Study on the Internal Flow Field in the Tip Clearance of a Kaplan Turbine

Abstract

1. Introduction

2. Numerical Methodology

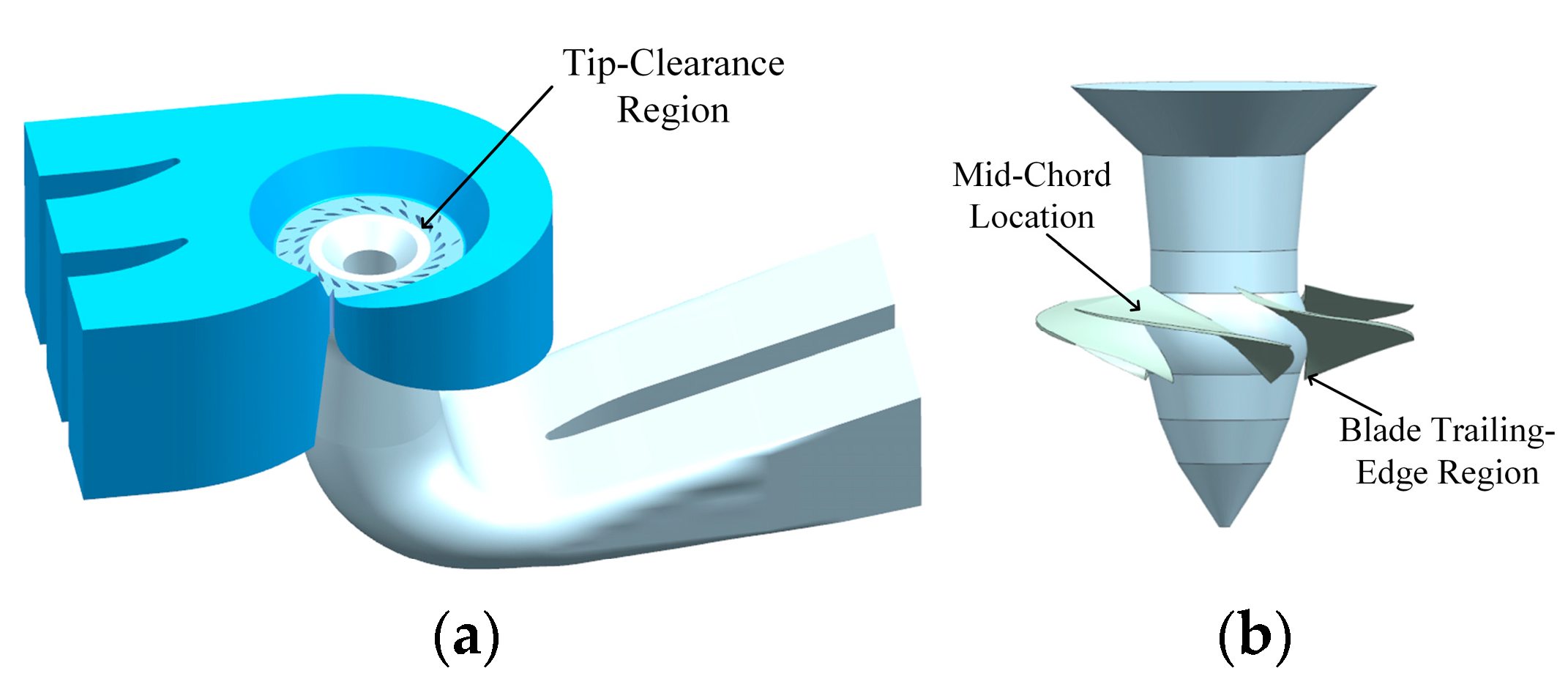

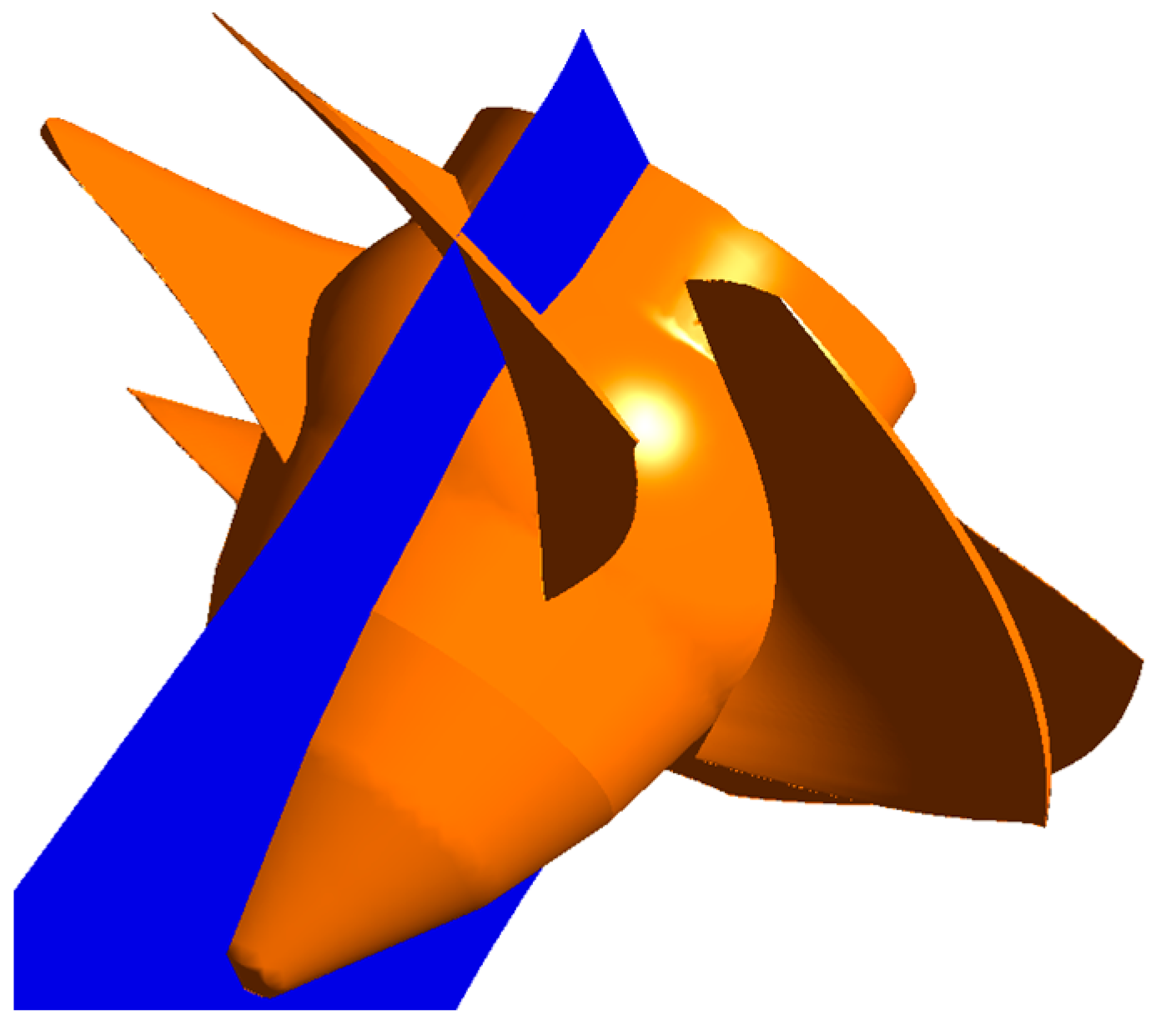

2.1. Computational Model of the Turbine

2.2. Mathematical Model

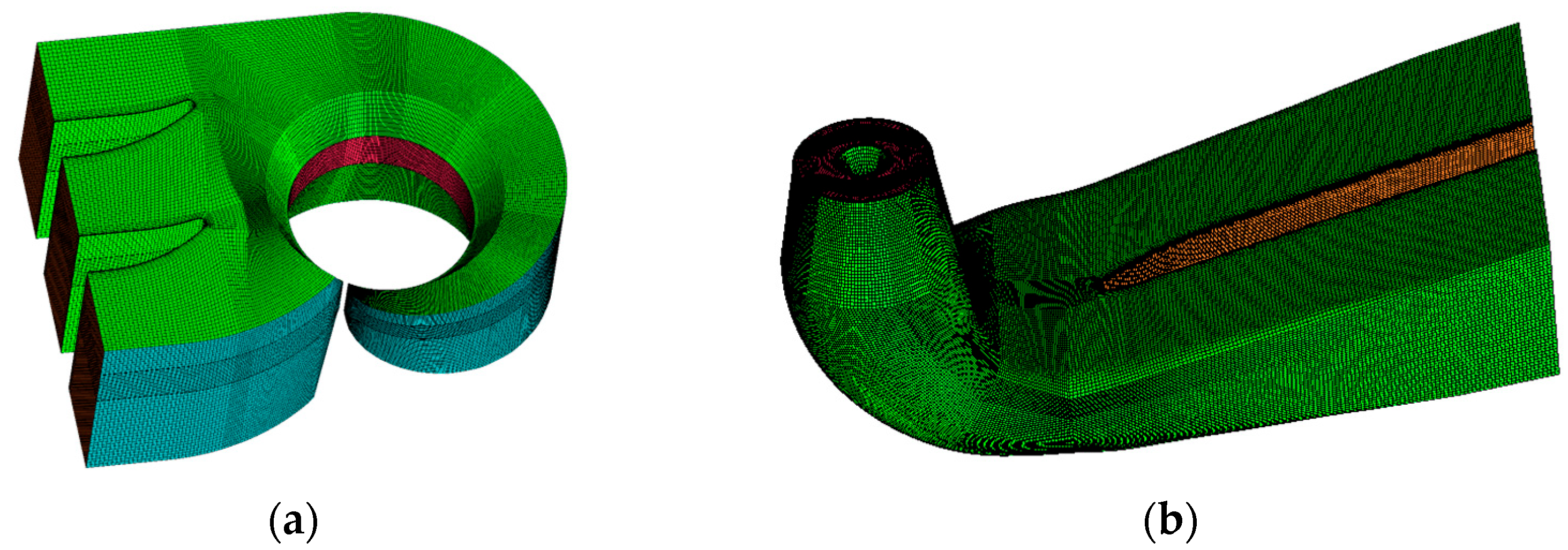

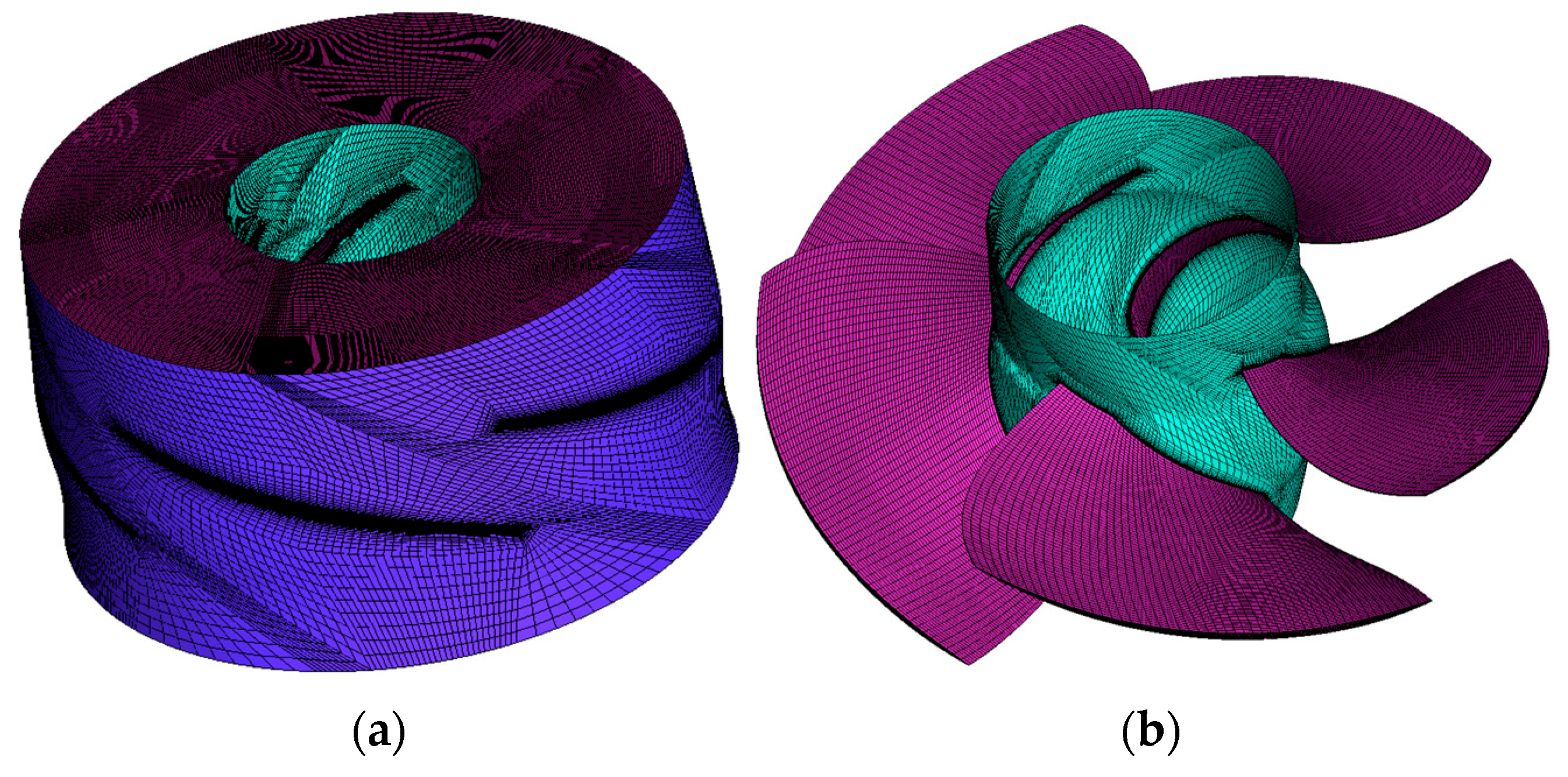

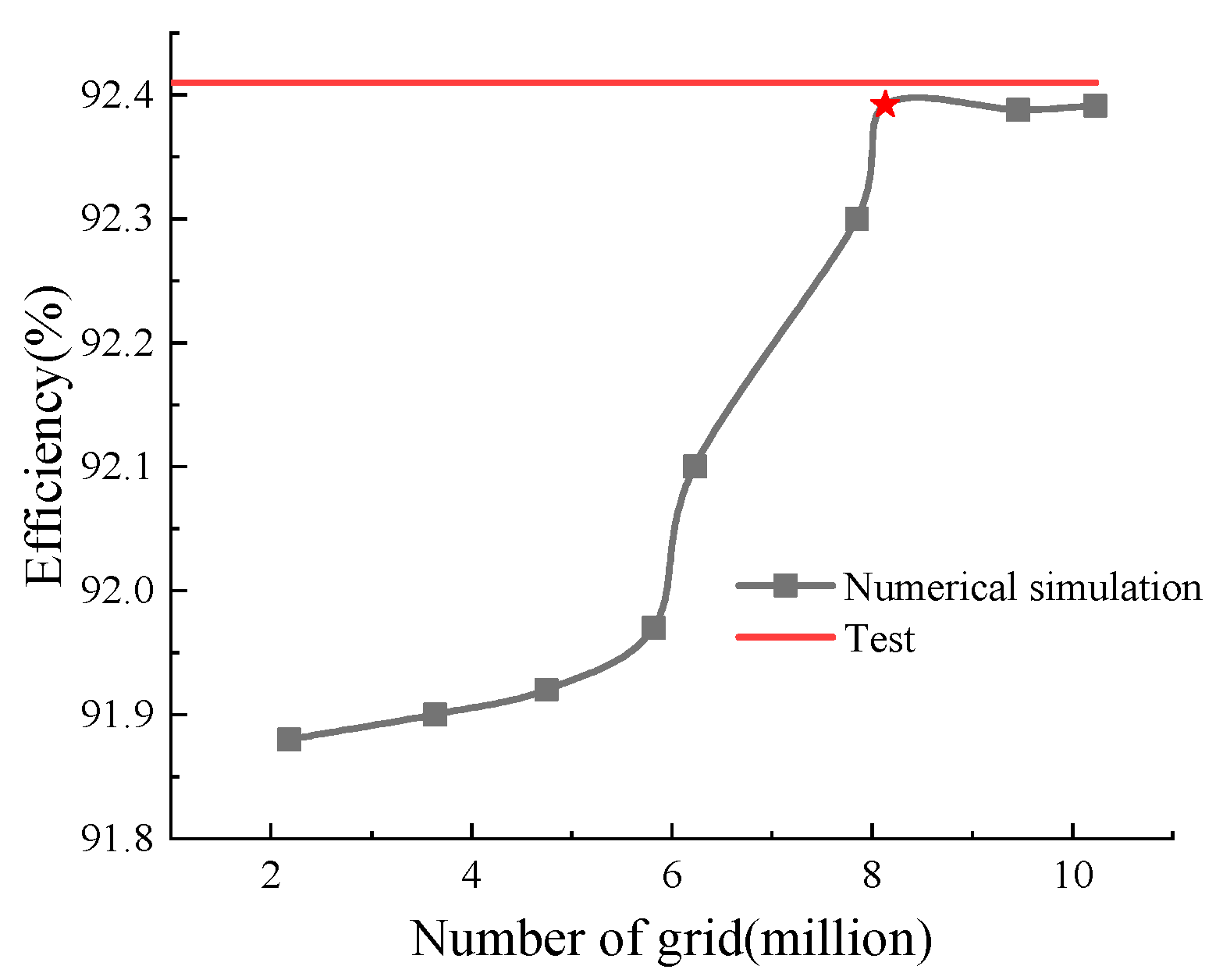

2.3. Grid Generation and Independence Verification

2.4. Boundary Conditions and Time-Step Independence

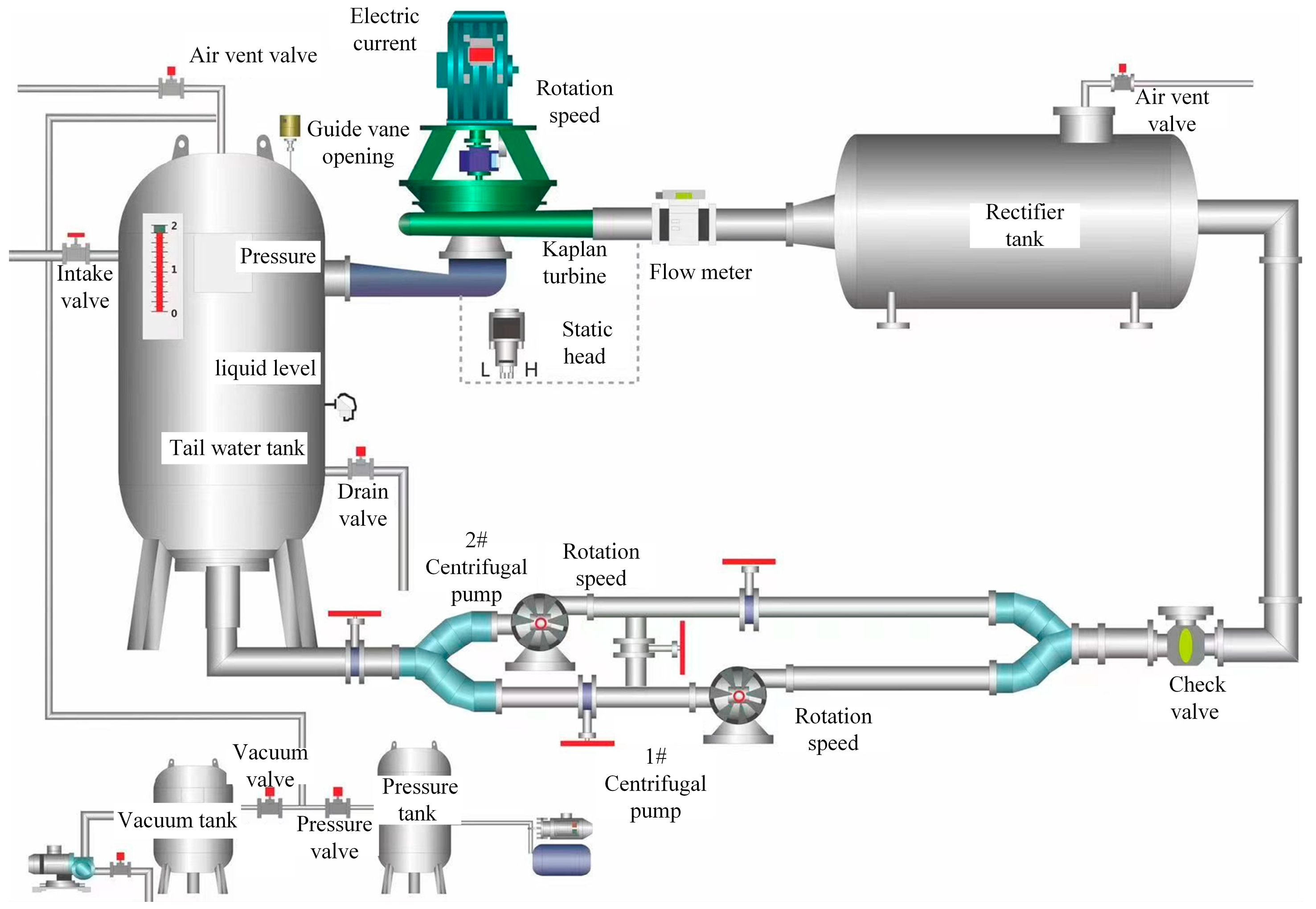

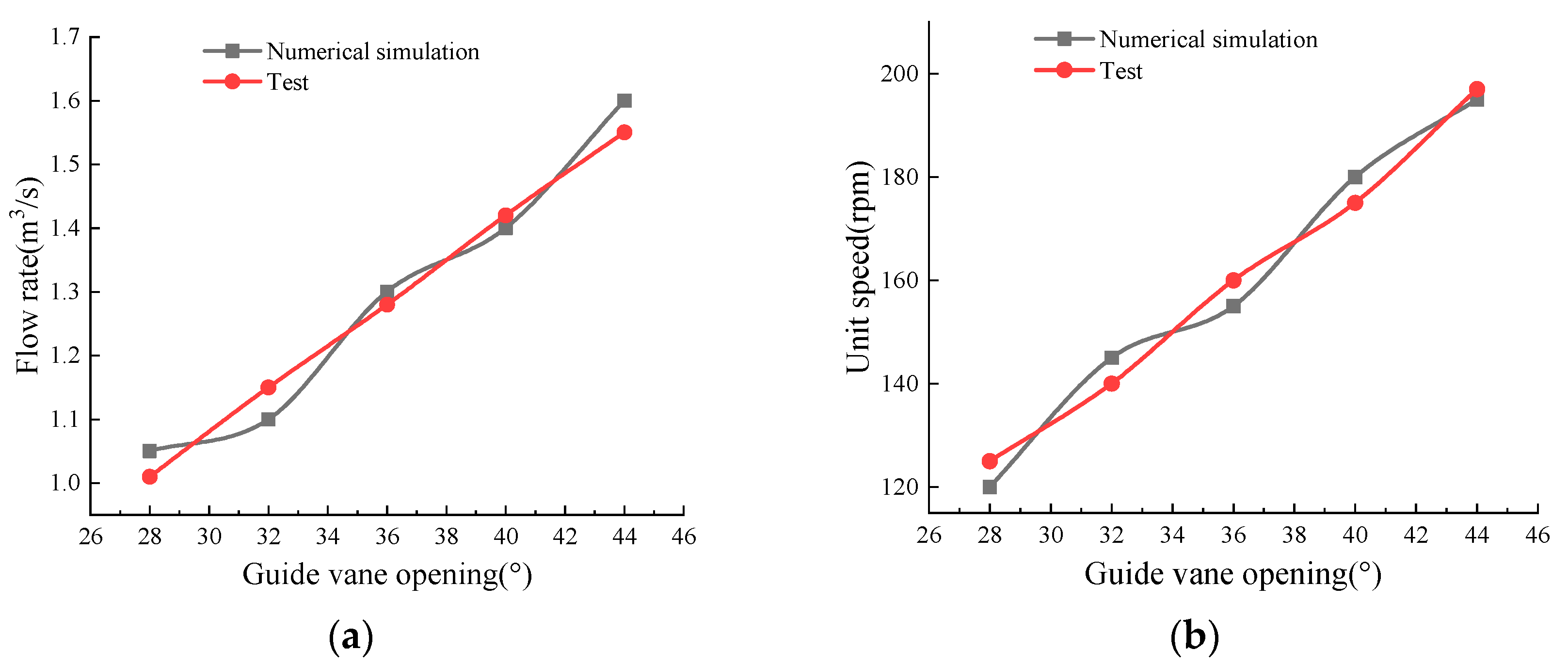

2.5. Experimental Validation

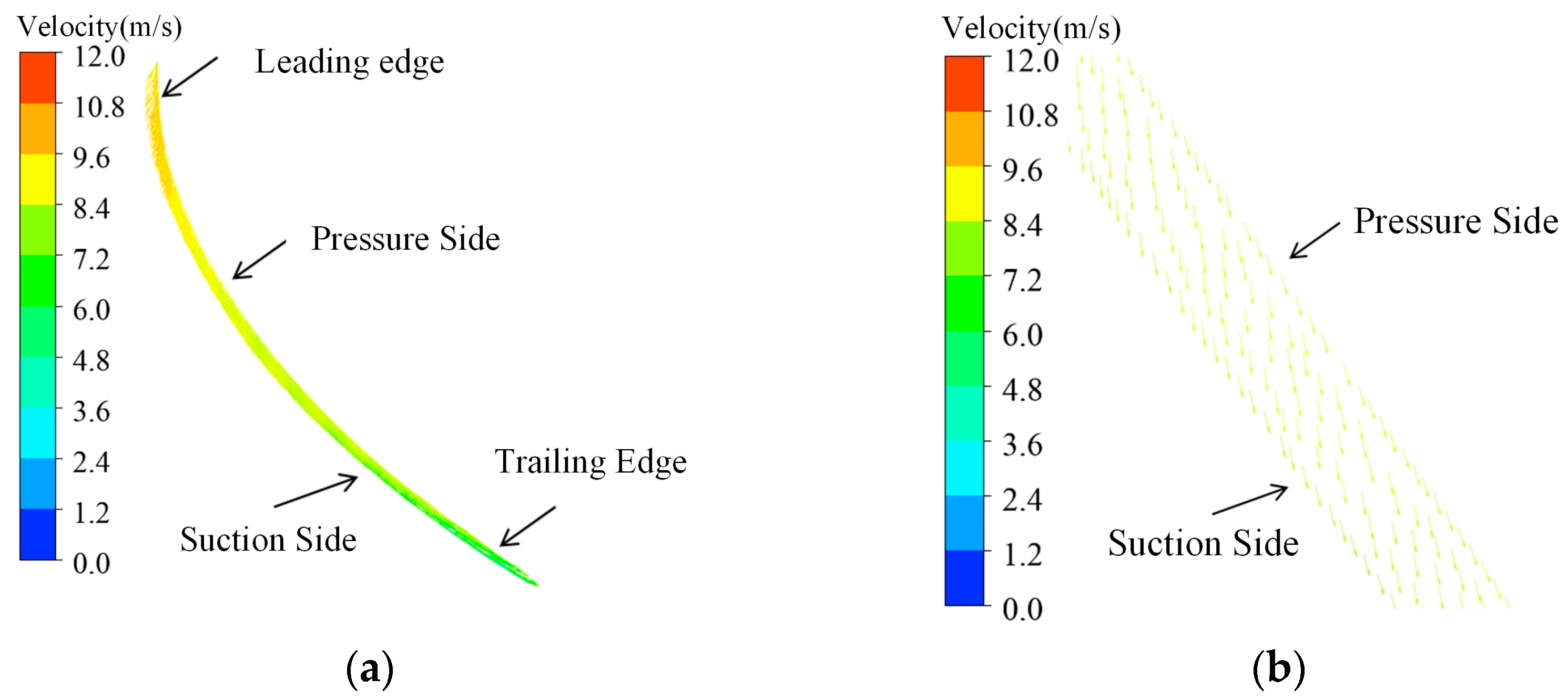

3. Investigation of the Flow Field Within the Blade-Tip Clearance of a Kaplan Turbine

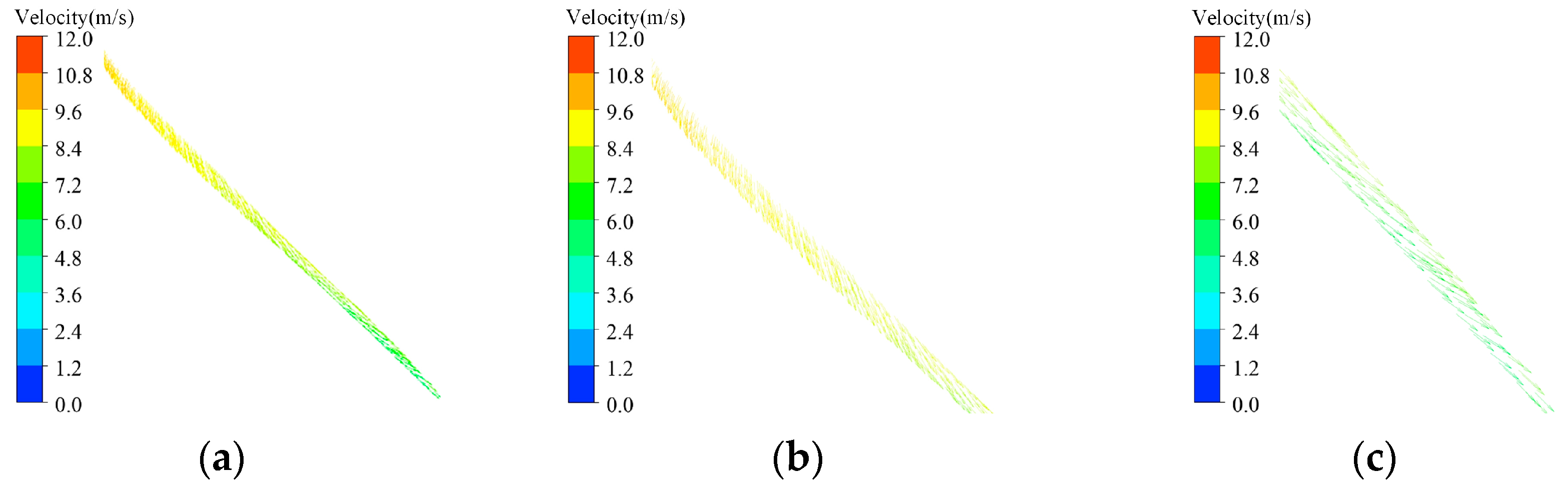

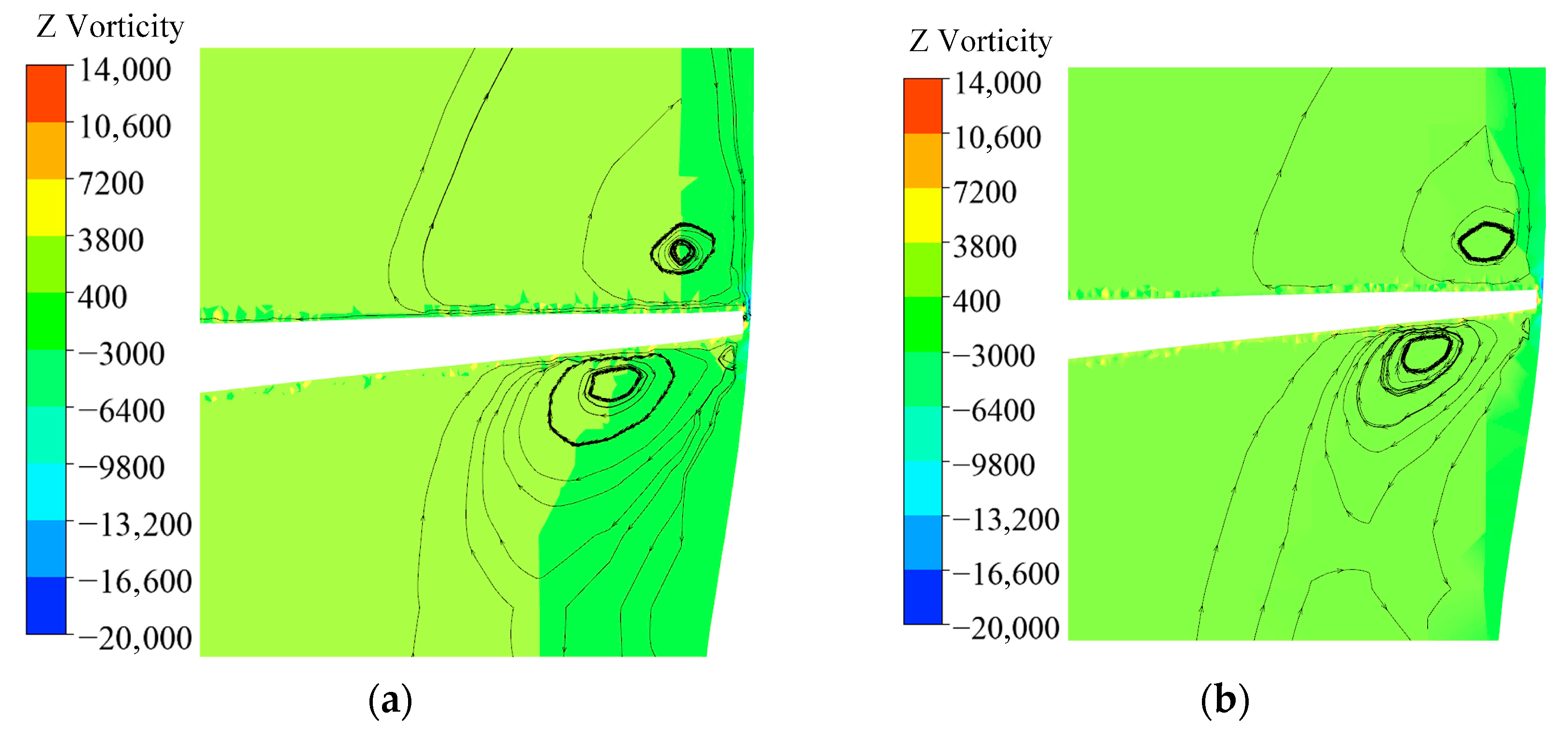

3.1. Influence of the Tip Clearance on the Runner Flow Field Under Different Operating Conditions

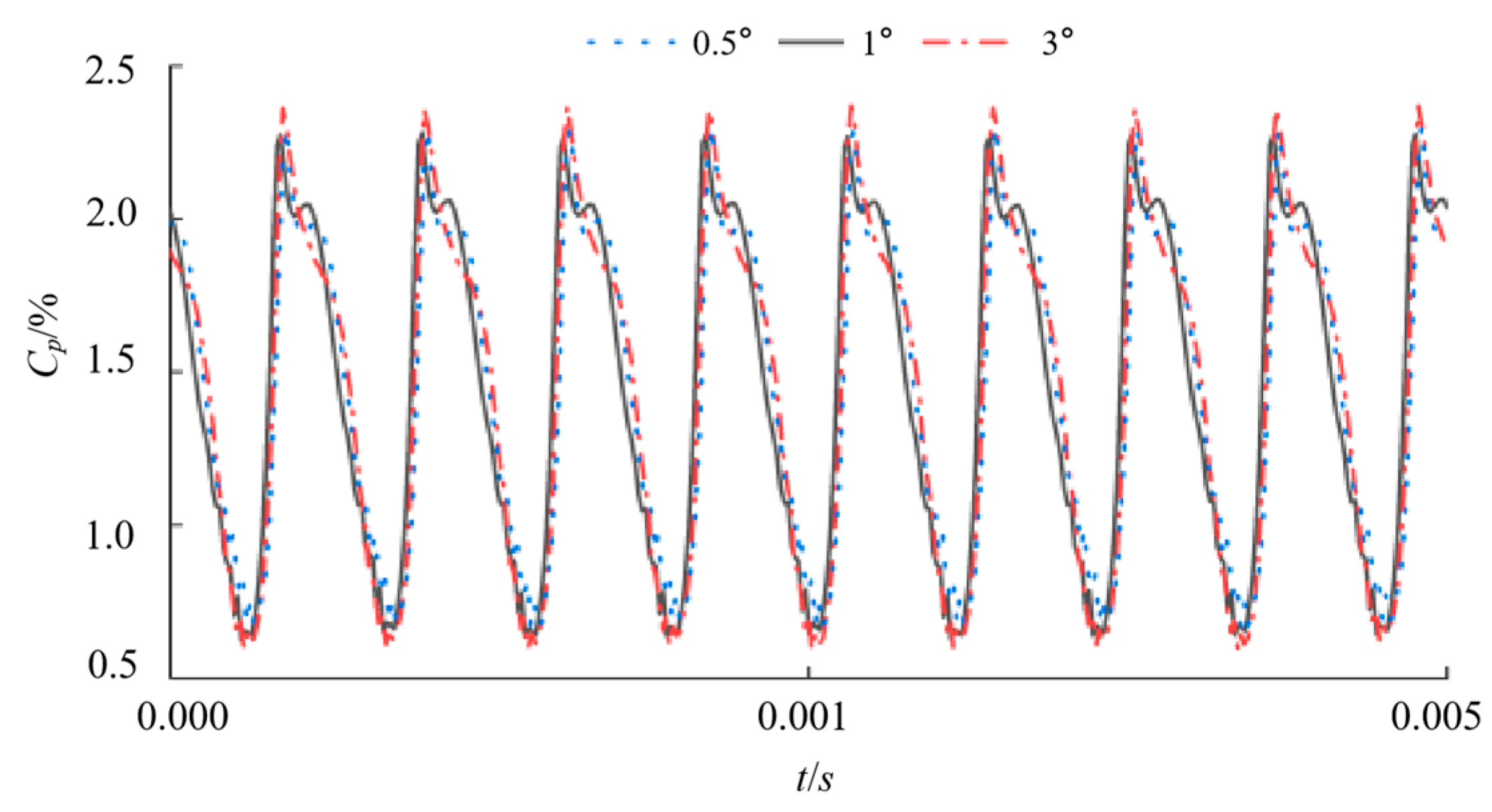

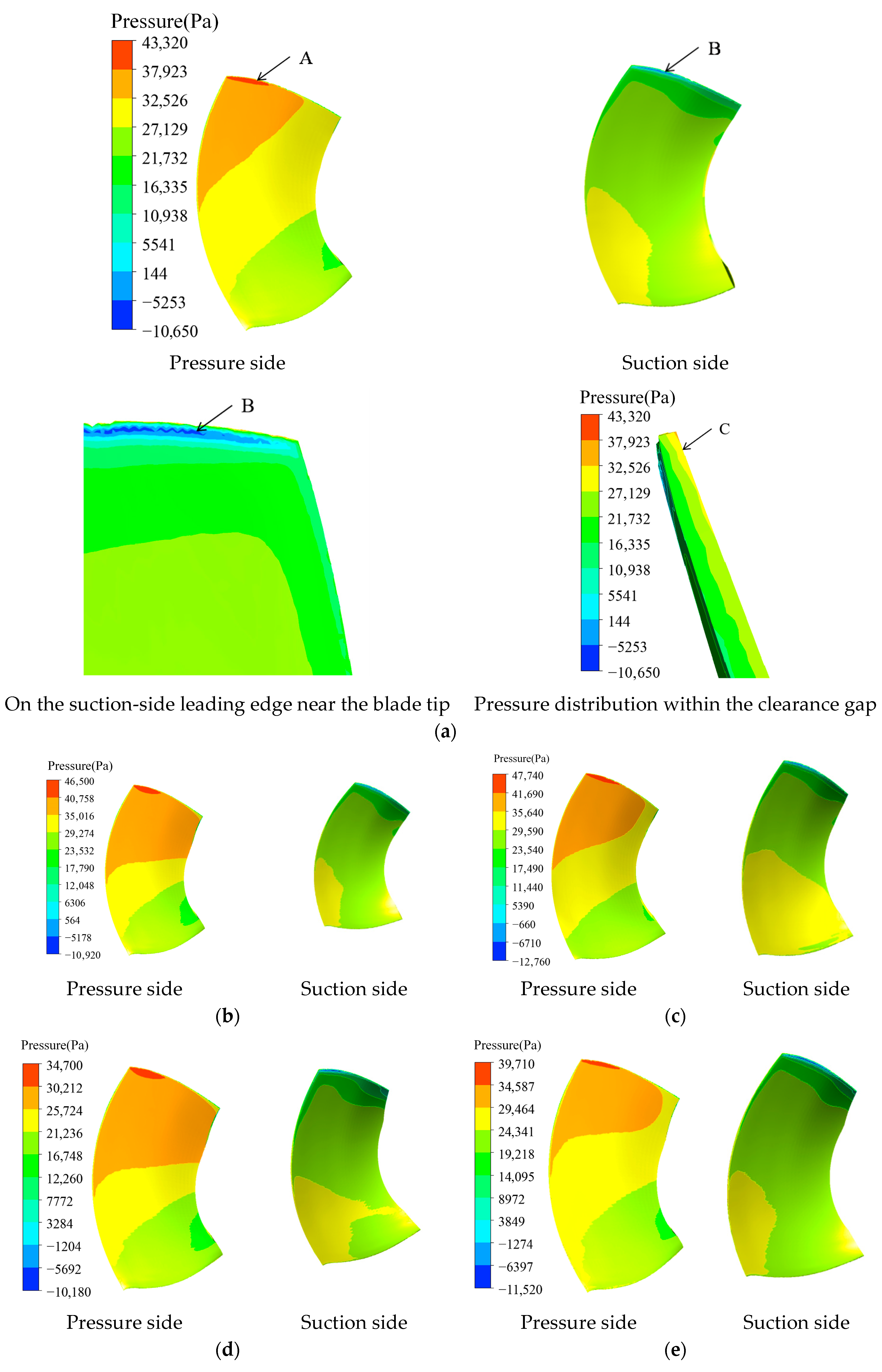

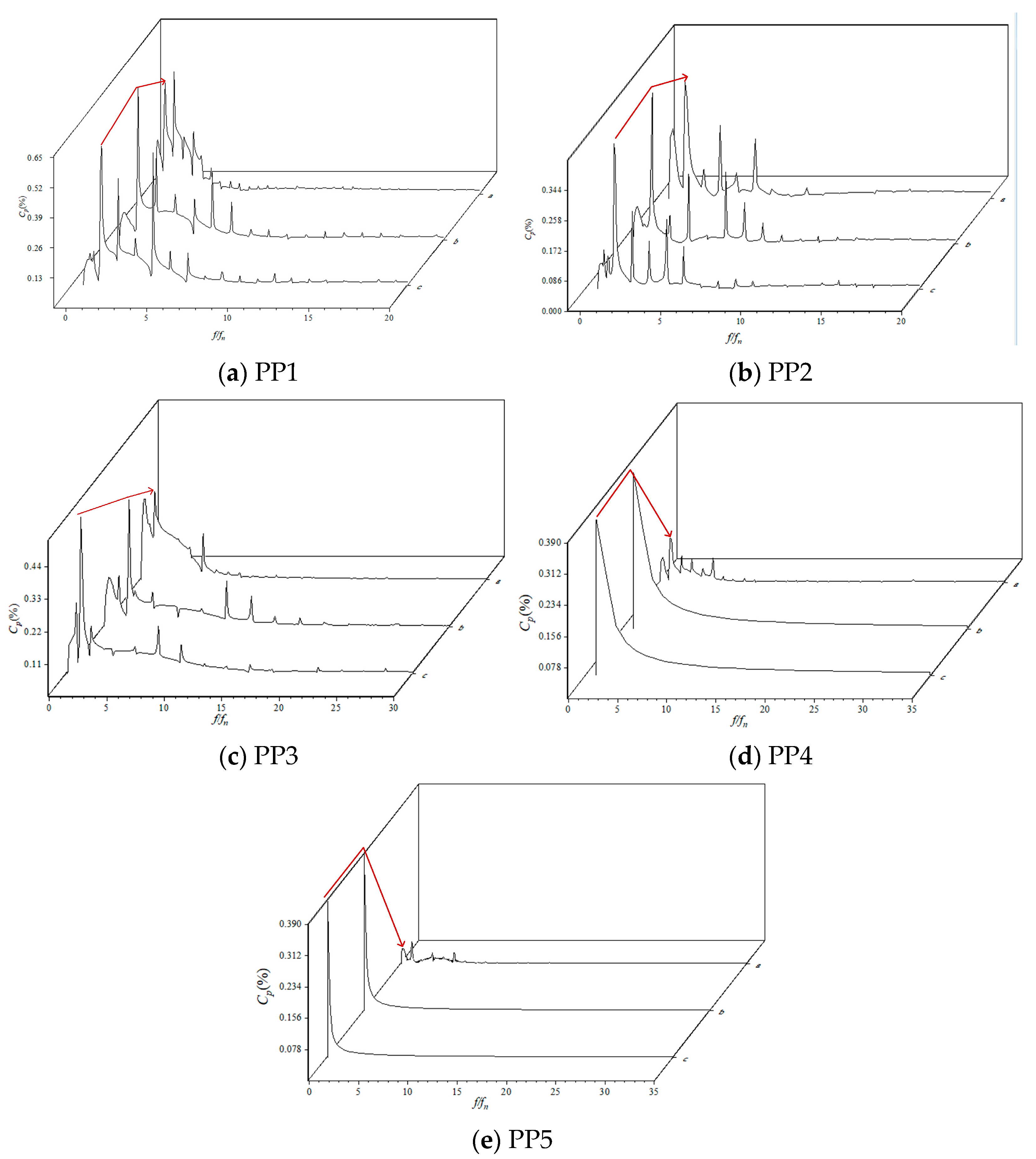

3.2. Blade-Surface Pressure Pulsation in the Tip Clearance Under Different Operating Conditions

4. Conclusions

- The tip clearance alters the local flow direction at the blade tip. At low discharge the leakage runs from the pressure side to the suction side, whereas at high discharge the rear part of the gap experiences a reverse flow from the suction side back to the pressure side.

- Under on-cam operation the blade pressure distribution is the most uniform, the turbine efficiency reaches its maximum, and the hub-corner vortices attain their minimum strength.

- Pressure-pulsation analysis shows that the peak Cp in the clearance region is about 1. The frequency spectrum is dominated by 1 fn and 2 fn, indicating that rotor rotation and clearance-leakage vortices are the main sources of blade-tip pressure fluctuation. The influence of these vortices is confined to the leading-edge and mid-chord portions of the tip clearance; the trailing-edge region is practically free of clearance-induced pulsation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Zheng, Y.; Zhao, Y.; Tao, Y.; Hui, J. Development path and prospects for renewables becoming the dominant energy source under the carbon-neutral vision (Part 1). China Energy 2021, 43, 7–13. [Google Scholar]

- Chen, M. Overview of global small-hydropower development. China Power Enterp. Manag. 2017, 13, 88–89. [Google Scholar]

- Semenova, A.V.; Zakharov, A.V.; Seleznev, V.N.; Chernyshev, V.D. Adaptation of Kaplan Turbines for Operation Under New Conditions of Continuous Control: Secondary Frequency Regulation. Power Technol. Eng. 2025, 1–6. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Chen, Y.; Jin, H. Preliminary analysis of the causes for the loss of on-cam relationship in Kaplan turbines. Sichuan Water Power 2010, 29, 122–123. [Google Scholar]

- Ma, W.S. Simulation of the Whole Passagein Prototype Turbine and Analysis of Precisionin Calculation; China Agricultural University: Beijing, China, 2005; p. 3. [Google Scholar]

- Hu, Z.; Liu, Q.; Wang, X.; Fang, M.; Chen, T.; Tao, R.; Ding, J.; Zhu, D.; Xiao, R.; Wang, H. Prediction of runner eccentricity and Alford force of a Kaplan turbine based on variational mode decomposition. Energy Sci. Eng. 2024, 12, 1569–1591. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, T.; Li, J.; Yu, J. Experimental Study of Load Variations on Pressure Fluctuations in a Prototype Reversible Pump Turbine in Generating Mode. J. Fluids Eng. Trans. ASME 2017, 139, 74501. [Google Scholar]

- Yan, D.; Chen, S.; Ren, P.; Zhao, W.; Chen, X.; Liu, C.; Zhou, L.; Wang, Z. Vibration and Flow Characteristics of a 200 MW Kaplan Turbine Unit under Off-Cam Conditions. Machines 2024, 12, 586. [Google Scholar] [CrossRef]

- Ruprecht, A.; Heitele, M.; Helmrich, T. Numerical Simulation of a Complete Francis Turbine Including Unsteady Rotor/Stator Interactions; IAHR: Madrid, Spain, 2000. [Google Scholar]

- Amiri, K.; Mulu, B.; Cervantes, J.M. Experimental investigation of the interblade flow in a Kaplan runner at several operating points using laser doppler anemometry. J. Fluids Eng. 2015, 138, 21106. [Google Scholar] [CrossRef]

- Motycak, L.; Skotak, A.; Obrovsky, J. Analysis of the Kaplan turbine draft tube effect. IOP Conf. Ser. Earth Environ. Sci. 2010, 12, 12038. [Google Scholar] [CrossRef]

- Matsunuma, T. Unsteady Flow Field of an Axial-Flow Turbine Rotor at a Low Reynolds Number. J. Turbomach. 2007, 129, 360–371. [Google Scholar] [CrossRef]

- Pang, J.; Liu, H.; Liu, X.; Yang, H.; Peng, Y.; Zeng, Y.; Yu, Z. Study on sediment erosion of high head Francis turbine runner in Minjiang river basin. Renew. Energy 2022, 192, 849–858. [Google Scholar] [CrossRef]

- Liu, J.; Liu, X.; Chang, X.; Qin, B.; Pang, J.; Lai, Z.; Jiang, D.; Qin, M.; Yao, B.; Zeng, Y. Research on the mechanism of sediment erosion in the bucket of a large-scale Pelton turbine at a hydropower station. Powder Technol. 2025, 455, 120805. [Google Scholar] [CrossRef]

- Liu, J.; Liu, X.; Gang, Y.; Yao, B.; Xie, B.; Pang, J.; Lan, G.; Zhang, X. Study of multiphase flow and sediment erosion of large Pelton turbine bucket in sandy river. Phys. Fluids 2025, 37, 83384. [Google Scholar] [CrossRef]

- Chen, F.N.; Lei, H.M.; Ahn, S.H.; Fan, H.G.; Jiang, X.P.; Hu, J.W.; Zhang, J.; Luo, Y.Y.; Wang, Z.W. Numerical simulation of the performance of a low-head prototype Kaplan turbine. IOP Conf. Ser. Earth Environ. Sci. 2018, 163, 12070. [Google Scholar] [CrossRef]

- Shamsuddeen, M.M.; Park, J.; Choi, Y.-S.; Kim, J.-H. Unsteady multi-phase cavitation analysis on the effect of anti-cavity fin installed on a Kaplan turbine runner. Renew. Energy 2020, 162, 861–876. [Google Scholar] [CrossRef]

- Dreyer, M.; Decaix, J.; Münch, C.; Farhat, M. Mind the gap-tip leakage vortex in axial turbines. IOP Conf. Ser. Earth Environ. Sci. 2014, 22, 52023. [Google Scholar] [CrossRef]

- Rivetti, A.; Lucino, C.; Liscia, S.; Muguerza, D.; Avellan, F. Pressure pulsation in Kaplan turbines: Prototype-CFD comparison. IOP Conf. Ser. Earth Environ. Sci. 2012, 15, 62035. [Google Scholar] [CrossRef]

- Sirojuddin; Tony; Dewi, N.S.; Zahara, A.A.; Jumhur, A.A. Investigation of variation of inner blade height of the five blade runner on the kaplan turbine against turbine power. AIP Conf. Proc. 2024, 2836, 070007. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Number of runner blades Z | 5 | Number of guide vanes | 24 |

| Guide-vane height b0 (mm) | 150 | Runner diameter D1 (mm) | 400 |

| Runner blade pitch range (°) | −12~12 | Guide-vane opening range (°) | 18~54 |

| Turbulence Model | Computational Efficiency (%) | Rated Efficiency (%) | Relative Error |

|---|---|---|---|

| Standard k-ε | 86.67 | 92.41 | −5.74 |

| RNG k-ε | 92.38 | 92.41 | −0.03 |

| SST k-ω | 91.24 | 92.41 | −1.17 |

| Component | Cell Count | Node Count | Minimum Orthogonality (°) |

|---|---|---|---|

| Spiral casing | 995,116 | 949,352 | 11.2231 |

| Stay vane | 582,687 | 51,430 | 16.3518 |

| Guide vane | 242,239 | 112,177 | 12.4756 |

| Runner | 3,617,175 | 4,051,420 | 12.1647 |

| Draft tube | 3,390,811 | 3,732,350 | 26.2382 |

| Total | 8,128,028 | 7,896,729 | \ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, Z.; Jiang, H.; Li, Z.; Liu, J.; Liu, X.; He, Z.; Xu, K. Study on the Internal Flow Field in the Tip Clearance of a Kaplan Turbine. Processes 2025, 13, 3479. https://doi.org/10.3390/pr13113479

Lai Z, Jiang H, Li Z, Liu J, Liu X, He Z, Xu K. Study on the Internal Flow Field in the Tip Clearance of a Kaplan Turbine. Processes. 2025; 13(11):3479. https://doi.org/10.3390/pr13113479

Chicago/Turabian StyleLai, Zhenming, Hang Jiang, Zhen Li, Jitao Liu, Xiaobing Liu, Zhaobin He, and Kang Xu. 2025. "Study on the Internal Flow Field in the Tip Clearance of a Kaplan Turbine" Processes 13, no. 11: 3479. https://doi.org/10.3390/pr13113479

APA StyleLai, Z., Jiang, H., Li, Z., Liu, J., Liu, X., He, Z., & Xu, K. (2025). Study on the Internal Flow Field in the Tip Clearance of a Kaplan Turbine. Processes, 13(11), 3479. https://doi.org/10.3390/pr13113479