Study on the Mechanism of Cross-Layer Fracture Propagation in Deep Coal Rock Based on True Triaxial Physical Simulation Experiments

Abstract

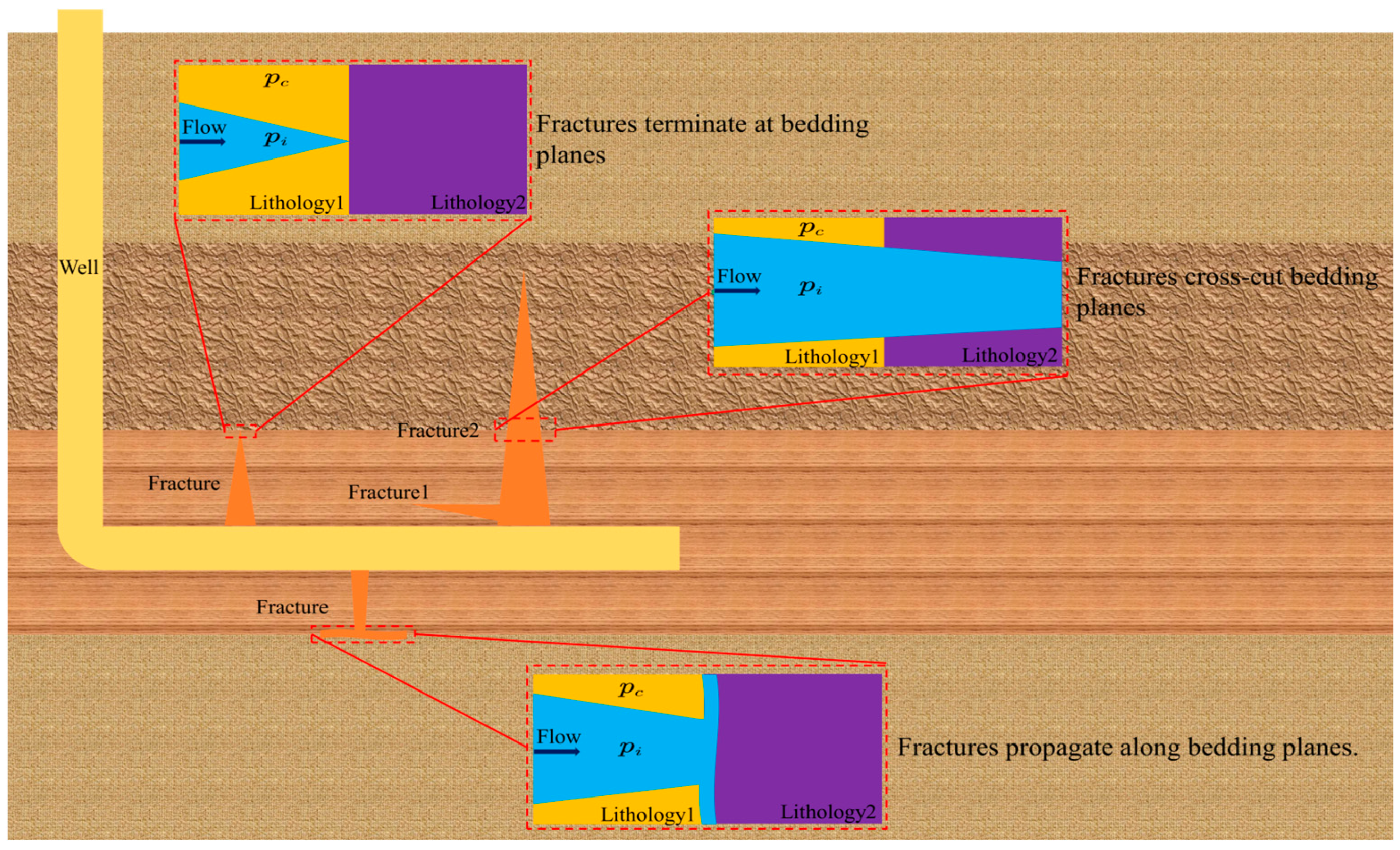

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

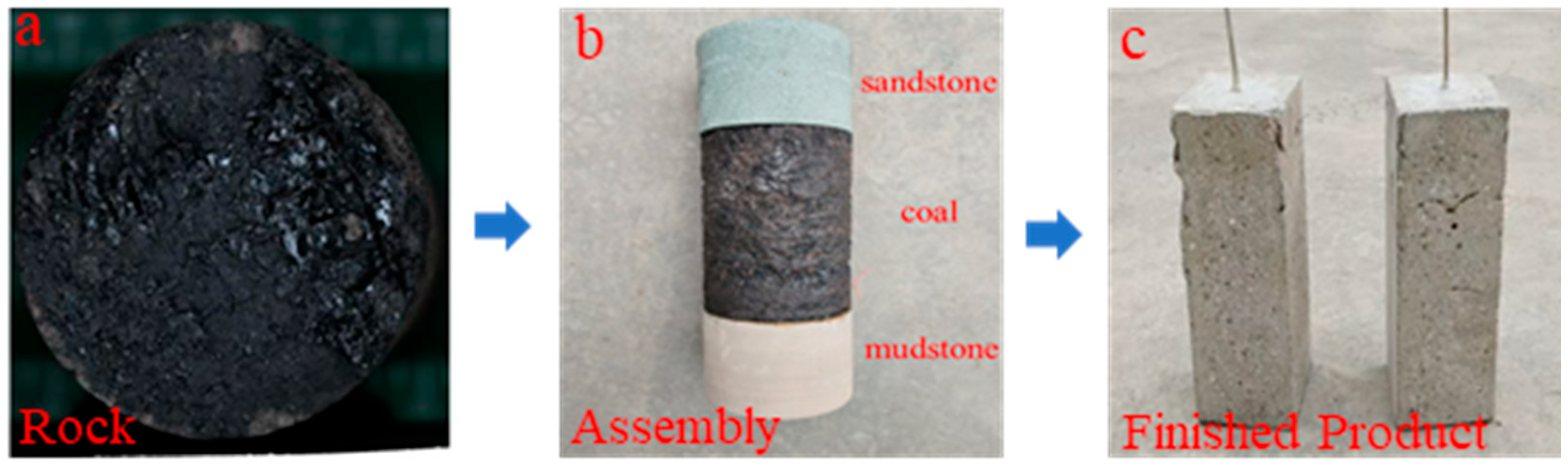

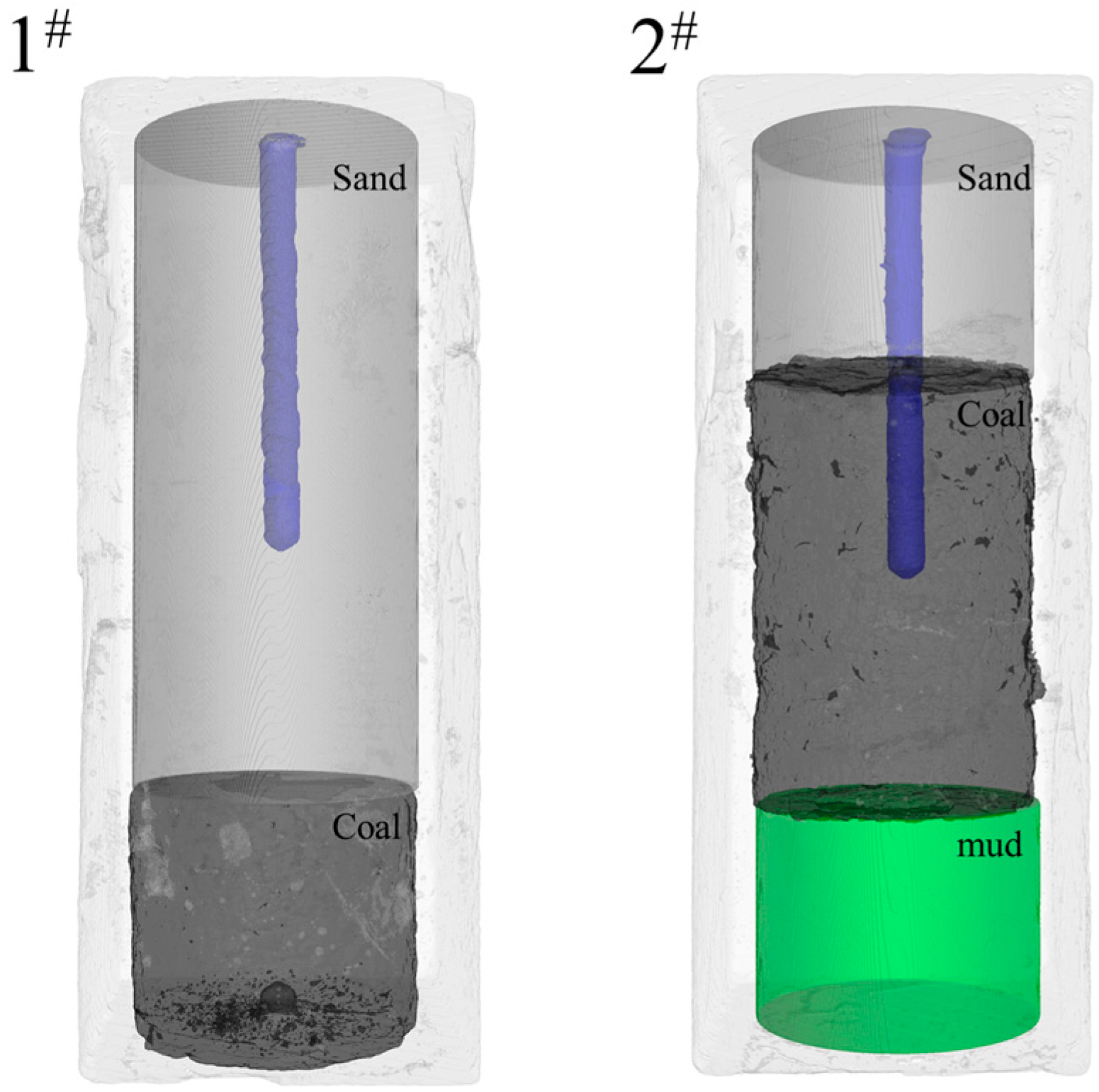

- (1)

- Sampling: The experimental rock samples were all selected from the outcrops of coal rock, sandstone and mudstone in the Ordos area.

- (2)

- Cutting: To meet the requirements of large physical model test samples, each selected lithologic sample is cut into cylindrical samples with a diameter of 80 mm, and efforts are made to ensure that the surface of the rock sample is flat during the cutting process.

- (3)

- Splicing: The selected rock samples are longitudinally superimposed in the order of perforation, and different rock types are bonded with strong glue. And to minimize errors as much as possible, keep the bonding surface thin (<2 mm) and flat. Wait until the bonding surface is fully dry.

- (4)

- Pouring: Place the assembled experimental rock samples into the mold, and pour a thin layer of cement on the outside to form a casting piece of 100 mm × 100 mm × 240 mm. Ensure that the surface of the rock samples is flat during the pouring process to facilitate the subsequent experiments.

- (5)

- Drilling: After the cement has dried, drill a hole at the center of the upper part of the sample, perpendicular to the coal rock layer. The diameter of the hole is 8 mm and the length is 140 mm ± 5 mm.

- (6)

- Wellbore installation: The wellbore is embedded inside the sample in the direction of the borehole. The wellbore specification is a liquid injection steel pipe with an outer diameter of 6 mm, and its embedding depth is 120 mm. A 20 mm open hole well section is retained at the bottom of the hole.

- (7)

- Cementation: Subsequently, high-strength adhesives are used to seal the wellbore and wellbore. To avoid problems such as stress concentration caused by uneven coal and rock surfaces during hydraulic fracturing experiments, two-component adhesives are used to repair the missing corners on the outside of the samples to obtain samples with smooth surfaces. The finished product is shown in Figure 3.

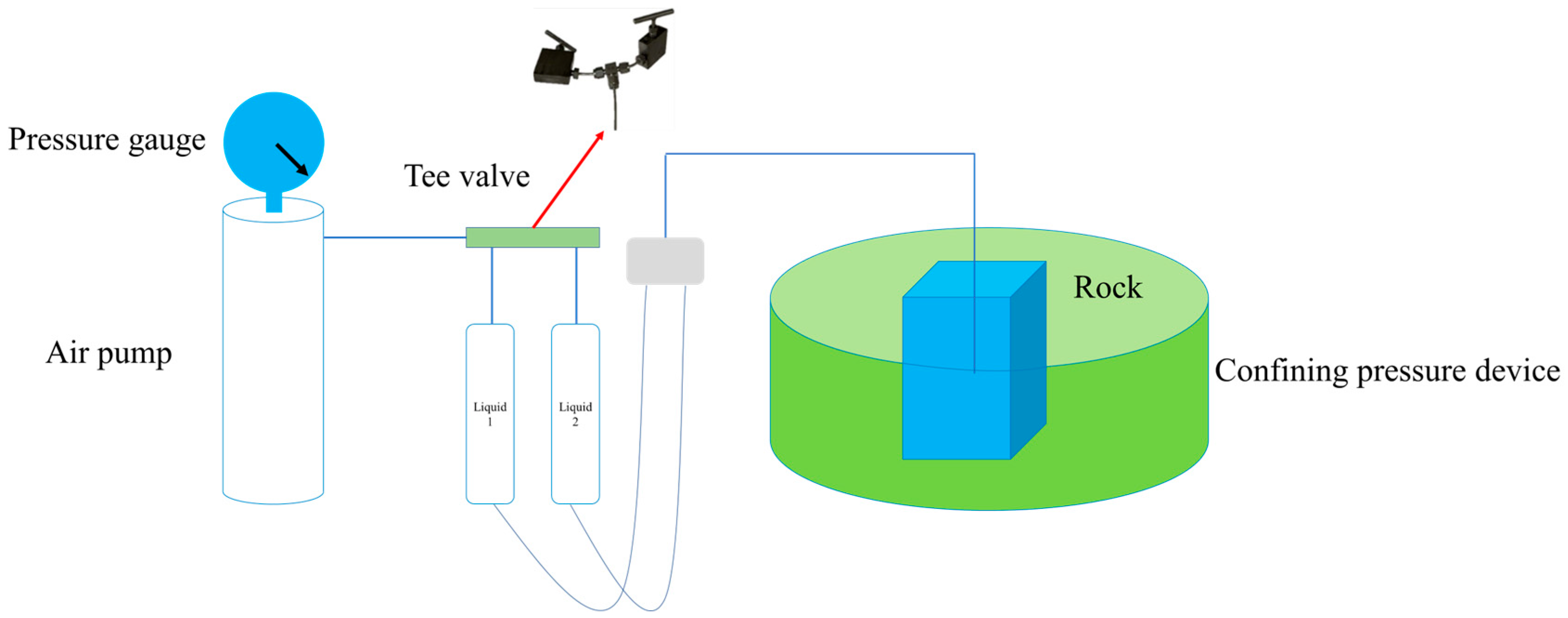

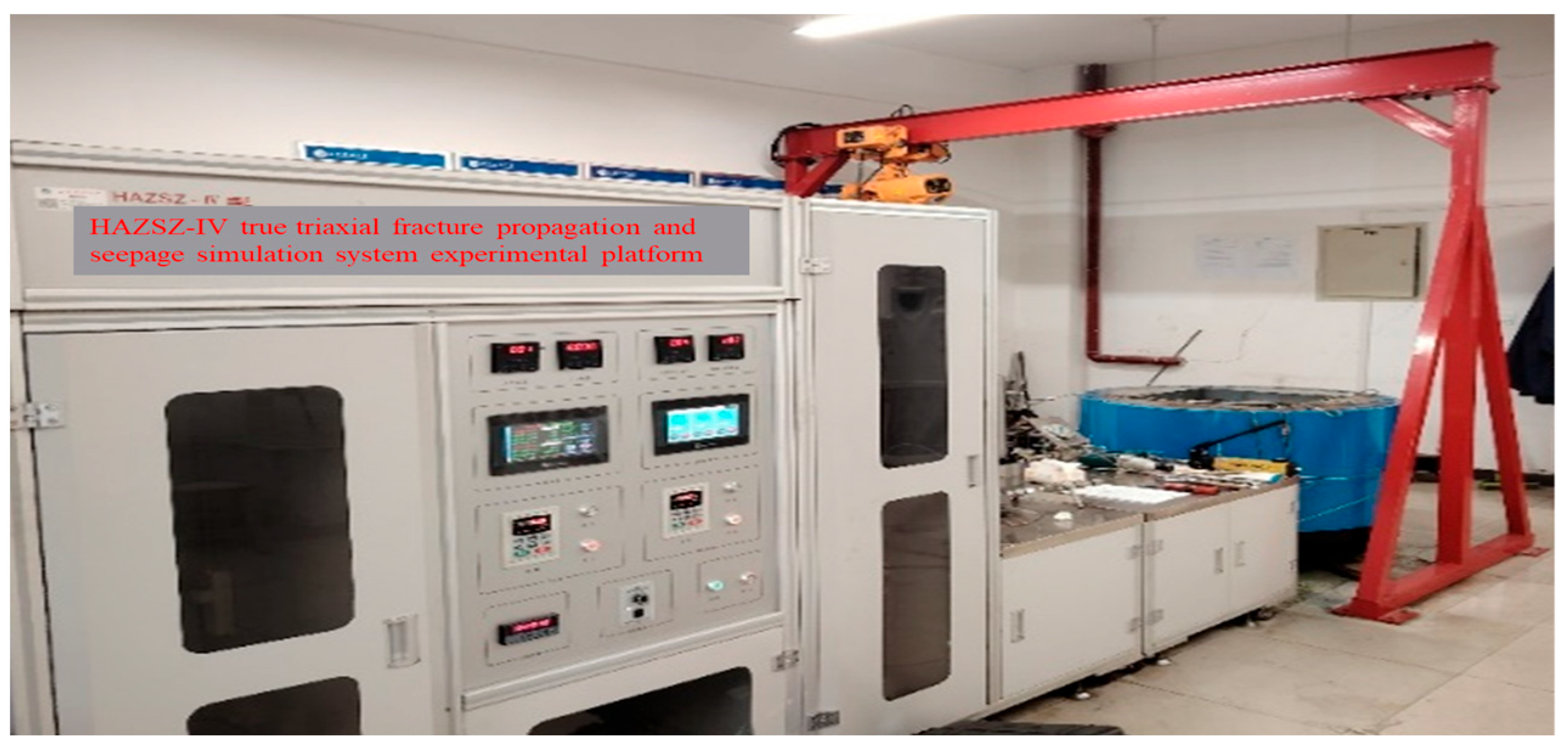

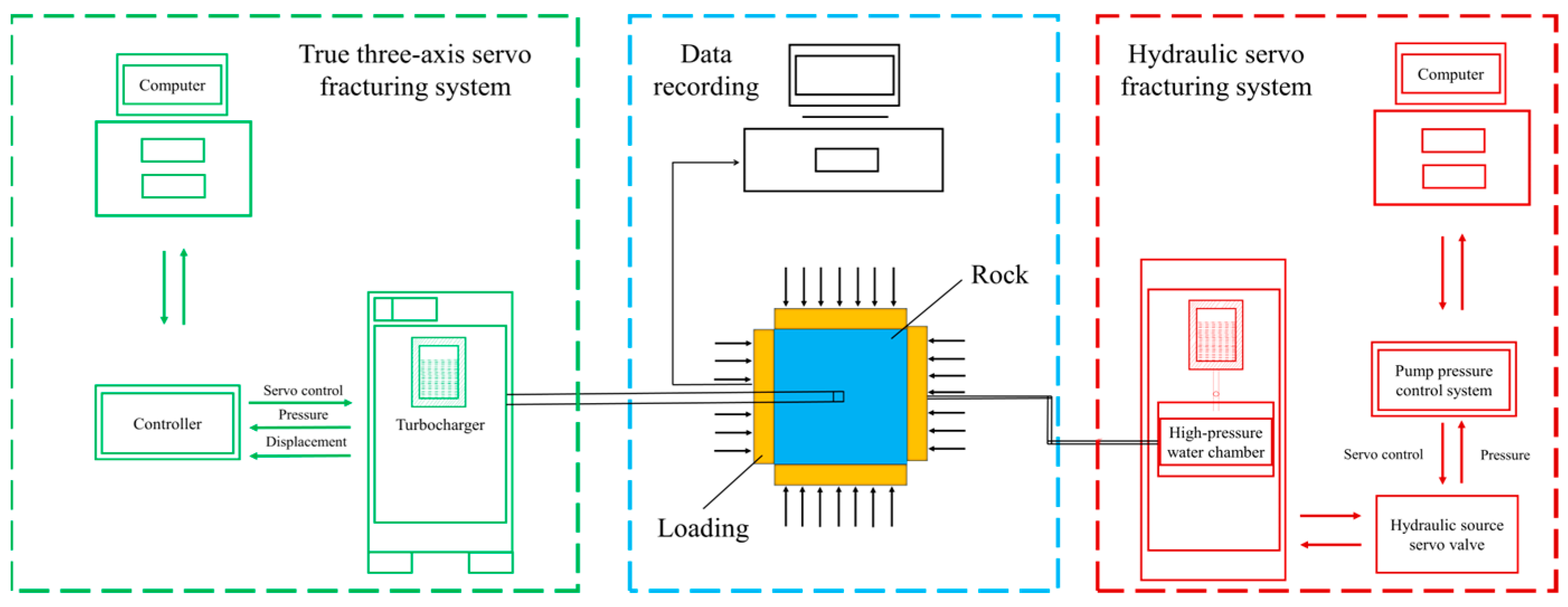

2.2. Experimental Equipment

2.3. Experimental Procedure

3. Results

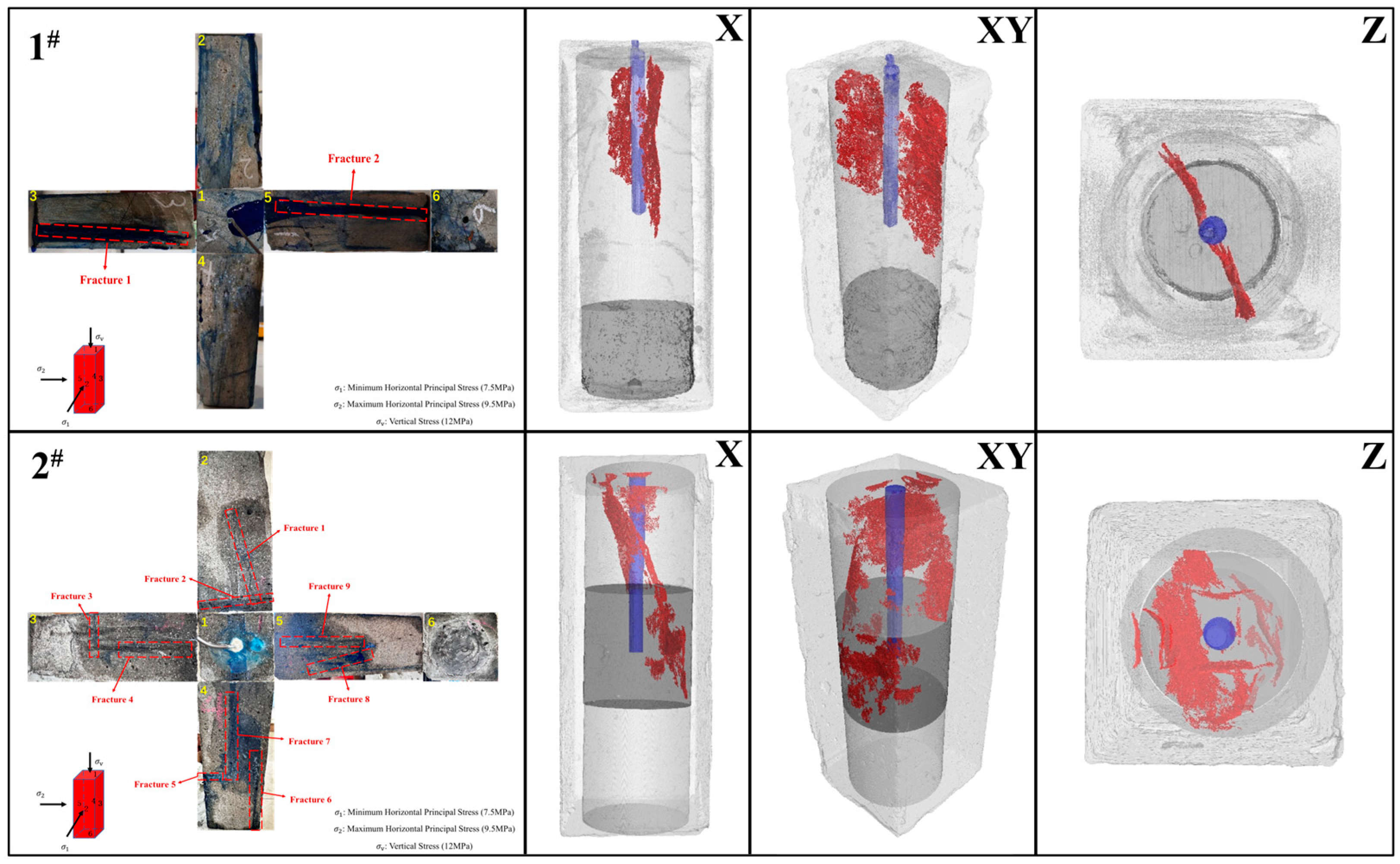

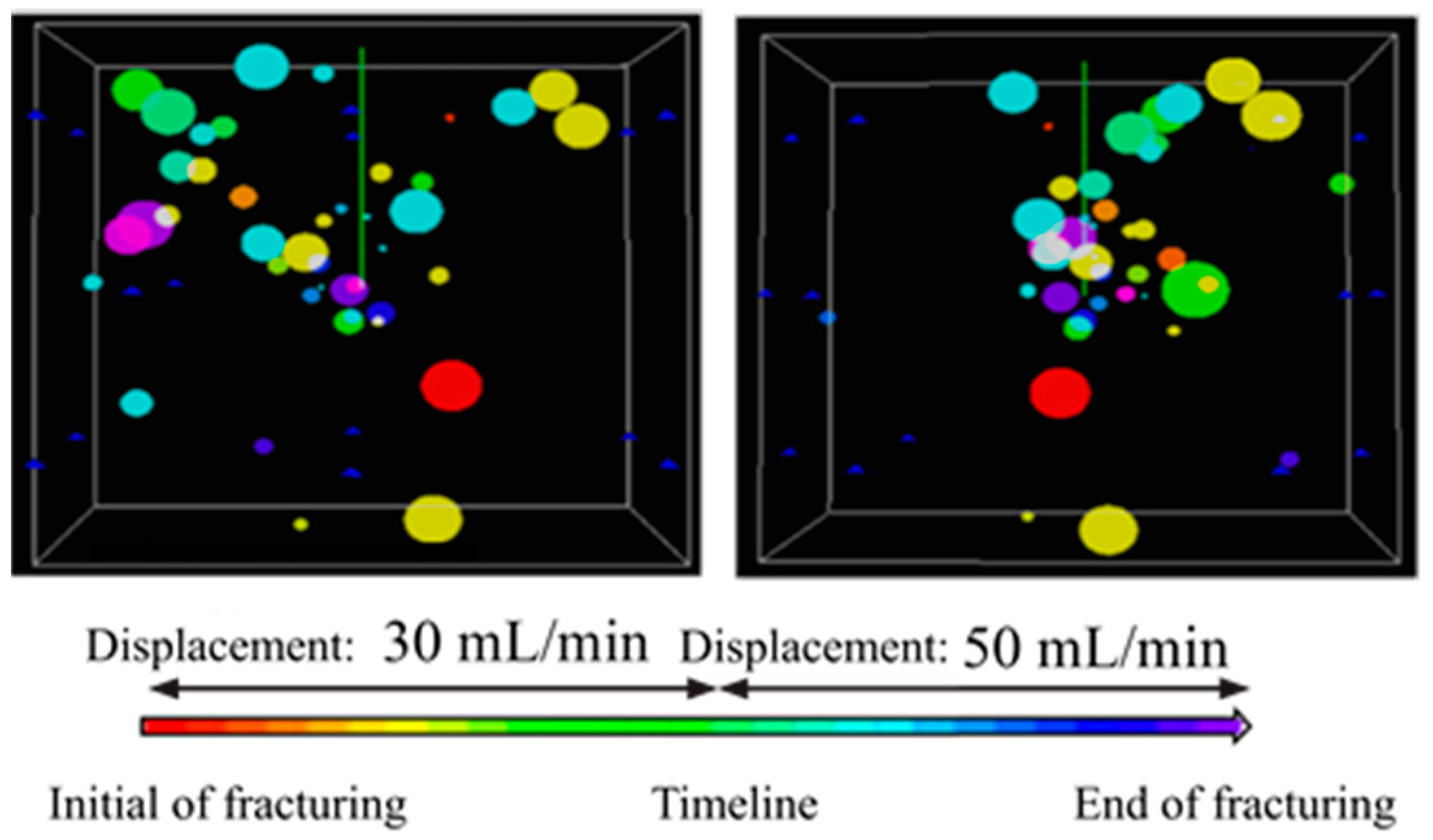

3.1. Pre-Fracture Fracture Distribution Pattern

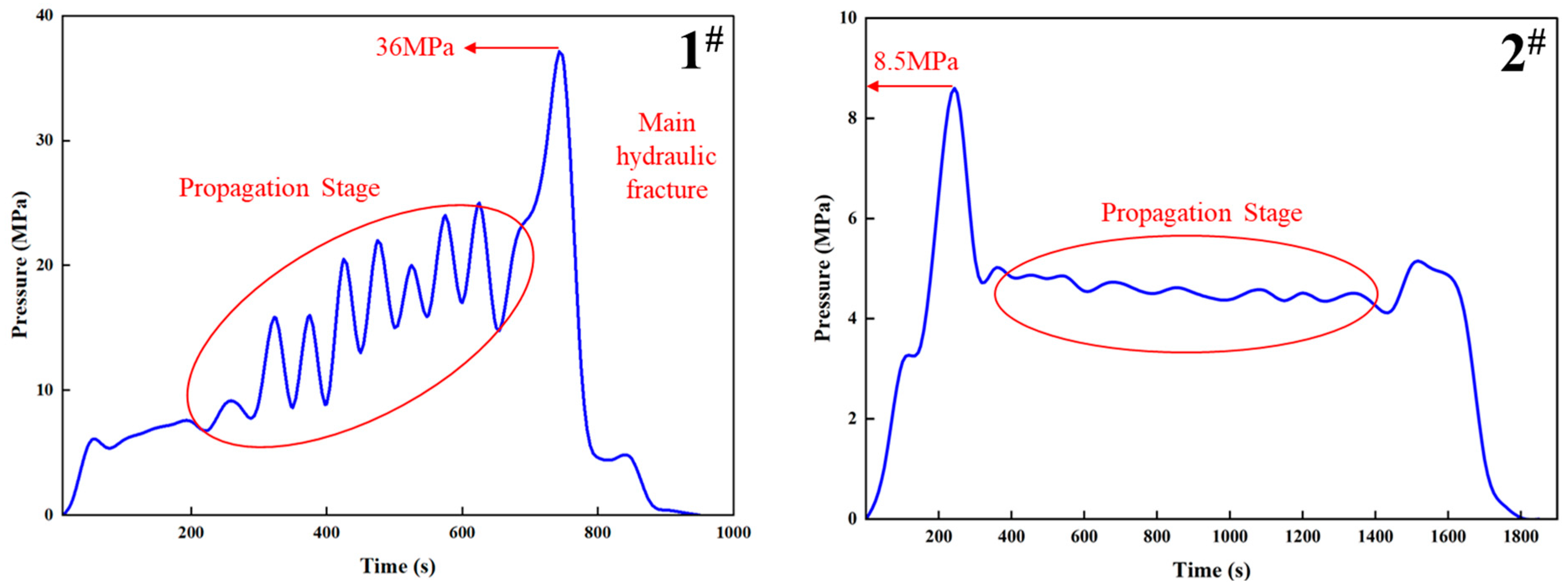

3.2. Pressure Curve Analysis

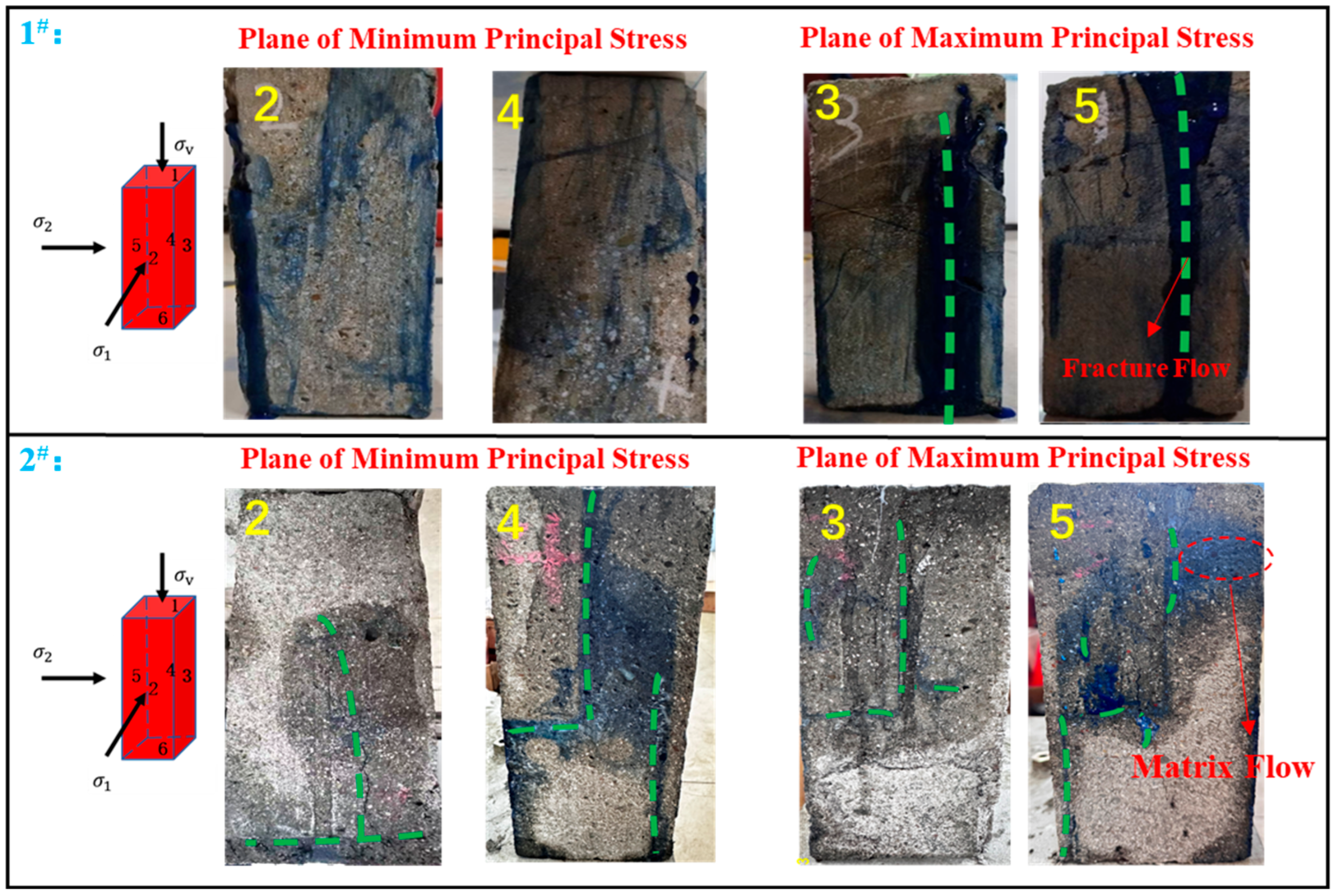

3.3. Failure Characteristics Analysis

4. Analysis of Fracturing Control Factors

4.1. Effect of Natural Fractures

4.2. Effect of Fracturing Fluid Injection Parameters

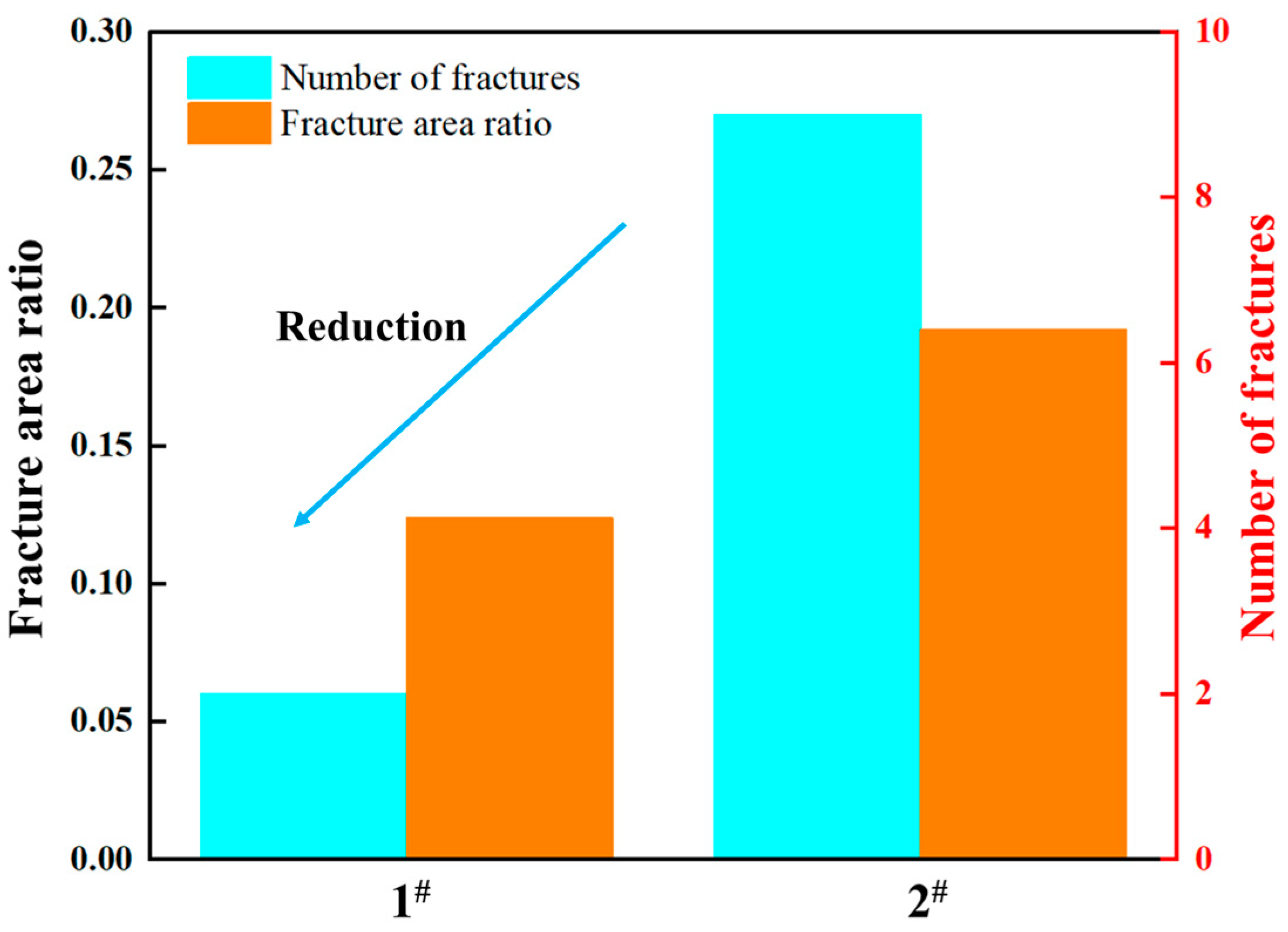

5. Fracture Complexity Analysis

6. Conclusions

- (1)

- Due to the well-developed weak planes, such as natural fractures, in coal rock, perforating in coal rock significantly reduces the breakdown pressure compared to perforating in sandstone.

- (2)

- The fracture complexity achieved by perforating in thin coal rock far exceeds that from sandstone perforation. Furthermore, the pressure fluctuations during the fracture propagation phase are markedly lower in coal rock than in sandstone. This results in superior fracturing effectiveness.

- (3)

- In the quantitative characterization of fracture complexity, the number of perforation fractures in coal rock fracturing reached 450% of that in sandstone, and the fracture area ratio reached 131.7%.

- (4)

- Perforating in coal rock enables fractures to penetrate through layers to effectively connect the adjacent sandstone formation. Conversely, while perforating in sandstone forms a main hydraulic fracture, it fails to establish connectivity with the adjacent coal rock layer.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Feng, G.; Wang, G.F.; Xie, H.Q.; Hu, Y.Q.; Meng, T.; Li, G. A review of exploration and development technologies for coal, oil, and natural gas. Energies 2024, 17, 3600. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Zhao, S.H.; Hu, Z.Q.; Shen, B.J.; Feng, D.J.; Zhang, J.Q.; Ye, J.C.; Ma, C.; Dong, Z.X. Characteristics and controlling factors of coal-measure unconventional reservoirs—A case study of the carboniferous-permian in the ordos basin. Unconv. Resour. 2025, 6, 100153. [Google Scholar] [CrossRef]

- Tong, T.; Wang, J.H. The pathway to the natural gas industry: Financial development, coal consumption, and carbon dioxide emissions in P.R. China. Sci. Prog. 2023, 106, 368504231160643. [Google Scholar] [CrossRef] [PubMed]

- Qiao, W.; Howard, K.W.F.; Li, W.; Zhang, S.; Zhang, X.; Niu, Y. Coordinated exploitation of both coal and deep groundwater resources. Environ. Earth Sci. 2020, 79, 186. [Google Scholar] [CrossRef]

- Kang, H.; Gao, F.Q.; Xu, G.; Ren, H.W. Mechanical behaviors of coal measures and ground control technologies for china’s deep coal mines -a review. J. Rock. Mech. Geotech. Eng. 2023, 15, 37–65. [Google Scholar] [CrossRef]

- Li, Q.G.; Deng, Y.Z.; Hu, Q.T.; Wu, X.B.; Wang, X.G.; Jiang, Z.Z.; Liu, L.; Qian, Y.N.; Song, M.Y. Review and prospect of coal rock hydraulic fracturing physical experimental research. Coal Sci. Technol. 2022, 50, 62–72. [Google Scholar]

- Li, X.G.; Tang, Z.; Zhu, J.Y.; Yang, Z.Z.; Li, Y.; Xie, P.; Liao, Y. Research progress and prospect of deep coalrock fracturing. Nat. Gas. Ind. 2024, 44, 126–139. [Google Scholar]

- Wen, H.T.; Yang, R.Y.; Jing, M.Y.; Huang, Z.W.; Hong, C.Y.; Chen, J.X.; Cong, R.C. Rock mechanical properties of coal in cryogenic condition. Pet. Sci. 2023, 20, 407–423. [Google Scholar] [CrossRef]

- Liang, W.; Wang, J.G.; Leung, C.F.; Goh, S.; Sang, S.X. Opportunities and challenges for gas coproduction from coal measure gas reservoirs with coal-shale-tight sandstone layers: A review. Deep Undergr. Sci. Eng. 2025, 4, 83–104. [Google Scholar] [CrossRef]

- Blunschi, J.; Wang, J.; Ertekin, T. Hydraulic fracturing mechanisms in coal: A review. Int. J. Oil Gas Coal Technol. 2017, 14, 247–263. [Google Scholar] [CrossRef]

- Huang, L.S.; Li, B.; Wu, B.; Li, C.; Wang, J.X.; Cai, H.W. Study on the extension mechanism of hydraulic fractures in bedding coal. Theor. Appl. Fract. Mec. 2024, 131, 104431. [Google Scholar] [CrossRef]

- Kang, H.; Xia, Y.X.; Feng, M.H.; Lu, C.; Gao, F.Q. Case study of hydraulic fracturing for coal burst risk mitigation. Int. J. Coal Sci. Technol. 2025, 12, 10. [Google Scholar] [CrossRef]

- Yadali, B. A critical review of common models in hydraulic-fracturing simulation: A practical guide for practitioners. Theor. Appl. Fract. Mec. 2021, 113, 102937. [Google Scholar] [CrossRef]

- Lu, Y.X.; Hu, S.Y.; Li, G.F.; Wu, X.; Lu, J.Q.; Yang, Y.T.; Zhang, C.; Su, Y. Experimental study and application of hydraulic fracturing in underlying coal seam. Coal Sci. Technol. 2024, 52, 231–242. [Google Scholar]

- Li, B.; He, Y.Z.; Shi, Z.; Jian, W.; Wang, N.N.; Zhang, Y.P. Mutual feedback and fracturing effect of hydraulic fractures in composite coal−rock reservoirs under different fracturing layer sequence conditions. Int. J. Rock. Mech. Min. 2024, 184, 105968. [Google Scholar] [CrossRef]

- Pang, T.; Jiang, Z.B.; Hui, J.T.; Jia, B.Y. Fracture propagation mechanism in directional perforation and hydraulic fracturing of coal seam horizontal wells. Coal Geol. Explor. 2024, 52, 68–75. [Google Scholar]

- Wu, L.D.; Zhang, Y.; Di, S.J.; Tao, Z.Z.; Liu, Z.B. Study of fracture propagation mechanism of horizontal well fracturing in roof of coal seams. J. Energy Eng. 2024, 150, 04024008. [Google Scholar] [CrossRef]

- Huang, D.B.; Kang, X.T.; Xu, Z.H.; Ren, C.; Long, Y.Y.; Cao, P. Influence of strength inhomogeneity on transboundary expansion characteristics of hydraulically fractured fractures in coal seams. Sci. Rep. 2024, 14, 29094. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Ge, Z.L.; Yan, F.; Xia, B.W.; Tan, J.R. Progress on the hydraulic measures for grid slotting and fracking to enhance coal seam permeability. Int. J. Min. Sci. Technol. 2017, 27, 867–871. [Google Scholar] [CrossRef]

- Zhang, X.; Si, G.Y.; Bai, Q.S.; Xiang, Z.Z.; Li, X.; Oh, J.; Zhang, Z.Y. Numerical simulation of hydraulic fracturing and associated seismicity in lab-scale coal samples: A new insight into the stress and aperture evolution. Comput. Geotech. 2023, 161, 105507. [Google Scholar] [CrossRef]

- Ou, Y.J.; Liang, H. Study on the law of hydraulic fracture propagation in low permeability thin interbed reservoir. Engineering 2023, 25, 187–199. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, F. A review of experimental and theoretical research on the deformation and failure behavior of rocks subjected to cyclic loading. J. Rock. Mech. Geotech. Eng. 2021, 13, 1203–1230. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.F.; Tian, G.D.; Wang, C.L.; Bi, J. A new model for predicting hydraulic fracture penetration or termination at an orthogonal interface between dissimilar formations. Pet. Sci. 2022, 19, 2810–2829. [Google Scholar] [CrossRef]

- Ma, Z.G.; Yan, P.F.; Cheng, S.X.; Gong, P.; Qi, F.Z.; Wang, J.G. Experimental study of the dynamic mechanical responses and failure characteristics of coal under true triaxial confinements. Int. J. Min. Sci. Technol. 2023, 33, 761–772. [Google Scholar] [CrossRef]

- Li, Q.; Li, T.; Cai, Y.D.; Liu, D.M.; Li, L.F.; Ru, Z.X.; Yin, T.T. Research progress on hydraulic fracture characteristics and controlling factors of coalbed methane reservoirs. J. China Coal Soc. 2023, 48, 4443–4460. [Google Scholar]

- Li, R.; Zhai, H.Y.; Jiang, C.S.; Zhu, W.; Li, X.Y.; Wang, Z.; Wang, Y.B. A review of laboratory hydraulic fracturing experiments on shales. Geoenergy Sci. Eng. 2025, 254, 214028. [Google Scholar] [CrossRef]

- Zhou, A.T.; He, Y.Z.; Wang, K.; Yang, Y.X.; Wang, Y.D.; Liu, Y.F. Optimization study on separate-layer fracturing of a coal–rock composite based on inter-fracture interference effect. Eng. Geol. 2025, 344, 107930. [Google Scholar] [CrossRef]

- Ma, J.Q.; Li, X.H.; Li, Y.H.; Wang, X.H.; Yao, Q.L. Numerical simulation of hydraulic fracture extension patterns at interfaces of coal-measure rock strata and a new theoretical prediction model. Simul. Model. Pract. Theory 2025, 138, 103063. [Google Scholar] [CrossRef]

- Xiong, D.; He, J.Y.; Ma, X.F.; Qu, Z.L.; Guo, T.K.; Ma, S.Y. Fracturing simulation with different perforation positions at deep coal seam and roof/floor rock—Case study at the no.8 deep coal seam of a gas field in the ordos basin. J. China Coal Soc. 2024, 49, 4897–4914. [Google Scholar]

- Al-Yaari, A.; Ching, D.L.C.; Sakidin, H.B.; Muthuvalu, M.S.; Zafar, M.; Alyousifi, Y.; Saeed, A.A.H.; Bilad, M.R. Thermophysical Properties of Nanofluid in Two-Phase Fluid Flow through a Porous Rectangular Medium for Enhanced Oil Recovery. Nanomaterials 2022, 12, 1011. [Google Scholar] [CrossRef] [PubMed]

- Yao, W.J.; Liu, X.W.; Liu, B.; Fan, Y.; Zhu, L.; Zheng, Z. Experimental and numerical simulation study on mechanical properties of coal-transition layer-rock composite structures. Chin. J. Rock. Mech. Eng. 2024, 43, 184–205. [Google Scholar]

- Lu, J.; Huang, G.; Gao, H.; Li, X.; Zhang, D.M.; Yin, G.Z. Mechanical properties of layered composite coal–rock subjected to true triaxial stress. Rock. Mech. Rock. Eng. 2020, 53, 4117–4138. [Google Scholar] [CrossRef]

- Lucca, A.; Balsamo, F.; De Risio, C.A.; Ogata, K.; Porta, F.; Tavani, S.; Storti, F. Facies and mechanical stratigraphy control fracture intensity, topology and fractal dimension in folded turbidite sandstones, Northern Apennines, Italy. J. Struct. Geol. 2025, 191, 105307. [Google Scholar] [CrossRef]

- Liu, J.; Regenauer-Lieb, K.; Hines, C.; Zhang, S.; Bourke, P.; Fusseis, F.; Yuen, D.A. Applications of microtomography to multiscale system dynamics: Visualisation, characterisation and high performance computation. In Advances in Geophysics, Tectonics and Petroleum Geosciences; Springer: Cham, Switzerland, 2013; pp. 653–674. [Google Scholar]

- Wang, B.; Liu, X.; Sima, L. Grading evaluation and prediction of fracture-cavity reservoirs in Cambrian Longwangmiao Formation of Moxi area, Sichuan Basin, SW China. Pet. Explor. Dev. 2019, 46, 301–313. [Google Scholar] [CrossRef]

- Li, T.; Li, Q.; Hu, Y.; Peng, X.; Feng, X.; Zhu, Z.; Zhao, Z. Quantitative characterization of irregular micro-fracture network and its effect on the permeability of porous media. Pet. Explor. Dev. 2021, 48, 368–378. [Google Scholar] [CrossRef]

| Sample | Lithology | Depth (m) | Confining Pressure (MPa) | Young’s Modulus (GPa) | Poisson’s Ratio | UCS (MPa) |

|---|---|---|---|---|---|---|

| 1 | Coal | 3231.34 | 10 | 5.18 | 0.43 | 72.61 |

| 2 | Coal | 3236.16 | 10 | 6.29 | 0.36 | 45.70 |

| 3 | Sandstone | 3152.12 | 50 | 35.64 | 0.25 | 292.10 |

| Sample | Vertical Stress (MPa) | Maximum Horizontal Stress (MPa) | Minimum Horizontal Stress (MPa) | Horizontal Stress Difference (MPa) | Viscosity (mPa·s) | Displacement (mL/min) |

|---|---|---|---|---|---|---|

| 1# | 12 | 9.5 | 7.5 | 2 | 20~40 | 10~20 |

| 2# | 12 | 9.5 | 7.5 | 2 | 20~40 | 10~20 |

| Technique Name | Application | References | |

|---|---|---|---|

| 1 | Fractal dimension | Quantitatively describe the complexity and strength of the fracture | Lucca et al. [33] |

| 2 | Voxel-based characterization | Detailed quantification of 3D fracture complexity at the microscale | Liu et al. [34] |

| 3 | 3D digital core analysis | Visual reconstruction of internal micro-fracture network morphology | Wang et al. [35] |

| 4 | Fracture network orientation index and connectivity coefficient | Quantitative characterization of irregular micro-fracture networks | Li et al. [36] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, R.; Xu, H.; Li, X.; Deng, Y.; Yang, G.; Lv, S.; Hu, F.; Qu, X.; Bai, Z.; Zhang, R. Study on the Mechanism of Cross-Layer Fracture Propagation in Deep Coal Rock Based on True Triaxial Physical Simulation Experiments. Processes 2025, 13, 3411. https://doi.org/10.3390/pr13113411

Xu R, Xu H, Li X, Deng Y, Yang G, Lv S, Hu F, Qu X, Bai Z, Zhang R. Study on the Mechanism of Cross-Layer Fracture Propagation in Deep Coal Rock Based on True Triaxial Physical Simulation Experiments. Processes. 2025; 13(11):3411. https://doi.org/10.3390/pr13113411

Chicago/Turabian StyleXu, Ruiguo, Haoyin Xu, Xudong Li, Yinxin Deng, Guojun Yang, Shuang Lv, Fuping Hu, Xinghua Qu, Zhao Bai, and Ran Zhang. 2025. "Study on the Mechanism of Cross-Layer Fracture Propagation in Deep Coal Rock Based on True Triaxial Physical Simulation Experiments" Processes 13, no. 11: 3411. https://doi.org/10.3390/pr13113411

APA StyleXu, R., Xu, H., Li, X., Deng, Y., Yang, G., Lv, S., Hu, F., Qu, X., Bai, Z., & Zhang, R. (2025). Study on the Mechanism of Cross-Layer Fracture Propagation in Deep Coal Rock Based on True Triaxial Physical Simulation Experiments. Processes, 13(11), 3411. https://doi.org/10.3390/pr13113411