1. Introduction

At present, China’s backbone oil and gas pipeline network has been largely established, covering more than 30 provinces, autonomous regions, and special administrative regions, and benefiting nearly one billion people. This network has played a crucial role in safeguarding national energy security. Natural gas receiving and storage facilities are vital means for peak shaving, and the coming decade represents a strategic window for large-scale development of UGS. Accelerating UGS construction is essential to compensate for the current shortfall in storage capacity and to further strengthen energy security. Within the UGS system, the inlet and outlet pipelines constitute critical structural components. These pipelines typically adopt a bimetallic composite configuration, consisting of an outer carbon steel structural pipe mechanically sleeved with an inner stainless-steel liner under high-pressure conditions. Notably, the two layers are mechanically bonded without welding [

1,

2]. During long-term service, bimetal composite pipes inevitably experience defects such as structural cracking, corrosion, and liner collapse, which may lead to structural failure. Therefore, ensuring the structural integrity of bimetal composite pipes is of paramount importance for the safe operation of UGS facilities [

3,

4] (see

Figure 1).

For structural cracks and corrosion defects in bimetal composite pipes, conventional nondestructive testing (NDT) methods such as eddy current testing (ECT), ultrasonic testing (UT), and magnetic flux leakage (MFL) can provide effective detection [

5,

6,

7]. However, the collapse of the stainless-steel liner in bimetal composite pipes has long been a persistent challenge in practical engineering inspection. In field applications, widely used UT and MFL methods are inherently ineffective for liner collapse detection. Specifically, due to the weak bonding between the two pipe layers, ultrasonic waves undergo severe reflection at the interface [

8], rendering UT essentially invalid for detecting liner collapse. Meanwhile, as the liner is composed of non-ferromagnetic stainless steel, MFL cannot capture collapse defects from a physical principle standpoint [

9,

10]. Furthermore, the presence of the outer carbon steel layer introduces a large magnetic reluctance at the carbon steel–stainless steel interface, which restricts magnetic flux penetration into the liner. As a result, induced eddy currents in conventional ECT or pulsed eddy current testing (PECT) [

11,

12,

13,

14,

15] cannot effectively penetrate the stainless-steel liner, making these methods intrinsically inadequate for detecting liner collapse.

Research on magnetic-saturation-assisted ECT/PECT spans multiple architectures and domains. Early pulsed magnetic-saturation systems detected OD-side flaws in thick ferromagnetic tubes using computer-controlled excitation and time-gated features [

16]. Subsequent studies optimized flux density and probe design for ferritic stainless-steel reheater tubing, improving sizing of service-induced wear and fatigue cracking under saturation [

17]. In the nuclear sector, stabilizing and lowering effective permeability in claddings (austenitic and ferritic–martensitic) enhanced inspection quality for spent fuel elements [

18]. For pipelines, saturation-regime ECT/PECT has advanced ID/OD discrimination via impedance-angle features compatible with MFL co-location [

19], and high-speed inline inspection via short-pulse PEC and differential pickup with arrayed PIG implementations [

20]. Quantitative wall-thinning evaluation under saturation has also been investigated by coupling B–H-based static-field modeling with efficient PEC forward solvers [

21]. Together, these studies show that saturation extends penetration and improves detectability in ferromagnetic steels; however, an outside-in, cross-layer quantification of an austenitic inner-liner collapse concealed behind a thick ferromagnetic base in bimetal pipes remains unestablished.

To address this gap, we present an application-oriented magnetically saturated PECT (MS-PECT) framework for outside-in assessment of liner collapse in heterogeneous bimetal pipes used in UGS [

21]. A quasi-static permanent-magnet yoke drives the base pipe toward near saturation

, which increases the effective skin depth

and redistributes magnetic flux across the base/air/liner stack, thereby enhancing cross-layer responsiveness. Building on this mechanism, we derive dimensionless identifiability conditions under which the measured differential-peak response varies monotonically with the liner–base air-gap height, enabling quantitative evaluation from the outer surface. We implement a portable probe that combines the magnetizing yoke with pulsed excitation and differential reception to improve robustness to thermal drift and lift-off, and we establish performance through finite-element modeling, controlled tests on composite pipes (14 mm carbon-steel base +2 mm stainless-steel liner), and in-service validation at a UGS facility. Benchmarks against non-saturated and saturated-but-non-differential baselines confirm improved through-thickness sensitivity and practical applicability.

The remainder of this paper is organized as follows: First, the limitations of conventional eddy current testing in detecting liner collapse are analyzed, with particular emphasis on the mechanism by which eddy current fields and magnetic flux lines fail to penetrate the carbon steel layer into the stainless-steel liner. Next, the proposed MS-PECT method is introduced and its underlying principle explained. This is followed by a numerical simulation study to preliminarily verify the feasibility of MS-PECT for liner collapse detection. Finally, a prototype MS-PECT system is constructed, and its effectiveness is validated through experimental testing, including successful detection of liner collapse in in-service bimetal composite pipes at the Hutubi UGS in Xinjiang.

2. Challenges of Eddy Current Testing for Detecting Collapse in Heterogeneous Bimetallic Structures

The key issue of this study lies in how to maximize the penetration of the eddy current field, induced by the excitation coil, into the stainless-steel liner of the pipeline. To this end, the effectiveness of conventional eddy current testing (ECT) for detecting collapse defects in heterogeneous bimetallic structures was first investigated through numerical simulations.

A two-dimensional axisymmetric model of a carbon steel–stainless steel bilayer structure was established, as shown in

Figure 2a. Collapse defects of varying severity were simulated by introducing air gaps of different thicknesses within the stainless-steel liner. Finite-element setup: a transient 2D axisymmetric eddy-current formulation in magnetic vector potential was solved using first-order edge triangular elements. The computational domain was truncated at 8× the outer radius with magnetic insulation on the truncation boundary and axial symmetry at r = 0. Boundary-layer meshing at all interfaces (carbon steel/air/liner) used a maximum element size ≤0.20 mm with graded growth ≤1.2; the final mesh contained 1.7 × 10

5 elements (9.0 × 10

4 nodes). A fixed time step of Δt = 10 μs was adopted; further mesh/time-step refinements changed the coil response by <2%.

Figure 2b illustrates the influence of air-gap size on the detection-coil signal, indicating that the effect is minimal. To further clarify this phenomenon,

Figure 2c presents the magnetic-field distribution in the carbon steel and stainless-steel layers when the air gap is set to 10 mm. The results show that the majority of magnetic-flux lines are concentrated within the carbon-steel layer, with only a negligible portion penetrating into the stainless-steel liner. Consequently, conventional ECT methods are unable to reliably detect the presence or severity of collapse defects represented by the air gap.

The findings can be summarized as follows: owing to the high magnetic permeability of carbon steel, (i) the magnetic reluctance at the carbon steel–stainless steel/air interface is very large, allowing only a negligible portion of the magnetic field to penetrate into the stainless-steel liner; and (ii) the penetration depth of eddy currents within the carbon steel is also very limited. As a result, it is extremely difficult to directly detect the size of air gaps in bilayer pipes using conventional PECT.

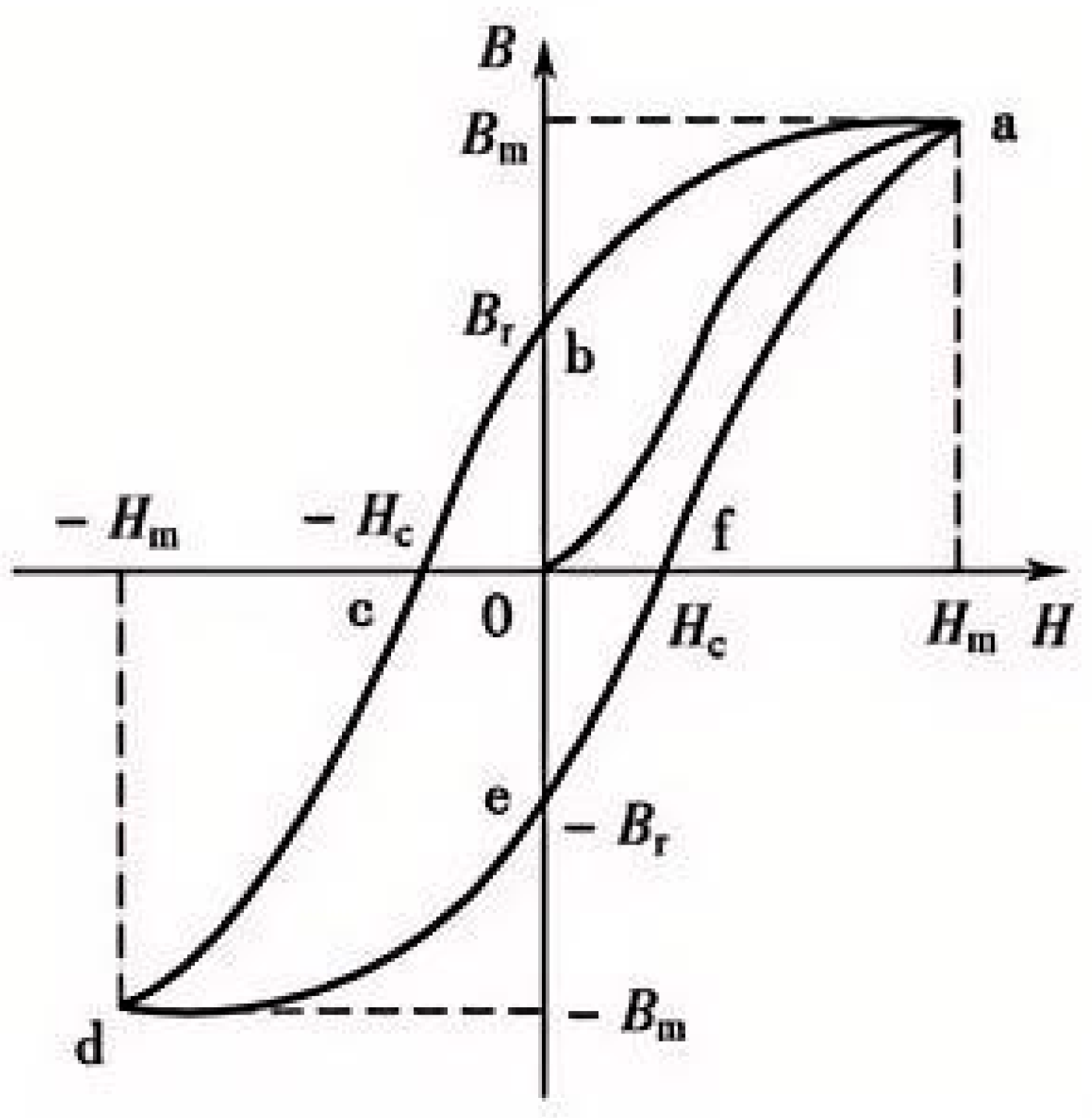

To address this limitation, the present study innovatively introduces the concept of magnetic saturation. As illustrated in

Figure 3, magnetic saturation refers to the phenomenon whereby the magnetization of a ferromagnetic material increases with the applied external magnetic field until it reaches a critical level, beyond which further increases in field strength do not result in additional magnetization. Under saturation conditions, the relative magnetic permeability of carbon steel approaches unity, comparable to that of stainless steel. This eliminates the magnetic flux confinement effect of carbon steel, enabling both magnetic flux lines and the eddy current field to more readily penetrate into the stainless-steel liner.

Based on this principle, an MS-PECT method was developed in this study, and its effectiveness in detecting liner collapse in heterogeneous bimetal composite pipes was systematically verified.

3. Mechanism of Enhanced Eddy Current Skin Depth via Magnetic Saturation

MS-PECT is an advanced technique developed on the basis of conventional PECT. As illustrated in

Figure 4, the fundamental principle of PECT is to apply a square-wave excitation signal with a specified frequency and duty cycle to the excitation coil. This generates a rapidly varying pulsed magnetic field in the surrounding space of the coil. When the coil approaches the test specimen, a transient eddy current field and the corresponding secondary magnetic field are induced within the material. The intensity and distribution of this eddy current field are influenced by factors such as the material properties and the presence of defects. Therefore, by monitoring the magnetic field distribution on the specimen surface using pickup coils or magnetic field sensors, it is possible to detect the presence of defects, as well as to infer their location and size.

Since the distribution of the induced eddy current field exhibits a skin effect—i.e., the closer to the specimen surface, the higher the eddy current density—the detection depth of conventional PECT is inherently limited. This limitation is characterized by the skin depth. Assuming that the electrical conductivity and magnetic permeability of the specimen are denoted by γ and μ, respectively, and the angular frequency of the excitation signal is ω, the skin depth d can be expressed as:

From Equation (1), it can be observed that higher excitation frequency, electrical conductivity, or magnetic permeability leads to a smaller skin depth, thereby intensifying the skin effect. Since the electrical conductivity of non-ferromagnetic and ferromagnetic materials differs only slightly, but the magnetic permeability of non-ferromagnetic materials is far lower than that of ferromagnetic ones, the skin effect is weaker in non-ferromagnetic materials. Consequently, conventional PECT usually performs better in detecting non-ferromagnetic materials. However, according to the magnetization curve of ferromagnetic materials, once a ferromagnetic material reaches magnetic saturation, its magnetic permeability decreases sharply. Under such conditions, the performance of PECT for ferromagnetic specimens can be significantly improved. Based on this analysis, the fundamental principle of MS-PECT lies in exploiting the magnetization characteristics of ferromagnetic materials: by driving the specimen into magnetic saturation, the skin effect is weakened, thus enhancing the effectiveness of PECT in detecting defects in ferromagnetic components.

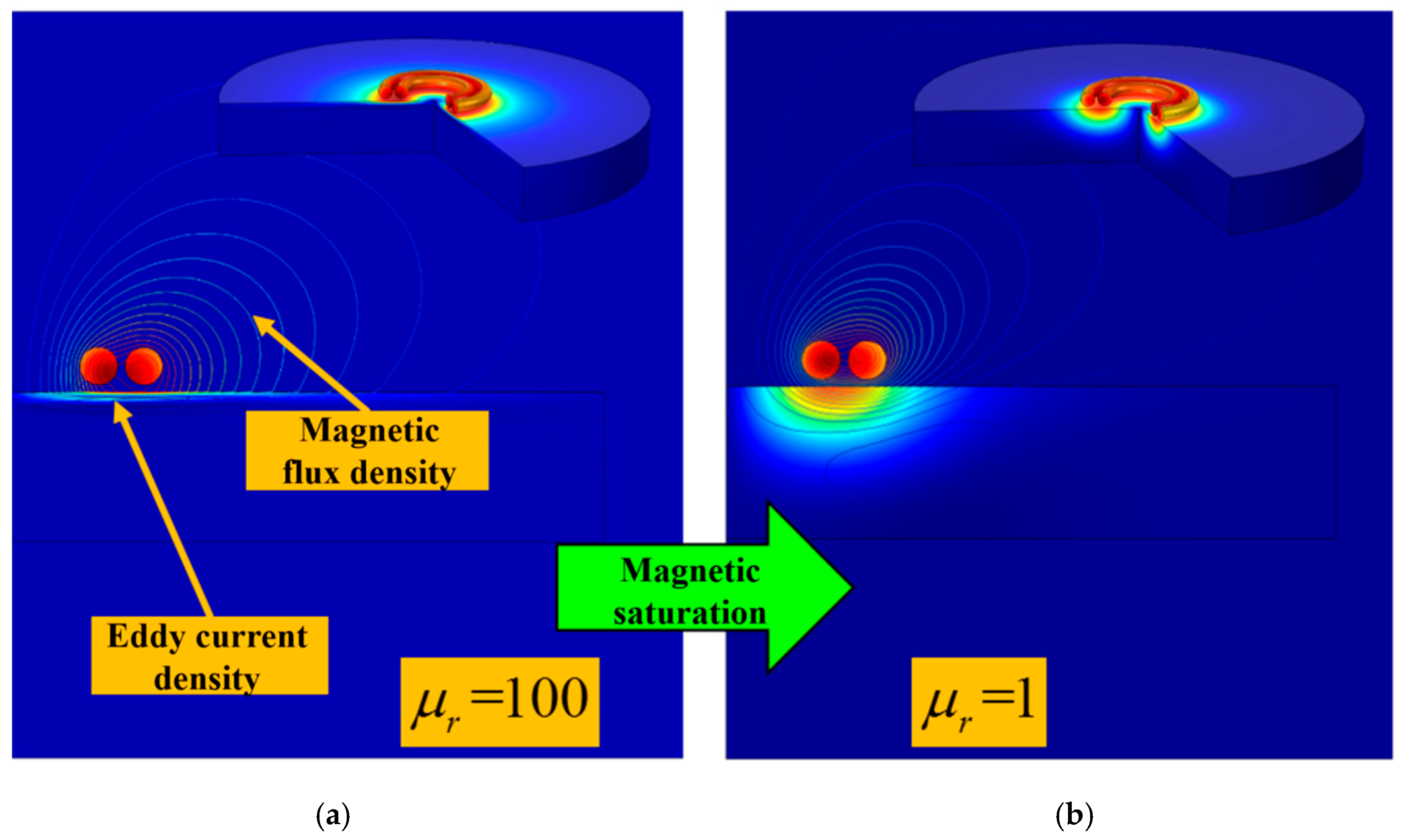

To further clarify the influence of magnetic saturation on skin depth, numerical simulations of single-frequency eddy currents were conducted, and the results are shown in

Figure 5. When the relative magnetic permeability is set to 100, the magnetic flux density is predominantly concentrated near the conductor surface, with negligible penetration into deeper regions. Accordingly, the induced eddy currents are confined to the near-surface area, which makes the detection signal highly sensitive to surface defects but ineffective for deeper defects. In contrast, when the relative permeability decreases to unity, the magnetic flux density becomes more uniformly distributed along the depth of the conductor, and the eddy current penetration depth increases significantly. As a result, the detection signal becomes capable of identifying defect information across a deeper range, thereby enhancing the overall detection capability of ECT.

Furthermore, from the perspective of the Fourier transform, the pulsed excitation signal can be considered as a linear superposition of multiple single-frequency eddy current signals. Hence, the improvement in detection capability at individual frequencies also enhances the overall performance of PECT. In addition, the rich frequency components and the ability to deliver higher current amplitude make PECT superior to single-frequency eddy current testing.

The above analysis, combining both theoretical modeling and numerical simulation, explains the mechanism by which magnetic saturation improves PECT performance by increasing the effective skin depth of eddy currents, and preliminarily validates the feasibility of the proposed MS-PECT method.

4. Numerical Validation of MS-PECT for Detecting Liner Collapse

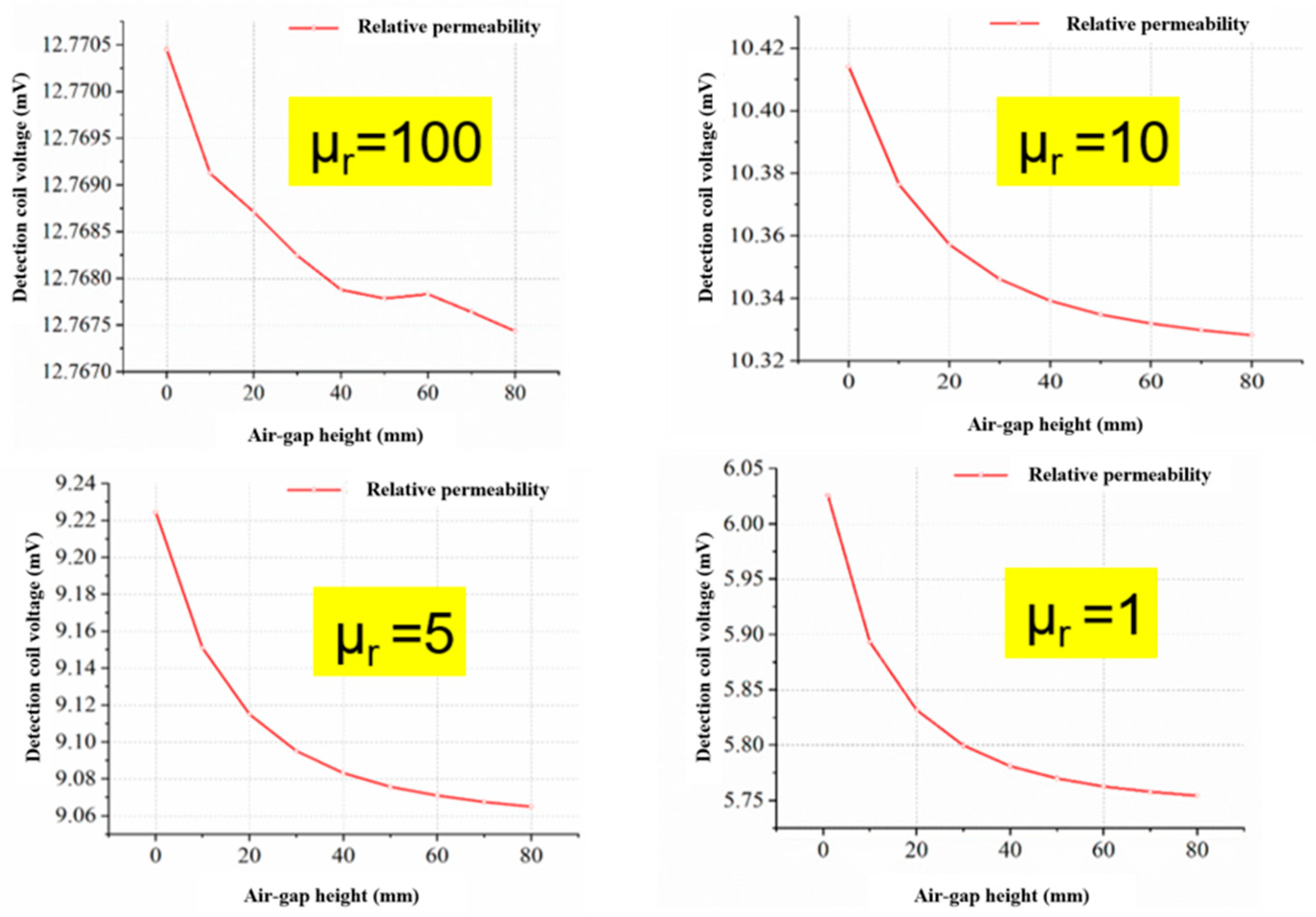

To further investigate the effectiveness of PECT for detecting stainless-steel liner collapse in heterogeneous bimetal composite pipes under magnetic saturation, finite element method (FEM)-based simulations were conducted. As discussed above, magnetic saturation reduces the relative magnetic permeability of carbon steel, thereby allowing a greater portion of the magnetic field to penetrate into the stainless-steel liner. Based on this principle, numerical simulations were performed to evaluate the detection performance of PECT with varying relative magnetic permeability of carbon steel, focusing on its capability to identify the height of air gaps between the carbon steel and stainless-steel layers.

Figure 6 illustrates the influence of air gap size on the detection coil voltage signal when the relative permeability of carbon steel is set to 100, 10, 5, and 1, respectively. The results reveal that although the absolute magnitude of the detection coil signal decreases with decreasing permeability, both the absolute difference and the relative difference in signal amplitude corresponding to different air gap sizes increase significantly. This enhancement improves the ability to distinguish and detect air gaps effectively.

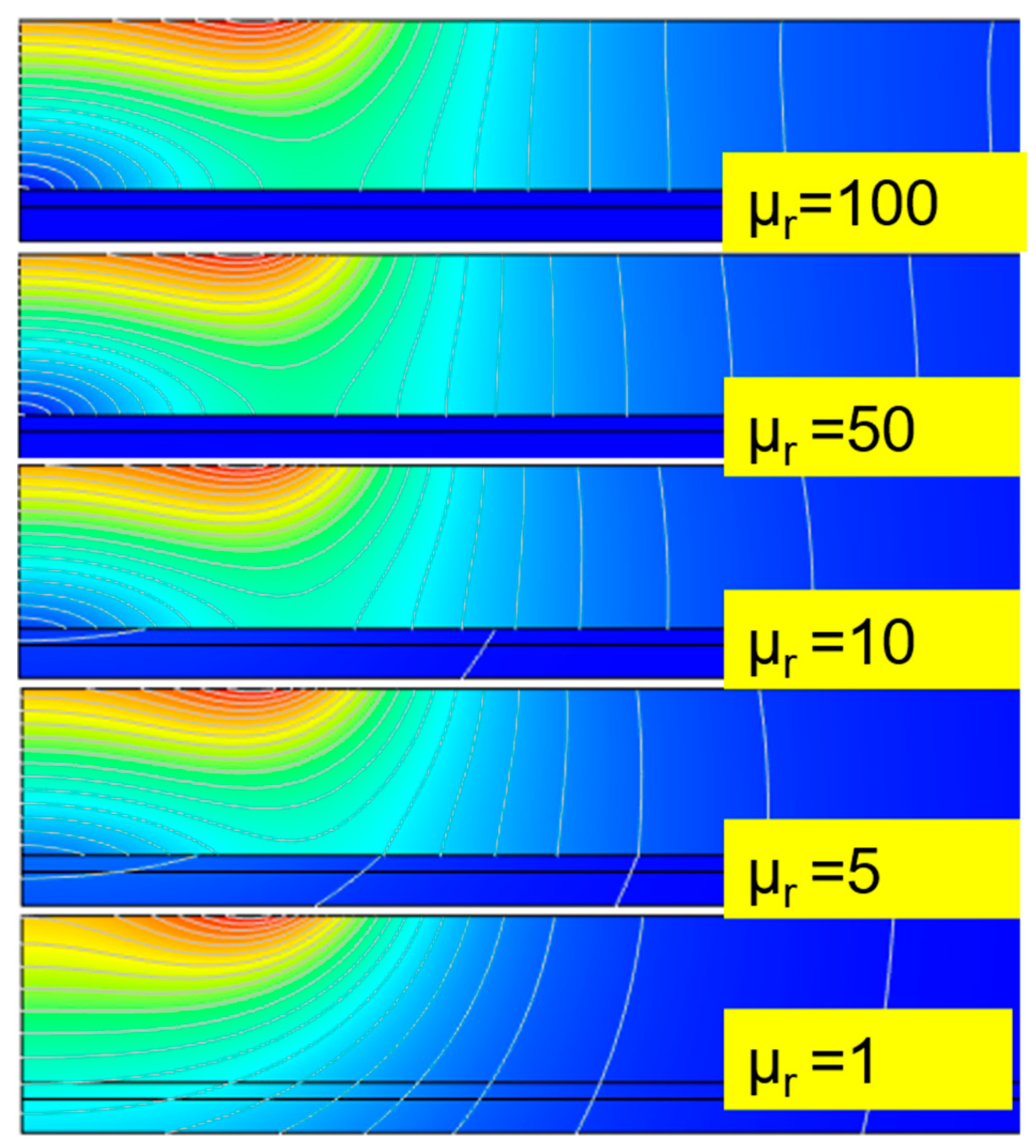

Furthermore,

Figure 7 demonstrates that as the relative permeability of carbon steel decreases, magnetic flux lines penetrate more deeply into the stainless-steel liner. This phenomenon provides a mechanistic explanation for the improved detectability of air gaps under magnetic saturation.

5. Experimental Validation of MS-PECT for Detecting Liner Collapse

After analyzing the mechanism of MS-PECT and validating its feasibility through numerical simulations, experimental studies were carried out to further verify its effectiveness. Based on the fundamental principle of MS-PECT, a complete detection system was developed. Using this system, experimental validation was conducted, including the successful detection of liner collapse in in-service bimetal composite pipes from the Hutubi UGS in Xinjiang.

5.1. Experimental System and Specimens

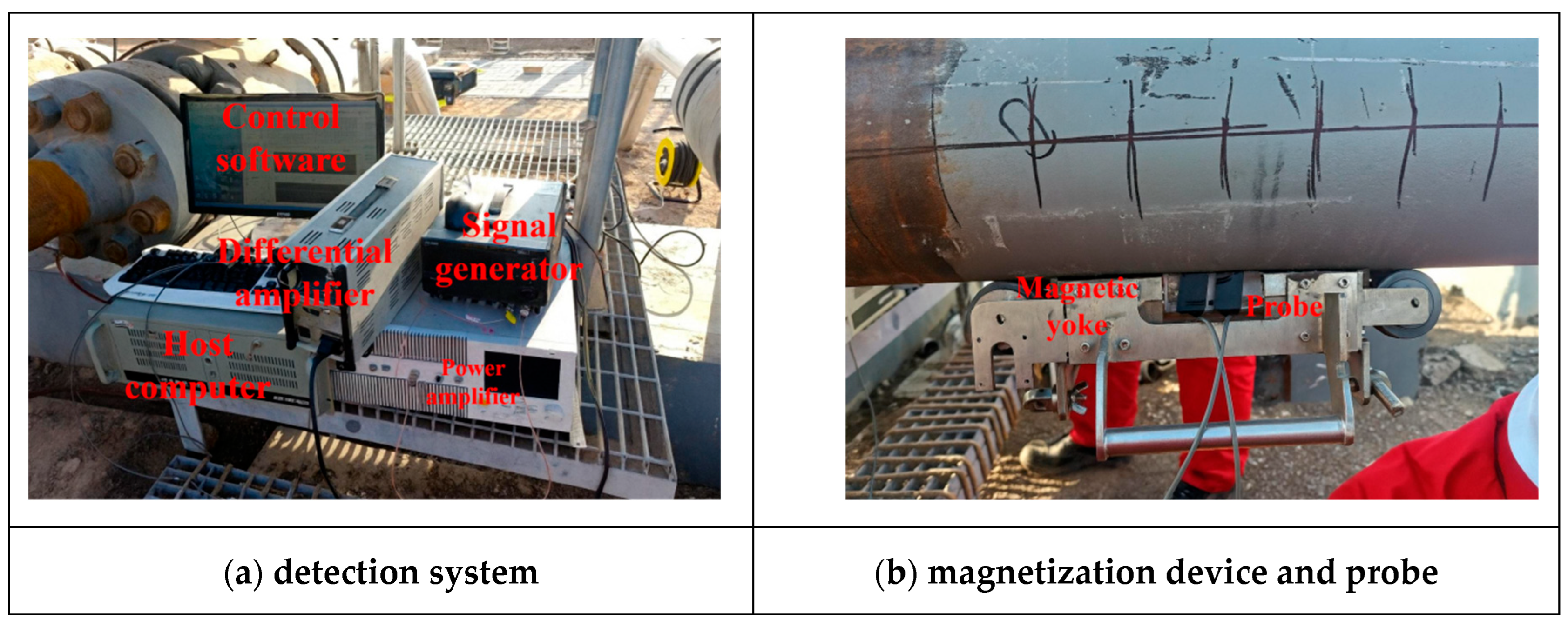

The schematic diagram of the MS-PECT system developed in this study is shown in

Figure 8. The system consists of control software, a host unit, a differential amplifier, a signal generator, a power amplifier, a probe, and permanent magnets. The workflow is as follows: first, the magnets are placed on the pipeline to drive it into magnetic saturation, and the probe is fixed within the magnetic yoke. A square-wave signal of a given frequency is then generated by the signal generator and amplified through the power amplifier before being applied to the excitation coil. This process induces eddy currents and magnetic fields in the pipeline. The pickup coil detects variations in the surface magnetic field of the specimen and outputs a time-varying voltage signal. This signal is subsequently amplified by the differential amplifier and collected and processed by the host unit to obtain defect information of the pipe structure.

Figure 9a and

Figure 9b show the experimental MS-PECT system and the magnetization–probe assembly, respectively.

The detailed parameters of the probe are listed in

Table 1, and the center spacing of the probe was maintained at 20 mm throughout the experiments.

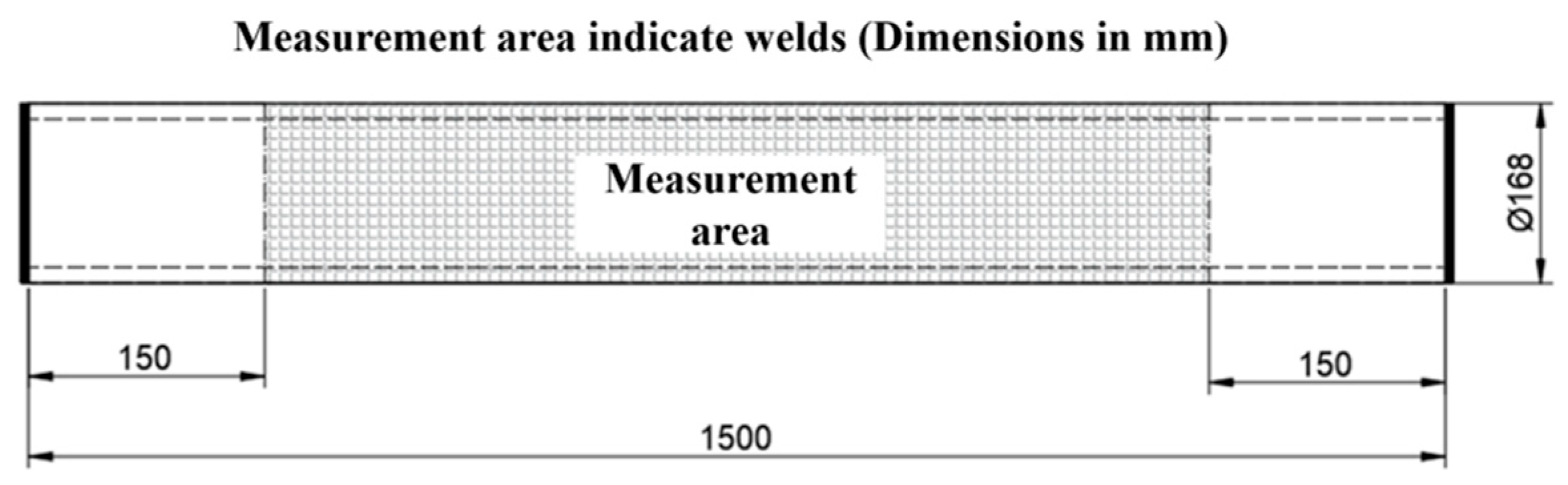

The specimen used in this experiment was a heterogeneous bimetal composite pipe removed from service at the Hutubi UGS in Xinjiang. The outer carbon steel layer had a diameter of 168 mm and a thickness of 14 mm, while the inner stainless-steel liner had a wall thickness of 2 mm. The distance between the two weld seams was 150 cm. According to endoscopic inspection, liner collapse was observed within the region approximately 15–80 cm from the left weld seam.

For testing, four detection lines were uniformly arranged along the circumferential direction of the pipe. The origin of the circumferential coordinate system was defined as the center of the liner collapse region. Along each detection line, measurement points were distributed axially at 5 cm intervals, with 25 points per line, resulting in a total of 4 × 25 = 100 measurement points for the entire pipe.

Figure 10 and

Figure 11 present the photographs and schematic dimensions of the tested pipe, respectively.

5.2. Experimental Results and Analysis

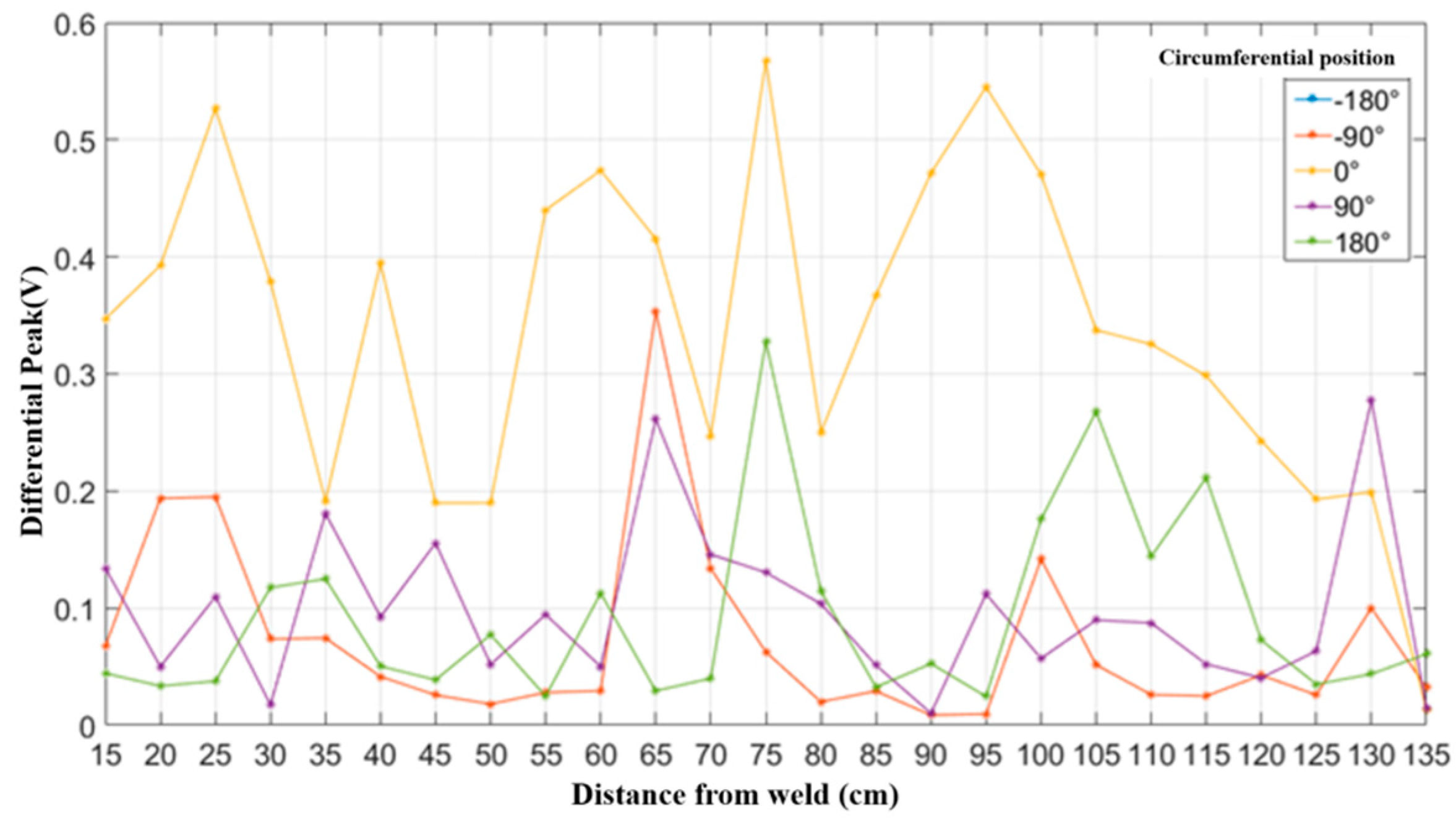

After acquiring the data at each measurement point, the last measurement point on each axial detection line was selected as the reference point, since no liner collapse was present at the right end of the pipe. Differential signals were obtained by subtracting the signal of the reference point from those of all other measurement points along the same detection line (the reference differential signal being the difference between two successive detections at the reference point). The peak value of each differential signal was then extracted, and the variation curves of differential peak values along the detection lines were plotted, as shown in

Figure 12.

As observed in

Figure 12, the differential peak values at locations without liner collapse are not zero. This phenomenon can be attributed to two primary factors: (i) temperature rise of the probe during operation, and (ii) lift-off variations introduced when moving the magnet assembly, both of which generate additional noise in the signals.

Based on the above data processing method, the differential peak value variation curves for all detection lines were obtained, as shown in

Figure 9. It can be observed that the differential peak values along the 0° detection line are significantly larger than those at other circumferential positions, which corresponds precisely to the location of the liner collapse. This result demonstrates the feasibility of using MS-PECT for detecting stainless-steel liner collapse in heterogeneous bimetal composite pipes. The spatial localization of the liner-collapse region and its borescope confirmation are shown in

Figure 13.

To obtain a more intuitive representation of the detection results, interpolation and visualization post-processing were applied to the measured data, and the final detection map is shown in

Figure 14. In this figure, the blue solid box indicates the actual collapse location identified by endoscopic inspection, while the red dashed box corresponds to the collapse region detected using the proposed MS-PECT method. As can be seen, the two results exhibit good agreement, confirming that the proposed method can effectively detect stainless-steel liner collapse in heterogeneous bimetal composite pipes.

It is also noted that a pronounced peak appears outside the actual collapse region in the MS-PECT detection results. This anomaly may be attributed to the presence of other types of defects in that area, such as surface corrosion or cracking, which can introduce localized variations in conductivity or magnetic permeability and thereby generate secondary responses in the differential pickup coils. Although this phenomenon does not significantly affect the identification of the main collapse region, it highlights the need for further refinement of discrimination criteria when multiple defect mechanisms coexist.

To interpret the detection map and guide parameter selection, we use a control-oriented model that links inputs—magnetizing current, pulse width, and duty cycle—and disturbances (lift-off, temperature) to the outputs used for decision-making: the differential peak and a saturation indicator. Linearization around the operating point shows that, within the inspected range, the differential peak exhibits a monotonic sensitivity to the liner–base air-gap a (0–1.5 mm), while the near-saturation condition reduces the incremental permeability of the base pipe toward μ, thereby enlarging the effective skin depth and stabilizing cross-layer response. The model also indicates that lift-off mainly appears as a multiplicative perturbation on the coupling term, which is attenuated by differential reception, and that excessively long pulses increase thermal load without further sensitivity gain. Consequently, the recommended setting is to maintain the saturation indicator above a threshold while choosing pulse widths that resolve the fast edge but avoid coil heating, which aligns with the trends observed in the detection map.

In addition to the visual validation, it is important to consider the accuracy and reliability of the method. While destructive verification or direct measurement of the liner–base air gap was not feasible in this in-service case, accuracy can be formally defined through established nondestructive evaluation metrics. Specifically, the air-gap estimation accuracy should be quantified by mean absolute error (MAE) and root mean square error (RMSE) when ground-truth measurements are available. For collapse classification, the most relevant indicators are receiver operating characteristic (ROC)–based area under the curve (AUC), as well as accuracy, sensitivity, and specificity. Furthermore, the method’s robustness under operational variations—such as coil lift-off and temperature fluctuations—should be evaluated using the coefficient of variation (CV) across repeated measurements. These definitions align with standard practice in the electromagnetic NDE community and provide a clear framework for future quantitative assessment.

For the current dataset, we restrict our claims to relative comparisons, namely that the proposed MS-PECT approach yields consistent detection of collapse regions and matches the location confirmed by endoscopy. A full set of numerical accuracy benchmarks will be obtained in controlled trials where ground truth is accessible. By clarifying the evaluation framework and acknowledging the limitations of the present dataset, the study ensures that the conclusions remain robust while also pointing to future work required for establishing absolute accuracy levels.

6. Conclusions

The core innovation of this study lies in applying magnetic saturation to the base pipe of heterogeneous bimetallic composite structures. First, magnetic saturation reduces the magnetic permeability of the base pipe, thereby effectively increasing the penetration depth of pulsed eddy currents. Second, by significantly weakening the confinement of magnetic flux lines within the base pipe, magnetic saturation enables the flux to traverse both the base pipe and the air gap between the two layers, reaching the stainless-steel liner and inducing eddy currents within it. The induced eddy currents in the liner are affected and perturbed by variations in the air gap size, i.e., different levels of liner collapse. Thus, by magnetically saturating the base pipe, the sensitivity of the detection probe to different degrees of liner collapse can be greatly enhanced, significantly improving the accuracy of liner collapse detection.

Building on this principle, this study carried out numerical simulations, developed a complete MS-PECT system, and performed experimental investigations on collapse detection in heterogeneous bimetal composite pipes. The experiments successfully achieved effective detection of liner collapse in in-service composite pipes from the Hutubi UGS. Future work will focus on optimizing the magnetic yoke design and advancing quantitative evaluation methods for different collapse severities.

Author Contributions

Conceptualization, S.X.; Methodology, S.X.; Validation, L.M.; Formal analysis, S.X. and P.X.; Investigation, S.X., P.X., L.M., T.L. and X.M.; Resources, J.L. and L.L.; Data curation, S.X., P.X., L.M., T.L. and X.M.; Writing–original draft, S.X.; Supervision, J.L.; Funding acquisition, P.X., J.L. and L.L. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful for the funding support of the Scientific research and technology development project of CNPC: Research on safety assessment technology of injection production conversion process in gas storage (KT2020-16-06).

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

Authors Shuyi Xie, Jinheng Luo and Lifeng Li were employed by the company CNPC Tubular Goods Research Institute. Authors Peng Xu, Liya Ma, Tao Liang, Xiaoxiao Ma were employed by the company Gas Storage Co., Ltd., PetroChina Xinjiang Oilfield Company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhang, S.; Xie, F.; Li, X.L.; Luo, J.; Su, G.; Zhu, L.Z.; Chen, Q. Failure analysis of the leakage in girth weld of bimetal composite pipe. Eng. Fail. Anal. 2023, 143, 106917. [Google Scholar]

- Zhang, S.; Ma, Q.; Xu, C.; Li, L.; Wang, M.; Zhang, Z.; Wang, S.; Li, L. Root cause analysis of liner collapse and crack of bi-metal composite pipe used for gas transmission. Eng. Fail. Anal. 2022, 132, 105942. [Google Scholar] [CrossRef]

- Chen, H.; Ma, H.; Chen, X.; Jiang, S.; Wang, H. Failure analysis of butt weld of bimetal composite pipes. J. Fail. Anal. Prev. 2015, 15, 563–570. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, T. Buckling failure mechanism of liner pipe in bimetal mechanical clad pipe under complex loading. Ocean Eng. 2022, 262, 112091. [Google Scholar] [CrossRef]

- Hu, T.; Guo, J. Development and application of new technologies and equipment for in-line pipeline inspection. Nat. Gas Ind. B 2019, 6, 404–411. [Google Scholar] [CrossRef]

- Li, X.; Yu, W.; Lin, X.; Iyengar, S.S. On optimizing autonomous pipeline inspection. IEEE Trans. Robot. 2011, 28, 223–233. [Google Scholar] [CrossRef]

- Ma, Q.; Tian, G.; Zeng, Y.; Li, R.; Song, H.; Wang, Z.; Gao, B.; Zeng, K. Pipeline in-line inspection method, instrumentation and data management. Sensors 2021, 21, 3862. [Google Scholar] [CrossRef]

- Lyu, F.; Zhou, X.; Ding, Z.; Qiao, X.; Song, D. Application research of ultrasonic-guided wave technology in pipeline corrosion defect detection: A review. Coatings 2024, 14, 358. [Google Scholar] [CrossRef]

- Feng, B.; Wu, J.; Tu, H.; Tang, J.; Kang, Y. A review of magnetic flux leakage nondestructive testing. Materials 2022, 15, 7362. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Zhang, C.; Li, R.; Cai, M.; Jia, G. Theory and application of magnetic flux leakage pipeline detection. Sensors 2015, 15, 31036–31055. [Google Scholar] [CrossRef] [PubMed]

- Xie, S.; Yang, S.; Tian, M.; Zhao, R.; Chen, Z.; Zheng, Y.; Uchimoto, T.; Takagi, T. A hybrid nondestructive testing method of pulsed eddy current testing and electromagnetic acoustic transducer techniques based on wavelet analysis. NDT E Int. 2023, 138, 102900. [Google Scholar] [CrossRef]

- Xie, S.; Tian, M.; Xiao, P.; Pei, C.; Chen, Z.; Takagi, T. A hybrid nondestructive testing method of pulsed eddy current testing and electromagnetic acoustic transducer techniques for simultaneous surface and volumetric defects inspection. NDT E Int. 2017, 86, 153–163. [Google Scholar] [CrossRef]

- Xie, S.; Chen, Z.; Takagi, T.; Uchimoto, T. Quantitative non-destructive evaluation of wall thinning defect in double-layer pipe of nuclear power plants using pulsed ECT method. NDT E Int. 2015, 75, 87–95. [Google Scholar] [CrossRef]

- Cheng, W. Pulsed Eddy Current Testing of Carbon Steel Pipes’ Wall-thinning Through Insulation and Cladding. J. Nondestruct. Eval. 2012, 31, 215–224. [Google Scholar] [CrossRef]

- Xie, S.; Zhang, L.; Zhao, Y.; Wang, X.; Kong, Y.; Ma, Q.; Chen, Z.; Uchimoto, T.; Takagi, T. Features extraction and discussion in a novel frequency-band-selecting pulsed eddy current testing method for the detection of a certain depth range of defects. NDT E Int. 2020, 111, 102211. [Google Scholar] [CrossRef]

- Dodd, C.V.; Deeds, W.E.; Chitwood, L.D. Eddy Current Inspection of Ferromagnetic Materials Using Pulsed Magnetic Saturation; Oak Ridge National Lab.: Oak Ridge, TN, USA, 1988. [Google Scholar]

- Lee, H.J.; Cho, C.H.; Nam, M.W.; Yoo, H.J.; Hong, S.-Y. Eddy current testing of type-439 stainless steel tubing using magnetic saturation technique. J. Mech. Sci. Technol. 2012, 26, 2081–2085. [Google Scholar] [CrossRef]

- Sukhikh, A.V.; Sagalov, S.S. Application of the magnetic saturation method for eddy-current inspection of spent fuel elements from fast reactors. At. Energy 2007, 102, 139–145. [Google Scholar] [CrossRef]

- Long, Y.; Huang, S.; Zheng, Y.; Wang, S.; Zhao, W. A method using magnetic eddy current testing for distinguishing ID and OD defects of pipelines under saturation magnetization. Appl. Comput. Electromagn. Soc. J. (ACES) 2020, 35, 1089–1098. [Google Scholar] [CrossRef]

- Piao, G.; Guo, J.; Hu, T.; Deng, Y.; Leung, H. A novel pulsed eddy current method for high-speed pipeline inline inspection. Sens. Actuators A Phys. 2019, 295, 244–258. [Google Scholar] [CrossRef]

- Xie, S.; Tian, M.; Chen, H.-E.; Zhao, Y.; Wu, L.; Chen, Z.; Uchimoto, T.; Takagi, T. Evaluation of wall thinning defect in magnetic material based on PECT method under magnetic saturation. Int. J. Appl. Electromagn. Mech. 2017, 55, 49–59. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).