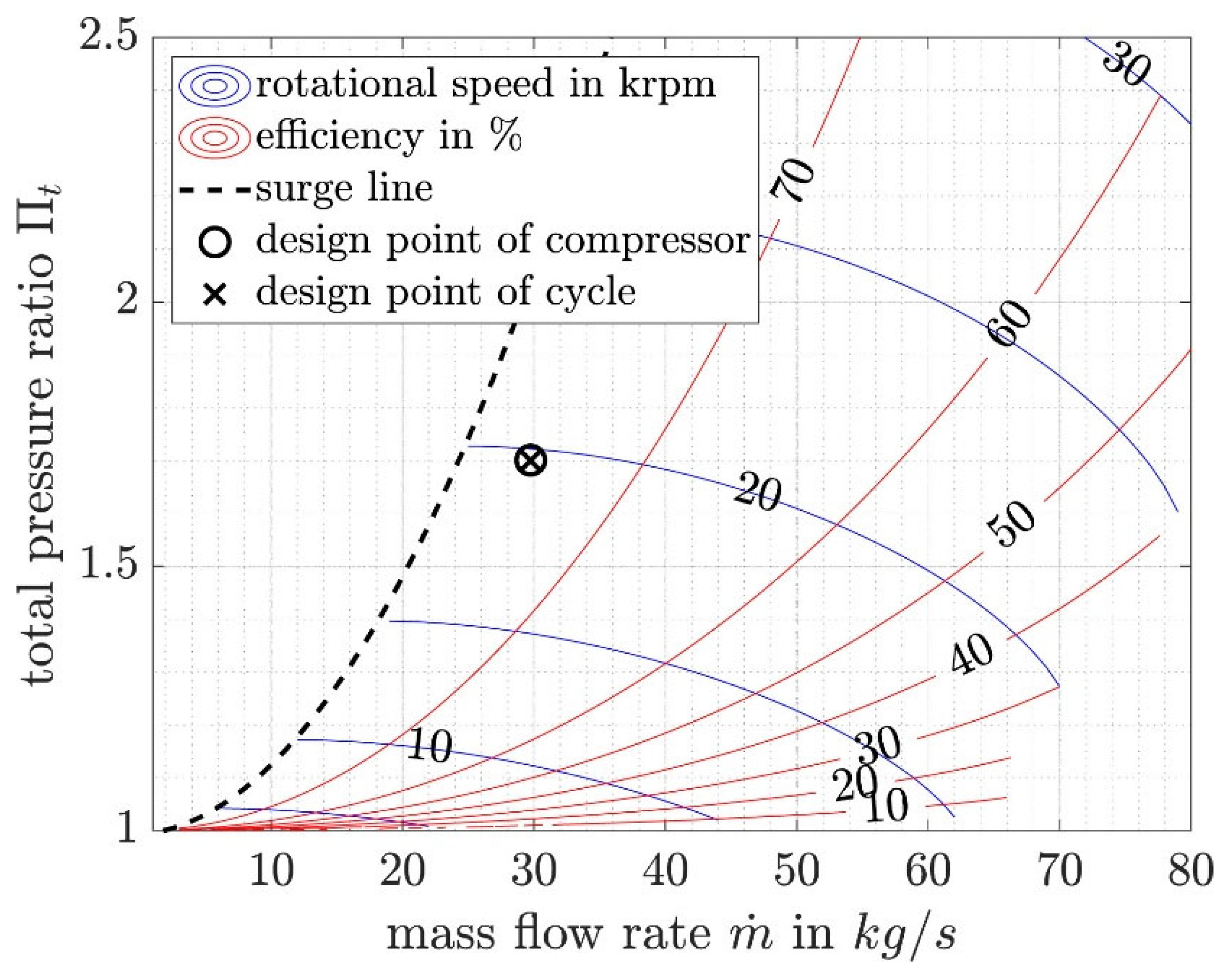

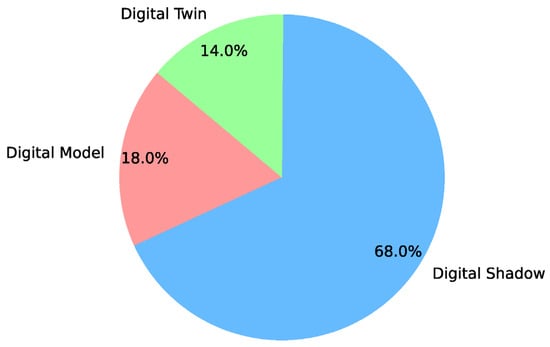

Pipelines. HYSYS/PIPEPHASE class tools are less common than dedicated transient pipeline codes but have been coupled for gathering systems where compositional effects dominate, serving as boundary condition providers to pipeline solvers [16]. Compressor trains. Rigorous unit models with vendor maps enable the evaluation of anti-surge margins, recycle strategies, and load-sharing logic under changing gas compositions; the same plant model supports fuel-minimization studies when integrated with compression-train controls [16]. Figure 3 illustrates a typical compressor performance map (plot of pressure ratio vs. flow with efficiency contours and surge line), which is used in digital twins to model compressor behavior and limits [55]. Incorporating vendor-supplied maps into HYSYS or similar models enables the twin to represent compressor performance across its entire operating envelope accurately. Evaluation: HYSYS excels in validated process fidelity and vendor-supported property packages (suitable for design/commissioning). Limitation: Proprietary data models and licensing hinder seamless federation with open co-simulation environments, requiring wrappers or adapters for lifecycle-wide twins.

Figure 3.

Compressor speed lines, efficiency contours, and surge line, ideal for illustrating surge/stonewall margins and performance maps in compressor twins [55].

4.2. MATLAB/Simulink (Numerical Prototyping and Control-Oriented Twins)

Pipelines. MATLAB/Simulink is widely used to derive and test control-oriented reduced-order models for transient thermal-hydraulics; Wang et al. [26] demonstrate hot-oil line transients and restart logic with validated predictions against field data. Munari et al. [27] develop nonlinear observers for multiphase transport, showing that reduced models can preserve key dynamics needed for leak and slug detection. Process plants & compressor trains. Simulink co-simulation with process simulators is used to prototype supervisory control (MPC/anti-surge) before PLC/DCS deployment; map-based compressor elements within Simulink enable rapid what-if testing while maintaining a clear control-systems representation [27]. Evaluation: Simulink is unmatched for control prototyping and hardware-in-the-loop simulation; it is ideal for validating automation logic before deployment in a PLC/DCS system. Limitation: requires care to integrate with plant simulators for plant-wide fidelity and with standards for lifecycle traceability.

4.3. Implemented Code (Bespoke Solvers and In-House Frameworks)

Pipelines. Where commercial licenses or special physics are limiting, in-house finite-volume solvers offer transient compressible-flow capabilities with leak detection and batch tracking; Woldeyohannes et al. [9] present a validated dynamic network model for gas pipelines.

Compressor trains. Garcia-Hernandez & Garibay [29] implement performance-map handling, surge criteria, and control logic in custom code to enable real-time capable simulation, a pattern commonly embedded into operational twins where deterministic execution is required.

Process plants. Bespoke code is often used to wrap vendor models and enforce execution determinism/traceability in on-premise twins while maintaining IP control [29].

4.4. Integrated Platforms (Co-Simulation/Co-Execution)

Compressor trains & plant integration. Co-simulation frameworks that orchestrate process, control, and mechanical models enable holistic evaluation of start-up sequences and trip responses. Martin-Villalba et al. [12] show a platform coupling process and control simulation for reciprocating/centrifugal trains with surge-avoidance and load-sharing logic validated against plant data. Such platforms support hardware-in-the-loop testing prior to commissioning (Martin-Villalba et al., [12]).

4.5. Other Platforms: EMSO (Equation-Oriented Modeling Simulator)

Compressor trains & process units. Gesser et al. [25] demonstrate equation-oriented modeling of process equipment and compression systems in EMSO, enabling detailed thermodynamic consistency and fast resolves for optimization. EMSO’s open architecture supports custom property packages and facilitates integration into digital twin pipelines where full transparency of equations and solver strategies is required [25].

4.6. Machine Learning (Surrogates, Observers and Hybrid Twins)

Compressor trains. Chu et al. [31] illustrate data-driven modeling for compressor performance/health inference, providing fast surrogates for map correction and fault detection that can be embedded in hybrid twins (physics + ML). Pipelines & plants. Similar surrogate approaches accelerate optimizer calls and enable soft-sensing (e.g., hydrate risk, viscosity), provided the training domain is periodically refreshed and uncertainty is tracked.

Table 4 summarizes the principal high-fidelity modeling platforms and approaches applied in oil & gas digital twin development, classified by application domain (process plants, pipelines, and compressor trains). For each category, the table outlines the core capabilities, the role in operational and design-phase DTs, and representative literature references. Commercial simulators such as ASPEN HYSYS [56] offer plant-wide thermodynamic rigor, while MATLAB/Simulink supports reduced-order control prototyping. Bespoke implemented codes ensure deterministic execution and accommodate special physics, whereas integrated co-simulation platforms enable cross-domain model orchestration. EMSO exemplifies equation-oriented openness for optimization-centric twins. Ultimately, machine learning approaches yield surrogate and hybrid models that enhance physics-based twins with rapid inference and adaptive sensing capabilities. Role in multi-fidelity architecture: ML surrogates accelerate optimization and embedded inference for monitoring and soft sensing. Their effective integration requires retraining protocols, uncertainty quantification, and alignment with physics-based constraints to avoid unsafe extrapolation in topside equipment control.

Table 4.

Comparison of High-Accuracy/High-Fidelity Modeling Approaches in Oil & Gas Digital Twin Applications.

Table 5 consolidates a comparative evaluation of modeling tools and frameworks used for FPSO topside digital twins. The assessment maps each tool to core evaluation criteria, highlighting lifecycle coverage, openness, interoperability, validation maturity, and deployment readiness.

Table 5.

Comparative Matrix of Approaches, Standards, and Tools for Digital-Twin Implementation in FPSO Topside Systems.

5. Data Structures and Modeling Approaches

This section discusses the enabling data infrastructure, security, and standards for digital twins (Section 5.1, Section 5.2 and Section 5.3), and then examines advanced modeling methodologies (Section 5.4, Section 5.5, Section 5.6, Section 5.7 and Section 5.8) that ensure twins remain accurate and maintainable.

5.1. Real-Time Data Architecture (Edge ↔ Cloud)

Deterministic control requirements and cloud-scale analytics impose conflicting demands on data architecture. Field evaluations demonstrate that edge-assisted deployments reduce latency and bandwidth consumption compared to cloud-only designs, enabling surge-avoidance and anti-slug controllers to respond within the required time budgets on offshore assets [22]. Commercial architectures pairing private 5G backhaul with publish–subscribe data fabrics are emerging to deliver deterministic updates across multi-operator domains. The resulting partitioning places latency-sensitive analytics at the edge, while batch optimization and fleet-level learning remain in the cloud, connected through robust data pipelines [22].

A relevant contribution comes from the offshore structural domain, where digital twins have been developed for semi-submersible platforms using ensemble learning and deep neural networks. In the case of the HYSY982 drilling platform, stress sensors and wave monitoring systems provide continuous data streams that are used to detect anomalies and assess fatigue damage levels. A machine learning-based method was proposed to identify data distortion caused by sensor aging, transmission failures, or human error, ensuring that corrupted measurements do not compromise safety-critical analytics. By iteratively updating the digital twin with verified data, the system enhances structural reliability and provides real-time decision support for inspection and maintenance planning [58].

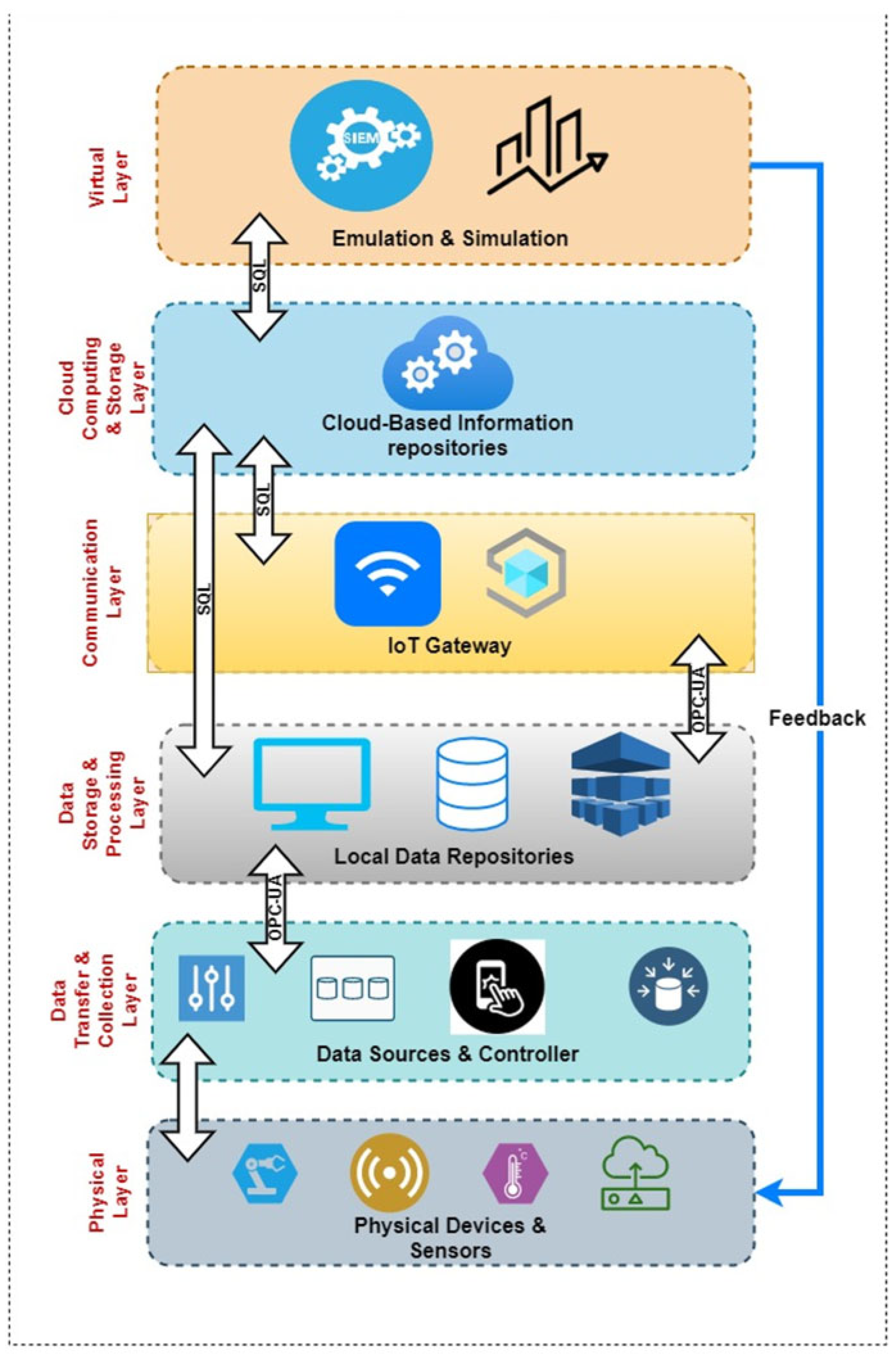

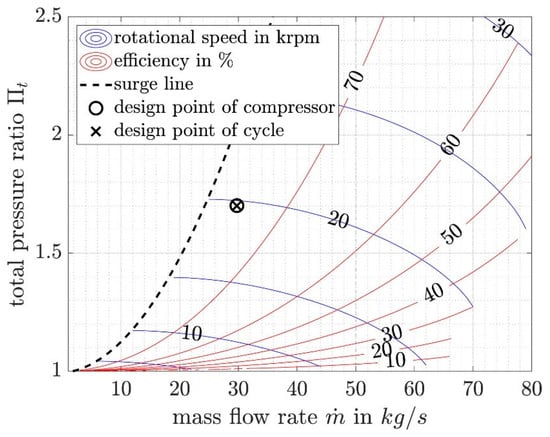

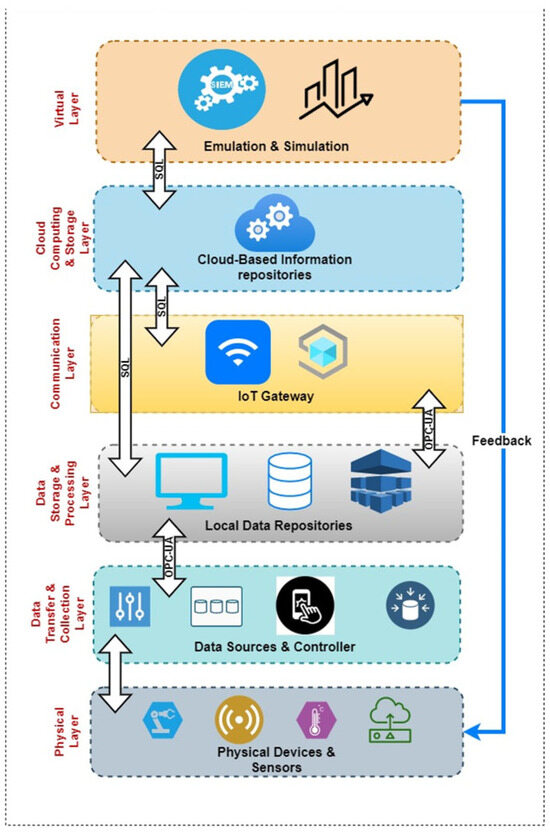

A six-layer DT architecture, presented in Figure 4, provides a structured framework for integrating physical assets with their virtual counterparts, enabling accurate simulation, monitoring, and optimization. The first layer, Physical Layer, represents the real-world asset and its operational environment. The second layer, Data Acquisition Layer, involves sensors, IoT devices, and communication systems that capture real-time operational data. The third layer, Data Processing and Storage Layer, ensures that raw data is cleaned, preprocessed, and stored securely for further analysis. The fourth layer, Modeling and Simulation Layer, uses physics-based models, machine learning algorithms, and system identification techniques to replicate asset behavior and predict performance. The fifth layer, Application Layer, delivers actionable insights through visualization dashboards, predictive maintenance tools, and decision-support systems. Finally, the sixth layer, Integration and Feedback Layer, enables continuous synchronization between the physical and digital systems, allowing two-way communication for real-time control, optimization, and adaptive decision-making. This layered approach ensures scalability, interoperability, and robust lifecycle management of the DT [59].

Figure 4.

Six-layer architecture of digital twin [59].

5.2. Cyber-Security & Data Governance

Digital twins extend the traditional IT perimeter into OT layers, making defense-in-depth and zero-trust core design principles. Following IEC 62443-3-2, partitioning assets into zones and conduits and assigning target security levels improves containment and risk visibility, while IEC 62443-3-3 [48] details system-level security requirements for historians, message brokers and edge gateways. Field experience and guidance for OT further emphasize segmentation and a centralized monitoring plane to reduce time-to-detect incidents. For governance, FAIR-aligned metadata, lineage, and role-based access across the twin’s data pipeline support both auditability and security. For a digital-twin-specific risk method, see IEC 62443/NIST and other offshore studies such as [49].

5.3. Standards & Interoperability

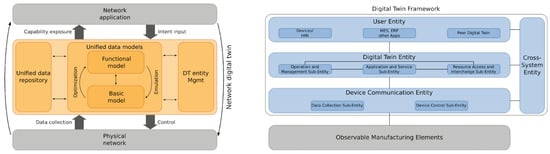

Scalable digital-twin ecosystems depend on open standards that guarantee semantic and functional consistency across heterogeneous tools. Sector guidance and empirical evaluations demonstrate that adopting a reference architecture and shared information models enables vendor-neutral model exchange and federated twins that span process, control, and enterprise layers [52]. In practice, these standards underpin long-term maintainability and lifecycle traceability while reducing integration rework during upgrades [52]. Figure 5 shows that the Digital Twin Consortium’s cross-domain stack (ingest → model → federation → apps), which visually illustrates the reference-architecture guidance.

Figure 5.

ISO/IEC 23247-aligned digital-twin reference architecture [60].

To make the standards linkage explicit, Figure 5 summarizes an ISO/IEC 23247-1 [52] aligned reference architecture for manufacturing digital twins. The view highlights the domain/Entity decomposition and the interfaces between the observable manufacturing layer, device communication & control, the digital twin core, and the user/application domain. This organization mirrors the ISO 23247 series’ guidance for semantically consistent integration across OT/IT boundaries and supports vendor-neutral federation of process/control/enterprise services. Utilizing an ISO-conformant layout alongside plant information models (e.g., ISO 15926 [61] and IEC 62424/CAEX [48]) enhances lifecycle traceability and minimizes integration rework during upgrades.

Integrated view: ISO 15926, ISO 23247, and IEC 62424 form complementary layers — asset/ontology, DT reference architecture, and P&ID/CAD data exchange, respectively. Limitation for FPSO: the standards were not originally authored for offshore-specific semantics (turret systems, risers, topside CRCs), so practical adoption typically requires domain profiles or mapping layers to preserve semantic fidelity across legacy vendor systems.

Adapted from Wallner et al. [60], which implements ISO 23247 in a flexible manufacturing cell and motivates standards-based DT governance.

The ISO 15926 and ISO 23247 standards define fundamental structures for lifecycle interoperability in digital twin environments. However, their direct applicability to the oil and gas (O&G) domain, particularly FPSO topside systems, faces several limitations. Firstly, ISO 15926′s ontology is highly generic and often lacks direct mappings to offshore-specific asset hierarchies such as turret systems, risers, or subsea control modules. Secondly, ISO 23247 focuses on manufacturing-oriented reference models, which do not fully address the harsh operational conditions, safety requirements, and asset integrity constraints of offshore production. Moreover, implementation in O&G projects typically requires extensive customization and vendor-specific extensions, leading to fragmented adoption and limited interoperability between legacy systems. Finally, the integration of these standards with proprietary digital platforms (e.g., AVEVA, Honeywell, Siemens) often introduces challenges related to data ownership and semantic consistency. Despite these limitations, the standards provide a valuable foundation for cross-disciplinary interoperability when adapted to domain-specific ontologies and verified against real FPSO operations.

5.4. General Modeling Approaches

A digital twin’s explanatory power depends on model structure and data treatment. Foundational texts distinguish first-principles (mechanistic) models, derived from conservation laws and constitutive relations, from empirical and hybrid approaches that fuse data-driven elements with physics to meet accuracy and run-time constraints [62]. In practice, engineers iterate across three layers: (i) structure selection (lumped vs. distributed, linear vs. nonlinear, continuous vs. hybrid); (ii) parameter/state estimation; and (iii) validation under operating variability. For plants with limited instrumentation, grey-box identification (e.g., continuous-time state-space with physically meaningful parameters) is preferred because it encodes constraints while leveraging data to capture unmodelled losses [63]. Receding horizon controllers and anomaly detectors benefit from feature-robust preprocessing, gap filling, outlier rejection, resampling, and normalization, applied consistently to both historian archives and live streams so that offline-trained observers behave identically online [62,63]. For brownfield twins, a pragmatic workflow is: start from a mechanistic baseline, add surrogate terms only where residuals persist, and re-estimate parameters as feed composition and ambient conditions drift.

Machine learning has also been applied to production forecasting across the petroleum value chain. Recent studies show that regression techniques and neural networks can capture nonlinearities in flow rate and pressure profiles, enabling more accurate prediction of production performance compared with traditional empirical models. These applications highlight the importance of robust data preprocessing—such as gap filling, outlier rejection, resampling, and normalization—when dealing with noisy and incomplete field data, ensuring that models trained on historical records generalize effectively to real-time operational conditions [64].

5.5. Complex Nonlinear Systems

Compressor trains and gas-processing subsystems exhibit nonlinear, multi-domain dynamics (thermofluid–mechanical–control) [65]. The gas-turbine literature consolidates templates for identification, simulation, condition monitoring, and optimal control that can be directly applied to compression trains [66]. Reviews emphasize mixed-fidelity stacks, fast reduced models for estimation and control, backed by high-fidelity thermo-fluid simulations for map generation and validation [67]. Practically, engineers linearize around multiple operating points to design gain-scheduled or LPV controllers, while maintaining a nonlinear plant model for surge-margin verification and trip studies [66,67]. Model reduction and regularization are essential to avoid overfitting and to guarantee real-time execution in the twin.

5.6. Bond-Graph and Causal Approaches

Bond graphs provide an energy-based, domain-agnostic formalism where power variables (effort/flow) yield conservative interconnections and explicit causality. This helps detect algebraic loops early, design observers that respect conservation laws, and compose reusable sub-models [65]. Industrial practice pairs bond-graph schematics with equation-oriented implementations to obtain numerically well-posed models under switching and fault scenarios [68]. In power process applications, bond graph-derived causal models of boilers, condensers and shaft trains have been validated against dynamic tests, supporting controller design and fault isolation logic [69,70].

5.7. Modelica and Equation-Based Object-Oriented Modeling

Why Modelica. Modelica is a declarative, equation-based, object-oriented language that supports multi-domain acausal modeling with strong typing and modularity, well-suited to plant-wide twins spanning thermofluid and mechanics [13].

Libraries. Mature, peer-reviewed libraries such as ThermoPower/ThermoCycle provide compressor–turbine shaft trains, heat-exchangers and cycle components with validated media and flow models [14,71,72,73].

Scaling up. Large-scale studies report strategies for robust initialization, over-determined start-up, and efficient hybrid-system simulation, enabling long transient runs needed for start-up/shutdown and trip analysis [72,74]. For co-simulation, FMU export integrates Modelica components into broader DT orchestration.

Methodology synthesis: First-principles approaches (bond graphs, Modelica) supply physical correctness and causal structure; LPV and gain-scheduled strategies bridge nonlinear control design; hybrid and surrogate methods deliver runtime tractability. Practical deployment demands composing these methods in a tiered fashion: validated first-principle cores for safety-critical verification plus reduced/hybrid layers for real-time control and fleet analytics.

5.8. Object-Oriented Patterns (Recent Advances)

Beyond language choice, modeling patterns determine maintainability and code generation for real-time twins. Recent work (e.g., LIED) shows how linear-implicit formulations improve robustness for stiff thermo-fluid networks and enable deterministic step sizes on resource-constrained edge hardware [75]. Open toolchain advances (OpenModelica) streamline optimization, debugging and verification at scale, which is critical when twins must be requalified after changes to control logic or equipment [13]. For turbo-machinery and energy-conversion subsystems, nonlinear dynamics and strong cross-couplings demand control-oriented reduced models and robust identification. The gas-turbine modeling literature consolidates identification, simulation, condition monitoring and optimal control for highly nonlinear plants, offering templates transferable to compressor-train subsystems of topsides [69].

Table 6 summarizes the principal data structure strategies and modeling approaches underpinning oil & gas digital twin implementations. The comparison covers architectural, security, interoperability, and modeling aspects, from real-time edge–cloud orchestration to domain-agnostic formalisms such as bond graphs and equation-based modeling with Modelica. Each method’s core purpose, distinguishing features, and representative references are outlined, providing a reference framework for selecting the appropriate combination of methods for scalable, secure, and accurate twin deployment. The table demonstrates that practical twin implementation requires a stacked approach, integrating low-latency architectures, robust cybersecurity, open standards, and modeling methodologies tuned for both physical fidelity and operational constraints.

Table 6.

Comparative Overview of Data Structures and Modeling Approaches for Oil & Gas Digital Twins.

6. Topside Configuration and Process Plant and a Real Case Study

To illustrate how the above considerations come together, we examine a representative case: the standard of FPSO processing plant design used in Brazil’s pre-salt fields.

6.1. Brazilian Pre-Salt Standard FPSO—Specifics on the Process Plant

Scope and resolution. The Brazilian Pre-Salt fields present unique challenges for process plants, most notably concerning the high gas-to-oil ratio and the presence of contaminants. In response, operators have adopted a standardized solution for some Pre-Salt fields. These platforms were built using a common design, a strategy made possible because the produced fluid from different wells presents similar processing challenges. The topside of this FPSO covers the hydrocarbon and utility systems that materially influence production rate, energy use, and safety barriers (separation train, compression, gas dehydration, refrigeration, flare and relief, fuel gas, steam, cooling media, metering) [57]. Each unit operation is represented by a first-principles model calibrated to site data and linked to the P&ID/CAE environment to preserve tag-level traceability. Lifecycle and tag semantics follow ISO 15926 reference data so that equipment, function, and signal identities remain stable across projects and operations, while IEC 62424 provides the P&ID ↔ CAE data-exchange mapping that keeps instrument/logic requests synchronized with the digital twin [48,53]. The model granularity is chosen to satisfy the use cases: steady-state fidelity for mass/energy reconciliation and planning, and dynamic fidelity where surge/slug, trip, or start-up/shutdown transients must be reproduced for operator training and advisory.

Data bindings and governance. Real-time bindings include: (i) time-stamped process measurements, (ii) controller set-points and modes, (iii) calculated properties from the EOS package, and (iv) events/alarms. All tags are typed and versioned under an ISO 15926 information model; instrument requests and loop associations follow IEC 62424 CAEX-based exchange, so engineering changes propagate consistently to the twin. These standards ensure the FPSO can be validated, audited, and handed over between EPC and operator without loss of meaning [48,53].

6.2. Compressor Design and Performance Data

Minimum constructive dataset. Centrifugal/axial compressor sub-models require wheel stack and casing geometry (impeller outlet/inlet diameters and widths, blade counts/angles, diffuser type and throat area, return channel geometry), rotor train configuration (single-shaft vs. integrally geared, shaft speeds/gear ratios, bearings, seal type/clearances), inlet guide vane settings, side stream locations/flows, cooling type, allowable operating envelope, and design/guarantee points [65,78]. API 617 (9th Ed., 2022) specifies the minimum design/verification data and mechanical clearances for axial and centrifugal process compressors used in petroleum and gas service, while ASME PTC 10-2022 provides the test procedures and acceptance methodology for deriving and certifying performance maps and uncertainty [79]. Constructive data are reconciled with factory PTC-10 test reports and site performance tests to initialize the twin, and subsequent map-scaling or remapping follows PTC-10 guidance when gas composition or sidestream conditions differ from shop tests [79].

Operational envelope and control. The FPSO embeds the verified performance maps (head/efficiency vs. corrected flow and speed) and surge/stonewall margins, enabling realistic anti-surge, load-sharing and fuel-minimization studies across compression trains. Where expander-compressors are present, API 617 clauses for expander-compressors govern additional constructive and control data requirements [79]

6.3. Fluid Properties

Equation-of-state (EOS) selection. Property packages underpinning the topside twin must reproduce real-gas effects over the plant envelope (gas, liquid, and two-phase) [80]. For natural-gas-dominant mixtures, the GERG-2008 wide-range EOS (Helmholtz explicit) remains the reference mixture model, providing density, enthalpy, speed of sound, and phase behavior across pipeline to cryogenic conditions [19]. For LNG-region accuracy, EOS-LNG refines GERG-2008 binary departure functions to reproduce high-accuracy liquid-phase data, achieving <0.05% AARD in key binaries and improving bubble/dew-point predictions [81]. In custody/measurement contexts or hydrogen-rich mixtures, AGA8-DC92 [82] may be preferred or used for validation because of established practice and specified uncertainty bounds; comparative studies show circumstances where AGA8-DC92 remains advantageous for certain mixtures, while GERG-2008 offers broader region coverage and phase-equilibrium consistency [19,81,82,83].

Integration into the twin. The EOS package supplies compressibility, isentropic exponent, viscosity/thermal conductivity (with suitable correlations), and flash calculations to the compressor and separator models, so surge lines, anti-surge margins, and machine corrected-flow computations are thermodynamically consistent with the operating gas. EOS choices and parameter limits are documented and version-controlled within the FPSO to maintain V&V traceability against plant tests [19,79,81,82,84].

6.4. Verification, Validation & Certification (VVC)

Operational deployment of digital twins in safety-critical environments depends on demonstrable credibility under recognized standards. Class-society and agency guidance converges on tiered evidence for verification, validation and uncertainty quantification (VVUQ), including explicit statements of model form, code verification, data-source quality and quantified predictive uncertainty [50,51]. Emerging recommended practices add governance for change control, evidence retention and lifecycle management of the twin, and introduce cryptographic mechanisms to lock validated baselines for auditability [85]. Recent surveys synthesize statistical and physics-based approaches and highlight the need for automated regression testing to preserve certification as models evolve [50,51]. To establish credibility and trustworthiness, a rigorous workflow for verification, validation, and uncertainty quantification (VVUQ) is essential for safety-critical digital twins. This process, as outlined in works such as Unal et al. [86], involves several sequential and iterative steps. These include code and solution verification to ensure the model’s accuracy; validation against targeted benchmarks after a Phenomena Identification and Ranking Table (PIRT) analysis; and calibration via data assimilation to align the model with real-world data. The workflow concludes with forward uncertainty quantification (UQ) to assess the model’s domain of validity, enabling risk-informed decision-making crucial for regulated oil and gas applications.

Table 7 synthesizes the core specifications required to configure a validated, standards-compliant topside process plant digital twin. The comparison spans four main categories: (i) FPSO specifics, detailing scope, modeling granularity, and real-time data bindings; (ii) compressor constructive data, covering the minimum geometry, performance, and standard compliance requirements; (iii) fluid properties, focusing on equation-of-state selection and integration into thermodynamic models; and (iv) V&V, outlining recognized best practices for demonstrating and maintaining model credibility. By mapping these practices to authoritative standards and peer-reviewed sources, the table offers a practical reference for engineering teams tasked with developing or auditing digital twins for offshore topside applications.

Table 7.

Comparative Overview of Topside Configuration and Process Plant Digital Twin Specifications.

Adhering to these specifications and practices (as summarized in Table 7) ensures that the digital twin can be trusted for operational decision support and regulatory compliance, thereby accelerating adoption in actual FPSO operations.

7. Summary of Reference Sources

To provide a comprehensive overview of the literature base supporting this study, the classification of the references used is presented at the end of the manuscript. Accordingly, the related tables have been relocated to the final section of the paper. Table 8 summarizes the distribution of reference sources by type, including peer-reviewed journal articles, books, theses, industrial standards, technical reports, vendor reports, and professional or industry publications.

Table 8.

Summary of Sources by Type.

Table 8 summarizes the distribution of all sources used in the current review by type (Peer-reviewed journal articles, books, theses, industrial standards, technical reports, vendor reports, and professional and industry sources).

Table 9 summarizes the distribution of reviewed works by category and focus area.

Table 9.

Distribution of Reviewed Sources by Thematic Cluster.

8. Latest Developments and Future Directions

Digital twin research and deployment in the oil and gas industry have accelerated in recent years, aligning with the industry’s digital transformation initiatives [87]. Latest developments include more automated twin creation, integration of AI, and broader adoption of standards:

- Automation and Scalability: As seen with Sierla et al. [38] and Santillán Martínez [37], there is a push toward automating the generation of twins for existing facilities. This involves using artificial intelligence to parse engineering documents and sensor logs to build the twin’s model. A related development is the concept of a self-updating or adaptive twin. Walmsley et al. [88] introduced the concept of adaptive digital twins for energy-intensive industries, which can adjust their fidelity or scope according to the current needs (for example, simplifying certain aspects to focus computational power on a critical subsystem during an anomaly). This adaptability helps manage computational load and maintain real-time performance.

- Integration of AI/ML: Modern digital twins increasingly incorporate machine learning for anomaly detection, predictive analytics, and even controlling complex systems. The combination of physics-based models with data-driven models (hybrid twins) leverages the strengths of both: physics models ensure consistency with known laws and provide extrapolation capability, while ML models can capture subtle patterns and uncertainties from historical data. There is also a trend of using DTs to generate synthetic data for training AI, as demonstrated by Aiken et al. [46]. This is particularly useful when real failure data is scarce—a twin can simulate failure scenarios to augment training datasets for predictive maintenance algorithms.

- Edge Computing and 5G: With the advent of 5G networks and better edge computing hardware, deploying parts of the twin closer to the field equipment is becoming practical. This reduces latency for critical control decisions. For instance, a compressor’s twin might run directly on a rugged edge computer at a remote compressor station, ensuring that if a surge condition is detected, the system can respond immediately to prevent damage. Meanwhile, cloud connectivity allows less time-sensitive analysis and fleet-level aggregation (comparing twins of multiple similar assets to identify best practices or deviations).