3.1. Orthogonal Experimental Design

To reduce the cutting force during the finishing process, obtain the optimal combination of process parameters, and ensure that the surface quality of the small impeller was at its best, the orthogonal experimental method was selected for process parameter optimization. This is because orthogonal experiments not only reduce the number of experiments but also ensure that the values of each group of factors are both global and representative.

The primary process parameters affecting the surface quality of small impellers during finishing are spindle speed

, feed per tooth

, axial cutting depth

, and radial cutting depth

. These four primary process parameters were selected as the influencing factors for the orthogonal experiment design, and a four-factor, four-level orthogonal experiment table was designed, as shown in

Table 2.

3.2. Simulation Experiment Design and Result Analysis

Finite element simulation technology has a high degree of automation, so finite element simulation software is used to perform simulation analysis on small impellers. However, due to the complex overall structure of small impellers, they are affected by many factors during the manufacturing process, and finite element simulation cannot take all factors into account. To reduce computer simulation time without affecting the accuracy of the results [

4].

The following settings were made for the simulation:

- (1)

The workpiece material was selected from the aluminum alloy library, with a plastic material constitutive model.

- (2)

During the simulation process, the tool is prone to wear, so an elastoplastic material was selected as the tool type, with WC-type cemented carbide as the tool material.

- (3)

The temperature remains constant at 20 °C.

- (4)

The friction system is a constant value with a friction coefficient of 0.6.

- (5)

The workpiece material number selected from the library is Al7075-T6, as it exhibits good plastic mechanical properties after solution treatment [

5].

Finite element simulation analysis was performed on 16 different process parameter combinations in an orthogonal experiment. One blade was selected as the simulation object. The simulation was terminated when the force on the tool path stabilized after initial fluctuations. The changes in milling force in the X, Y, and Z directions were obtained. The milling force values in the three directions under different process parameter combinations are shown in

Table 3.

Select the multi-factor analysis of variance function method to analyze the simulation data results in

Table 3, and derive the degree of influence of the four process parameters on the milling force, as shown in

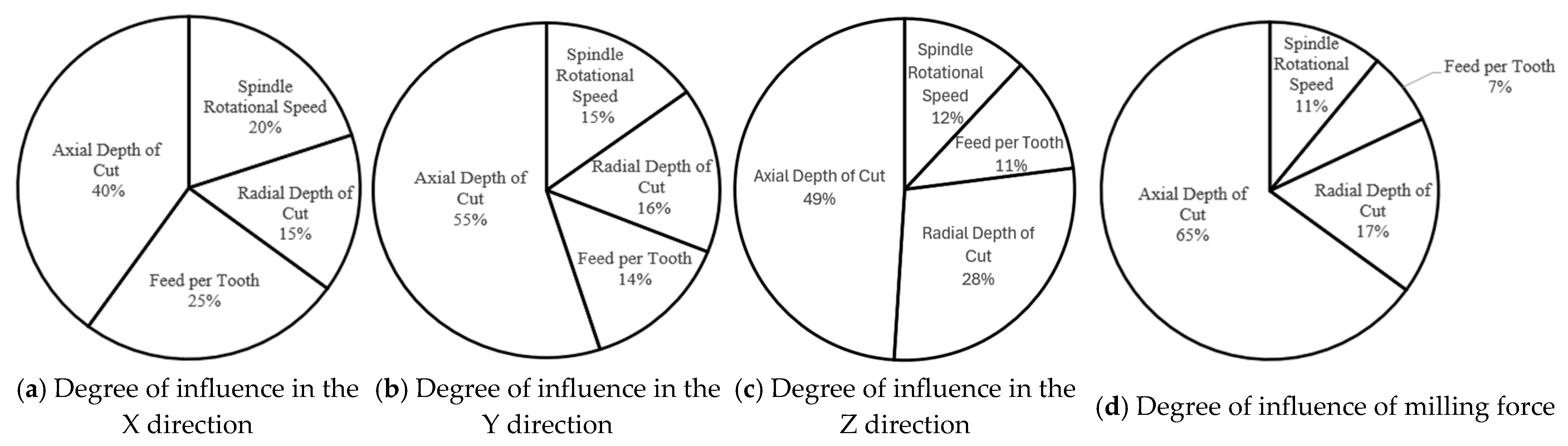

Figure 2 below.

Figure 2a shows the degree of influence in the

X-direction,

Figure 2b shows the degree of influence in the

Y-direction,

Figure 2c shows the degree of influence in the

Z-direction and

Figure 2d shows the degree of influence of milling joint force.

Based on the above analysis, we can conclude that:

- -

The influence of X-direction process parameters on milling force is as follows: ap and fZ are the most significant, followed by n and ae.

- -

The influence of Y-direction process parameters on milling force is as follows: ap and fZ are the most significant, followed by ae and n.

- -

The influence of Z-direction process parameters on milling force is as follows: ap and ae are the most significant, followed by fZ and n.

- -

The degree of influence of process parameters on the milling force is as follows: ap and ae are greater, fZ and n are next.

3.3. Establishment and Validation of a Milling Force Prediction Model

To effectively control and predict the surface quality of small impellers during the machining process, we decided to use the non-linear regression function provided by MATLAB 2020 software to construct a mathematical model of milling force. The standard formula for calculating milling force is defined as shown in Equation (1) according to the Metal Cutting Handbook [

6]:

In Equation (1):

CF is the milling force coefficient,

KFZ is the operating condition coefficient, and

XFZ,

YFZ,

YFZ,

WF are the indices of various cutting parameters. According to the above formula, the milling force is directly related to the four selected process parameters, and thus, it is necessary to determine the exponent corresponding to each parameter. In this experiment, considering the machining material of the small impeller and the selected cemented carbide ball-end mill, the above formula was simplified, and the resulting expression is presented in Equation (2).

In this experiment, the processing material of the impeller and the selected carbide ball-end milling cutter were simplified and took logarithm in Equation (2), the result is shown in Equation (3):

If

Equation (2) can be transformed into Equation (4):

After substituting the 16 sets of experimental data from the orthogonal array into Equation (2), calculations were performed using a non-linear regression function. On this basis, the accurate values of each coefficient of the milling force were calculated, respectively, and prediction models for the milling forces in the X, Y, and Z directions as well as the resultant milling force were established.

The correlation coefficient of the predicted milling force in the resulting model is

The correlation coefficient in the prediction model for the X-direction milling force is

The correlation coefficient in the prediction model for the Y-direction milling force is

The correlation coefficient in the prediction model for the Z-direction milling force is

On the basis of the correlation coefficients obtained from the operation of the aforementioned program, substituting them into Equation (2) further enables the derivation of the prediction models for the milling forces in the

X,

Y, and

Z directions as well as the resultant milling force, which are, respectively, given by Equations (5)–(8):

To verify the accuracy and reliability of the model, four sets of simulation results were randomly selected for validation. The theoretical values of the milling force were compared with the measured values, as shown in

Table 4.

Based on the comparison results in

Table 4, the average error of the milling force in the

X-direction is 1.26%, the average error in the

Y direction is 0.88%, and the average error in the

Z-direction is 1.05%. From the average errors, it can be concluded that the predicted values are generally consistent with the measured values, proving that the model is accurate and reliable [

7].

3.4. Establishment of a Mathematical Model for Surface Quality Evaluation Indicators

3.4.1. Establishment of Surface Roughness Model

Milling experiments were conducted using 7075 aluminum alloy rods. Based on the orthogonal test plan table, multiple actual processing tests were carried out, and surface roughness values were measured for different parameter combinations. To ensure measurement accuracy, multiple blades of the impeller were selected for measurement, and the average value of the measurement results was taken. The results are recorded in

Table 5.

A multi-factor analysis of variance was performed on the results in

Table 5, and the four process parameters were found to have the following order of influence on surface roughness:

>

>

>

. During the milling process of small impellers, the surface roughness decreases as

and

decreases and increases as

and

increases. The variation regularity of the surface roughness of 7075 aluminum alloy processing was verified, proving the correctness of the established model [

8]. The mathematical expression for surface roughness is shown in Equation (9):

In the equation:

Ra is the surface roughness value; μm,

C1 is the correction coefficient;

is the exponent of each process parameter. After converting both sides of Equation (9) to their logarithmic forms, the result is shown in Equation (10):

After multiple iterations using MATLAB program code, the final prediction model for surface roughness was obtained and shown in Equation (11):

3.4.2. Residual Stress Model Establishment

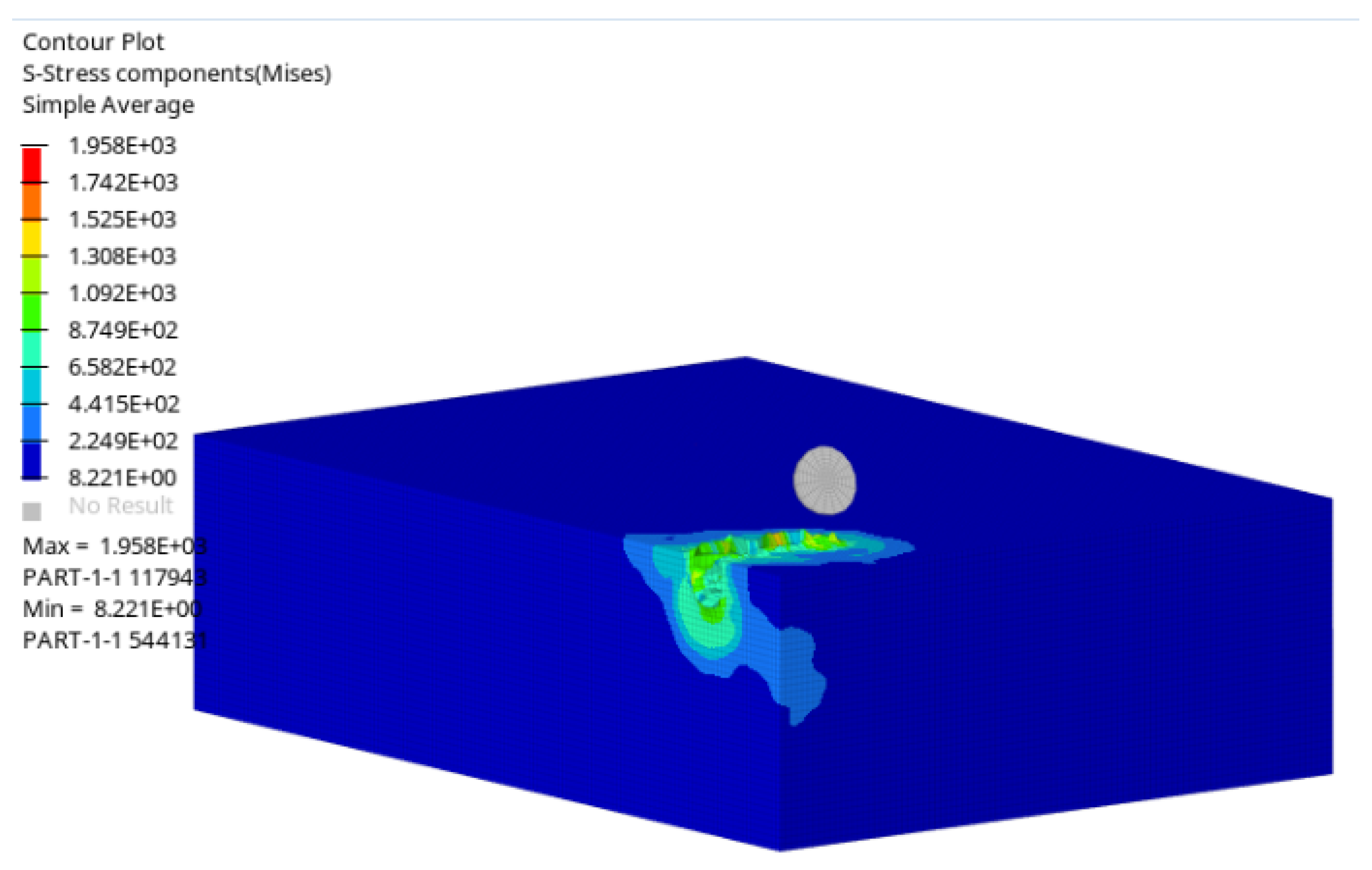

In finite element simulation, complex workpieces and tools are typically simplified to reduce computation time and ensure the accuracy of results [

9]. This paper simplifies the blades of the small impeller into

size workpieces and selects a 2° ball-end milling cutter as the tool. The models of the workpiece and tool are created in the 3D software NX 12.0 and exported.

Simulation analysis is then conducted in the ABAQUS 2020 software. For computational efficiency, the tool is simplified by excluding the tool holder and retaining only the tool head. The ball-end mill is modeled as a rigid body, with tool wear effects neglected. The C3D8R element type is employed for discretization, which exhibits reduced susceptibility to shear self-locking under bending loads, thereby demonstrating superior performance in bending-dominated problems. Additionally, this element provides relatively accurate displacement solutions and maintains solution accuracy even under conditions of mesh distortion or deformation. The tool model consists of 544 elements and 694 nodes, with a seed size of 0.1. The workpiece is discretized using C3D8R reduced-integration hexahedral elements, resulting in 560,000 elements and 583,881 nodes. The total number of elements in the global model is 560,544, with a total of 584,575 nodes. Numerical simulations are performed using the ABAQUS explicit dynamic solver, with a computational time of 0.06 s.

The tool is inclined at a 20° angle relative to the workpiece plane. During the milling process, the tool exhibits a composite motion of high-speed rotation and translation. The milling process simulation is shown in

Figure 3, and the surface residual stresses obtained under different milling process parameter combinations are shown in

Table 6.

A multi-factor analysis of the results in

Table 6 reveals that the variation regularity of surface residual stress under the influence of four process parameters is as follows:

ap >

ae >

fZ >

n. During the milling process of small impellers, residual stress decreases as

ap and

ae decreases, and increases as

n and

fZ increases, consistent with the variation regularity of surface residual stress in 7075 aluminum alloy [

10], thereby validating the accuracy of the established model. Residual stress

σ is also expressed by an exponential function composed of four process parameters, as shown in Equation (12):

In Equation (12):

C2 is the coefficient of the workpiece material and milling conditions;

,

,

,

are the exponents of each processing parameter. Conversion of both sides of Equation (12) to their logarithmic forms is shown in Equation (13):

Let

, then Equation (13) transforms into Equation (14):

In Equation (13), parameters may all be acquired from the preceding experimental data, while the remaining parameters () are derived via computational programming using 16 sets of the aforementioned experimental data in MATLAB.

Finally, after multiple iterations using MATLAB program code, the final residual stress prediction model was obtained, as shown in Equation (15):

3.5. Optimization of Small Impeller Process Parameters Based on Genetic Algorithms

3.5.1. Genetic Algorithm

A genetic algorithm is an optimization algorithm based on the theory of natural selection and the genetic mechanisms of similar species. First, the parameter space is replaced with an encoded space, and then a fitness function is defined and used as the basis for evaluation. The encoded population serves as the basis for population evolution. The iterative process of genetic algorithms is based on selection and genetic mechanisms, achieving random recombination of superior genes in individual bit strings, so that the newly generated offspring population set is superior to the parent population set [

11].

3.5.2. Multi-Objective Optimization Mathematical Model

Through the selection of the above design variables, the determination of constraints, and the establishment of the objective function, a multi-objective optimization mathematical model for small impeller process parameters was obtained, as shown in Equation (16):

In Equation (16), n, nmax and nmin denote the machine tool spindle speed, maximum spindle speed, and minimum spindle speed, respectively, with the unit of r/min; vc, vcmax, and vcmin referring to the machining feed rate, maximum allowable feed rate during machining, and minimum allowable feed rate, respectively, with the unit of mm/min; ap, apmax, and apmin representing the axial depth of cut in the machining process, maximum allowable axial depth of cut, and minimum allowable axial depth of cut, respectively, with the unit of mm; ae, aemax, and aemin standing for the radial depth of cut in the machining process, maximum allowable radial depth of cut, and minimum allowable radial depth of cut, respectively, with the unit of mm.

With specific parameters in Equation (16) held constant, the remaining parameters were systematically varied and analyzed to examine the effect of their variations on the residual stress induced during the machining process of the small impeller. The resulting functional graphs are presented in

Figure 4a–d. The points corresponding to minimum residual stress are selected for optimization, followed by a detailed analysis of the machining parameters of the small impeller.

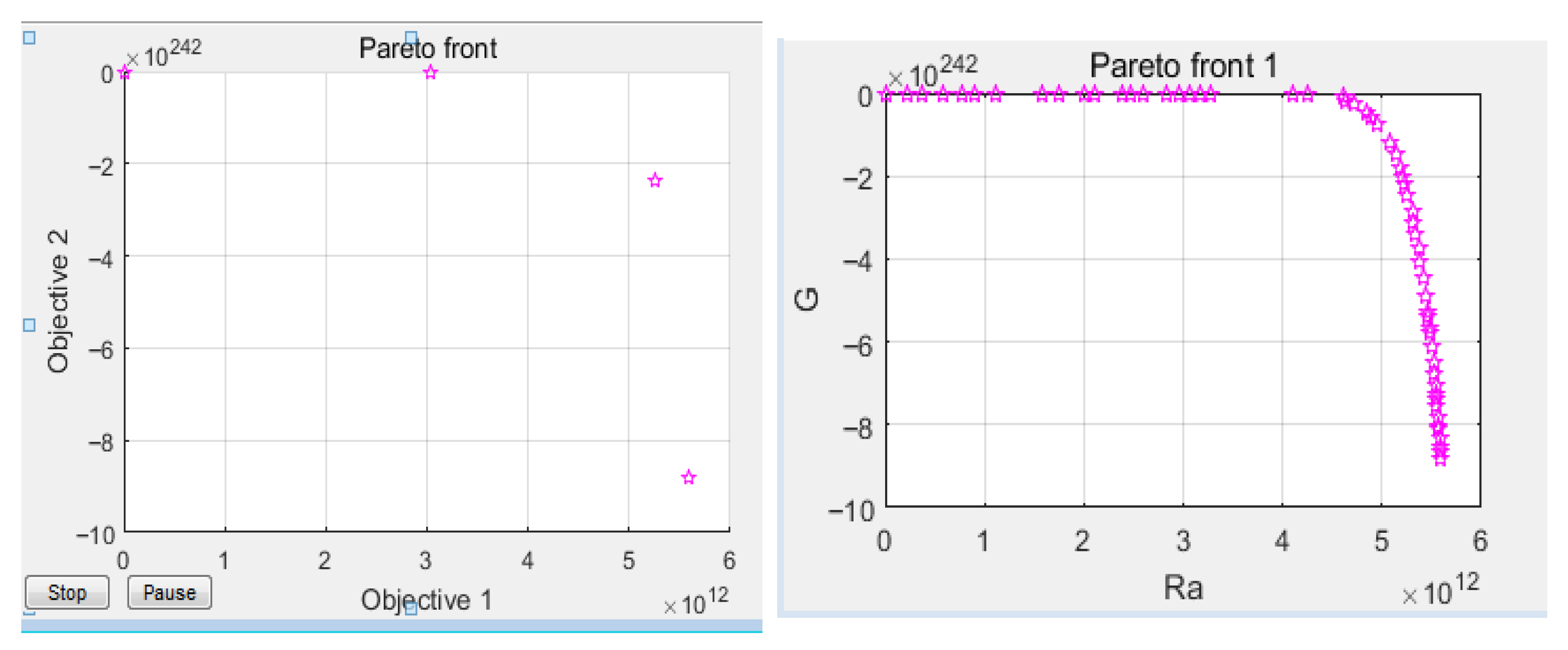

3.5.3. Process Parameter Optimization Based on Genetic Algorithms

For convenience of calculation, Population Size is set to 200, Crossover Fraction is set to 0.9, Migration Fraction is set to 0.15, and Evolutionary Generations is set to 300 [

12]. The results of the program running in MATLAB 2020 are shown in

Figure 5.

The optimal parameter combination obtained is shown in

Figure 5. Within the range of experimental parameters, the optimal solution obtained by MATLAB genetic algorithms

ap and

ae is close to the minimum value, while

n and

fZ take relatively large values, ensuring that surface roughness and residual stress are minimized, thereby improving the surface quality of the small impeller. The corresponding process parameter combination is shown in

Table 7.

3.5.4. CNC Machining Experimental Verification

The optimized process parameters and CNC machining program were applied to the CNC machining experiment of the small impeller. The experimental machine tool selected is Beijing Jingdiao JDGR200A10SH five-axis machining center. After completing the processing, the experimenter used detection instruments to measure the surface roughness and residual stress of the small impeller.

(1) Verify surface roughness

Blades are a critical component in the design and manufacture of small impellers. The surface precision and quality of the blades directly impact the overall mechanical performance of the small impeller [

13]. Strict requirements are imposed on the deformation during the blade manufacturing process, particularly regarding surface roughness, which is

. As shown in

Figure 6, a surface roughness measurement instrument was used to measure the surface roughness of the physical blades of the small impeller before and after optimization of the CNC machining process.

Nine sets of blade surfaces were randomly selected for surface roughness measurement, and the results were compared with those of small impellers processed using unoptimized process parameters. The measurement results are shown in

Table 8.

According to the measurement results in

Table 8, it can be seen that using the optimized process parameters for milling the small impeller reduced the surface roughness by 34.2% and met the processing technical requirements of

Ra ≤ 3.2 μm, indicating that the surface quality of the small impeller processed under the optimized process parameters met the standards and was of good quality.

(2) Verification of residual stress

Measurements were taken at three random points on the small impeller blades using an X-350A X-ray stress tester, and the measurement results for the random points on the blades are shown in

Table 9,

Table 10 and

Table 11.

Based on the average measurement results of three random points, the optimized residual stress value is 129.7, which is 28.6% lower than the pre-optimization value of 181.6. This indicates that the surface quality of the small impeller processed under the optimized process parameters meets the standards and is of good quality.

After comparing the results before and after testing, it was found that when processing was carried out using the unoptimized process parameters, the small impeller flow channels were extremely narrow, leading to tool breakage, and the surface quality of the processed small impellers did not improve. However, when CNC machining was performed using the optimized process parameters, the CNC machine operated stably during processing, and no tool interference or collisions occurred. The tool’s service life was significantly extended. After parameter optimization, the surface roughness and residual stress of the small impeller were both reduced compared to the values before optimization. This indicates that the optimized process parameters can improve the surface quality of the small impeller.