Effects of the Fluctuating Wind Loads on Flow Field Distribution and Structural Response of the Dish Solar Concentrator System Under Multiple Operating Conditions

Abstract

1. Introduction

2. Finite Element Model and Mathematical-Physical Model

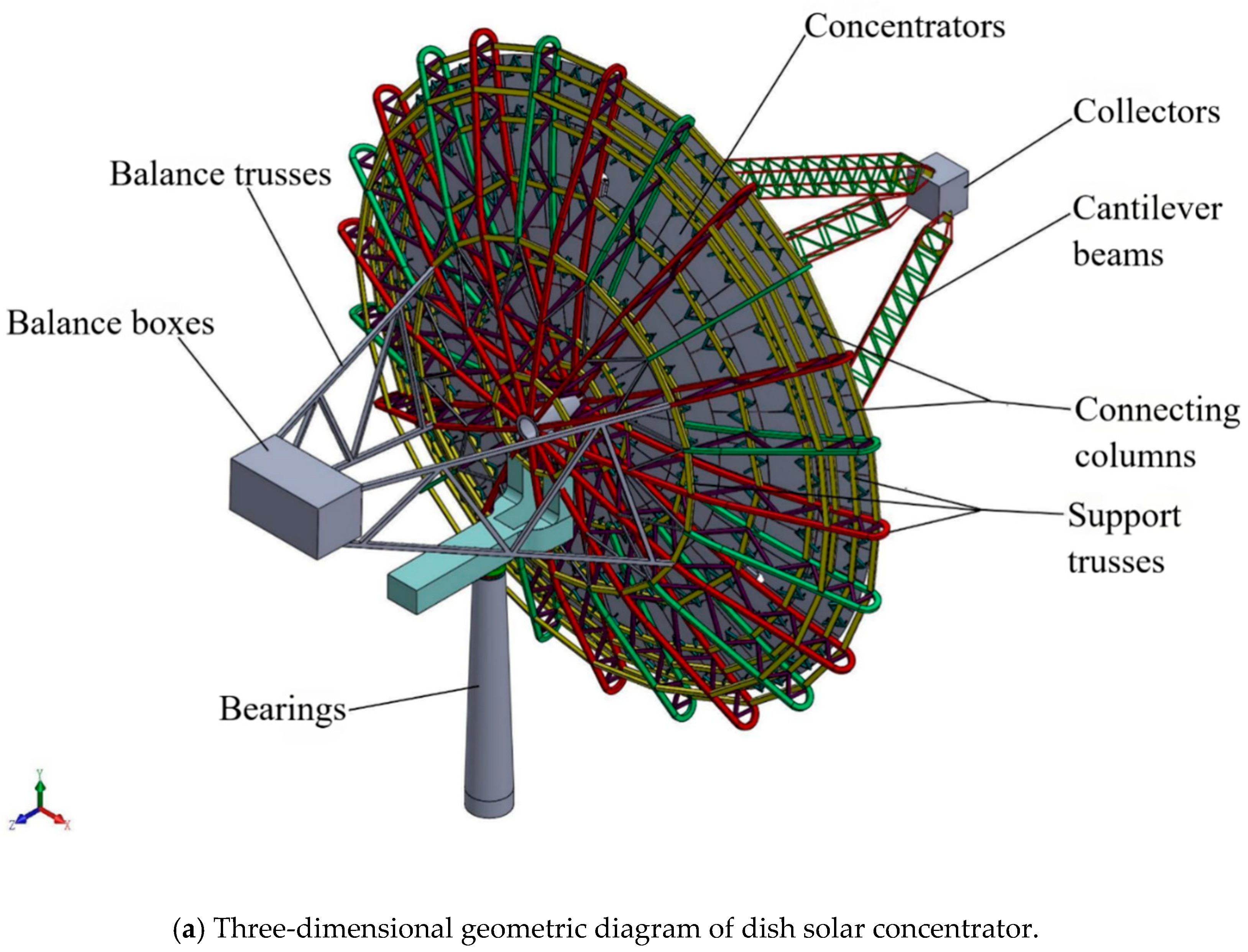

2.1. Establishment of Finite Element Simulation Model for Concentrators

2.2. Mathematical-Physical Model

2.2.1. Governing Equations for Fluid Motion

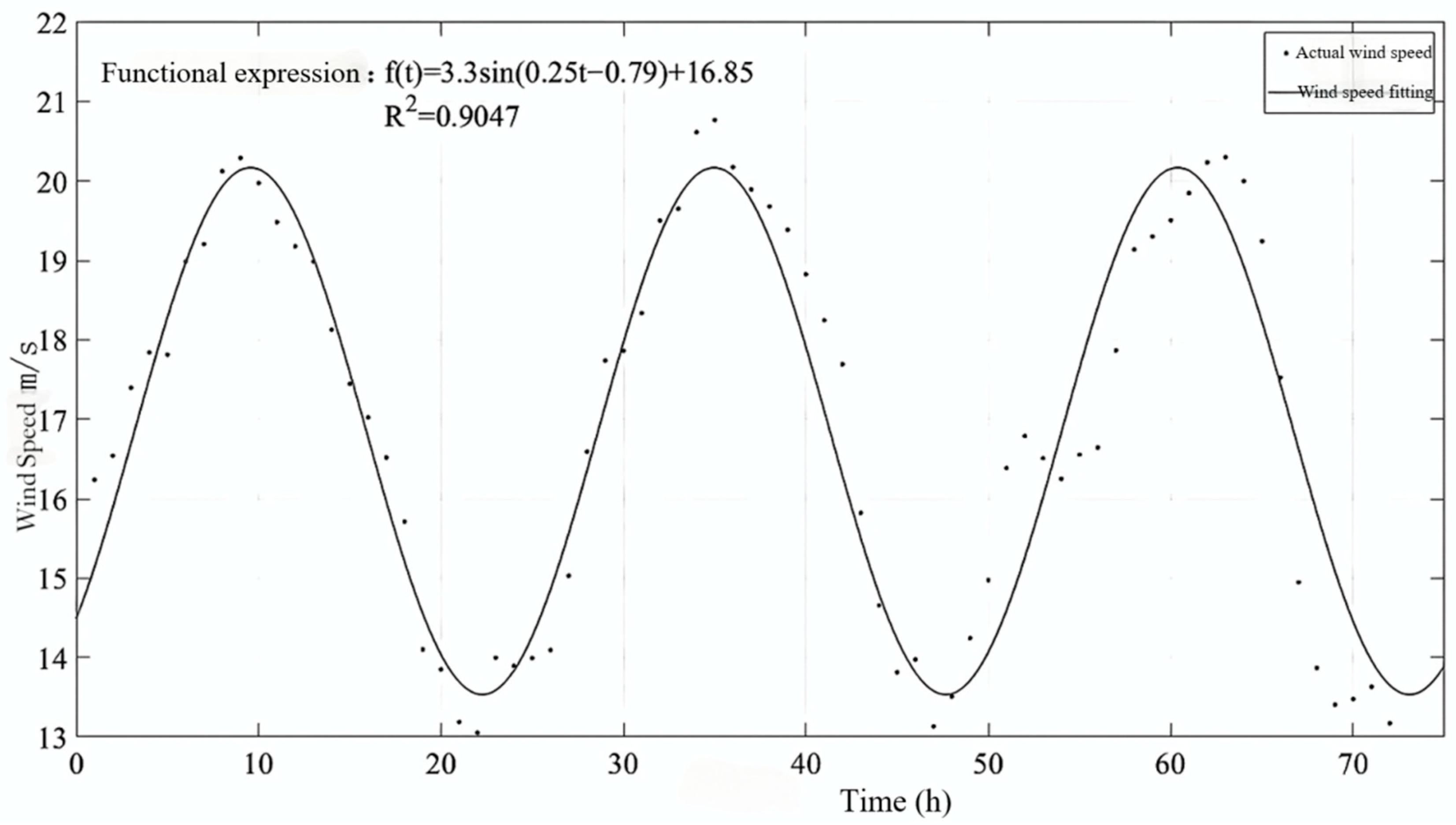

2.2.2. Numerical Methods in Computational Fluid Dynamics

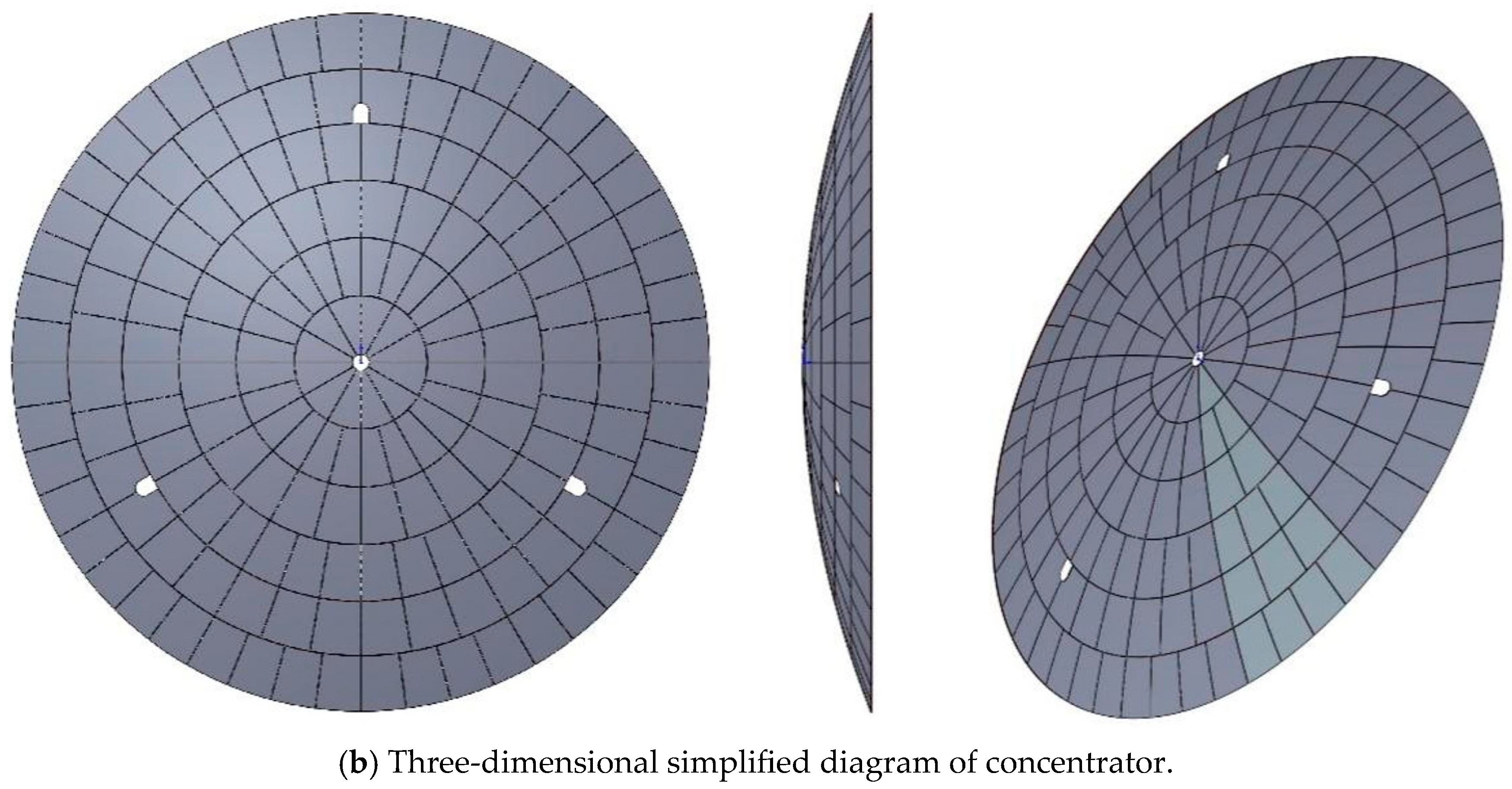

2.3. Parameter Settings

2.4. Grid Independence Verification

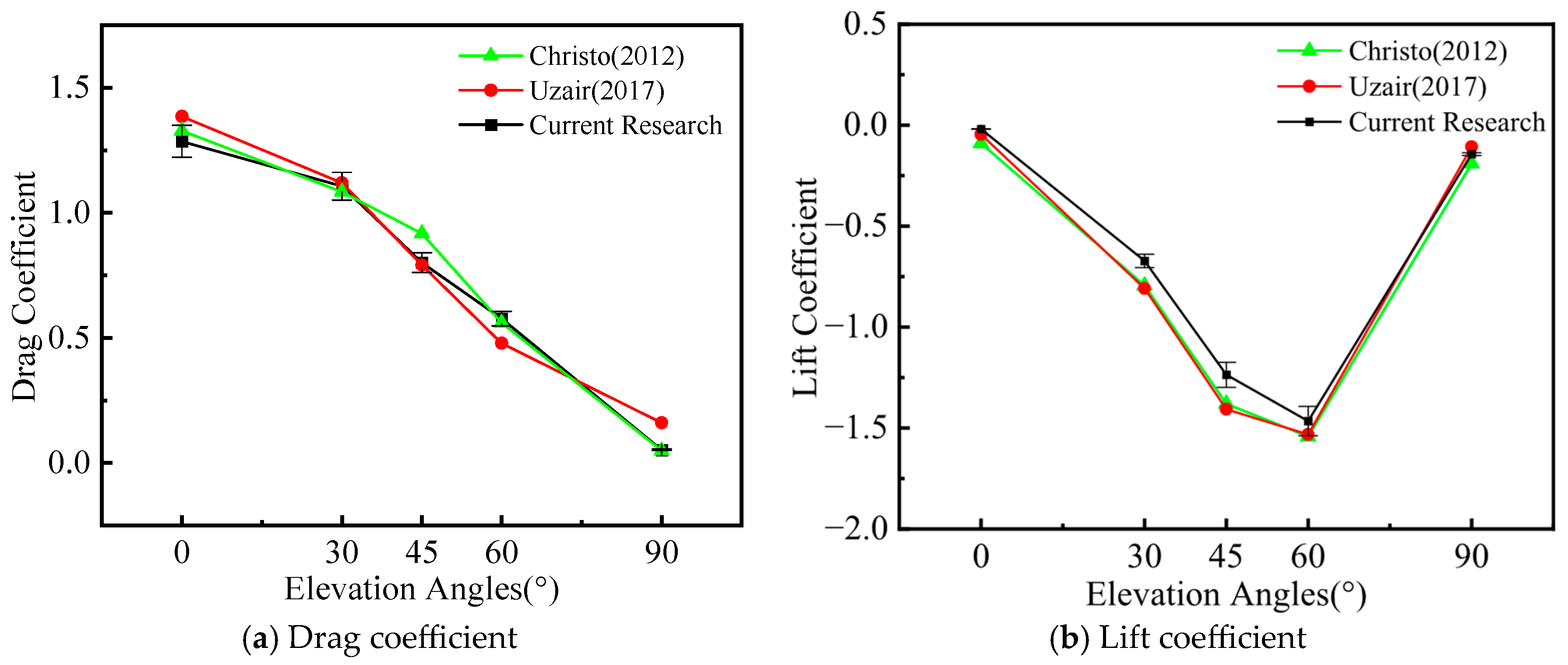

2.5. Model Validation

3. Analysis and Discussion of Computational Results

3.1. Simulation Analysis of Flow Field Distribution in Dish Solar Systems Under Varying Wind Speeds

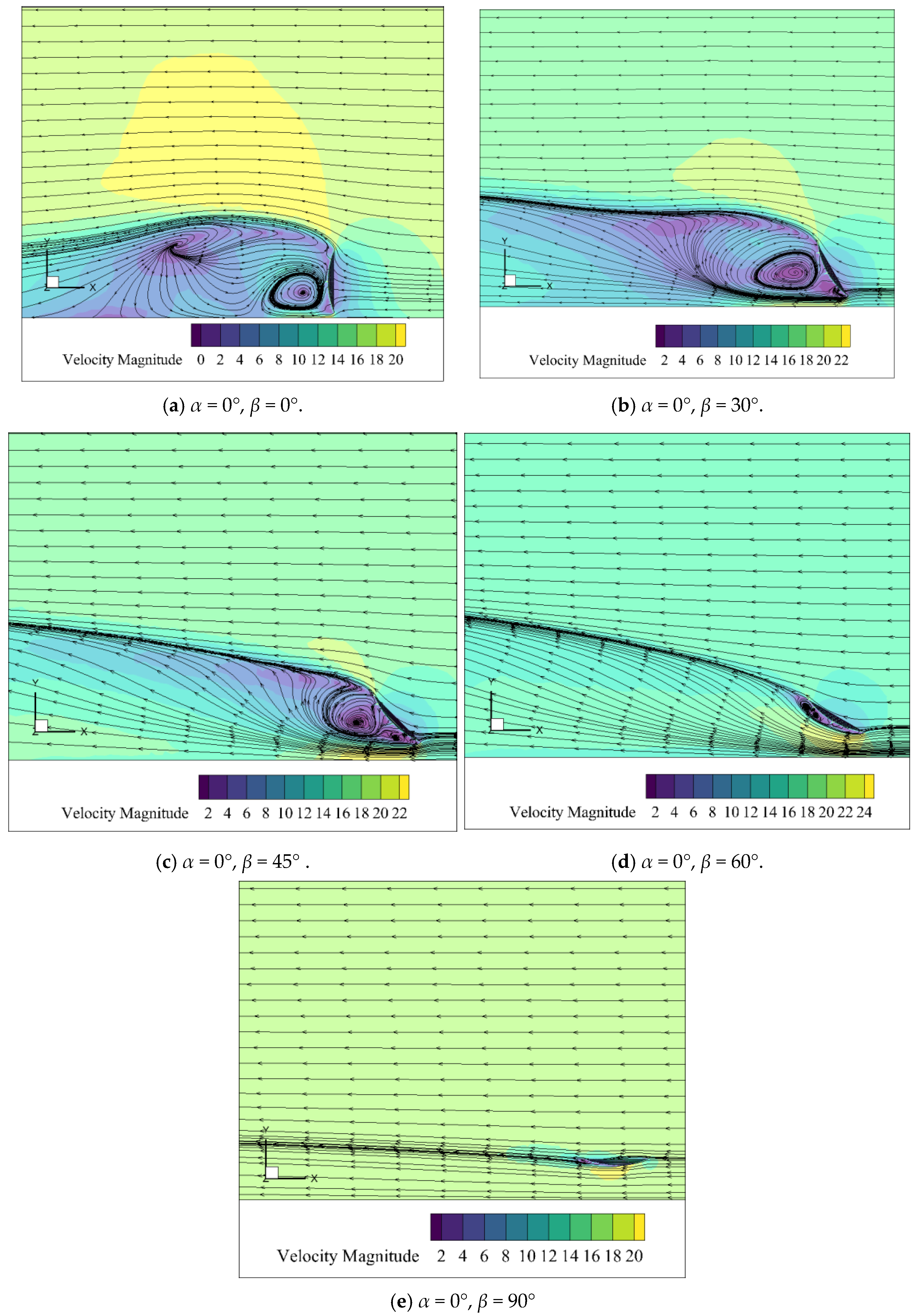

3.1.1. Variation Characteristics of System Flow Field Distribution with Elevation Angle Under Varying Wind Speeds

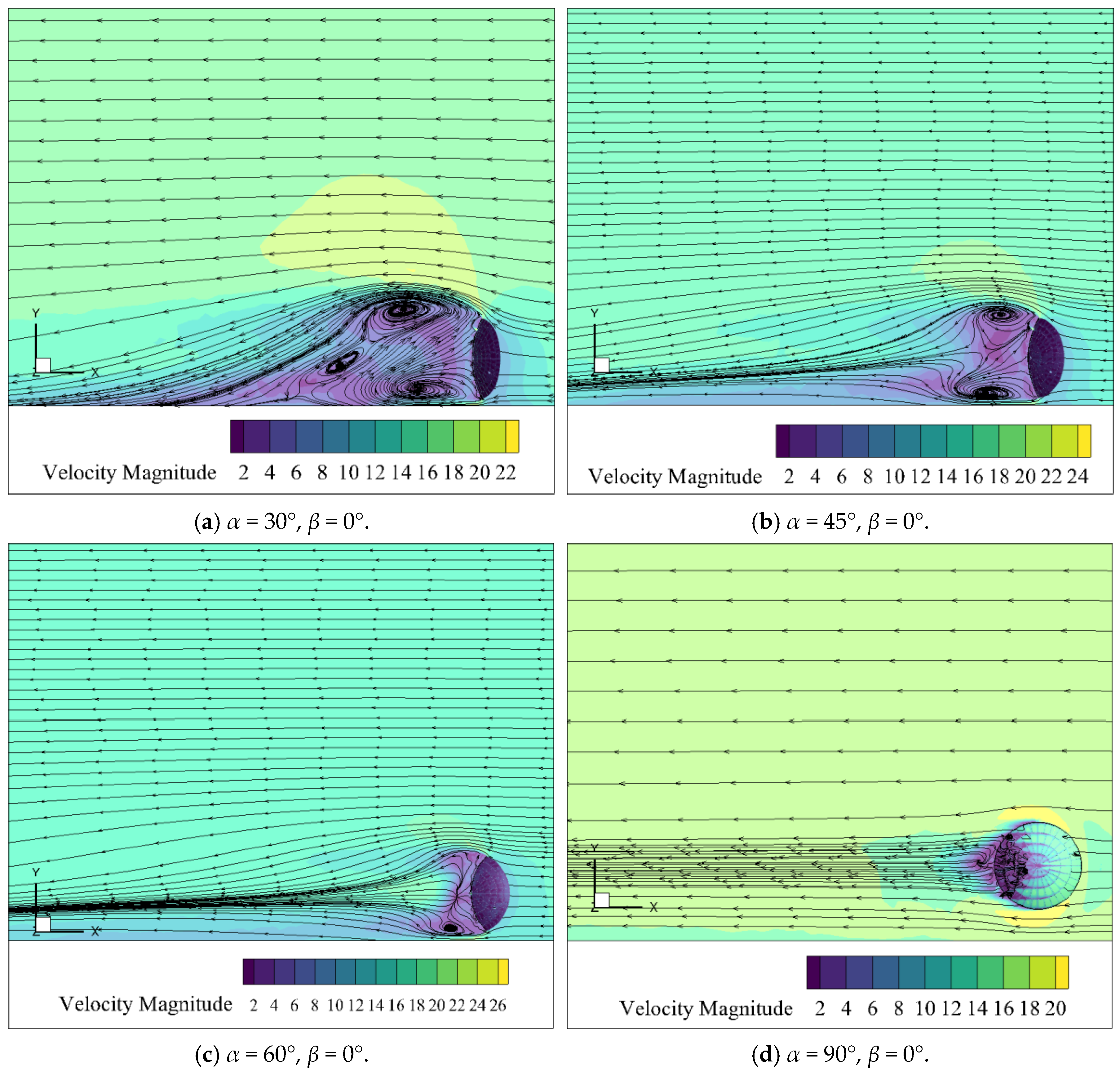

3.1.2. Variation Characteristics of System Flow Field Distribution with Azimuth Angle Under Varying Wind Speeds

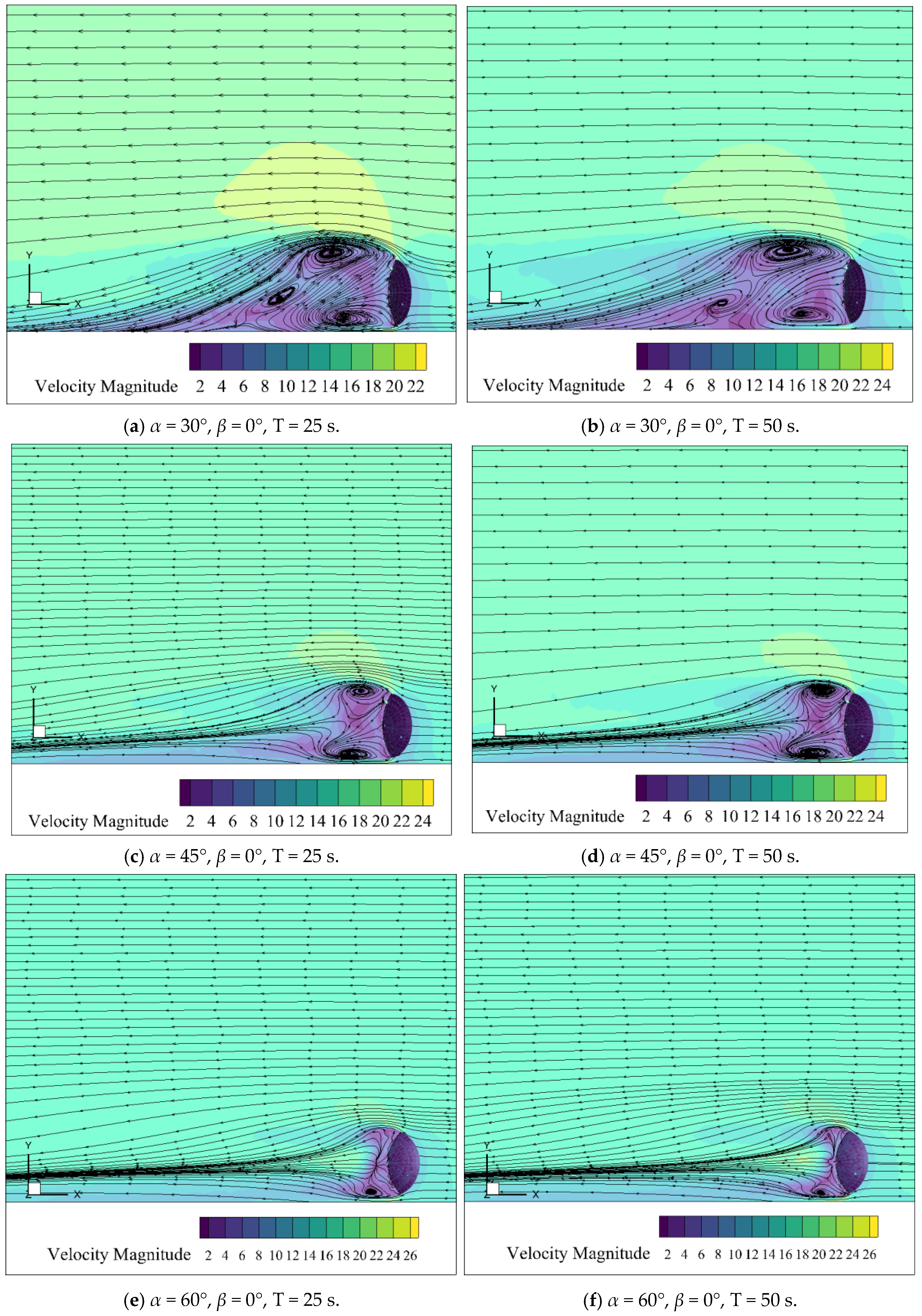

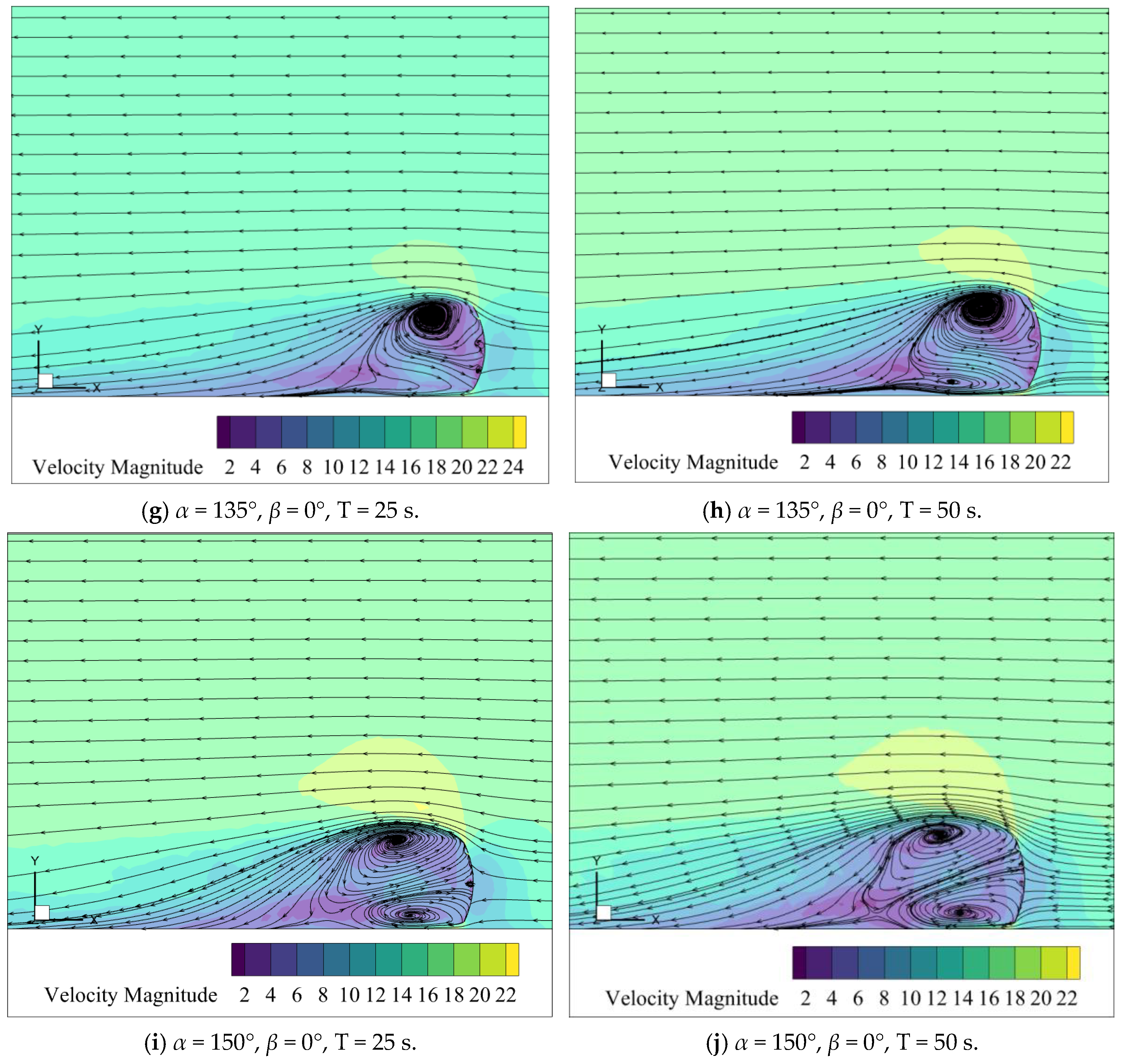

3.2. Variation Characteristics of the Flow Field Distribution Under Fluctuating Winds with Different Periods

3.3. Force Analysis of a Dish Solar Energy System Under Variable Wind Speeds

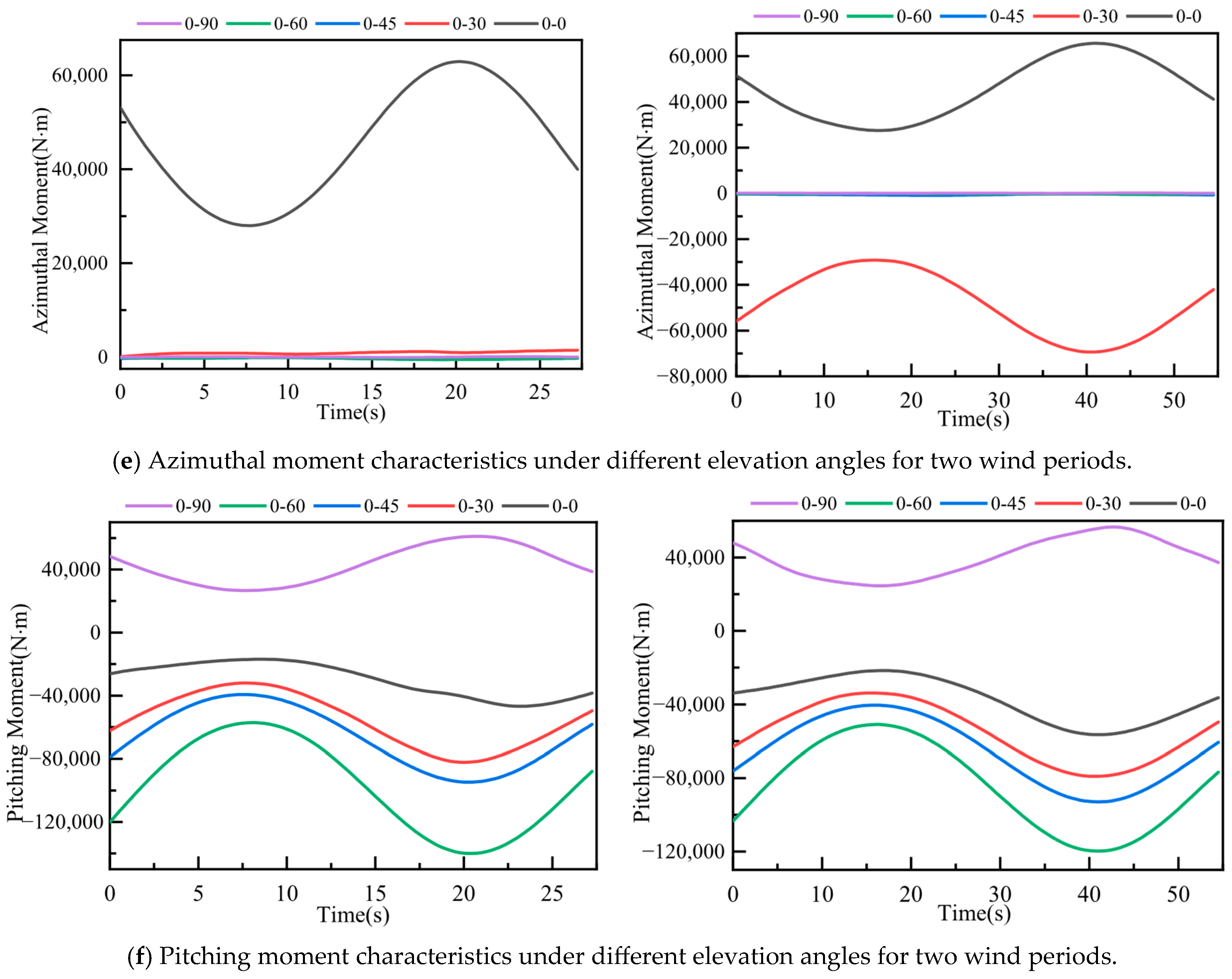

3.3.1. Effect of Elevation Angle and Wind Load Periodicity on Force Characteristics of the Concentrator

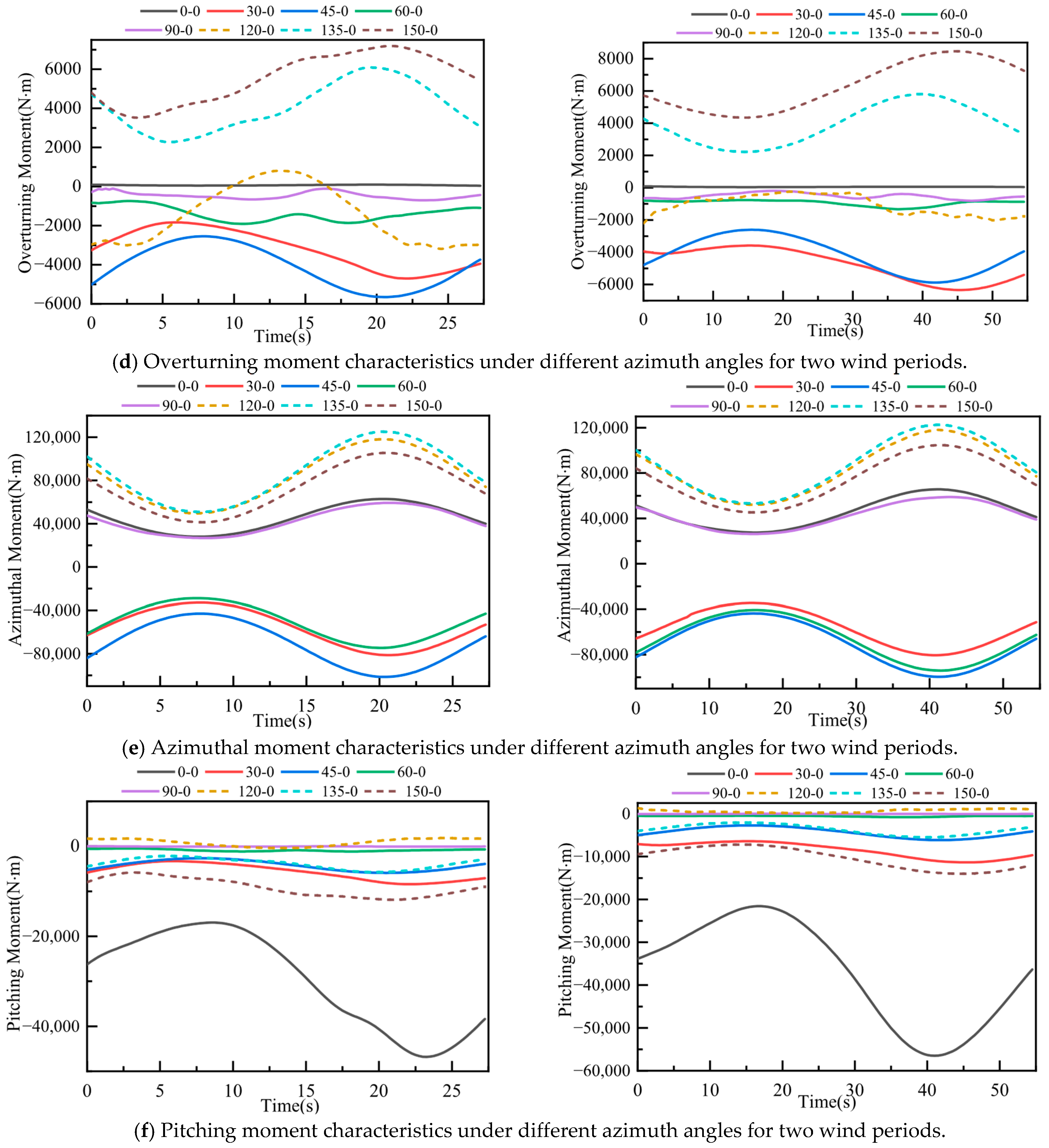

3.3.2. Effects of Azimuth Angle and Wind Load Period on Force Characteristics of Solar Concentrators

4. Conclusions and Engineering Implications

5. Limitations and Future Work

- (1)

- Turbulence Model: The standard k-ε model may not fully capture complex separation and vortex dynamics. Future work should use more advanced models (e.g., SST k-ω) or LES for improved accuracy.

- (2)

- Structural Response: The focus is on aerodynamic loads; direct structural analysis (e.g., stress, deformation) was not included. Coupled FSI simulations are recommended for comprehensive stability assessment.

- (3)

- Validation: Deviations from experimental data (7–10% for lift) indicate the need for more rigorous validation, including uncertainty quantification and sensitivity analysis.

- (4)

- Scale Effects: Full-scale simulations may not perfectly match scaled experiments; future studies should investigate Reynolds number effects.

- (5)

- Atmospheric Conditions: The model assumes neutral stratification; real-world atmospheric boundary layer effects could alter results.

- (6)

- Frequency Analysis: Frequency domain analysis (e.g., FFT) of force time histories was not performed due to limitations in simulation time required for statistical convergence.

- (7)

- Wind Speed Trajectory: This study is limited to a single periodic wind speed profile (Figure 2) to systematically investigate the effects of wind period and concentrator orientation. Although this profile is representative of typical fluctuations, other trajectories such as turbulent gusts, ramp-up winds, or stochastic variations prescribed by standards may induce different dynamic responses. Future research should incorporate a wider spectrum of wind speed histories to assess the generality of the current findings.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shi, P.; Li, J.; Song, Y.; Xu, N.; Zhu, J. Cogeneration of clean water and valuable energy/resources via interfacial solar evaporation. Nano Lett. 2024, 19, 5673–5682. [Google Scholar] [CrossRef] [PubMed]

- Ho, C.K.; Iverson, B.D. Review of high-temperature central receiver designs for concentrating solar power. Renew. Sustain. Energy Rev. 2014, 29, 835–846. [Google Scholar] [CrossRef]

- Conceição, R.; González-Aguilar, J.; Merrouni, A.A.; Romero, M. Soiling effect in solar energy conversion systems: A review. Renew. Sustain. Energy Rev. 2022, 162, 112434. [Google Scholar] [CrossRef]

- Paneru, B.; Paneru, B.; Alexander, V.; Nova, S.; Bhattarai, N.; Poudyal, R.; Narayan Poudyal, K.; Dangi, M.B.; Boland, J.J. Solar energy for operating solar cookers as a clean cooking technology in South Asia: A review. Sol. Energy 2024, 283, 113004. [Google Scholar] [CrossRef]

- Gomez-Garcia, F.; Gonzalez-Aguilar, J.; Tamayo-Pacheco, S.; Olalde, G.; Romero, M. Numerical Analysis of Radiation Attenuation in Volumetric Solar Receivers Composed of a Stack of Thin Monolith Layers. Energy Procedia 2014, 57, 457–466. [Google Scholar] [CrossRef]

- Yang, X.; Zou, T.; Xu, Y.; Chen, F.; Luo, H.; ullah, S.; Li, R. Research dynamics and applications of tracking technology and devices in solar energy utilization system. Sustain. Energy Technol. Assess. 2025, 75, 104256. [Google Scholar] [CrossRef]

- Ho, C.K. Advances in central receivers for concentrating solar applications. Sol. Energy 2017, 152, 38–56. [Google Scholar] [CrossRef]

- Chen, C.; Wang, M.; Chen, X.; Chen, X.; Fu, Q.; Deng, H. Recent progress in solar photothermal steam technology for water purification and energy utilization. Chem. Eng. J. 2022, 448, 137603. [Google Scholar] [CrossRef]

- Ho, C.K.; Khalsa, S.S.; Kolb, G.J. Methods for probabilistic modeling of concentrating solar power plants. Sol. Energy 2011, 85, 669–675. [Google Scholar] [CrossRef]

- Shan, C.; Wang, J.; Cao, Y.; Li, H. Multi-objective optimization of a novel combined cooling, heating and power solar thermal energy storage system: A comprehensive analysis of energy, exergy, exergoeconomic, and exergoenvironmental performance. Energy 2025, 316, 134464. [Google Scholar] [CrossRef]

- Ho, C.K. A review of high-temperature particle receivers for concentrating solar power. Appl. Therm. Eng. 2016, 109, 958–969. [Google Scholar] [CrossRef]

- González-Pardo, A.; González-Aguilar, J.; Romero, M. Analysis of glint and glare produced by the receiver of small heliostat fields integrated in building façades. Methodol. Appl. Conv. Cent. Receiv. systems. Sol. Energy 2015, 121, 68–77. [Google Scholar]

- Xu, X.; Zhang, L.; Zhang, H.; Ma, J.; Sambatmaryde, K. Performance analysis of a novel small-scale integrated solar-ORC system for power and heating. Sol. Energy 2024, 274, 112605. [Google Scholar] [CrossRef]

- Martínez-Hernández, A.; Conceição, R.; Asselineau, C.-A.; Romero, M.; González-Aguilar, J. Advanced surface reconstruction method for solar reflective concentrators by flux mapping. Sol. Energy 2023, 266, 112162. [Google Scholar] [CrossRef]

- Khan, M.I.; Asfand, F.; Al-Ghamdi, S.G.; Bicer, Y.; Khan, M.; Faqooq, M.; Pesyridis, A. Realizing the promise of concentrating solar power for thermal desalination: A review of technology configurations and optimizations. Renew. Sustain. Energy Rev. 2024, 208, 115022. [Google Scholar] [CrossRef]

- Rodriguez, J.; Canadas, I.; Monterreal, R.; Enrique, R.; Galindo, J. PSA SF60 solar furnace renewed. AIP Conf. Proc. 2019, 2126, 030046. [Google Scholar] [CrossRef]

- Guk, E.; Kalkan, N. Large Scale Solar Thermal Systems for the Solution of Europe’s Expansion of Energy Demand. J. Eng. Sci. Technol. Rev. 2014, 7, 94–96. [Google Scholar] [CrossRef]

- Guoyan, Z.; Xiutian, Y.; Yi, Z.; Weigang, Z.; Guozhong, C. Study on the water-lubricated high-speed non-contact mechanical face seal supported by a disc spring. Braz. Soc. Mech. Sci. Eng. 2018, 40, 351. [Google Scholar] [CrossRef]

- Elango, C.; Gunasekaran, N.; Sampathkumar, K. Thermal Modelling of Solar Still-A comprehensive review. Renew. Sustain. Energy Rev. 2015, 47, 856–911. [Google Scholar] [CrossRef]

- Guarino, S.; Buscemi, A.; Ciulla, G.; Bonomolo, M.; Lo Brano, V. A dish-stirling solar concentrator coupled to a seasonal thermal energy storage system in the southern mediterranean basin: A cogenerative layout hypothesis. Energy Convers. Manag. 2020, 222, 113228. [Google Scholar] [CrossRef]

- Graham, P.; Fadlallah, S.O.; Boulbrachene, K. Wind incidence and pedestal height effect on the flow behaviour and aerodynamic loading on a stand-alone solar parabolic dish. Renew. Energy 2024, 227, 120451. [Google Scholar] [CrossRef]

- Liu, G.; E, J.; Liu, T.; Zuo, W.; Zhang, Q. Effects of different poses and wind speeds on flow field of dish solar concentrator based on virtual wind tunnel experiment with constant wind. J. Cent. South Univ. 2018, 25, 1948–1957. [Google Scholar] [CrossRef]

- Zuo, H.; Liu, G.; E, J.Q.; Zuo, W.; Wei, K.; Hu, W.; Tan, J. Catastrophic analysis on the stability of a large dish solar thermal power generation system with wind-induced vibration. Solar Energy 2019, 183, 40–49. [Google Scholar] [CrossRef]

- Zuo, H.; Tan, J.; Wei, K.; Huang, Z.; Zhong, D.; Xie, F. Effects of different poses and wind speeds on wind-induced vibration characteristics of a dish solar concentrator system. Renew. Energy 2021, 168, 1308–1326. [Google Scholar] [CrossRef]

- Yu, M.; Gong, J.; Cai, H. Numerical simulation of impact on wind load due to mirror gap effect for parabolic dish solar concentrator. Proc. Inst. Mech. Eng. Part A J. Power Energy 2019, 233, 1056–1067. [Google Scholar] [CrossRef]

- Yan, J.; Peng, Y.; Xie, X.; Liu, Y. Optical performance maintenance of solar dish collector system under service loads based on tracking compensation and receiver translational compensation methods. Energy 2024, 313, 134125. [Google Scholar] [CrossRef]

- Ali, H.; Fadlallah, S.O.; Serradj, D.E.B. Wind-induced structural behavior and optical performance of a lightweight composite-based paraboloidal solar dish. Mech. Based Des. Struct. Mach. 2025, 53, 4542–4571. [Google Scholar] [CrossRef]

- Egerer, U.; Dana, S.; Jager, D.; Stanislawski, B.J.; Xia, G.; Yellapantula, S. Field measurements reveal insights into the impact of turbulent wind on loads experienced by parabolic trough solar collectors. Sol. Energy 2024, 280, 112860. [Google Scholar] [CrossRef]

- Jian, Y.; Peng, Y.D.; Liu, Y.X. An optical-mechanical integrated modeling method of solar dish concentrator system for optical performance analysis under service load. Energy 2022, 261, 125283. [Google Scholar] [CrossRef]

- Ji, B.; Qiu, P.; Xu, F.; Liu, Q.; Zhang, X.; Zhang, L. Concentrating efficiency loss of heliostat with multiple sub-mirrors under wind loads. Energy 2023, 281, 128281. [Google Scholar] [CrossRef]

- Merarda, H.; Toumi, M.; Boutelhig, A. Analysis of heliostat fatigue: Impact of wind speed distribution, studied over six regions of Algeria. Sol. Energy 2024, 278, 112776. [Google Scholar] [CrossRef]

- E, J.Q.; Liu, G.; Liu, T.; Zhang, Z.; Zuo, H.; Hu, W.; Wei, K. Harmonic response analysis of a large dish solar thermal power generation system with wind-induced vibration. Sol. Energy 2019, 181, 116–129. [Google Scholar] [CrossRef]

- Glynn John, S.; Lakshmanan, T. Cost optimization of dish solar concentrator system for improved scalability decisions. Renew. Energy 2017, 114, 600–613. [Google Scholar] [CrossRef]

- Faddouli, A.; Hajji, M.; Fadili, S.; Hartiti, B.; Labrim, H.; Habchi, A. A comprehensive review of solar, thermal, photovoltaic, and thermoelectric hybrid systems for heating and power generation. Int. J. Green Energy 2024, 21, 413–447. [Google Scholar] [CrossRef]

- Chen, C.; Huo, L.; Wang, Z.; Li, H. Experimental study on fluctuating wind pressure on a long-span dome roof subjected to stationary downburst-like winds. Adv. Struct. Eng. 2025, 28, 574–591. [Google Scholar] [CrossRef]

- Simmons, S.C.; Lubitz, W.D. Analysis of internal fluid motion in an Archimedes screw using computational fluid mechanics. J. Hydraul. Res. 2021, 59, 932–946. [Google Scholar] [CrossRef]

- Graebel, W.P.; Paintal, A.S. Engineering Fluid Mechanics. Eng. Fluid Mech. 2001, 54, 77–96. [Google Scholar] [CrossRef]

- Molerus, O. Fluid mechanics and continuum mechanics. Heat Mass Transf./Waerme-Und Stoffuebertragung 2008, 44, 625–633. [Google Scholar] [CrossRef]

- Elmisaoui, S.; Kissami, I.; Ghidaglia, J.-M. High-Performance Computing to Accelerate Large-Scale Computational Fluid Dynamics Simulations: A Comprehensive Study. Lect. Notes Netw. Syst. 2024, 930LNNS, 352–360. [Google Scholar]

- Gou, Q.; Wang, X.; Chen, G.; Liu, S. Effect of particle shape on particle flow and heat transfer behavior based on computational fluid dynamics-discrete element modeling. Phys. Fluids 2025, 37, 023332. [Google Scholar] [CrossRef]

- Zhan, Y.J. Assessment of subgrid method in a finite-volume model. Comput. Math. Appl. 2021, 81, 220–236. [Google Scholar] [CrossRef]

- Pratik, N.A.; Ali, M.H.; Lubaba, N.; Hasan, N.; Asaduzzaman, M.; Miyara, A. Numerical investigation to optimize the modified cavity receiver for enhancement of thermal performance of solar parabolic dish collector system. Energy 2024, 290, 130133. [Google Scholar] [CrossRef]

- Wang, H.; Blocken, B.; Lin, Z. CFD simulation of the stratified atmospheric boundary layer: Consistency between Monin-Obukhov similarity theory and the standard k-Ε model. Build. Environ. 2025, 267, 112284. [Google Scholar] [CrossRef]

- Meng, F.-Q.; He, B.-J.; Zhu, J.; Zhao, D.-X.; Darko, A.; Zhao, Z.-Q. Sensitivity analysis of wind pressure coefficients on CAARC standard tall buildings in CFD simulations. J. Build. Eng. 2018, 16, 146–158. [Google Scholar] [CrossRef]

- Lai, Y.; Ha, J.H.; Deo, K.A.; Yang, J.; Yin, P.; Park, S. Reflow Recipe Establishment Based on CFD-Informed Machine Learning Model. IEEE Trans. Compon. Packag. Manuf. Technol. 2023, 13, 127–134. [Google Scholar] [CrossRef]

- Jin, C. Embedding numerical methods and MATLAB programming in a fluid mechanics course for undergraduates in engineering technology. Int. J. Mech. Eng. Educ. 2024, 3, 564–580. [Google Scholar] [CrossRef]

- Christo, F.C. Numerical modelling of wind and dust patterns around a full-scale paraboloidal solar dish. Renew. Energy 2012, 39, 356–366. [Google Scholar] [CrossRef]

- Uzair, M.; Anderson, T.N.; Nates, R.J. The impact of the parabolic dish concentrator on the wind induced heat loss from its receiver. Sol. Energy 2017, 151, 95–101. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J.; Zuo, H.; Jia, G.; Su, Y.; E, J. Effects of the Fluctuating Wind Loads on Flow Field Distribution and Structural Response of the Dish Solar Concentrator System Under Multiple Operating Conditions. Processes 2025, 13, 3444. https://doi.org/10.3390/pr13113444

He J, Zuo H, Jia G, Su Y, E J. Effects of the Fluctuating Wind Loads on Flow Field Distribution and Structural Response of the Dish Solar Concentrator System Under Multiple Operating Conditions. Processes. 2025; 13(11):3444. https://doi.org/10.3390/pr13113444

Chicago/Turabian StyleHe, Jianing, Hongyan Zuo, Guohai Jia, Yuhao Su, and Jiaqiang E. 2025. "Effects of the Fluctuating Wind Loads on Flow Field Distribution and Structural Response of the Dish Solar Concentrator System Under Multiple Operating Conditions" Processes 13, no. 11: 3444. https://doi.org/10.3390/pr13113444

APA StyleHe, J., Zuo, H., Jia, G., Su, Y., & E, J. (2025). Effects of the Fluctuating Wind Loads on Flow Field Distribution and Structural Response of the Dish Solar Concentrator System Under Multiple Operating Conditions. Processes, 13(11), 3444. https://doi.org/10.3390/pr13113444