Comparison of CBM Productivity with Hydraulic Fracturing, Slotting, and Cavity Creation in Cleat–Developed Coal Seams

Abstract

1. Introduction

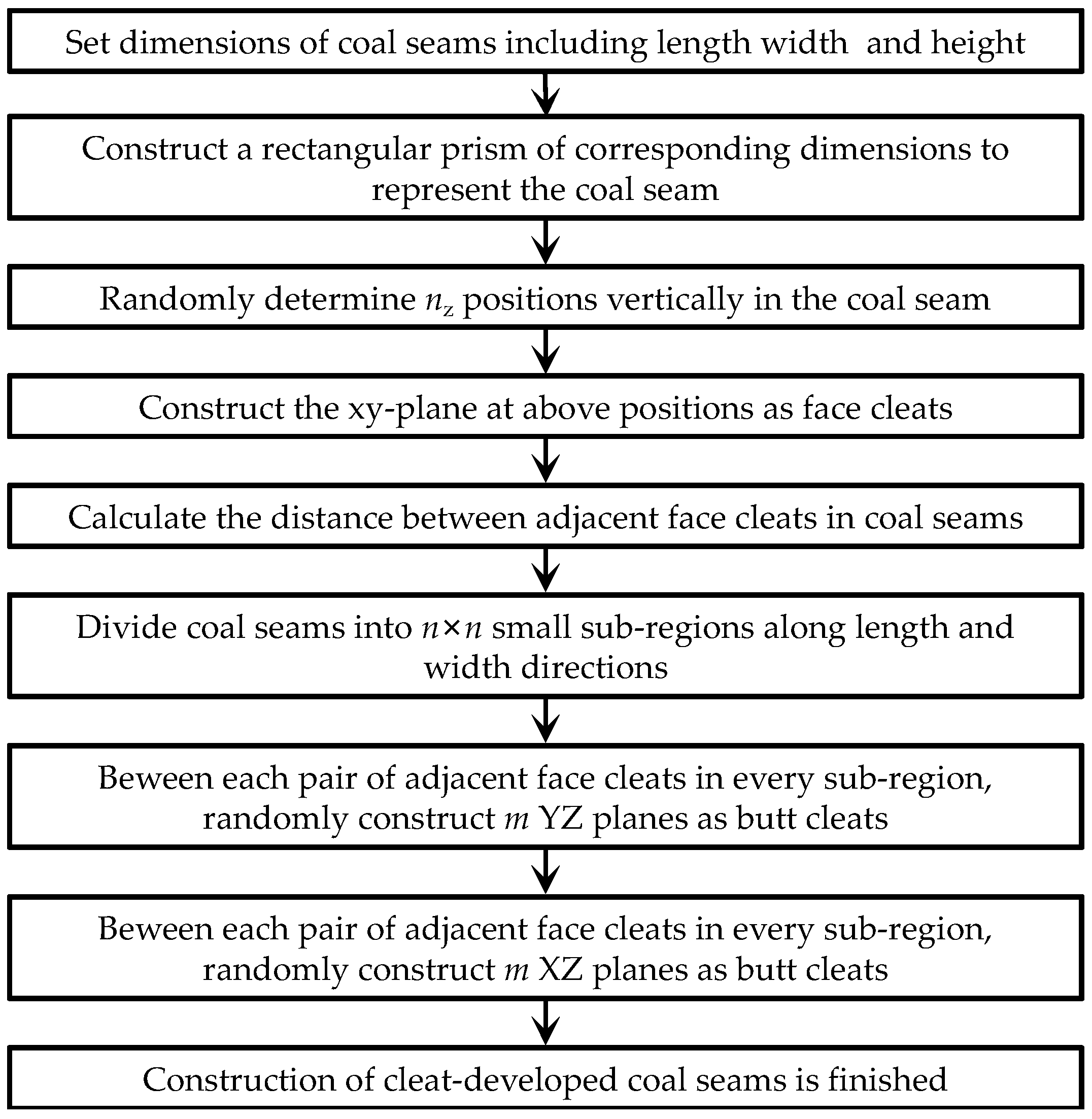

2. Coal Seam Stimulation Models

3. Development Model of CBM

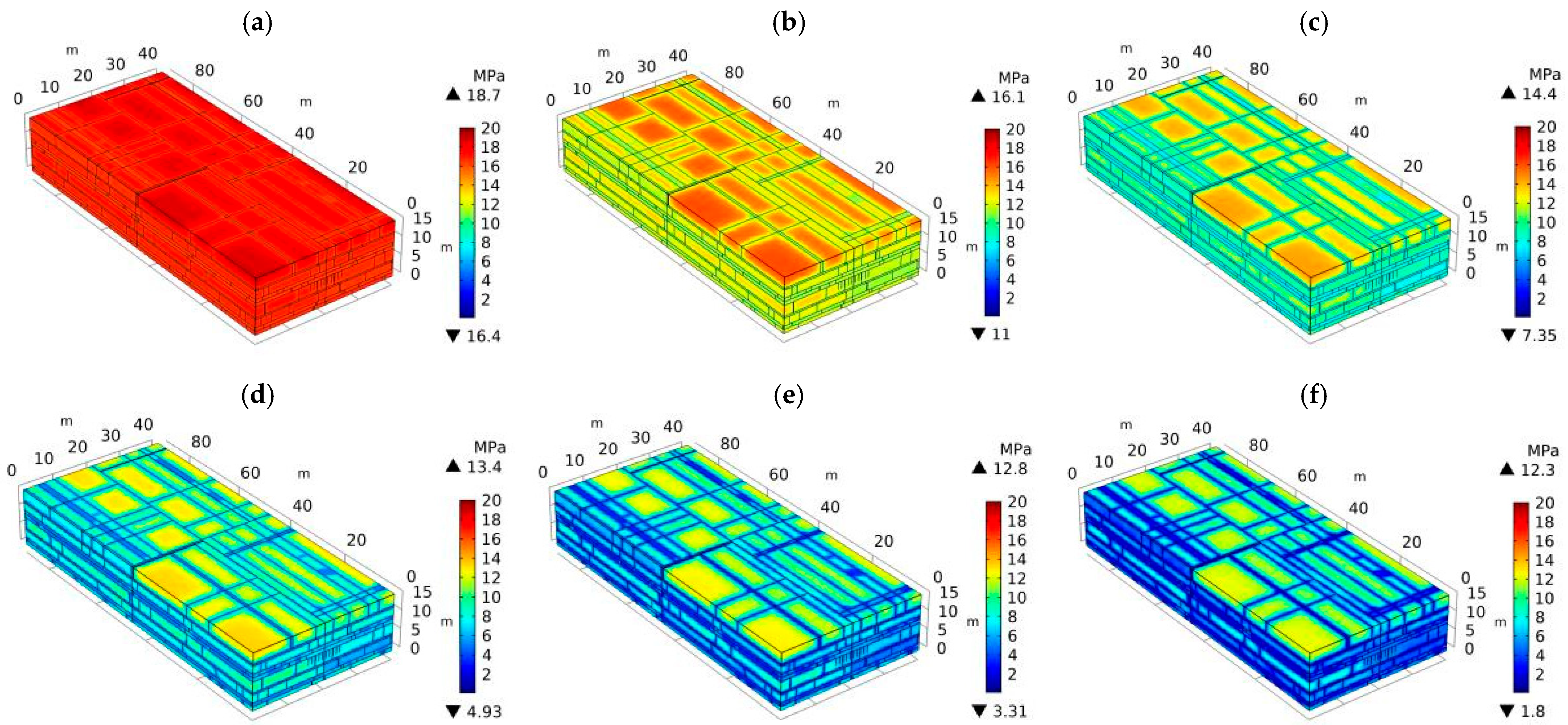

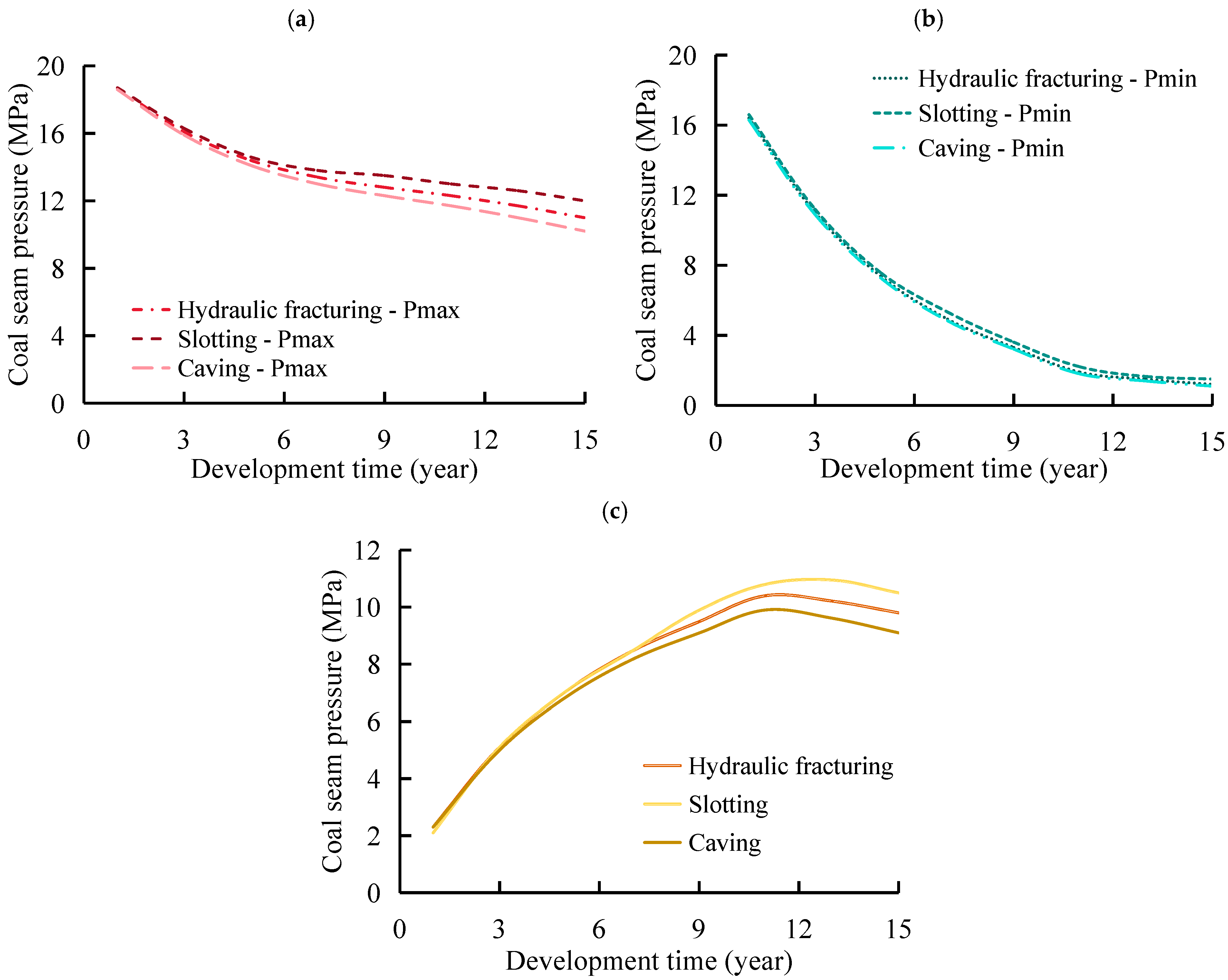

4. Simulation Results

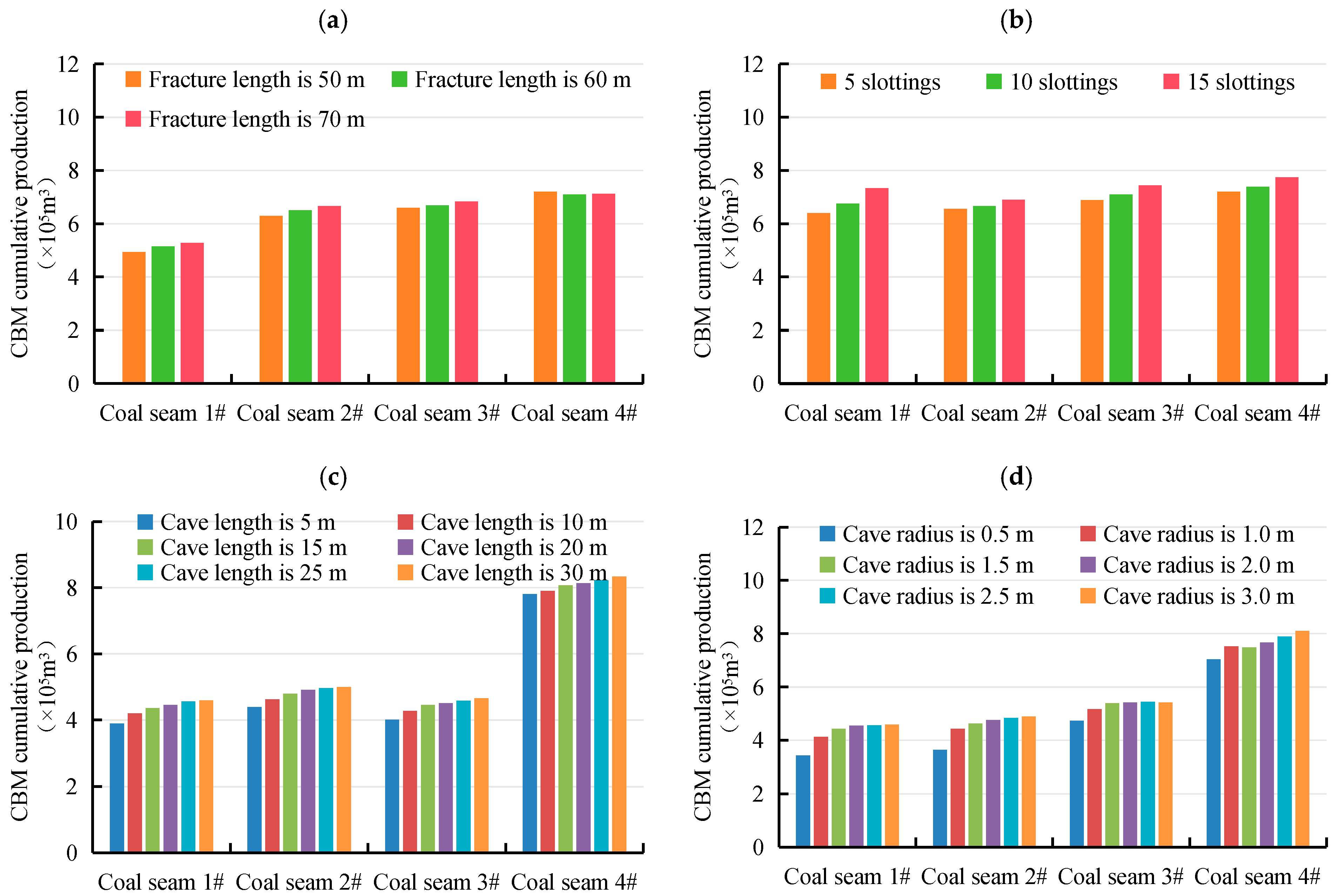

4.1. Effects of Fracture Length on CBM Productivity

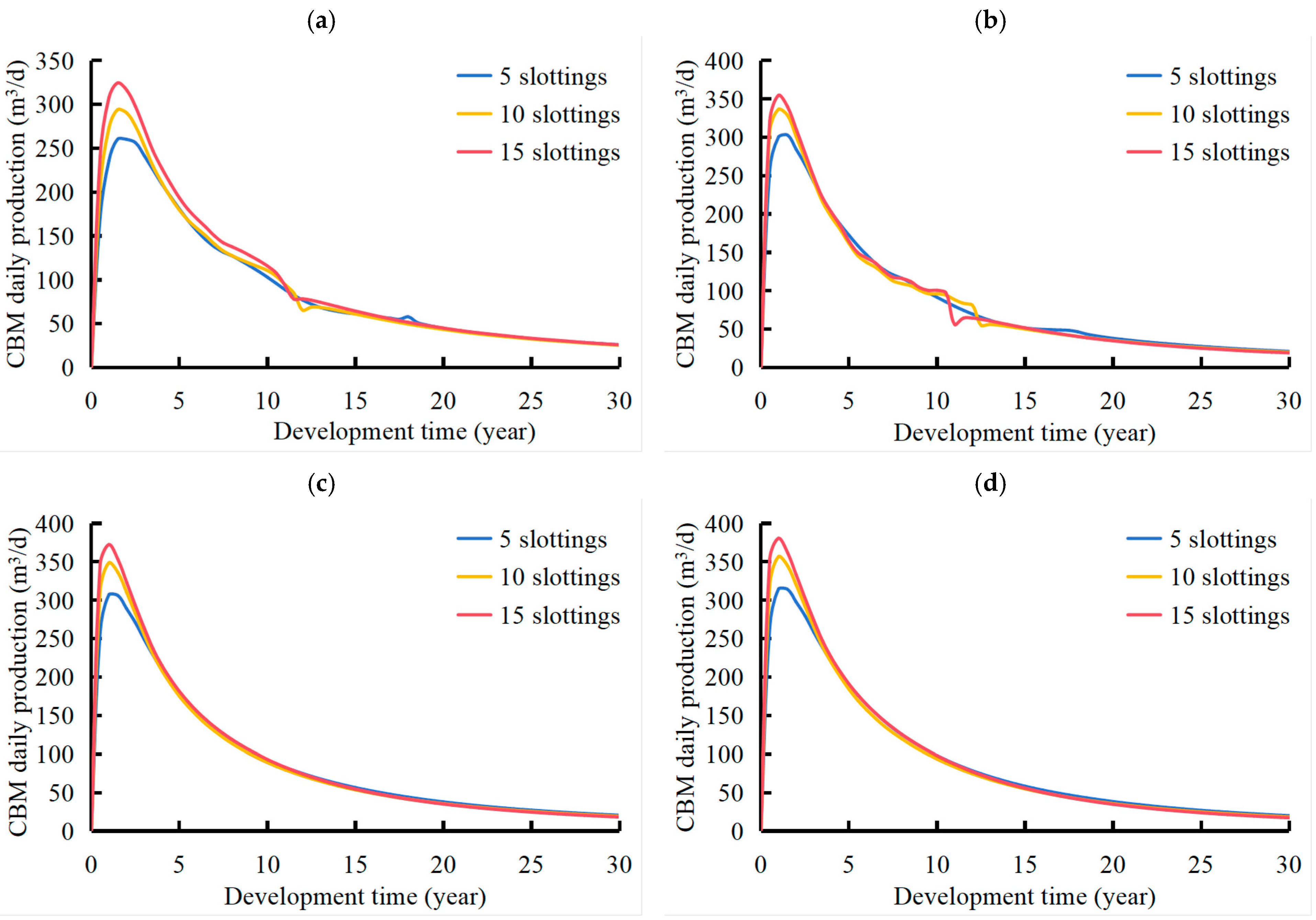

4.2. Effects of Slot Number on CBM Productivity

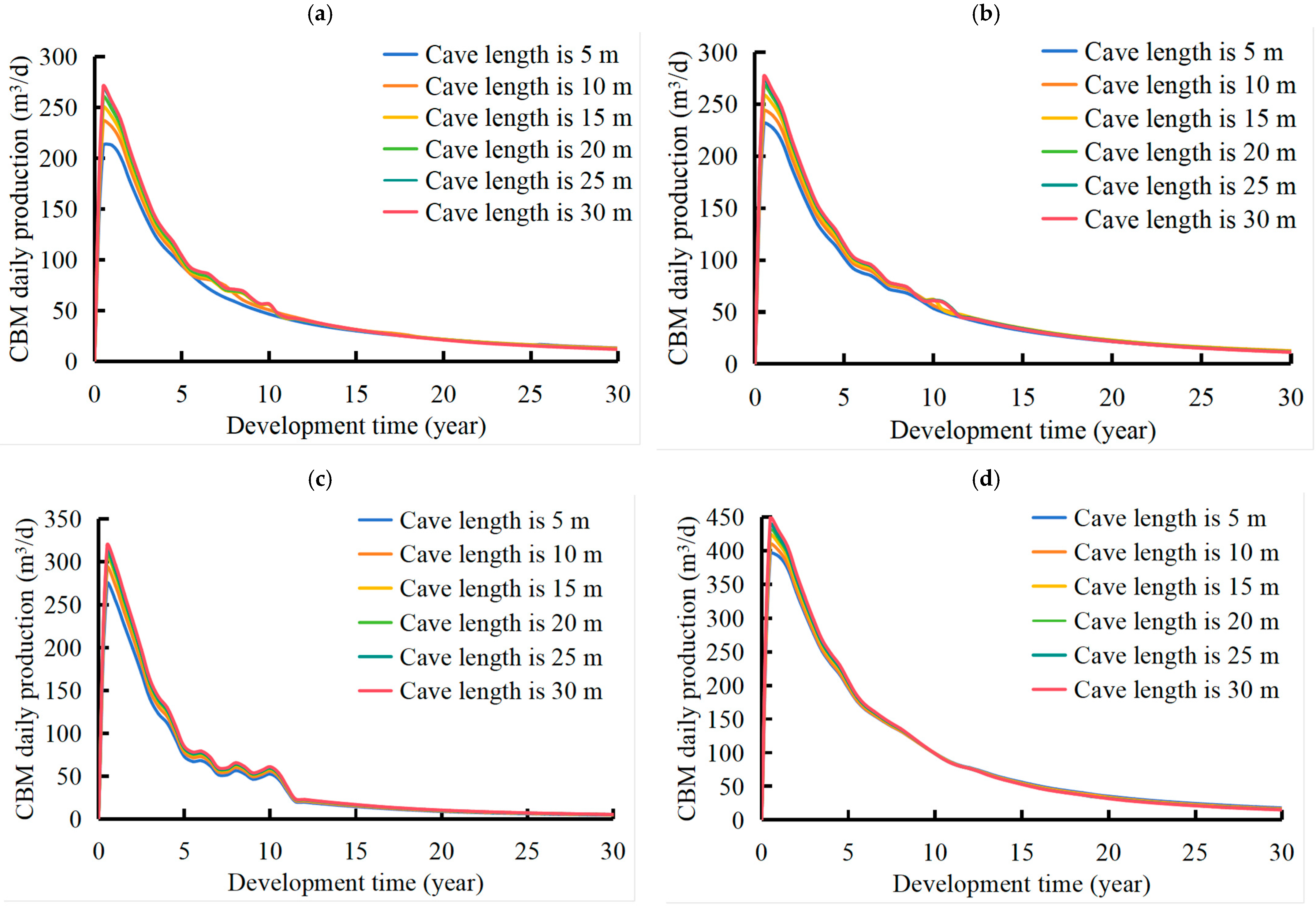

4.3. Effects of Cave Length on CBM Productivity

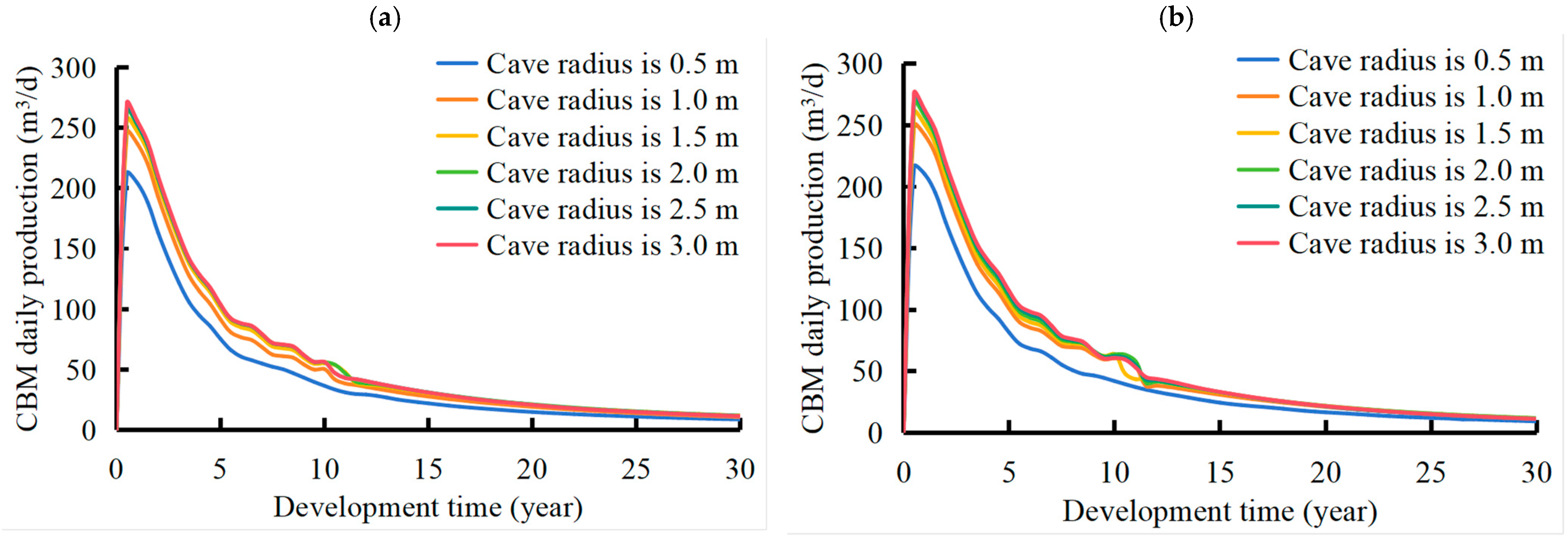

4.4. Effects of Cave Radius on CBM Productivity

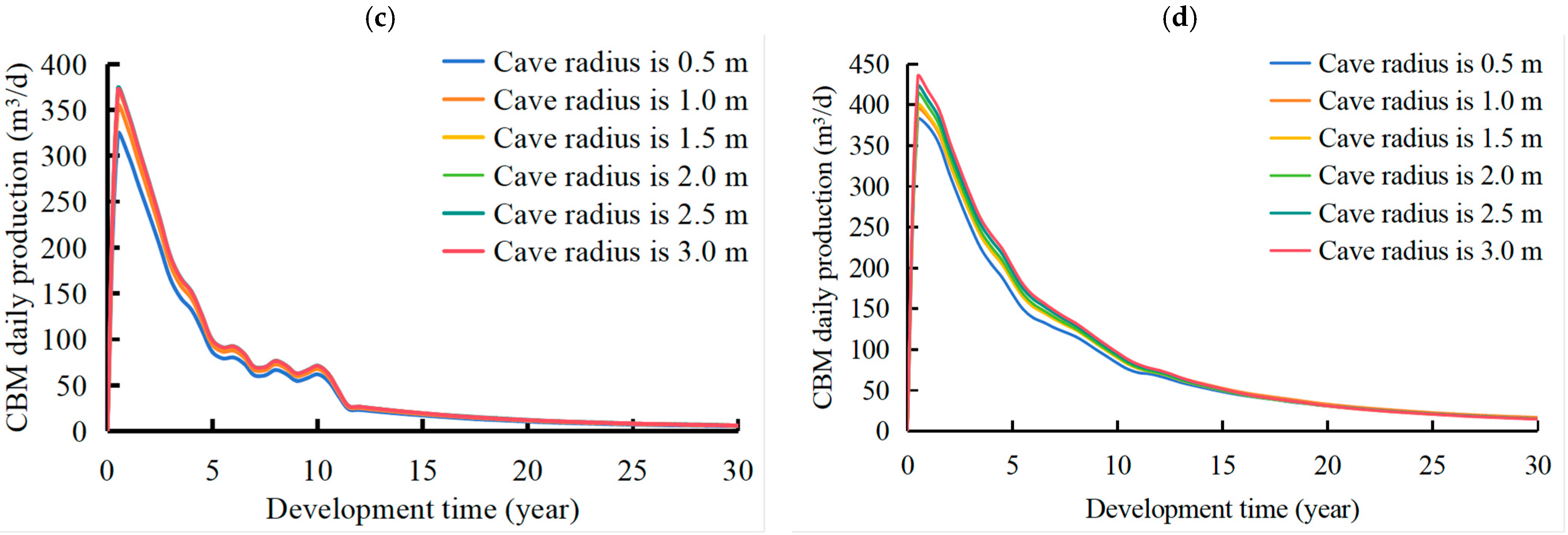

4.5. CBM Stable Production Time and Cumulative Production

5. Conclusions

- (1)

- Both the peak daily production and cumulative production of CBM can be enhanced by increasing the number of slots, as well as by increasing the length of hydraulic fractures and the dimensions (length and radius) of cavities. However, due to the random distribution of cleats within the coal seam, there can be significant variability in the impact of increasing cleat numbers on cumulative production. This is particularly true for the impact on cumulative production by slotting, which appears to be minimal.

- (2)

- Regarding the stable production period for CBM, in coal seams with 19 cleats, slotting results in the longest stable production time, about 10.57 years, followed by hydraulic fracturing, with cavity creation being the least effective, only 4.98 years. Conversely, in coal seams with a higher number of cleats, the stable production periods with cavity creation and slotting have little difference, about 9.47 years, whereas hydraulic fracturing is the least effective, only 7.86 years.

- (3)

- In terms of cumulative production of CBM, in low–cleat coal seams, slotting results in the highest cumulative production, about 68 × 104 m3, followed closely by hydraulic fracturing, with cavity creation being the least effective, only 43 × 104 m3. In contrast, in coal seams with a greater number of cleats, cavity creation achieves the highest cumulative production, reaching 78 × 104 m3, followed by slotting, with hydraulic fracturing being the least effective.

- (4)

- For hydraulic fracturing, this technique is more effective in coal seams with more cleats. In contrast, slotting is not sensitive to the development of cleats within the coal seam and is more effective than hydraulic fracturing regardless of the cleat development level. However, cavity creation is highly sensitive to cleat development; it is suitable for coal seams with well–developed cleats, but its effectiveness is inferior to both hydraulic fracturing and slotting in coal seams where cleats are not well–developed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Johnson, R.C.; Flores, R.M. Developmental geology of coalbed methane from shallow to deep in Rocky Mountain basins and in Cook Inlet–Matanuska basin, Alaska, USA and Canada. Int. J. Coal Geol. 1998, 35, 241–282. [Google Scholar] [CrossRef]

- Lau, H.C.; Li, H.; Huang, S. Challenges and opportunities of coalbed methane development in China. Energy Fuels 2017, 31, 4588–4602. [Google Scholar] [CrossRef]

- Li, D.; Gao, X.; Liu, Z.; Zan, X.; Zheng, Z.; Jia, J.; Wu, J. Comparison and revelation of coalbed methane resources distribution characteristics and development status between China and America. Coal Sci. Technol. 2018, 46, 252–261. Available online: https://www.mtkxjs.com.cn/en/article/id/aa806860-c1b6-4b75-831b-41c5db988ffd (accessed on 10 August 2025).

- Tao, S.; Chen, S.; Pan, Z. Current status, challenges, and policy suggestions for coalbed methane industry development in China: A review. Energy Sci. Eng. 2019, 7, 1059–1074. [Google Scholar] [CrossRef]

- Qin, Y.; Moore, T.A.; Shen, J.; Yang, Z.; Shen, Y.; Wang, G. Resources and geology of coalbed methane in China: A review. In Coal Geology of China; Routledge: London, UK, 2020; pp. 247–282. Available online: https://www.taylorfrancis.com/chapters/edit/10.4324/9780429449369-12/resources-geology-coalbed-methane-china-review-yong-qin-tim-moore-jian-shen-zhaobiao-yang-yulin-shen-geoff-wang (accessed on 9 August 2025).

- Ma, H.; Yang, Y.; Xue, Z.; Clarkson, C.R.; Chen, Z. Transitioning from emission source to sink: Economic and environmental trade-offs for CO2-enhanced coalbed methane recovery of Mannville coal Canada. Sci. Total Environ. 2025, 966, 178721. [Google Scholar] [CrossRef] [PubMed]

- Prabu, V.; Mallick, N. Coalbed methane with CO2 sequestration: An emerging clean coal technology in India. Renew. Sustain. Energy Rev. 2015, 50, 229–244. [Google Scholar] [CrossRef]

- Pan, Z.; Ye, J.; Zhou, F.; Tan, Y.; Connell, L.D.; Fan, J. CO2 storage in coal to enhance coalbed methane recovery: A review of field experiments in China. Coal Geol. China 2020, 224–246. [Google Scholar] [CrossRef]

- Khoshmagham, A.; Hosseini Alaee, N.; Shirinabadi, R.; Bangian Tabrizi, A.H.; Gholinejad, M.; Kianoush, P. Geological Characteristics of Coal Mines in the Zagros Basin of Iran: Unveiling Rock Mechanical Properties and Time-Dependent Behavior. Energy Geosci. 2025, 6, 100361. [Google Scholar] [CrossRef]

- Tambaria, T.N.; Sugai, Y.; Nguele, R. Adsorption factors in enhanced coal bed methane recovery: A review. Gases 2022, 2, 1–21. [Google Scholar] [CrossRef]

- Zhou, F.; Liu, S.; Pang, Y.; Li, J.; Xin, H. Effects of coal functional groups on adsorption microheat of coal bed methane. Energy Fuels 2015, 29, 1550–1557. [Google Scholar] [CrossRef]

- Liu, X.; He, X. Effect of pore characteristics on coalbed methane adsorption in middle-high rank coals. Adsorption 2017, 23, 3–12. [Google Scholar] [CrossRef]

- Liu, X.; Song, D.; He, X.; Nie, B.; Wang, Q.; Sun, R.; Sun, D. Coal macromolecular structural characteristic and its influence on coalbed methane adsorption. Fuel 2018, 222, 687–694. [Google Scholar] [CrossRef]

- Lv, F.; Yang, R.; Gao, W.; Zhao, L.; Liu, Y.; Yan, Z.; Shi, F.; Zhang, B.; Tang, J.; Yi, T. Critical depth prediction based on in–situ stress and gas content model of deep coalbed methane in Liupanshui Coalfield in China. Sci. Rep. 2025, 15, 297. [Google Scholar] [CrossRef]

- Liu, S.; Fan, K.; Jin, Y.; Yu, Z.; Dong, J.; Wang, C. Stress sensitivity characteristics of deep coal reservoirs and its influence on coalbed methane productivity. Coal Geol. Explor. 2022, 50, 56–64. [Google Scholar] [CrossRef]

- Liu, S.; Wang, J.; Wu, J.; Tang, Y. Modification and enhancement of permeability of coal seam using mined CO2 foam fracturing fluid. J. Nat. Gas Sci. Eng. 2018, 60, 32–39. [Google Scholar] [CrossRef]

- Huang, Q.; Li, M.; Li, J.; Gui, Z.; Du, F. Comparative experimental study on the effects of water-and foam-based fracturing fluids on multiscale flow in coalbed methane. J. Nat. Gas Sci. Eng. 2022, 103, 104648. [Google Scholar] [CrossRef]

- Xu, J.; Zhai, C.; Qin, L. Mechanism and application of pulse hydraulic fracturing in improving drainage of coalbed methane. J. Nat. Gas Sci. Eng. 2017, 40, 79–90. [Google Scholar] [CrossRef]

- Zhou, F.; Chen, Z.; Rahman, S.S. Effect of hydraulic fracture extension into sandstone on coalbed methane production. J. Nat. Gas Sci. Eng. 2015, 22, 459–467. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Ning, X.; Wang, Y.; Bai, B. Settling behavior and mechanism analysis of kaolinite as a fracture proppant of hydrocarbon reservoirs in CO2 fracturing fluid. Colloids Surf. A Physicochem. Eng. Asp. 2025, 724, 137463. [Google Scholar] [CrossRef]

- Li, Q. Reservoir Science: A Multi-Coupling Communication Platform to Promote Energy Transformation, Climate Change and Environmental Protection. Reserv. Sci. 2025, 1, 1–2. [Google Scholar] [CrossRef]

- Hao, C.; Cheng, Y.; Wang, L.; Liu, H.; Shang, Z. A novel technology for enhancing coalbed methane extraction: Hydraulic cavitating assisted fracturing. J. Nat. Gas Sci. Eng. 2019, 72, 103040. [Google Scholar] [CrossRef]

- Li, H.; Cao, Y.; Zhou, D.; Chai, X.; Liu, T.; Feng, P.; Shi, B.; Tian, L. Fracturing parameters analysis and productivity evaluation of vertical coalbed methane wells with nitrogen foam. Coal Geol. Explor. 2020, 48, 11. [Google Scholar] [CrossRef]

- Zhang, J. Numerical simulation of hydraulic fracturing coalbed methane reservoir. Fuel 2014, 136, 57–61. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, J.; Wu, H. Effects of fractures on the well production in a coalbed methane reservoir. Arab. J. Geosci. 2017, 10, 494. [Google Scholar] [CrossRef]

- Zhu, J.; Tang, J.; Hou, C.; Shao, T.; Zhao, Y.; Wang, J.; Lin, L.; Liu, J.; Jiang, Y. Two-phase flow model of coalbed methane extraction with different permeability evolutions for hydraulic fractures and coal reservoirs. Energy Fuels 2021, 35, 9278–9293. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, T. Evaluation Method of Coal-Bed Methane Fracturing in the Qinshui Basin. Math. Probl. Eng. 2020, 2020, 1545729. [Google Scholar] [CrossRef]

- Yang, R.; Chen, J.; Qin, X.; Huang, Z.; Li, G.; Liu, L. Stress evolution and permeability enhancement mechanism of multistage cavity completion in coalbed methane horizontal wells. SPE J. 2023, 28, 2767–2789. [Google Scholar] [CrossRef]

- Zhong, J.; Ge, Z.; Lu, Y.; Zhou, Z.; Zheng, J. New mechanical model of slotting–directional hydraulic fracturing and experimental study for coalbed methane development. Nat. Resour. Res. 2021, 30, 639–656. [Google Scholar] [CrossRef]

- Yang, R.; Huang, Z.; Li, G.; Sepehrnoori, K.; Li, K. Slotted Liner Sheathing Coiled Tubing Fishbone Jet Drilling: An Efficient Approach for Coalbed Methane Recovery. In Proceedings of the International Petroleum Technology Conference (IPTC), Bangkok, Thailand, 14–16 November 2016. IPTC-18893-MS. [Google Scholar] [CrossRef]

- Holditch, S.A. Completion methods in coal-seam reservoirs. J. Pet. Technol. 1993, 45, 270–276. [Google Scholar] [CrossRef]

- Palmer, I.D.; Mavor, M.J.; Seidle, J.P.; Spitler, J.L.; Voiz, R.F. Openhole cavity completions in coalbed methane wells in the San Juan Basin. J. Pet. Technol. 1993, 45, 1072–1080. [Google Scholar] [CrossRef]

- Palmer, I. Coalbed Coalbed methane completions: A world view. Int. J. Coal. Geol. 2010, 82, 184–195. [Google Scholar] [CrossRef]

- Shi, J.Q.; Durucan, S.; Sinka, I.C. Key parameters controlling coalbed methane cavity well performance. Int. J. Coal Geol. 2002, 49, 19–31. [Google Scholar] [CrossRef]

- Wei, G.; Wen, H.; Deng, J.; Li, Z.; Fan, S.; Lei, C.; Liu, M.; Ren, L. Enhanced coalbed permeability and methane recovery via hydraulic slotting combined with liquid CO2 injection. Process Saf. Environ. Prot. 2021, 147, 234–244. [Google Scholar] [CrossRef]

- Lin, B.; Yan, F.; Zhu, C.; Zhou, Y.; Zou, Q.; Guo, C.; Liu, T. Cross-borehole hydraulic slotting technique for preventing and controlling coal and gas outbursts during coal roadway excavation. J. Nat. Gas Sci. Eng. 2015, 26, 518–525. [Google Scholar] [CrossRef]

- Si, G.; Durucan, S.; Shi, J.Q.; Korre, A.; Cao, W. Parametric analysis of slotting operation induced failure zones to stimulate low permeability coal seams. Rock Mech. Rock Eng. 2019, 52, 163–182. [Google Scholar] [CrossRef]

- Cheng, S.; Li, Q.; Zhou, Y.; Xia, B.; Gong, T.; Yang, J.; Zhang, Y. Stress relief cracking and permeability improvement by high-pressure water jet slotting to enhance coalbed methane extraction. Pet. Sci. Technol. 2025, 43, 1444–1465. [Google Scholar] [CrossRef]

- Qin, L.; Li, J.; Mu, M.; Lv, S.; Chen, N.; Xiong, M. Impact of controllable parameters in hydraulic slotting on stress relief effects around coal seam. Phys. Fluids 2025, 37, 037105. [Google Scholar] [CrossRef]

- Zhen, H.; Zhao, H.; Wei, K.; Liu, Y.; Li, S.; Wei, Z.; Wang, C.; Chen, G. Innovative Stress Release Stimulation Through Sequential Cavity Completion for CBM Reservoir Enhancement. Processes 2025, 13, 1567. [Google Scholar] [CrossRef]

- Geng, Y.L.; Qi, X.Y.; Jia, S.P. Gas-solid Coupling Model by Considering Desorption Effect. J. Hunan Univ. Sci. Technol. Nat. Sci. Ed. 2020, 35, 40–48. [Google Scholar] [CrossRef]

- Tao, S.; Pan, Z.; Tang, S.; Chen, S. Current status and geological conditions for the applicability of CBM drilling technologies in China: A review. Int. J. Coal Geol. 2019, 202, 95–108. [Google Scholar] [CrossRef]

- Beaton, A.; Langenberg, W.; Pană, C. Coalbed methane resources and reservoir characteristics from the Alberta Plains, Canada. Int. J. Coal Geol. 2006, 65, 93–113. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Elsworth, D.; Qu, H.; Chen, D. Interactions of multiple processes during CBM extraction: A critical review. Int. J. Coal Geol. 2011, 87, 175–189. [Google Scholar] [CrossRef]

| Coal Seam Length (m) | Coal Seam Width (m) | Coal Seam Height (m) | Number of Face Cleats | Number of Butt Cleats | Coal Seam Name |

|---|---|---|---|---|---|

| 90 | 40 | 15 | 3 | 16 | Coal seam 1# |

| 5 | 96 | Coal seam 2# | |||

| 7 | 168 | Coal seam 3# | |||

| 9 | 320 | Coal seam 4# |

| Stimulation Methods | Length (m) | Width (mm) | Height (m) | Radius (m) | Number | Space (m) |

|---|---|---|---|---|---|---|

| Hydraulic fracturing | 50/60/70 | 10 | 10 | – | 1 | – |

| Slotting | 5 | 5 | 2 | – | 5/10/15 | 1 |

| Cavity creation | 5/10/15/20/25/30 | – | – | 0.5/1.0/1.5/2.0/2.5/3.0 | 1 | – |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Coal seam depth (m) | 2185 | Cleats width (mm) | 1.4 |

| Coal seam thickness (m) | 7.8 | Matrix permeability (10−3 μm2) | 0.09 |

| Coal seam porosity (%) | 3.69 | Langmuir volume constant (m3/t) | 25.3 |

| Density of face cleats (1/m) | 60–240 | Langmuir pressure constant (MPa) | 2.87 |

| Density of butt cleats (1/m) | 40–200 | Poisson’s ratio of coal seam | 0.38 |

| Fracture length (m) | 78 | Young’s modulus of coal seam (GPa) | 4.5 |

| Fracture width (mm) | 3.5 | Bulk modulus of coal seam (GPa) | 6.5 |

| Fracture height (m) | 7.68 | Reservoir pressure coefficient | 0.93 |

| Fracture permeability (μm2) | 12 | Gas saturation (%) | 93.6 |

| Parameters | Value | Unit |

|---|---|---|

| Coal seam depth | 1800 | m |

| Coal seam density | 1520 | kg·m−3 |

| Initial porosity of coal seam | 0.1 | – |

| Initial permeability of coal seam | 0.01 | 10−3 μm2 |

| Initial permeability of cleats in coal seam | 10 | 10−3 μm2 |

| Initial permeability of hydraulic fractures | 10 | μm2 |

| Initial permeability of slotting | 1 | μm2 |

| Initial pressure in coal seam | 20 | MPa |

| CBM density at standard atmospheric pressure | 0.716 | kg·m−3 |

| Langmuir volume constant | 35 | m3·t−1 |

| Langmuir pressure constant | 2.5 | MPa |

| Langmuir volumetric strain constant | 0.03 | – |

| Molar mass of CBM | 16 | g·mol−1 |

| Dynamic viscosity of CBM | 1.65 | 10−5 Pa·s |

| Bulk modulus of coal seam | 1000 | MPa |

| Poisson’s ratio of coal seam | 0.26 | – |

| Cleat stress sensitivity coefficient | 0.45 | – |

| Slotting stress sensitivity coefficient | 0.48 | – |

| Fracture stress sensitivity coefficient | 0.50 | – |

| Biot coefficient | 0.93 | – |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, H.; Xu, J.; Xiao, Y.; Wang, M.; Zhang, X.; Fu, W.; Zhu, X. Comparison of CBM Productivity with Hydraulic Fracturing, Slotting, and Cavity Creation in Cleat–Developed Coal Seams. Processes 2025, 13, 3228. https://doi.org/10.3390/pr13103228

Lu H, Xu J, Xiao Y, Wang M, Zhang X, Fu W, Zhu X. Comparison of CBM Productivity with Hydraulic Fracturing, Slotting, and Cavity Creation in Cleat–Developed Coal Seams. Processes. 2025; 13(10):3228. https://doi.org/10.3390/pr13103228

Chicago/Turabian StyleLu, Haibing, Jiaxiang Xu, Yuhang Xiao, Meizhu Wang, Xueying Zhang, Wanxin Fu, and Xingyuan Zhu. 2025. "Comparison of CBM Productivity with Hydraulic Fracturing, Slotting, and Cavity Creation in Cleat–Developed Coal Seams" Processes 13, no. 10: 3228. https://doi.org/10.3390/pr13103228

APA StyleLu, H., Xu, J., Xiao, Y., Wang, M., Zhang, X., Fu, W., & Zhu, X. (2025). Comparison of CBM Productivity with Hydraulic Fracturing, Slotting, and Cavity Creation in Cleat–Developed Coal Seams. Processes, 13(10), 3228. https://doi.org/10.3390/pr13103228