Numerical Simulation of Shallow Coalbed Methane Based on Geology–Engineering Integration

Abstract

1. Introduction

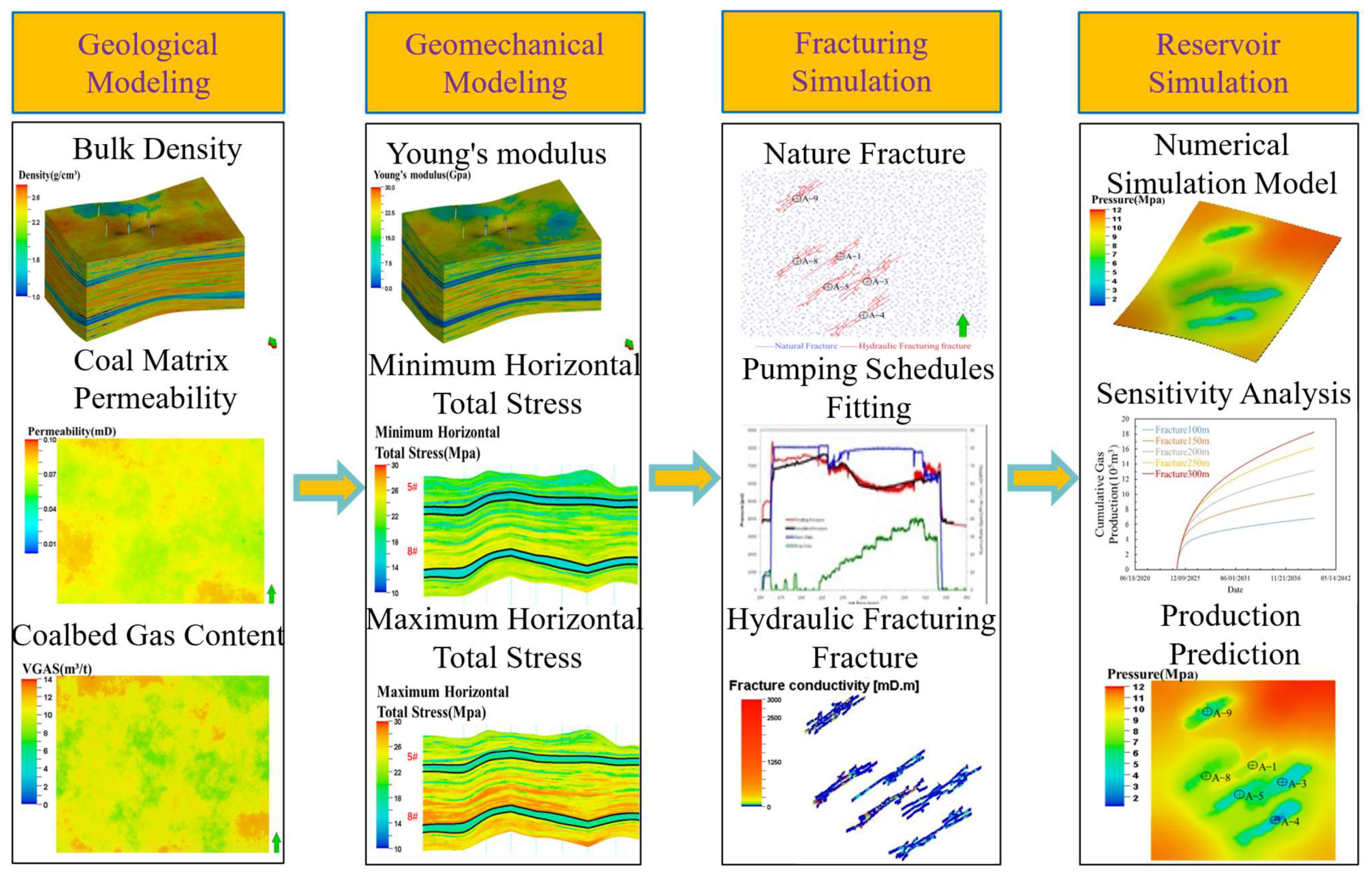

2. Geology–Engineering-Integrated Simulation for CBM

2.1. Overview of the Study Area

2.2. Geology–Engineering-Integrated Simulation

3. The Geological and Geomechanical Models of CBM

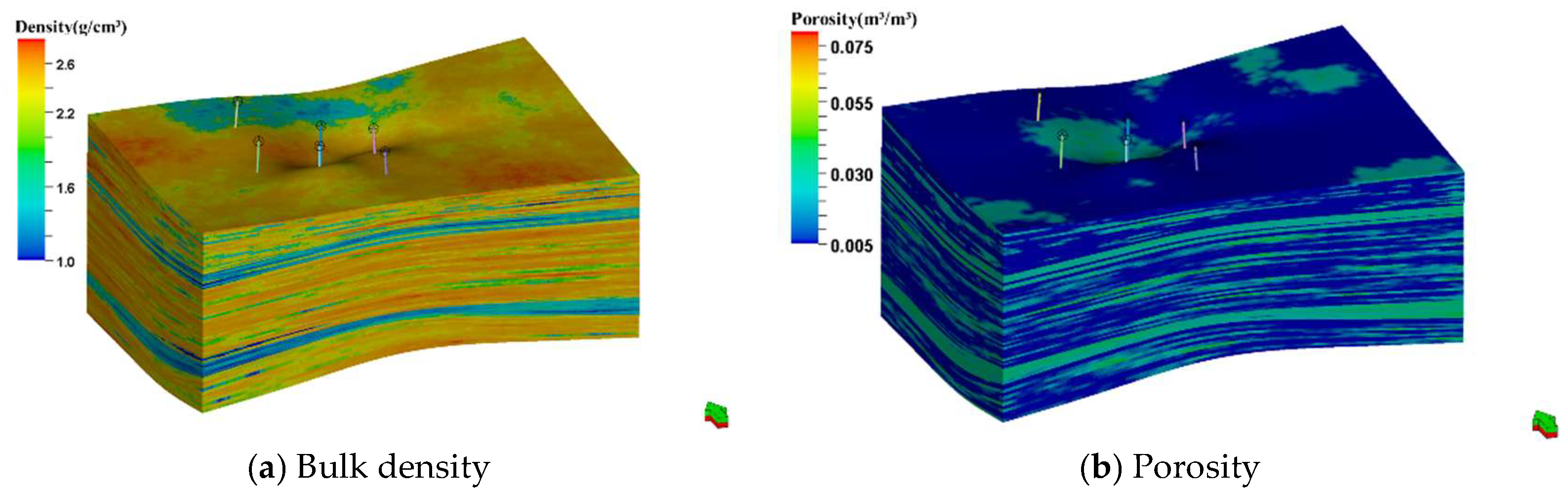

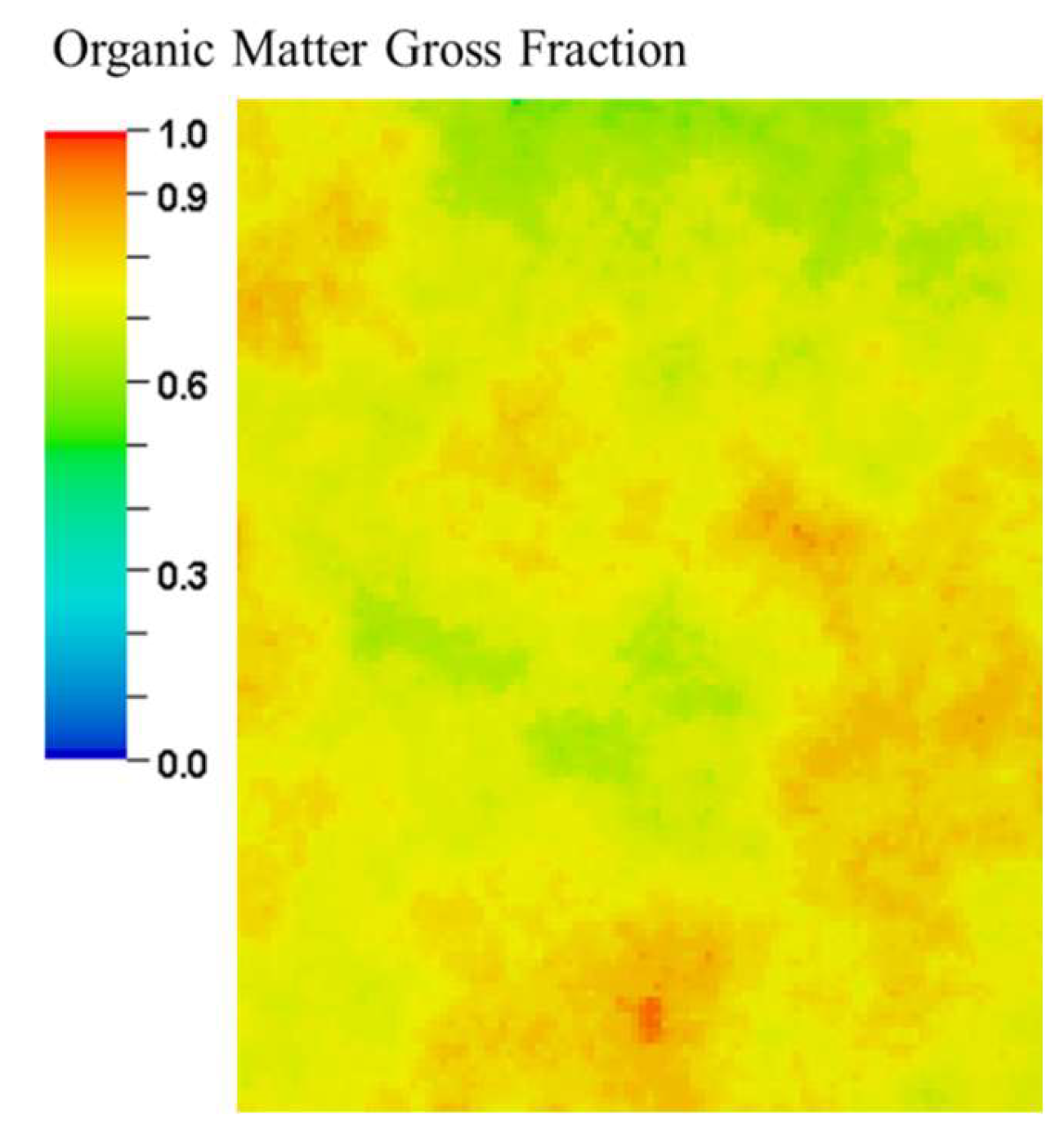

3.1. Construction of Geological Model

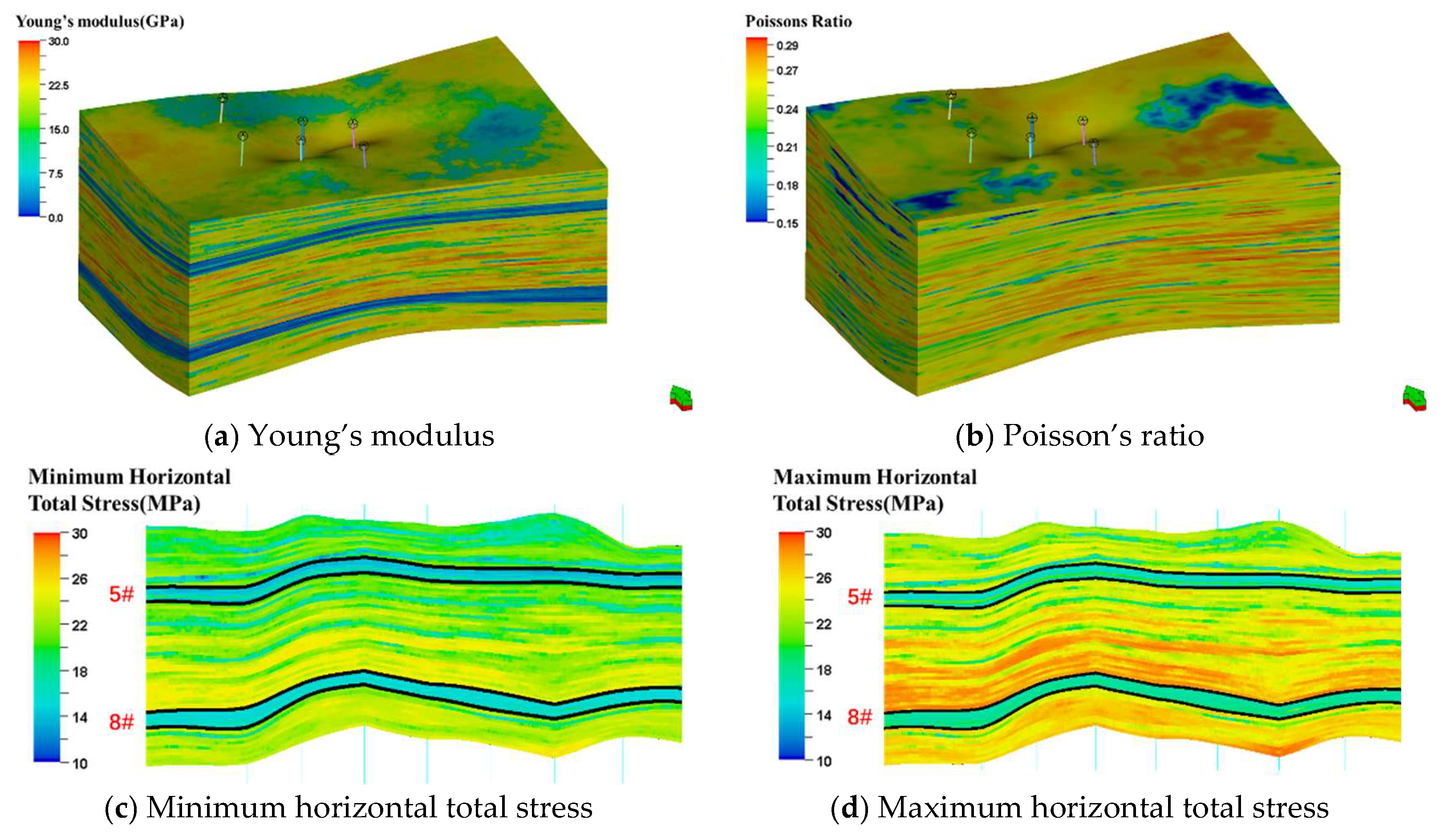

3.2. Construction of Geomechanical Model

4. Fracturing-Production Coupling Simulation for CBM

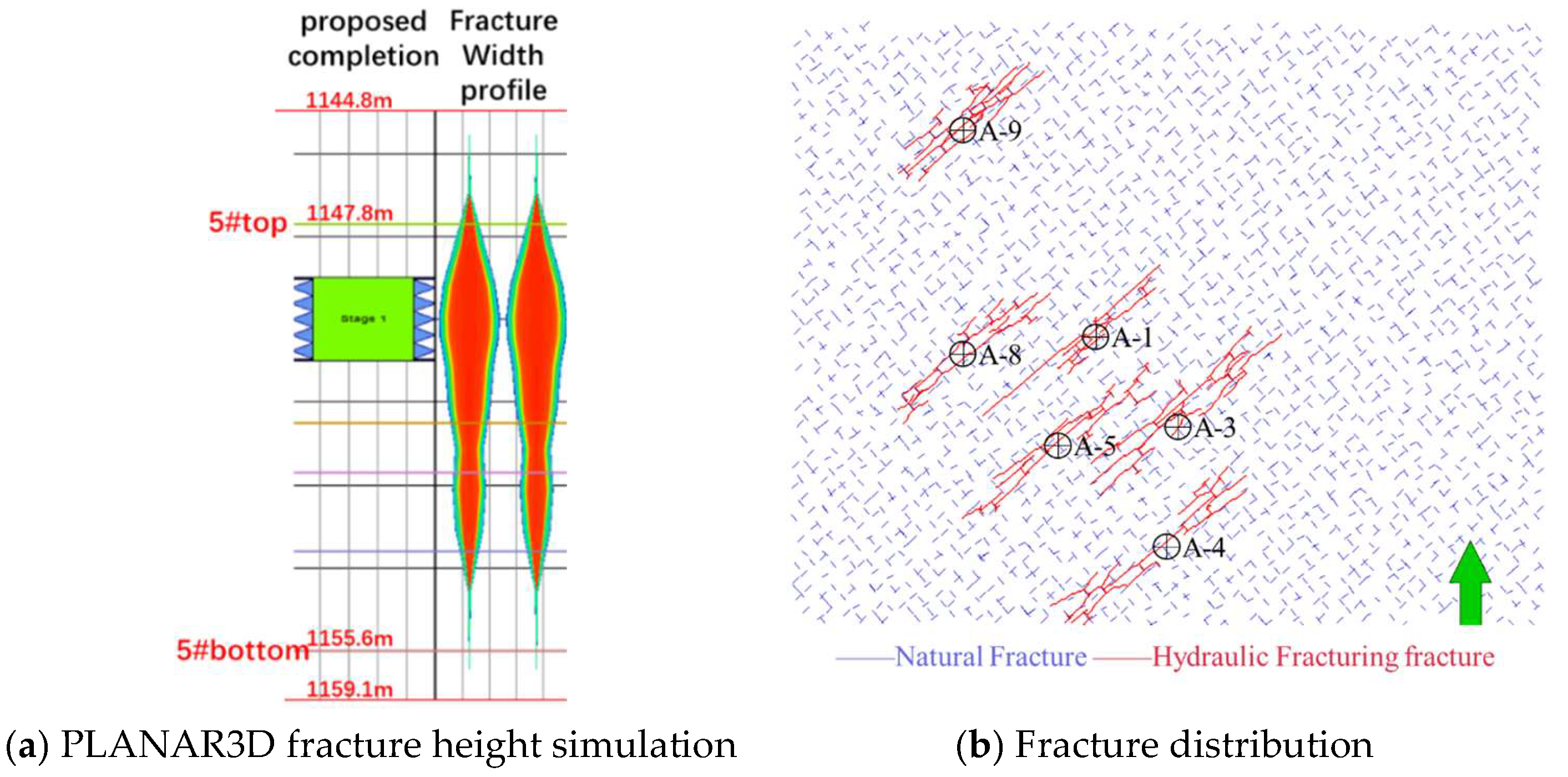

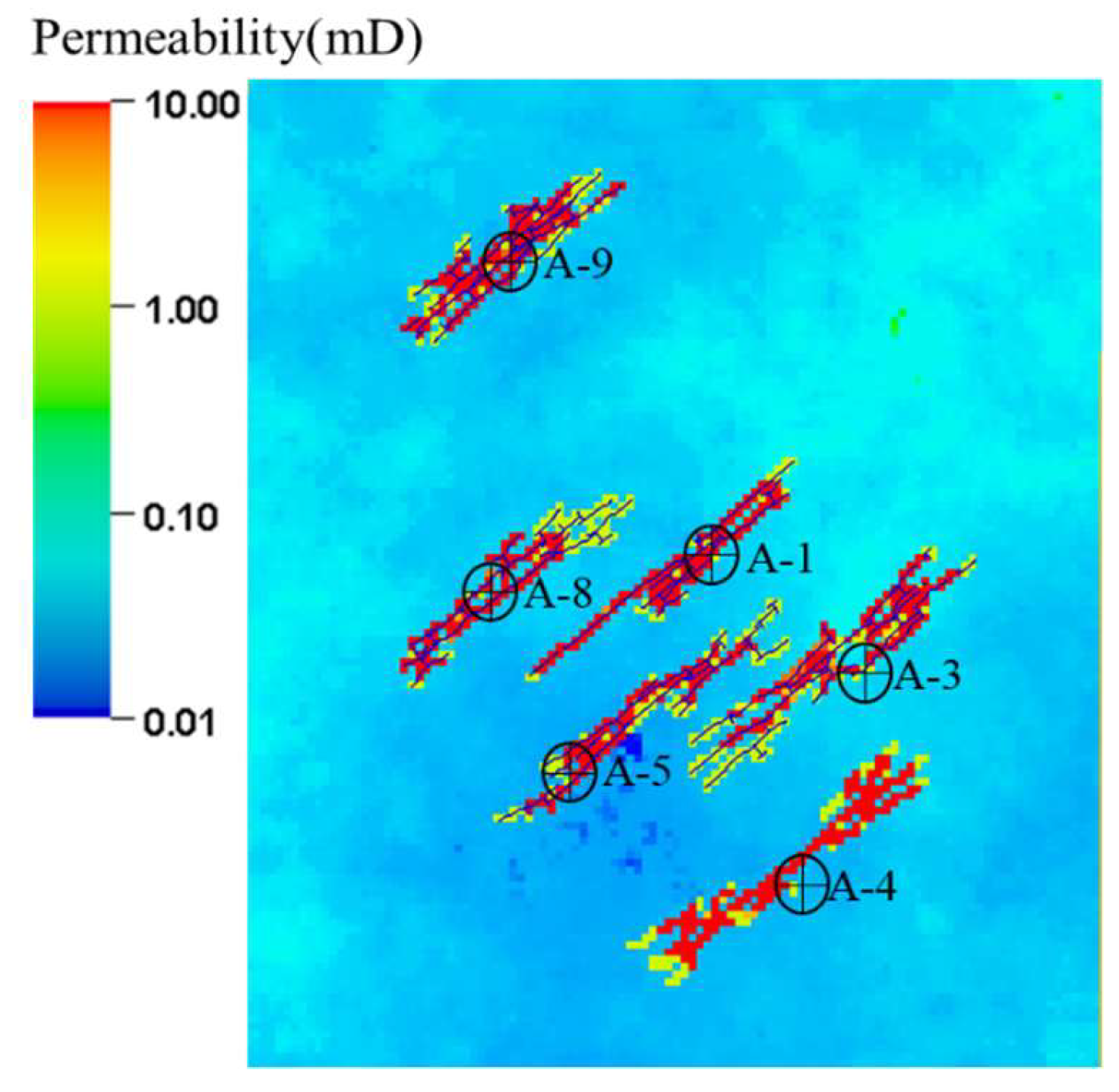

4.1. Well-Group Fracturing Simulation

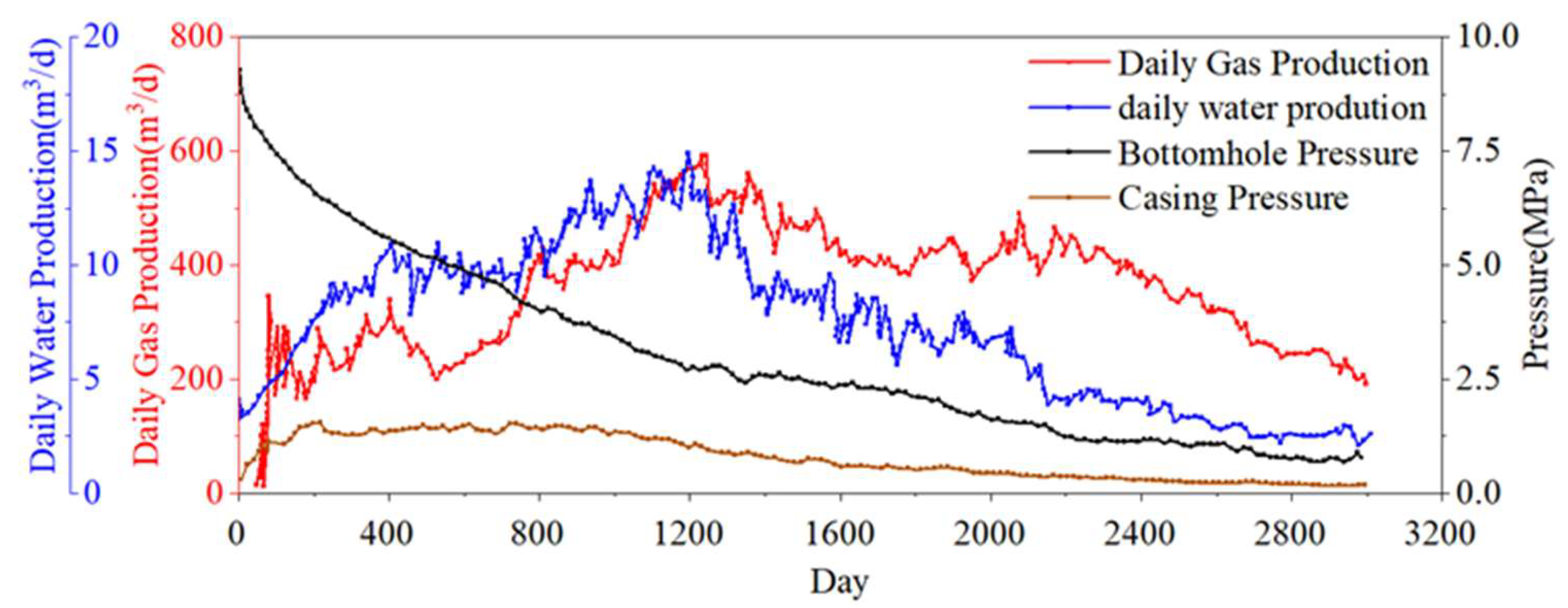

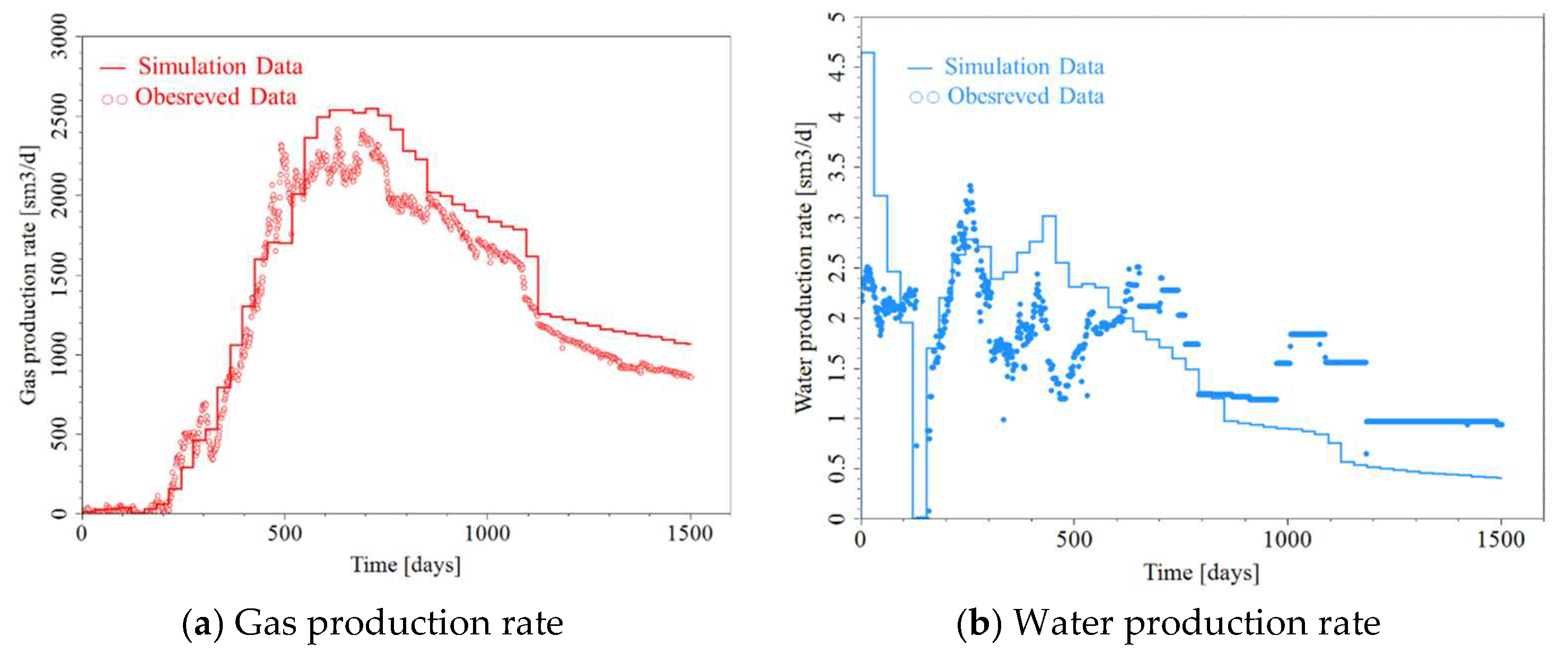

4.2. Well-Group Production History Fitting

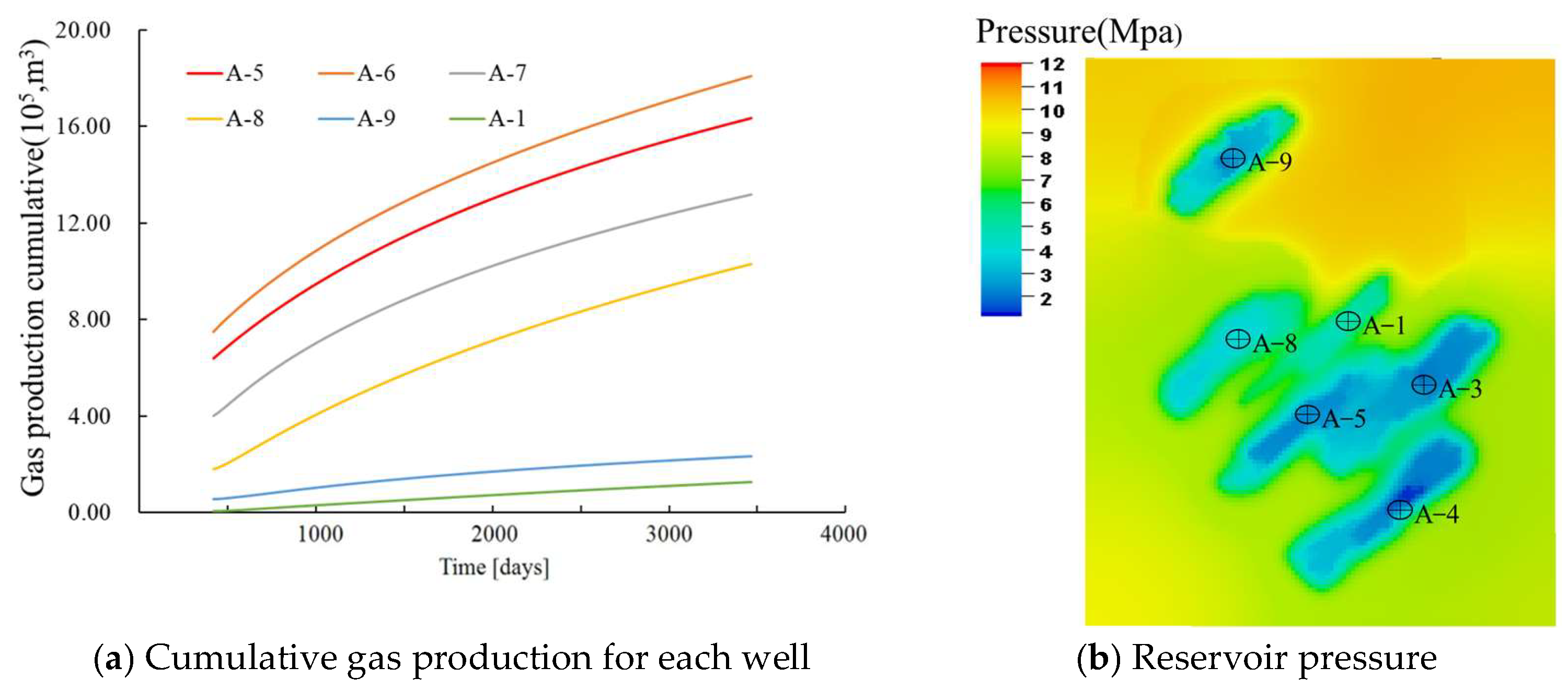

4.3. Production Dynamics Prediction

5. Sensitivity Analysis

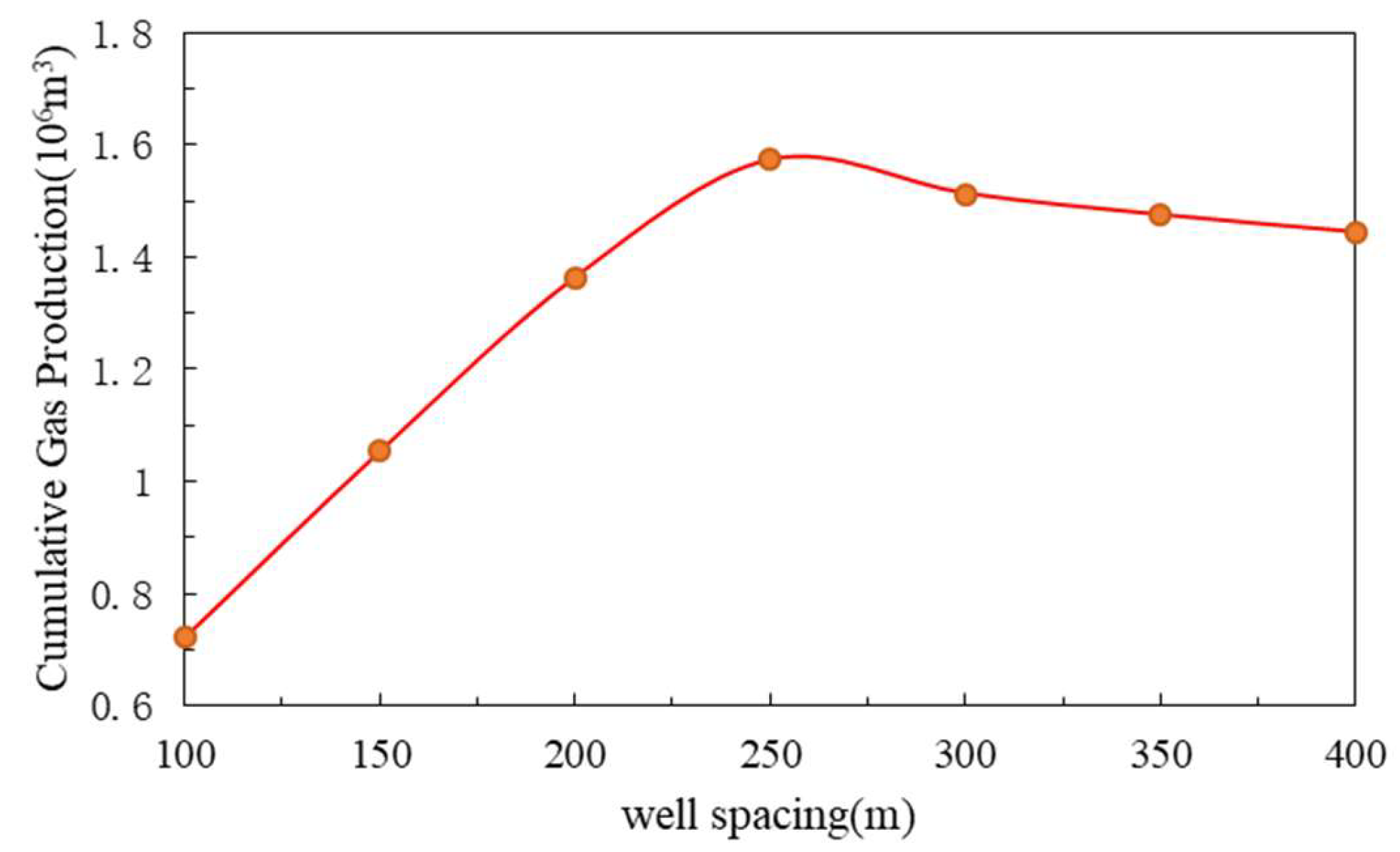

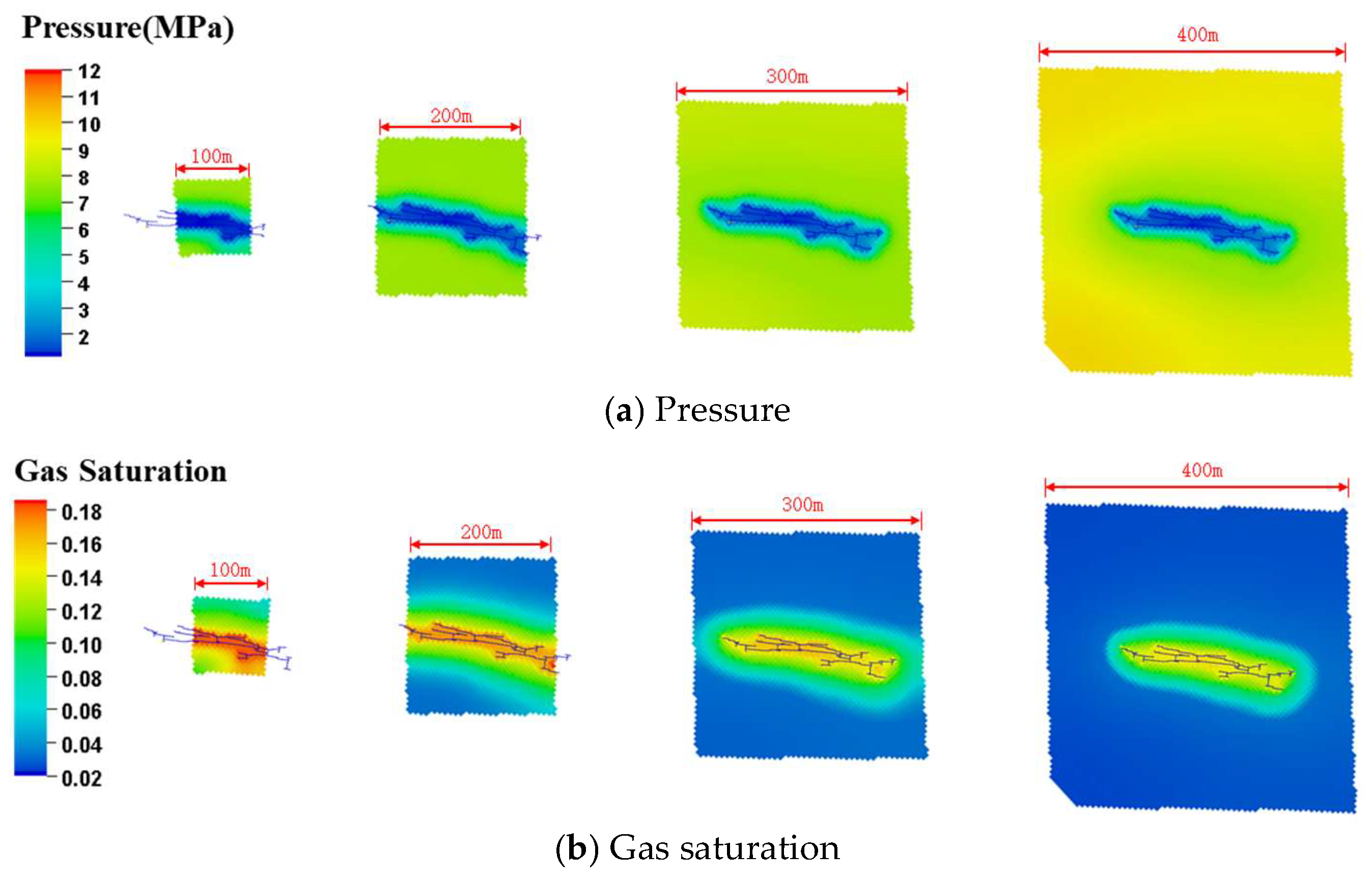

5.1. Well-Spacing Analysis

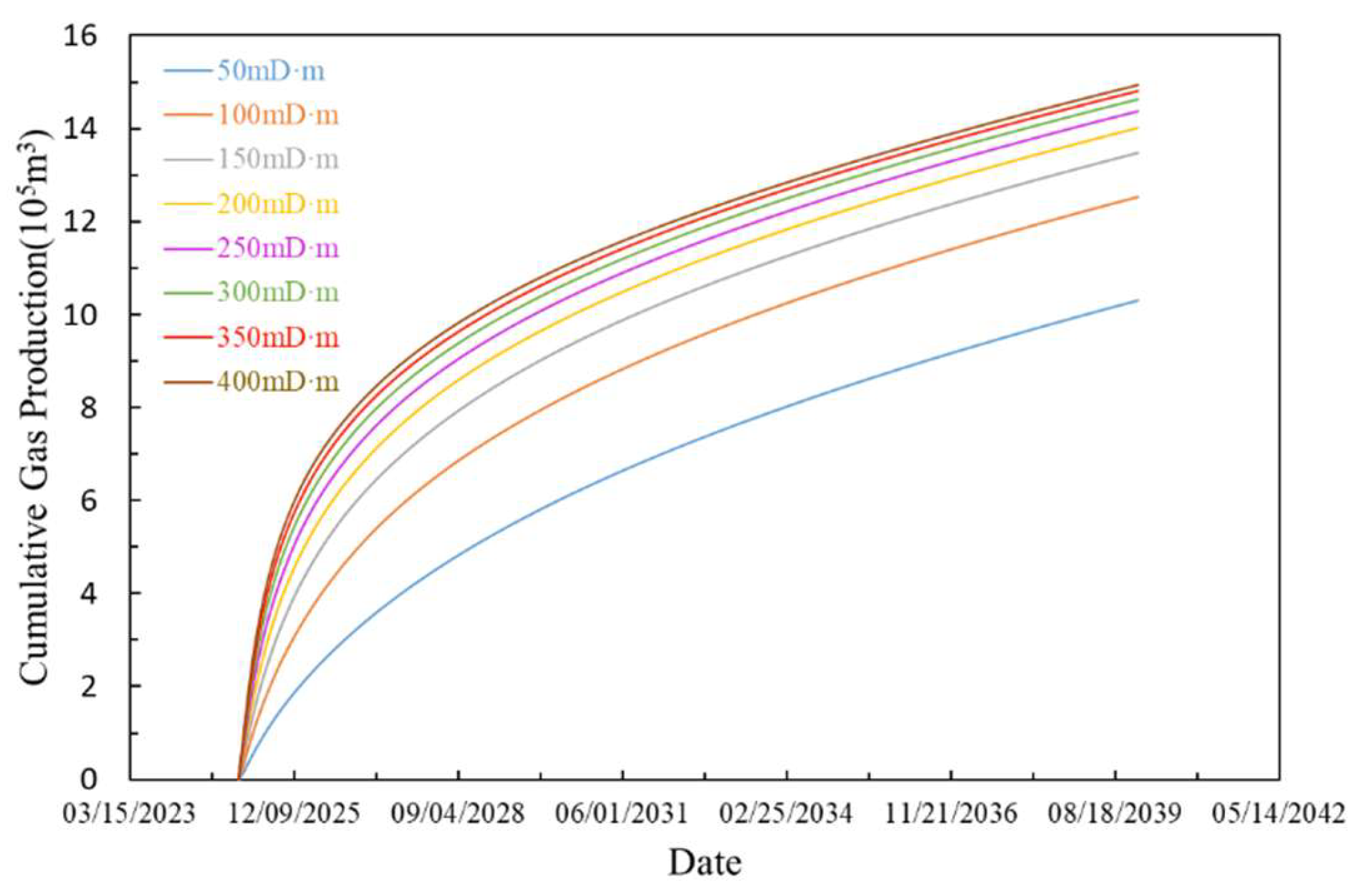

5.2. Analysis of Conductivity

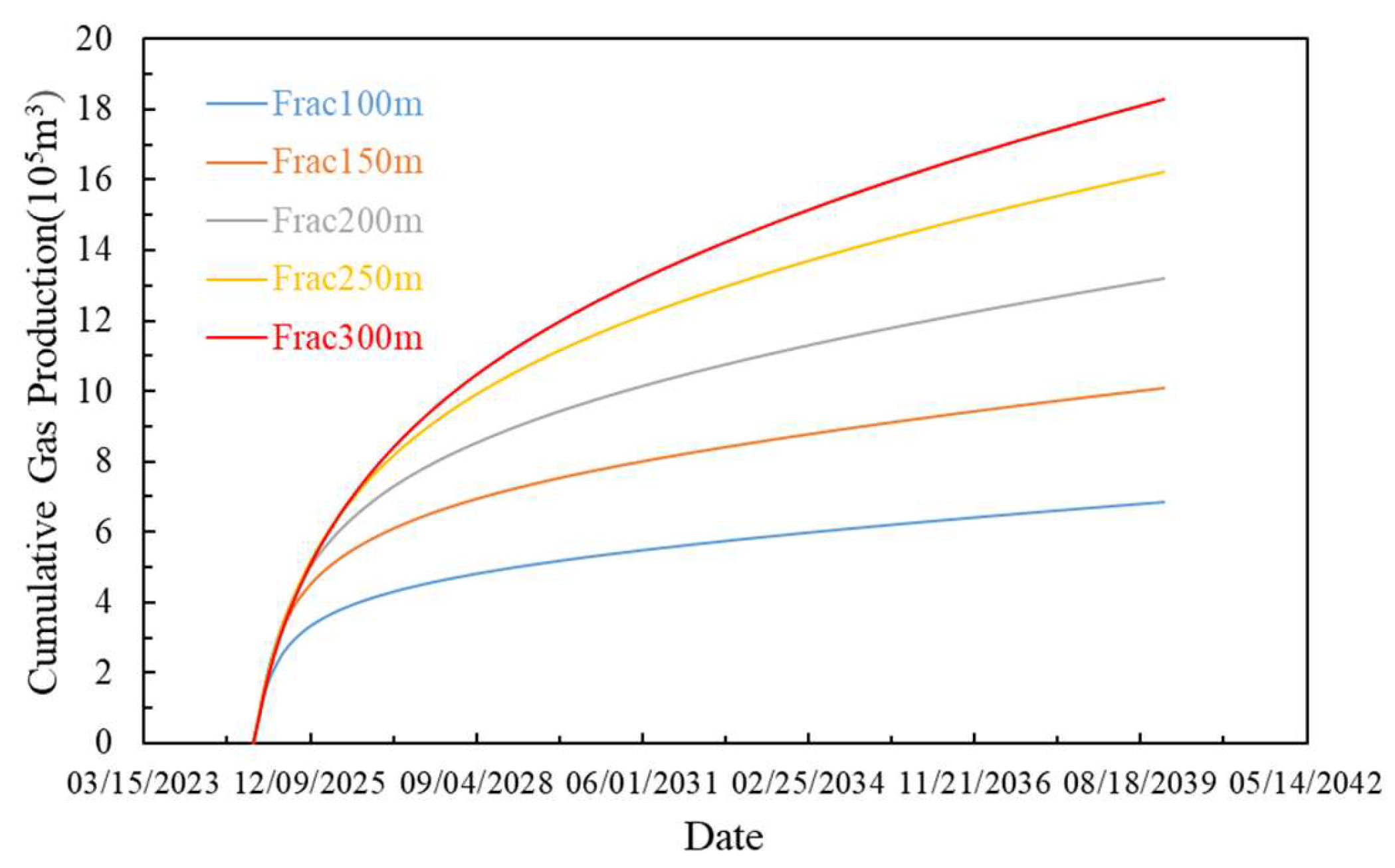

5.3. Fracture-Length Analysis

6. Conclusions

- (1)

- Coalbed methane’s roof and floor properties have a significant impact on the height of hydraulic fractures. The minimum horizontal principal stress difference between the coal seam and its roof and floor in the study area ranges from 3.41 to 5.90 MPa, and the fracture height is almost entirely constrained within the coal seam. The simulated hydraulic fracture length averages 169.79–215.84 m, the fracture height is 8.91–10.45 m, and the fracture conductivity is 121.92–248.71 mD·m.

- (2)

- By adjusting uncertain parameters (fracture permeability, isothermal adsorption curves, matrix permeability, etc.), a reliable model for CBM production dynamics and residual gas prediction is established. Due to the low matrix permeability, pressure drop and desorption primarily occur in the SRV region. The cumulative gas production predicted for the well group is 616 × 104 m3, with a recovery rate of only 10.17%. This indicates that the study area has good potential for enhanced recovery.

- (3)

- As well spacing increases, the cumulative gas production first rises and then declines. Desorption efficiency peaks when well spacing is slightly greater than fracture length, yielding maximum cumulative production. As fracture conductivity increases, cumulative production gradually increases. When fracture conductivity exceeds 200 mD·m, its influence on cumulative gas production diminishes. Cumulative gas production shows approximate linearity as fracture length increases from 100 m to 250 m, but the increase slows significantly when fracture length exceeds 250 m.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, F.Y.; Hou, W.; Xiong, X.Y.; Xu, B.R.; Wu, P.; Wang, H.Y.; Feng, K.; Yun, J.; Li, S.G.; Zhang, L.; et al. The status and development strategy of coalbed methane industry in China. Pet. Explor. Dev. 2023, 50, 765–783. [Google Scholar] [CrossRef]

- Li, S.; Qin, Y.; Tang, D.; Shen, J.; Wang, J.; Chen, S. A comprehensive review of deep coalbed methane and recent developments in China. Int. J. Coal Geol. 2023, 279, 104369. [Google Scholar] [CrossRef]

- Wang, L.; Sun, Y.; Zheng, S.; Shu, L.; Zhang, X. How efficient coal mine methane control can benefit carbon-neutral target: Evidence from China. J. Clean. Prod. 2023, 424, 138895. [Google Scholar] [CrossRef]

- Jia, X.Y.; Xia, Y.; Yan, Z.M.; Gao, H.J.; Qiu, D.W.; Guerrero, J.M.; Li, Z.M. Coordinated operation of multi-energy microgrids considering green hydrogen and congestion management via a safe policy learning approach. Appl. Energy 2025, 401, 126611. [Google Scholar] [CrossRef]

- Xu, A.; Han, S.; Wei, Y.; Zhou, P.; Zhang, J.; Guo, Z. Methane adsorption during pore evolution and its microscale impact on coalbed methane recovery: A case study of middle- and high-rank coals in the Western Guizhou. ACS Omega 2025, 10, 14. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Liu, C.; Liu, Y. Mechanism of coalbed methane migration and production based on micro-pore overpressure environment. Pet. Sci. Technol. 2022, 40, 2971–2987. [Google Scholar] [CrossRef]

- Yang, L.; Fan, C.; Luo, M.; Wen, H.; Zhou, L.; Zou, Q.; Sun, H.; Wang, D. Permeability-driven optimization of carbon dioxide injection timing in enhanced coalbed methane recovery. Int. J. Coal Sci. Technol. 2025, 12, 90. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, W.; Liu, X.; Wen, Y.; Li, Y. Research on the adsorption characteristics and mechanisms of surfactants for coalbed methane. Powder Technol. 2025, 466, 121410. [Google Scholar] [CrossRef]

- Li, W.; Yang, K.; Cheng, Y.P. Kinetic model of methane marbon isotope fractionation during coalbed gas desorption and diffusion. J. China Coal Soc. 2022, 47, 849–859. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, X.; Yao, Y.; Liu, D.; Qiu, Y. CO2-enhanced methane recovery in deep coalbeds: Displacement and diffusion/pressure-driven behaviors. Gas Sci. Eng. 2025, 143, 205730. [Google Scholar] [CrossRef]

- Xu, H.; Tang, D.; Zhao, J.; Li, S.; Tao, S. A new laboratory method for accurate measurement of the methane diffusion coefficient and its influencing factors in the coal matrix. Fuel 2015, 158, 239–247. [Google Scholar] [CrossRef]

- Lu, B.; Yang, Z.; Hou, Y.; Li, C.; Wang, J.; Liu, C.; Yao, Y. Desorption-diffusion specificity of deep coalbed methane under high-temperature effects: Implications for development. Int. J. Min. Sci. Technol. 2025; in press, corrected proof. [Google Scholar] [CrossRef]

- Cheng, Y.; Pan, Z. Reservoir properties of Chinese tectonic coal: A review. Fuel 2020, 260, 116350. [Google Scholar] [CrossRef]

- Akilu, S.; Padmanabhan, E.; Sun, Z. A review of transport mechanisms and models for unconventional tight shale gas reservoir systems. Int. J. Heat Mass Transf. 2021, 175, 121125. [Google Scholar] [CrossRef]

- Al-Rbeawi, S.; Al-Kaabi, M.H.H. A hybrid model for the combined impact of non-Darcy flow, stimulated matrix permeability, and anomalous diffusion flow in the unconventional reservoirs. Upstream Oil Gas Technol. 2020, 5, 100020. [Google Scholar] [CrossRef]

- Liu, W.; Xu, H.; Qin, Y.; Chu, X.; Liu, J.; Wu, D.; Zhao, W. Theoretical model and numerical solution of gas desorption and flow mechanism in coal matrix based on free gas density gradient. J. Nat. Gas Sci. Eng. 2021, 90, 103932. [Google Scholar] [CrossRef]

- Sepehrnoori, K.; Xu, Y.; Yu, W. Embedded Discrete Fracture Modeling and Application in Reservoir Simulation; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Luo, S.G.; Zhao, Y.L.; Zhang, L.H.; Chen, Z.X.; Zhang, X.Y. Integrated Simulation for Hydraulic Fracturing, Productivity Prediction, and Optimization in Tight Conglomerate Reservoirs. Energy Fuels 2021, 35, 18. [Google Scholar] [CrossRef]

- Cao, J.; Cai, M.; Li, J.; Guo, Z.; Jiang, X.; Dong, G. Optimization of volumetric fracturing stages and clusters in continental shale oil reservoirs based on geology-engineering integration. Energies 2025, 18, 3066. [Google Scholar] [CrossRef]

- Qin, Y.; Guo, T.; Ding, H.; Liu, T.; Chen, M.; Zhang, M.; Feng, Y. Mechanism of inter-well hydraulic fracture interference in the primary horizontal well pattern. Geoenergy Sci. Eng. 2024, 241, 213165. [Google Scholar] [CrossRef]

- Wang, X.; He, J.; Qiu, X.; Li, L.; Zhang, L. An Improved acid fracturing design through RoqSCAN technology: A case study from Daniudi Gas Field in Ordos Basin, China. Processes 2023, 11, 1475. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Feng, J.; Huang, L.; Qin, S.; Kang, K.; Lian, L.; Yang, H. Fracturing design and field application of tight sandstone reservoir with ripple lamination and natural fractures. Chem. Technol. Fuels Oils 2022, 58, 707–716. [Google Scholar] [CrossRef]

- Yang, R.-Y.; Li, G.-S.; Qin, X.-Z.; Huang, Z.-W.; Li, J.-B.; Sheng, M.; Wang, B. Productivity enhancement in multilayered coalbed methane reservoirs by radial borehole fracturing. Pet. Sci. 2022, 19, 2844–2866. [Google Scholar] [CrossRef]

- Lü, Q.; Lü, J.; Cheng, Z.; Song, Y.; Hou, J. Four-dimensional in-situ stress evolution law of shale reservoirs based on mechanical time-varying characteristics. Pet. Geol. Recovery Effic. 2024, 31, 56–65. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, Q.; Zhang, X.; Bai, J.; Karacan, C.Ö.; Wang, Y.; Elsworth, D. A two-stage step-wise framework for fast optimization of well placement in coalbed methane reservoirs. Int. J. Coal Geol. 2020, 225, 103479. [Google Scholar] [CrossRef]

- Li, P.; Liu, Q. A dual porous and fractures medium CBM numerical model development and analysis. J. Pet. Sci. Eng. 2022, 214, 110511. [Google Scholar] [CrossRef]

- Chen, G.; Zhao, Q.B.; Li, W.Z. Control of in-situ stress field on high-permeability zones in Daning-Jixian Area. China Coalbed Methane 2009, 6, 15–20. [Google Scholar] [CrossRef]

- Sun, B.; Zhao, Q.B.; Li, W.Z. Coalbed methane resources and exploration strategies in China. Nat. Gas Geosci. 1998, 9, 1–10. [Google Scholar]

- Sun, B.; Wang, X.H.; Chen, C.H. Distribution characteristics of coalbed methane in Daning-Jixian area of Ordos Basin. Nat. Gas Ind. 2004, 24, 17–20. [Google Scholar] [CrossRef]

- Fan, Y. Key Technologies and insights of geology-engineering integration for efficient and fast drilling of deep coalbed methane in Sichuan Basin. Drill. Prod. Technol. 2025, 48, 56–61. [Google Scholar] [CrossRef]

- Ren, Z.K.; Wang, S.C.; Liu, H. Research, Development and application of geology-engineering integration platform for oil and gas exploration and development. Mud Logging Eng. 2024, 35, 1–10. [Google Scholar] [CrossRef]

- Ren, Q.Q.; Li, L.F.; Wang, J.; Jiang, R.T.; Li, M.-P.; Feng, J.W. Dynamic evolution mechanism of the fracturing fracture system—Enlightenments from hydraulic fracturing physical experiments and finite element numerical simulation. Pet. Sci. 2024, 21, 3839–3866. [Google Scholar] [CrossRef]

- Zou, L.; Su, Y.; Xu, X.; Li, W.; Zhao, H.; Zhang, M.; Jiao, S. Study on the propagation law of hydraulic fractures in heterogeneous permeability reservoirs. PLoS ONE 2025, 20, e0328689. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Chen, J.; Zhao, Z.; Qiang, J. Hydraulic fracture network propagation in a naturally fractured shale reservoir based on the “well factory” model. Comput. Geotech. 2023, 153, 105103. [Google Scholar] [CrossRef]

- Kresse, O.; Weng, X.; Gu, H.; Wu, R. Numerical Modeling of Hydraulic Fractures Interaction in Complex Naturally Fractured Formations. Rock Mech. Rock Eng. 2013, 46, 555–568. [Google Scholar] [CrossRef]

- Chuprakov, D.; Melchaeva, O.; Prioul, R. Hydraulic fracture propagation across a weak discontinuity controlled by fluid injection. In Proceedings of the ISRM International Conference for Effective and Sustainable Hydraulic Fracturing, Brisbane, QLD, Australia, 20–22 May 2013. [Google Scholar]

- Wu, R.; Kresse, O.; Weng, X. Modeling of interaction of hydraulic fractures in complex fracture networks. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 6–8 February 2012. [Google Scholar]

- Chang, C.; Tao, S.P.; Wang, X.C.; Liu, C.X.; Yu, W.; Miao, J.J. Post-frac evaluation of deep shale gas wells based on a new geology-engineering integrated workflow. Geoenergy Sci. Eng. 2023, 231, 212228. [Google Scholar] [CrossRef]

- Chen, H.; Liu, H.; Shen, C.; Xie, W.; Liu, T.; Zhang, J.; Lu, J.; Li, Z.; Peng, Y. Research on geological-engineering integration numerical simulation based on EUR maximization objective. Energies 2024, 17, 3644. [Google Scholar] [CrossRef]

| Name | Net Coal Thickness (m) | Coal Density (t/m3) | Gas Content (m3/t) | Geological Reserves (108 m3) | Technically Recoverable Reserves (108 m3) |

|---|---|---|---|---|---|

| 5# | 6.1 | 1.44 | 12.7 | 113.34 | 56.67 |

| 8# | 6.0 | 1.43 | 12.5 | 108.97 | 54.48 |

| Layer Name | Poisson’s Ratio | Young’s Modulus (GPa) | Vertical Stress (MPa) | Minimum Horizontal Total Stress (MPa) | Maximum Horizontal Total Stress (MPa) | Minimum Horizontal Total Stress Difference (MPa) |

|---|---|---|---|---|---|---|

| 5# Roof | 0.245 | 17.59 | 27.30 | 21.32 | 23.02 | / |

| 5# Coal | 0.239 | 5.285 | 27.43 | 17.91 | 18.43 | 3.41 |

| 5# Floor | 0.253 | 19.00 | 27.51 | 22.12 | 23.94 | 4.19 |

| 8# Roof | 0.273 | 22.59 | 29.00 | 24.79 | 26.91 | / |

| 8# Coal | 0.241 | 5.24 | 29.11 | 18.89 | 19.39 | 5.90 |

| 8# Floor | 0.245 | 18.31 | 29.22 | 22.64 | 24.40 | 3.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pang, B.; Ge, T.; Wu, J.; Gong, Q.; Luo, S.; Liu, Y.; Yin, D. Numerical Simulation of Shallow Coalbed Methane Based on Geology–Engineering Integration. Processes 2025, 13, 3381. https://doi.org/10.3390/pr13113381

Pang B, Ge T, Wu J, Gong Q, Luo S, Liu Y, Yin D. Numerical Simulation of Shallow Coalbed Methane Based on Geology–Engineering Integration. Processes. 2025; 13(11):3381. https://doi.org/10.3390/pr13113381

Chicago/Turabian StylePang, Bin, Tengze Ge, Jianjun Wu, Qian Gong, Shangui Luo, Yinhua Liu, and Decai Yin. 2025. "Numerical Simulation of Shallow Coalbed Methane Based on Geology–Engineering Integration" Processes 13, no. 11: 3381. https://doi.org/10.3390/pr13113381

APA StylePang, B., Ge, T., Wu, J., Gong, Q., Luo, S., Liu, Y., & Yin, D. (2025). Numerical Simulation of Shallow Coalbed Methane Based on Geology–Engineering Integration. Processes, 13(11), 3381. https://doi.org/10.3390/pr13113381